Patents

Literature

52results about How to "Geometrically accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Template structure and method for template support of cast-in-place concrete arc-shaped terrace

ActiveCN103362300AMeet construction requirementsEasy constructionForms/shuttering/falseworksBuilding material handlingShaped beamEngineering

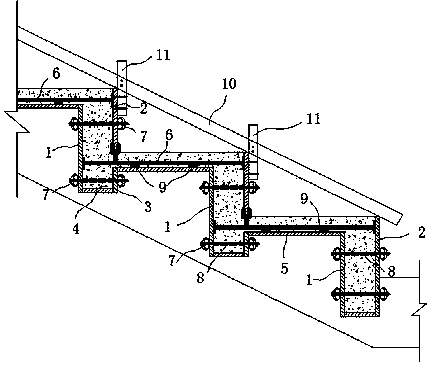

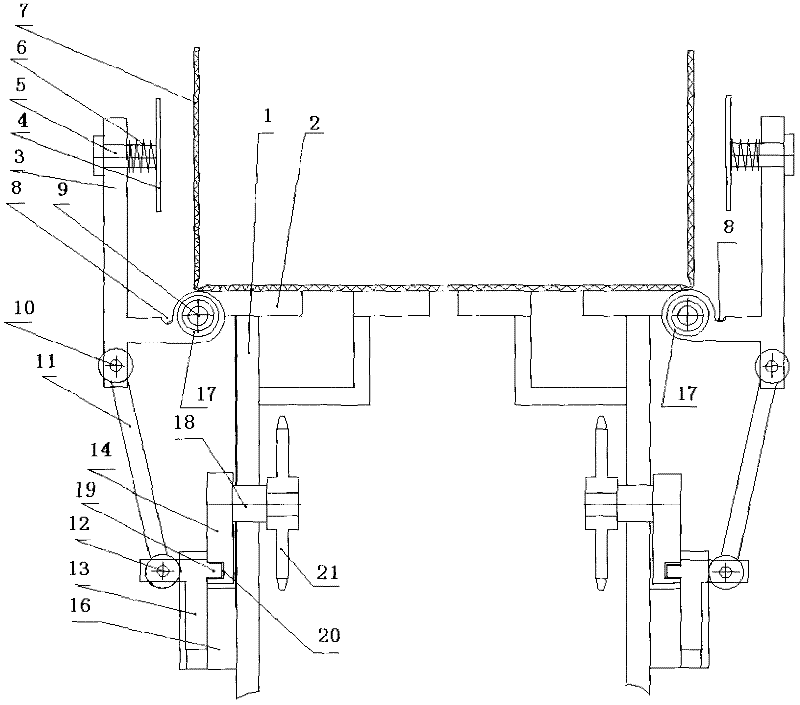

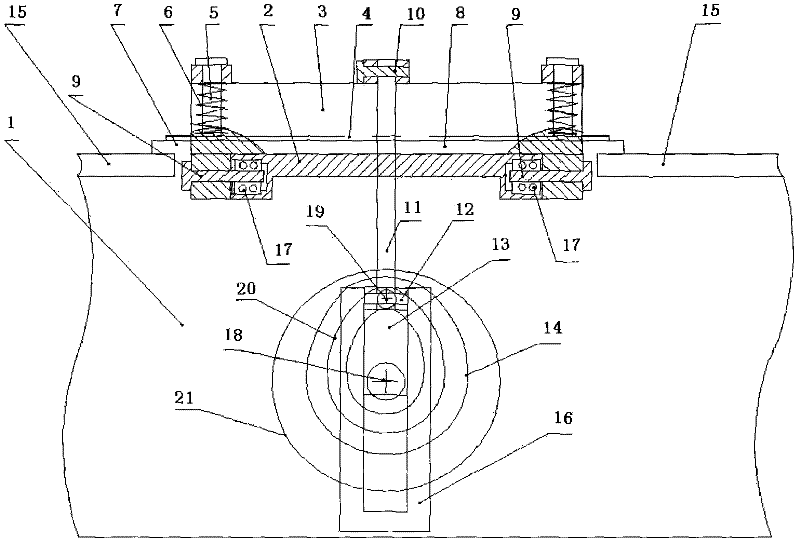

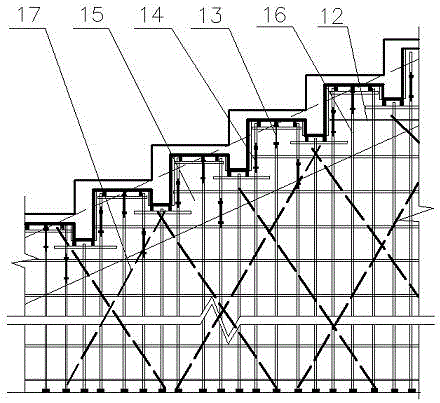

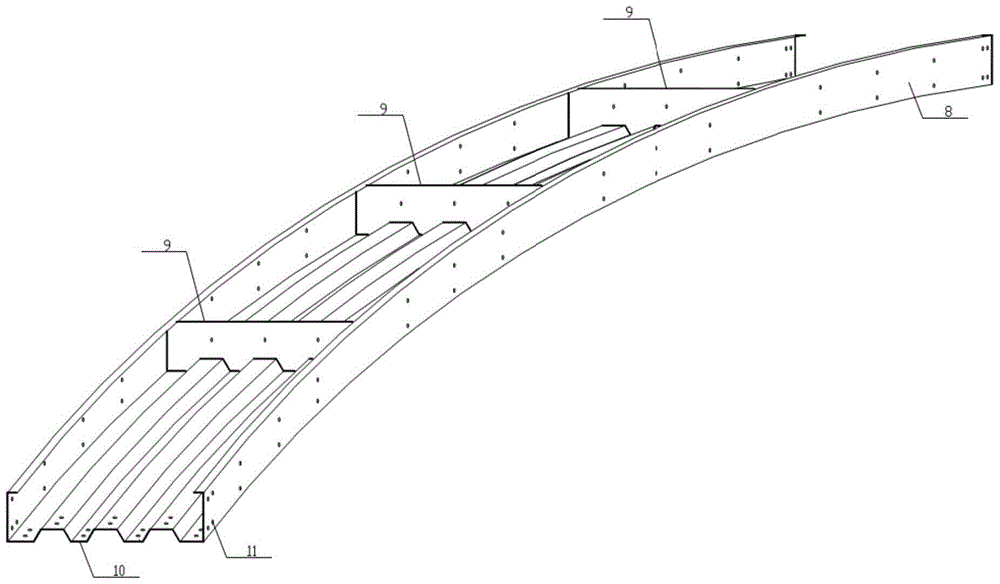

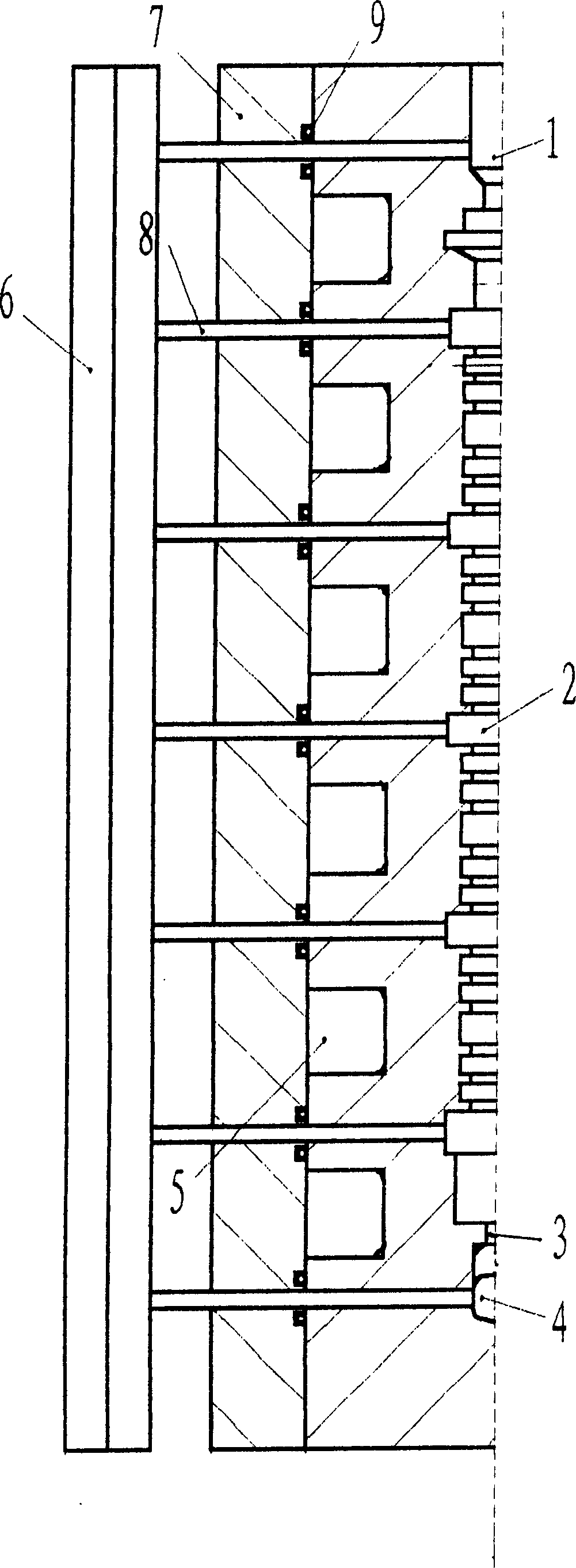

The invention discloses a template structure and a method for template support of a cast-in-place concrete arc-shaped terrace. The template structure comprises a template support frame body and a template fixing system, wherein the template fixing system comprises arc-shaped beam bottom plate templates, seat plate bottom templates, arc-shaped beam outside upper templates, arc-shaped beam outside lower templates and arc-shaped beam inside templates, wherein the arc-shaped beam outside lower templates are positioned below the arc-shaped beam outside upper templates; internal supports are arranged between the arc-shaped beam outside upper templates and the arc-shaped beam inside templates for supporting and enable the arc-shaped beam outside upper templates and the arc-shaped beam inside templates to keep set intervals; split bolts are used for connecting and fixing the arc-shaped beam outside upper templates and the arc-shaped beam inside templates; split bolts are used for connecting and fixing the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the arc-shaped beam bottom plate templates are respectively connected and fixed with the bottom ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the seat plate bottom templates are respectively connected and fixed with the upper ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

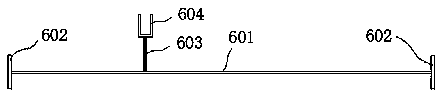

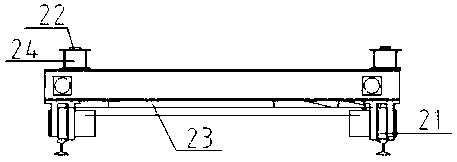

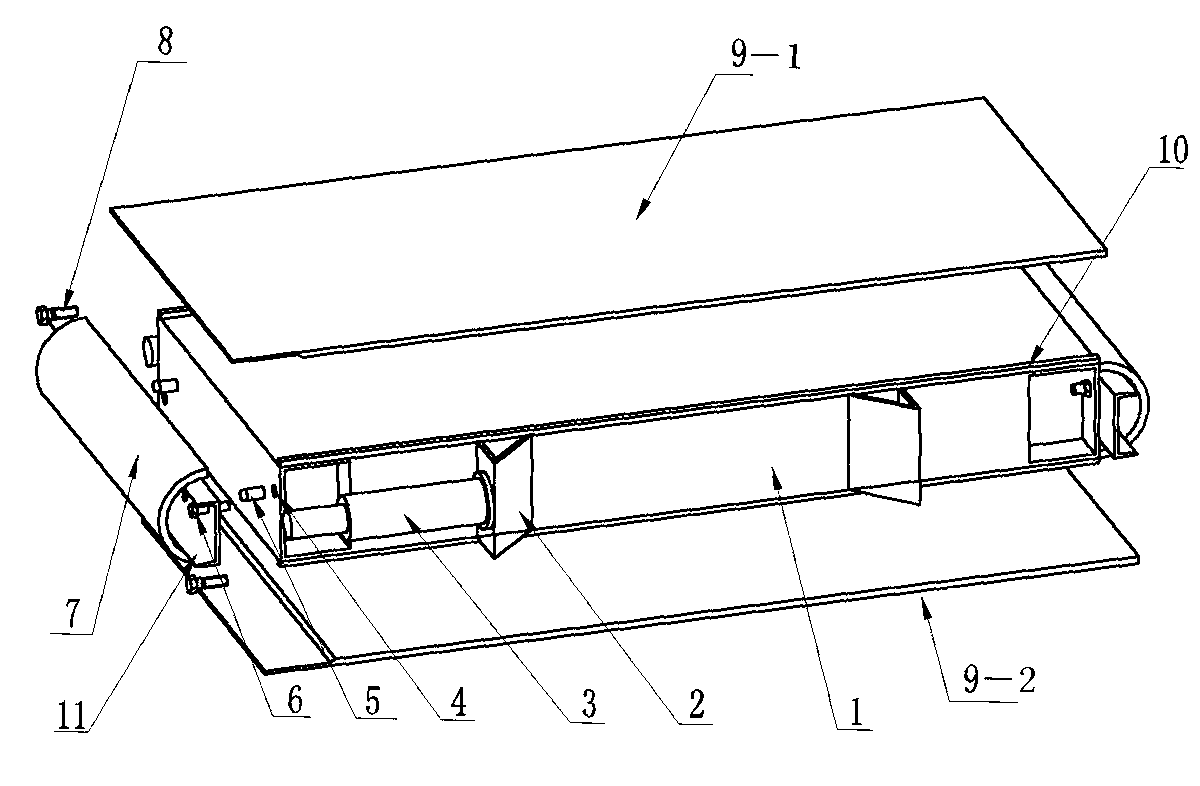

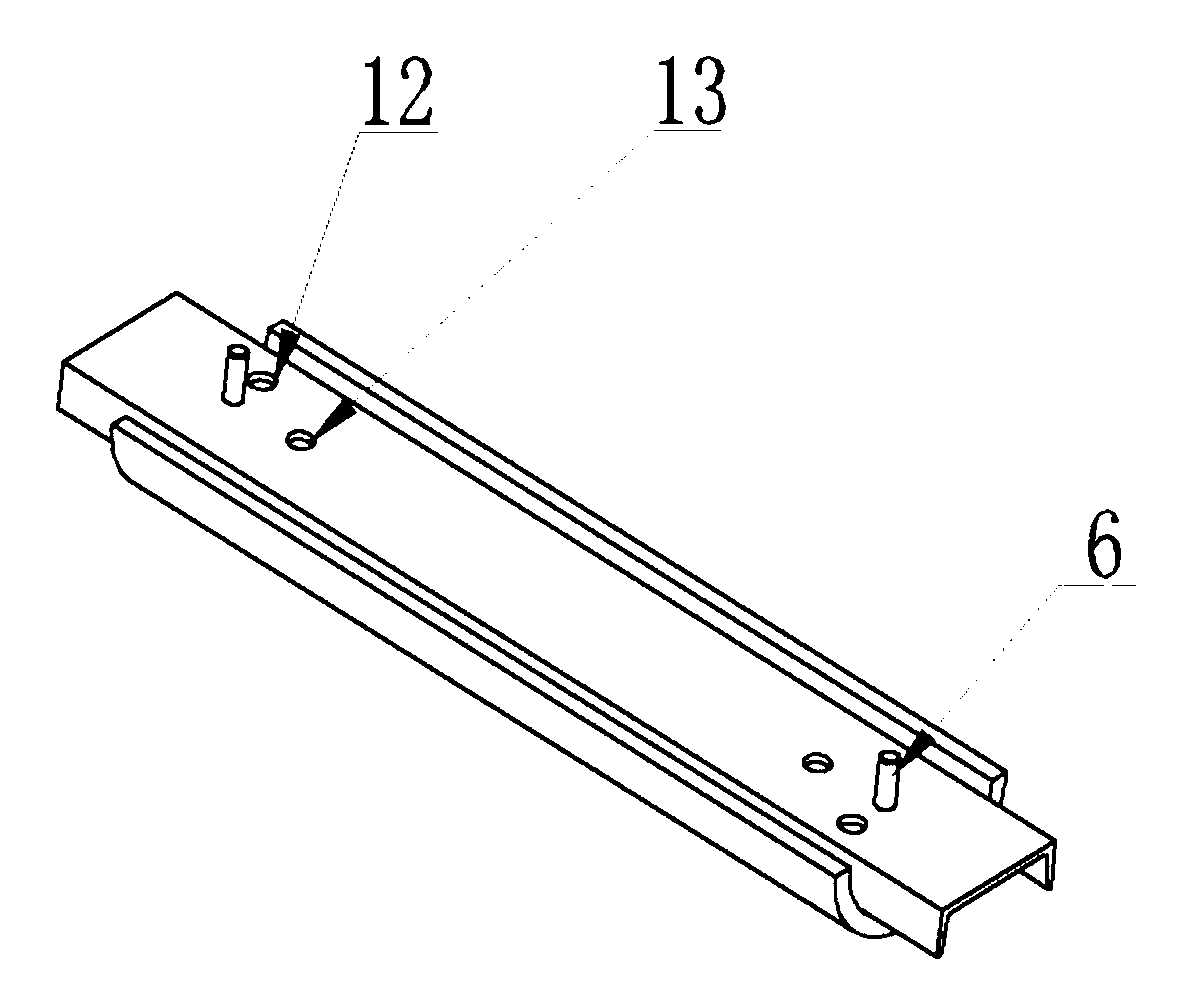

Directional automatic folding device for corrugated carton gluing machines

InactiveCN102343688AGeometrically accuratePrecise positioning of geometric dimensionsContainer making machineryCardboardEngineering

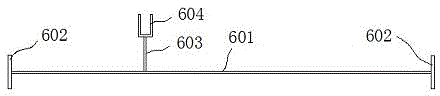

The invention discloses a directional automatic folding device for corrugated carton gluing machines. The device comprises a paper pressing assembly and a moving connection assembly, wherein the paper pressing assembly comprises a folding substrate, a folding support arm, a sliding shaft and a paper pressing plate which are sequentially connected; the moving connection assembly comprises a connecting bar, a slide block and an eccentric cam which are sequentially connected; and the folding substrate is arranged at the upper end of an external side guide seat of a corrugated carton gluing machine, and the eccentric cam is arranged on the outside of the external side guide seat of the corrugated carton gluing machine. The directional automatic folding device disclosed by the invention replaces the traditional belt continuous rolling and folding, the stressed area of a folded carton is large and equalized in exerted force; the folded carton moves along a preset direction, thus being precisely positioned, and no scissors gap and 'fishtail' phenomenon is generated; and a corrugated carton can have a precise geometric size, thereby meeting the need for large-scale and automatic production of the packaging industry.

Owner:施从高

Forming method of high-precision thin-wall ceramic tube

InactiveCN102431086AImprove plasticityImprove liquidityCeramic shaping apparatusClaywaresHigh densityMethylcellulose Powder

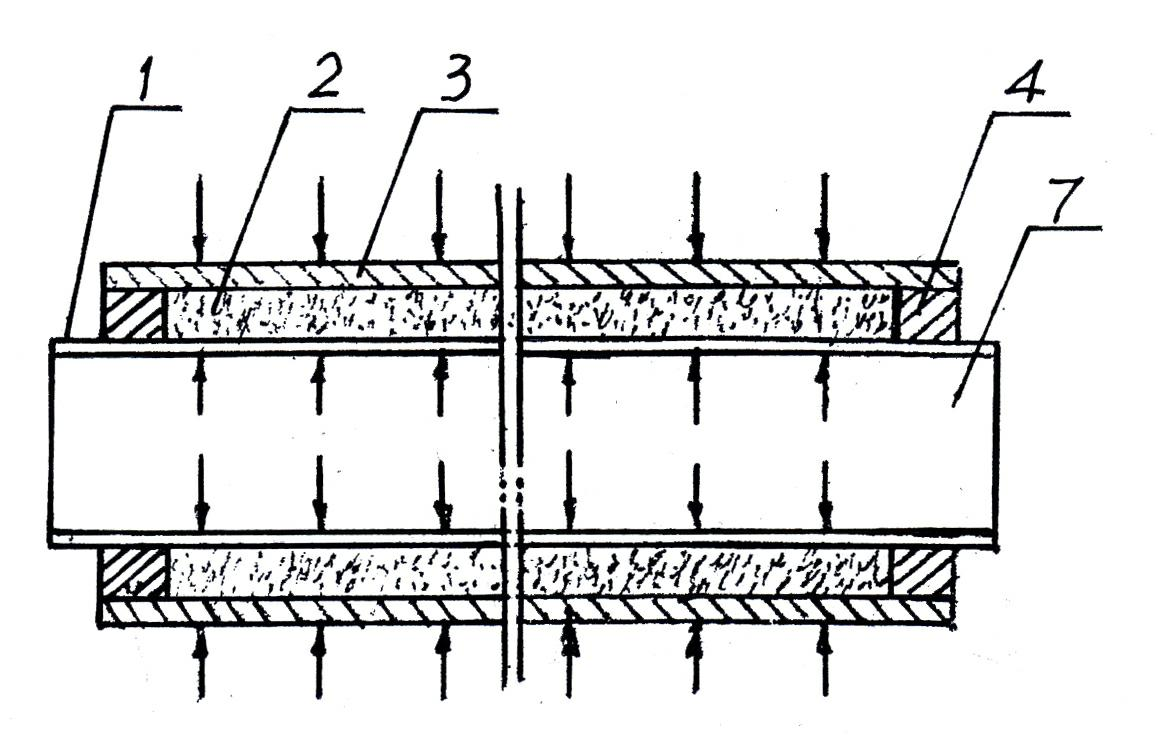

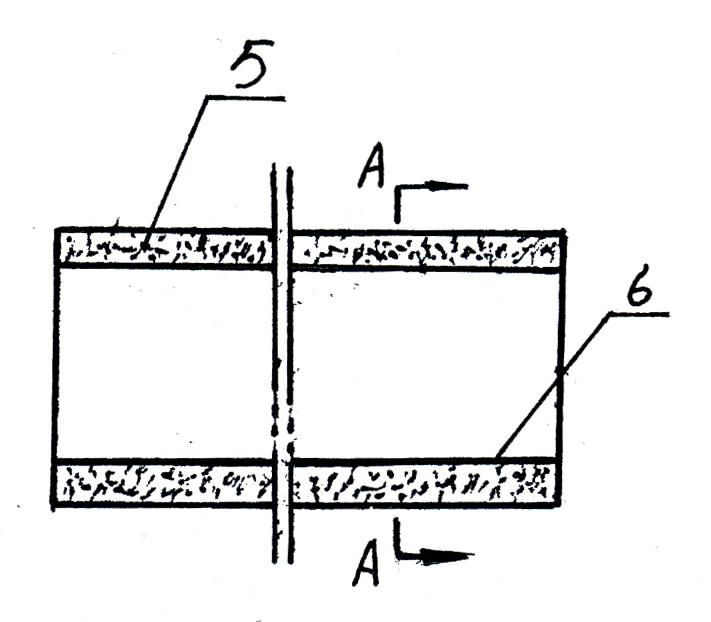

The invention discloses a forming method of high-precision thin-wall ceramic tube which can produce high-precision thin-wall ceramic tube with high density, accurate physical dimension of tube inside and external wall, and internal wall smooth as mirror. The forming method of thin-wall ceramic tube comprises steps as follows: (1) adding water to the formula material, ball milling to obtain mud material; (2) adding 1-3% methylcellulose powder into the mud material and smelting into mud bars; (3) extruding the mud bar into thin-wall ceramic tube blank and directly applying to a metal internal die tube, and drying to be pressed; (4) sleeving flexible oilproof rubber external die on external wall of the thin-wall ceramic tube blank and sealing the metal internal die tube and the rubber sleeve at two ends of the ceramic tube blank by oilproof rubber; (5) putting the ceramic tube assembly into a high pressure container, and forming by bidirectional isostatic pressing, removing the internal and external dies to obtain the high-precision thin-wall ceramic tube; (6) hoisting and sintering the high-precision thin-wall ceramic tube by conventional sintering method.

Owner:何剑明

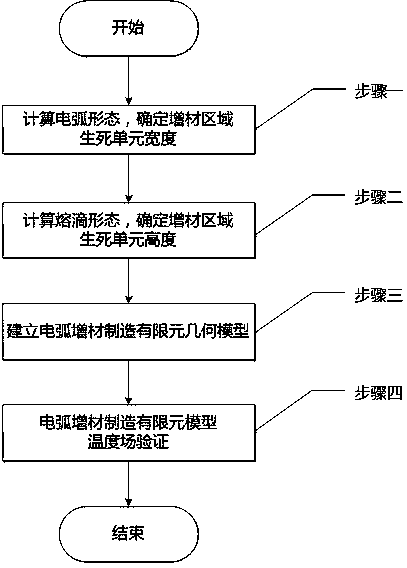

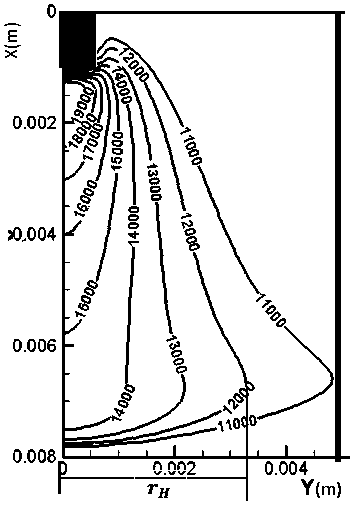

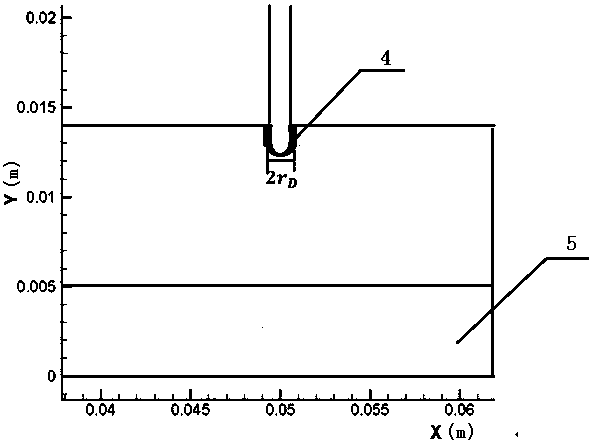

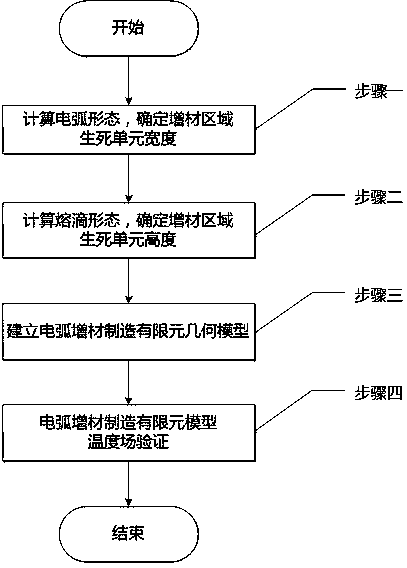

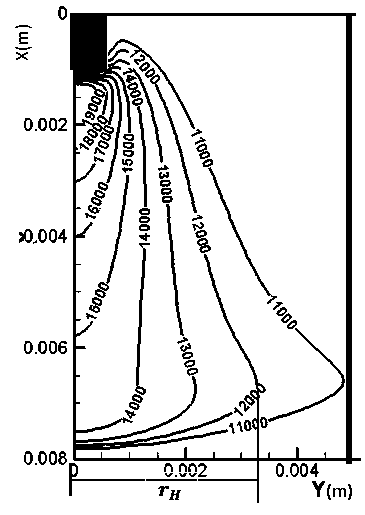

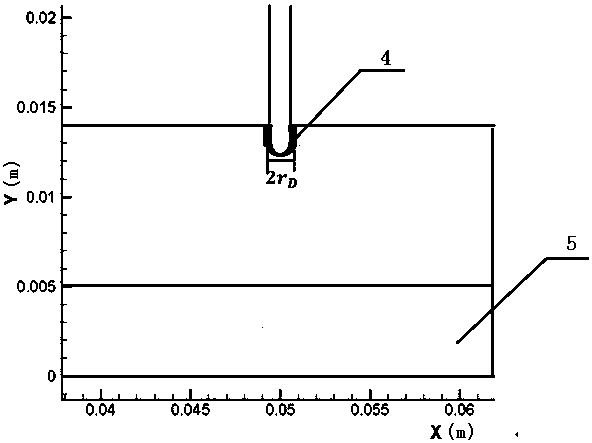

Arc additive manufacturing finite element modeling method

ActiveCN107066700AReduce the amount of experimentsImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsGeometric modelingElement modeling

The invention discloses an arc additive manufacturing finite element modeling method. The method comprises the following steps of: calculating an arc shape and determining the width of an additive area birth-death element; calculating a molten drop shape and determining the height of the additive area birth-death element; establishing an arc additive manufacturing finite element geometric model according to the width of the additive area birth-death element and the height of the additive area birth-death element; correcting the arc shape and the molten drop shape through verifying the temperature distribution of the arc additive manufacturing finite element geometric model, so as to correct the arc additive manufacturing finite element geometric model. According to the method disclosed by the invention, the geometric size of the additive area birth-death element can be determined before the arc additive manufacturing finite modeling by adopting an arc additive manufacturing simulation process, combining an arc shape simulation technology, a molten drop shape simulation technology and a finite element simulation technology and carrying out experimental verification, so as to realize the correct calculation of arc additive manufacturing finite element simulation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

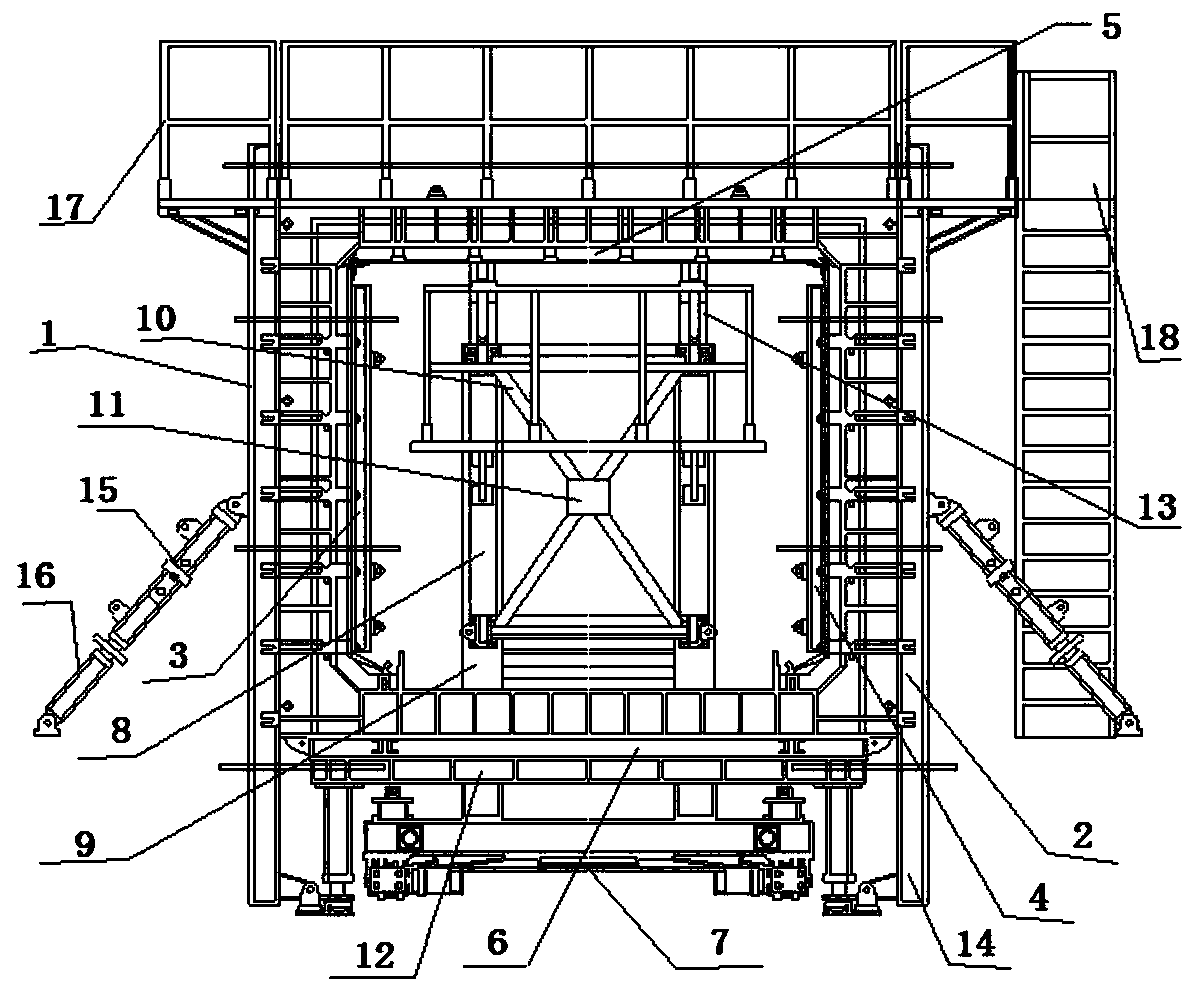

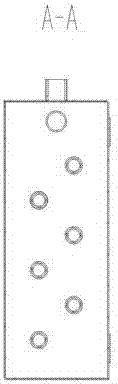

Integral hydraulic formwork applied to box culvert prefabrication

ActiveCN110394885AGuaranteed installation qualityQuick demolitionMouldsAuxillary shaping apparatusHigh surfacePrefabrication

The invention belongs to the field of box culvert pouring, and provides an integral hydraulic formwork applied to box culvert prefabrication. The integral hydraulic formwork comprises an internal formwork component, a bottom formwork component, an external formwork component, an end formwork component and a retaining formwork component; the internal formwork component includes internal formworks and an internal top formwork; the internal formworks include the first internal formwork and the second internal formwork; the bottom formwork component includes a bottom formwork; the external formwork component includes external formworks; the external formworks include the first external formwork and the second external formwork; the retaining formwork component includes a first retaining formwork and a second retaining formwork; the end formwork component includes a convex end formwork and a concave end formwork; and the space enclosed by the first external formwork, the second external formwork, the first internal formwork, the second internal formwork, the internal top formwork, the bottom formwork, the first retaining formwork, the second retaining formwork, the convex end formwork and the concave end formwork is used for pouring concrete. By mean of the integral hydraulic formwork applied to box culvert prefabrication, the prefabrication quality is high and stable, the adopted set shaped steel formwork has high surface rigidity, is not prone to deforming, and has good flatness.

Owner:INNER MONGOLIA ROAD & BRIDGE

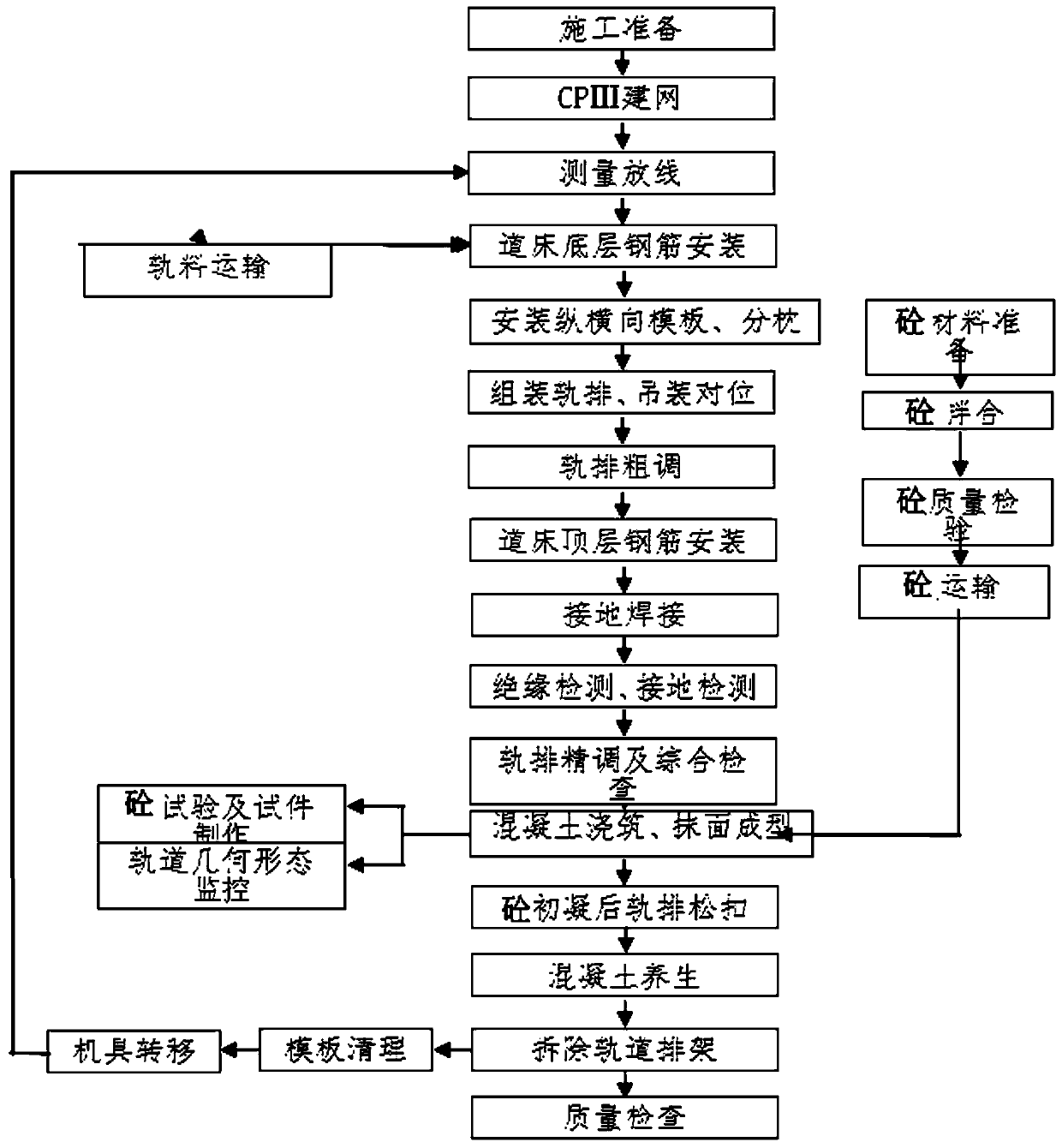

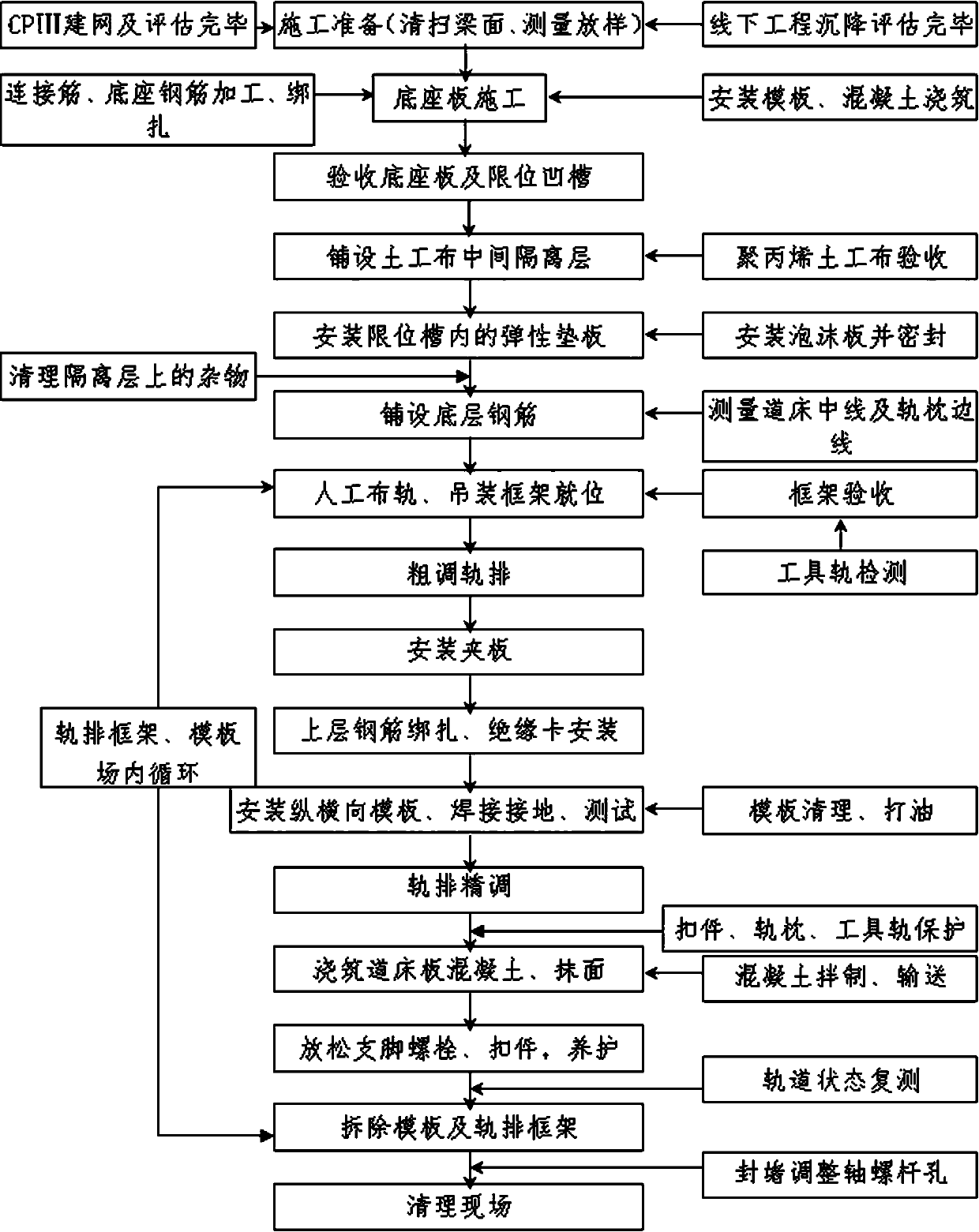

Construction method of ballastless tracks of tunnel group of heavy haul railway

ActiveCN110541329AAdvanced technologyHigh precisionBallastwayRailway track constructionRailway tunnelRebar

The invention relates to a construction technology of a heavy haul railway, specifically relates to a construction method of ballastless tracks of a tunnel group of a heavy haul railway. According tothe characteristics of high requirement on the construction precision of a ballastless track bed and difficulty in control in the construction of the ballastless tracks, the principle of near laying and convenience in precision control is adopted; a double-block sleeper is hung and placed to a position to be laid near a construction track bed plate; after key processes of steel bar binding, trackpanel assembly, comprehensive grounding, track coarse adjustment and the like are carried out, the geometric dimension of the tracks is finely adjusted by using a track inspection trolley measuring system, so that the design precision requirement is met, and finally, the track bed concrete is poured for one-step forming. The technology has the characteristics of being simple and convenient to operate, safe, practical, accurate in track geometric dimension, quick to position and the like.

Owner:CHINA RAILWAY SIXTH GROUP +2

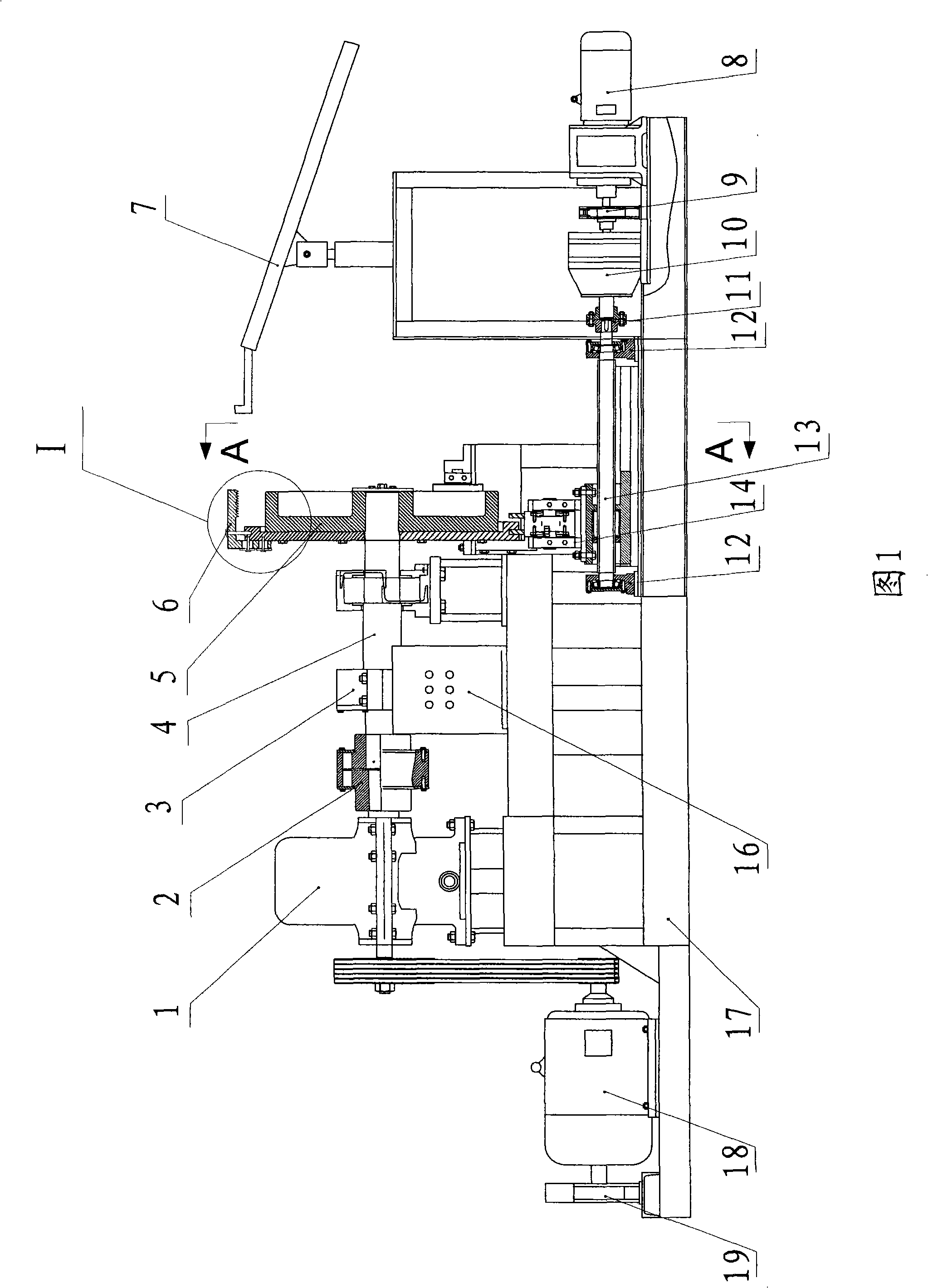

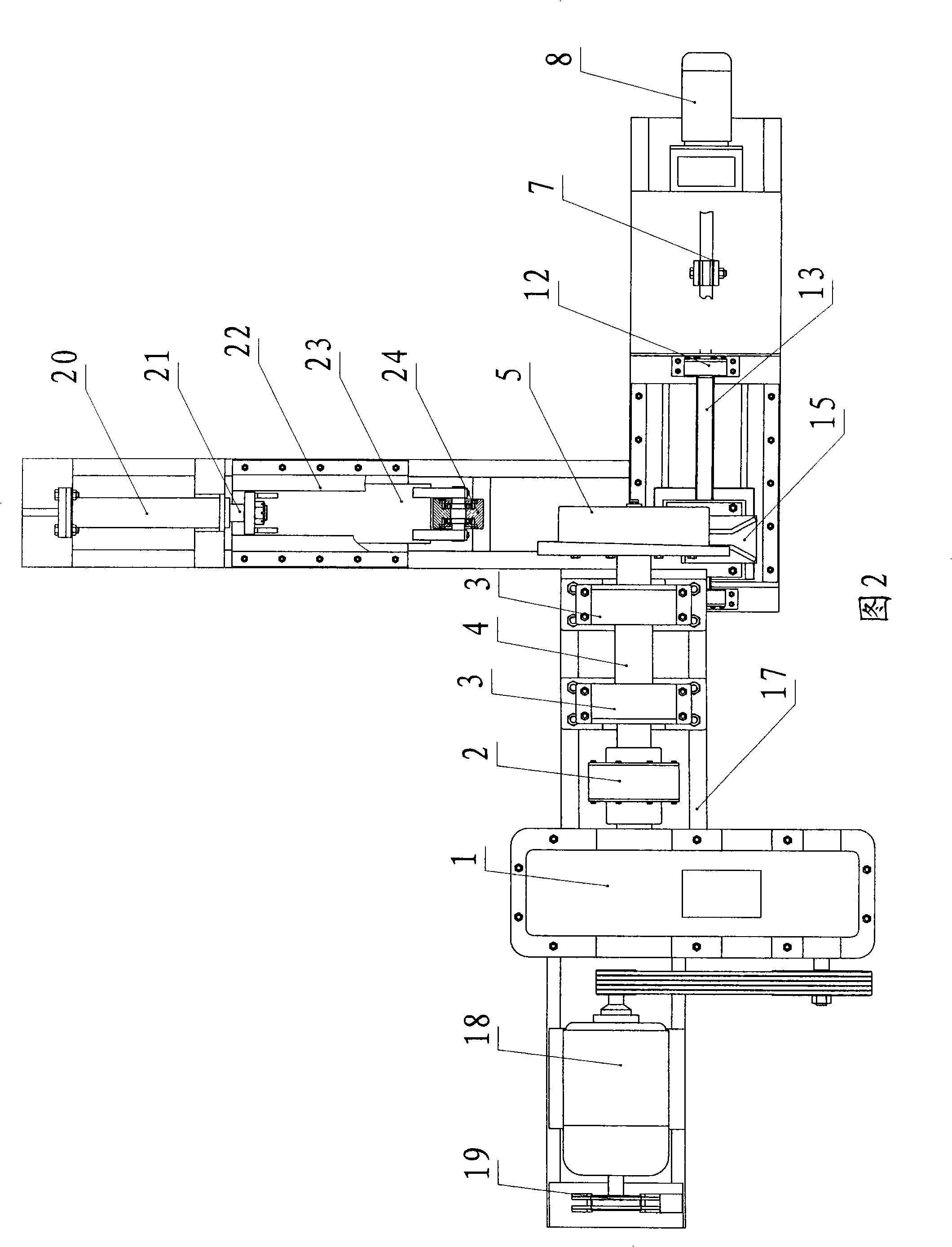

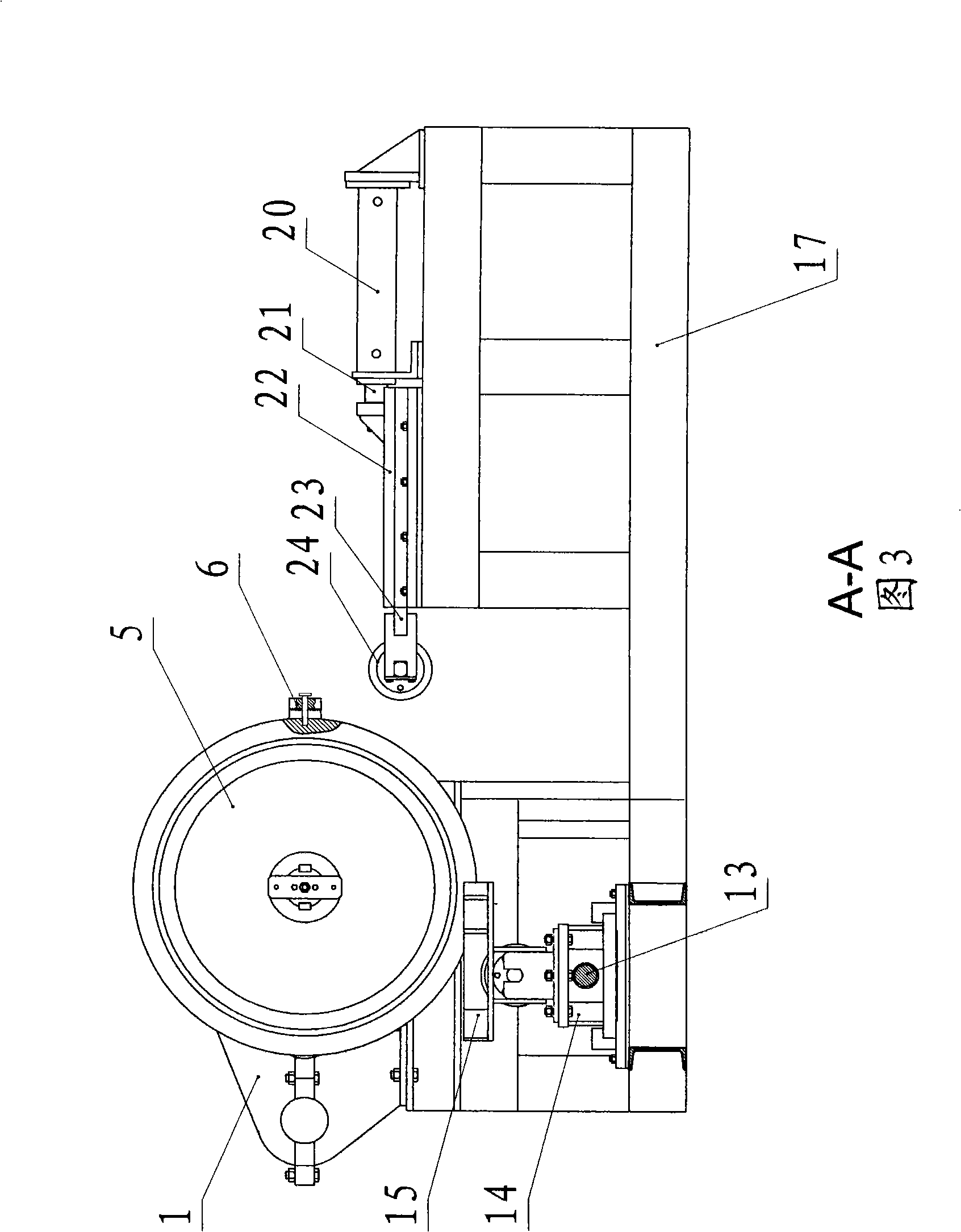

Hot-winding machine for flange workblank

InactiveCN101342553ASave raw materialsSolve problems that cannot be ruled outMetal-working feeding devicesPositioning devicesWinding machineCoupling

The present invention relates to a hot rolling machine of a flange roughcast, which comprises a stander, a power machine that is fixed on the stander, a reducer, a bearing box and a flat-steel guiding device, wherein, a main shaft passes through and is arranged inside the bearing box; one end of the main shaft is connected with the output shaft of the reducer through a coupler, and the other end is provided with a disc-shaped curling mold; the edge of the curling mold is provided with an end clip; a hydraulic jacked device is arranged in the same plane of the curling mold; a jacked wheel is arranged at the end of the jacked device. The hot rolling machine of the flange roughcast saves material, and has high processing precision, high processing speed and high production efficiency, and is favorable to be popularized.

Owner:CHANGTONG TECH

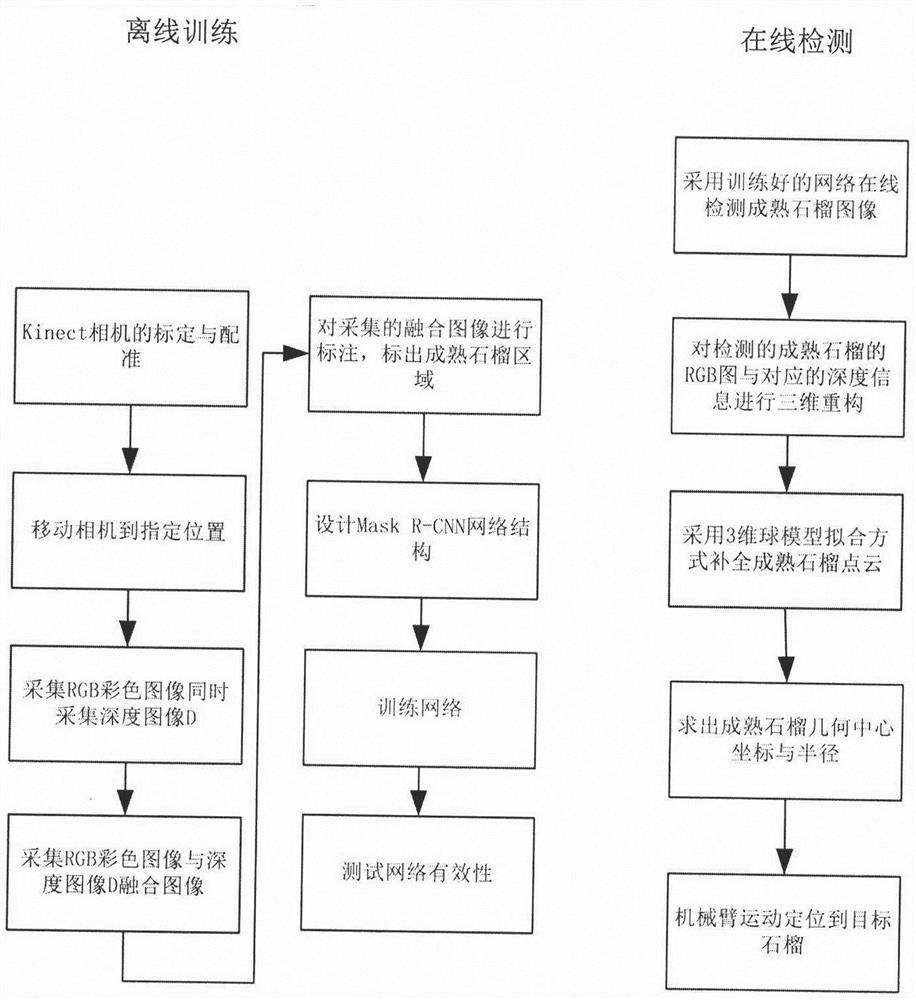

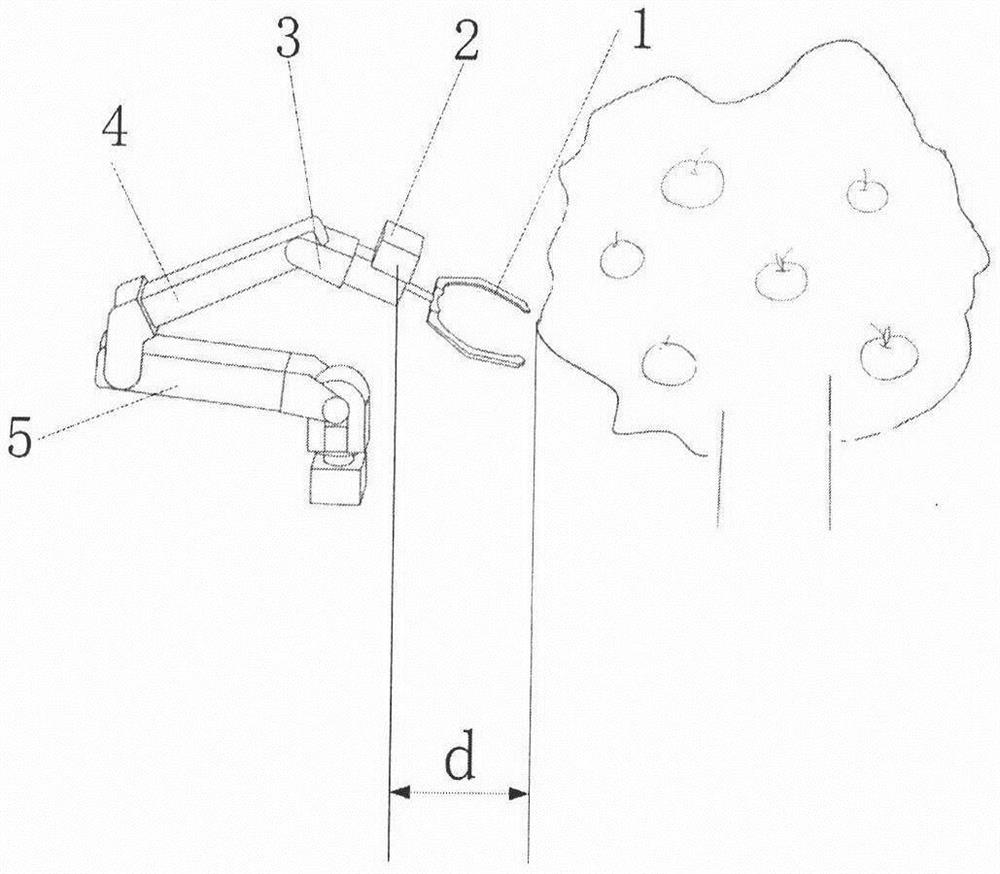

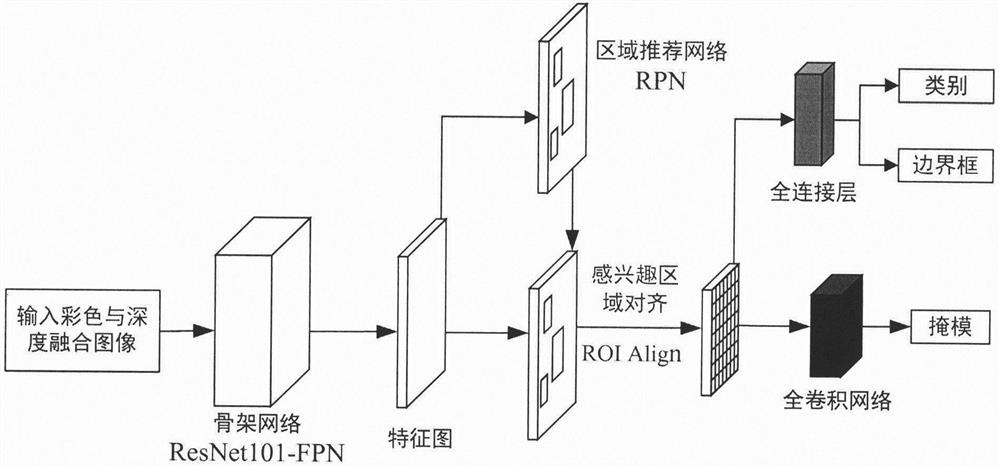

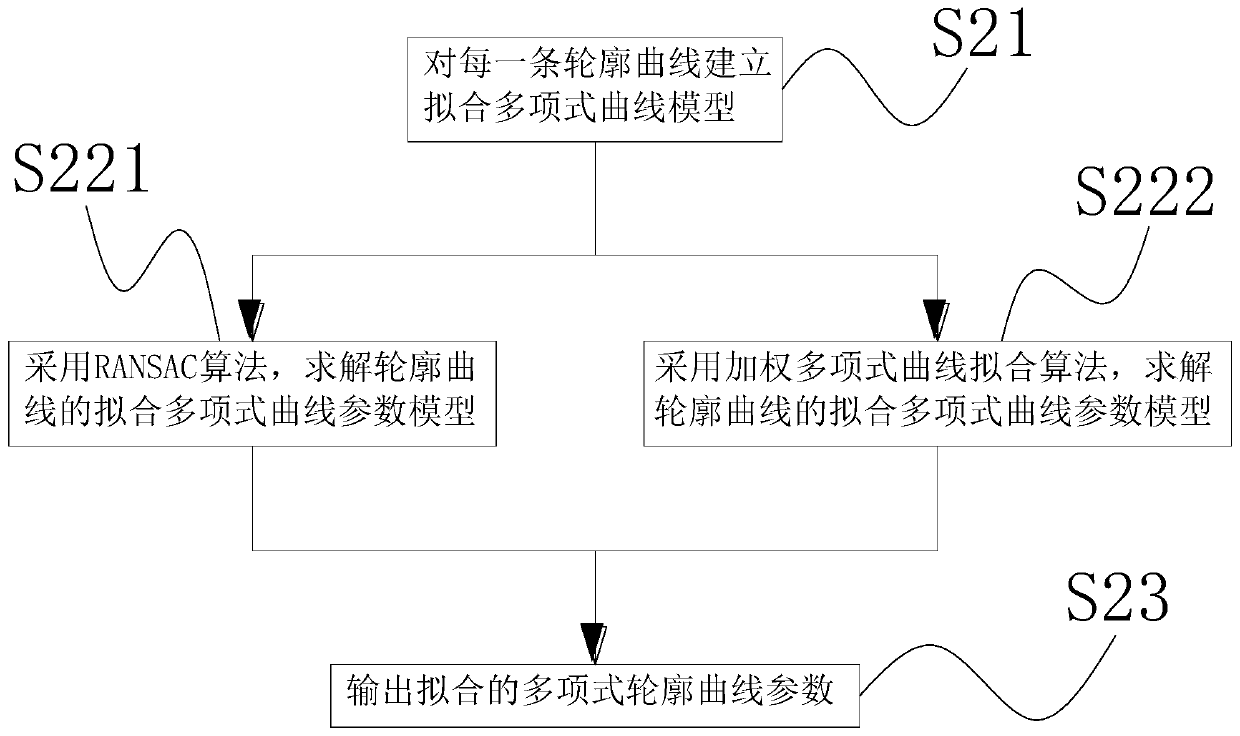

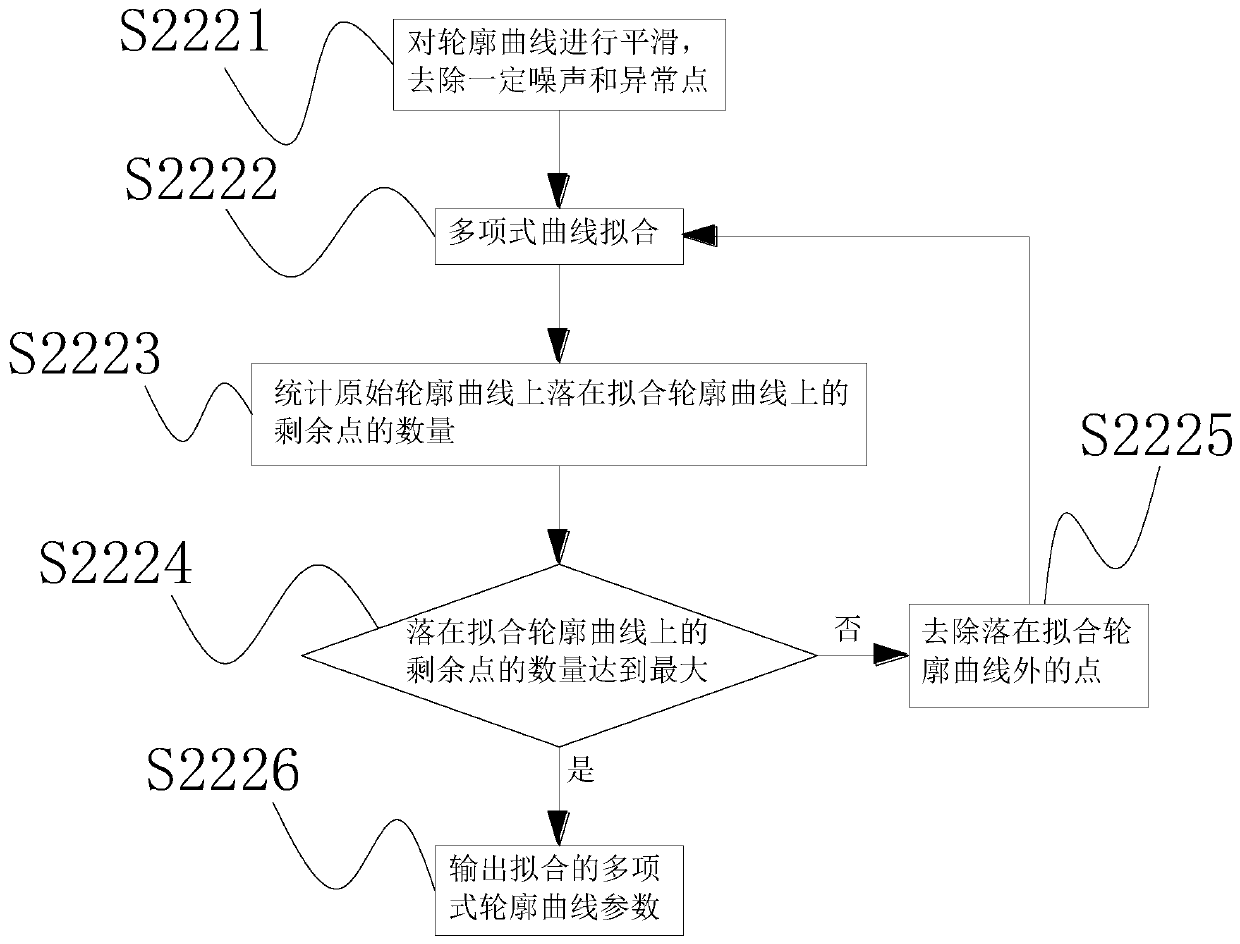

Mature pomegranate positioning method based on Mask R-CNN and three-dimensional sphere fitting

PendingCN112529948APrecise positioningEasy to pickImage enhancementImage analysisColor imagePoint cloud

The invention discloses a mature pomegranate positioning method based on Mask R-CNN and three-dimensional sphere fitting, and relates to the field of fruit picking and positioning of agricultural robots. Rapid and accurate positioning of fruits is the premise of accurate picking of the picking robot. According to the method, a pomegranate color image RGB and a depth image D are acquired by adopting Kinect V2.0, the acquired color image RGB is rapidly positioned to the picture position of a mature pomegranate by adopting Mask R-CNN, then a corresponding depth picture is segmented according to the RGB picture of the mature pomegranate, and three-dimensional point cloud reconstruction is performed by adopting camera calibration parameters and a rotation matrix; finally, the mature pomegranatepoint cloud is complemented for the single mature pomegranate point cloud data by adopting a mode of fitting a sphere based on a least square algorithm to obtain complete mature pomegranate point cloud data, and a target pomegranate is positioned. According to the method, the mature pomegranate is positioned by integrating the color image RGB and the depth image D, the defect that the actual sizeof the fruit is difficult to obtain only by using an RGB image positioning method is overcome, the complex matching process of multi-azimuth point cloud data fusion is also overcome, and the real-time performance and the precision of fruit positioning are greatly improved.

Owner:NANJING FORESTRY UNIV

Centre spinning method of boiler center barrel

The invention discloses a centrifugal casting method of central cylinder for boiler, main procedures of the invention are as follows: a corresponding forming mould of roller is produced, a forming stripping bush is prepared, sprinkled, and dried, fireproof coating is sprayed and dried, cast, a formed central cylinder cast for boiler is cooled by steam, a martensite is formed on the inner surface of the alloy steel molten and so on. The central cylinder for boiler produced by the centrifugal casting method of central cylinder for boiler has accurate geometric dimensioning with the length L between +-0.1 percent and the diameter theta between +-1 percent, high rigidity which is HRC45-65, thinning metallurgical structure and the equiax crystal reaches 30 to 70 percent. The service life of the central cylinder is 3 to 5 times longer than that produced by sand casting, and can be widely used for the production of central cylinder for boiler.

Owner:贾友军

Imaging detection method and system

PendingCN112415010AFast mosaicGeometrically accurateOptical rangefindersPhotogrammetry/videogrammetryMulti-imageRadiology

The invention discloses an imaging detection system and method, and aims to solve the problems that an imaging area lacks matching characteristics and needs more than two times of imaging for effective coverage, and geometric parameters of flaws, defects and other diseases in an image need to be accurately measured. A background conformation device generates a laser background pattern and projectsthe background pattern to an imaging detection area. An imaging device is composed of a camera and a corrected pattern projection device. The imaging device acquires a target image having a correctedpattern and a background pattern. When one background conformation device cannot cover the imaging detection area, a plurality of background conformation devices are used for projecting background patterns, the background patterns projected by the plurality of background conformation devices are overlapped in the imaging area, and the space combination relation of the background patterns formed by the plurality of background conformation devices is not changed in the imaging process. Image geometric correction processing is completed according to the corrected pattern projected by the imagingdevice, and multi-image mosaic matching is completed based on the background pattern.

Owner:CHENGDU ZHONGXIN HUARUI TECH CO LTD

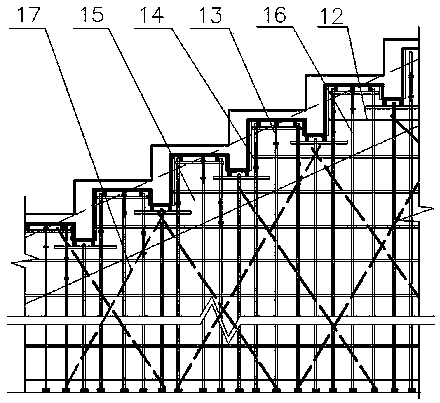

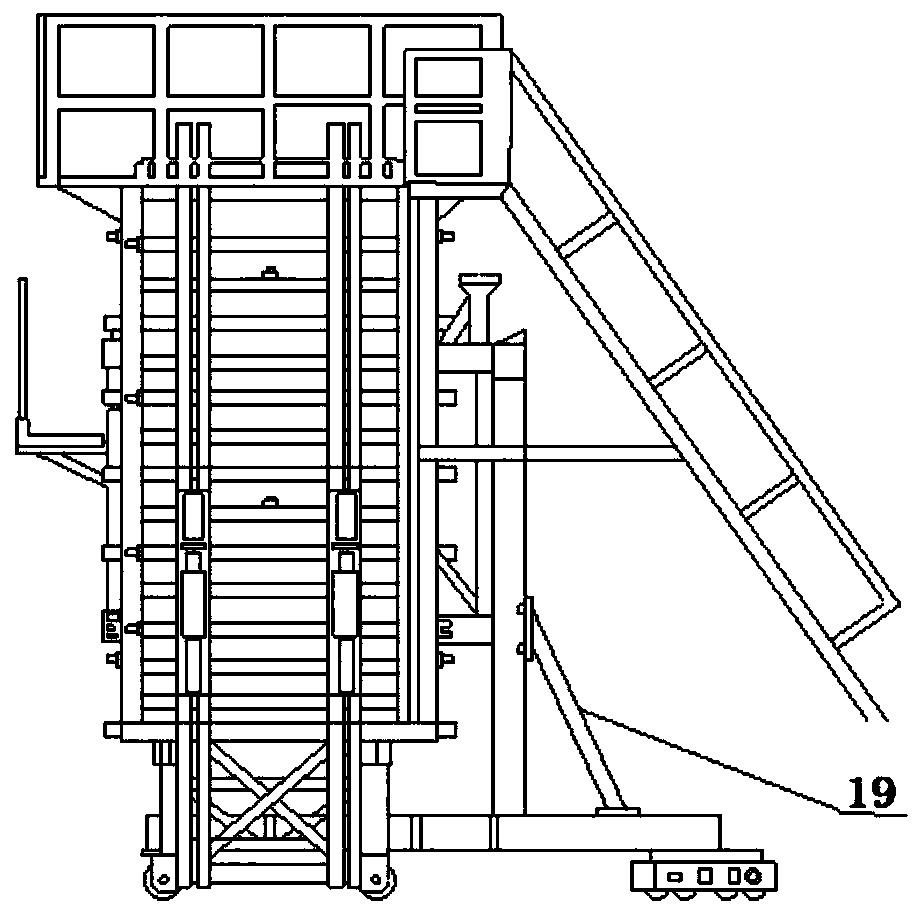

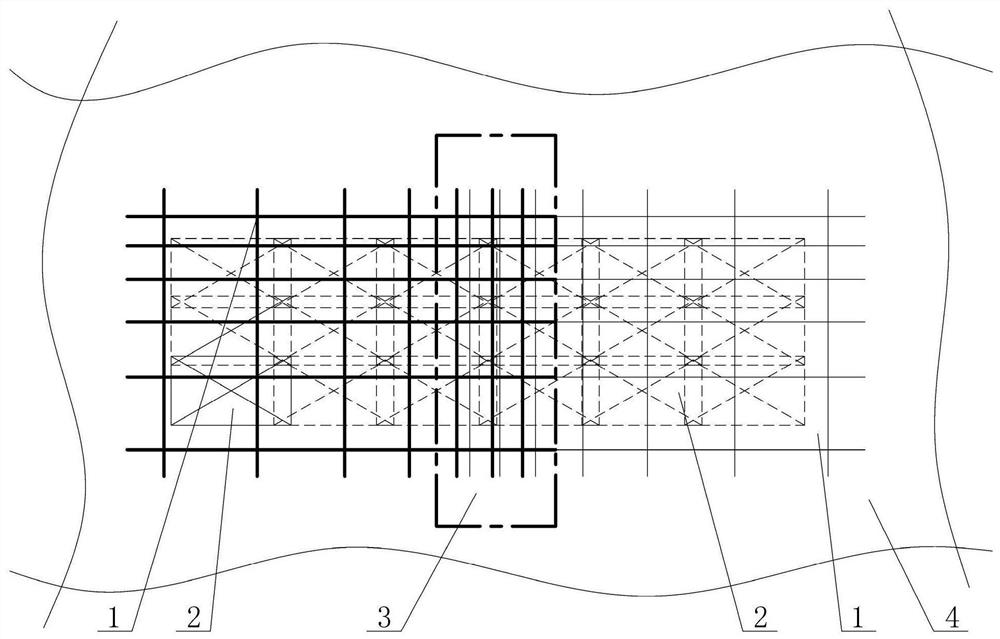

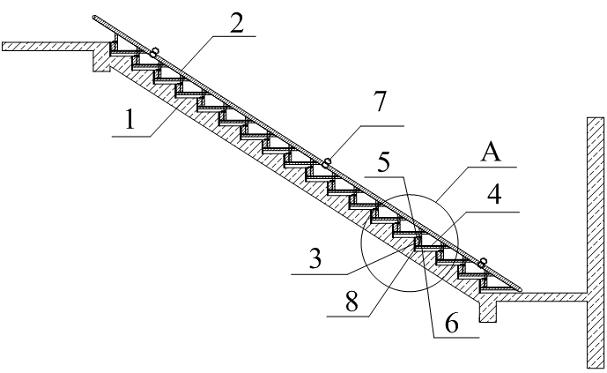

Staircase shaping support formwork

ActiveCN102140839ATotal class reductionSimple construction processForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksBuilding constructionStairs

Owner:四川省建筑机械化工程有限公司 +1

Producing technique for steel pipe cool sizing

InactiveCN101085452ASolve the problem of low yieldSimple processMetal rolling arrangementsThermal expansionEngineering

The steel tube cold radius fixing comprises the procedures of selecting material with the outer radius of the material bigger than the upper limit of the standard, composed of the design, adjustment and radius calibration of the rolling hole, inspection, cutting and final product delivery. It completely solves the difficulty of low yield rate of oil sleeve tube. It is simple, high in productivity, adjusted by corresponding roller, relying on the hydraulic pushing force to form the rolling hole, to get to the shrink of radius, calibrating circle, and rectifying the tube with quick operation. It is energy economical. It requires small investment and land occupation, free from heating furnace and cold bed. The yield rate is high, precise in adjustment dimension, free from influence of thermal expansion.

Owner:TIANJIN PIPE GROUP CORP

Method for manufacturing X 90 grade pipeline steel large-diameter thick-wall spiral submerged-arc welding pipe

The invention discloses a method for manufacturing an X 90 grade pipeline steel large-diameter thick-wall spiral submerged-arc welding pipe. The method comprises the following working procedures: uncoiling, flattening, edge milling, forming, welding, pipe end expanding, X-ray continuous detection, static hydrostatic testing, weld joint and base metal ultrasonic flaw detection, pipe end chamfering, pipe end shooting and finished product inspection; the welding working procedure comprises inside and outside prewelding, finish inside and outside welding; through reasonably selecting welding parameters, a weld joint and base metal can transit smoothly to reduce or eliminate undercut, and the weld joint has excellent mechanical property and ensures obdurability match of the welding pipe and a welded joint; while the pipe end expanding working procedure is carried out, an automatic spiral submerged-arc welding pipe perimeter measuring device is adopted to measure the perimeter in real time, so that real-time measurement and monitoring on the welding pipe perimeter during the forming process are realized, and precise geometric dimensioning of the welding pipe is ensured.

Owner:BAOJI PETROLEUM STEEL PIPE

Novel photoelectric heating device

PendingCN107062369ACompact structureExpand areaLighting and heating apparatusElectric heating systemAutomatic controlNew energy

The invention belongs to the technical field of new energy, and particularly relates to a novel photoelectric heating device. The novel photoelectric heating device comprises a shell, wherein a water tank body is arranged in the shell; a water inlet tube is arranged on one side of the water tank body; a water outlet tube is arranged at the bottom of the water tank body; sleeves are arranged in the water tank body; medium water is arranged between the water tank body and each sleeve; a quartz glass tube is arranged in each sleeve; a first high-temperature-resistant insulation porcelain seat is arranged on one side of each sleeve; and a second high-temperature-resistant insulation porcelain seat is arranged on the other side of each sleeve. The novel photoelectric heating device is initiated in China, has the characteristics of zero pollution, high efficiency and energy conservation, automated control, safety and reliability, multiple protection, mechanical and electrical integration, small size, zero noise and convenience in use, and can be widely used for places such as residential communities, workshops of plants, office buildings, villas, scenic areas, hotels, universities and colleges, hospitals, various petrol stations, expressway service areas, bath centers, railway stations and airports.

Owner:中创杰能(天津)科技有限公司

Aluminum alloy template assembling system for building

InactiveCN106401169AStable structureImprove stabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemSupport system

The invention discloses an aluminum alloy template assembling system for a building. The aluminum alloy template assembling system comprises a wall surface pouring system consisting of an aluminum alloy template, and a panel supporting system, wherein supporting structures for supporting are arranged on the outer wall of the wall surface pouring system; and the panel supporting system comprises supporting columns supporting the bottom end. By the adoption of a buckled aluminum plate structure, the aluminum alloy template system disclosed by the invention is simple in structure, attractive in appearance and high in functionality; the phenomena of easy deformation and breakage due to long-time use of cylindrical vertical columns in the technical field process such as warehousing equipment are solved, and the appearance performance of the aluminum alloy template system is improved; the aluminum alloy template system is relatively good in popularization and application prospect; and furthermore, a main beam of the aluminum alloy template system is relatively good in heavy effect, so that the safety and the stability of the integrated system are guaranteed.

Owner:湖北森峰铝模科技有限公司

Material-saving type inclination linking and supporting plate column cap wood formwork and construction method thereof

InactiveCN106639306AReduce inputReduce loss rateForms/shuttering/falseworksResource utilizationPlate column

The invention discloses a material-saving type inclination linking and supporting plate column cap wood formwork and a construction method thereof. The material-saving type inclination linking and supporting plate column cap wood formwork comprises four horizontal supporting plates, four inclination reverse moulds and four frame column formworks which are supported by steel pipe supporting frames composed of steel pipes. The four frame column formworks are vertically arranged and form a square-shaped upright column. The inclination reverse moulds extend outwards and obliquely upwards from the four sides of the top of the square-shaped upright column. The horizontal supporting plates are connected with the upper ends of the inclination reverse moulds and extend outwards in the horizontal directions. According to the column cap wood formwork and the construction method thereof, under the condition that the mounting construction process of the column cap formwork is met, whole wood formwork cutting is avoided as far as possible, and maximization, rationalization and economization utilization of the formworks and cants which are purchased newly and in the stipulated turnover frequency and repeatable resource utilization of the waste formworks and cants can be achieved.

Owner:徐仁贵

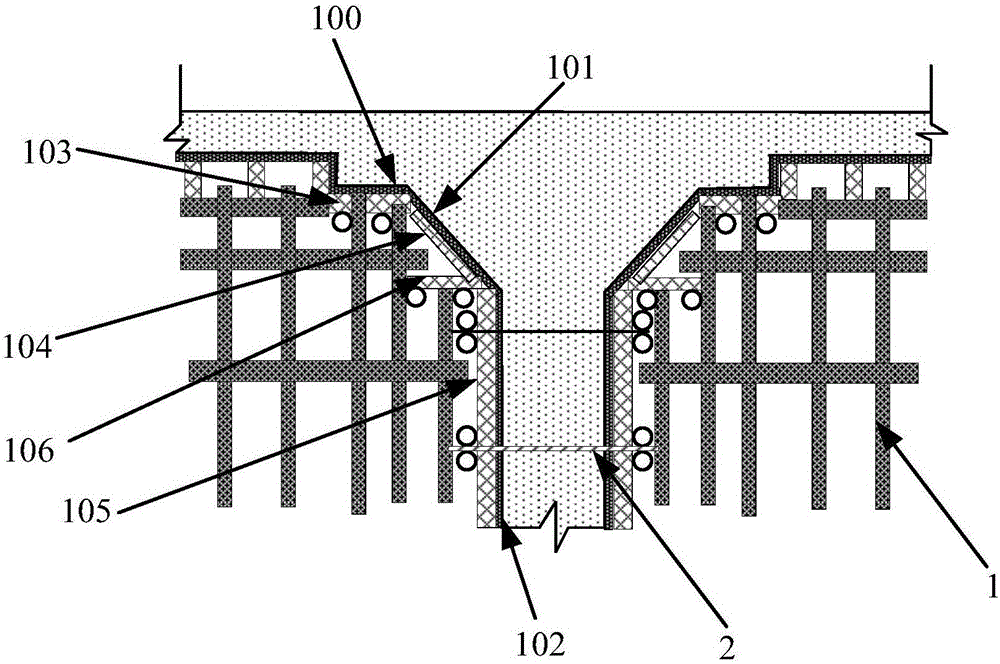

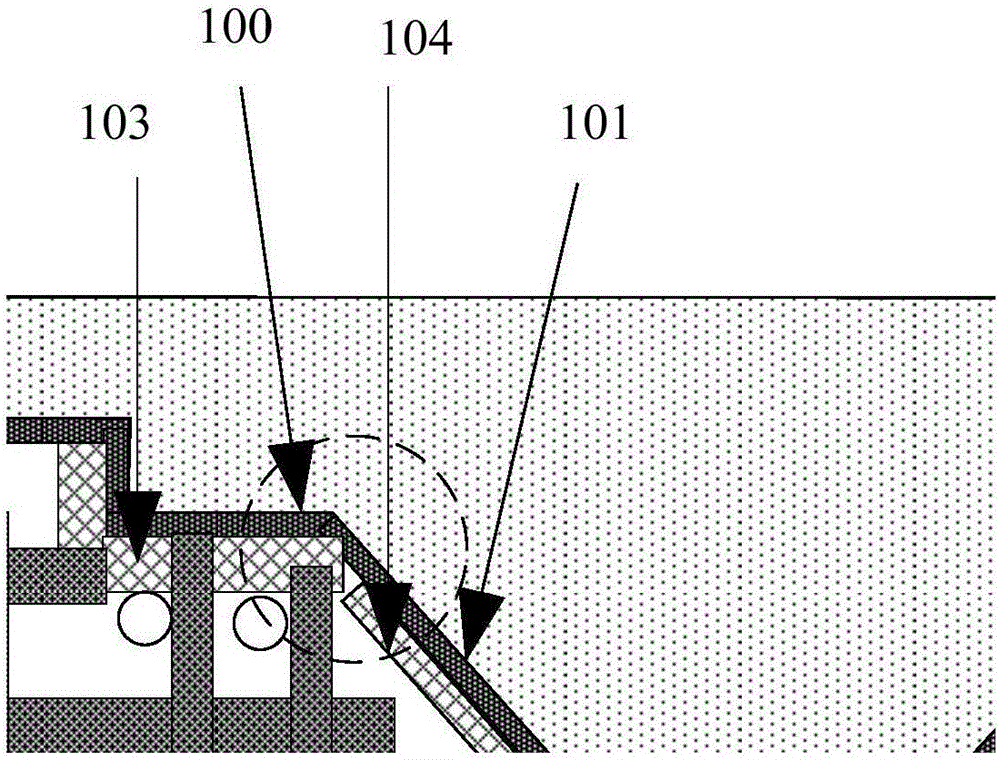

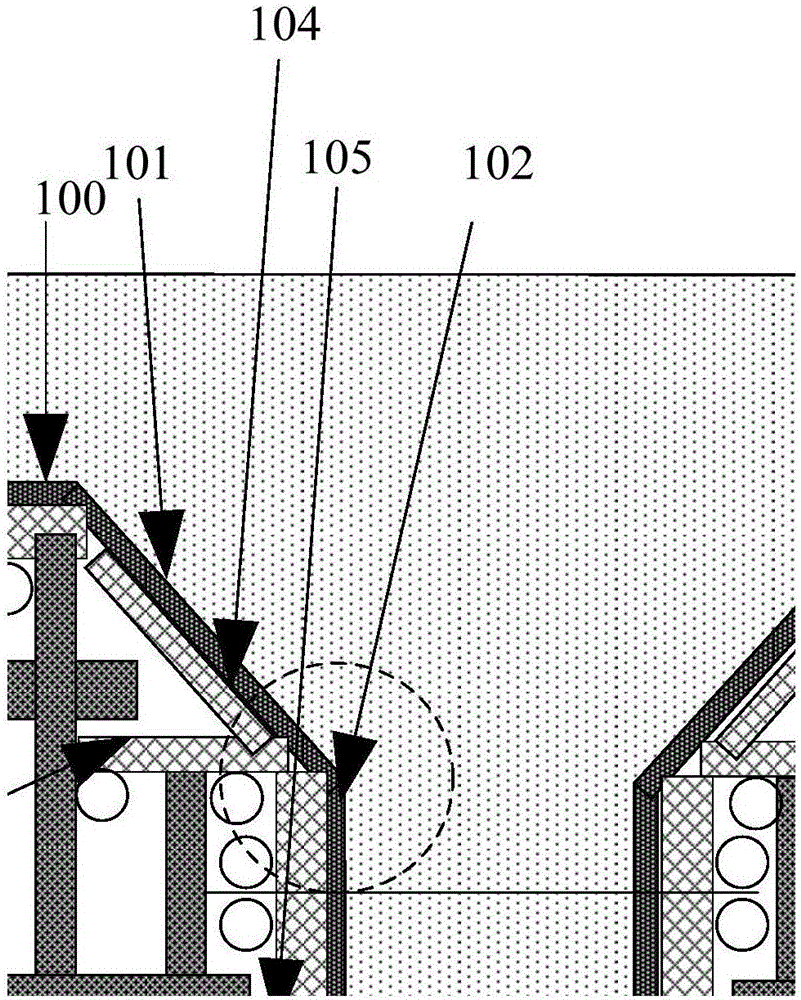

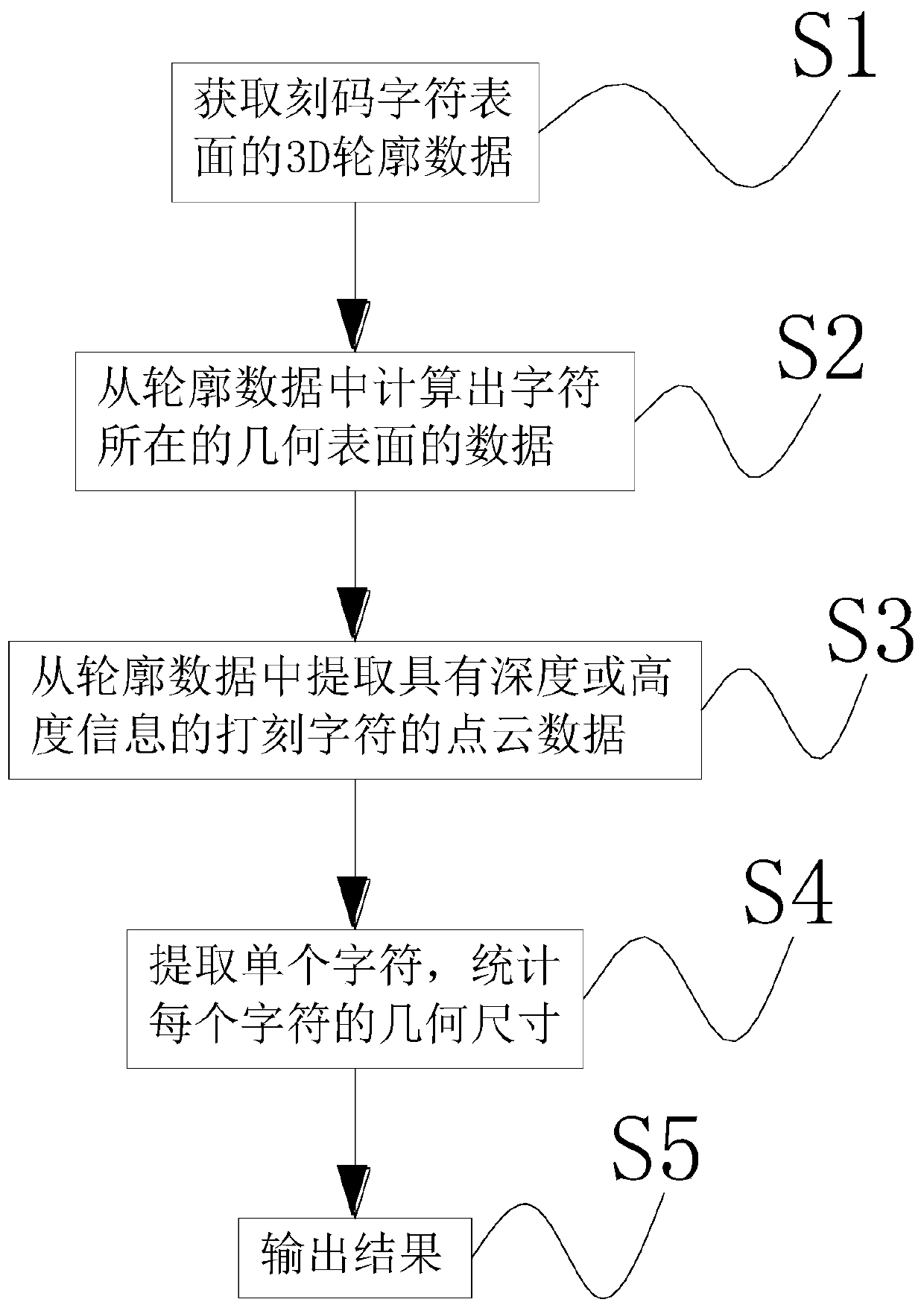

Method and device for detecting character size

ActiveCN110375645AReduce manual inspection costsImprove detection accuracyUsing optical meansPoint cloudComputer graphics (images)

The invention discloses a method and device for detecting a character size. The method comprises the steps: acquiring 3D contour data of the surface of an engraved code character; calculating data ofa geometric surface on which the character is located from the contour data; extracting point cloud data of an engraved character with depth or height information; extracting a single character and carrying out statistics of the geometric size of each character; and outputting a result. Besides, the device includes a 3D contour measuring unit, a guide rail, a rail fixing unit base, a motor, a motor driving unit, a displacement sensor and a processing unit. According to the invention, with full-automatic detection of the depth or height of the engraved character, the character size and adjacentcharacter spacing, the manual testing costs of the motor vehicle VIN code, engine number and the like in the motor vehicle manufacturing and inspection fields can be reduced; the detection accuracy and detection efficiency can be improved; and thus the method and device for detecting a character size have the great significance in promoting the inspection automation in the industry.

Owner:成都绝影智能科技有限公司

Method of supporting large-height shear wall form

ActiveCN103397779ARigidity is safe and reliableStrong, Safe and ReliableBuilding material handlingEngineeringRebar

The invention discloses a method of supporting a large-height shear wall form. According to the technical scheme, the method includes firstly, tying rebars on the lower three-meter portion of a shear wall, erecting a form, and pouring concrete; secondly, removing the form; thirdly, placing a scaffold plate 400*50mm on each triangular support, and erecting a 1100mm high guard rail on an inserting head of each triangular support through scaffold steel pipes; fourthly, attaching double-sided adhesive tape to the top of the existing shear wall, tightly attaching the form to the existing shear wall, and placing the lower portion of the form on the triangular supports; fifthly, repeating the steps for both sides, pouring the concrete, maintaining, and removing the form. The method has the advantages that stress performance is good, the rigidity and strength of the form are guaranteed, the form is safe and reliable, over-standard deformation under the constructional load action of poured concrete is avoided, and the geometry of the constructed concrete can be accurate.

Owner:CHINA MCC17 GRP

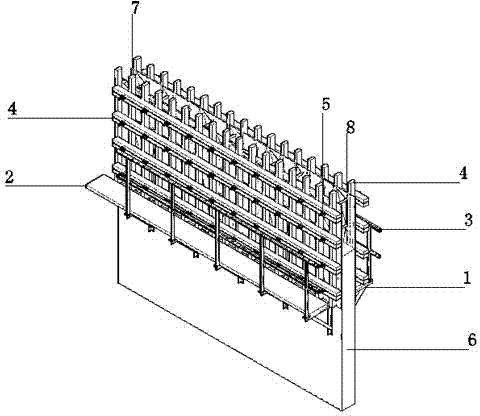

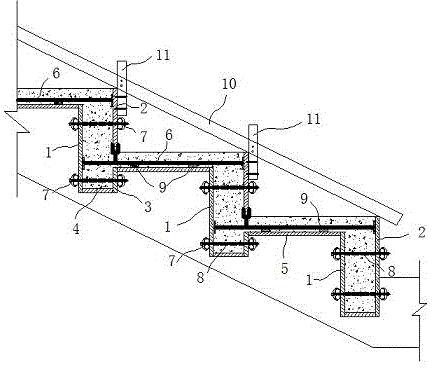

Cast-in-place Concrete Curved Ladder Stand Formwork Structure and Formwork Supporting Method

ActiveCN103362300BStable structureMeet construction requirementsForms/shuttering/falseworksBuilding material handlingShaped beamEngineering

The invention discloses a template structure and a method for template support of a cast-in-place concrete arc-shaped terrace. The template structure comprises a template support frame body and a template fixing system, wherein the template fixing system comprises arc-shaped beam bottom plate templates, seat plate bottom templates, arc-shaped beam outside upper templates, arc-shaped beam outside lower templates and arc-shaped beam inside templates, wherein the arc-shaped beam outside lower templates are positioned below the arc-shaped beam outside upper templates; internal supports are arranged between the arc-shaped beam outside upper templates and the arc-shaped beam inside templates for supporting and enable the arc-shaped beam outside upper templates and the arc-shaped beam inside templates to keep set intervals; split bolts are used for connecting and fixing the arc-shaped beam outside upper templates and the arc-shaped beam inside templates; split bolts are used for connecting and fixing the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the arc-shaped beam bottom plate templates are respectively connected and fixed with the bottom ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates; the seat plate bottom templates are respectively connected and fixed with the upper ends of the arc-shaped beam outside lower templates and the arc-shaped beam inside templates.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

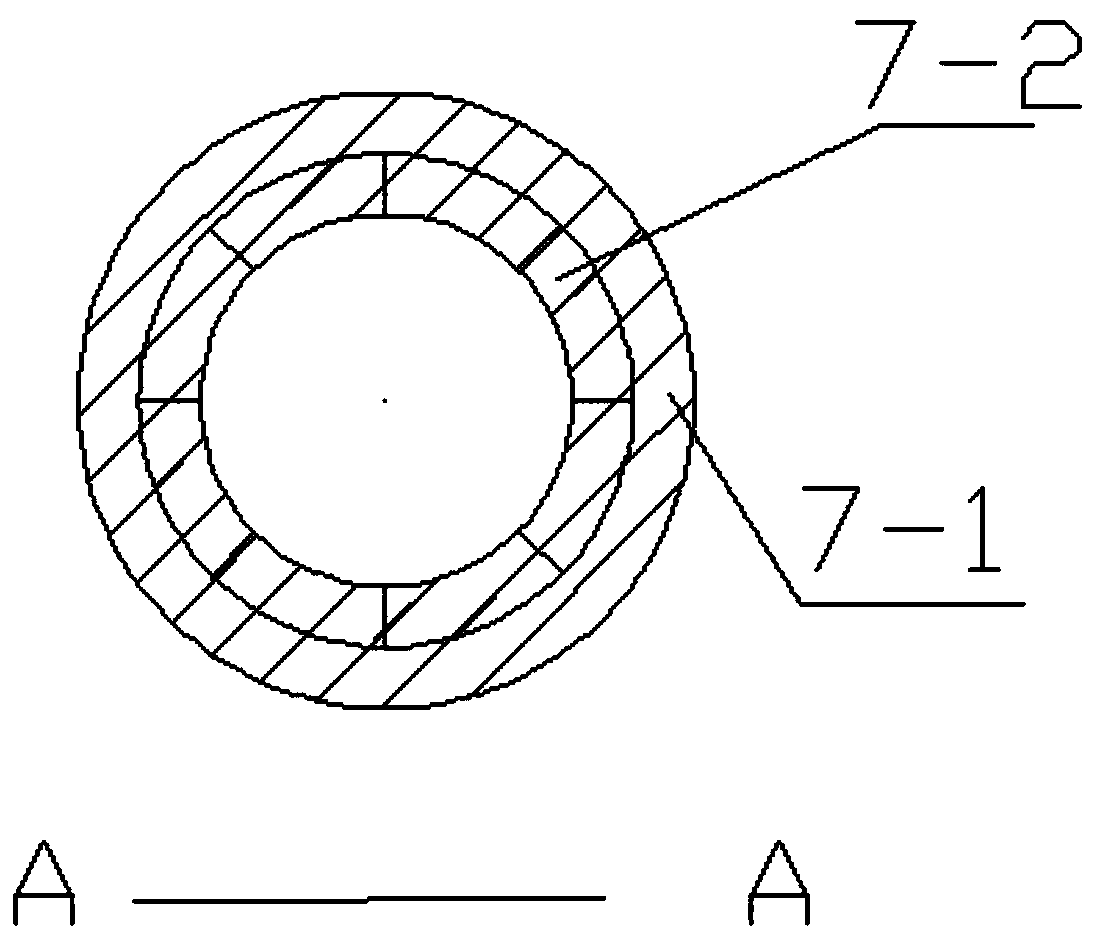

Test mould for preparation of shear thickening glue test piece and using method thereof

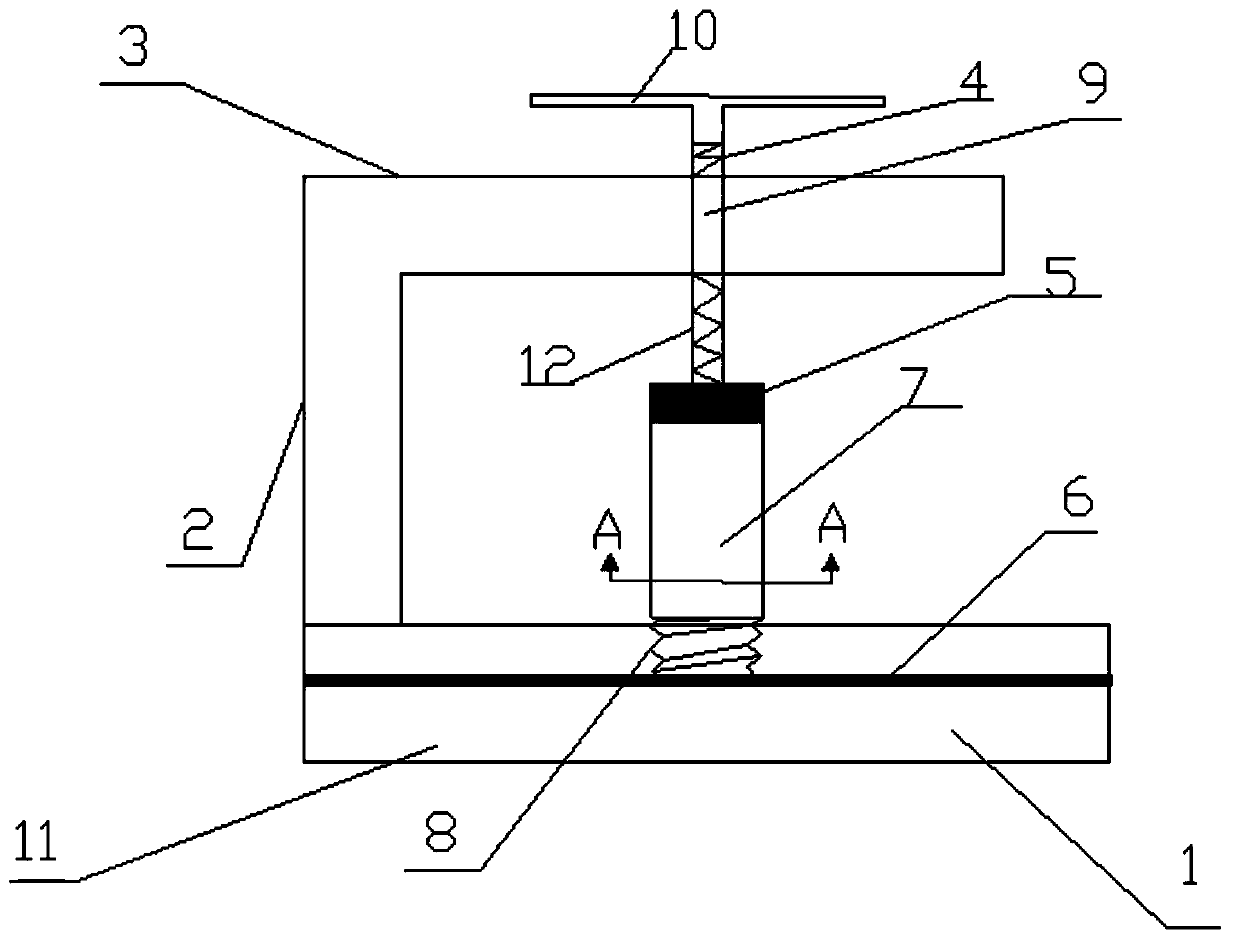

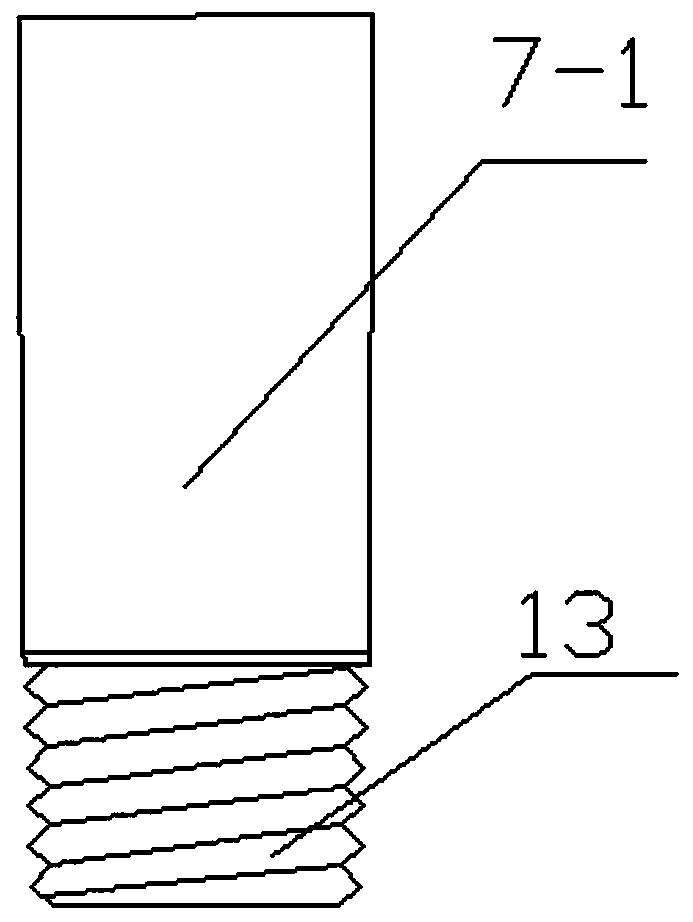

PendingCN109765092AGeometrically accurateDense internal structurePreparing sample for investigationMoulding devicePiston

The invention relates to a test mould for preparation of a shear thickening glue test piece and a using method thereof. The test mould comprises a base device, a test piece mould device and a test piece compaction device, wherein the base device comprises a base, a fixed slot, a buffer foam layer, a support frame, a cross beam and a threaded hole; the test piece mould device comprises an outer design finalizing cylinder and a jointable sheet-like cylinder; and the test piece compaction device comprises a screw, a piston type pressing plate and a handle. The test mould is capable of improving the compaction and moulding quality of the shear thickening glue test piece while simplifying the manufacturing process of the shear thickening glue test piece, and is suitable for the manufacturing ofthe shear thickening glue test piece for rheological test. On the basis of characteristics of shear thickening glue, the shearing speed is relatively low in the test piece preparation process, and the fluid state between shear thickening glue particles is lubricating contact and deformation is easy to occur, the jointable sheet-like cylinder overcomes the difficulty, solves the problem that the test pieces is easy to destroy when being directly taken during traditional test piece preparation, and a broad application prospect is provided in the aspect of preparing the shear thickening glue test piece in laboratories.

Owner:ANHUI UNIV OF SCI & TECH

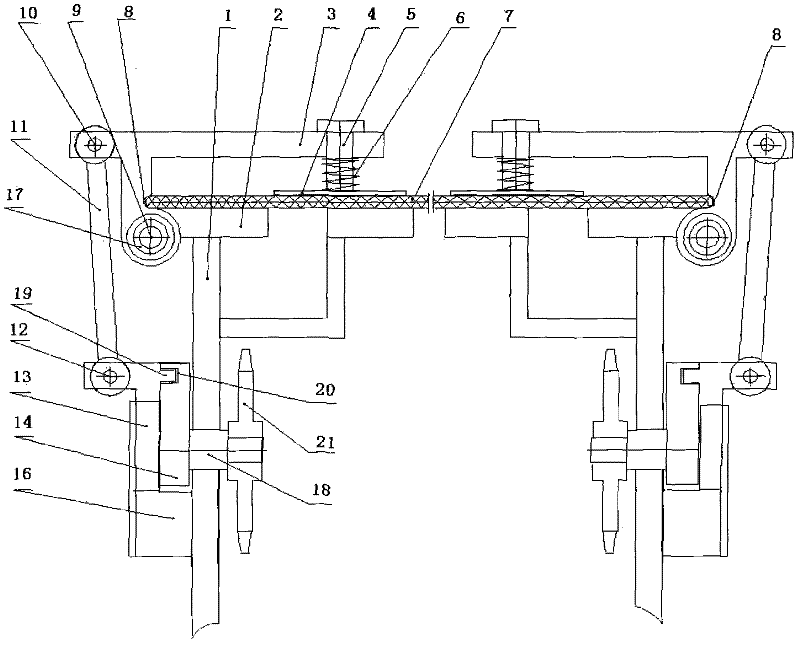

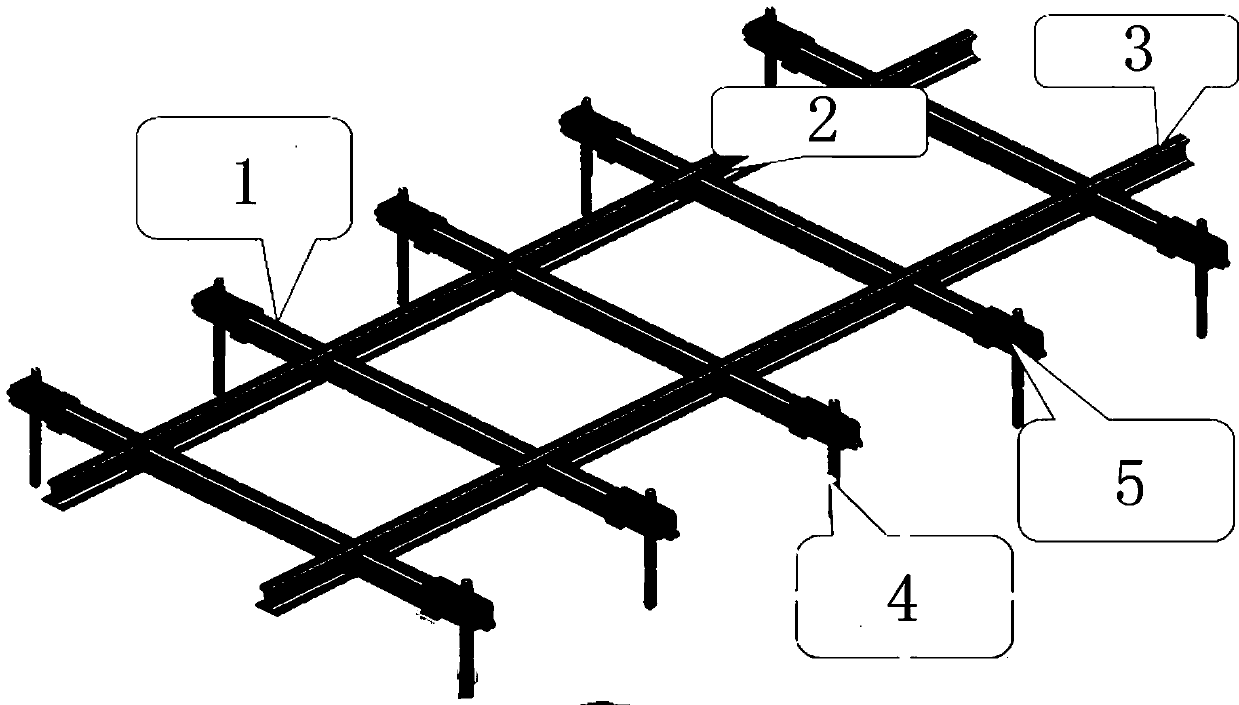

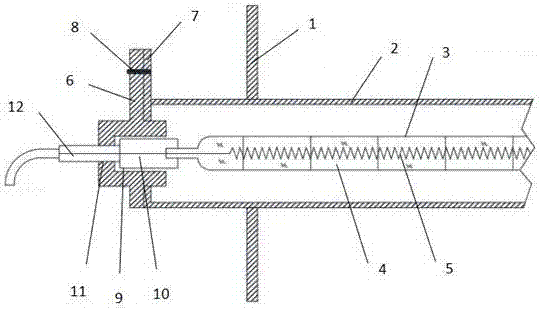

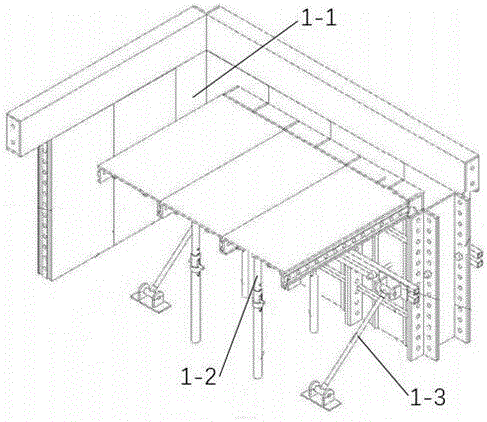

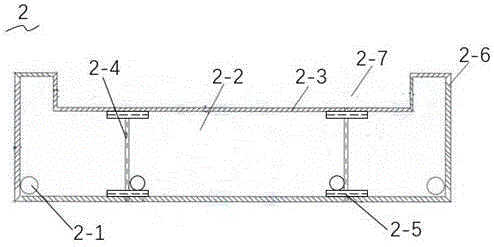

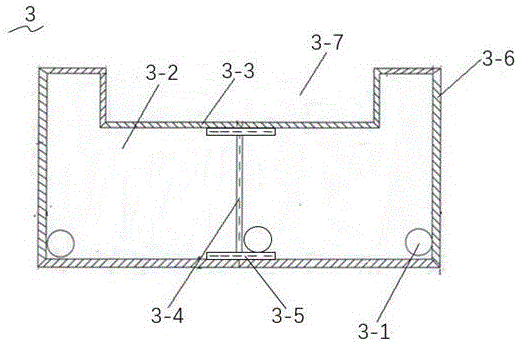

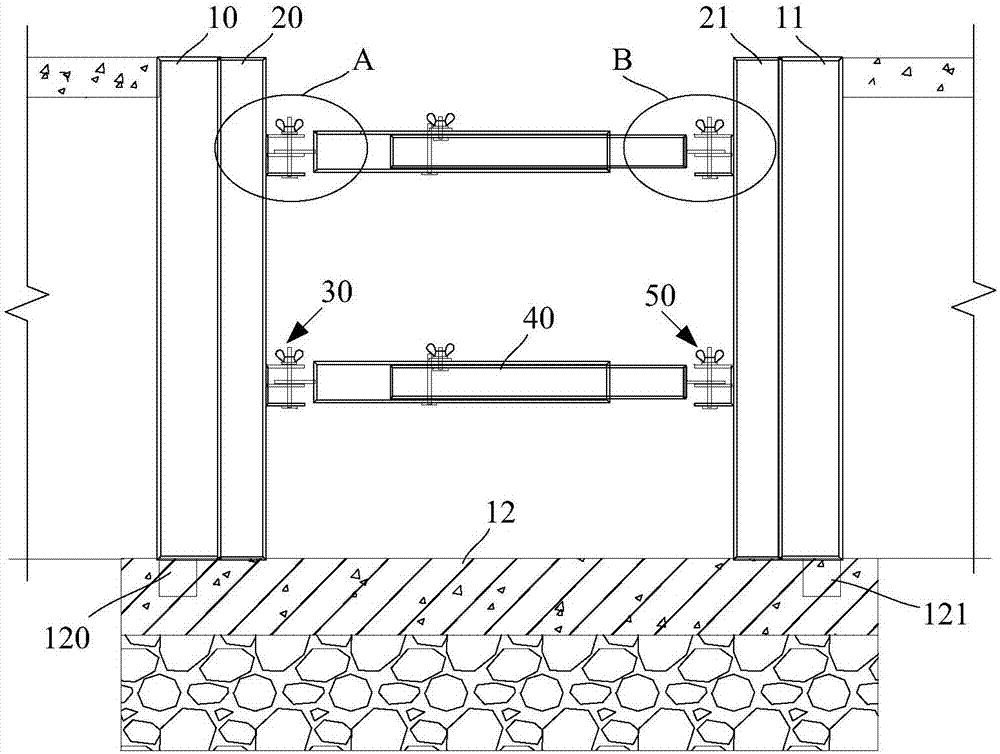

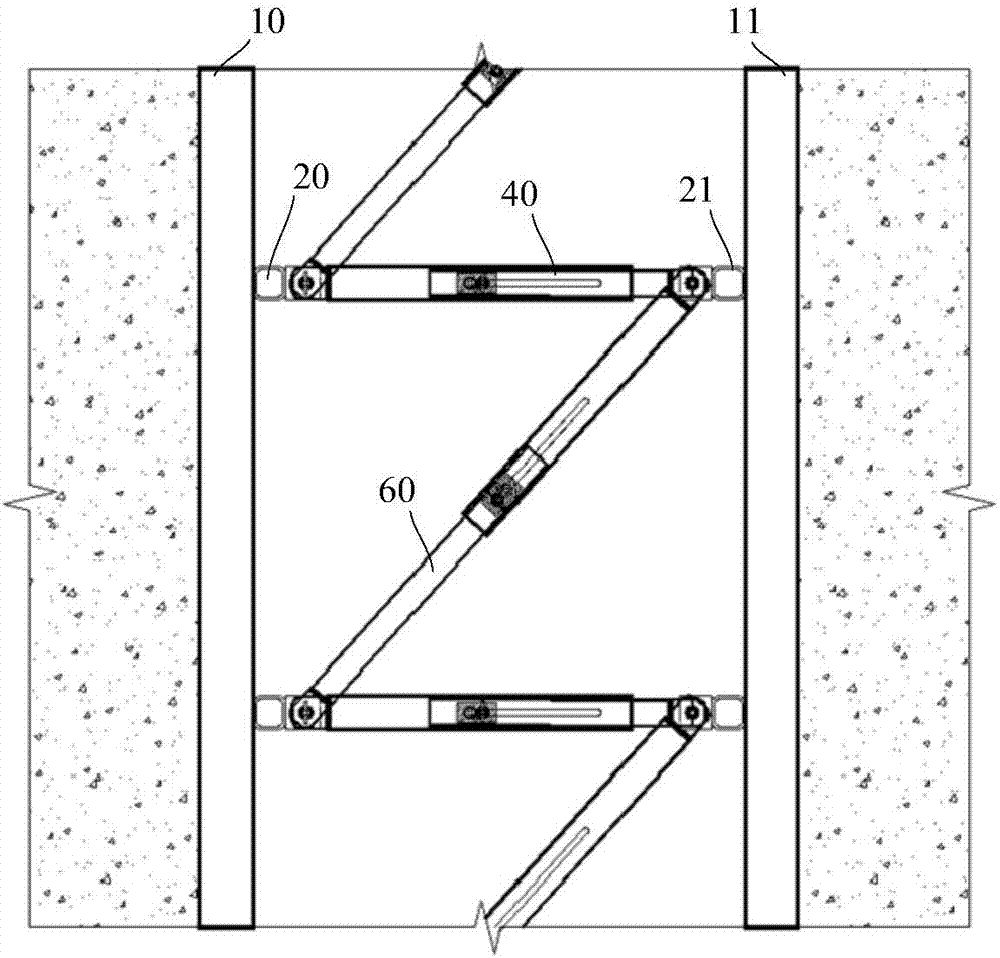

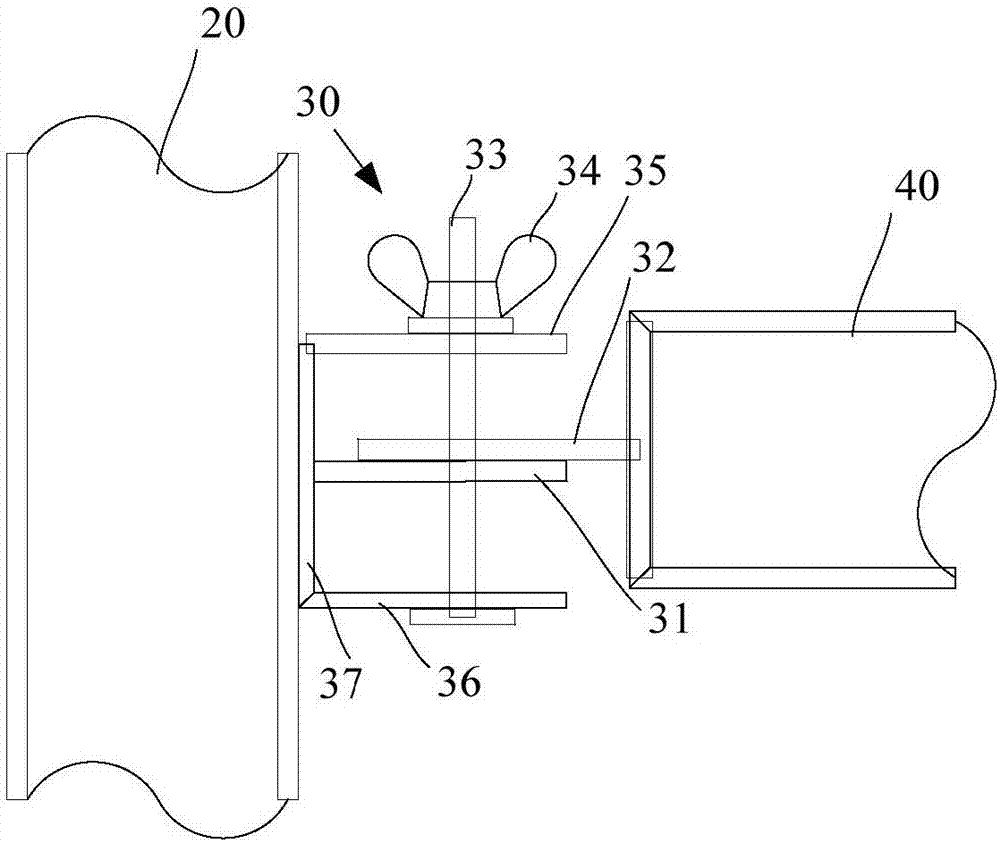

Inner support device of basement precast slab mold and construction method

ActiveCN107313451AGeometrically accurateStable structureArtificial islandsUnderwater structuresBasementCushion

The invention relates to an inner support device of a basement precast slab mold and a construction method. The device is used for supporting between a first precast slab and a second precast slab oppositely arranged; the first precast slab and the second precast slab are vertically arranged on the edge of a basement cushion layer; and the inner support device of the basement precast slab mold comprises at least one first stand column vertically arranged in a basement and bonded on the first precast slab, at least one second stand column vertically arranged in the basement and bonded on the second precast slab, at least one first hinge piece fixed on the first stand column, at least one second hinge piece arranged corresponding to the first hinge piece and fixed on the second stand column, and at least one support pipe capable of adjusting the length, connected between the first hinge piece and the second hinge piece and supported between the first stand column and the second stand column. The device is convenient in disassembly and capable of recycling.

Owner:CHINA CONSTR EIGHTH ENG DIV CORP LTD ZHEJIANG CONSTR CO LTD

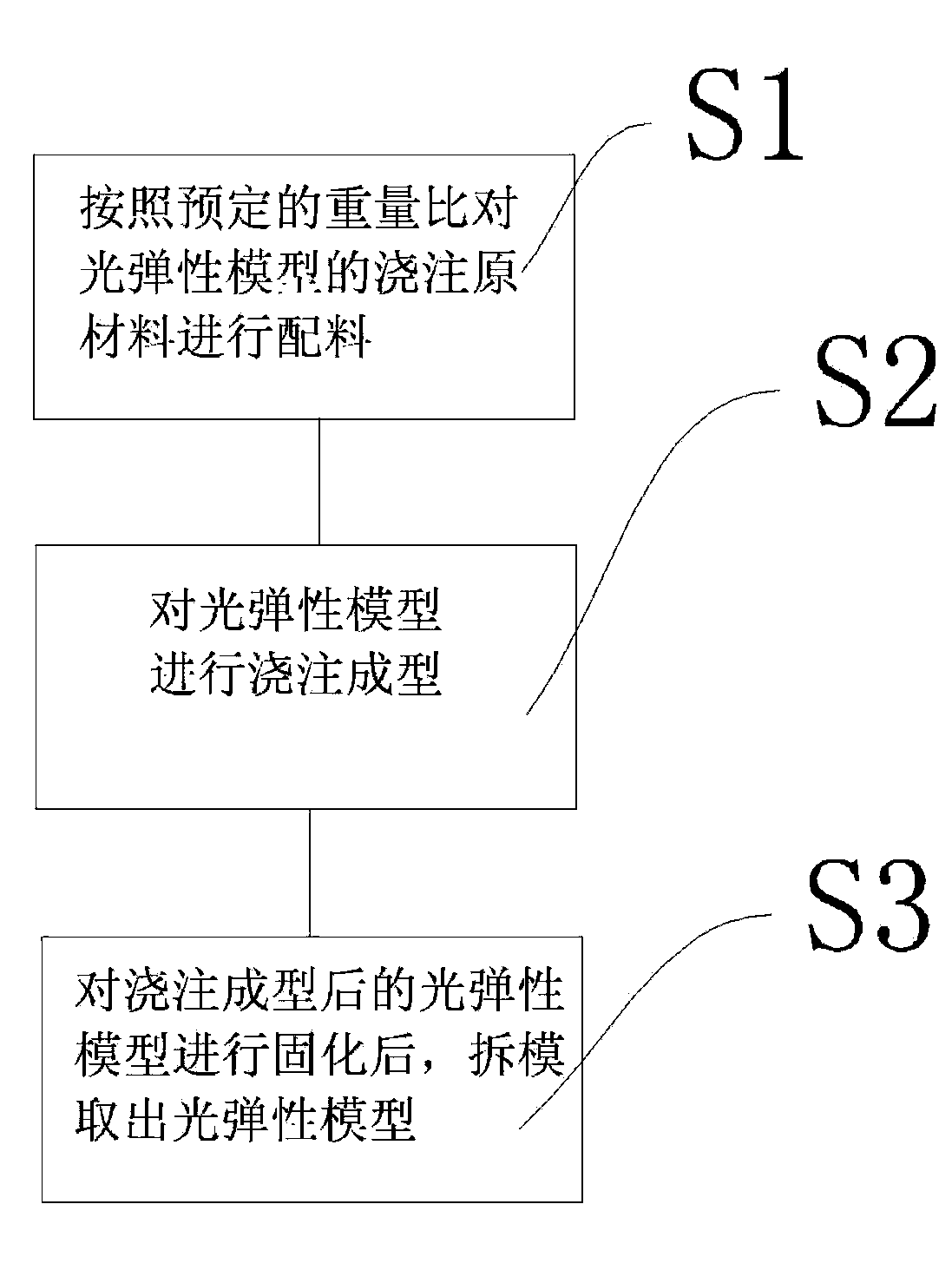

Vacuum casting process method of photoelastic model

The invention relates to a vacuum casting process method of a photoelastic model. A vacuum casting forming machine and a silicon rubber female mold arranged in the vacuum casting forming machine are used for casting forming, the automation degree is high, the errors are few, and in addition, the harm to human bodies by harmful gas released in the casting process because of artificial participation is avoided. The process comprises the following steps that: step 1, epoxy resin 128 and succnic acid are respectively weighed according to the weight proportion being 100:30-35 in accordance with the photoelastic model to be cast, in addition, the epoxy resin 128 and the succnic acid are uniformly mixed under the vacuum condition of a vacuum stirring temperature control room, the purity of raw materials is improved, and the nonuniformity of materials is avoided; step 2, after a forming chamber of the model is subjected to vacuum pumping, the poxy resin 128 and the succnic acid uniformly mixed in the step 1 are filled into the silicon rubber female mold, and the casting forming is carried out; and step 3, the photoelastic model after the cast forming is solidified.

Owner:CHINA AVIATION POWER MACHINE INST

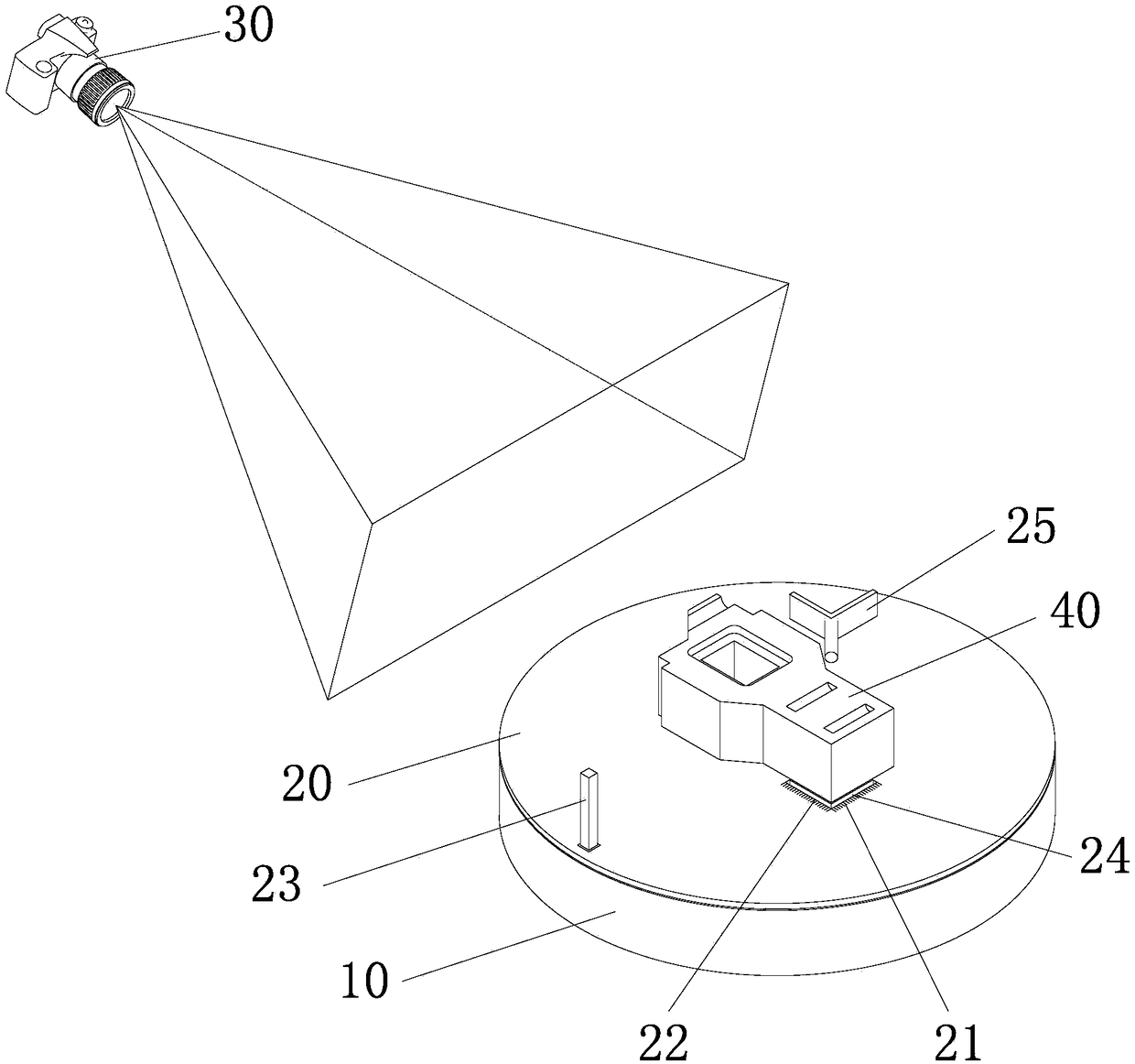

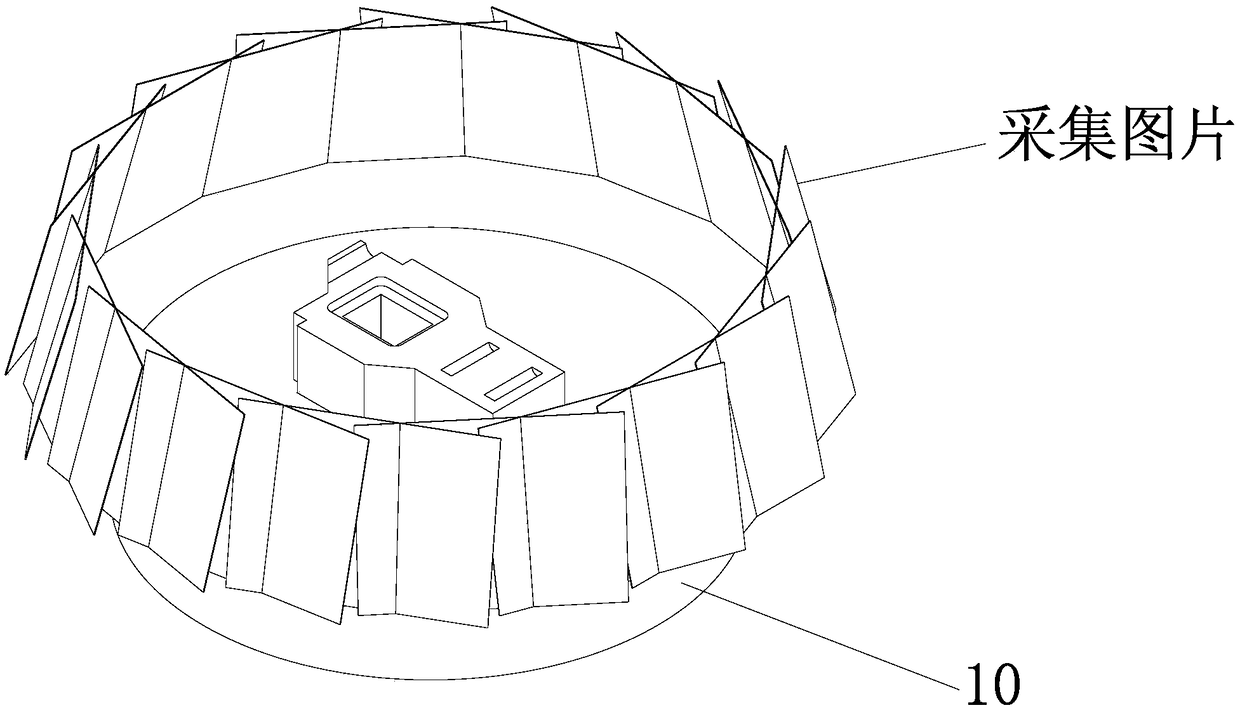

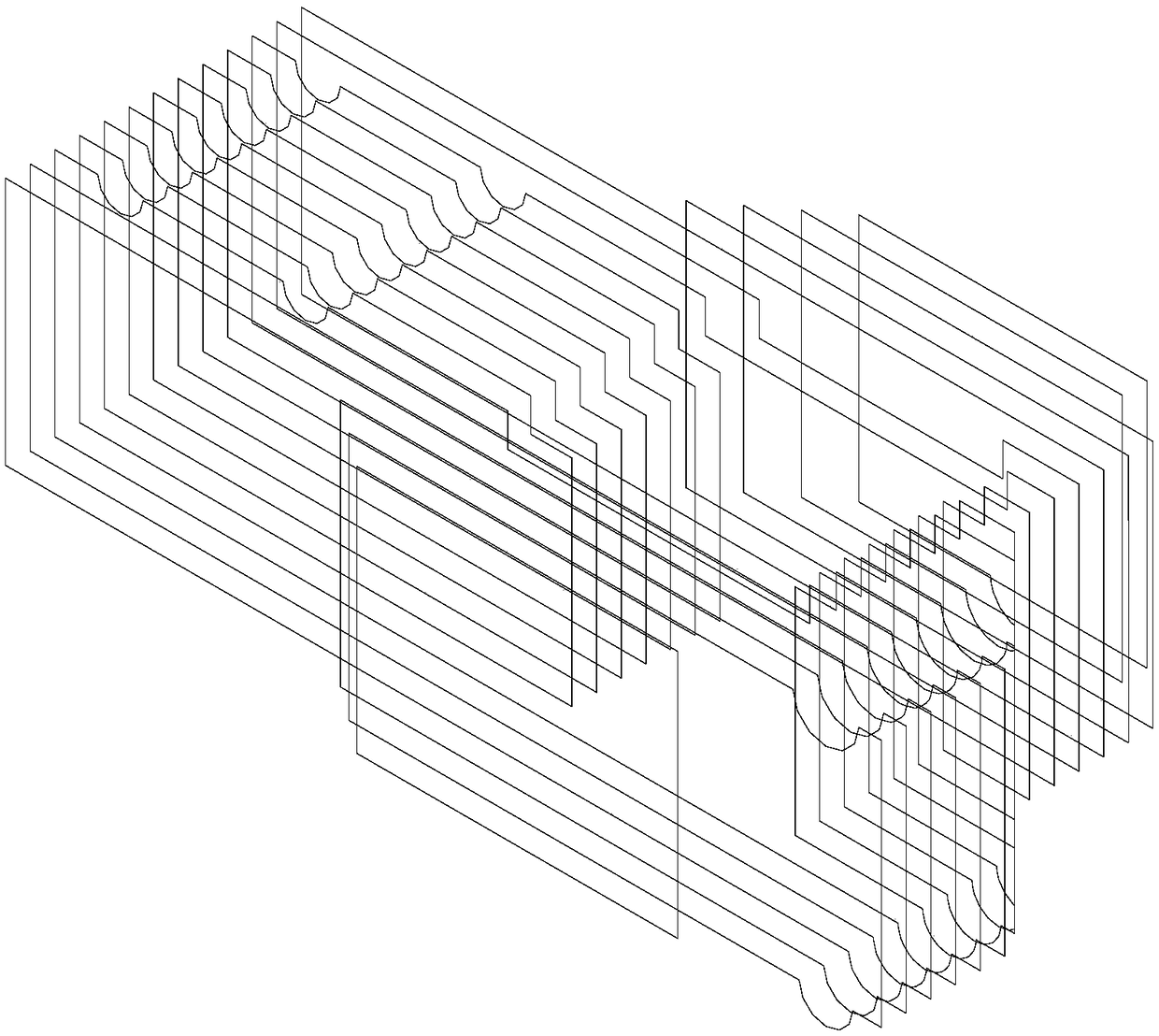

Brick reverse modeling auxiliary refractory material management method

ActiveCN109190234AConducive to simplificationAvoid inconvenienceGeometric CADSpecial data processing applicationsGraphicsBrick

The invention relates to a brick reverse modeling auxiliary refractory material management method. Based on the reverse modeling technology, firstly, bricks are sequentially formed into a real-scene model according to the use position; and secondly, the real scene model with dense mesh surfaces is exported to 3ds Max in an obj format, and the model is cut into two-dimensional graphics, that is, the three-view drawing of the model reconstruction; brick family files are created through the three-view drawing and are loaded into the project for combination, to complete the coke oven masonry modelof each part, and matching board construction is performed for coke oven masonry according to the daily plan, personnel positioning, brick positioning, positioning boards, fixed-point masonry methodfor board allocation construction. The method of the invention adopts the reverse modeling technology, can precisely reduce the geometric size of the special-shaped brick of the coke oven, and provides the basis for the modeling of the brick; the real scene model with dense mesh surfaces is quickly cut in 3ds Max, the three-view drawing of the model is extracted, and then the three-view drawing isimported into CAD, and the brick solid model is drawn by software tools, which is conducive to the simplification of the model surface.

Owner:CHINA FIRST METALLURGICAL GROUP

Ethene/acrylic ester rubber hose preparation method

InactiveCN1788975AHigh temperature rapid vulcanizationMeet performance requirementsTubular articlesTemperature controlEngineering

The present invention is injection process to produce ethyl acrylate copolymer pipe. AEM material is first made to enter the injector tube from the material pan and injected with the injecting plunger in the pressure of 150-180 bar and certain speed into the mold cavity at the upper and lower mold temperature controlled in 150-180 deg.c and material feeding section temperature and injecting section temperature controlled in 50-80 deg.c; and then sulfurized for 2-10 min. The said technological process can produce hard-to-produce corrugated pipe, and has simple technological process, simple operation, once injection, low labor strength, high mechanization and automation, high temperature and fast sulfurization of rubber product and short production period. The pipe product has homogeneous and stable physical and mechanical performance, precise sizes, high quality and less material loss.

Owner:TIANJIN PENGYI GRP CO LTD

Cement tea ware preparation process based on reverse mold technology

ActiveCN106541488ASimple processReduce energy consumptionCeramic shaping apparatusCompanion animalMaterials science

The invention provides a method for preparing a concrete process tea ware through the reverse mold technology. The method comprises the following steps that (1) a mold frame capable of accommodating a tea ware original model is manufactured according to the tea ware original model such as a tea tray, a saucer, a tea hold, a tea pet and a tea holder; (2) a mold pouring material is blended; (3) the pre-blended mold pouring material is poured till overflows the top end of the mold frame by 1-5 cm, bubbles are removed, mold opening is conducted after the pouring material is hardened, the mold frame is taken out, and a tea ware mold is obtained; (4) a cement-based mixture is prepared, prepared cement concrete is poured into the tea ware mold, vibration is conducted so that all spaces can be sufficiently filled with the concrete, plastering and finishing are conducted, and a top mold body is covered; and (5) a cement tea ware is maintained in the mold, and a finished cement tea ware is obtained. According to the method, the cement concrete is applied to prepare the tea ware for the first time, the prepared cement tea ware is good in fragrance gathering effect, and the plain texture of the cement material is sufficiently achieved.

Owner:WUHAN UNIV OF TECH

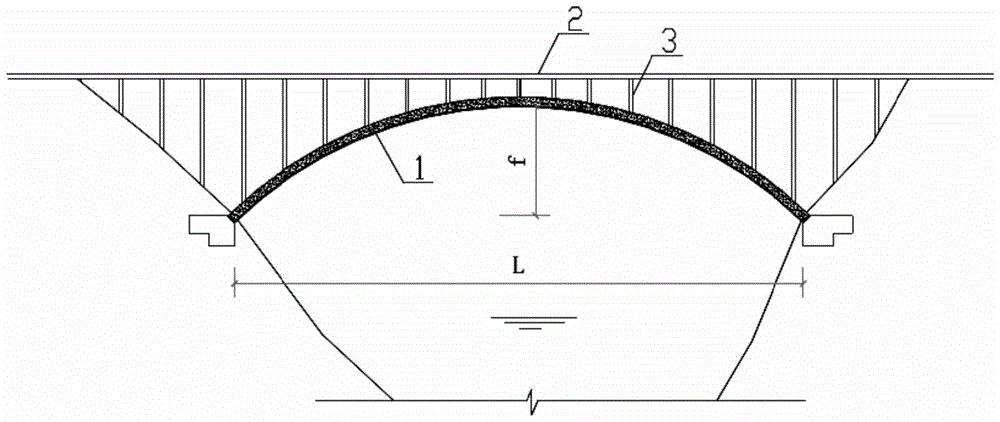

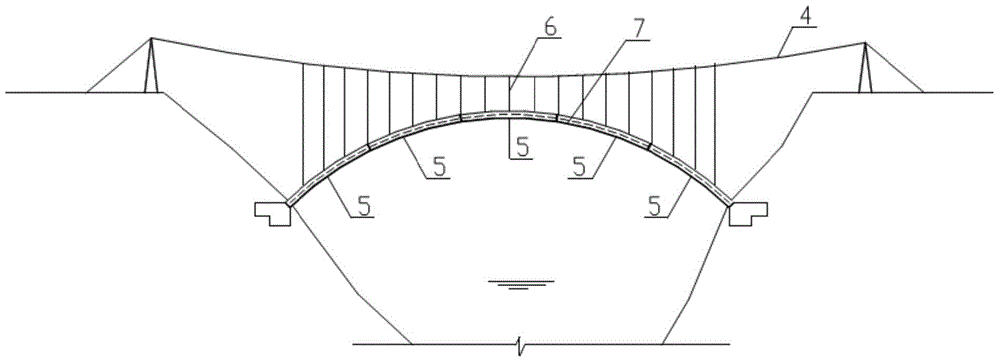

Modular steel form-concrete composite arch bridge and its suspension cable suspension construction method

InactiveCN104499413BGeometrically accurateReduce on-site construction errorsBridge erection/assemblyArch-type bridgeModular compositionBridge deck

The invention provides a modularized steel die and concrete combined arch bridge and a suspending construction method of a suspension cable thereof in the technical field of bridge building. The modularized steel die and concrete combined arch bridge comprises a combined arch ring with cast-in-place concrete, and vertical stand columns, a bridge deck beam and a bridge deck plate which are arranged on the combined arch ring, wherein the modularized combined arch ring is formed from one or multiple split mounting type steel arches, and each split mounting type steel arch comprises a plurality of modularized steel die units which are fixedly connected in the arc length direction. Modularized production of the steel die units can be carried out in a factory, and the manufacturing cost is low and the transport is convenient. The modularized steel die and concrete combined arch bridge is excellent in integral performance; due to the adoption of the steel die units, a large quantity of templates used when a traditional concrete pouring construction method is adopted are no longer needed, and manpower waste caused by disassembly after the completion of the arc bridge is also avoided; requirements for the combined arch ring with a larger span and a higher construction rigidity can be met, and the requirements for different spans and rigidities as well as construction stability can be met.

Owner:SHANGHAI JIAO TONG UNIV

A Finite Element Modeling Method for Arc Additive Manufacturing

ActiveCN107066700BReduce the amount of experimentsImprove calculation accuracyDesign optimisation/simulationSpecial data processing applicationsModelSimGeometric modeling

The invention discloses an arc additive manufacturing finite element modeling method. The method comprises the following steps of: calculating an arc shape and determining the width of an additive area birth-death element; calculating a molten drop shape and determining the height of the additive area birth-death element; establishing an arc additive manufacturing finite element geometric model according to the width of the additive area birth-death element and the height of the additive area birth-death element; correcting the arc shape and the molten drop shape through verifying the temperature distribution of the arc additive manufacturing finite element geometric model, so as to correct the arc additive manufacturing finite element geometric model. According to the method disclosed by the invention, the geometric size of the additive area birth-death element can be determined before the arc additive manufacturing finite modeling by adopting an arc additive manufacturing simulation process, combining an arc shape simulation technology, a molten drop shape simulation technology and a finite element simulation technology and carrying out experimental verification, so as to realize the correct calculation of arc additive manufacturing finite element simulation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Casting dies for engine cam shaft

InactiveCN1730196AImprove surface qualityGeometrically accurateFoundry mouldsFoundry coresMetallic materialsCam

The invention relates to a casting mould of motor cam shaft made by metallic material and used to cast integral cam shaft. Material is copper alloy such as adnic alloy, chrome copper or copper-tungsten alloy with copper taking up 78-93% of gross weight. Compared with sand mold, it is convenient in modeling and removing from mould due to the low affinity between copper alloy and steel material. Copper alloy mould is equipped with coolant passage due to softening temperature of copper alloy being lower than that of feed liquid. The invention has the advantages of high-quality surface, accurate physical dimension and preferred physical-mechanical properties.

Owner:象山巨象机模有限公司

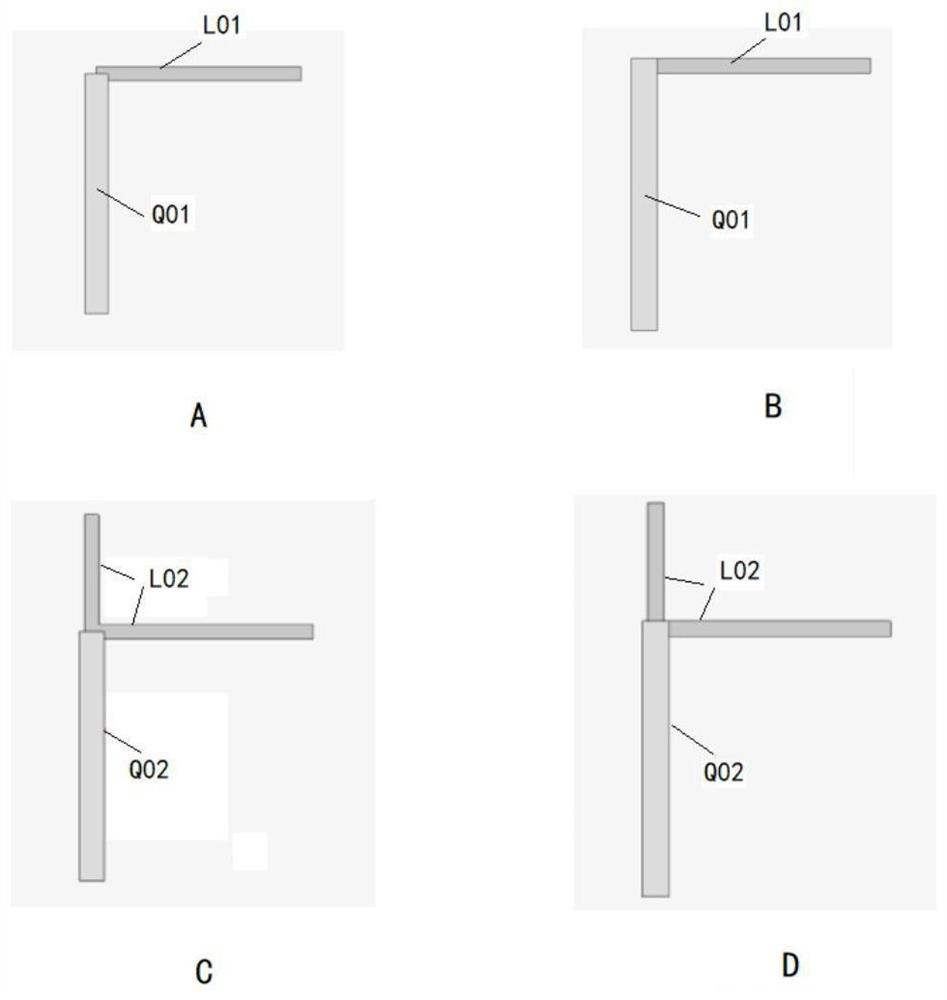

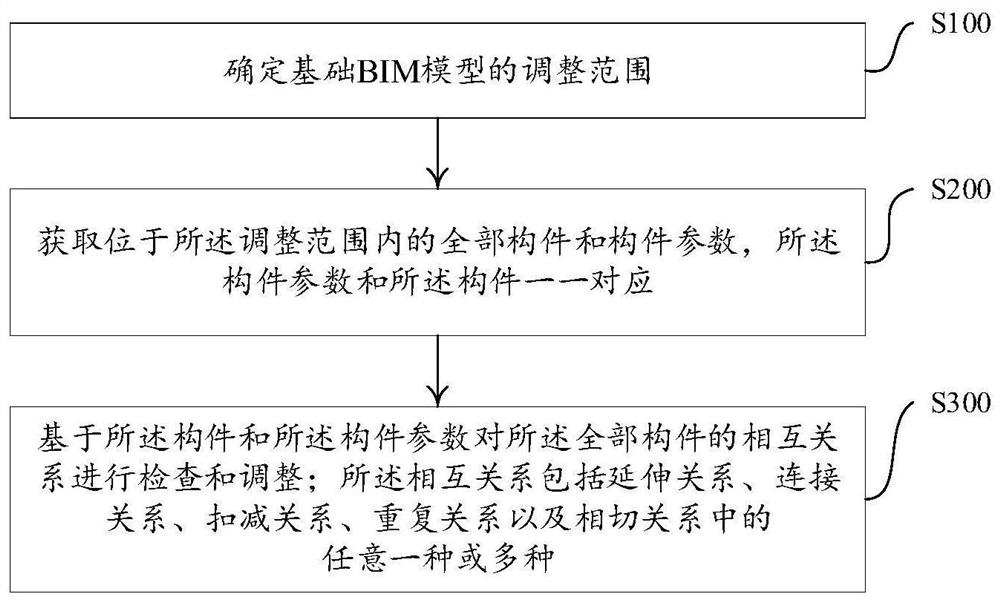

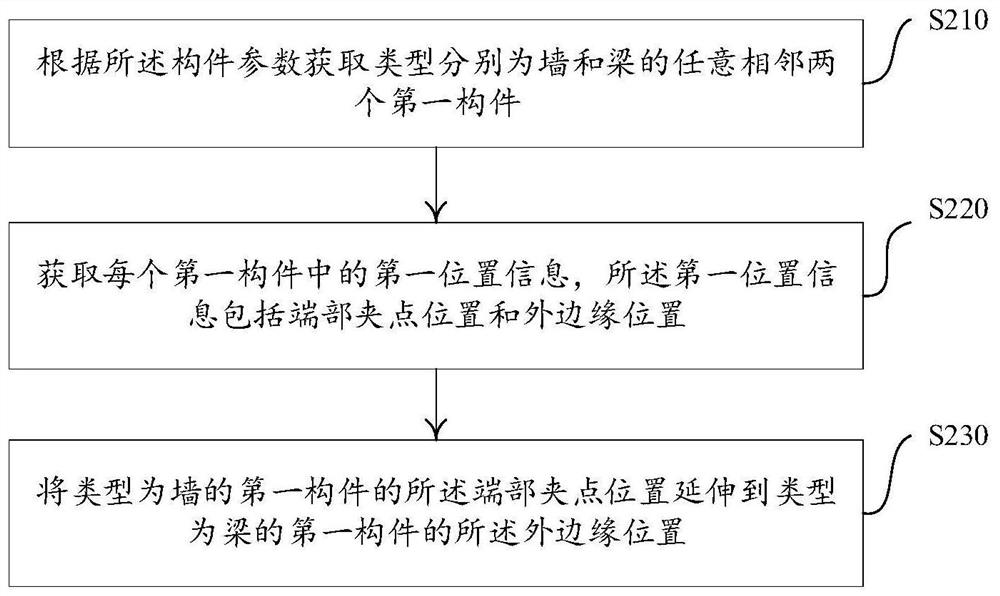

Component adjustment method and device in BIM model, computer equipment and storage medium

PendingCN113919027AGeometrically accurateSatisfy partition needsGeometric CADSpecial data processing applicationsAlgorithmIndustrial engineering

The invention provides a component adjustment method and device in a BIM model, computer equipment and a storage medium. The method comprises the following steps: determining an adjustment range of a basic BIM model; obtaining all components and component parameters within the adjustment range, where the component parameters correspond to the components one to one; checking and adjusting the mutual relation of all the components based on the components and the component parameters, where the mutual relationship comprises any one or more of an extension relationship, a connection relationship, a deduction relationship, a repetition relationship and a tangent relationship. The BIM model after component adjustment not only inherits basic common information of design and quantity calculation models, but also rapidly endows construction business attributes and deepening of geometric accurate positions.

Owner:GLODON CO LTD

Mould device for producing U-shaped heating body blank

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com