Patents

Literature

87results about How to "Does not generate static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly water-based paint and preparation method thereof

InactiveCN102690600AStrong covering powerReduce volatilityNatural resin coatingsEnvironmental resistanceWater based

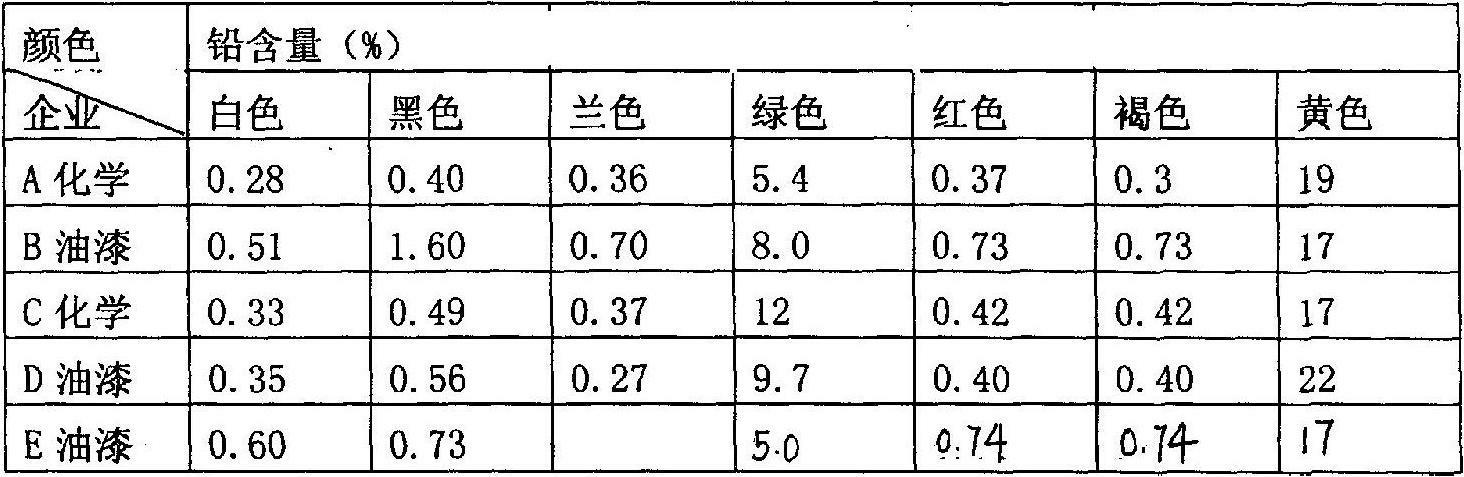

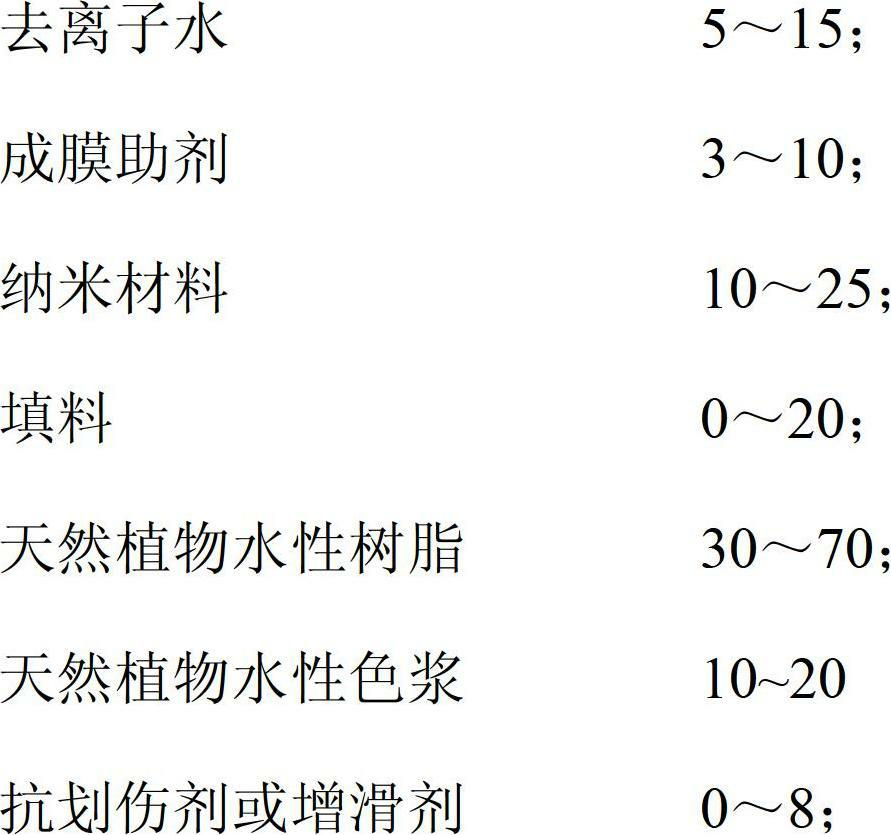

The invention provides an environment-friendly water-based paint and a preparation method thereof. The environment-friendly water-based paint comprises the following components in parts by weight: deionized water, a film formation accessory ingredient, a wetting agent, a dispersing agent, a nanometer material, a filling material, natural plant water-based resin, natural plant water-based color paste and a scratch resistance agent or a slipping agent. The preparation method comprises the following steps of: A, preparing a water-based dispersoid; B, adding the water-based dispersoid obtained in the step A into a stirred emulsion, then adding the film formation accessory ingredient and uniformly stirring and dispersing; C, adding pigment; and D, supplying water, and blending to obtain the water-based paint when the Stormer viscosity is 65 to 90 KU at the temperature of 25 DEG C. The environment-friendly water-based paint is wide in application range, has high covering power, high adhesive force and high water resisting property, chemical resistance and abrasion resistance and is safe and environment-friendly; a static electricity phenomenon is avoided; and the volatilization amount of organic compounds and the heavy metal content can be reduced.

Owner:TIANCHANG JULONG TRAVEL PAINT

Novel health-care underwear textile fabric

InactiveCN103284336AGood for healthGood moisture absorptionWoven fabricsUndergarmentsPolyesterCellulose fiber

The invention discloses a novel health-care underwear textile fabric. The novel health-care underwear textile fabric comprises the following components, by mass, 20%-25% of regenerated cellulose fibers, 15%-20% of soybean protein fibers, 15%-20% of milk protein fibers, 25%-30% of modified viscose and 15%-20% of polyester fibers, and is formed by warp and weft being interwoven, wherein the warp is made of the regenerated cellulose fibers, the soybean protein fibers and the milk protein fibers in a blending mode, and the weft is made of the modified viscose and the polyester fibers in a blending mode. Through the method, the fabric has superior moisture-absorbing and moisture-preserving functions, can keep cool and dry and stiff and smooth anytime, further has superior breathability and elasticity, is good in shape-keeping performance, cannot produce static, at the same time, has antimicrobial effect and health-care and nursing performance, and is beneficial to health of people.

Owner:WUXI HOUSETEX INDS

Tranquilizing and nerve-soothing down processing technology

InactiveCN104179023ACover up the tasteDoes not generate static electricityFibre treatmentAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses a tranquilizing and nerve-soothing down processing technology. According to the processing technology, tranquilizing and nerve-soothing down is processed through the following steps: (1) the down is prepared; (2) primary washing is implemented, wherein a detergent and a detergent are added in water for washing; (3) primary dehydration is implemented, wherein the content of water in the down reaches 22%-28%; (4) secondary washing is implemented, wherein a detergent, an anti-mite agent and a fragrance agent are added in water for secondary washing; (5) secondary dehydration is implemented, wherein the content of water in the down reaches 45%-63%; (6) drying sterilization is implemented, wherein a tranquilizing and nerve-soothing agent is added in high-temperature steam for drying sterilization, the tranquilizing and nerve-soothing agent contains the following ingredients in a weight ratio: 14-16 of spina date seeds, 8-11 of arborvitae seeds, 5-6 of tuber fleeceflower stem, 2-3 of thinleaf milkwort root-bark, 1-3 of silktree albizzia bark, 0-2 of drgon's bone, 0-3 of dens draconis, 5-7 of lavender, 7-9 of roses, and 1500-2000 of water, and all the ingredients are boiled for 15-22 minutes in clean water to obtain a filtrate. The technology is simple and novel; by virtue of twice washing, twice dehydrating and once steam drying, the active ingredients of chemical agents and the fragrance agent are kept on the surface of the down to the maximum degree; if being used for a long time, the tranquilizing and nerve-soothing down plays tranquilizing and nerve-soothing roles and has fragrance.

Owner:江苏欣隆羽绒有限公司

Spray type mildew-proof leather polishing agent and preparation method thereof

The invention discloses a spray type mildew-proof leather polishing agent which is characterized by comprising the following components in parts by weight: 5-15 parts of aloe fibroin collagen humectant, 30-50 parts of carnauba wax, 5-7 parts of castor oil, 5-20 parts of dimethyl silicon oil, 0.1-0.5 part of mildew preventive, 0.5-2 parts of cationic surfactant, 0.01-0.1 part of essence and 20-30 parts of water. The spray type mildew-proof leather polishing agent is simple and convenient to use, and the cleaning, maintenance and polishing are finished at one time; the spray type mildew-proof leather polishing agent has strong antifouling ability, does not generate static electricity and prevents dust; the spray type mildew-proof leather polishing agent is neutral and phosphorus-free, contains a benzoic acid preservative and can suppress mildew reproduction; the spray type mildew-proof leather polishing agent resists ultraviolet under strong light and prevents aging and cracking; and with natural aloe component, the spray type mildew-proof leather polishing agent can keep the fullness, elasticity and gloss of leather for long time.

Owner:SUZHOU XIELU NETWORK TECH

Natural plant water paint and its preparation

The pure natural aquatic plant paint is prepared with the materials including natural plant aquatic resin, natural plant aquatic colour paste, assistant and water. The present invention has the advantages of low amount of volatile organic compound, low heavy metal content, no Pb, Cr, Cd, Sb, Ba and other heavy metals contained, wide application range, no static electricity produced, excellent covering capacity, high adhesion, high water tolerance and chemical resistance, high wear resistance, solid content as high as 61 %, large covered area and low cost, etc.

Owner:张世刚

Woolen sweater

InactiveCN102845849ADoes not generate static electricityHigh affinityGarmentsArtifical filament manufactureFiberHuman body

The invention discloses a woolen sweater. The woolen sweater is manufactured by blending the following components in parts by weight: 60-70 parts of wool, 5-10 parts of cashmere, 10-20 parts of artificial cotton, 10-20 parts of soybean protein fiber and 5-10 parts of composite seaweed carbon fibers. The woolen sweater is manufactured by blending the soybean protein fibers and the composite seaweed carbon fibers, is of friendliness with the skin of a human body, contains various amino acids required by the human body, and has excellent healthcare functions; and the composite seaweed carbon fiber has a function of absorbing far infrared ray, and the far infrared ray not only has an excellent heating function, but also can activate cells to discharge old or dead cells or to apply regeneration capability to old or dead cells so as to be capable of reinforcing energy of the cells, functions of the cells, activities of the cells and the like. The woolen sweater disclosed by the invention utilizes the artificial cotton so as to be smooth relative to fluffs and to be unlikely to pill, and the artificial cotton has excellent heat and electricity conductivity and does not generate static electricity so that the whole woolen sweater is unlikely to generate static electricity.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

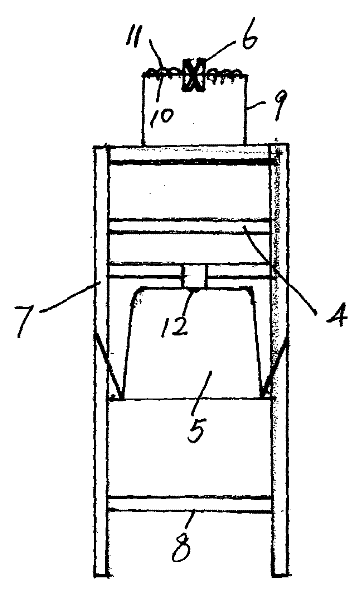

Chip packaging device

InactiveCN111341696AImprove yield rateEasy to assemble and disassembleSemiconductor/solid-state device manufacturingStructural engineeringElectrical and Electronics engineering

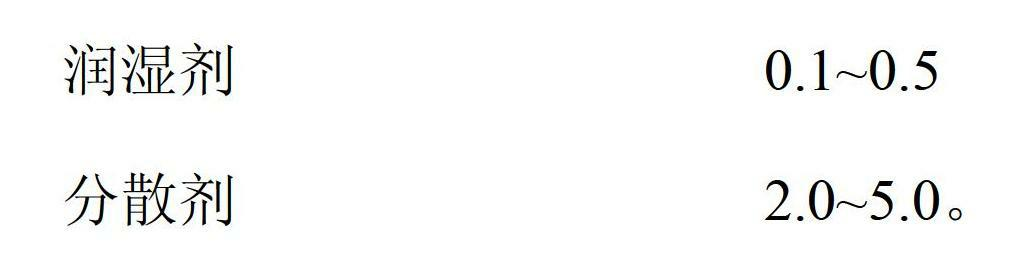

The invention discloses a chip packaging device. The chip packaging device comprises a bottom box, supporting legs are arranged under the bottom box, and a side plate is arranged on the upper surfaceof the bottom box. Bulges matched with each other are arranged at the bottom of the side plate and the top of the bottom box, threaded openings are formed at the bottom of the side plate and the top of the bottom box, and a lifting plate is arranged at the inner side of the side plate above the bottom box. A screw rod is arranged on the side face of the side plate, the top of the screw rod is fixedly connected with a first bearing at the top of the side plate, and the bottom of the screw rod is fixedly connected with a second bearing at the top of the bottom box. The top of the screw rod is movably connected with the first bearing, and the bottom of the screw rod is movably connected with the second bearing. A dust collector on the side face of a box body is matched with an air blower at the top of the lifting plate to work and then is connected through an air inlet pipe, so that in the chip packaging process, the head of the dust collector is aligned to the chip to suck out dust, andthe dust is discharged through the air blower, and accordingly the dust-free effect of a chip packaging environment is achieved, and the chip yield is increased.

Owner:湖州靖源信息技术有限公司

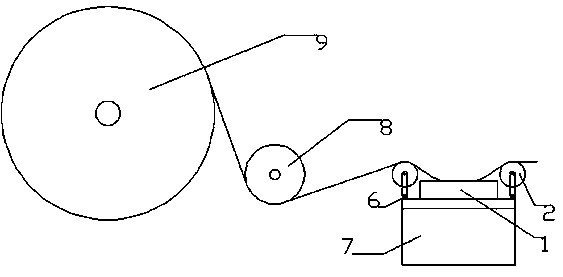

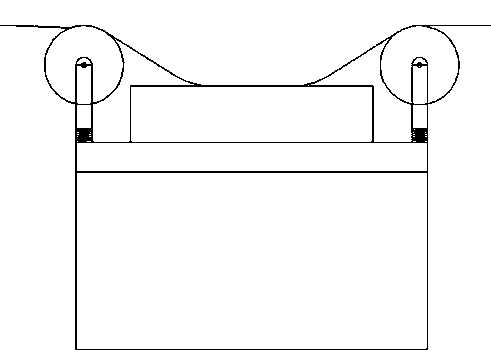

Crease-resist cloth rolling machine

The invention discloses a crease-resist cloth rolling machine. According to the invention, a cloth leveler, capable of generating a negative pressure on one side of the cloth, is arranged before the cloth is rolled on a cloth roll through cloth guide rollers, the cloth surface is tensioned through a plurality of auxiliary cloth guide rollers and the effect of the negative pressure, so that generation of drapes is prevented, and the drapes are eliminated.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

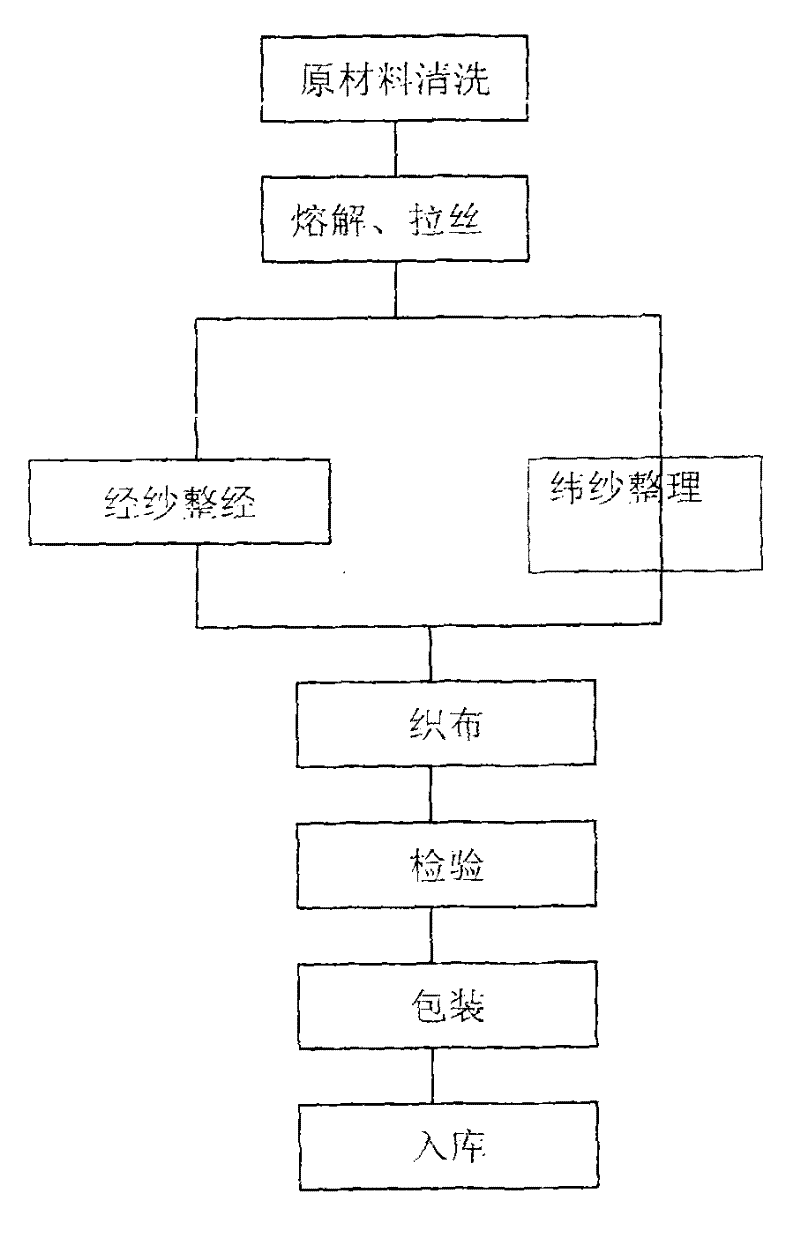

Glass fiber weaving process and special equipment thereof

InactiveCN101748546AAvoid wear and tearAvoid harmLoomsOther manufacturing equipments/toolsFiberGlass fiber

The invention discloses a glass fiber weaving process and special equipment thereof. The technological process is finished through procedures of cleaning, melting, wire drawing, warp yarn warping, weft yarn finishing, weaving, check and warehousing on raw materials. The special equipment is a warping tensioner and a weft yarn introduction device. When the process is adopted to manufacture a glass fabric, procedures of unwinding and twisting are removed from a finishing process of weft yarns, and a stranding procedure is removed from a finishing process of weft yarns so as to enable glass precursor fibers not to generate friction with equipment of unwinding, twisting and stranding, avoid abrasion and hurt to the glass precursor fibers, guarantee the tensile strength of the glass precursor fibers, enhance the product quality and the production efficiency and save the energy consumption and the product cost.

Owner:黄新春

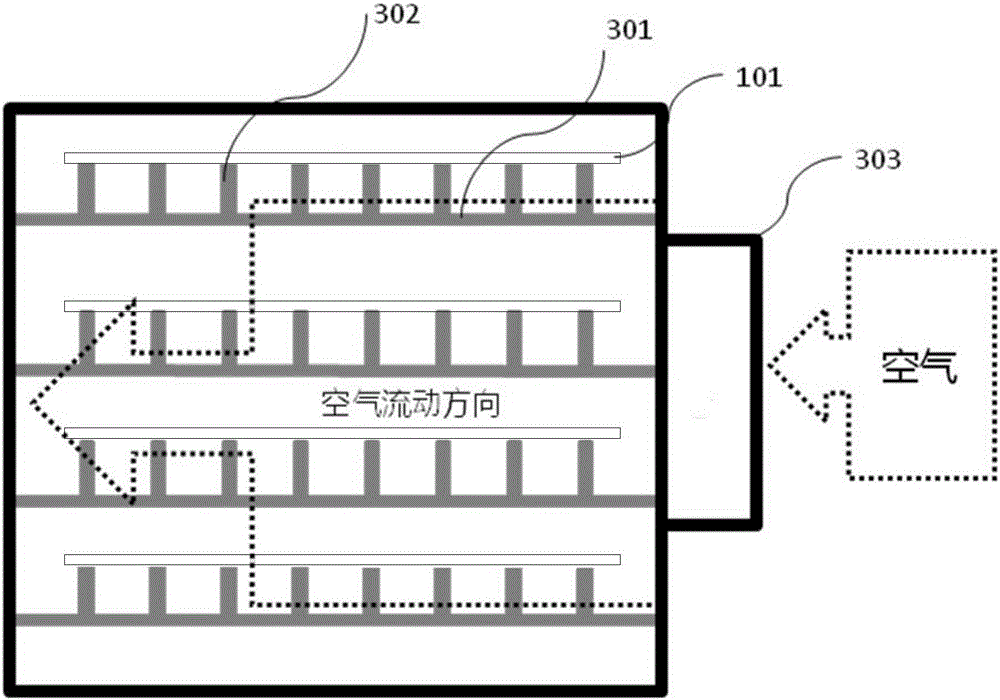

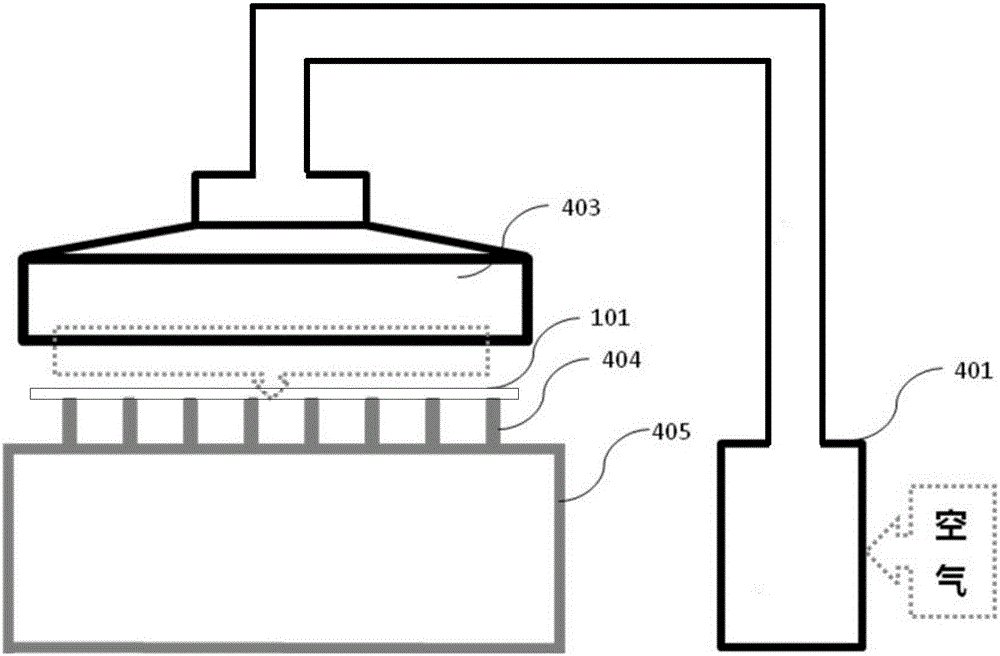

Display substrate cooling device

InactiveCN105810612AUniform thicknessQuality is not affectedSemiconductor/solid-state device manufacturingColor filmEngineering

The invention provides a display substrate cooling device. A display substrate is carried by a cooling disc, an air supply hole is formed in the cooling disc, an air supply device is used for delivering a cooling gas to the substrate base of the display substrate through the air supply hole from a part below the cooling disc, the cooling gas does not directly act on the surface of a color film of the display substrate while is blown to the back surface of the display substrate, so that the uniform thickness of the surface of the color film is ensured, and the product quality of the display substrate is improved; moreover, the quality of the surface of the color film of the cooled display substrate is not affected; and therefore, the display substrate cooling device provided by the invention also can be used for prebaking (curving after coating) and cooling of the color film substrate and is wider in application range.

Owner:BOE TECH GRP CO LTD +1

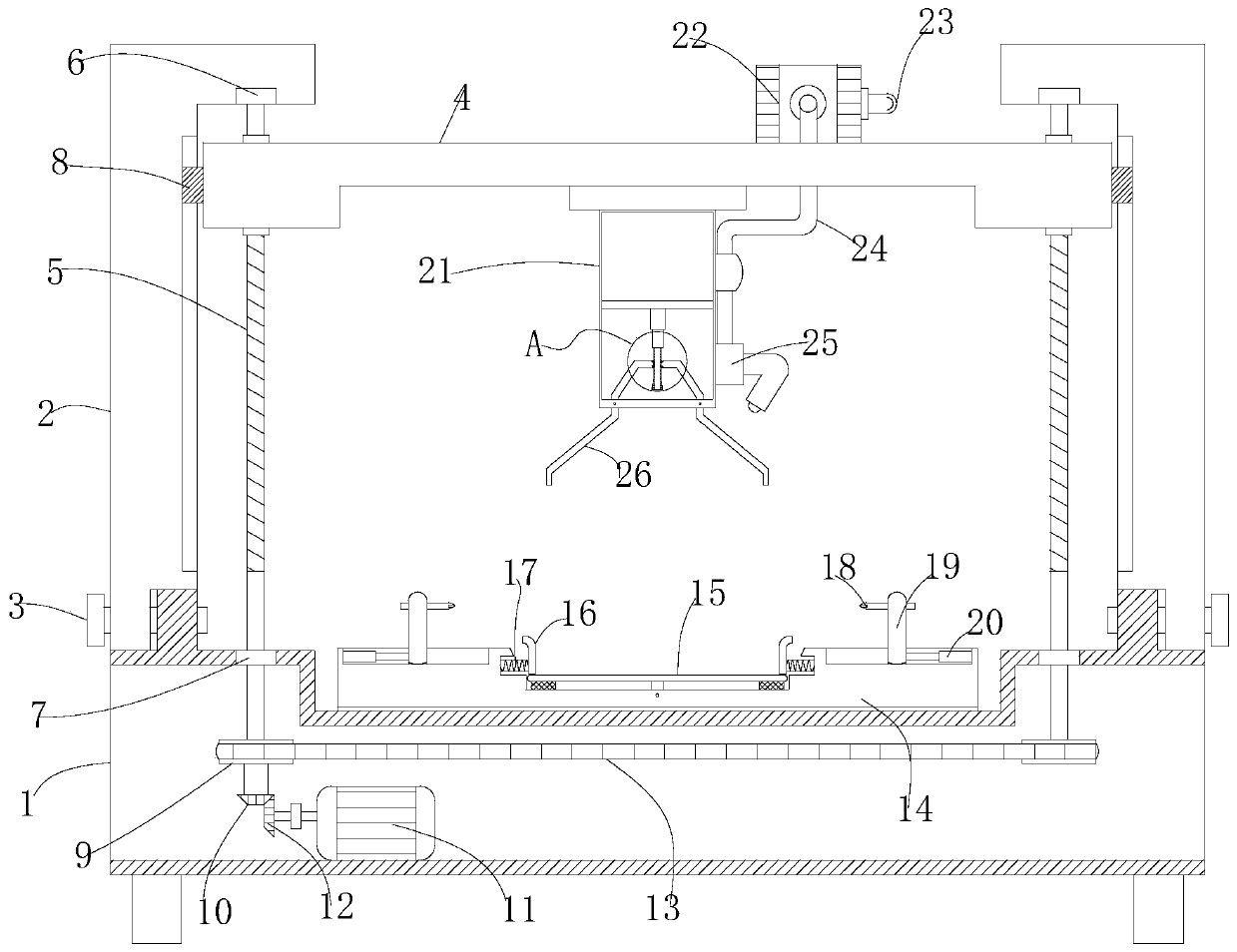

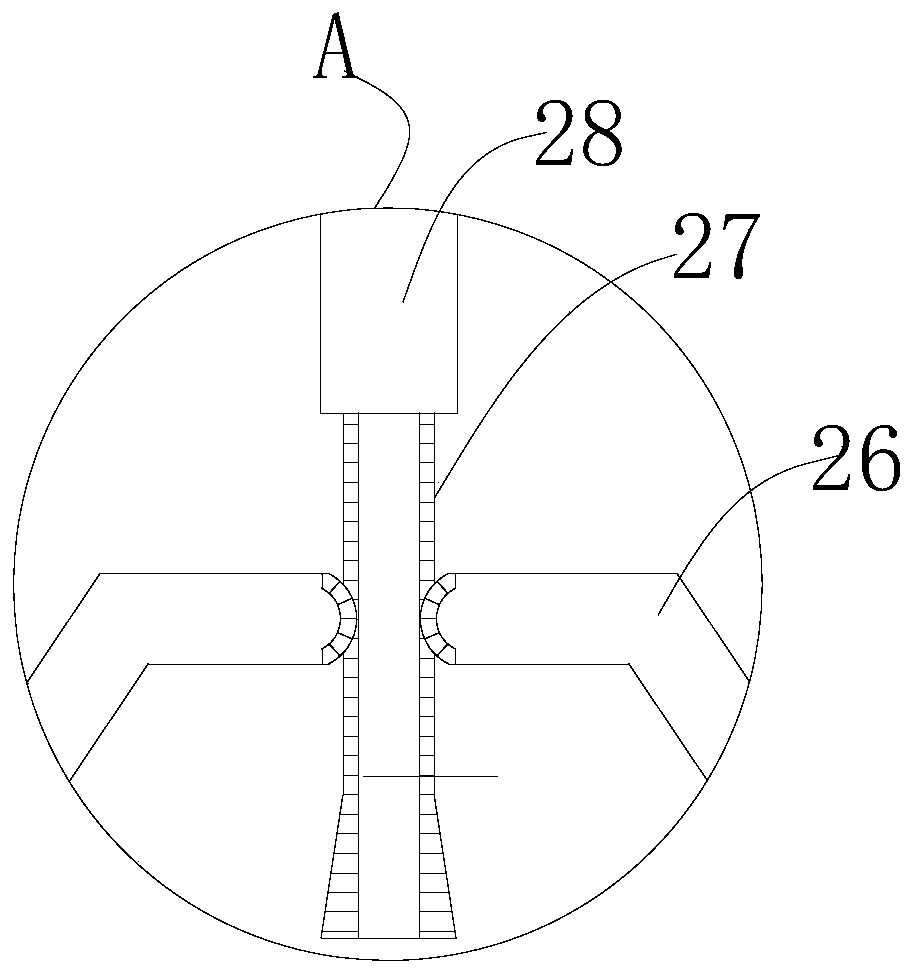

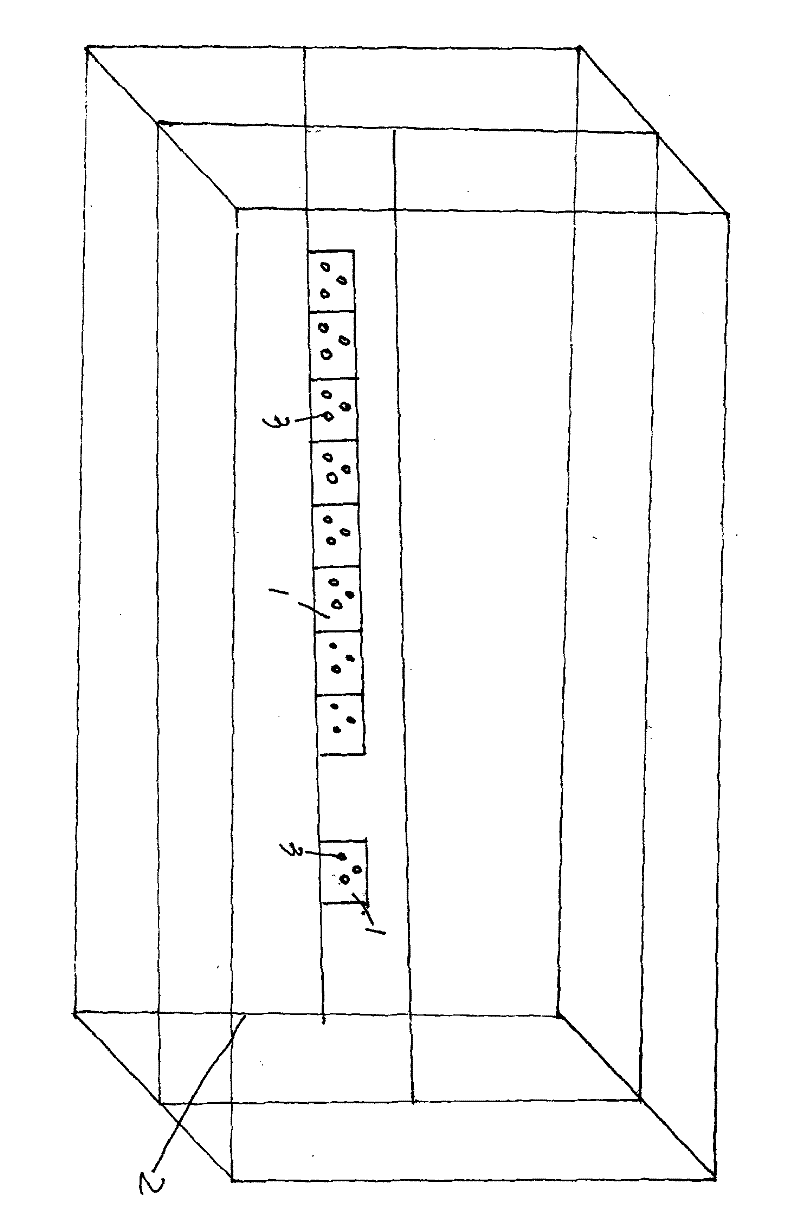

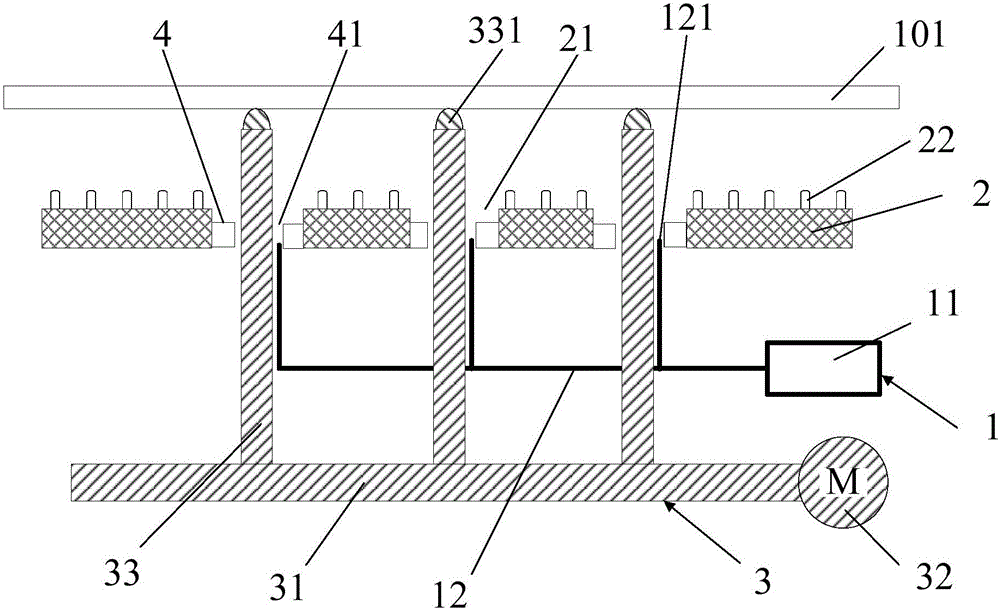

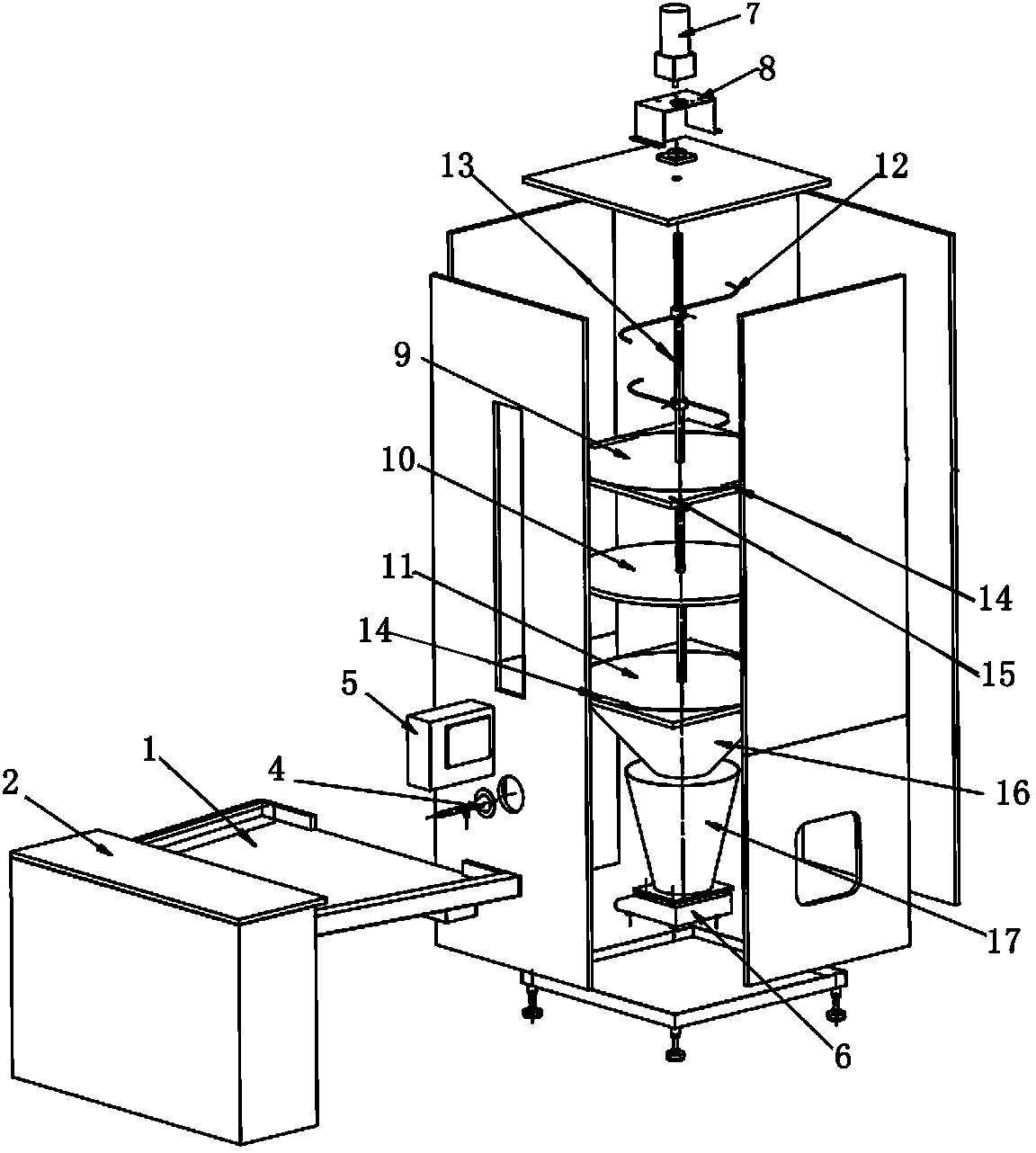

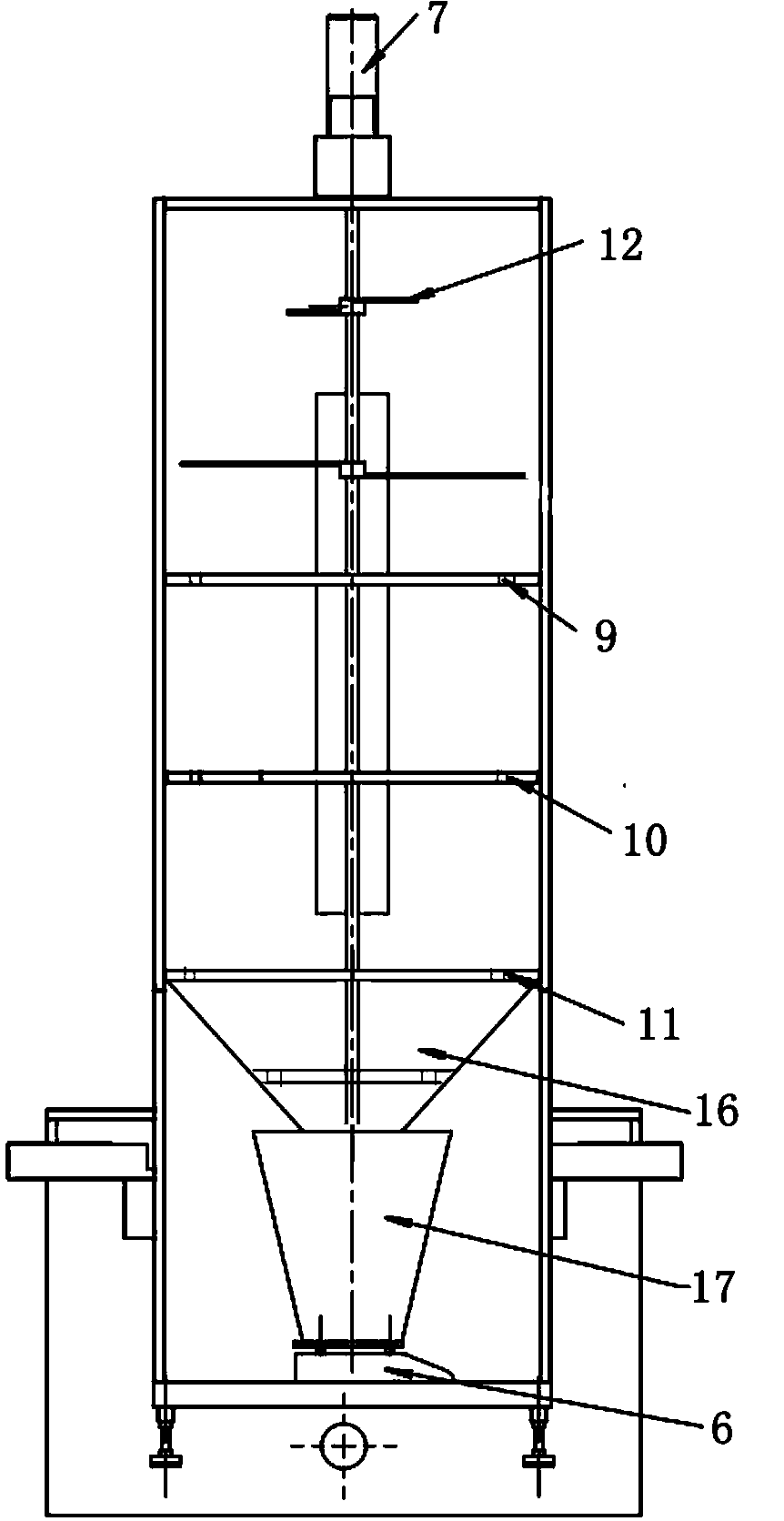

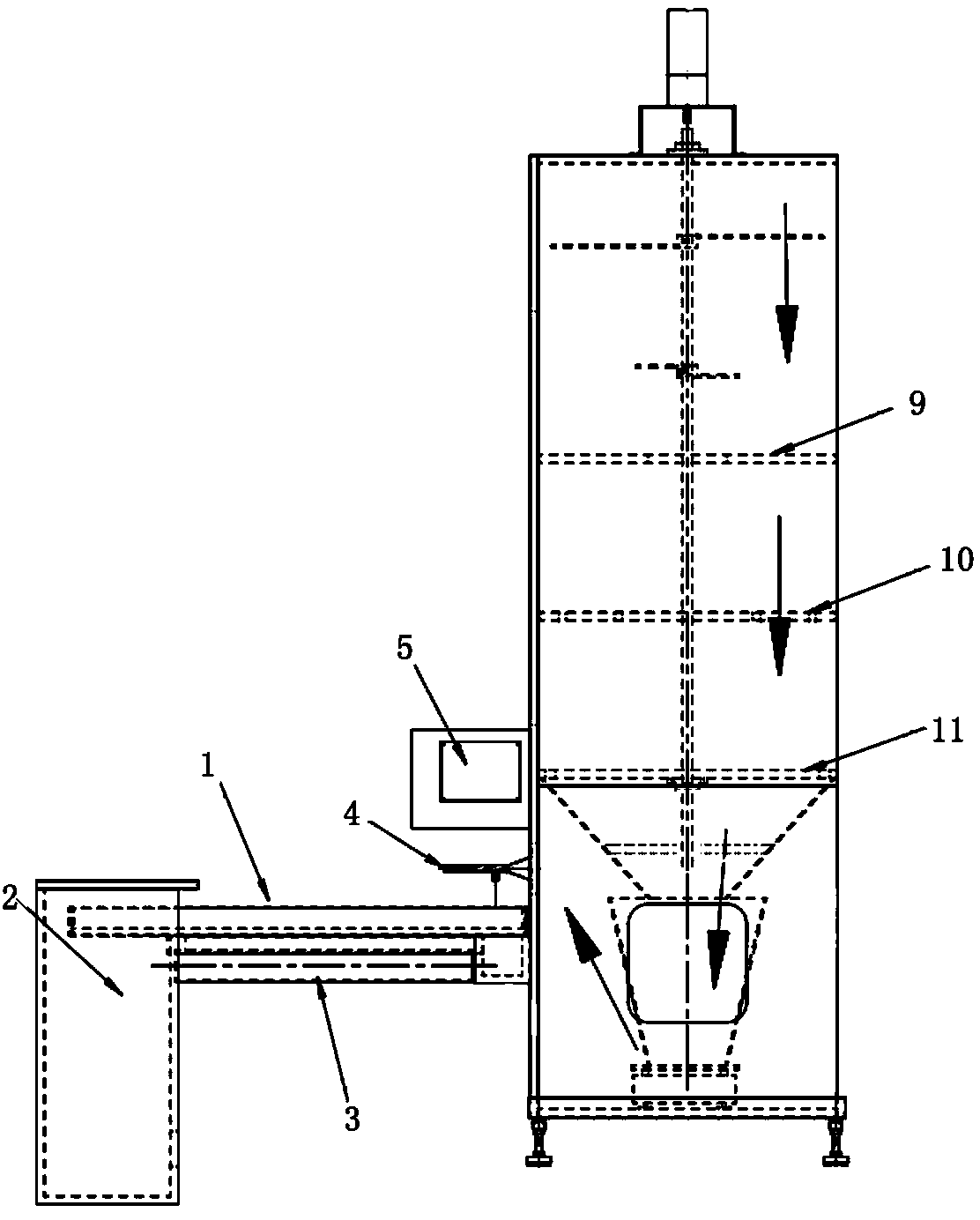

Quantitative down filling machine

InactiveCN104030228AReduce volumeWill not destroy formUpholstery manufactureEngineeringCentrifugal force

The invention discloses a quantitative down filling machine. The quantitative down filling machine comprises a cuboid-shaped main down storage box and a workbench connected to the side face of the main down storage box. An opening system, a centrifugal suspension system and a down storage system are respectively arranged inside the main down storage box from top to bottom. The centrifugal suspension system is composed of a circular top layer centrifugal board, a circular bottom layer centrifugal board and a circular middle layer centrifugal board which are parallel with the horizontal plane. The circular middle layer centrifugal board is located between the circular top layer centrifugal board and the circular bottom layer centrifugal board. An opening main shaft extends vertically and downwards from the center of the top of the main down storage box and is fixed to the center of the top layer centrifugal board, the center of the middle layer centrifugal board and the center of the bottom layer centrifugal board in a penetrating mode. The brand new vertical type structure and the centrifugal suspension technology are adopted, only a small space is occupied, and down is separated through centrifugal force generated by high-speed rotation; no down stirring device exists in the down filling machine, and the down is not damaged, so that the original form of the down is not destroyed; meanwhile, no static electricity will be generated, and down discharge is more stable.

Owner:曾蕙玲

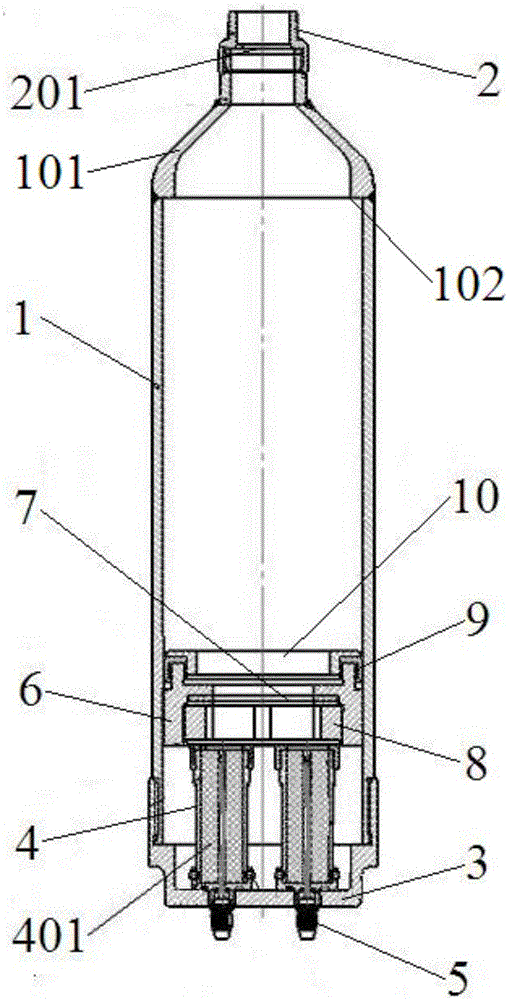

Stepped aerogenesis dry powder extinguishing device

The invention provides a stepped aerogenesis dry powder extinguishing device. The stepped aerogenesis dry powder extinguishing device comprises a tank body, a piston assembly and a stepped aerogenesis device; dry powder extinguishing agents are stored in the tank body; the tank body is provided with a first end and a second end; the first end of the tank body is provided with a pipeline connector for being connected with a flow collection pipeline, the pipeline connector is internally provided with a damp-proof diaphragm, and the second end of the tank body is provided with a lower end cover; the piston assembly is slidably arranged on the inner side of the tank body, and the middle of the piston assembly is provided with a pressure diaphragm; and the stepped aerogenesis device is arranged in a space which is formed between the lower end cover and the piston assembly. According to the stepped aerogenesis dry powder extinguishing device, the initial pressure of the extinguishing device is not too high during extinguishing, moreover, the pressure lasing time is long, and the extinguishing device is very suitable for an automatic extinguishing system with a long flow collection pipeline.

Owner:XIAN XINZHU FIRE & RESCUE EQUIP

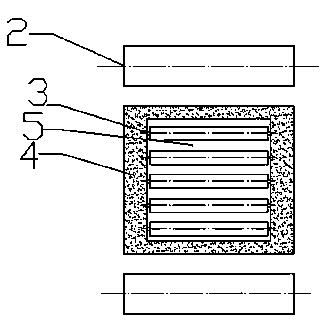

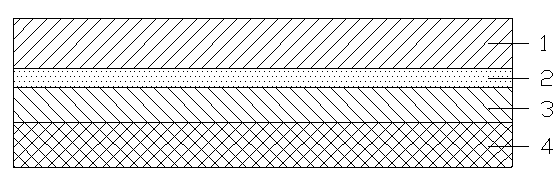

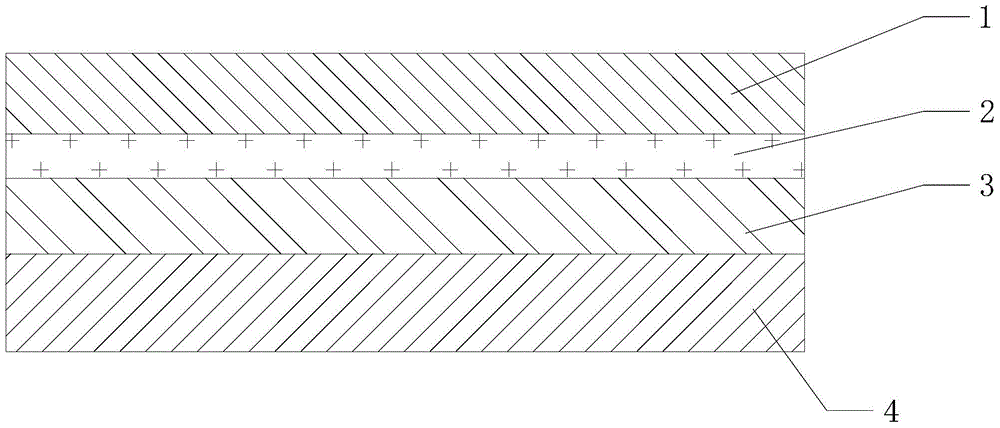

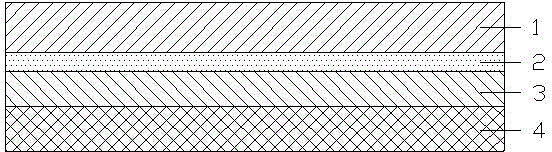

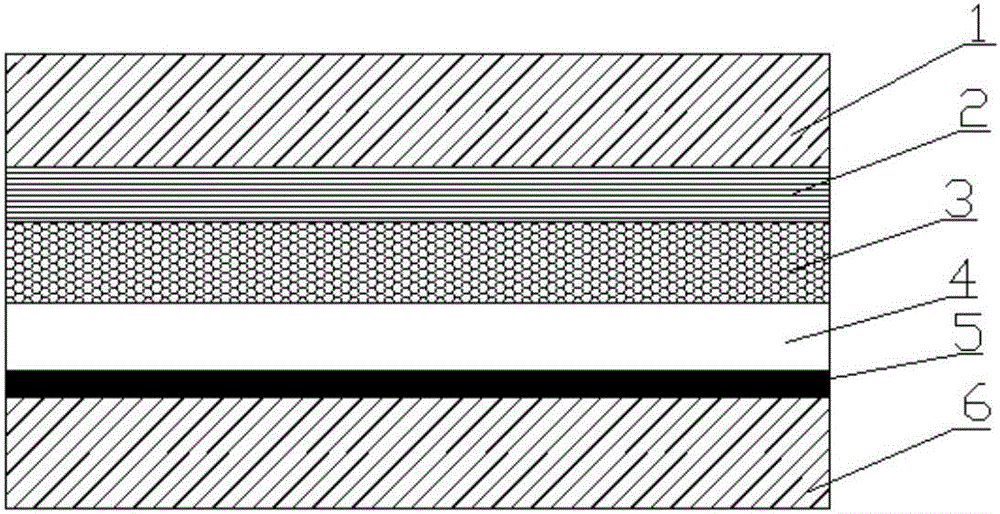

Antibacterial and anti-mite fabric

InactiveCN104228164AEliminate static electricityEasy to useSynthetic resin layered productsChemistryAcarus

The invention relates to an antibacterial and anti-mite fabric. The antibacterial and anti-mite fabric sequentially comprises a surface layer (1), a moisture-permeable bonding layer (2), an anti-mite film layer (3) and a base layer (4) from outside to inside. The antibacterial and anti-mite fabric disclosed by the invention has an anti-mite function, and good antibacterial property.

Owner:HEILAN HOME

Organosilicon paint for covering glass scratches and preparation method thereof

The invention relates to an organosilicon paint for covering glass scratches and a preparation method thereof. The paint comprises 2 to 6 parts of polymethyl siloxane compound, 0.5 to 2 parts of carnauba wax, 0.5 to 2 parts of bee wax, 1 to 3 parts of solid paraffin, 6 to 8 parts of petroleum spirit, 2 to 4 parts of anhydrous sorbitan monostearate and 1 to 5 parts of POE sorbitan monostearate (POE 20 mol), and the rest is water. Since the paint prepared with the mixed components consists of organic matters and does not contain heavy metals, pollution is effectively reduced, and thereby the environment is protected. The film of the paint has rich texture, cannot easily generate static electricity by friction, and has excellent water resistance, elasticity, flexibility, chemical resistance and wear resistance; and moreover, the paint has the advantages of high adhesive force, high covering rate, large unit coating area and low use cost.

Owner:高庆亮

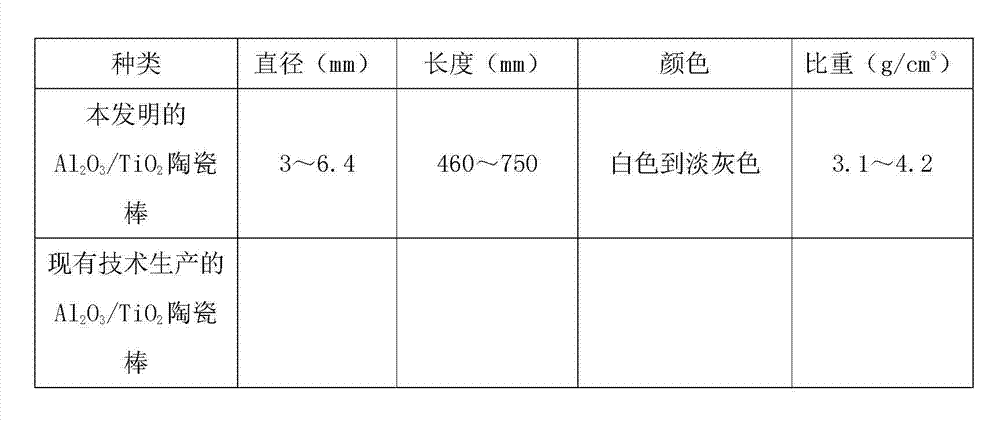

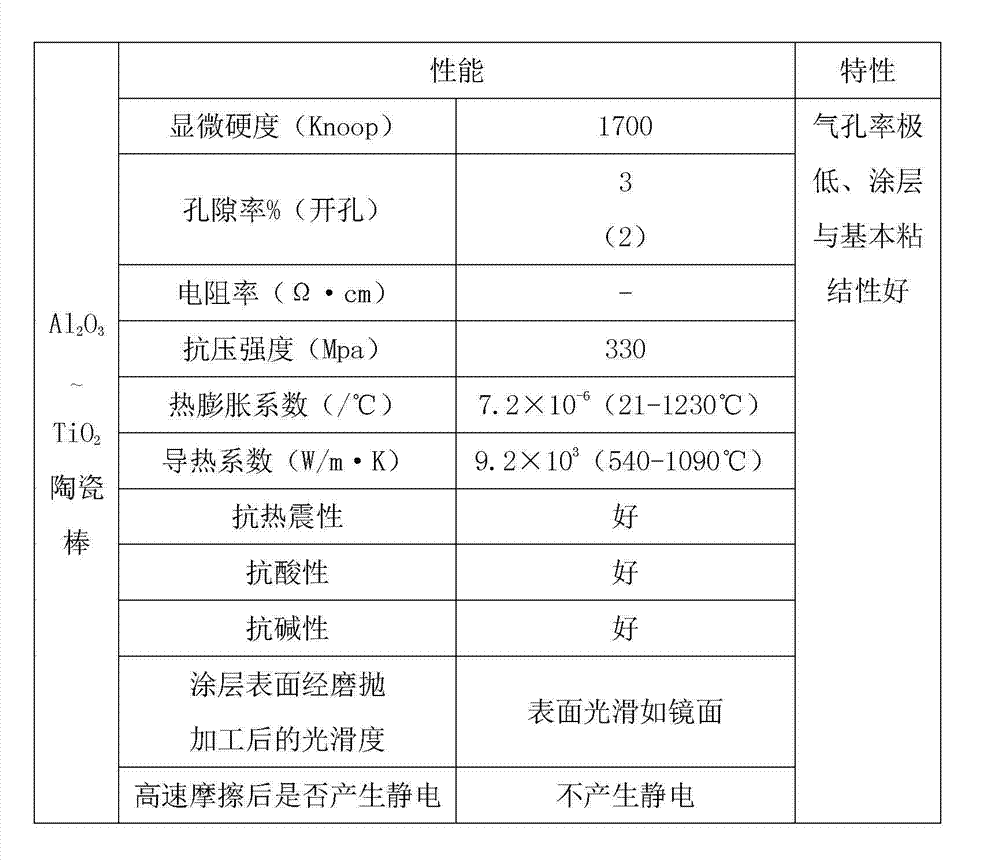

Preparation method of Al2O3/TiO3 ceramic stick for flame spraying

The invention discloses a preparation method of an Al2O3 / TiO3 ceramic stick for flame spraying. The preparation method comprises the following steps of: weighing ceramic raw materials, and batching; processing via ball milling; then blending in a dry way, so as to obtain mixed powder; adding modification styrene-acrylic emulsion and the like in the powder; mixing the materials; preparing and pugging; transferring the plastic clay block into a vacuum extruder to be extruded and formed; heating to degum through a horizontal burning way; and finally roasting at a certain temperature, thus obtaining the Al2O3 / TiO3 ceramic stick. The preparation method disclosed by the invention is simple in technology, high in product percent of pass, and greatly reduces producing coat. The prepared ceramic stick has a better coating performance; and the coated ceramic coating has a better mechanical property, and synchronously has a better heat insulation property, an insulating property, a corrosion resistance property, an antistatic property and high smoothness of a spray coating layer, and no static generated in friction at high speed, and the like, and has a good application prospect in cotton spinning and chemical fiber industries.

Owner:HEFEI RUIYONG CERAMIC MATERIAL TECH

Modified chlorinated rubber resin coating of bicyclopentenyl ester methacrylate and preparation method thereof

The invention relates to a modified chlorinated rubber resin coating of bicyclopentenyl ester methacrylate and a preparation method thereof. The coating comprises the following components by weight part: 13.1 parts of rutile-type TiO2, 13.1 parts of chlorinated rubber resin (solidification by 100%), 4.4 parts of chlorinated paraffin plasticizer, 17.5 parts of dimethylbenzene, 8.7 parts of DCPMA, 0.26 part of cobalt naphthenate (6% of Co) and 42.0 parts of dimethylbenzene. The coating can not be hardened or precipitated when being placed in a container for a plurality of months. When The coating is coated on a substrate exposed in the air by using a general method, the coating film also can be automatically oxidized and solidified fast without need of isolating the air. The coating is constructed by adopting a spraying method and an immersion method and is self-dried. The application range includes steel materials and parts and the like.

Owner:王虹

Real silk elastic shell fabric

InactiveCN102529182AImprove breathabilitySweat-absorbing and quick-dryingSynthetic resin layered productsPolymer scienceMoisture absorption

The invention discloses real silk elastic shell fabric, which comprises an outer layer, a middle layer and an inner layer and is characterized in that the middle layer is a film layer, and the outer layer and the inner layer are fabric. Air vents are arranged on the film layer with thickness ranging from 0.08mm to 0.15mm. The outer layer is cotton fabric, and the inner layer is silk fabric. By means of the flexibility of real silk, the fabric feels excellent and is suitable for wearing. The real silk elastic shell fabric has good elasticity, moisture absorption and breathable performance, and has a skin and health care function.

Owner:常熟市佳懿针纺织品有限公司

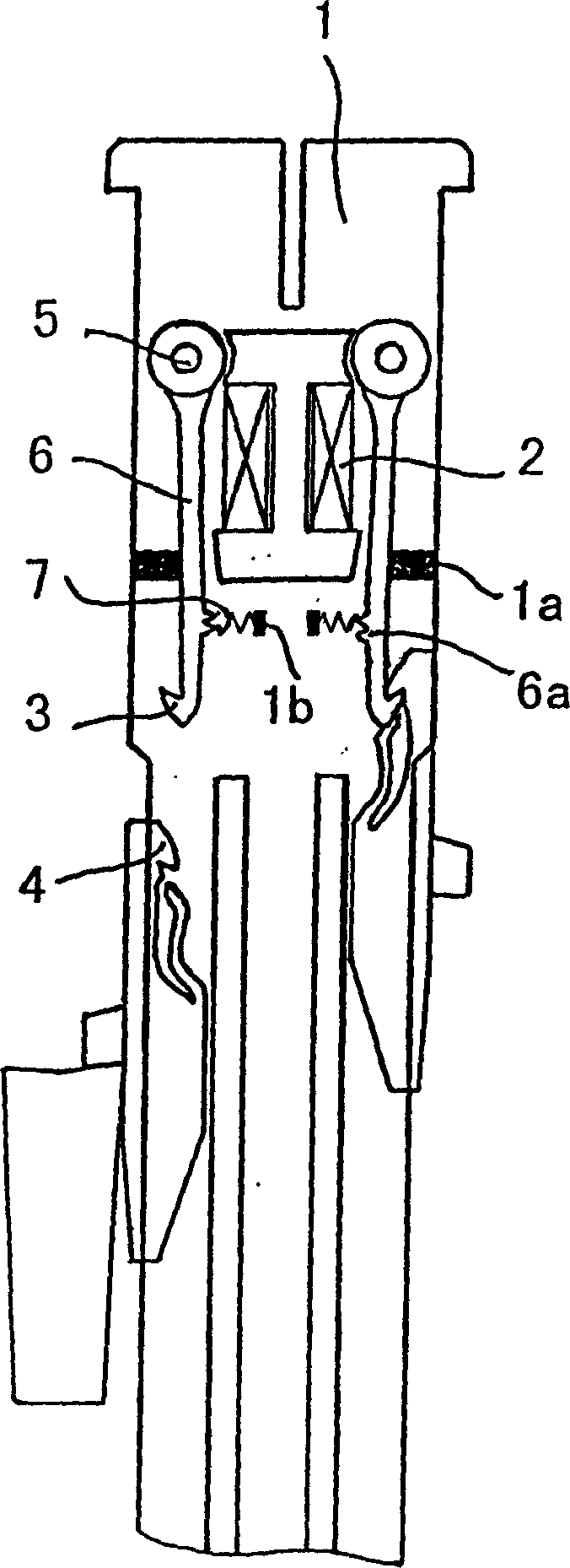

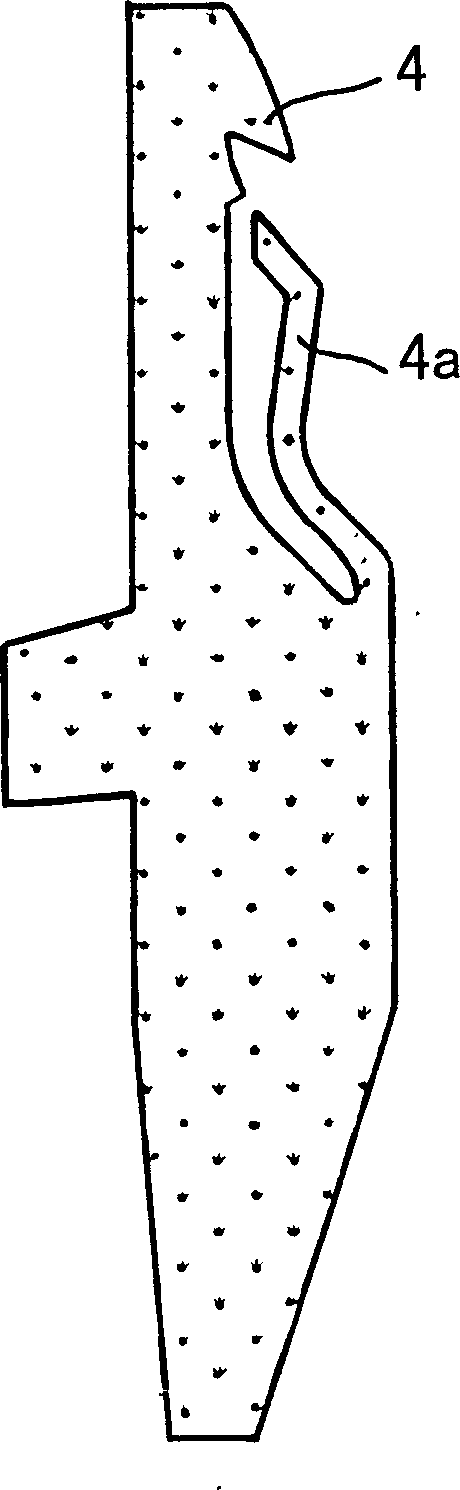

Electronic jacquard yarn selecting unit

A composite electronic jacquard interceptor includes pin axle, swing arm, spring, guiding block, electromagnet, saw shape slot with convex, hanging hook, and casing. Comparing with current technology, said invention has advantages of 1, simple structure with small arm swing range and high work frequency, 2, no electrostatic interference due to adopting plastic hook, 3, small magnetic gap, 4, energy saving due to the more windings turns and low voltage.

Owner:ZHEJIANG UNIV

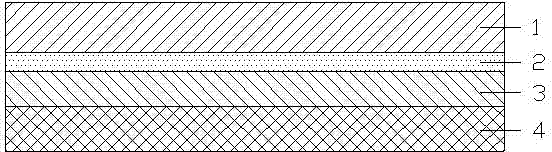

Anti-mite adhesive lining base cloth

InactiveCN104875454AReasonable structureImprove biological activitySynthetic resin layered productsClothingsSurface layerBiochemical engineering

The invention relates to lining base cloth in the field of spinning, and discloses an anti-mite adhesive lining base cloth. The anti-mite adhesive lining base cloth comprises a base cloth body, wherein the base cloth body sequentially comprises a surface layer, a breathable bonding layer, an anti-mite film layer and a base layer from outside to inside; the surface layer is a PU film mixed with an antibacterial agent; a micro-pore is formed in the anti-mite film layer; and the aperture of the micro-pore is between the diameter of a hydrone and the diameter of an air molecule. The anti-mite adhesive lining base cloth provided by the invention is reasonable in structure; the antibacterial agent of the surface layer is a silver ion mixed liquid antibacterial agent, and contains metal silver; a silver ion has high biological activity, so that protein inside and outside a bacterial cellular membrane is solidified, so as to prevent bacteria breeding and effectively resist the bacteria; meanwhile, due to high electrical conductivity of the silver, static electricity generated by friction is rapidly removed; and the fabric has waterproof and breathable characteristics and also has an antibacterial function due to the PU film mixed with the antibacterial agent on the surface layer and repellent elastic fabric on the base layer, so that the anti-mite adhesive lining base cloth is convenient and safe to use.

Owner:CHANGXING SHENGFAN TEXTILE

Silver fiber and bamboo charcoal fiber composite antibacterial and anti-mite fabric

The invention relates to a silver fiber and bamboo charcoal fiber composite antibacterial and anti-mite fabric. The fabric comprises a surface layer (1), a moisture permeable bonding layer (2), an anti-mite film layer (3) and a base layer (4) from outside to inside in sequence, wherein the base layer is at least formed through reclining and jointing of a layer of silver fiber fabric and a layer of bamboo charcoal fiber fabric, namely alternate combination of two layers, three layers or a plurality of layers of fabrics. The fabric not only has an anti-mite function but also has a good antibacterial property. The fabric can provide products with better properties and different grades of products and meet the actual use requirements.

Owner:JIANGYIN SHANGFENG TEXTILE

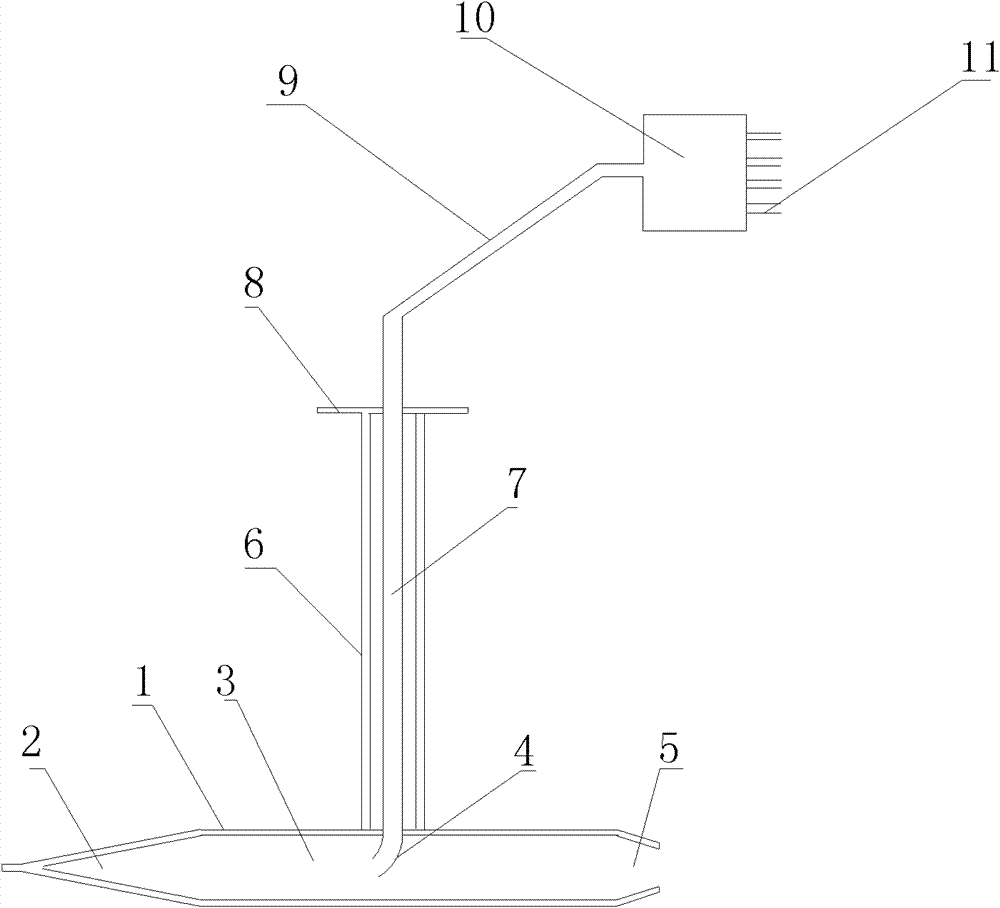

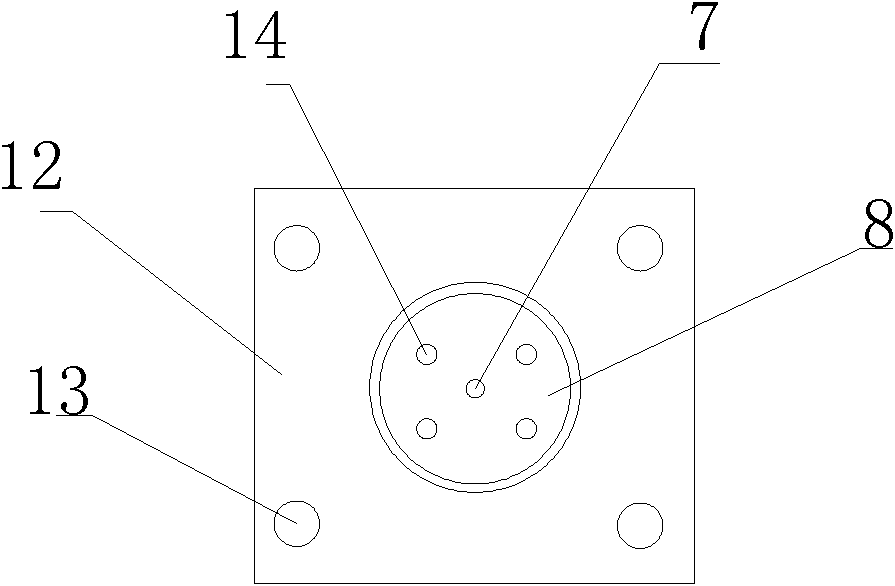

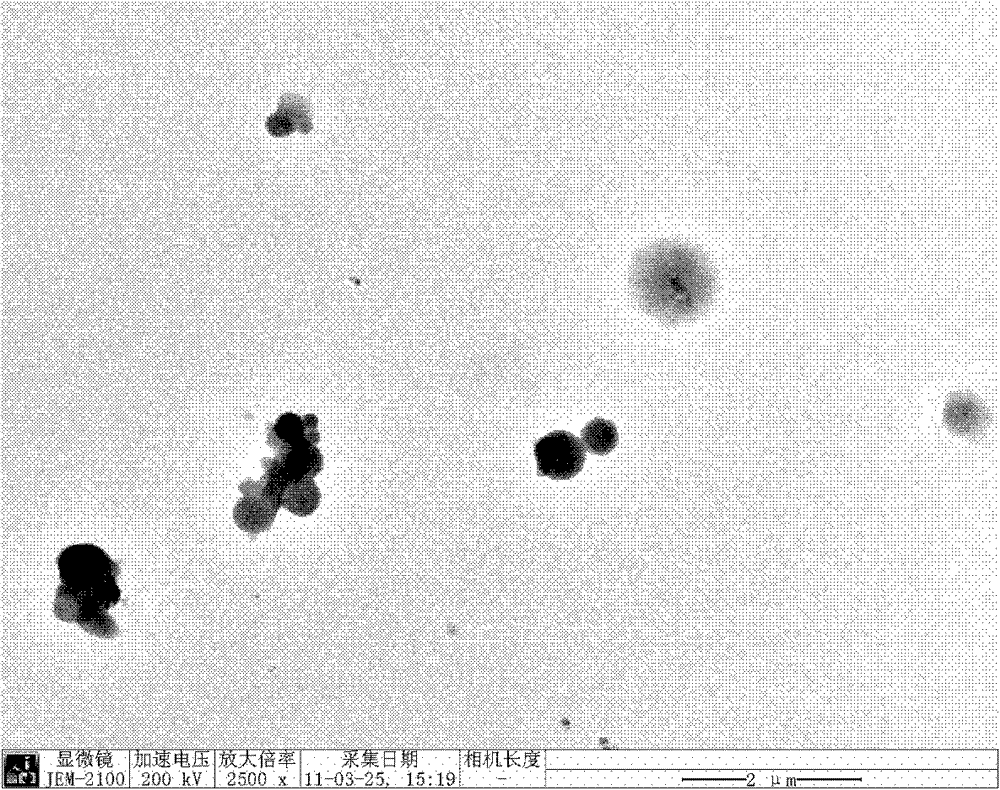

Externally hanging type atmospheric aerosol aviation airflow guide cover of airplane

InactiveCN102252875BEasy to collectAvoid stickingWithdrawing sample devicesJet aeroplaneParticulates

The invention relates to an atmospheric aerosol aviation airflow guide cover and belongs to the technical fields of atmospheric environment sampling and analysis. The atmospheric aerosol aviation airflow guide cover comprises a buffer and a sampling pipe, wherein a sampling port is formed at one end of the sampling pipe; the sampling pipe runs through the bottom of an airplane and extends into the buffer; the other end of the sampling pipe is connected with a quick interface; the buffer comprises an air inlet, a buffering cavity and an air outlet which are connected with one another sequentially and hermetically; the buffering cavity is cylindrical; the air inlet has a frustum conical shape; and the diameter of the right port round of the frustum conical shape is 10 to 12 times that of the left port round. A sampler is adopted, high-speed airflow is buffered and reduced into low-speed airflow, and the low-speed airflow enters the sampling pipe through the sampling port, so that the high-speed airflow is prevented from directly entering the sampling pipe, aerosol granules are prevented from being adhered to the wall of a buffering tank, the collection rate of the atmospheric aerosol granules entering the sampling port is increased, and loss of the granules is reduced.

Owner:SHANDONG UNIV

Medical antibacterial anti-mite fabric

InactiveCN105479900AEasy to useWith antibacterial functionWeft knittingSynthetic resin layered productsMoisture permeationEngineering

The present invention relates to a medical antibacterial anti-mite fabric, which sequentially comprises a surface layer (1), a moisture permeation binding layer (2), an anti-mite film layer (3) and a base layer (4) from outside to inside, wherein the base layer sequentially comprises a separation layer formed from a thermoplastic polyurethane film, a protection layer formed from a polypropylene fiber fabric, a protection layer formed from a polytetrafluoroethylene film, and a bottom layer formed from a weft knitted fabric and a warp knitted fabric of natural fibers, synthetic fibers and recycled fibers from top to bottom. The medical antibacterial anti-mite fabric of the present invention has functions of mite resistance, antibacterial property, blood permeation resistance, water resistance, moisture permeation, and the like.

Owner:吴银芝

Compression-resistance anti-bacteria pharmaceutical packaging composite film

InactiveCN106626590AGood shock absorption and compression resistanceAvoid damageFlexible coversWrappersComposite filmEngineering

The invention discloses a compression-resistance anti-bacteria pharmaceutical packaging composite film, and belongs to the technical field of pharmaceutical packaging. The composite film sequentially comprises a first polyethylene layer, a glass paper layer, a bubble layer, an aluminum foil layer, an aluminum-coated polyethylene film layer and a second polyethylene film from outside to inside, wherein the first polyethylene layer is in adhering connection with the glass paper layer through an adhesion agent, the glass paper layer is in adhering connection with the bubble layer through the adhesion agent, the bubble layer is in adhering connection with the aluminum foil layer through the adhesion agent, the aluminum foil layer is in adhering connection with the aluminum-coated polyethylene film layer through the adhesion agent, and the aluminum-coated polyethylene film layer is in adhering connection with the second polyethylene layer through the adhesion agent; bubbles in the bubble layer are all filled with nanoscale foam particles; an antibacterial agent is added into the first polyethylene layer and the second polyethylene layer, and the antibacterial agent accounts for 1% to 3% of the total content of the first polyethylene layer and the second polyethylene layer. The composite film has the advantages of being good in compression resistance and good in antibacterial effect, and the like.

Owner:滁州瑞林包装材料有限公司

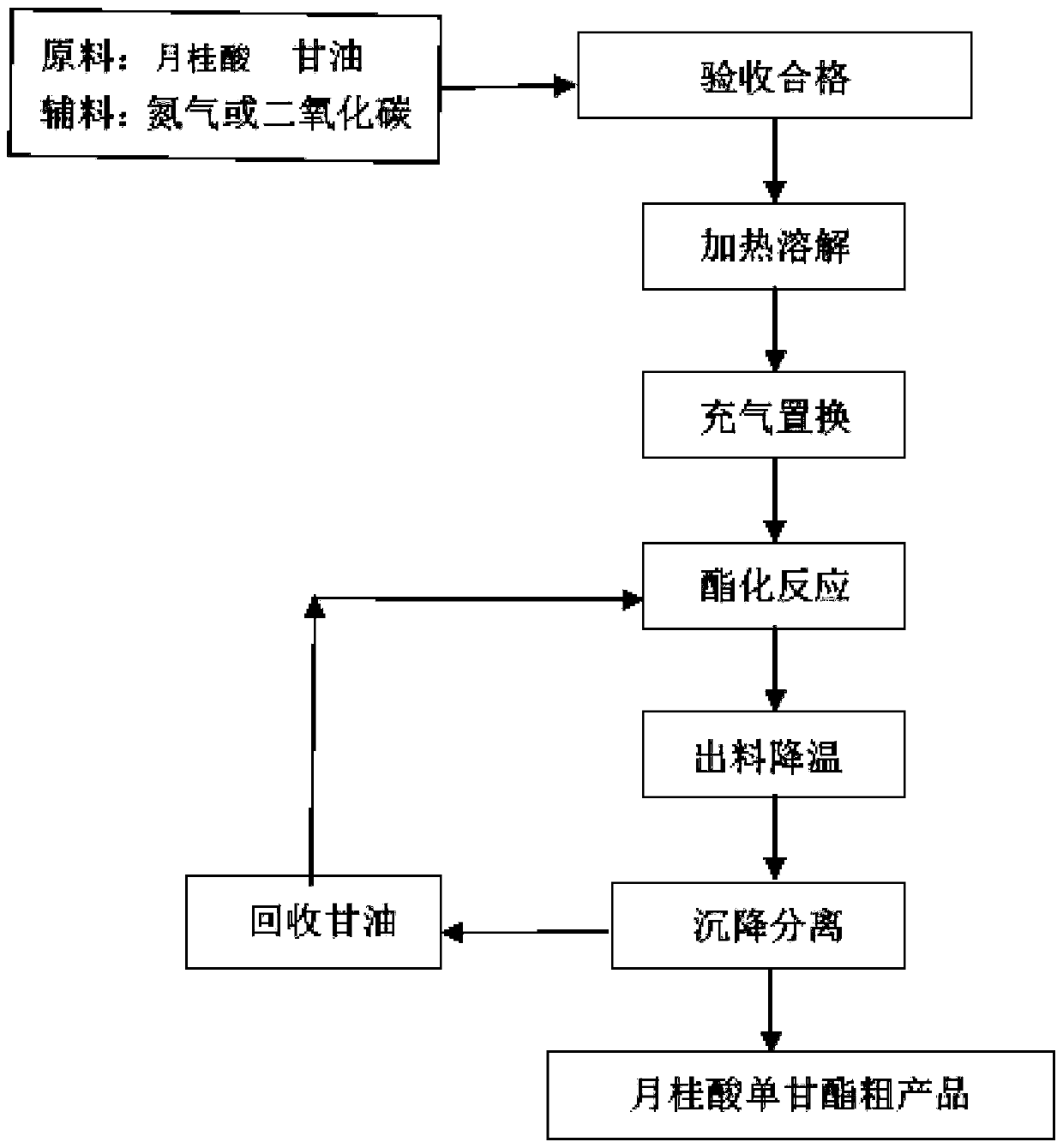

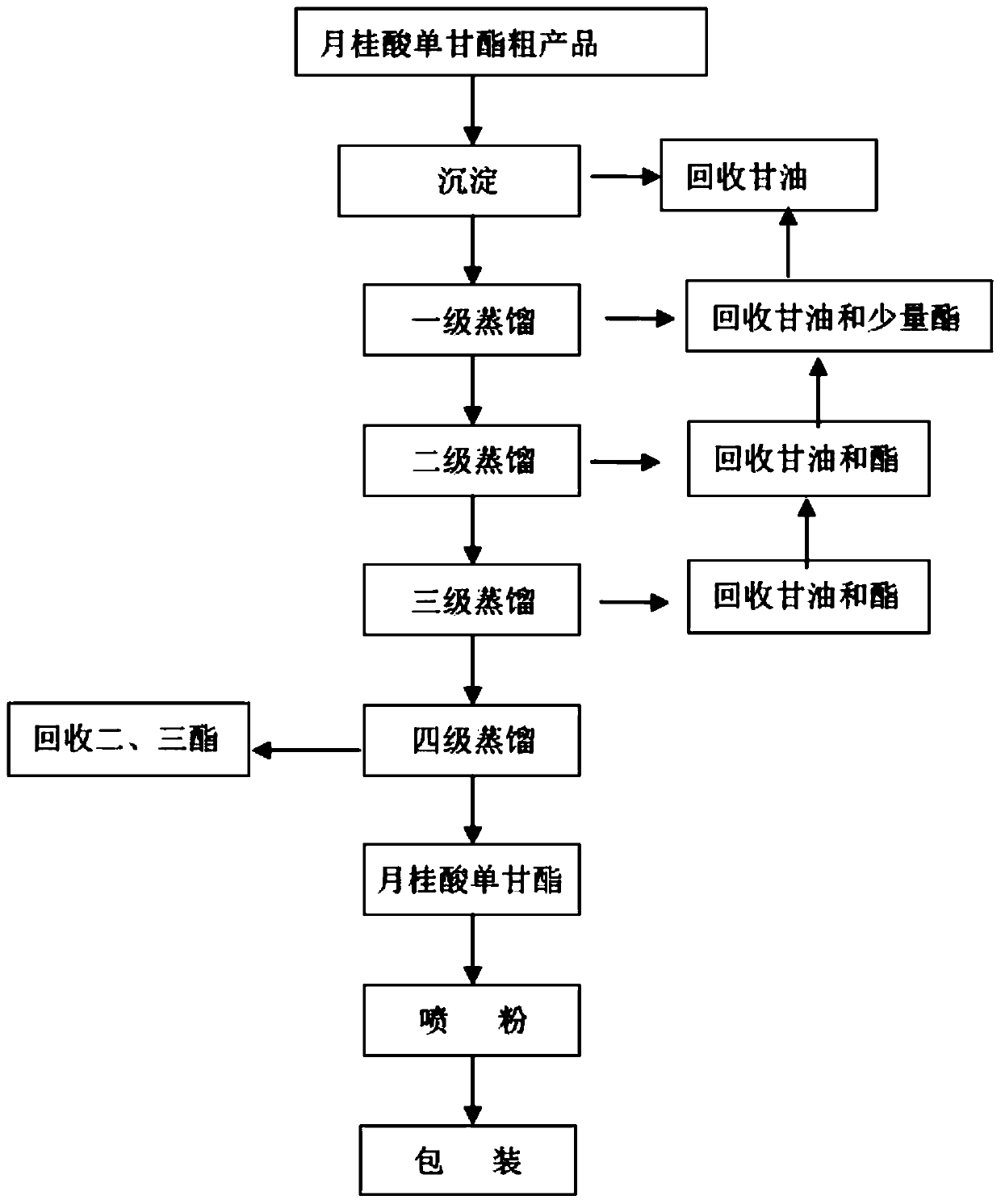

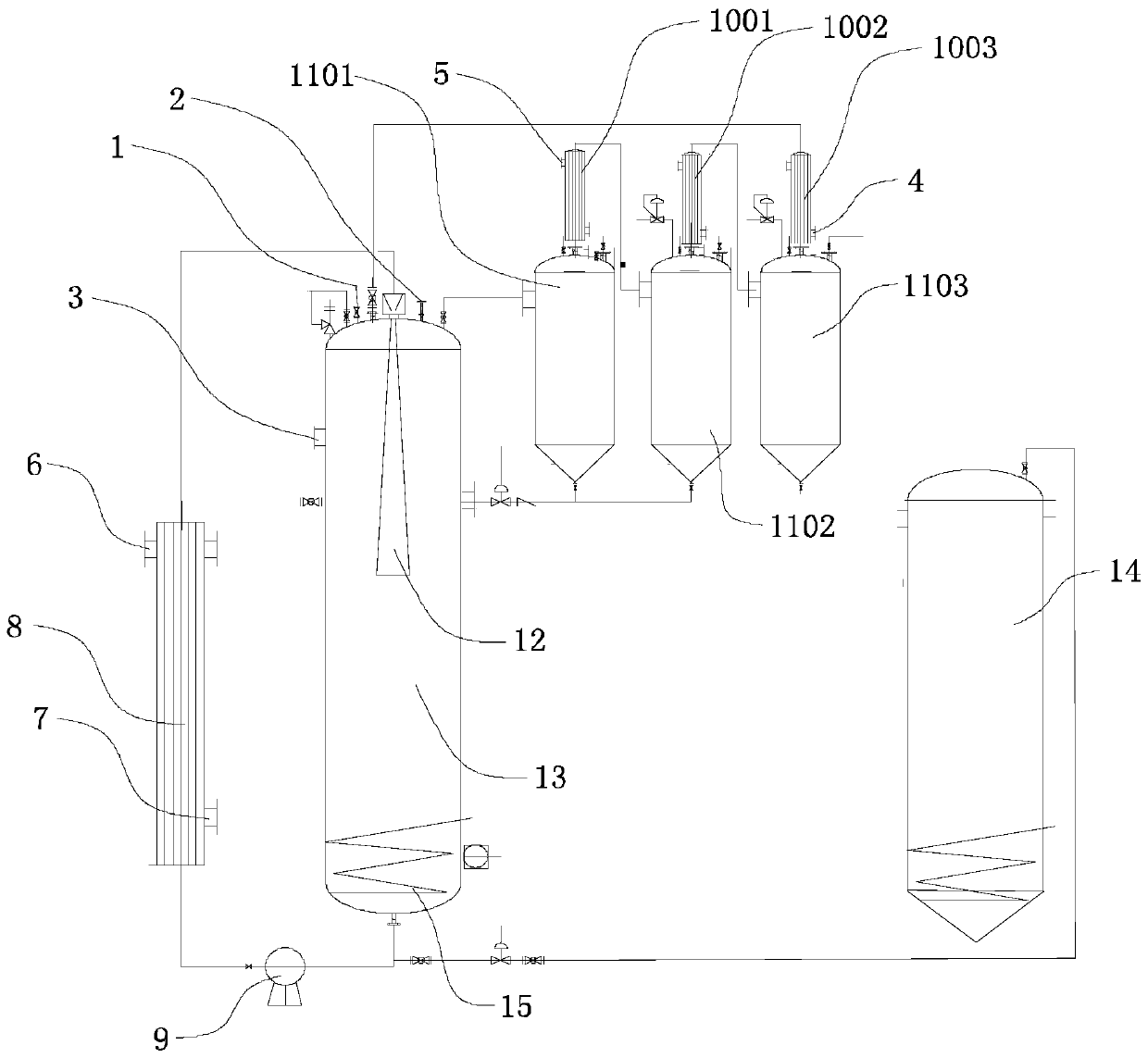

Preparation device of glycerol monolaurate and method thereof, and control system and method thereof

PendingCN111484408ASolve environmental pollutionReduce manufacturing costOrganic compound preparationCarboxylic acid esters separation/purificationPtru catalystPhosphate

The invention discloses a preparation device of glycerol monolaurate and a method thereof, and a control system and a method thereof. According to the preparation device of the glycerol monolaurate, acomputer adopts 14-point temperature acquisition, 8-point pressure acquisition and 1-point PH acquisition, and meanwhile, the opening degree of 14 valves is controlled. The preparation device of glycerol monolaurate is high in automation level and comprehensive and accurate in acquired data, multi-dimensional analysis and control of temperature, pressure and PH are performed, and product qualityand production efficiency are improved. The preparation method comprises the following step: under a nitrogen or carbon dioxide condition, reacting glycerol and lauric acid through an esterification reaction at high temperature for preparing glycerol monolaurate, no catalyst is used, no phosphate is generated, no pollution is caused to the environment, reaction equipment is totally closed and environmentally friendly, and the generated recovered glycerol is recycled to serve as a reactant of the next reaction, so that the production cost can be reduced.

Owner:广东凯闻生物科技有限公司

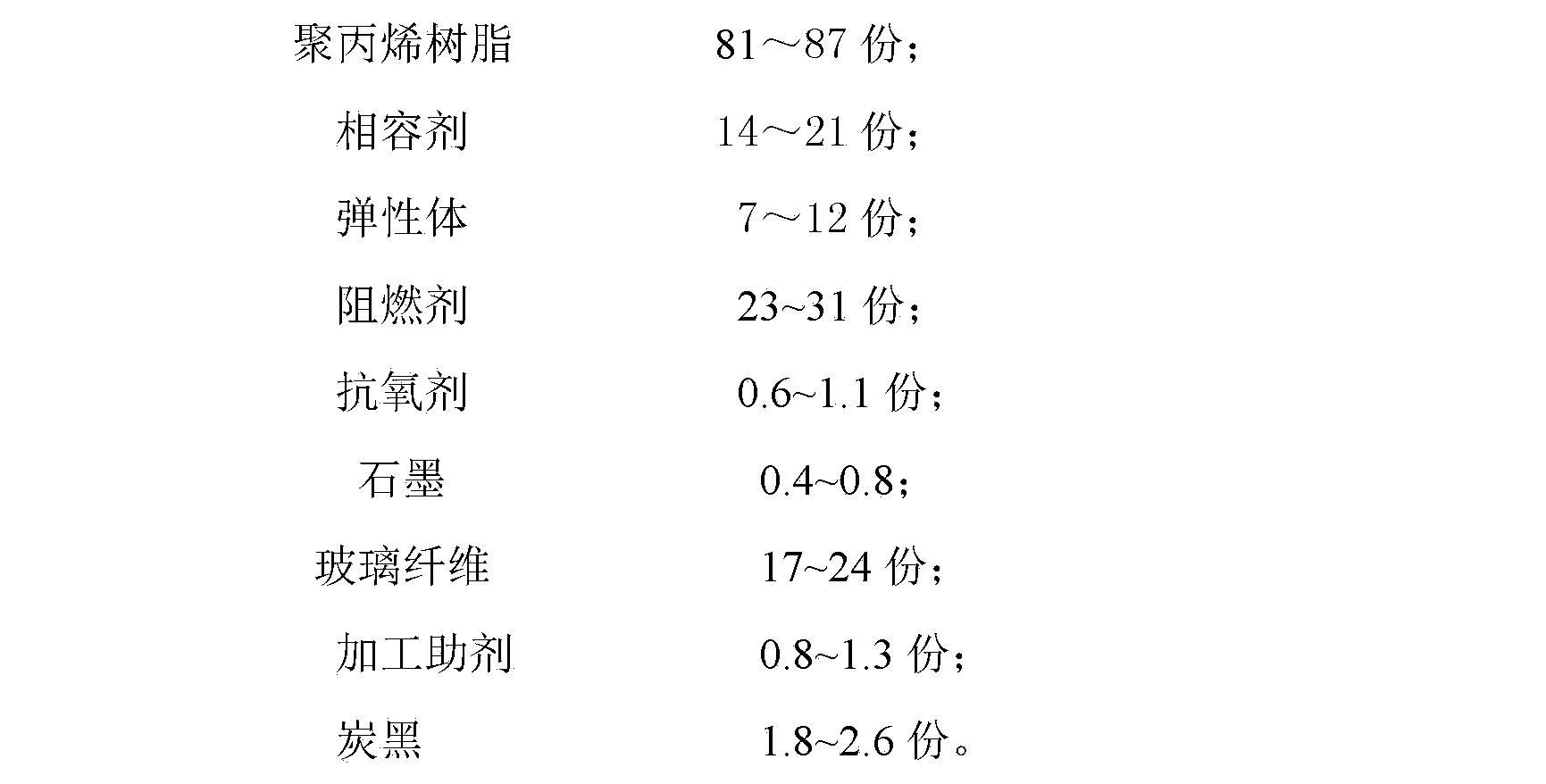

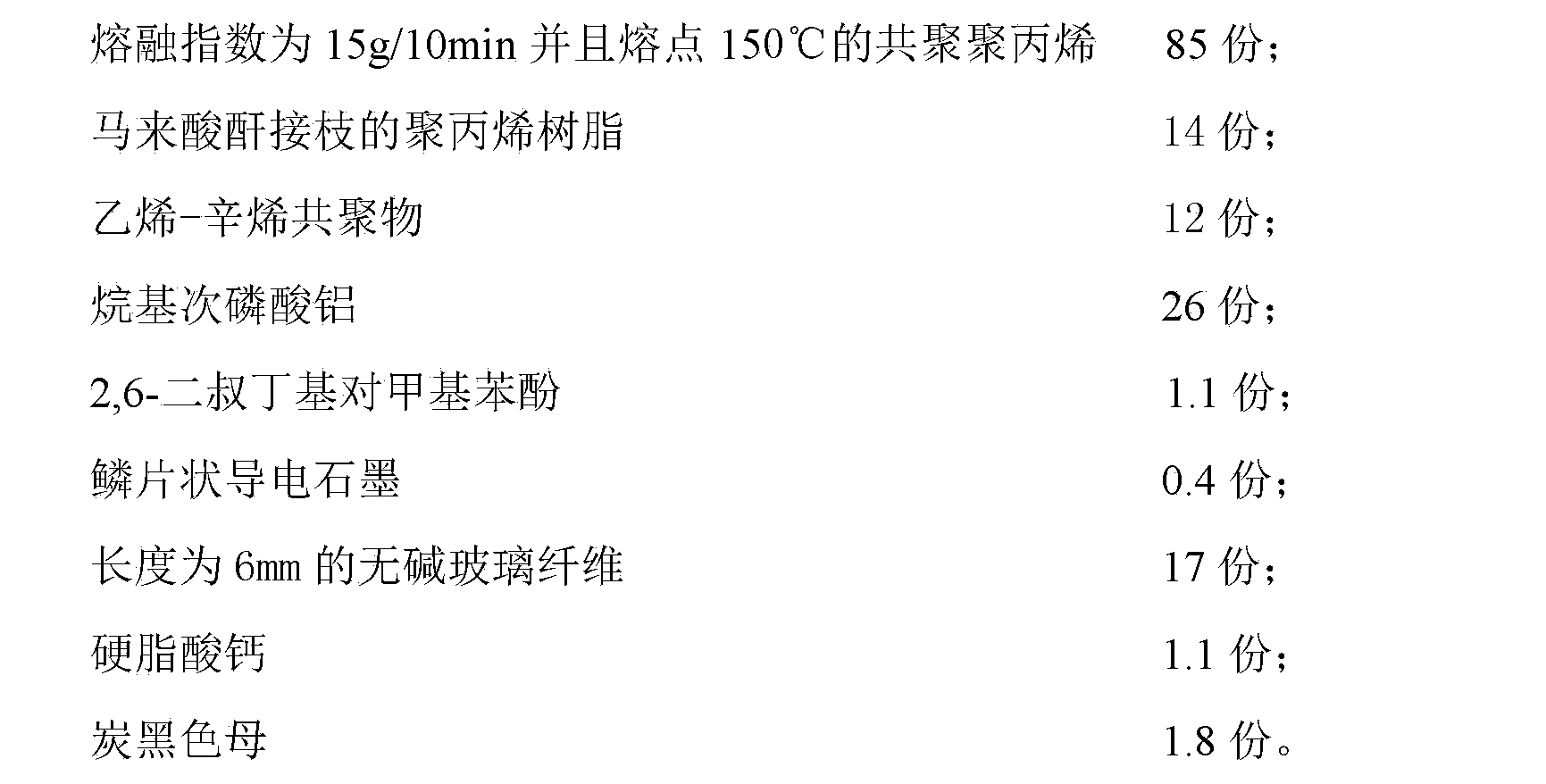

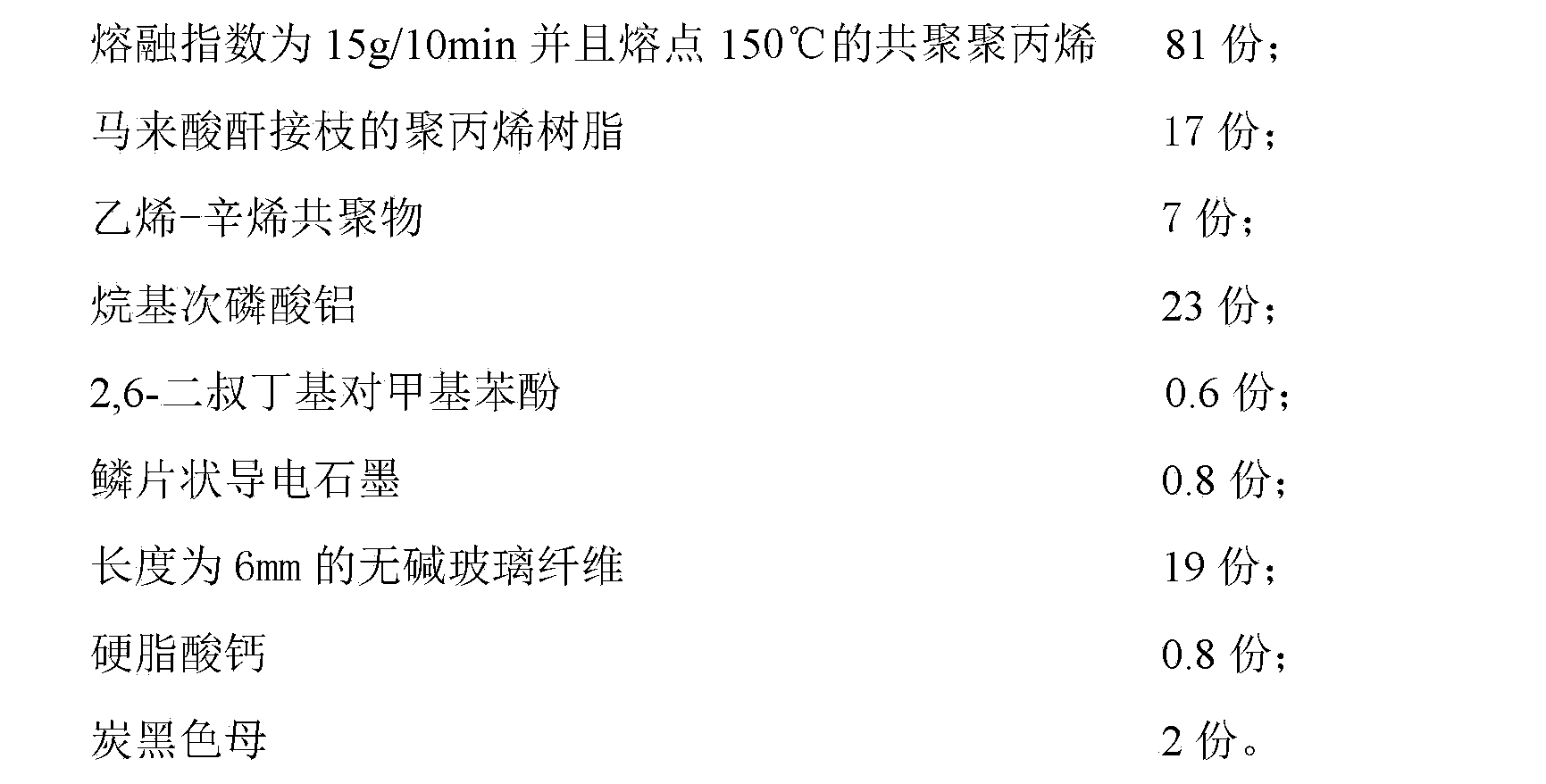

Halogen-free flame-retardant conductive polypropylene composite material

A halogen-free flame-retardant conductive polypropylene composite material belongs to the technical filed of polymer materials. The halogen-free flame-retardant conductive polypropylene composite material comprises, by weight, 81-87 parts of a polypropylene resin, 14-21 parts of a compatilizer, 7-12 parts of an elastomer, 23-31 parts of a flame retardant, 0.6-1.1 parts of an antioxidant, 0.4-0.8 parts of graphite, 17-24 parts of a glass fiber, 0.8-1.3 parts of a processing assistant and 1.8-2.6 parts of carbon black. Test results show that the halogen-free flame-retardant conductive polypropylene composite material has a bending strength of above 56-73MPa, a notch impact strength of above 12.5-15.2kj / m<2>, a thermal deformation temperature of 121-146DEG C and a flame retardation property of V-0 (UL-94-V-0-1.6mm), so the composite material has excellent strength and flame retardation property; the flame retardant is reasonably selected, so the composite material free from halogens is environmentally friendly; and the surface does not generate static electricity, so the safety is guaranteed.

Owner:CHANGSHU KASMAIN

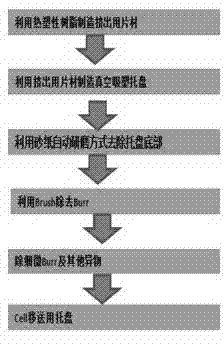

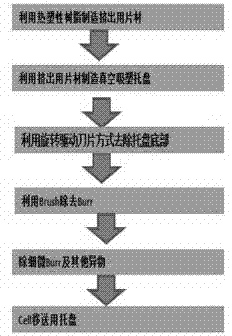

Method for manufacturing battery transfer tray

InactiveCN103587125AReduce manufacturing costLow bad and other issuesForeign matterManufacturing cost reduction

The invention provides a method for manufacturing a battery transfer tray, and particularly relates to a technique of a method for manufacturing a battery transfer tray that a vacuum shaping method is adopted, problems of static electricity generation and foreign matter elimination are prevented, and the manufacturing cost is lowered. The method comprises the following steps: a stage of manufacturing a thermoplastic extruded piece by using a thermoplastic resin, a stage of forming the extruded piece in vacuum so as to manufacture the battery transfer tray, and a stage of removing the bottom of the tray for enabling a battery to penetrate and be fixed. Through the stages provided by the invention, the purpose that the manufacturing cost is lowered as different molds do not needed to be manufactured for different batteries is achieved. In addition, no static electricity is generated in the injection molding process, and the problem of foreign matter elimination is also prevented, so that problems of product badness and the like caused by static electricity of electric products are greatly reduced.

Owner:恩斯盟防静电材料(镇江)有限公司

A kind of processing technology of sedative and tranquilizing down

InactiveCN104179023BCover up the tasteDoes not generate static electricityFibre treatmentAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses a tranquilizing and nerve-soothing down processing technology. According to the processing technology, tranquilizing and nerve-soothing down is processed through the following steps: (1) the down is prepared; (2) primary washing is implemented, wherein a detergent and a detergent are added in water for washing; (3) primary dehydration is implemented, wherein the content of water in the down reaches 22%-28%; (4) secondary washing is implemented, wherein a detergent, an anti-mite agent and a fragrance agent are added in water for secondary washing; (5) secondary dehydration is implemented, wherein the content of water in the down reaches 45%-63%; (6) drying sterilization is implemented, wherein a tranquilizing and nerve-soothing agent is added in high-temperature steam for drying sterilization, the tranquilizing and nerve-soothing agent contains the following ingredients in a weight ratio: 14-16 of spina date seeds, 8-11 of arborvitae seeds, 5-6 of tuber fleeceflower stem, 2-3 of thinleaf milkwort root-bark, 1-3 of silktree albizzia bark, 0-2 of drgon's bone, 0-3 of dens draconis, 5-7 of lavender, 7-9 of roses, and 1500-2000 of water, and all the ingredients are boiled for 15-22 minutes in clean water to obtain a filtrate. The technology is simple and novel; by virtue of twice washing, twice dehydrating and once steam drying, the active ingredients of chemical agents and the fragrance agent are kept on the surface of the down to the maximum degree; if being used for a long time, the tranquilizing and nerve-soothing down plays tranquilizing and nerve-soothing roles and has fragrance.

Owner:江苏欣隆羽绒有限公司

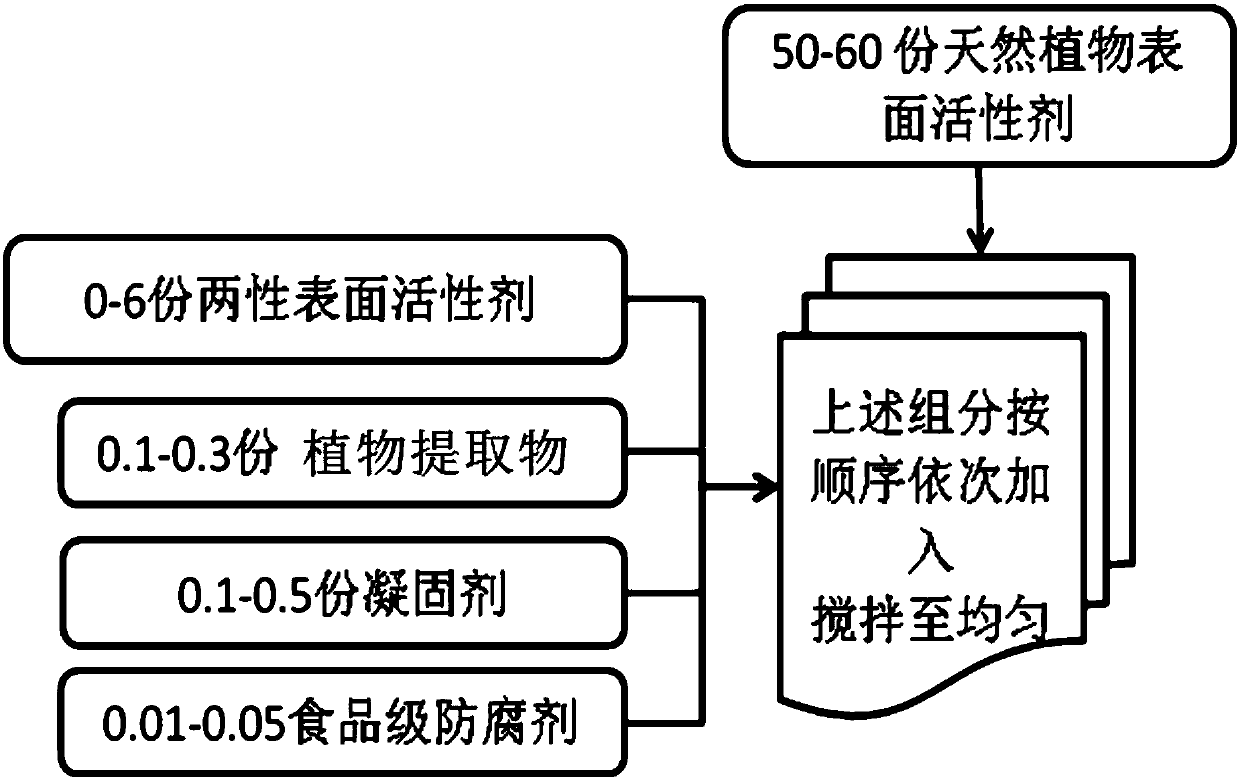

Plant shampoo containing no emulsifier and oil phase

PendingCN107737069ASuitable for daily washingDoes not generate static electricityCosmetic preparationsHair cosmeticsChemical synthesisPreservative

The invention relates to a plant shampoo containing no emulsifier and oil phase, in particular to a shampoo which uses a natural plant surfactant and plant extracts as main components and does not contain the emulsifier and the oil phase. The shampoo has the advantages that the usage amount of chemical synthesis surfactant and preservative is reduced, and the effects of relieving the premature graying and white hair due to nerve overstrain or aging, or inhibiting generation of dandruff, and relieving scalp allergy and itching are realized; the shampoo is suitable for hair care each day.

Owner:杭州至墨生物科技有限公司

Woolen sweater fabric

InactiveCN106617416ADoes not generate static electricityHigh affinityProtective garmentSpecial outerwear garmentsYarnFiber

The invention discloses a woolen sweater fabric. The formula of the fabric consists of the following components: wool, cashmere, artificial cotton, soybean protein fibers, algae carbon fibers, nylon, silk yarns and modal fibers. The woolen sweater fabric, which is prepared in accordance with the formula and is woven by blending the soybean protein fibers and the composite algae carbon fibers, is skin-friendly to human body; in addition, the fabric, which contains various amino acids required by human body, has a good health care function; the composite algae carbon fibers have a function of absorbing far infrared ray, and the far infrared ray not only has an excellent warm-keeping function but also is capable of activating cells, so that the excretion of old and dead cells is promoted or a regenerating capacity is guaranteed, the quantity of cells is increased and effects of enhancing function, activity and the like of the cells are achieved. The fabric, which adopts the artificial cotton, is smoother than nap and the fabric is not easy for piling; and the artificial cotton is good in heat conductivity and electrical conductivity and is free from the generation of static electricity, so that the entire woolen sweater cannot cause the static electricity easily.

Owner:RUGAO LIFU WEAVING CO LTD

Organic intensifying paint and preparation method thereof

InactiveCN101760128ARich textureImprove water resistanceCoatingsPolishing compositionsParaffin waxWater resistant

The invention relates to organic intensifying paint and a preparation method thereof. The paint comprises the following components in part by weight: 2-6 polymethyl siloxane composite, 0.5-2 carnauba wax, 0.5-2 beeswax, 1-3 solid olefin, 6-8 petroleum spirit, 2-4 glycidyl sorbitol monostearate, 1-5 POE sorbitol monostearate (POE20mol) and the balance of water. The paint formed by mixing the components is made of organics, does not contain heavy metal, reduces pollution effectively and is favorable for environmental protection. The product does not tend to generate static electricity when being rubbed and has the advantages of rich paint film texture, good water resistant property, elasticity, flexibility and chemical and abrasion resistant property, strong adhesive force, high covering ratio, large unit coating area and low use cost.

Owner:高庆亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com