Cleaning agent for stainless steel seamless stay tubes and preparation method for cleaning agent

A technology of seamless tube drawing and stainless steel, applied in the field of chemical cleaning, can solve problems such as polluted air, waste acid water polluted water resources, human hazards, etc., and achieves the effects of simple operation, strong cleaning power and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

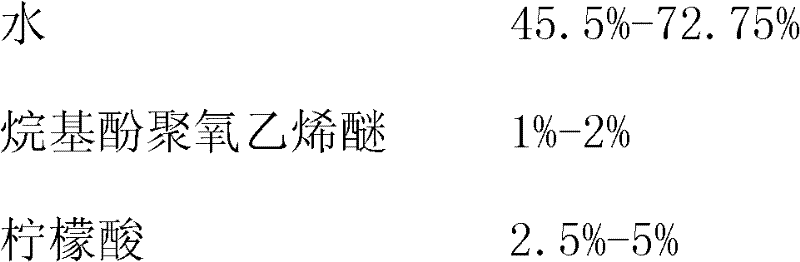

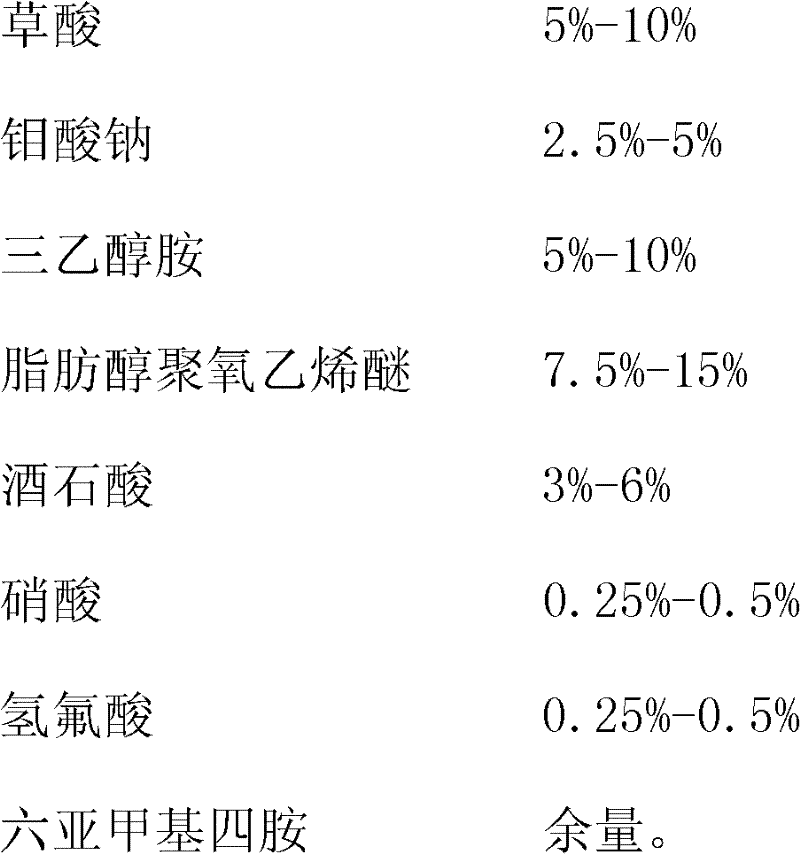

Method used

Image

Examples

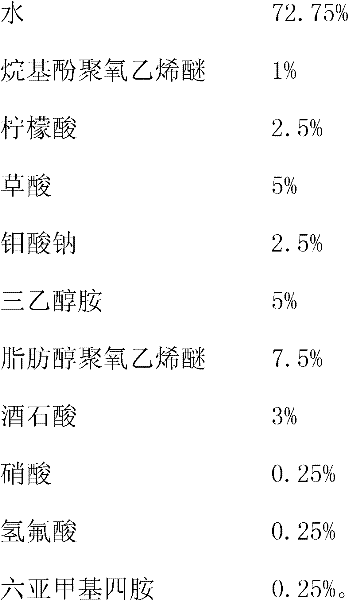

Embodiment 1

[0028] A preparation method of a stainless steel seamless pipe cleaning agent, which has the following steps: (1), at normal temperature, add 727.5 kg of water to the mixer; (2), add 10 kg of emulsifier with a content of 99% while stirring OP-10; (3), 25 kg of 99.5% citric acid was added while stirring; (4), 50 kg of 99.6% oxalic acid was added while stirring; (5), 99% molybdenum was added while stirring 25 kilograms of sodium nitrite; (6), while stirring, throwing in content is 50 kilograms of triethanolamines of 85%; (7), throwing in while stirring 75 kilograms of JFC penetrants; (8), putting in while stirring, content is 99% tartaric acid 30 kilograms; (9), while stirring, the content of feeding is 2.5 kilograms of 90% nitric acid; (10), while stirring, the content of feeding is 2.5 kilograms of 44% hydrofluoric acid; (11), while stirring, the content of feeding is 99% black 2.5 kilograms of luotropine; (12), after all the materials are added, stir for 20-30 minutes to be t...

Embodiment 2

[0030] A preparation method of a stainless steel seamless pipe cleaning agent, which has the following steps: (1), at normal temperature, add 619.5 kg of water into the mixer; (2), add 12 kg of emulsifier with a content of 99% while stirring OP-10; (3), 38 kg of 99.5% citric acid was added while stirring; (4), 65 kg of 99.6% oxalic acid was added while stirring; (5), 99% molybdenum was added while stirring 30 kilograms of sodium nitrate; (6), while stirring, throwing in content is 75 kilograms of triethanolamines of 85%; (7), throwing in while stirring 100 kilograms of JFC penetrating agent; (8), putting in while stirring, content is 99% tartaric acid 50 kilograms; (9), stirring while putting in content is 3 kilograms of 90% nitric acid; (10), stirring while putting in content is 3.5 kilograms of 44% hydrofluoric acid; (11), stirring while putting in content is 99% black 4 kilograms of luotropine; (12), stir 20-30 minutes again and be finished product after all feeding.

Embodiment 3

[0032] A preparation method of a stainless steel seamless pipe cleaning agent, which has the following steps: (1), at normal temperature, add 552.5 kg of water into the mixer; (2), add 17 kg of emulsifier with a content of 99% while stirring OP-10; (3), 43 kg of 99.5% citric acid was added while stirring; (4), 80 kg of 99.6% oxalic acid was added while stirring; (5), 99% molybdenum was added while stirring 40 kilograms of sodium nitrite; (6), while stirring, throwing in content is 80 kilograms of triethanolamines of 85%; (7), throwing in while stirring 120 kilograms of JFC penetrants; (8), putting in while stirring, content is 99% tartaric acid 55 kilograms; (9), stirring while putting in content is 4 kilograms of 90% nitric acid; (10), stirring while putting in content is 4 kilograms of 44% hydrofluoric acid; (11), stirring while putting in content is 99% black 4.5 kilograms of luotropine; (12), stir 20-30 minutes again after all feeding is finished and be finished product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com