Patents

Literature

337results about How to "Novel process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

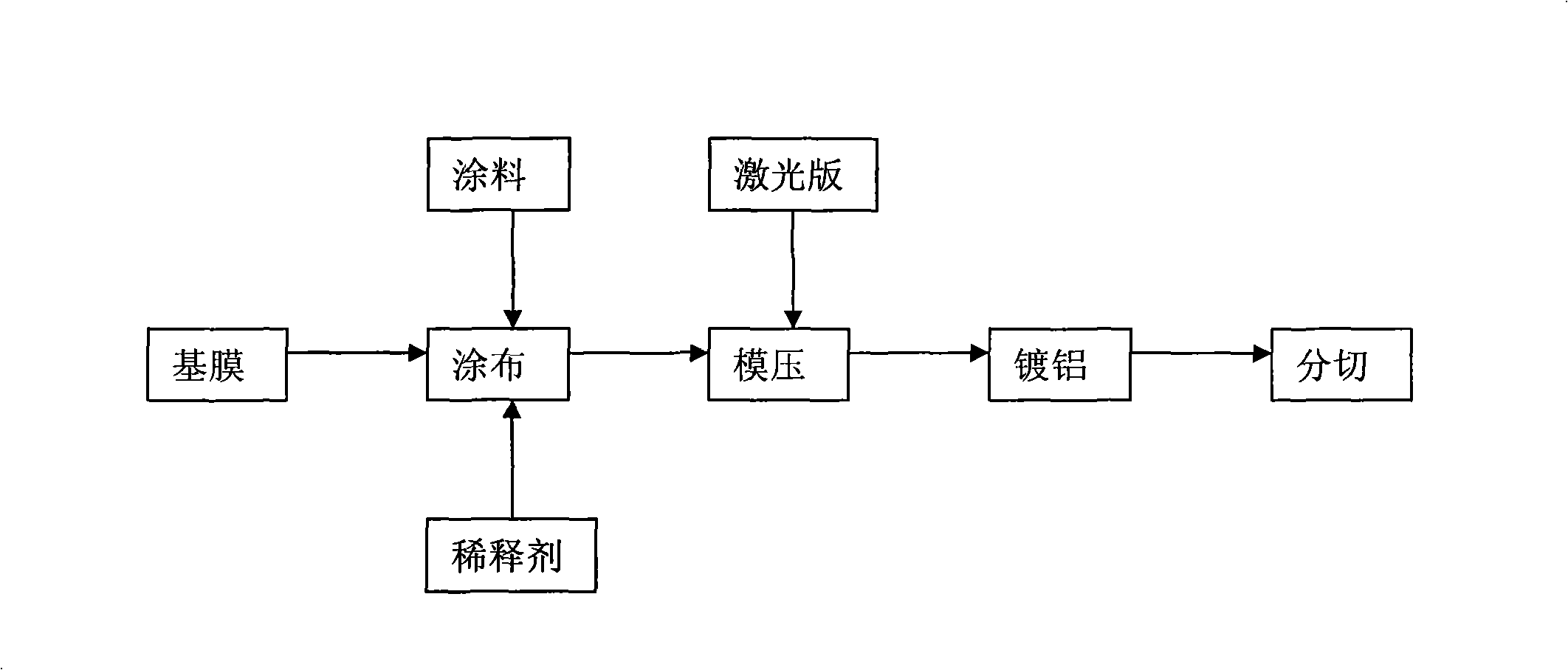

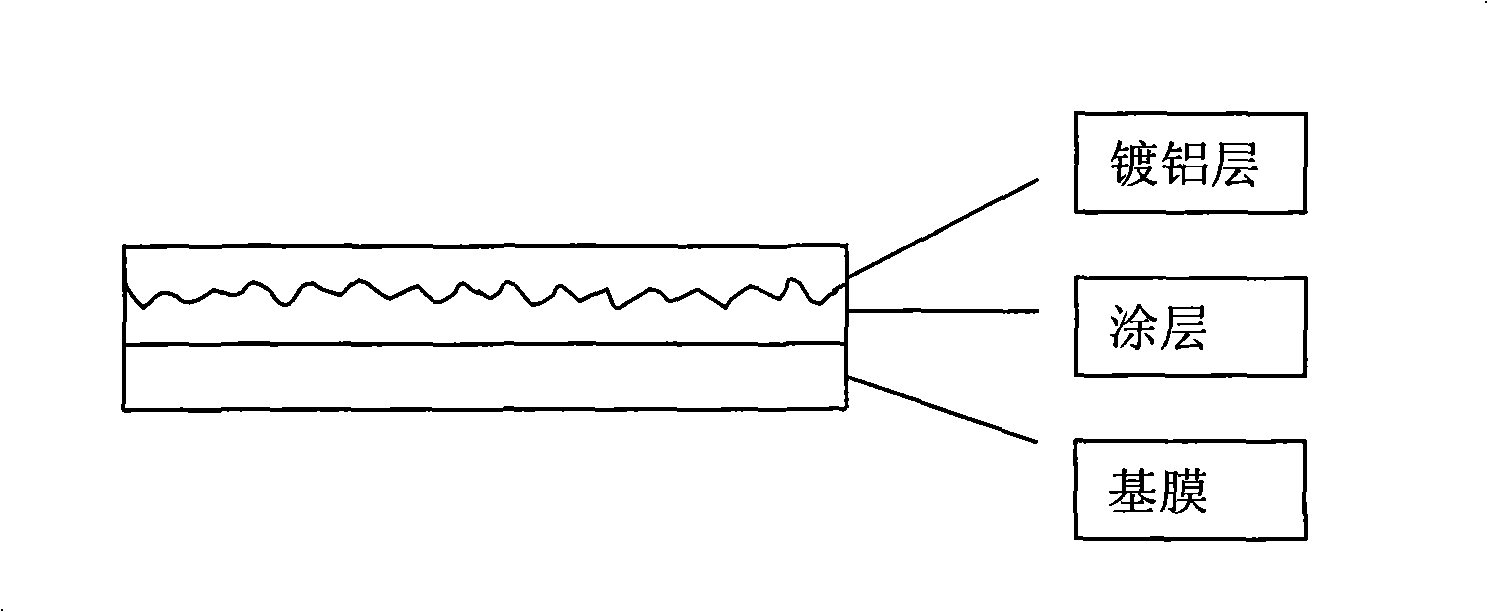

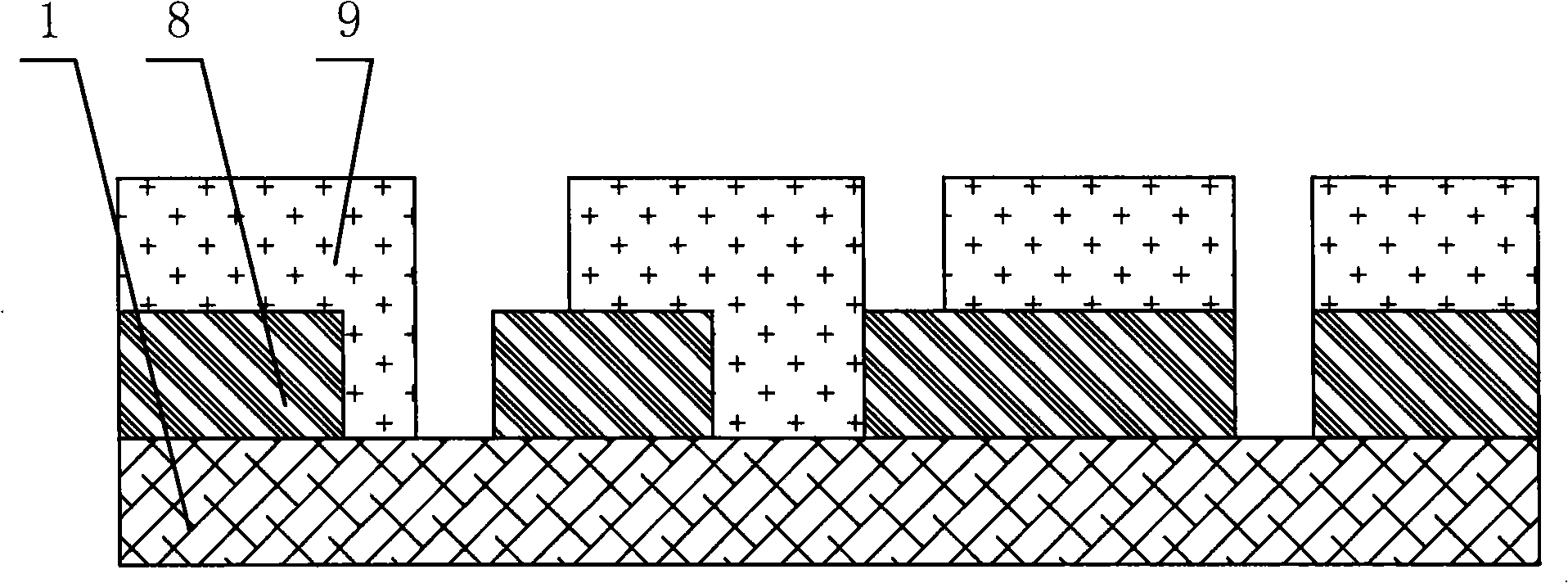

Process for producing PET laser transfer membrane

InactiveCN101537745ASimple processNovel processDecorative surface effectsPretreated surfacesBasementCoated membrane

The invention relates to a process for producing a PET laser transfer membrane. A PET membrane is used as a basement transfer membrane, and laser transfer pigment is coated and spread on the PET membrane. The method includes the following steps: a laser transfer pigment is coated and spread on the PET basement transfer membrane by an anilox roll at one step to form a coating layer, and a precoating membrane can be formed after the operation of drying is carried out; the precoating membrane is processed by the operation of laser mould pressing, and interference figures on a laser slab are printed on the coating layer of the precoating membrane by heat pressing so as to form a mould pressing membrane; and aluminum is coated on the mould pressing membrane, an aluminum layer is formed on an information layer, and the PET laser transfer membrane can be prepared, wherein the pigment includes thermoplastic acroid resin and cellulose acetate. The process has the advantages that the special singly coated laser transfer pigment and the unique manufacture process control are selected, and the entire process is simple, novel, stable and reliable. As the laser mould pressing transfer coating layer has the properties of easy mould pressing, favorable stripping, and the like, the operation of coating just needs to be carried out for one time, and therefore the production efficiency can be greatly improved. After being transferred and stripped, the aluminum coated membrane can be recycled to be repeatedly used for many times, and therefore cost can be greatly reduced; and the PET laser transfer membrane is the environmentally friendly anti-counterfeit laser material for packaging and printing.

Owner:上海宝绿包装材料科技有限公司

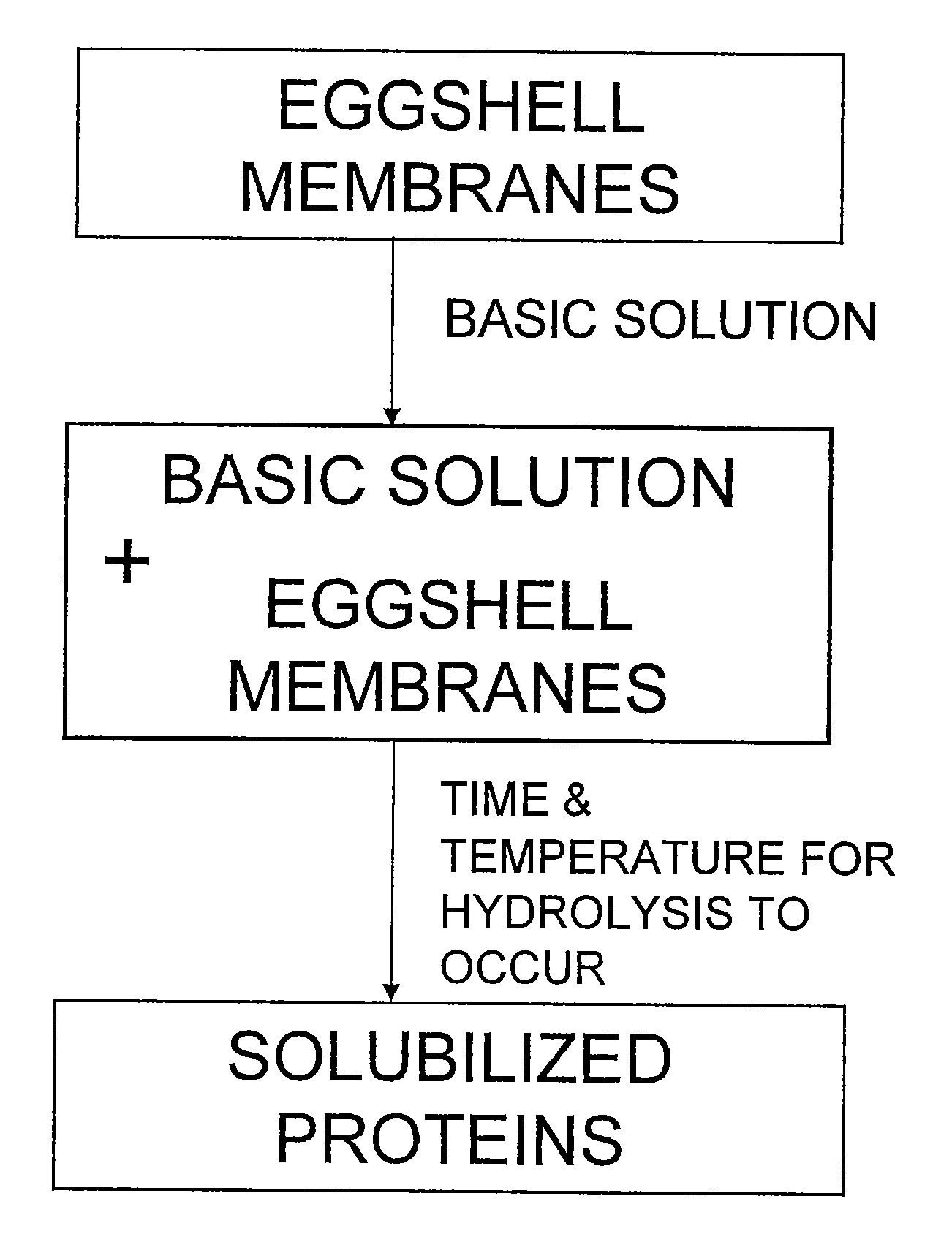

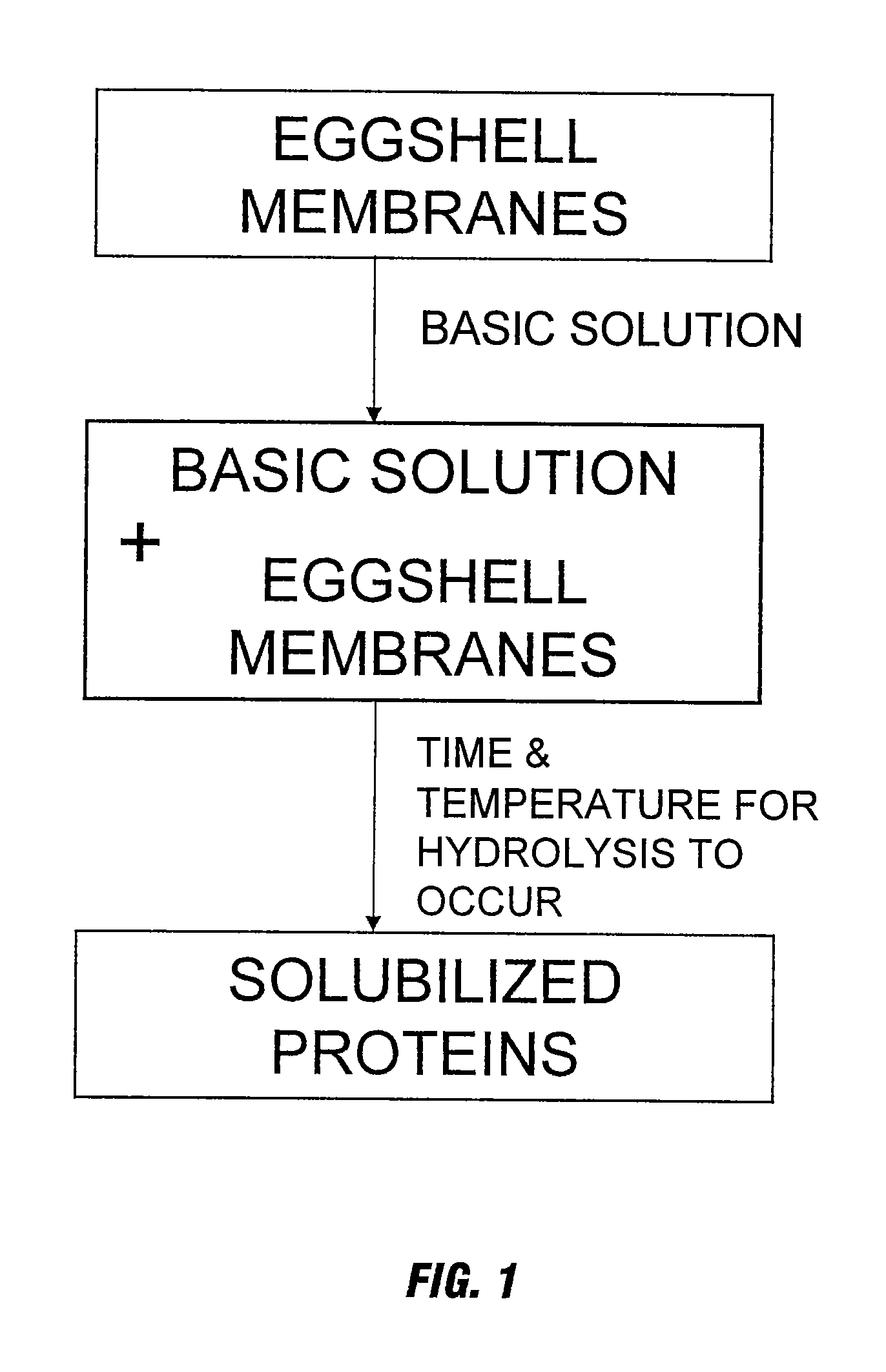

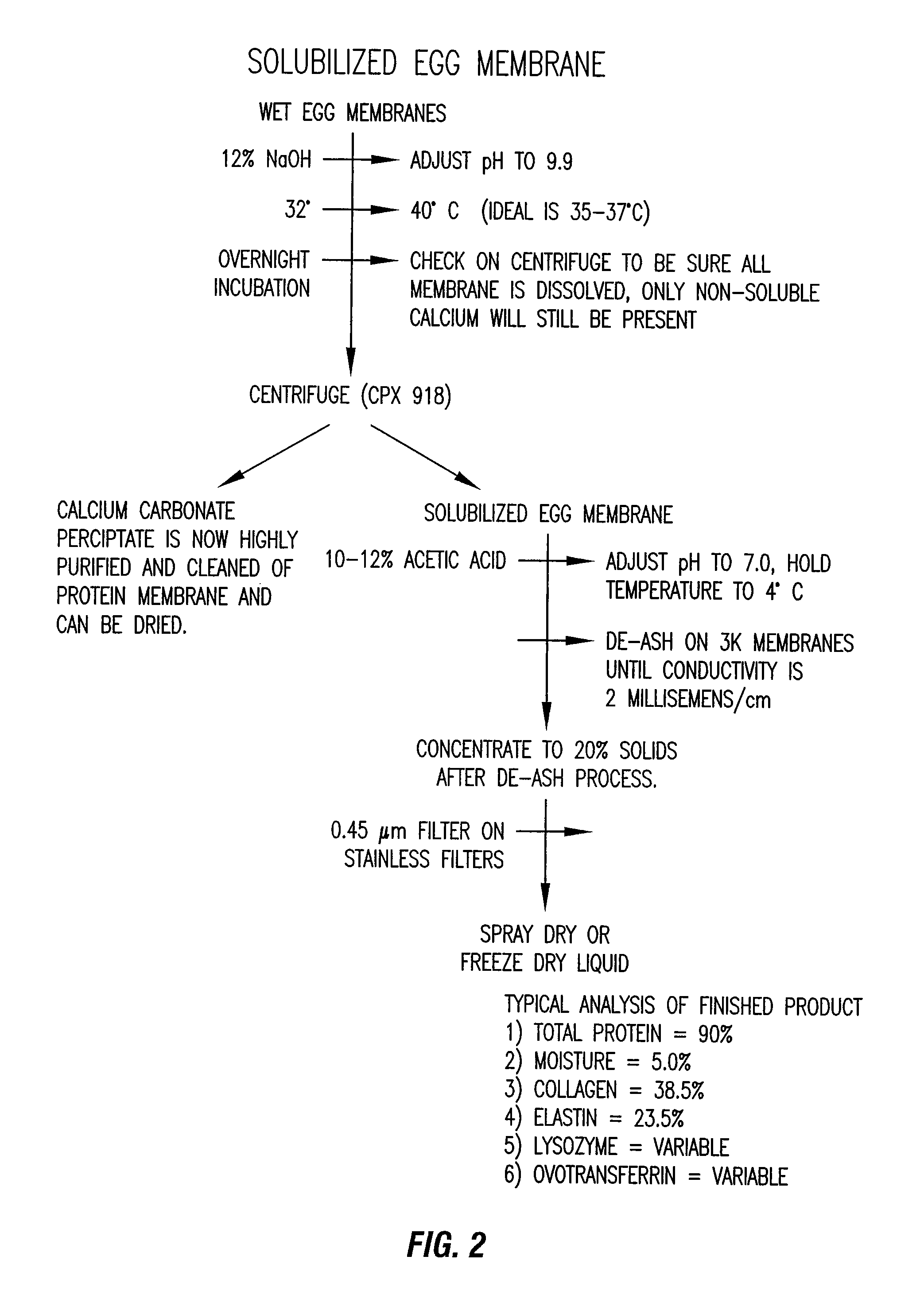

Novel process for solubilizing protein from a proteinaceous material and compositions thereof

ActiveUS20090104173A1New technologyLower mineral (ash) contentConnective tissue peptidesPeptide/protein ingredientsEggshell membraneProtein materials

The process for solubilizing proteinaceous material of the present invention includes subjecting the proteinaceous material to a sufficient amount of a basic solution to obtain a supernatant that has a basic pH and exposing the supernatant to the basic solution for a sufficient length of time and temperature for hydrolysis to occur. The process also includes cooling the mixture of the supernatant and proteinaceous material and optionally acidifying the mixture. This process may also include recovering the solubilized protein from the supernatant for use in various applications. Also provided herein is a composition of solubilized proteins from eggshell membrane obtained using processes of the present invention.

Owner:BIOVA

Bamboo waterproof antiseptic coloring plate and preparation method thereof

The invention discloses a bamboo waterproof antiseptic coloring plate and a preparation method thereof. The preparation method of the bamboo waterproof antiseptic coloring plate comprises the steps of cutting off bamboo materials, slicing, coarsely planing, drying, vacuum high-temperature high-pressure antiseptic coloring carbonization treatment, secondary drying, precision planing, sorting, gluing and thermal pressing, polishing and planing on four sides. The bamboo material is processed in the vacuum high-temperature high-pressure antiseptic coloring carbonization manner, the process is novel, the manipulability is strong, the produced bamboo board has a waterproof function, an antiseptic function and rich colors and can be used as an outdoor building material and indoor decoration material, and the application range is wide.

Owner:福建省祥福工艺有限公司

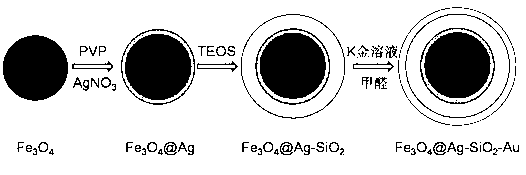

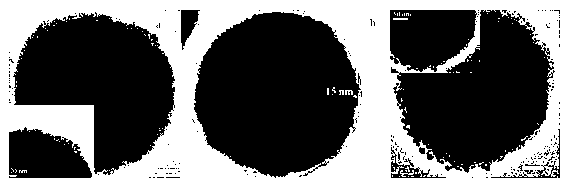

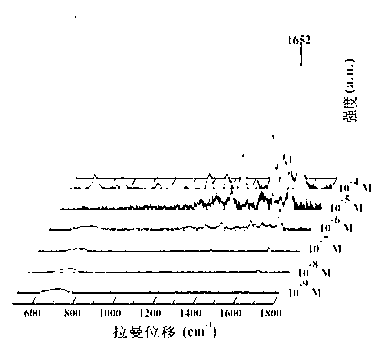

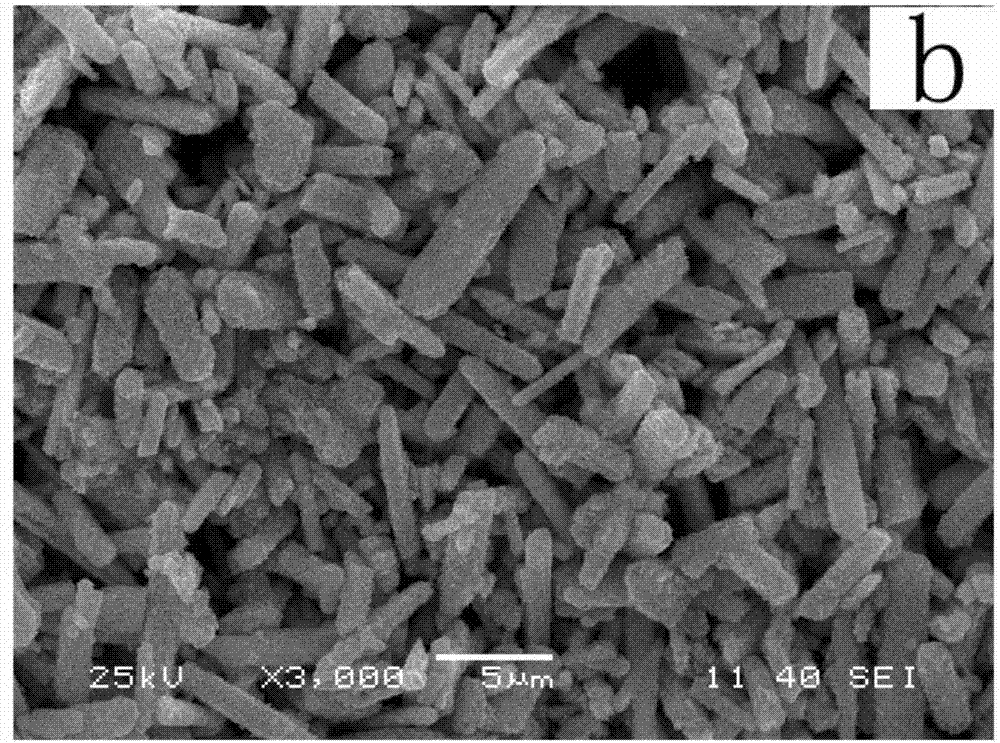

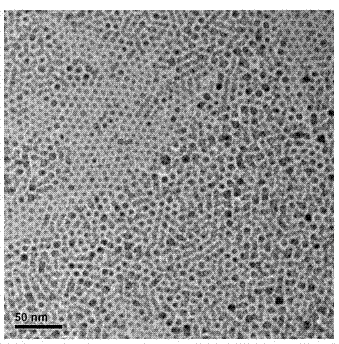

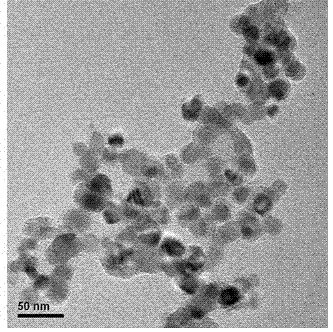

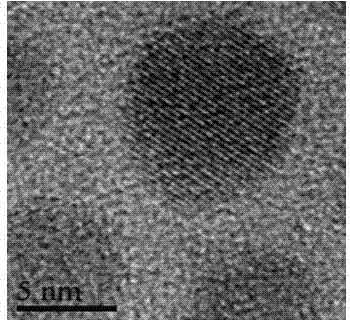

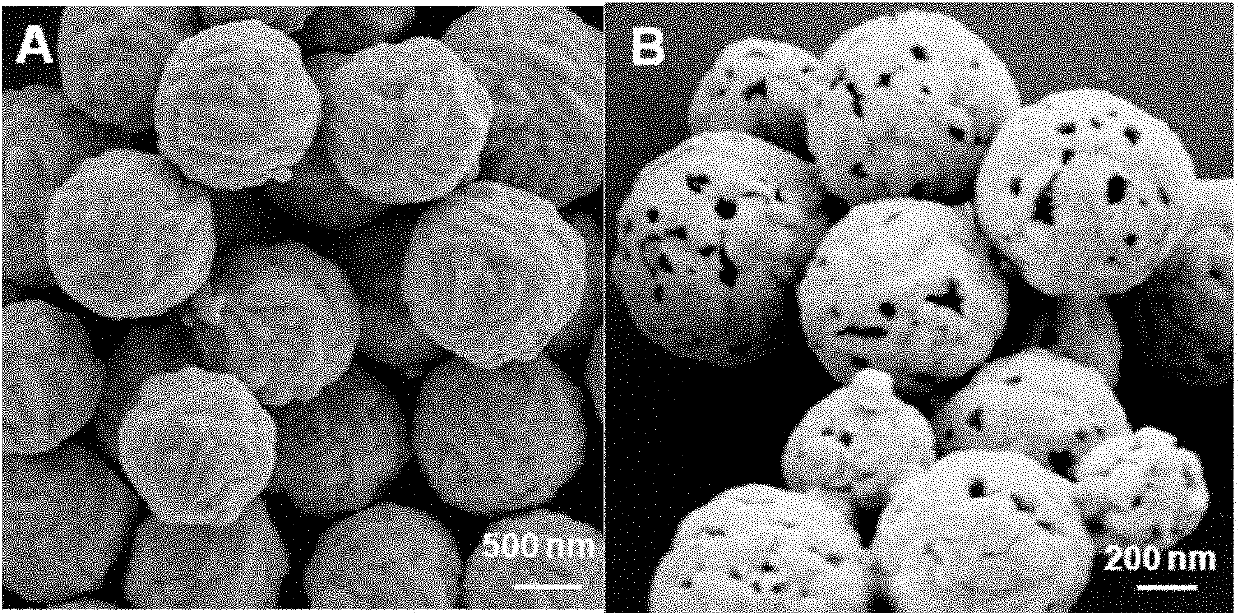

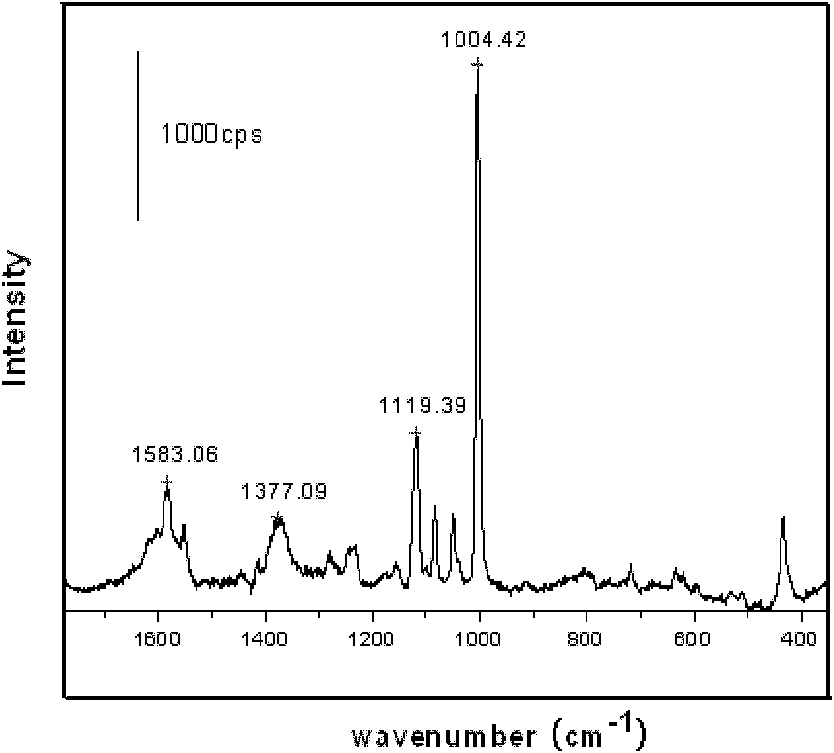

Plasma coupling structure microsphere for surface-enhanced Raman scattering (SERS) and manufacturing method thereof

The invention relates to a plasma coupling structure microsphere for surface-enhanced Raman scattering (SERS). By the plasma coupling structure microsphere, a magnetic microsphere serves as a kernel, and a metal cladding I, a nonmetallic isolating layer and a metal cladding II are formed outside the kernel one by one, wherein the metal cladding I or the metal cladding II has the thickness of 0 to 50nm; the nonmetallic isolating layer has the thickness of 0 to 100nm; and the plasma coupling structure microsphere has the particle size of 300 to 1,000nm and the specific saturation magnetization of 10 to 50emu / g. The plasma coupling structure microsphere is simple in manufacturing method and controllable in product structure, the obtained microsphere can be suitable for biological separation and detection, and when the microsphere is used for detecting a Raman-enhanced effect, the detection rate can reach 10<-9> mol / L; and moreover, the plasma coupling structure microsphere is applied to the fields of photochemical catalysis, disease detection, food safety and the like, and the application prospect integrating separation and SERS detection on biological medical molecules and the like can be realized.

Owner:EAST CHINA UNIV OF SCI & TECH

Cleaning agent for stainless steel seamless stay tubes and preparation method for cleaning agent

ActiveCN102400165AMaintain glossContact no harmMetallic material coating processesHexamethylenetetramineAlkylphenol

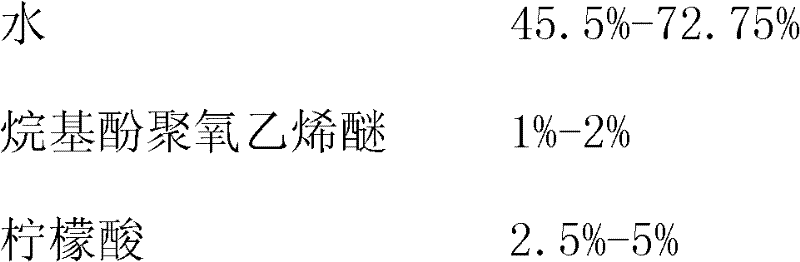

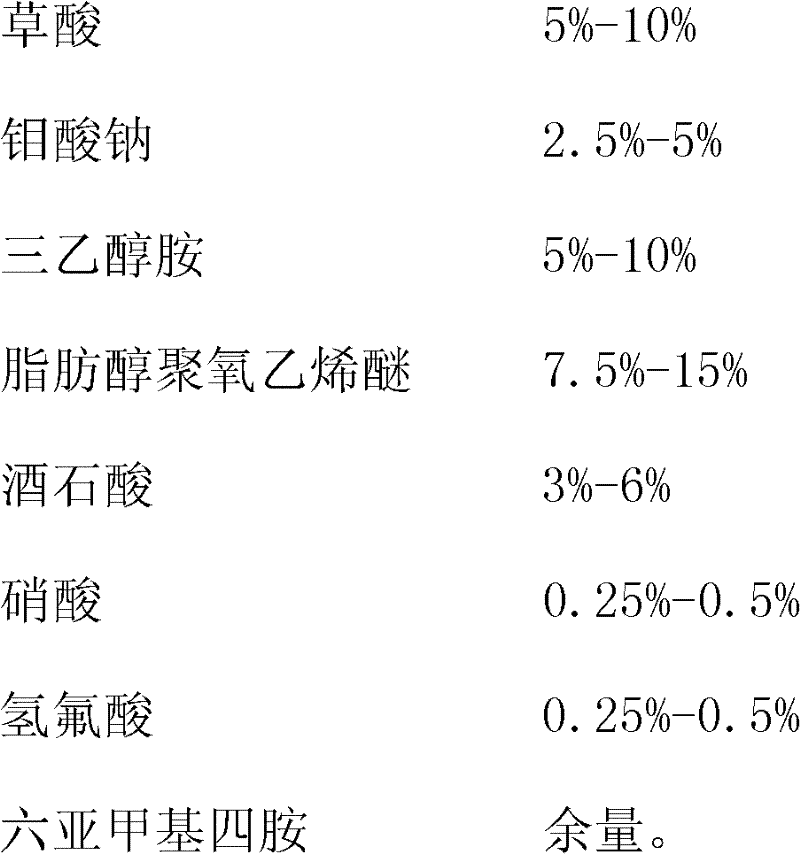

The invention relates to the technical field of chemical cleaning, in particular to a cleaning agent for stainless steel seamless stay tubes and a preparation method for the cleaning agent. The cleaning agent for the stainless steel seamless stay tubes is prepared by mixing the following raw materials in percentage by weight at normal temperature: 45.5 to 72.75 percent of water, 1 to 2 percent of alkylphenol polyoxyethylene, 2.5 to 5 percent of citric acid, 5 to 10 percent of oxalic acid, 2.5 to 5 percent of sodium molybdate, 5 to 10 percent of triethanolamine, 7.5 to 15 percent of fatty alcohol-polyoxyethylene ether, 3 to 6 percent of tartaric acid, 0.25 to 0.5 percent of nitric acid, 0.25 to 0.5 percent of hydrofluoric acid and the balance of hexamethylenetetramine. The cleaning agent for the stainless steel seamless stay tubes has novel process, is easy to operate and strong in cleaning force, does not need to be heated, can be reused, can be used for cleaning the stainless steel seamless stay tubes without corroding the surface of stainless steel, and keeps the glossiness of the stainless steel; and the cleaning agent for the stainless steel seamless stay tubes has no injury to the skin, is low-carbon and environment-friendly, has high cost performance, and saves the cost.

Owner:云霄县食品快检中心

Method for processing refuse in kitchen cupboard into biological feed

InactiveCN1579199APromote digestion and absorptionIncrease profitFood processingAnimal feeding stuffHigh pressureFatty acid

The invention provides a method of biologically making restaurant and kitchen rubbishes into feed, including: solid-liquid separation and oil-water separation. The oil separated out is made into fatty acid calcium particles by emulsifying and hydrogenating. The water separated out is added to feed saccharomycetes to obtain a saccharomycetes-containing solution. The solid separated out is sterilized at high pressure and then mixes with the solution to ferment into the feed. The method is special, the process is novel, and the final product is economic and practical. It converts the restaurant and kitchen rubbishes to the feed that has high-added value fatty acid calcium and high protein. The whole course does not discharge any pollutant and has no secondary pollution. The feed obtained contains various physiological active substances, helpful for the domestic animals and fowls to digest and assimilate the feed, thus increasing the utilization rate of the feed.

Owner:哈尔滨蓝雪科技开发有限公司

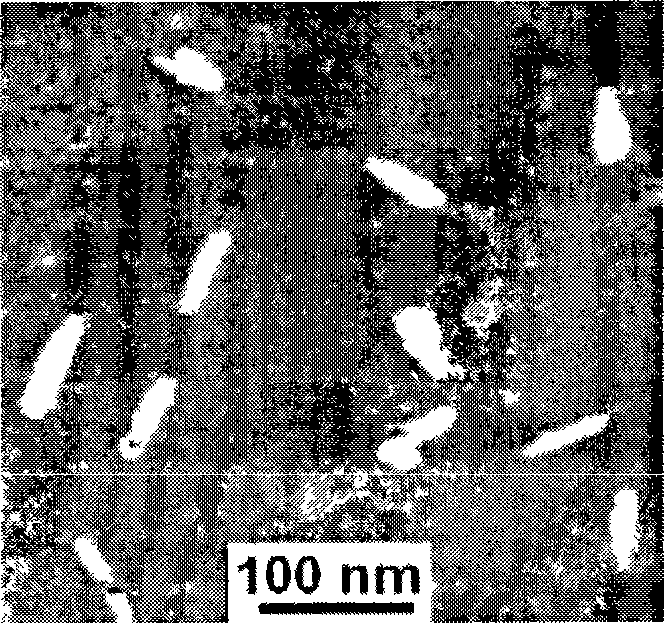

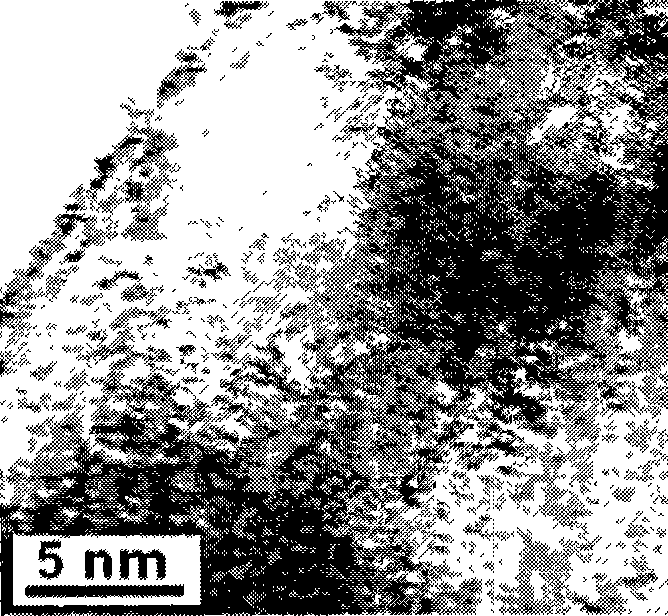

Method for preparing PAMAM dendrimer-modified gold nanorod composite carrier

InactiveCN101444847ANovel processReduce in quantityPolycrystalline material growthAfter-treatment detailsAcetic acidGold nanorod

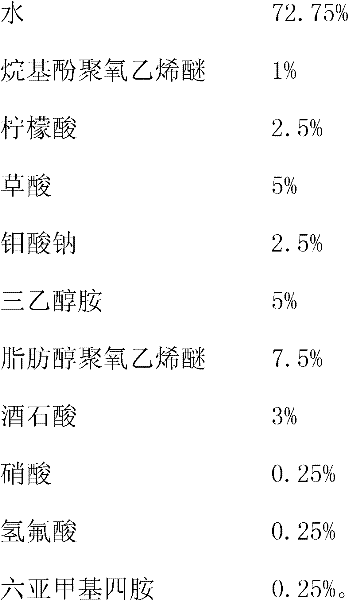

The invention relates to a method for preparing a PAMAM dendrimer-modified gold nanorod composite carrier, belonging to the field of nanocomposite materials. In the method, gold ions are firstly reduced into gold nanoseeds through the chemical reduction method in the presence of a coating agent, and the seeds are added into the growth solution of the gold ions for preparing gold nanorods, wherein, the growth solution contains the gold ions, a weak reducing agent and a surfactant; amino-PAMAM dendrimers of any generation are reacted with methyl mercaptoacetate, and mercapto-PAMAM dendrimers are obtained; finally, a hybrid reaction is carried out on the gold nanorods and the mercapto-PAMAM dendrimers, and PAMAM dendrimer-modified gold nanorod composite carrier is obtained. In the composite carrier, the PAMAM dendrimers are evenly coated on the surface of each gold nanorod in the composite carrier, and the maximum absorption peak of the composite carrier is about 542nm and 871nm.

Owner:SHANGHAI JIAO TONG UNIV

High-germination-rate highland barley and hulless oat composite beverage and production method thereof

InactiveCN103859541AGuaranteed germination ratePrevent the loss of nutrients and active ingredientsFood ingredient as emulsifierGerminationEnzyme

The invention provides a high-germination-rate highland barley and hulless oat composite beverage and a production method thereof, belongs to the field of food processing, and particularly relates to a production method of a cereal beverage. The production method comprises the following steps: with full-grain highland barleys and hulless oats with the germination rate of 80% and 90% respectively as raw materials, baking for the first time; mixing the highland barleys with the hulless oats in a mass ratio of 8:2 and baking for the second time; crushing and screening, and adding to 8-10 times of water based on mass to form a pasty type; carrying out same-batch enzyme adding treatment and gradient enzymolysis treatment; adding mixed glue and a composite emulsifier hot water solution according to a ratio amount to highland barley and hulless oat composite feed liquid subjected to enzyme deactivation treatment; adjusting the sugar degree to 8% by sucrose and making up to the volume so that the ratio of the raw materials accounts for 8% of the total amount of the materials; and performing secondary homogenization and UHT (Ultra Heat Treated) sterilization and then filling. The high-germination-rate highland barley and hulless oat composite beverage utilizes crop resources which are safe and healthy in alpine regions and have very high nutritive values, has a scientific formula and is novel in process; the defects of a traditional process are effectively avoided; the prepared composite beverage has balanced nutrition, mellow mouth feel and good stability and the industrialization of the technology is easy to realize.

Owner:HUBEI BAIDIAN IND

Qi benefiting and blood nourishing fragrant and hot walnut kernel and preparation method thereof

InactiveCN104886662AImprove film-forming propertiesFruityMulti-step food processesFood dryingAdditive ingredientGlycerol

The present invention discloses a qi benefiting and blood nourishing fragrant and hot walnut kernel which is made of following raw materials in parts by weight: walnut kernels 80-90 parts, watermelon seed kernels 10-20 parts, fish roes 20-30 parts, corn pollen 7-8 parts, oolong tea 8-10 parts, papaya 8-10 parts, capsicum frutescens 4-5 parts, kadsura longipedunculata 2-2.4 parts, elaeagnus pungens 0.7-1.5 parts, Chinese wolfberry fruits 0.7-2 parts, glycerol, sesbania gum, zein, and an appropriate amount of 3%-4% sodium carbonate aqueous solution. The qi benefiting and blood nourishing fragrant and hot walnut kernel utilizes zein to conduct film coating treatment on walnut kernels, which can completely cut off walnut kernels from the outside moisture and oxygen, inhibit oxidative and rancid process of walnut kernels, and extend the shelf life of walnut kernels; and the added kadsura longipedunculata, elaeagnus pungens and other traditional Chinese medicines increase the health-care efficacies of walnut kernels in clearing liver and improving eyesight, supplementing blood and beautifying features, and calming mind and benefiting qi.

Owner:石台县横渡镇香口二郎家庭农场

Tranquilizing and nerve-soothing down processing technology

InactiveCN104179023ACover up the tasteDoes not generate static electricityFibre treatmentAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses a tranquilizing and nerve-soothing down processing technology. According to the processing technology, tranquilizing and nerve-soothing down is processed through the following steps: (1) the down is prepared; (2) primary washing is implemented, wherein a detergent and a detergent are added in water for washing; (3) primary dehydration is implemented, wherein the content of water in the down reaches 22%-28%; (4) secondary washing is implemented, wherein a detergent, an anti-mite agent and a fragrance agent are added in water for secondary washing; (5) secondary dehydration is implemented, wherein the content of water in the down reaches 45%-63%; (6) drying sterilization is implemented, wherein a tranquilizing and nerve-soothing agent is added in high-temperature steam for drying sterilization, the tranquilizing and nerve-soothing agent contains the following ingredients in a weight ratio: 14-16 of spina date seeds, 8-11 of arborvitae seeds, 5-6 of tuber fleeceflower stem, 2-3 of thinleaf milkwort root-bark, 1-3 of silktree albizzia bark, 0-2 of drgon's bone, 0-3 of dens draconis, 5-7 of lavender, 7-9 of roses, and 1500-2000 of water, and all the ingredients are boiled for 15-22 minutes in clean water to obtain a filtrate. The technology is simple and novel; by virtue of twice washing, twice dehydrating and once steam drying, the active ingredients of chemical agents and the fragrance agent are kept on the surface of the down to the maximum degree; if being used for a long time, the tranquilizing and nerve-soothing down plays tranquilizing and nerve-soothing roles and has fragrance.

Owner:江苏欣隆羽绒有限公司

Flavored morchella raw fish and preparation method thereof

The invention discloses a flavored morchella raw fish which is prepared from the following raw materials in parts by weight: 90-110 parts of frozen tuna, 15-16 parts of lyophilized royal jelly powder, 22-24 parts of grape pulp, 8-9 parts of morchella, 5-7 parts of steamed bun, 9-11 parts of mango juice, 17-18 parts of walnut kernel, 7-8 parts of honey, 0.5-1 part of a mulberry root, 0.4-1 part of penthorum Chinese pursh, 1.8-2 parts of wax gourd seeds, 0.2-0.3 part of sodium glutamate, 0.1-0.3 part of ethyl maltol, 0.1-0.2 part of phosphate, 1-2 parts of lactic acid bacteria, 300mmol / L of CaCl2 solution, refined salt and a proper amount of sugar. The flavored morchella raw fish has the advantages of unique taste, long shelf life and good health effect; the flavored morchella raw fish is unfrozen by a pickling method and is pickled by an injection method; the technology is unique and novel; the value-added space and the extension benefits of the raw fish product are increased; and due to the addition of traditional Chinese medicine components such as mulberry root and penthorum Chinese pursh, walnut kernel is endowed with the health effects of moistening the lung for removing phlegm and clearing away heat and toxic materials.

Owner:合肥市韩林家庭农场有限公司

Multi-flavor chewable calcium tablets and production process thereof

ActiveCN101716194AHigh in calciumLow priceHydroxy compound active ingredientsMetabolism disorderIsomaltooligosaccharideOlder people

The invention discloses multi-flavor chewable calcium tablets, which is characterized in that the formulation of the tablets comprises nano calcium carbonate, oligoisomaltose, mannite, fruit and vegetable powder, gelatin, aspartame, vitamin and mineral substance in the weight ratio of 50 to 60: 15 to 20: 5 to 10: 1.5 to 2.5: 3 to 8:0.05 to 0.10:1 to 5:8 to 12. The production process of the tablets comprises the following steps: 1) preparing ultra-fine nanoscale CaCO3; 2) sieving and mixing the CaCO3 with the oligoisomaltose, the mannite, the fruit and vegetable powder and the aspartame; 3) adding the geltin to a mixture and granulating the mixture; 4) mixing granules with the vitamin and the mineral substance; and 5) tabletting, coating and packing the granules. The tablets have the advantages that: the tablets are suitable to be taken by all ages, particularly the middle-aged and old people; and the production process has the advantages of novelty, convenient operation and stable product performance, which is an ideal process for the large-scale industrial production of nano calcium carbonate products.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

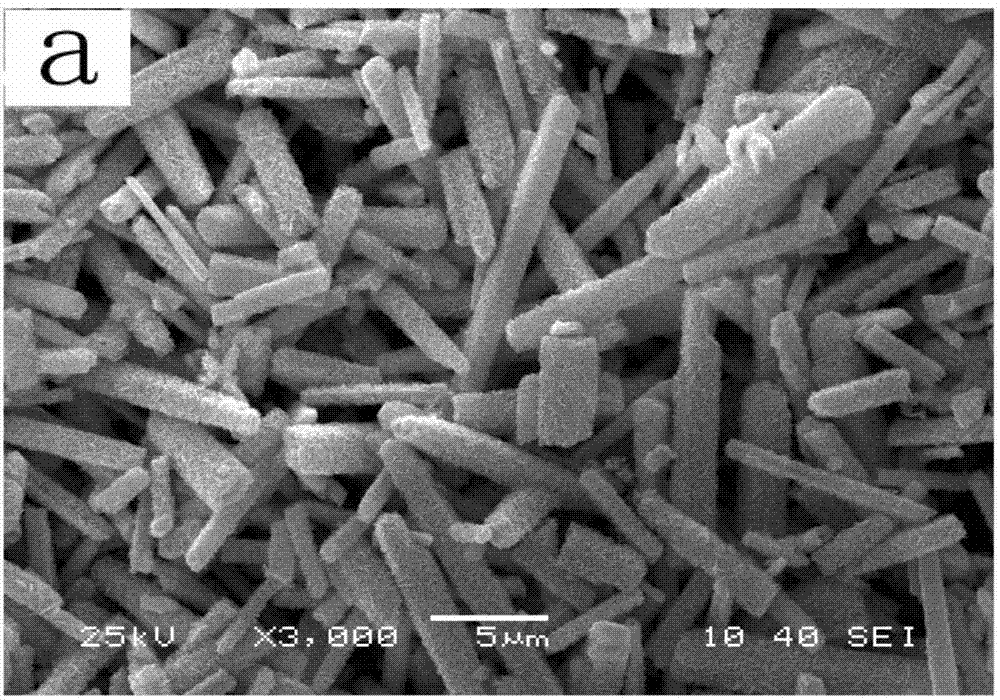

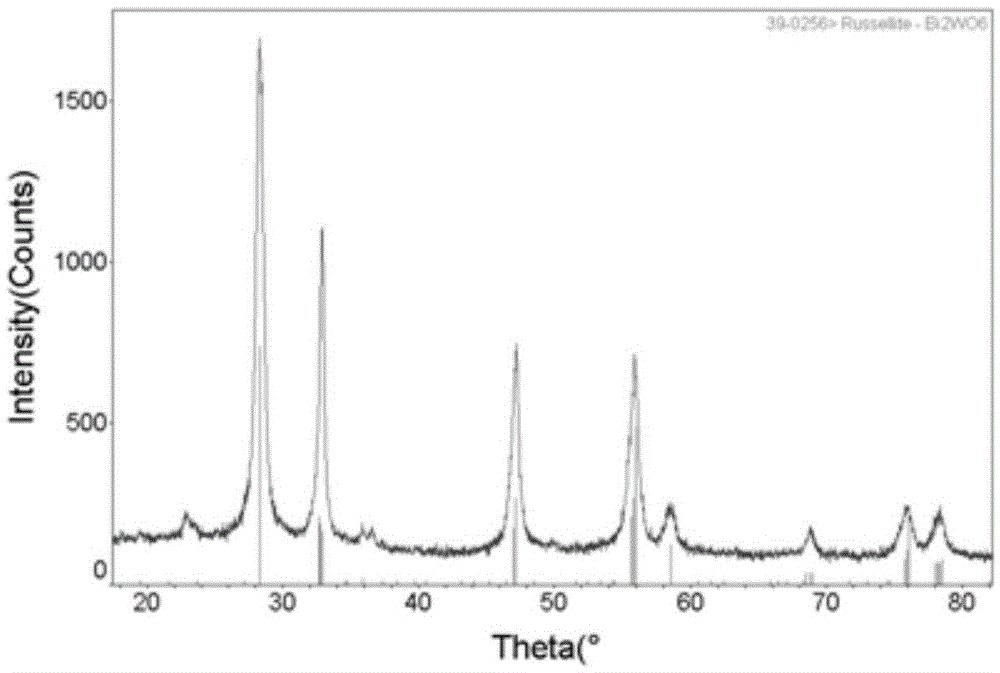

Method for preparing flowerlike bismuth tungstate by hydrothermal process

InactiveCN103112898AGood lookingUniform shapeNanotechnologyMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationDispersity

The invention discloses a method for preparing flowerlike bismuth tungstate by a hydrothermal process, which comprises the following steps: evenly mixing bismuth nitrate, sodium tungstate and potassium sulfate used as raw materials in a mol ratio of 2:1:(20-60), regulating the pH value of the solution, transferring into a reaction kettle to react, carrying out centrifugal separation on the product, washing, and drying to obtain the bismuth tungstate. The bismuth tungstate prepared by the simple hydrothermal reaction is in a micro flower shape, and has the advantages of uniform appearance and favorable dispersity. By utilizing the high-concentration salt environment, the substance has higher dispersity; and meanwhile, the formed bismuth tungstate has the advantages of novel appearance, pure phase, simple synthesis method and the like, and has favorable degradation effect on tetracycline.

Owner:CHANGAN UNIV

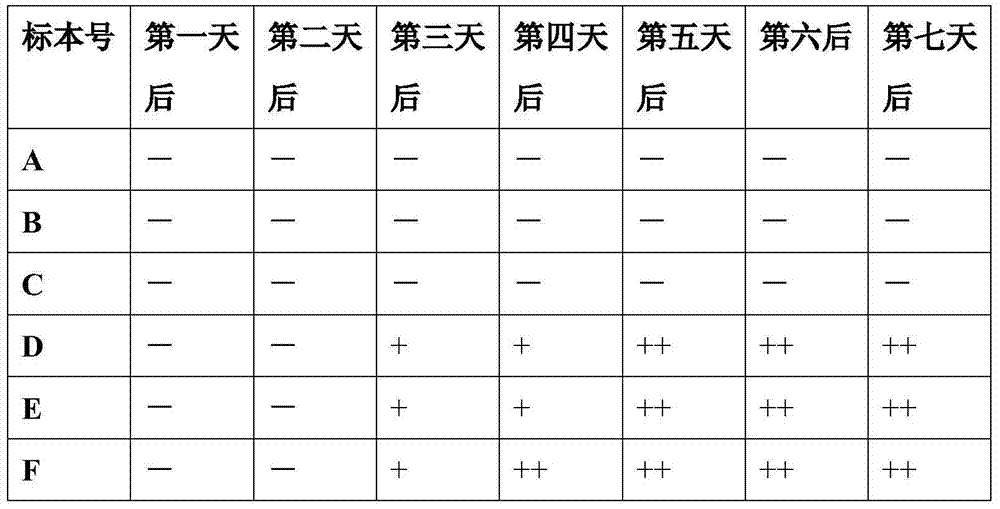

Method for preparing herbarium specimens

The invention relates to a method for preparing herbarium specimens. The method comprises the following steps: (1) collecting plant specimens and routinely preprocessing the specimens; (2) preparing a Chinese herbal medicine solution; (3) scalding the preprocessed fresh specimens in the Chinese herbal medicine solution under 10-100 DEG C for 1 second to 10 minutes; (4) drying the scalded specimens in air or absorbing all water from the scalded specimens, and flatly pressing in a specimen clip; (5) carrying out low-temperature airing treatment on the prepared specimens for 5-160 hours at the temperature of 5-20 DEG C. According to the method, the Chinese herbal medicine solution is directly utilized to scald the fresh plant specimens, has very good effects of killing bacteria and insects and preventing molds, and can be used for killing insect eggs and spores attached to the surfaces of plants to ensure that the plants are relatively bright in color. In addition, the low-temperature airing treatment can ensure that the plants can keep the original color and are prevented from being mildewed, so that the specimens can be stored for a relatively long time by using the method.

Owner:ANHUI NORMAL UNIV

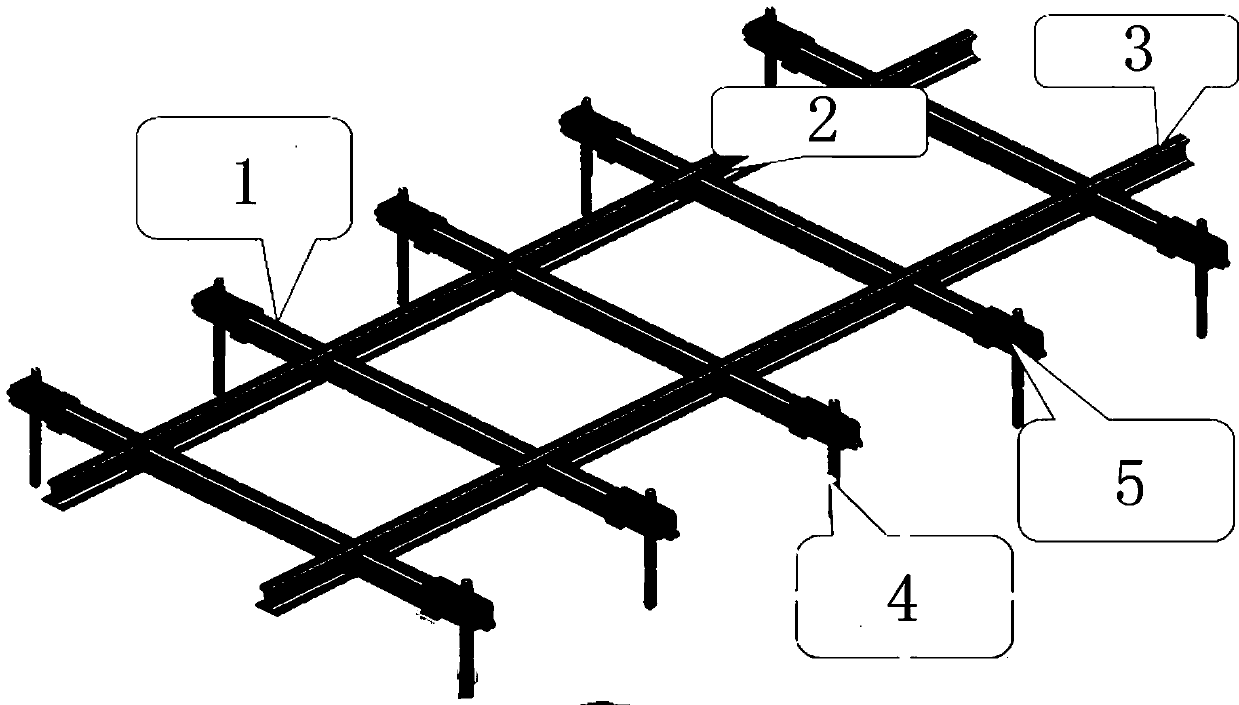

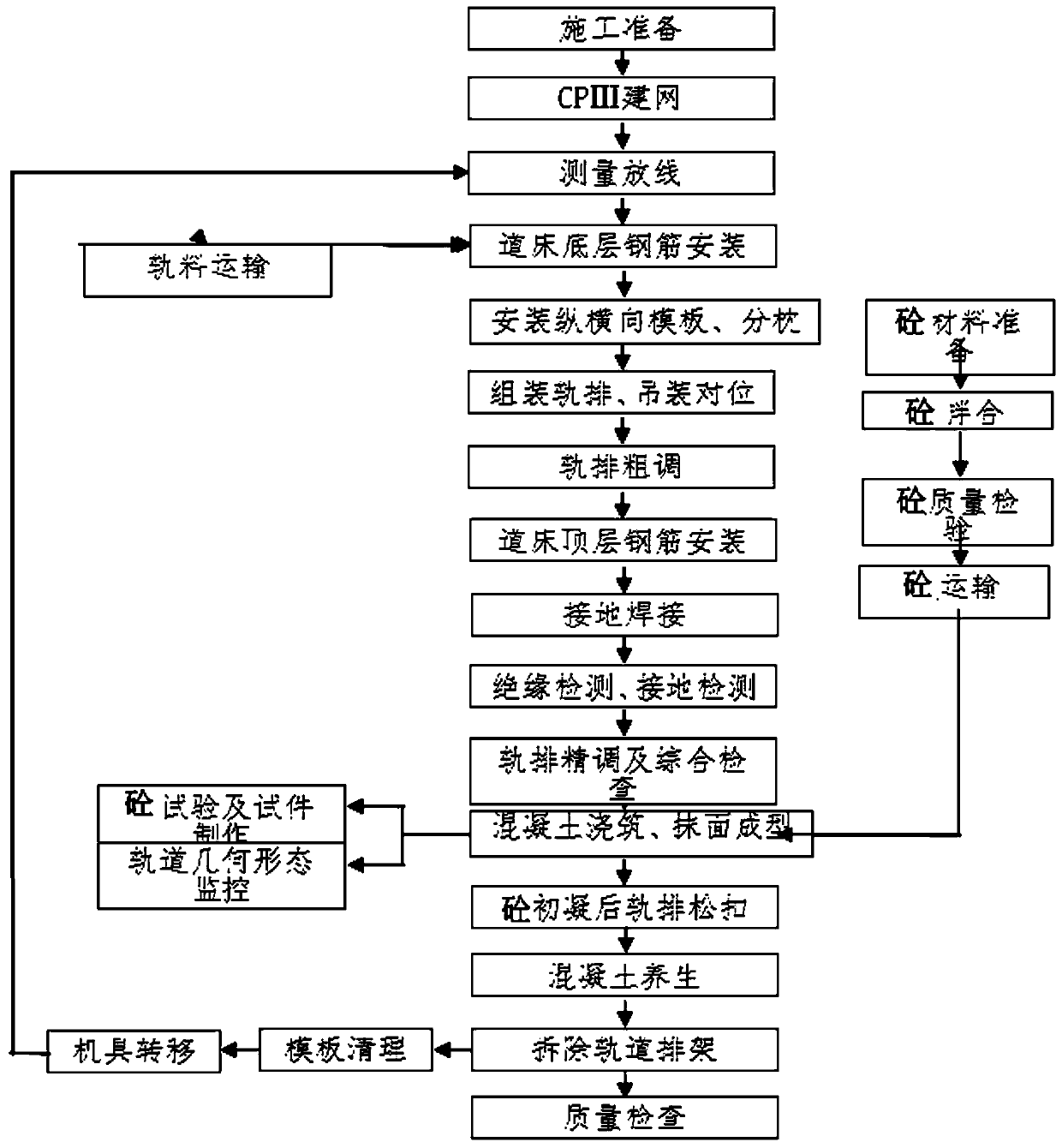

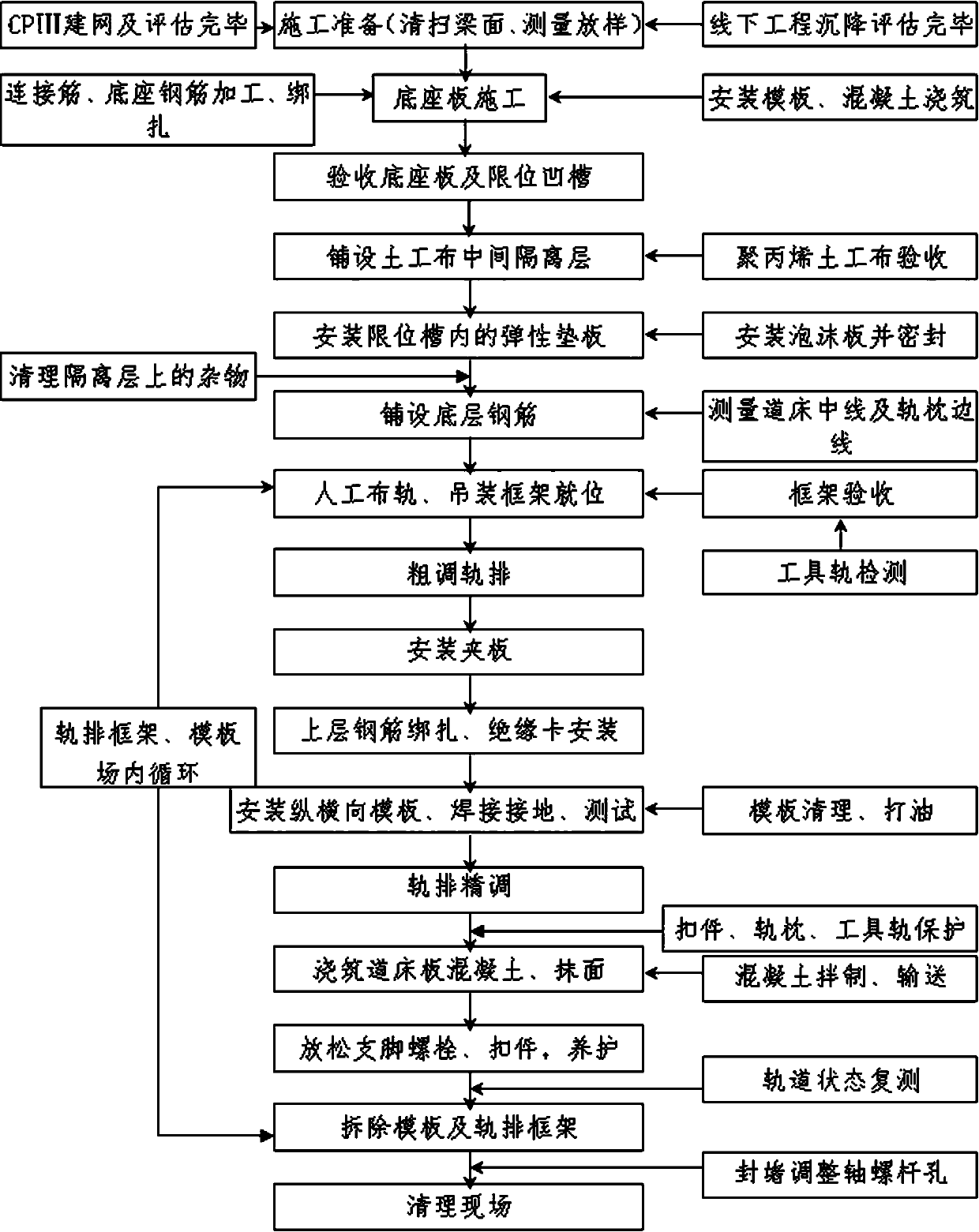

Construction method of ballastless tracks of tunnel group of heavy haul railway

ActiveCN110541329AAdvanced technologyHigh precisionBallastwayRailway track constructionRailway tunnelRebar

The invention relates to a construction technology of a heavy haul railway, specifically relates to a construction method of ballastless tracks of a tunnel group of a heavy haul railway. According tothe characteristics of high requirement on the construction precision of a ballastless track bed and difficulty in control in the construction of the ballastless tracks, the principle of near laying and convenience in precision control is adopted; a double-block sleeper is hung and placed to a position to be laid near a construction track bed plate; after key processes of steel bar binding, trackpanel assembly, comprehensive grounding, track coarse adjustment and the like are carried out, the geometric dimension of the tracks is finely adjusted by using a track inspection trolley measuring system, so that the design precision requirement is met, and finally, the track bed concrete is poured for one-step forming. The technology has the characteristics of being simple and convenient to operate, safe, practical, accurate in track geometric dimension, quick to position and the like.

Owner:CHINA RAILWAY SIXTH GROUP +2

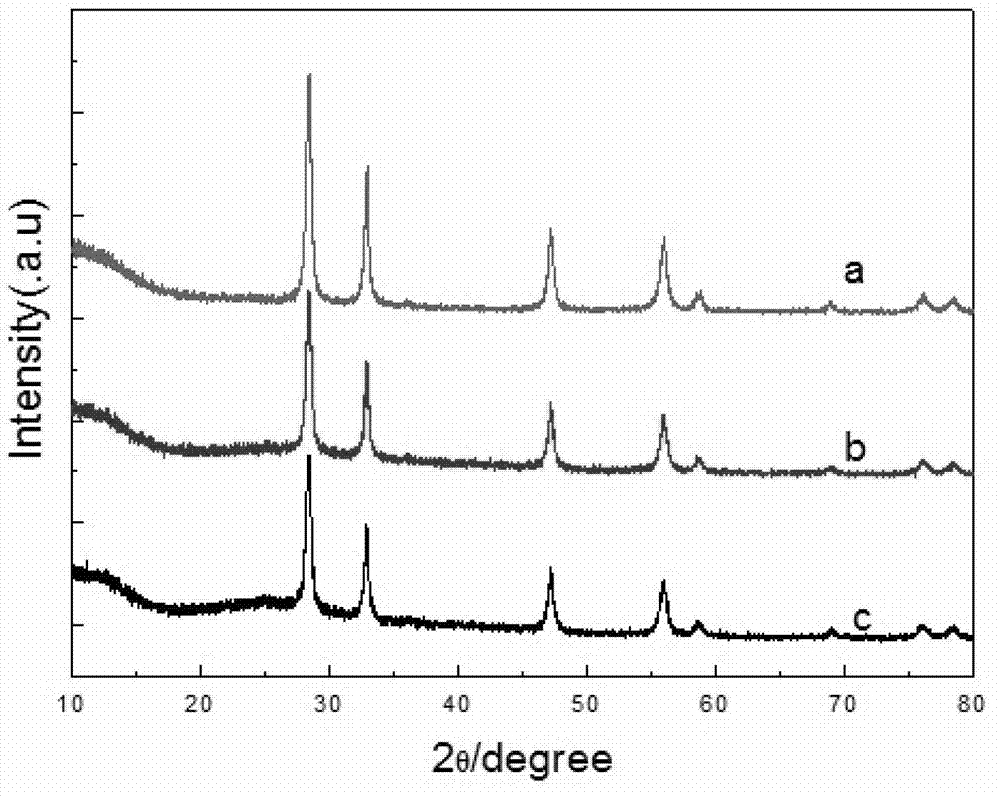

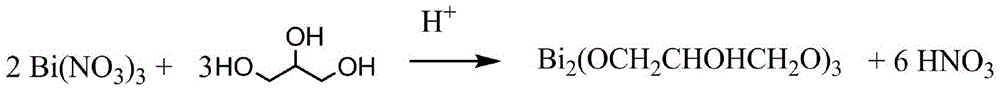

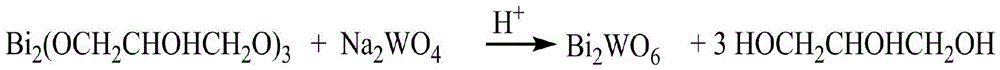

Visible-light-induced photocatalyst bismuth tungstate nano-chip and preparation method thereof

ActiveCN105597738ASpeed blockAvoid uniformityWater/sewage treatment by irradiationWater treatment compoundsTungstateGlycerol

The invention discloses a visible-light-induced photocatalyst bismuth tungstate nano-chip. A preparation method of this chip comprises the following steps: 1), subjecting bismuth nitrate and glycerol to solvothermal reaction in isopropyl alcohol solvent, and filtering, washing and drying to obtain bismuth glycerol; 2), dispersing the bismuth glycerol evenly in sodium tungstate solution, adjusting PH of an obtained solution system to 0-2, carrying out hydrothermal reaction, and filtering, washing and drying to obtain nano bismuth tungstate. The bismuth nitrate, the glycerol and the sodium tungstate are used as main materials, bismuth tungstate nano-chip powder is prepared by using a two-step method, related preparation equipment is simple, reaction conditions are mild, energy consumption is low, the technique is unique and novel, obtained finished sodium bismuth molybdate has grain size of 20-40 nm and may be directly used as a photocatalyst for degrading organic pollutants by photocatalysis in visible light.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

Lithium recovery process of waste lithium ion batteries

InactiveCN110396600ASimple processHigh purityWaste accumulators reclaimingProcess efficiency improvementCalcium hydroxideLithium electrode

The invention provides a lithium recovery process of waste lithium ion batteries. The process comprises the following steps of firstly crushing the waste lithium ion batteries and then sorting out toobtain positive and negative electrode active material powder and diaphragms; placing the sorted positive and negative electrode active material powder and diaphragms in a roasting furnace for roasting for a certain period of time based on a certain mass ratio at the temperature of 600 DEG C-650 DEG C; leaching roasting product through using oxalic acid solution and then filtering to obtain nickel-cobalt-manganese slag and lithium oxalate solution; adding calcium hydroxide into the lithium oxalate solution for reaction, and filtering to obtain lithium hydroxide solution and calcium oxalate; and finally, adding sulfuric acid into the obtained calcium oxalate for acidifying treatment, and then filtering to obtain oxalic acid solution. The method has the advantages of being simple and novel in process and high in the purity of the obtained lithium hydroxide solution and the recovery rate.

Owner:先进储能材料国家工程研究中心有限责任公司

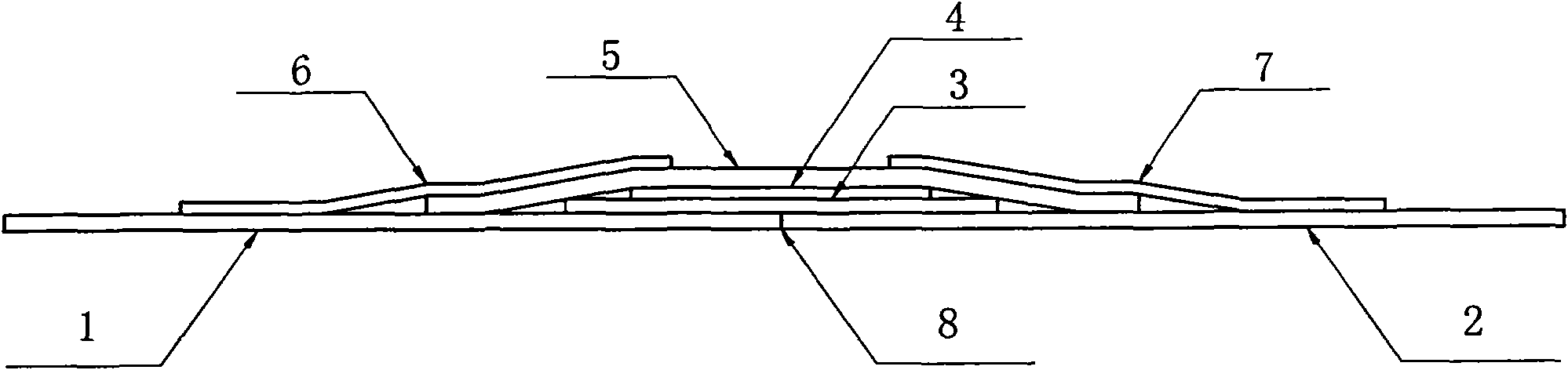

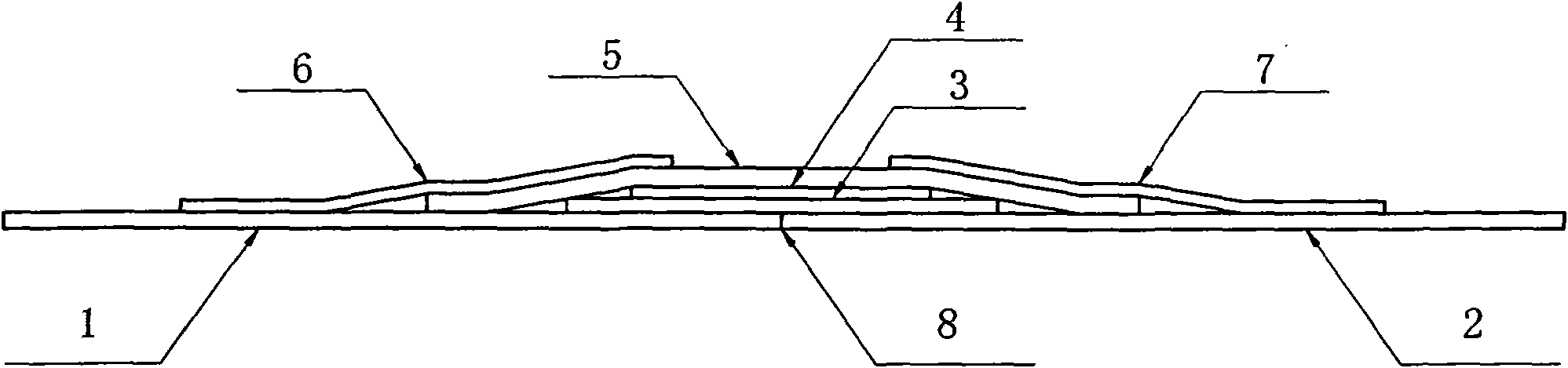

Pressing technology for nursing mat

ActiveCN104665994AHigh bonding strengthStable tensionAbsorbent padsBaby linensSuper absorbentToilet paper

The invention relates to the field of personal hygiene articles, in particular to a pressing technology for a nursing mat. The pressing technology sequentially includes the steps: manufacturing a core; performing composite shaping; performing slitting and packaging. Core manufacture sequentially includes the steps: feeding and mounting upper toilet paper and lower toilet paper; spraying wood pulp by the aid of atomized water and crushing the wood pulp; feeding SAP (super absorbent polymer); wrapping, shaping and compacting the core. Composite shaping sequentially includes the steps: slitting the core; combining materials; forming a guide groove; longitudinally folding a product; pressing a flow guide channel. The pressing technology for the nursing mat has the advantages that the pressing technology is novel and low in production cost, large-scale production is facilitated, and the produced nursing mat is comfortable to use.

Owner:HANGZHOU COCO HEALTHCARE PRODS

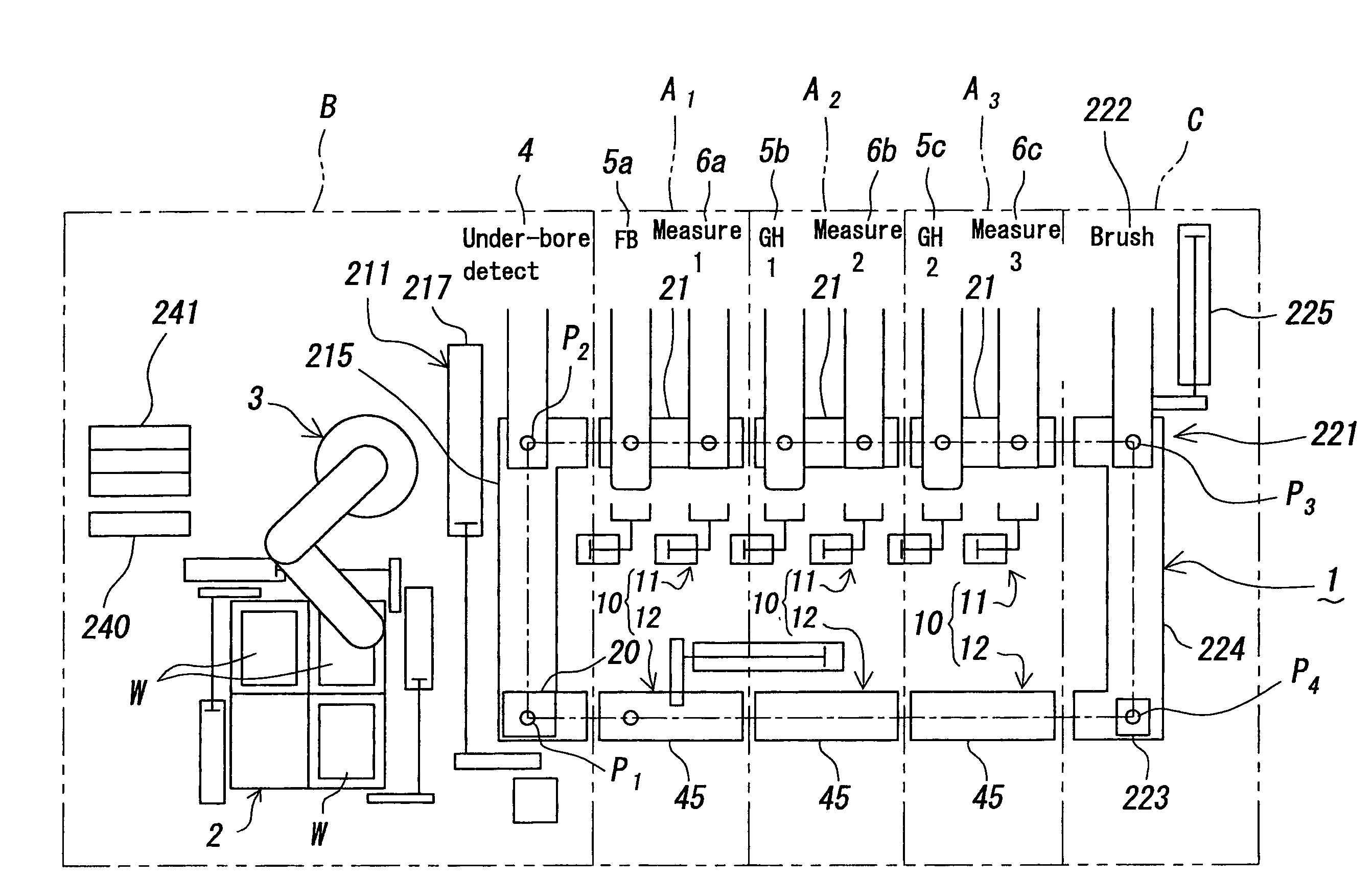

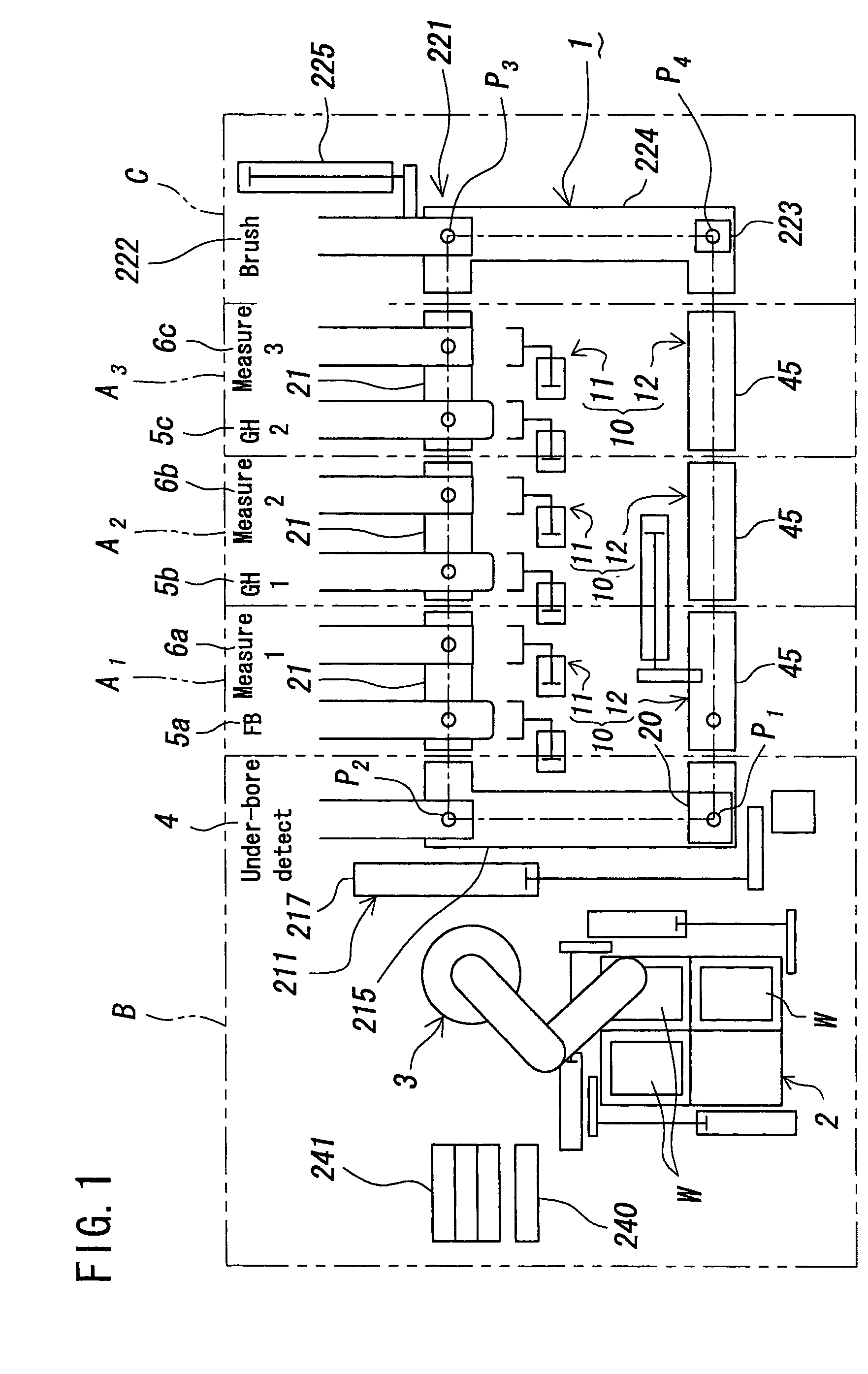

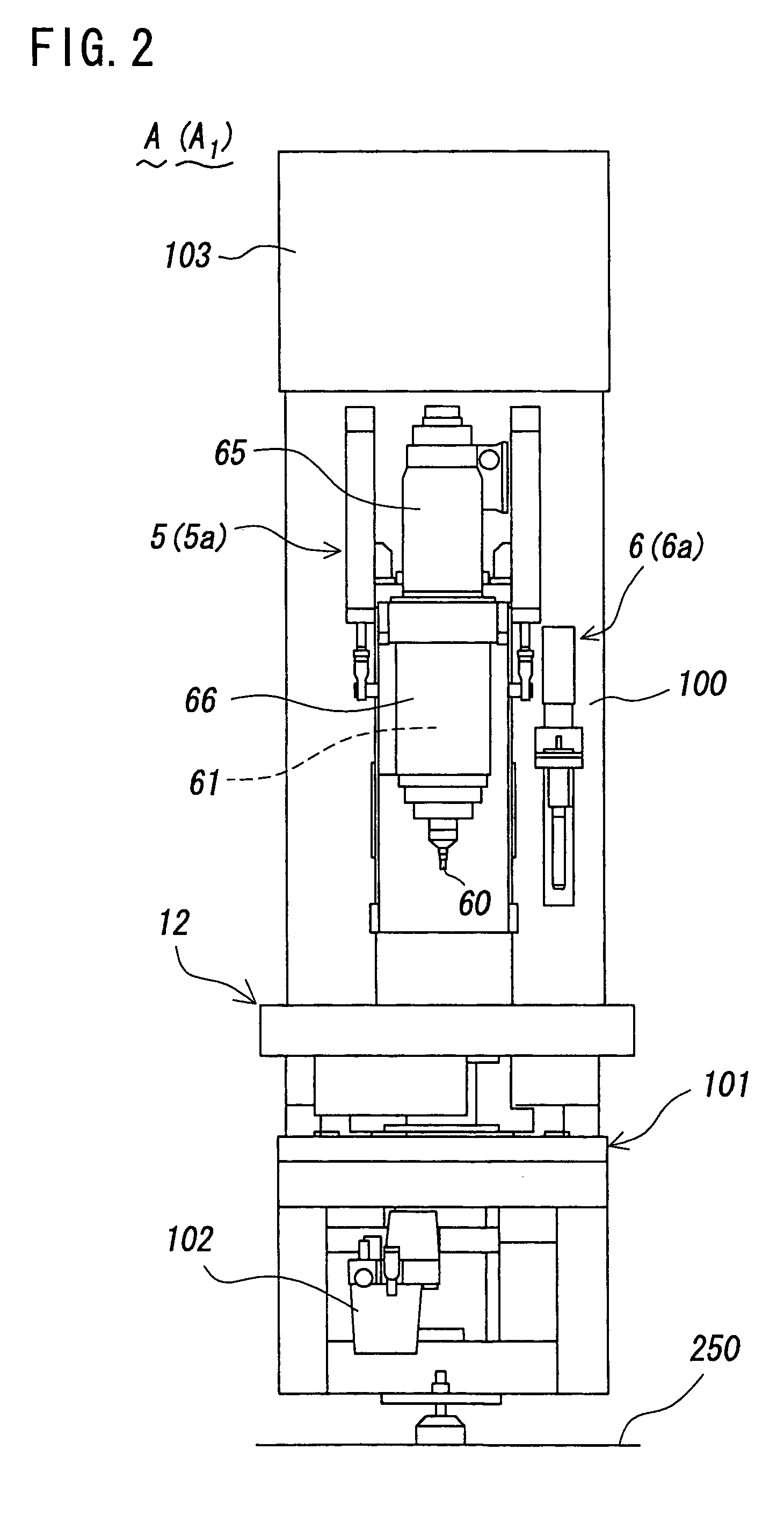

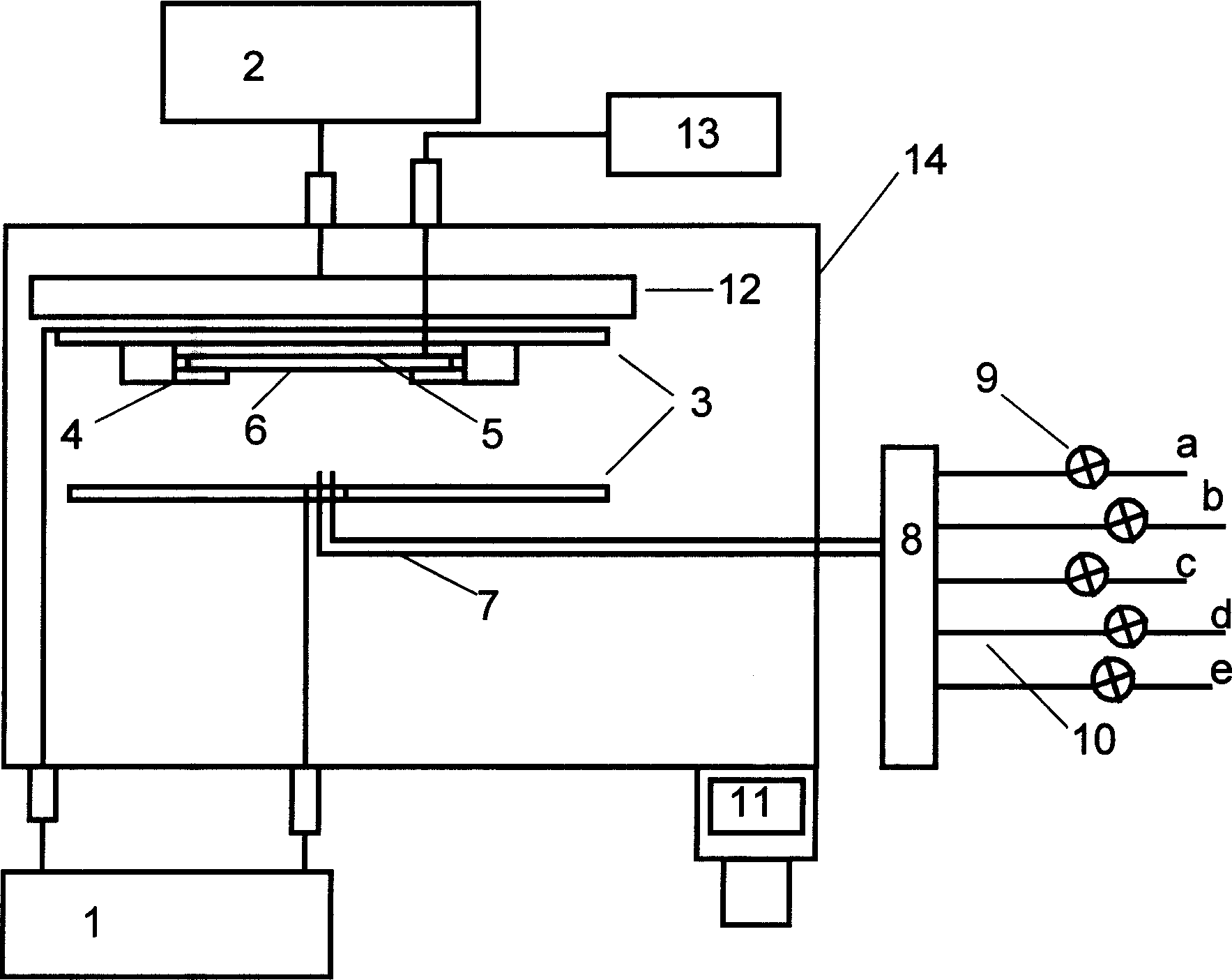

Processing cell of automatic machining system and automatic honing system

InactiveUS7346973B2New technologyReduce installation costsThread cutting feeding devicesThread cutting machinesMachining systemData storing

A processing cell of automatic machining system configured in that it is easy to decide or change the number of steps and to design, and to reduce the installation cost. The control unit of the processing cell comprises an operation data storing means for storing every position necessary data for operation at each position of the processing cell installed in the machining section of the automatic machining system, and a position designating means for designating the after-installation position. The control unit reads necessary data for operation out of the operation data storing means in accordance with the position designated by the position designating means. Thus, the operation of each cell can be switched in accordance with the position, and the processing cells can be easily changed in position and adjusted in quantity.

Owner:NISSIN MFG CO LTD

Preparation method of rare earth-doped sodium gadolinium tetrafluoride nanomaterial

InactiveCN102504821AUniform sizeGood biocompatibilityLuminescent compositionsTetrafluoroborateFreeze-drying

The invention discloses a method of preparing a rare earth-doped sodium gadolinium tetrafluoride nanomaterial. The method comprises the following steps of: (1) dissolving solid rare earth chloride and sodium oleate in a solvent and performing reflux treatment, separating and collecting the supernatant organic phase, washing with water, and vacuum drying to obtain a rare earth-oleic acid complex compound; (2) adding the rare earth-oleic acid complex compound and sodium oleate into oleic acid and completely dissolving to obtain a rare earth-oleic acid precursor solution; (3) taking out the rare earth-oleic acid precursor solution obtained in the step (2), transferring to the polytetrafluoroethylene inner container of a hydrothermal reaction kettle, and adding butylmethylimidazol tetrafluoroborate to the reaction kettle; and (4) putting the hydrothermal reaction kettle into a muffle furnace, allowing reactions to take place, centrifuging, washing the resulting white solid with distilled water and ethanol in order, and vacuum-drying or freeze-drying, to obtain the rare earth-doped sodium gadolinium tetrafluoride nanomaterial. The method has the advantages of simple process, small number of equipment, low energy consumption and environmental friendliness; and ensures uniform size of the nanomaterial product.

Owner:SHANGHAI JIAO TONG UNIV

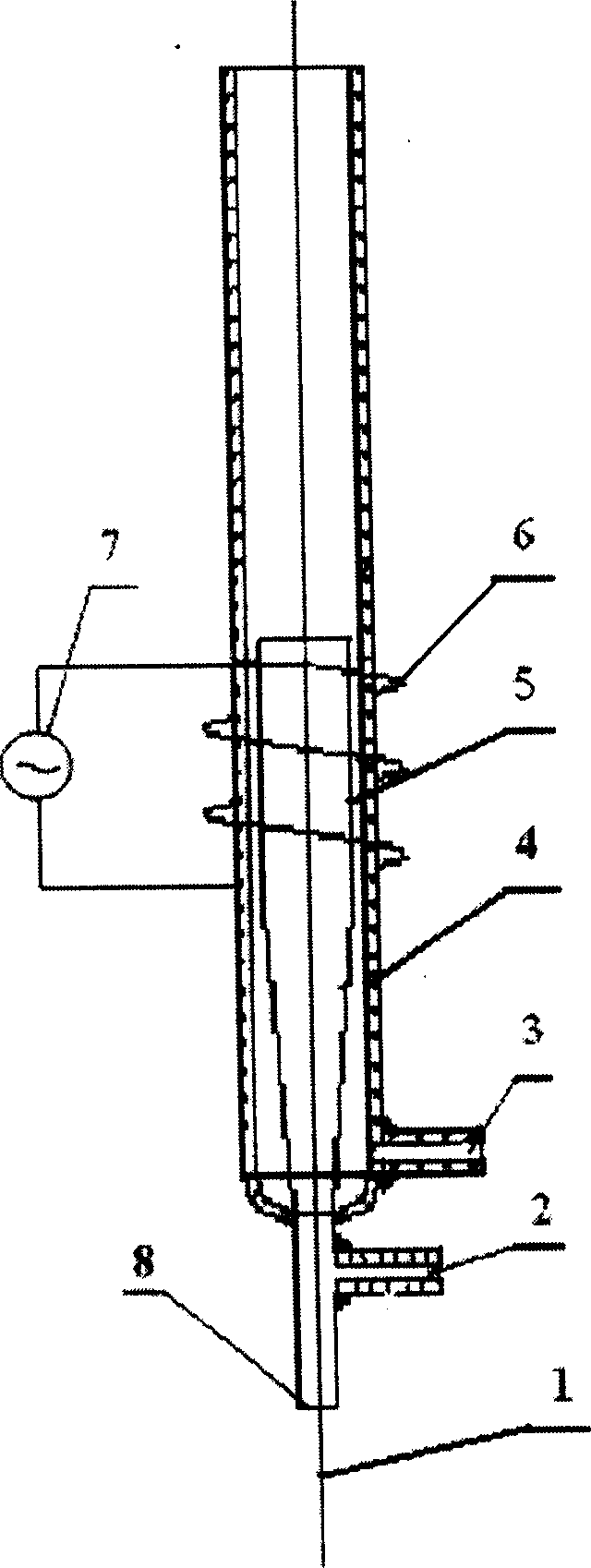

Continuous carbon fibre graphitizing method and apparatus

InactiveCN1746344ANovel processReduce energy consumptionArtificial filament chemical after-treatmentFiberCarbon fibers

A method of graphitization for carbon fiber has been provided in the invention. The carbon fiber is heated to graphitization by the plasma heating technology in the 2000-3000 Deg C.. The temperature of the plasma torch is monitored by being controlled the output power and the volume of the carrier gas.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

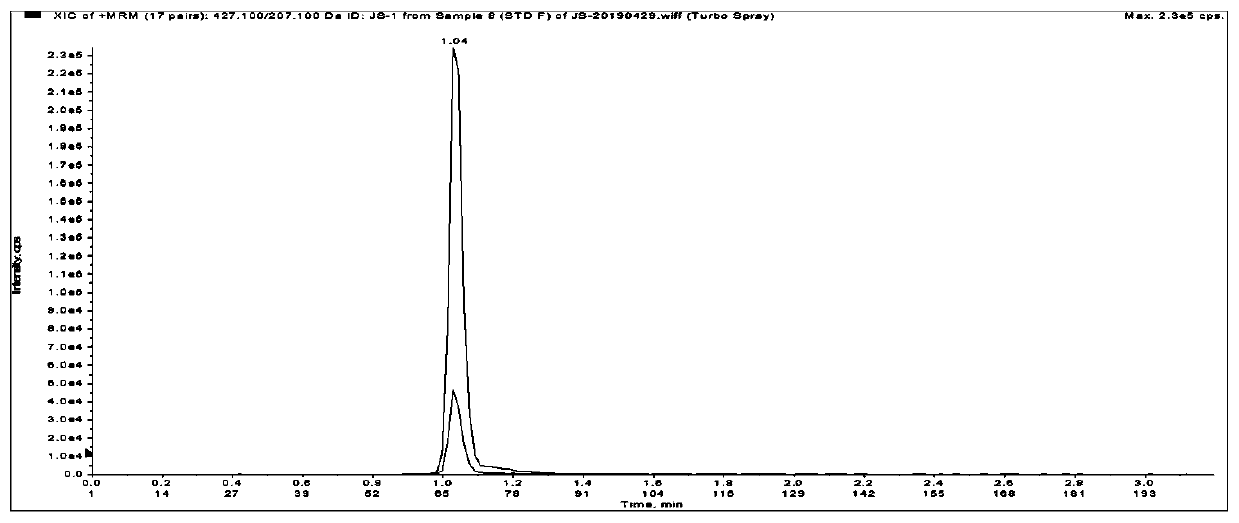

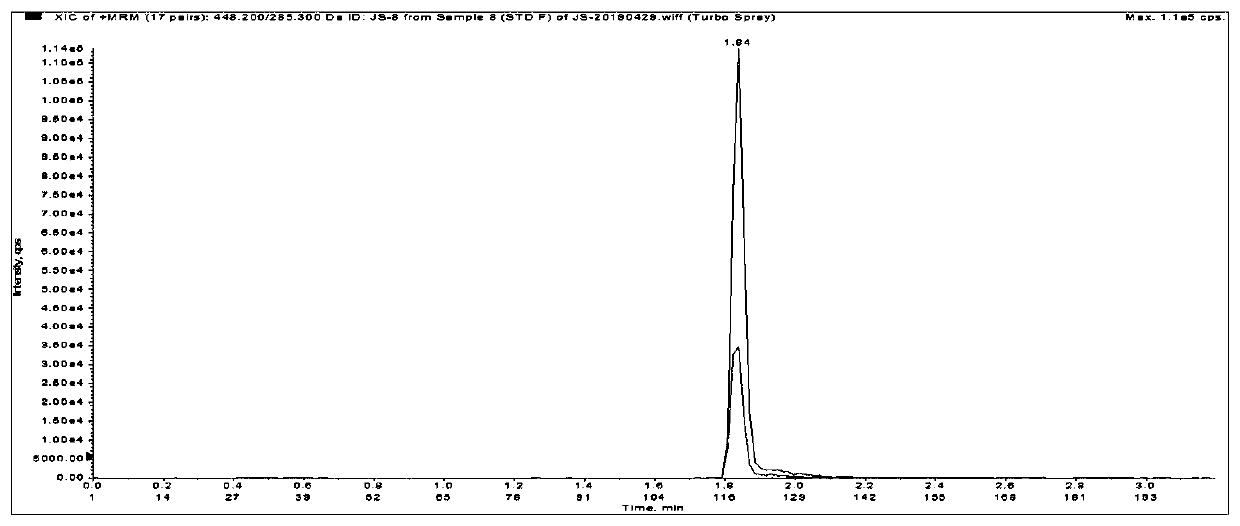

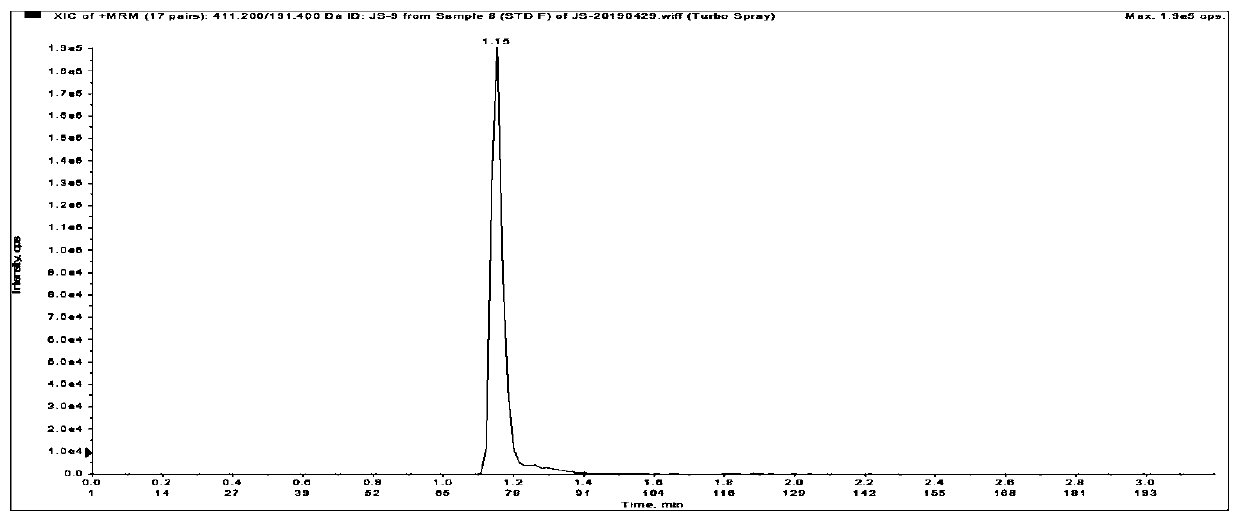

Method for detecting liquid quality of antipsychotic drug in serum or plasma

The invention relates to a method for detecting the liquid quality of an antipsychotic drug in serum or plasma and pretreatment of a specific purification material of the antipsychotic drug. The method comprises the following steps: a serum or plasma sample is subjected to protein precipitation by a certain proportion of organic reagents; a supernatant obtained through centrifugal precipitation ispretreated with a specific purification material to obtain a purified sample solution, the purified sample solution is subjected to liquid chromatography-tandem mass spectrometry detection and analysis, and eight antipsychotic drugs including olanzapine, clozapine, quetiapine, aripiprazole, flupiperidinol, risperidone, pariperidone and ziprasidone in serum or plasma are detected at the same time.The pretreatment of the specific purification material is a mixed solid-phase extraction column taking silica gel as a matrix, and the blood is purified by the specific purification material, so thatthe interference of the matrix in the blood can be removed, the matrix effect of eight antipsychotic drugs can be improved, and the recovery rate of the antipsychotic drugs can be better ensured.

Owner:大连润生康泰医学检验实验室有限公司

Plate splicing process of laser nickel plates

The invention relates to a plate splicing process of laser nickel plates, which comprises the following steps of: cutting the laser nickel plates with the thickness of 20-30mu m, wherein cut edges are flat and straight and have no burr; placing the two laser nickel plates with consistent thickness and downwards front surfaces on a magnetic rubber plate, oppositely splicing the respective cut edges which are flat and straight and have no burr, and mutually pressing a joint; bonding an adhesive tape at the joint of the back surfaces of the two laser nickel plates, and then bonding a double-faced adhesive tape with the width smaller than that of the adhesive tape at the middle part of the adhesive tape; pasting an reinforced nickel plate with the width larger than the adhesive tape to the double-faced adhesive tape, and wrapping the whole adhesive tape and the double-sided adhesive tape; and respectively bonding and fixing the reinforced nickel plate and the laser nickel plates at the left side and the right side of the reinforced nickel plate through the adhesive tape. The invention has the advantages that compared with the prior art, the invention has the key that plate cutting and plate splicing processes are different, the whole process is concise and novel, has strong operability, thinner plate splicing joint (which can be smaller than 0.1mm) and better evenness, can greatly improve the plate splicing quality and is applicable to the direct plate splicing of the laser nickel plates.

Owner:张雪飞

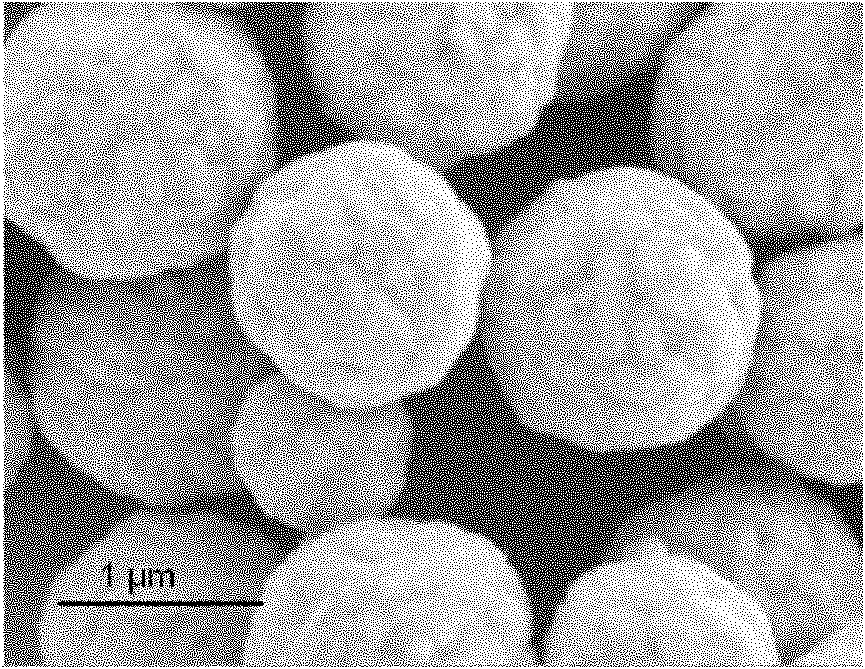

Hollow silver microballoon and preparation thereof as well as application method thereof in Raman detection

The invention provides a hollow silver microballoon, preparation thereof and an application method thereof in Raman detection, belonging to the biomedical technical field. The hollow silver microballoon is prepared by mixing Streptococcus thermophilus with silver nitrate, allowing the obtained mixture to react with ascorbic acid to obtain a product, and finally precipitating and washing the product. The preparation method of the invention has simple and novel process, simple materials, a small quantity of employed equipment, low energy consumption and high detection limit up to 10-15M while detecting Raman enhancement effect; and the invention is applicable to fields such as disease detection, gas adsorption, gas masks, photochemical catalysis, food safety and the like.

Owner:SHANGHAI JIAO TONG UNIV

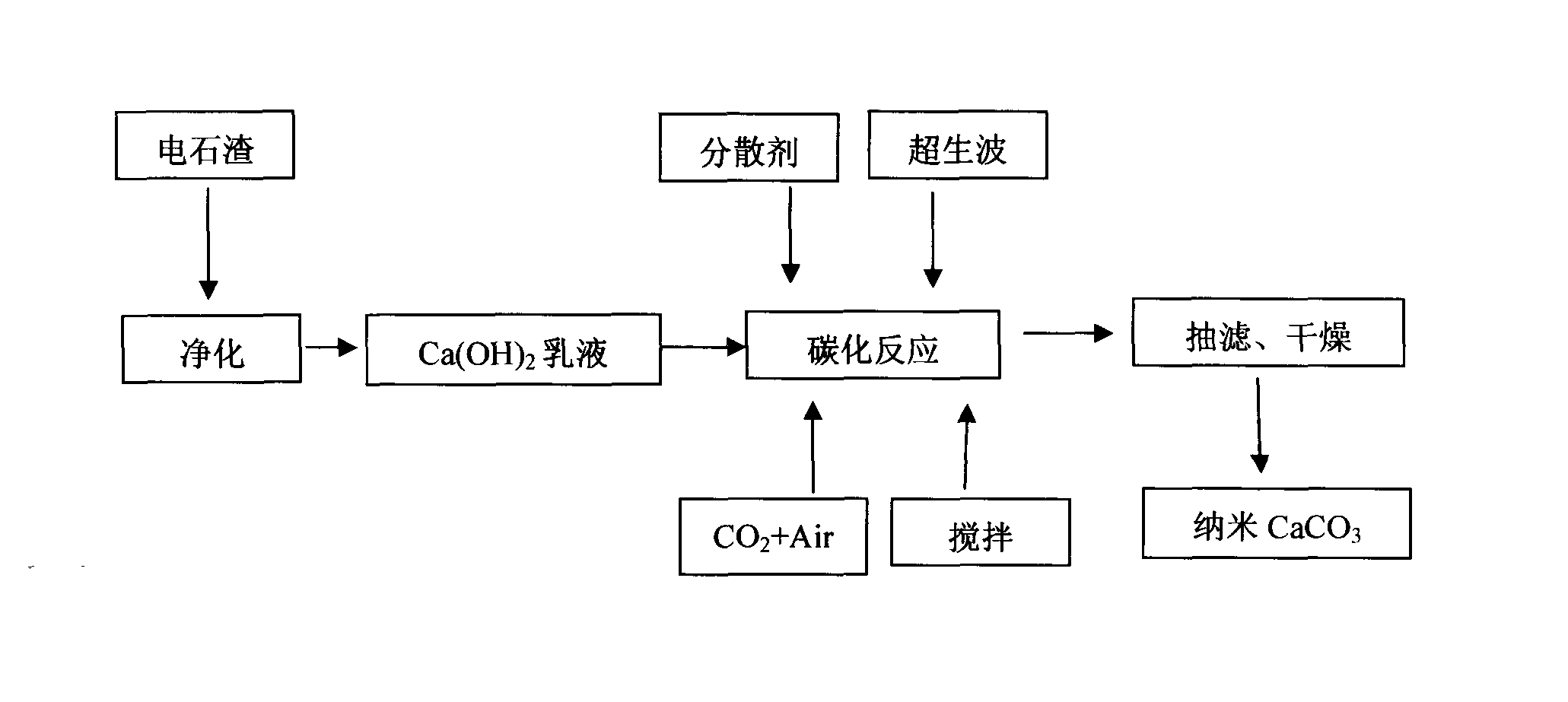

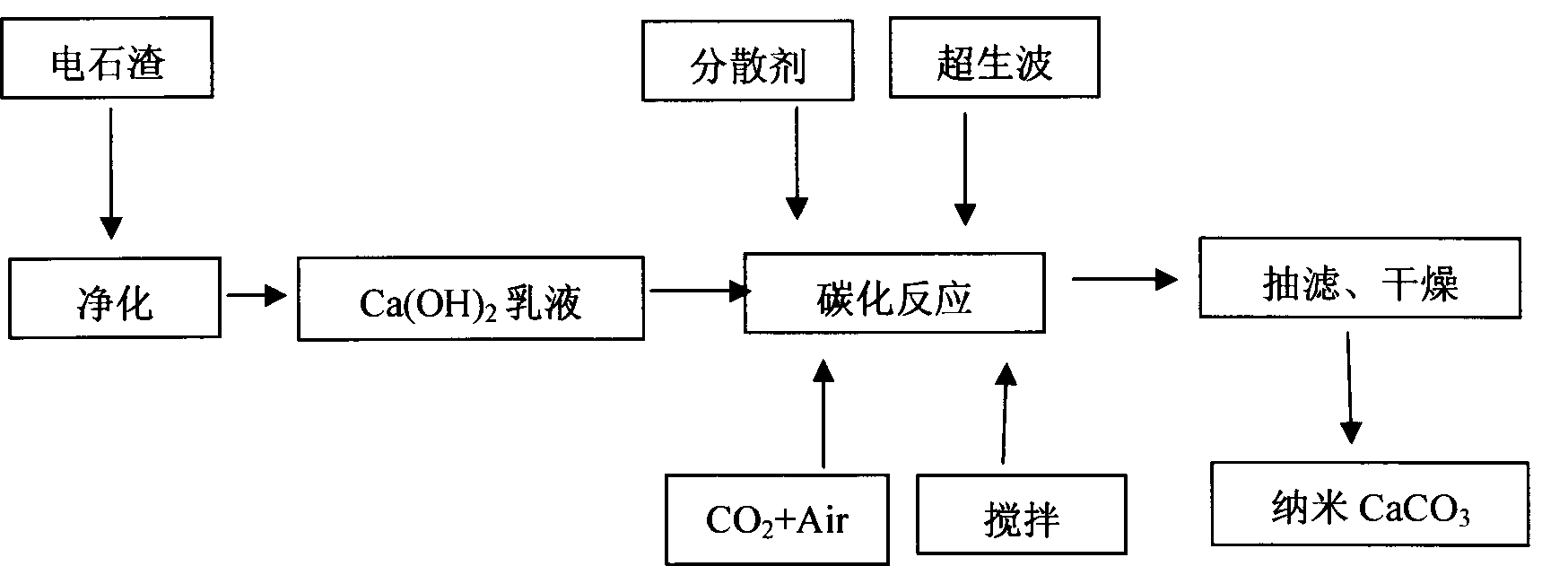

Method for preparing nanometer CaCO3 from calcium carbide slag through ultrasonic process

InactiveCN102515237AMass transfer speedReduce consumptionCalcium/strontium/barium carbonatesNanotechnologySlagToxic industrial waste

The invention relates to a method for preparing nanometer CaCO3 from calcium carbide slag through an ultrasonic process. The calcium carbide slag is purified to generate a Ca(OH)2 emulsion, the Ca(OH)2 emulsion which is added with a dispersant, CO2 and air is irradiated by ultrasonic waves, uniformly stirred, suck-filtered and dried to generate the nanometer CaCO3. The method for preparing the nanometer CaCO3 through adopting the ultrasonic process has the advantages of simple operation, no need of designing a new device, high product added value, gas-liquid-solid mass transfer speed improvement benefiting, realization of the resource comprehensive utilization of the industrial waste slag calcium carbide slag, limestone resource consumption reduction, production cost reduction, natural environment improvement, novel technology, operation benefiting, good product stability, substantial shortening of the preparation time, environment improvement, particle size of 30-200nm, and purity of above 99.2%. Production requirements of the rubber industry, the plastic industry and the coating industry are completely met.

Owner:XINJIANG TIANSHAN CEMENT CO LTD

Method for preparing nano crystal cubic boronnitride film

InactiveCN1850589ANovel processRaw materials are easy to getNitrogen compoundsGas phaseShielding gas

The invention discloses a method for preparing a nano crystal cubic boron nitride film, comprising the steps of: 1) cleaning the surface of a substrate and placing the substrate in the reaction chamber of a gas phase growing device, where vacuum degree in the reaction chamber is at least ten to the power -1 Pa; 2) charging protective gas into the reaction chamber, heating the substrate and controlling at 300-1100 deg.C, regulating pressure strength in the reaction chamber to 0.1-10 Pa and generating plasma in the reaction chamber; 3) controlling bias voltage on the substrate at 0-250 V, then in turn charging nitrogen source, chlorine source and boron source into the reaction chamber and making film growth. The invention has characters of simple process and equipment, easy to obtain raw materials, and the prepared film has high purity and low residual stress, size of crystal grains less than 50 nm, low surface roughness, and high hardness.

Owner:ZHEJIANG UNIV

Ester lubricant base oil and synthesis method thereof

InactiveCN105368537ALow costNovel processOrganic compound preparationCarboxylic acid esters preparationOrganic acidAlcohol

The invention relates to ester lubricant base oil and a synthesis method thereof. The synthesis method comprises that acidic solid as a catalyst is added into an organic acid and an organic alcohol in a reactor, the raw materials undergo a reaction at a temperature of 150-180 DEG C for 2-6h to produce a crude ester, the excess organic acid or organic alcohol is separated by a reduced pressure distillation or molecular distillation method, the acid is further removed by an anion exchange resin so that an acid value is reduced to 0.1mg KOH / g or less and the high-quality ester lubricating base oil is obtained, and the separated organic acid or organic alcohol can be recycled and be used as raw materials for the next same reaction system so that a cost is effectively reduced.

Owner:克拉玛依理工学院筹建办公室

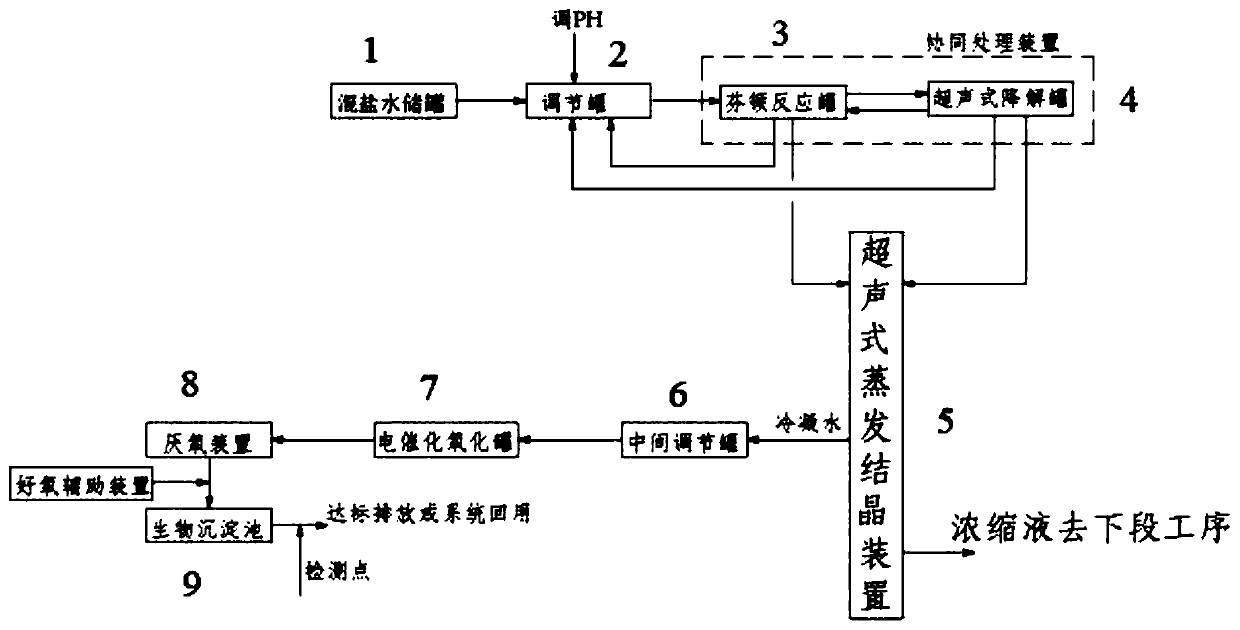

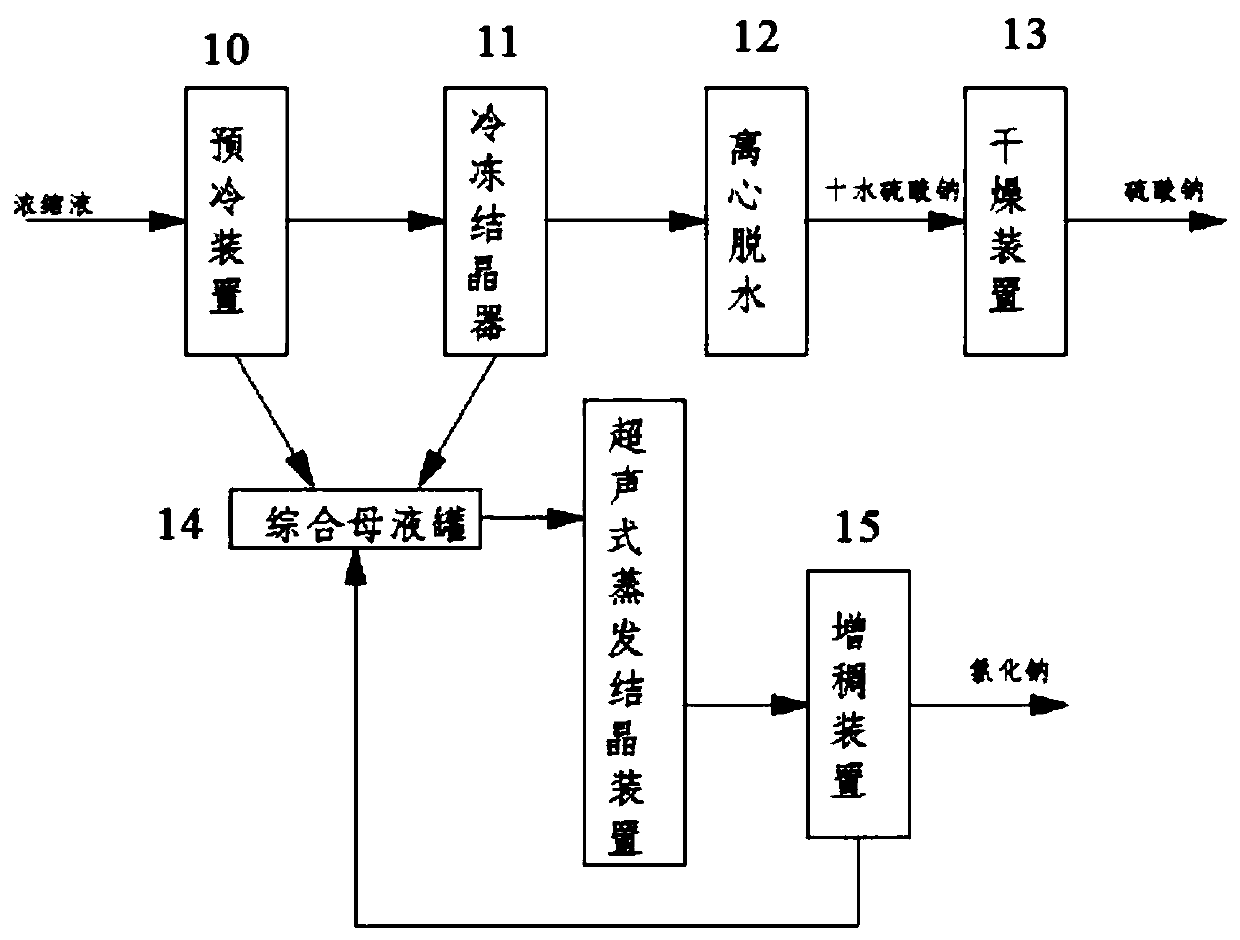

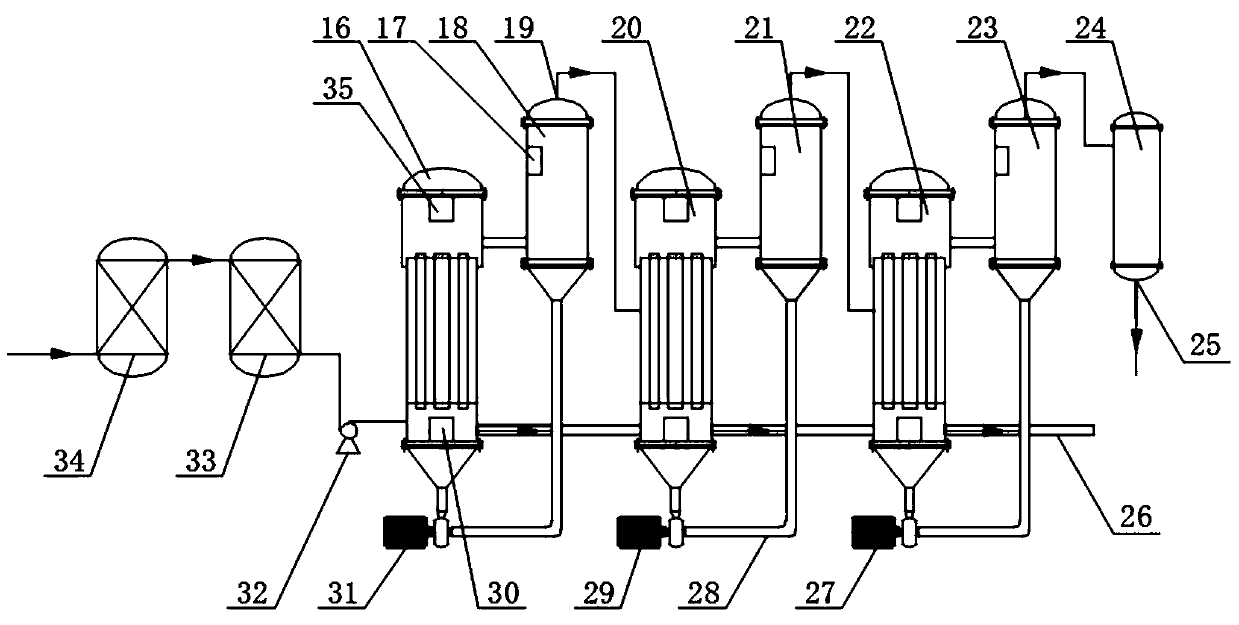

Sodium chloride and sodium sulfate ultrasonic type evaporative-crystallization salt separating system and method

PendingCN110040908ARealize recycling of resourcesGood for maintaining purityWater treatment compoundsWater contaminantsResource recoveryEvaporation

The invention relates to a sodium chloride and sodium sulfate ultrasonic type evaporating, crystallizing and salt separating system. The system is characterized by comprising a mixed salt wastewater storage tank, a regulating tank, a pretreating device, an ultrasonic type evaporative-crystallization device, a condensing treatment device and a salt separating device. The invention further relates to a sodium chloride and sodium sulfate ultrasonic type evaporating-crystallizing and salt separating method which comprises the steps: 1) pretreating high-salt wastewater; 2) performing ultrasonic type evaporative crystallization; 3) treating evaporation condensate water; 4) performing salt separating treatment. The system and method disclosed by the invention have the advantages of scientific andreasonable design and novel technology; by means of the system and the method, the high-salt wastewater can be recycled; meanwhile, salt resources can be recycled.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

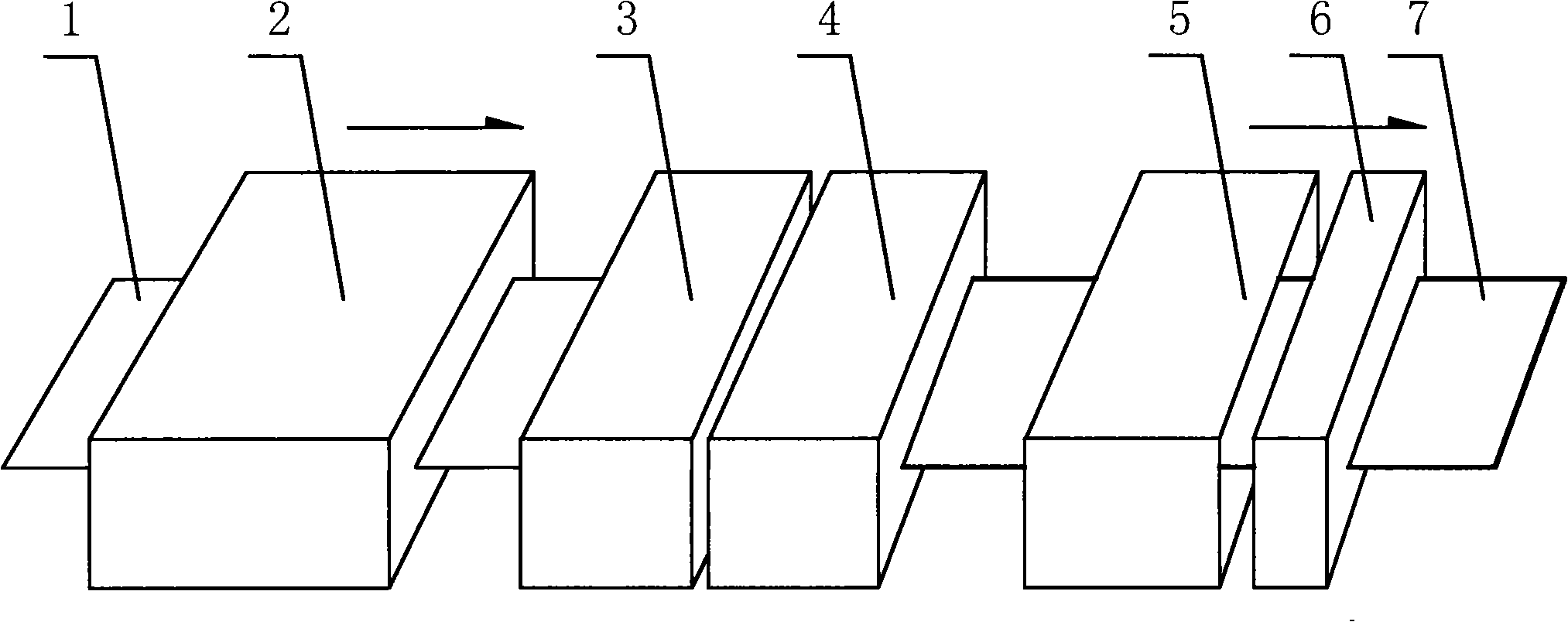

Environment-friendly laser anti-counterfeiting printing process

The invention relates to an environment-friendly and anti-counterfeiting laser printing technique, which pertains to the field of laser printing. The main point of the invention is that a plain paper is adopted by the technique, when in use, firstly an information layer of pictures and words is directly and continuously printed on the plain paper by a flexographic plate; then a bright layer is printed on the information layer of pictures and words by the flexographic plate, at the same time a laser layer of pictures and words is pressed on the bright layer by a film; the bright layer and the laser layer of pictures and words are solidified; finally with the continuous solidification of the bright layer and the laser layer of pictures and words, pressed films are continuously and immediately peeled off from the paper by a peeling device. The environment-friendly and anti-counterfeiting laser printing technique of the invention has an optimization and improvement on the existing technical process and has the advantages that by adopting the laser printing technique of the invention, printing can be directly processed on the plain paper, industrialized and continuous printing can be realized, and the product printed by the invention can present the effect of node laser. Furthermore, the laser printing technique of the invention is far superior to the products of the prior art in the aspects of practicability, environmental friendliness and economical efficiency.

Owner:ZIBO TAIBAO FP PROD CO LTD

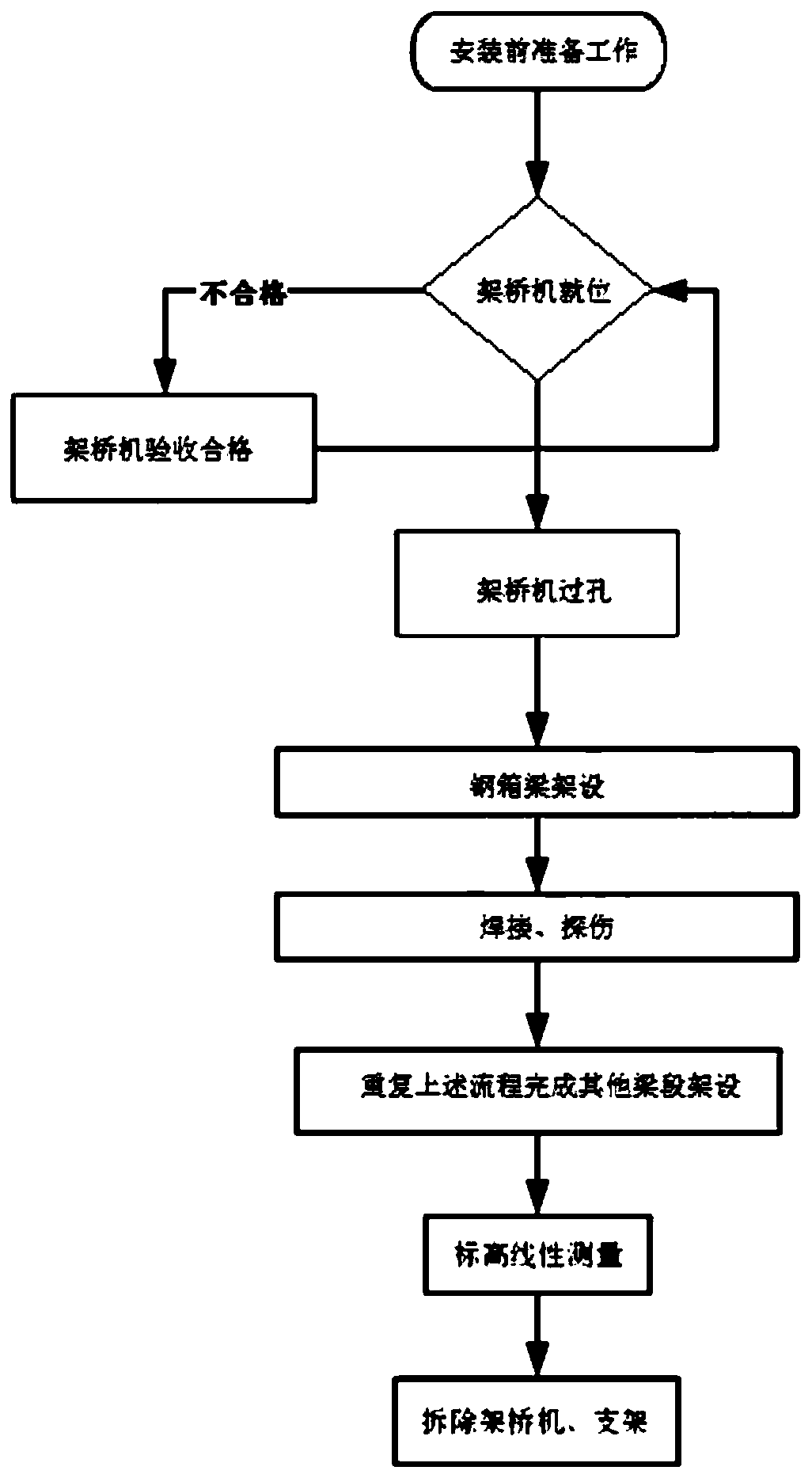

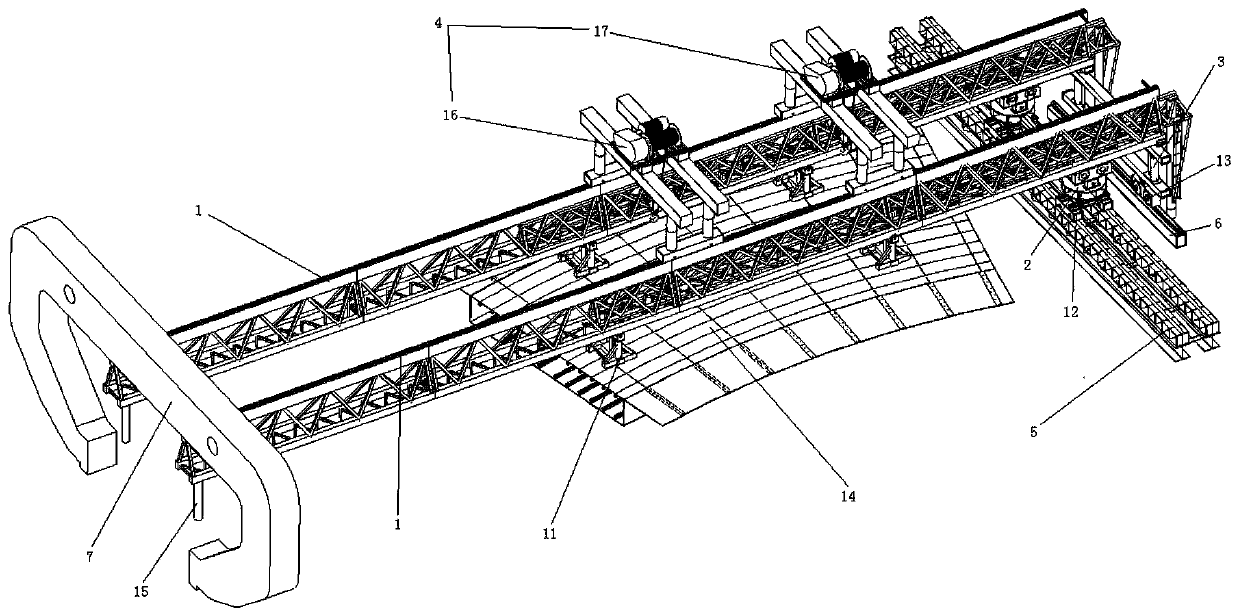

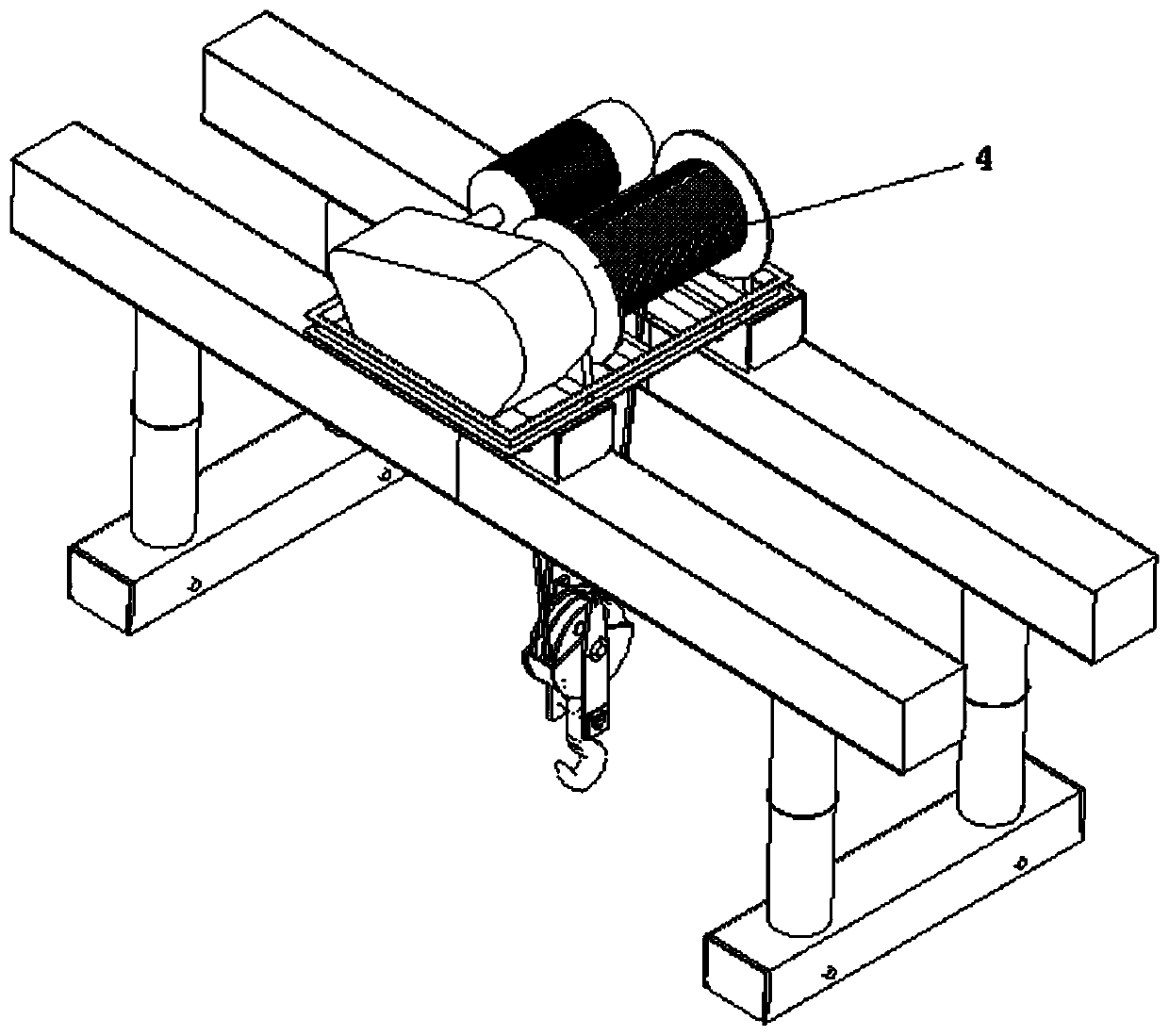

Small-curve-radius steel box girder bridge erecting machine and erecting construction method

ActiveCN111335178ASolve erection problemsAvoid difficultyBridge erection/assemblyArchitectural engineeringStructural engineering

The invention provides a small-curve-radius steel box girder bridge erecting machine and an erecting construction method. The bridge erecting machine comprises a bridge erecting machine main beam, a front supporting leg device arranged at the front end of the bridge erecting machine main beam, a rear supporting leg device arranged at the rear end of the bridge erecting machine main beam, a middlesupporting leg device arranged at the position, close to the rear end, of the bridge erecting machine main beam and a middle supporting leg transverse moving rail arranged in the transverse bridge direction, and the bottom of the middle supporting leg device is installed on the middle supporting leg transverse moving rail. And a front crown block 16 and a rear crown block 17 are arranged on the bridge girder erection machine main beam. When the middle supporting leg sliding block on the middle supporting leg transverse moving rail is moved; when the steel box girder is erected, the girder tailof the main girder of the bridge girder erection machine can move along with the main girder, the rotating angle of the bridge girder erection machine can be adjusted, the whole attitude of the bridge girder erection machine can be adjusted to the steel box girder erection attitude, the steel box girder erected by the bridge girder erection machine in the attitude is the set steel box girder attitude, and the method is suitable for erecting small-curve-radius steel box girders.

Owner:THE THIRD ENG CO LTD OF CHINA RAILWAY SEVENTH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com