Method for processing boards by dividing log

A technology for plates and logs, which is applied in the field of log dismantling and processing of plates, can solve the problems of uneven width, different lengths, and inaccurate square material dimensions, and achieve the effects of precise geometric dimensions, high processing efficiency, and precise dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

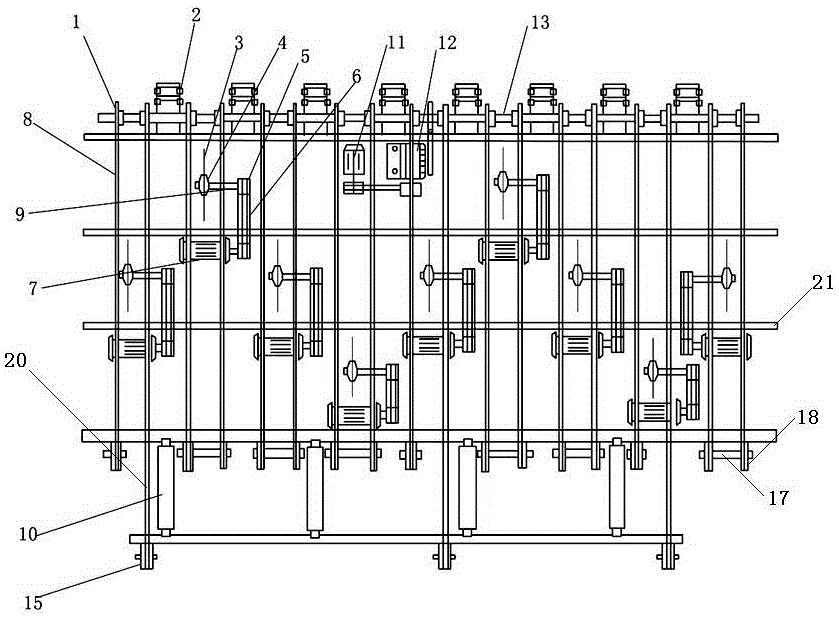

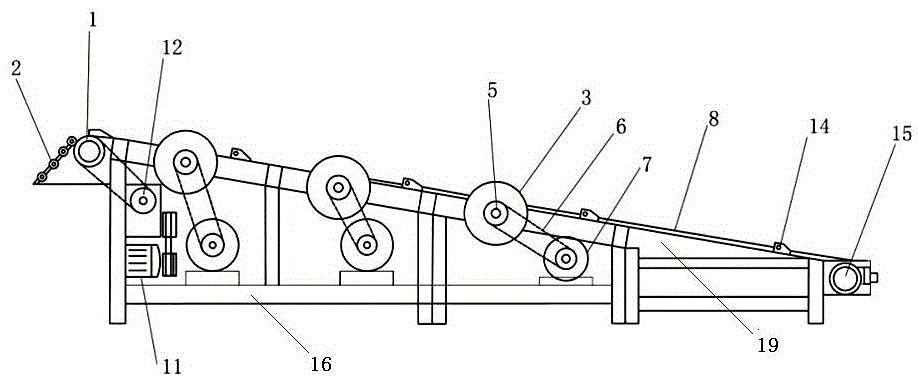

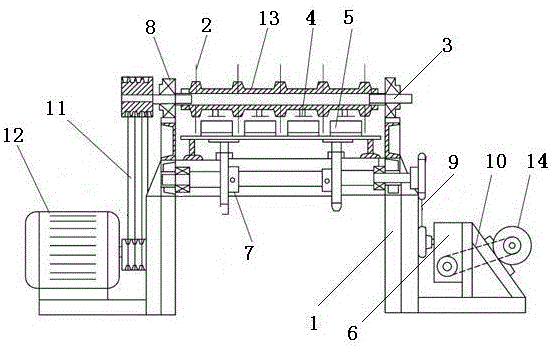

[0024] The method for unpacking and processing the logs, the steps are as follows:

[0025] (1) After the log is sawed by multiple logs, it is cut into multiple sheets at one time, and is driven by the transmission roller.

[0026] (2) Each sheet enters the automatic cutting machine horizontally, and completes the cross-cutting of the sheet at one time to obtain multiple fixed-length sheets.

[0027] (3) Each fixed-length board is sawed by a single piece, so that one side of the skin can be smoothed, forming a 90-degree right angle with the saw edge, and the side skin can be processed.

[0028] (4) Pass the board that has received the edge skin through the quadruple cutting machine, complete the cross-cutting of the board at one time, and process it into multiple fixed-length boards at one time.

[0029] (5) The fixed-length board passes through the automatic square cutting machine, trims the remaining edge of the board into a smooth surface, and forms a 90-degree right angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com