Quantitative down filling machine

A technology for storing down and down, applied in the field of quantitative down filling machine, can solve the problems of inability to be fast and accurate, occupy a large area, damage the original shape of down, etc. The effect of velvet stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

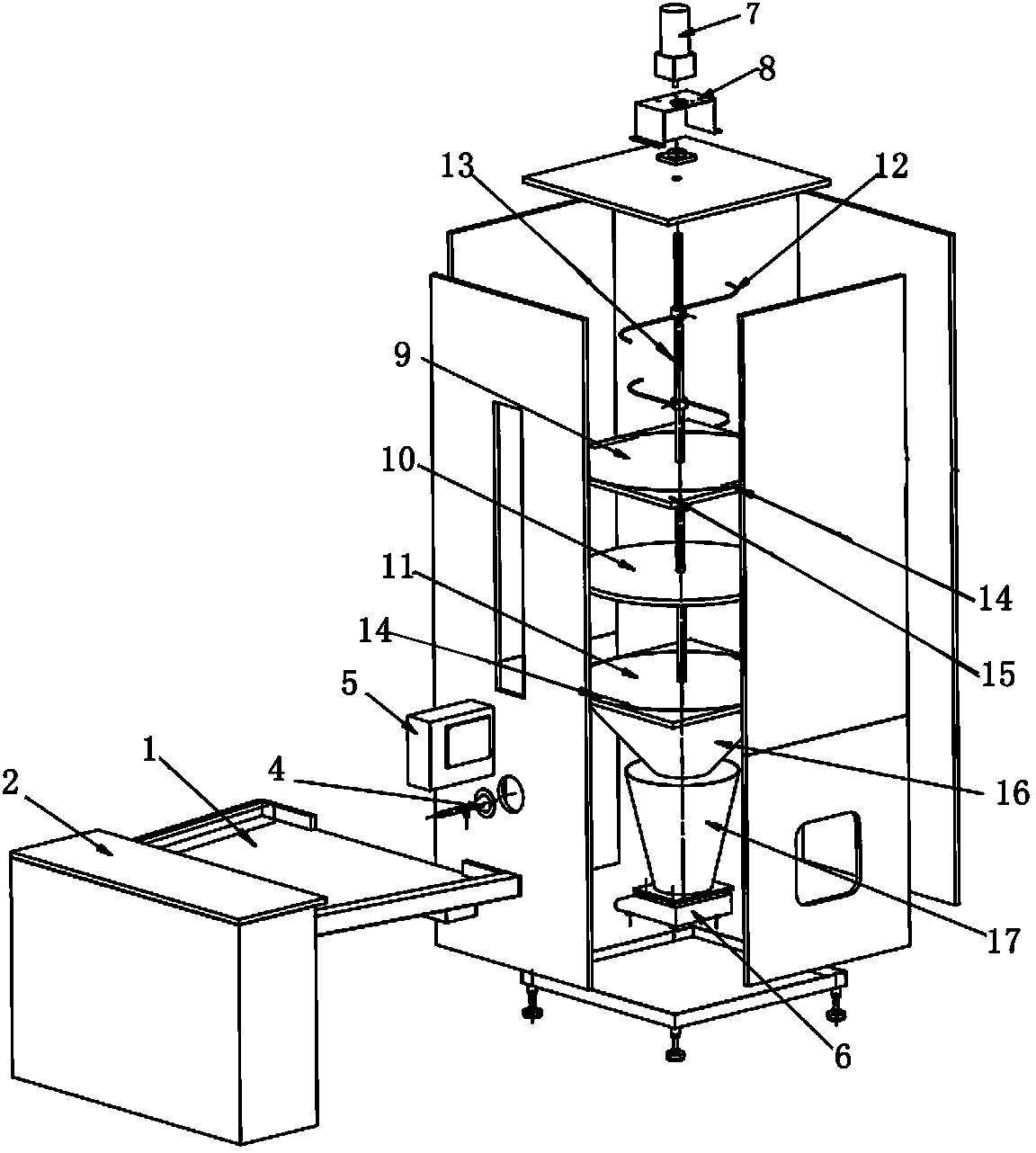

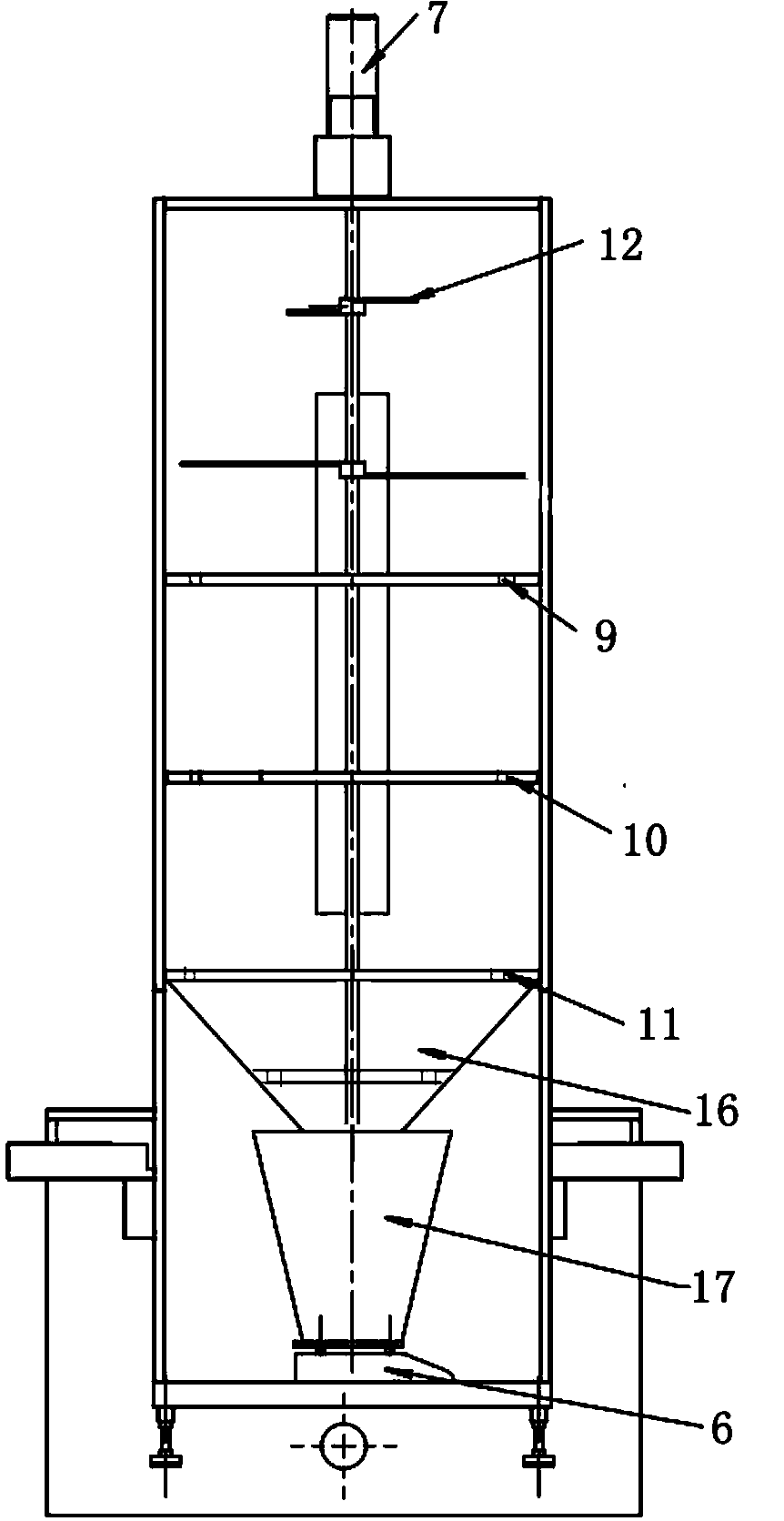

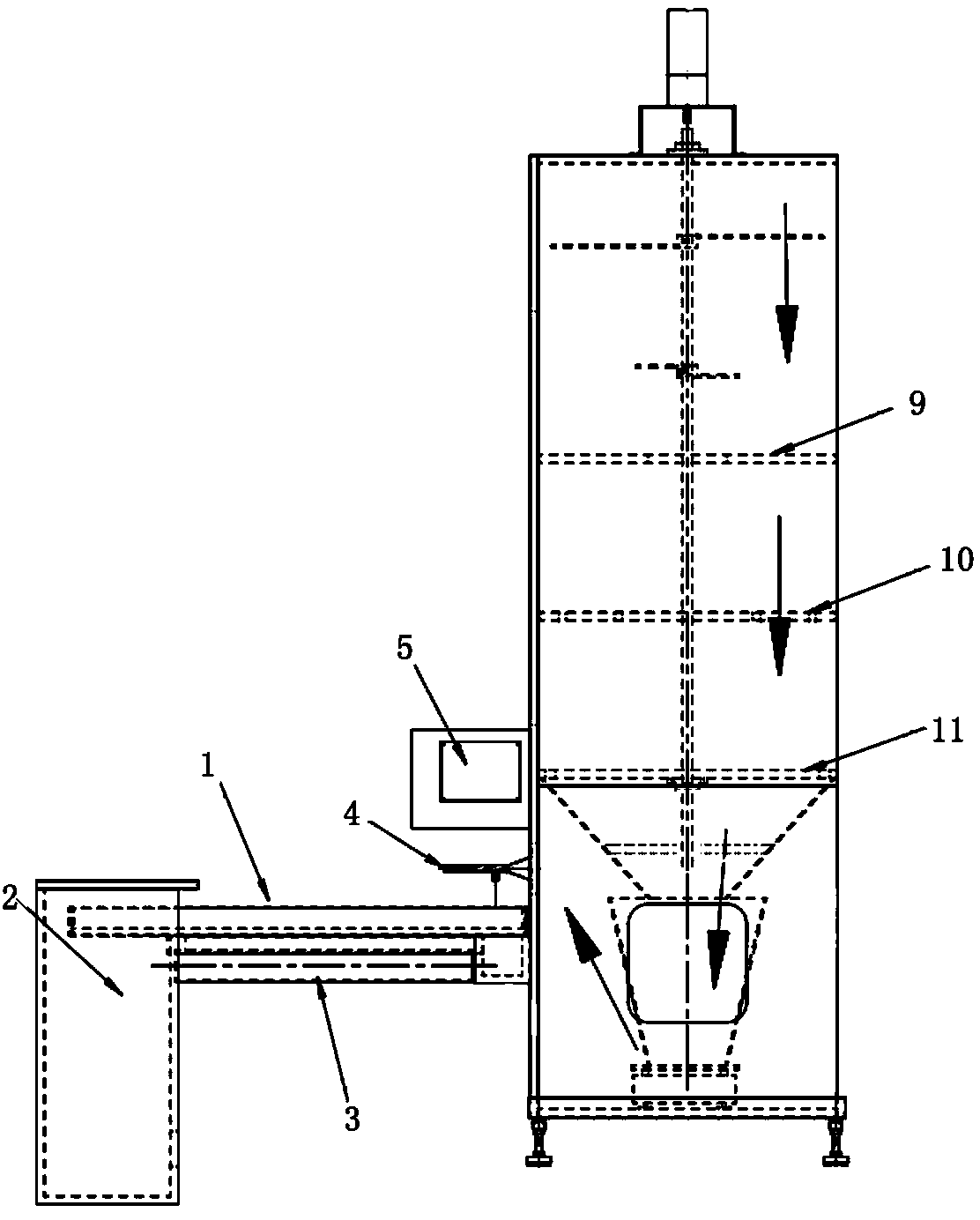

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] In this embodiment, refer to Figure 1 ~ Figure 3 , its specific embodiment comprises a cuboid-shaped cashmere storage main box and a workbench 1 connected to the side of the cashmere storage main box. Recovery lane 3. The side of the cashmere storage main box is provided with a cashmere outlet pipe 4 and a computer man-machine interface 5, and an observation window is also provided on the lower side of the cashmere storage main box. In terms of data setting and real-time display of the amount of down inside the down filling machine, etc.

[0024] This embodiment differs from the traditional structure in that an opening system, a centrifugal suspension system, and a down storage system are respectively arranged inside the down storage main chassis from top to bottom, the down storage system is connected with the down tube 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com