Preparation device of glycerol monolaurate and method thereof, and control system and method thereof

A technology of monoglyceride laurate and monoglyceride laurate, which is applied in the field of preparation equipment of monoglyceride laurate, and can solve problems such as reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

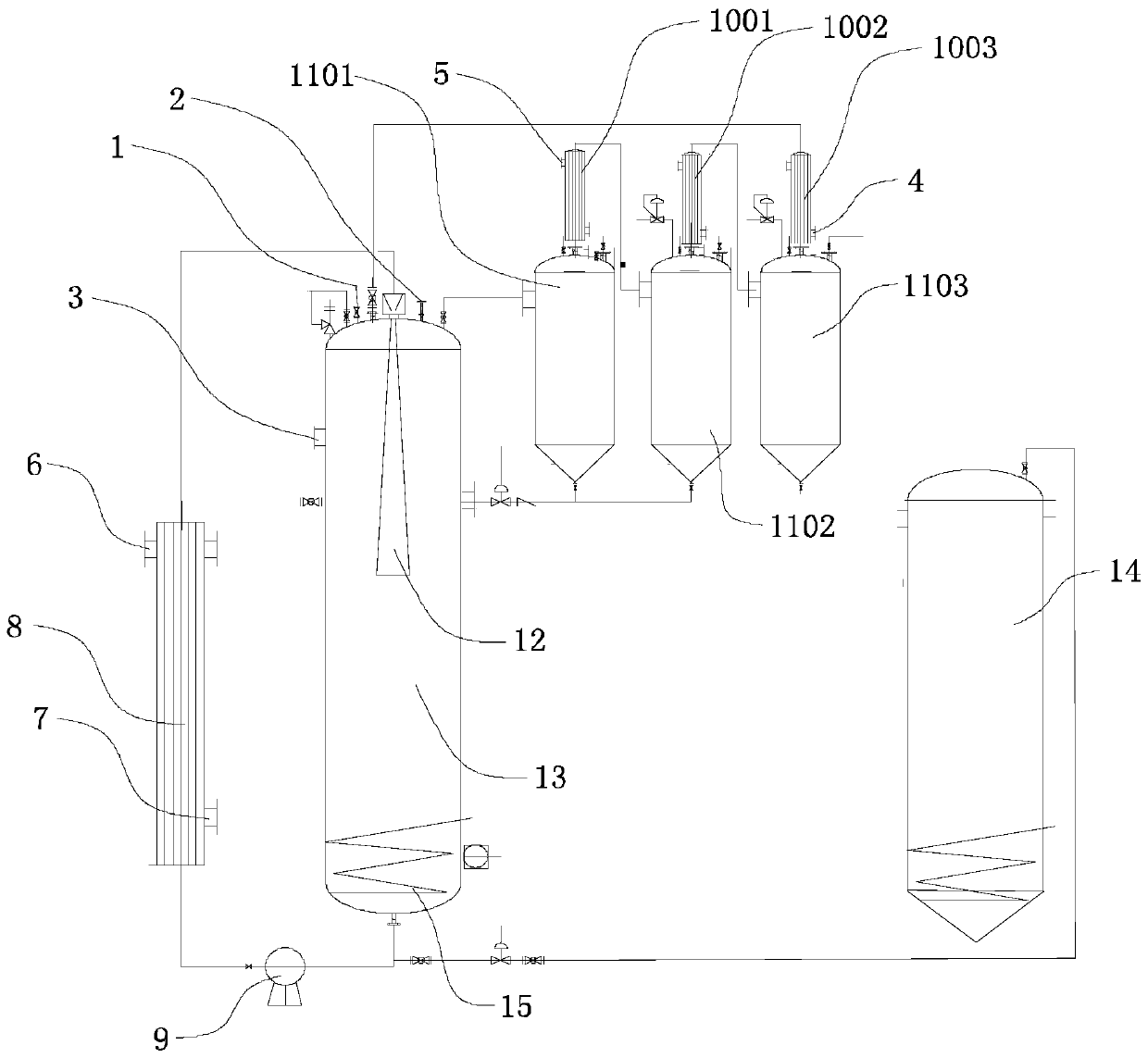

[0082] In this embodiment, the preparation device of monoglyceride laurate includes a production device of monoglyceride laurate, a distillation device of monoglyceride laurate and a powder spraying device of monoglyceride laurate.

[0083] Such as image 3 Shown is the production unit of monoglyceride laurate, comprises external circulation heat exchanger, reaction tank, condensing assembly, loop circulating pump, valve and detection device, is provided with loop reaction mixer (Italy PRESS company) in the described reaction tank Founded gas-liquid contact reactor-spray mixer), the top of the external circulation heat exchanger is connected with the loop reaction mixer, the bottom of the external circulation heat exchanger is connected with the bottom of the reaction tank by a loop circulation pump, and the The top of the reaction tank is connected to the condensing assembly; the top of the reaction tank is connected to the external circulation heat exchanger through a pipe, ...

Embodiment 2

[0096] The preparation method of monoglyceride laurate in the present embodiment, concrete steps are as follows:

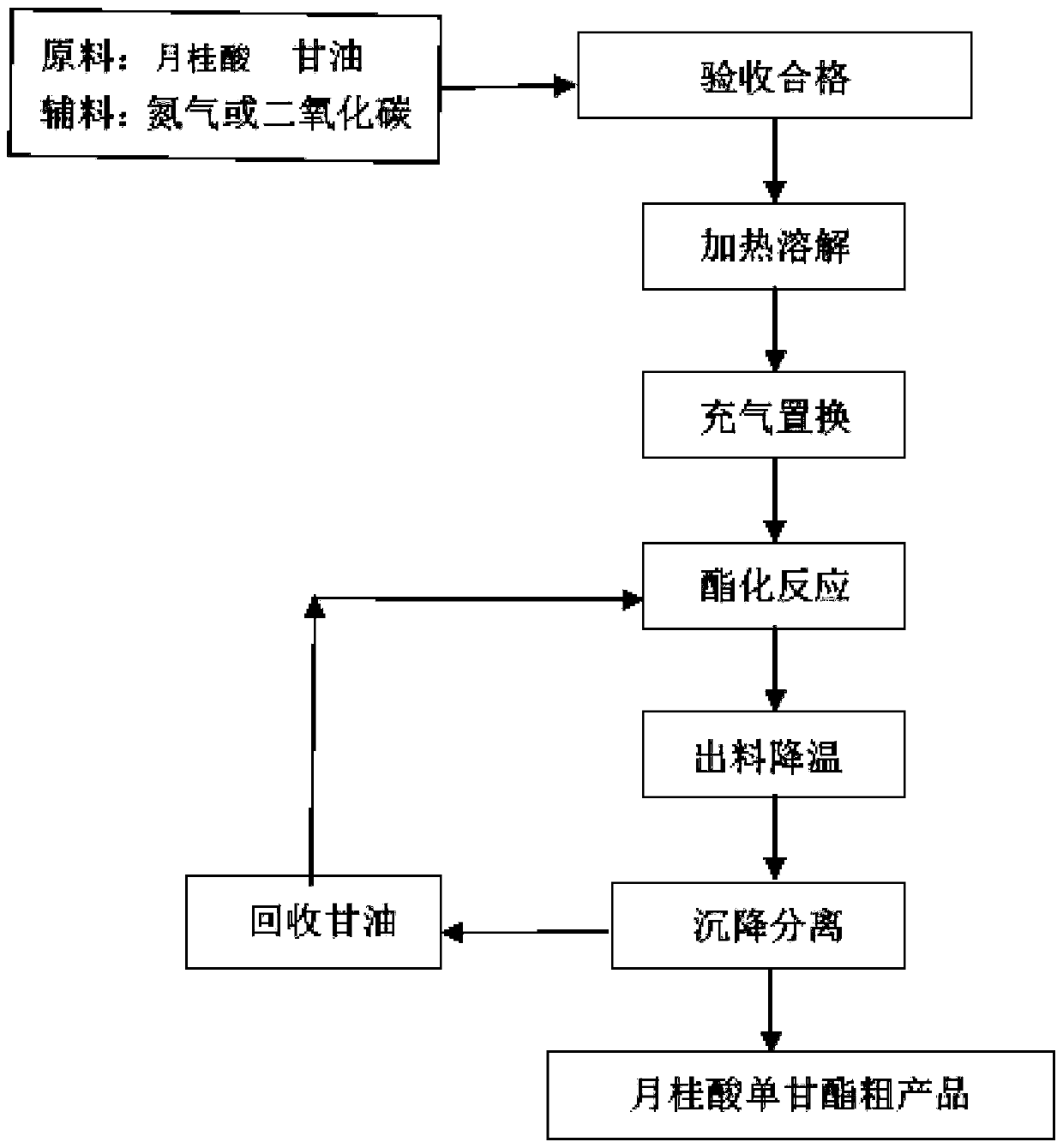

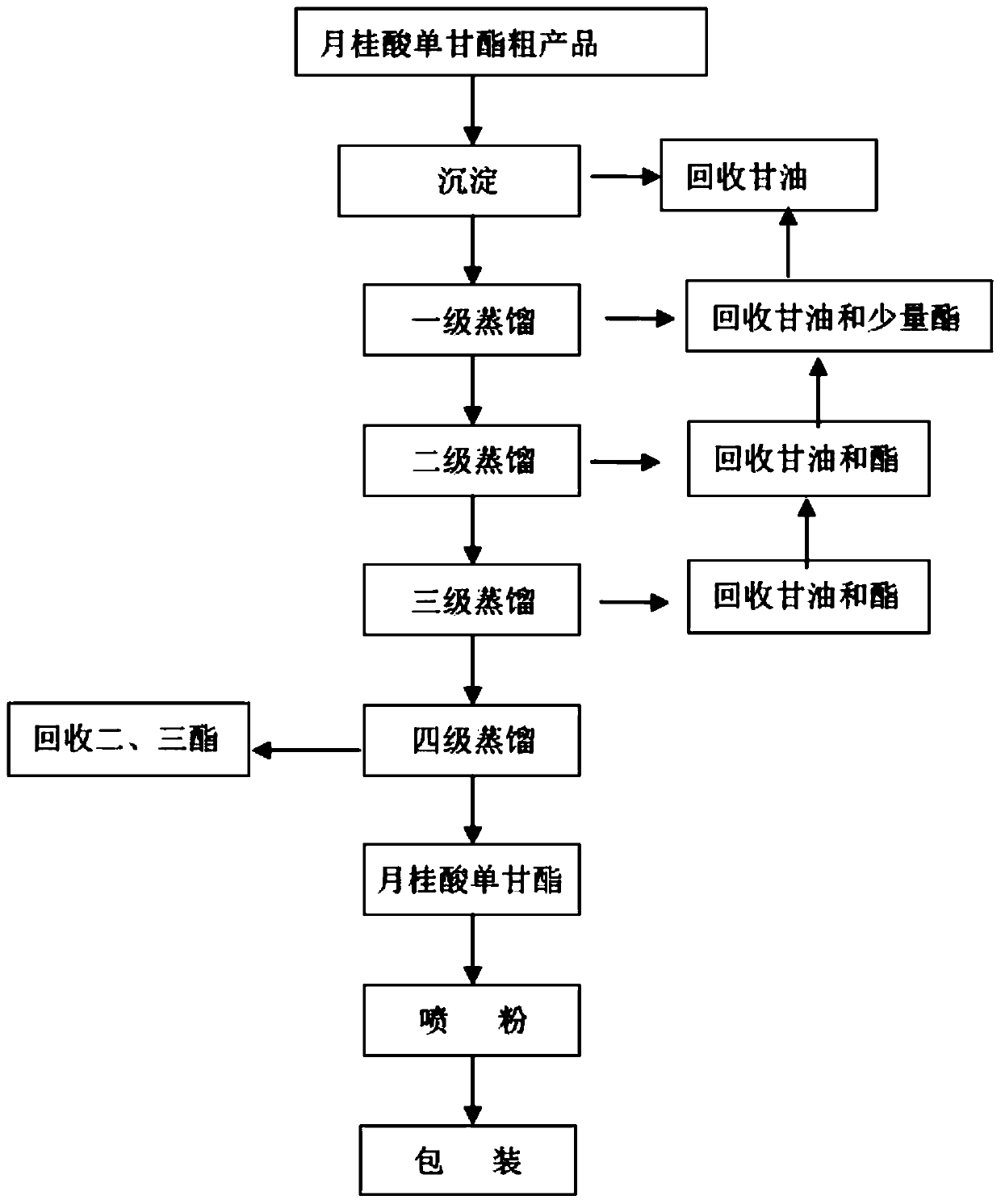

[0097] (1) if Figure 1 to Figure 6 As shown, configure lauric acid and glycerin at a molar ratio of 1:1, open the gas phase loop of the loop reactor, replace the system with nitrogen or carbon dioxide at least twice, and maintain the nitrogen or carbon dioxide pressure of the entire loop reactor system at 0.08MPa , glycerin flows in through the glycerin inlet on the top of the reaction tank, and lauric acid flows in through the lauric acid inlet on the upper part of the reaction tank. Glycerin and lauric acid are mixed and heated in the reaction tank under the action of the loop reaction mixer, and the temperature in the reaction tank is controlled to be 160 ~ 240°C; the gas and unreacted glycerin produced in the reaction tank enter the primary condenser from the upper part of the reaction tank to condense, the unreacted glycerin returns to the reaction tank to c...

Embodiment 3

[0106] The preparation method of monoglyceride laurate in the present embodiment, concrete steps are as follows:

[0107] (1) if Figure 1 to Figure 6 As shown, configure lauric acid and glycerin at a molar ratio of 1:1.5, open the gas phase loop of the loop reactor, replace the system with nitrogen or carbon dioxide at least twice, and maintain the nitrogen or carbon dioxide pressure of the entire loop reactor system at 0.05MPa , glycerin flows in through the glycerin inlet on the top of the reaction tank, and lauric acid flows in through the lauric acid inlet on the top of the reaction tank. Glycerin and lauric acid are mixed and heated in the reaction tank under the action of the loop reaction mixer, and the temperature in the reaction tank is controlled to be 225 ℃; the gas and unreacted glycerin produced in the reaction tank enter the first-stage condenser from the upper part of the reaction tank to condense, and the unreacted glycerin returns to the reaction tank to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com