Construction method of ballastless tracks of tunnel group of heavy haul railway

A technology of ballastless track and construction method, which is applied in the direction of track, track laying, track maintenance, etc., and can solve the problems that cannot meet the high-precision and high-efficiency requirements of heavy-haul railways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0355] 1. Project overview

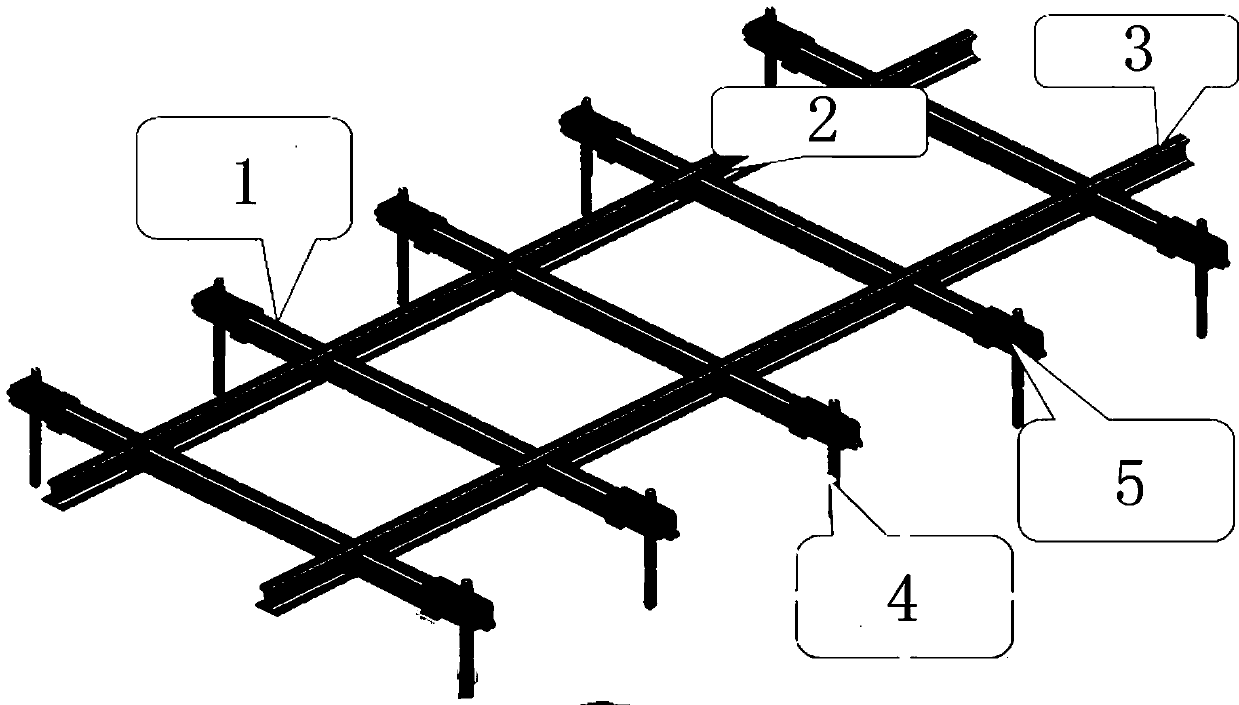

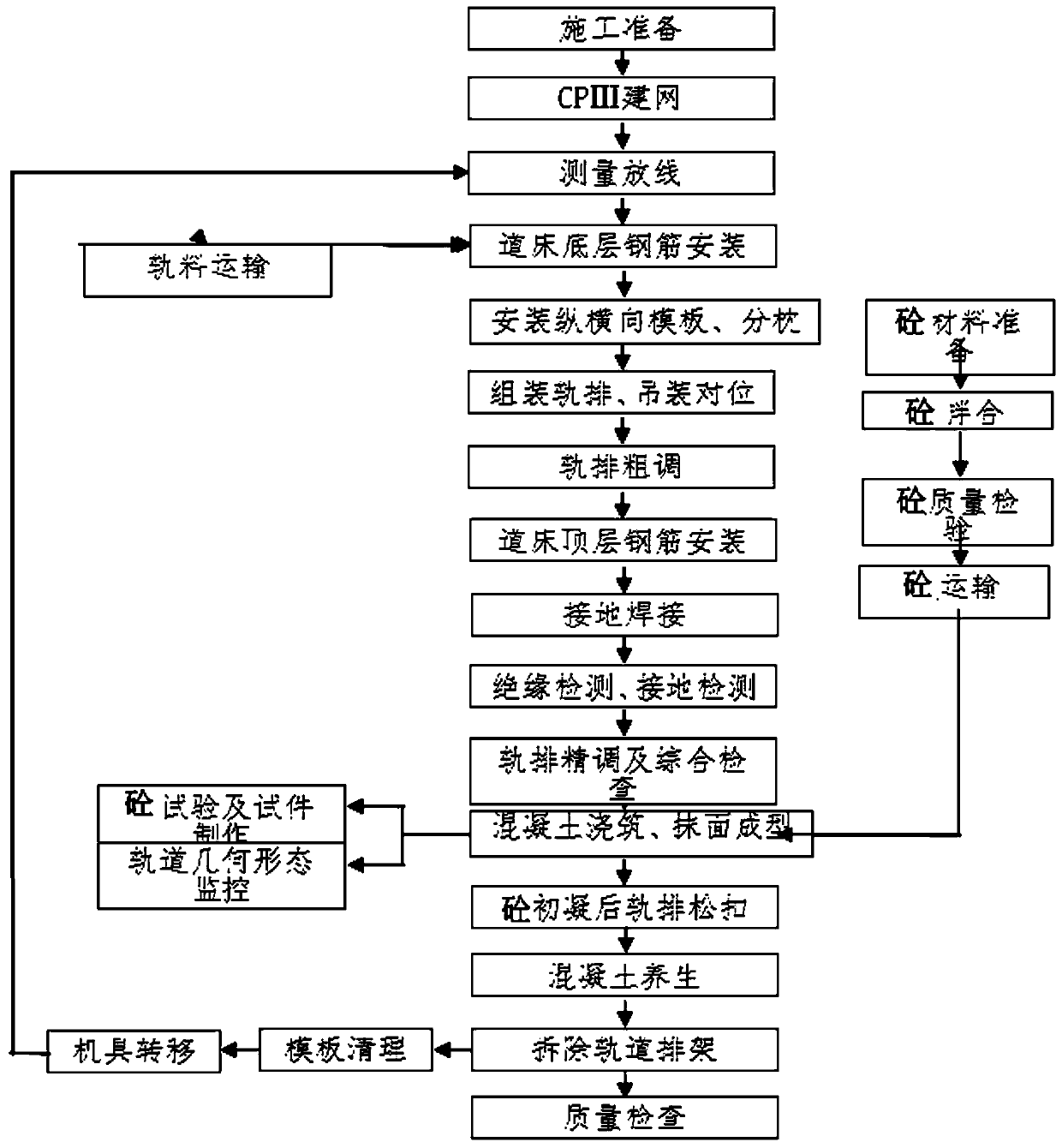

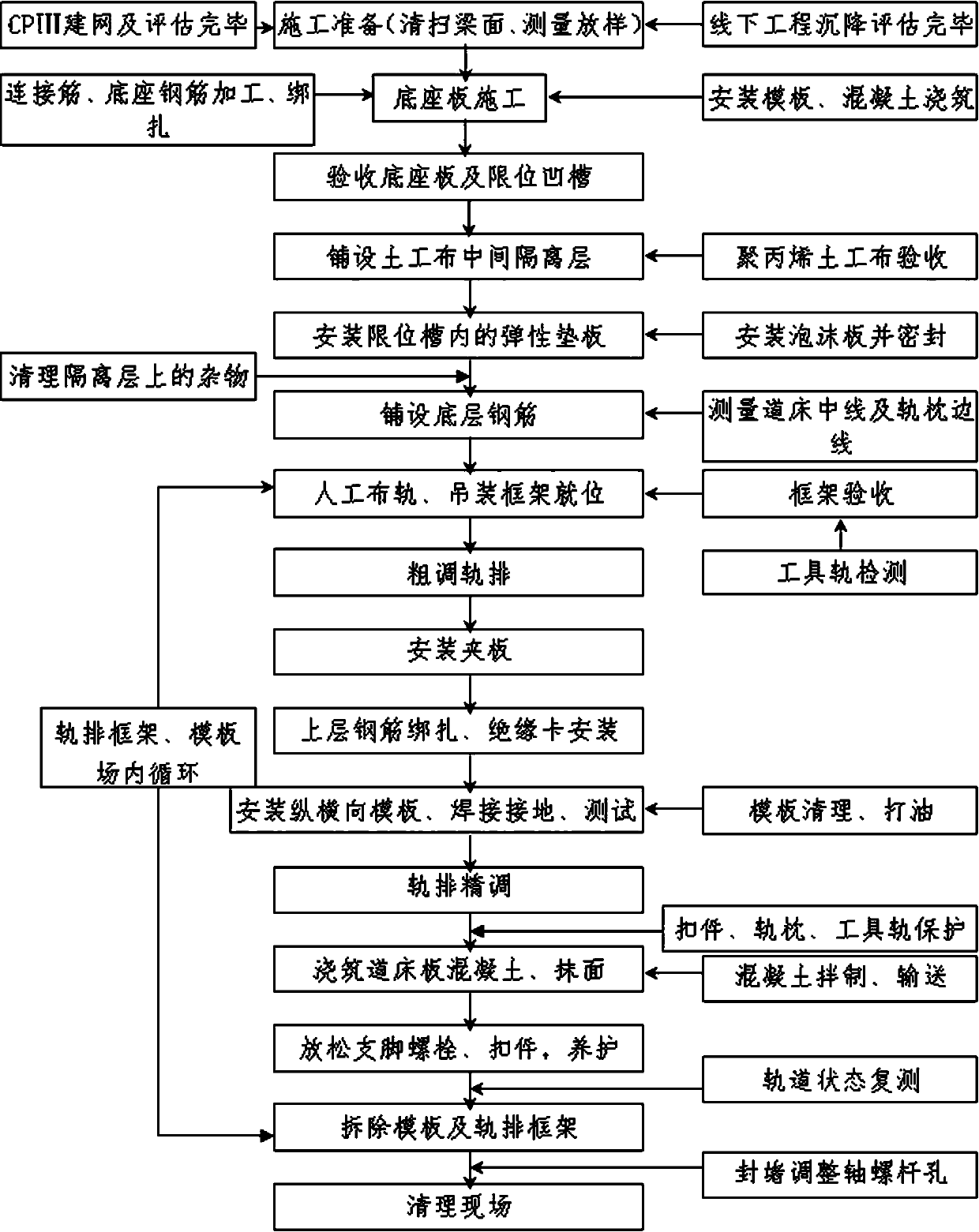

[0356] The starting and ending mileage of the new MHTJ-17 section of the civil engineering project of the railway coal transportation channel between West Inner Mongolia and Central China: DK828+253.5~DK883+289.5, of which the total length of the main line is 55.036 kilometers, and the upstream and downstream connecting lines are 2.2 kilometers. There are 26 tunnels in this section with a total length of 1,6804.3 meters, accounting for 30.5% of the total length of the line. In principle, a ballastless track is laid for tunnels with a length of 1km or more, and elastic supporting block type ballastless tracks are generally laid in the tunnel; when the ballastless track of the tunnel group section is considered to be laid in sections, heavy loads are laid on the tunnel entrance, the bridge outside the tunnel and the short-circuit foundation Long sleeper buried ballastless track. The total length of the ballastless track (single track) is 24.157km.

[03...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com