Pulverized fuel ash-based heat storage honeycomb ceramic and preparation method thereof

A technology of honeycomb ceramics and fly ash, which is applied in the field of fly ash-based thermal storage honeycomb ceramics and its preparation, can solve the problems of environmental pollution, increased cost of mullite, scarcity of mullite resources, etc., and achieve low energy consumption , low cost, good thermal shock resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

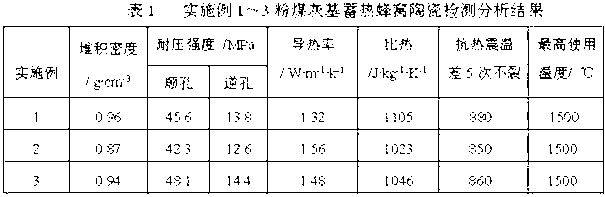

Examples

Embodiment 1

[0027] In terms of mass percentage, weigh 82% of fly ash, 18% of sintering aid (12% of bauxite, 2% of andalusite, 4% of magnesium nitrate), mix the above raw materials, and add 1% of surfactant (0.6% oleic acid, 0.4% simethicone oil) and grind to D 50 =5.3 μm. Move the mixture to a mixer, add 5.6% of binder (2.6% of hydroxypropyl cellulose, 3% of rapeseed oil), 6% of plasticizer (glycerin), 16% of water, wet Mix for 2 hours. The above-mentioned surfactants, binders, plasticizers and water are all added in the form of external additions, and the additions are all measured as a percentage of the total mass of fly ash and sintering aids. The following examples are the same; the fly ash used The mass percent content of aluminum oxide in the medium is 52%.

[0028] After mixing, the wet material is stale for 5 hours, and the mud is roughly refined by a vacuum mud mill (vacuum degree 0.09MPa), and the pressure is kept at 8MPa for 2 minutes. , 8MPa pressure hold for 2min. It was...

Embodiment 2

[0032] In terms of mass percentage, weigh 54% of fly ash, 46% of sintering aid (39% of bauxite, 5% of andalusite, 2% of kaolin), mix the above raw materials, and add 1.3% of surfactant ( Oleic acid) is loaded into a grinder with grinding media (the grinding media is pebbles, and the mass ratio of material: grinding media is 1:2.5) and grinds to D 50 =6.8μm. This mixture is moved to mixer, adds the water of 8% binding agent (carboxymethyl cellulose 3%, tung oil 5%), 4% plasticizer (triethylene glycol caproate), 21%, Wet mix for 2h. The mass percent content of alumina in the fly ash used is 37%.

[0033] After mixing, the wet material is stale for 5 hours, and the mud is roughly refined (vacuum degree 0.09MPa) by a vacuum mud mixer, and the pressure is maintained at 3MPa for 6 minutes. , 3MPa holding pressure for 6min. It was extruded continuously at 18 MPa using an extruder and a die for extrusion molding, and cut with a molybdenum wire. The inner hole of the fly ash-based...

Embodiment 3

[0037] In terms of mass percentage, weigh 66% of fly ash, 34% of sintering aid (27% of bauxite, 4% of andalusite, 3% of kaolin), mix the above raw materials, and add 1.2% of surfactant ( Simethicone) is loaded into a grinding medium (the grinding medium is zirconium silicate, the mass ratio of material: grinding medium is 1:2.5) and ground to D 50 =7.1 μm. Move the mixture to a mixer, add 7.6% of binder (2.6% of hydroxypropyl cellulose, 5% of paraffin), 3.3% of plasticizer (2% of dibutyl phthalate, 1.3% of oxalic acid %), 21% water, wet mixing for 2h. The mass percent content of alumina in the fly ash used is 45%.

[0038] After mixing, the wet material is stale for 8 hours, and the mud is roughly refined (vacuum degree 0.09MPa) by a vacuum mud mixer, and the pressure is maintained at 5MPa for 4 minutes. 5MPa holding pressure for 4min. It was extruded continuously at 18 MPa using an extruder and a die for extrusion molding, and cut with a molybdenum wire. The inner hole o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com