Patents

Literature

159results about How to "No burning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly diatom ooze wall material powder and wall material and preparation method thereof

InactiveCN101700965AImprove adsorption capacityAdequate adsorptionMoisture absorptionAir purification

The invention discloses environment-friendly diatom ooze wall material powder and a wall material as well as a preparation method and application thereof. The diatom ooze wall material with macromolecule sieve structure is prepared by taking a plurality of natural environment-friendly non-metal material having strong adsorbability and good plasticity as main materials through a simple process. The environment-friendly diatom ooze wall material powder has the advantages of low cost, air purification, moisture absorption, deodorization, inflaming retarding, heat insulation, easy popularization,and the like.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

Water epoxy floor coating, preparation method and construction method thereof

InactiveCN101565584ASafe and environmentally friendlyNo burningEmulsion paintsEpoxy resin coatingsOrganic solventEmulsion

The invention discloses a water epoxy floor coating which is a double-component emulsion coating comprising a component A and a component B, wherein the component A comprises water, a water epoxy curing agent, an addition agent, a filler and paint; and the component B comprises liquid epoxy resin, a reactive diluent and an environmentally-friendly type organic solvent; and the proportion of the component A to the component B is 10:3. The water epoxy floor coating has the advantages of the avoidance of the environmental pollution and the harm to the health of the human body, strong ventilation property, suitability for moist base planes and satisfaction of environmentally-friendly requirements and can be widely applied to the field of the industrial floor coating.

Owner:KOATWAY SHANGHAI CHEM IND CO LTD

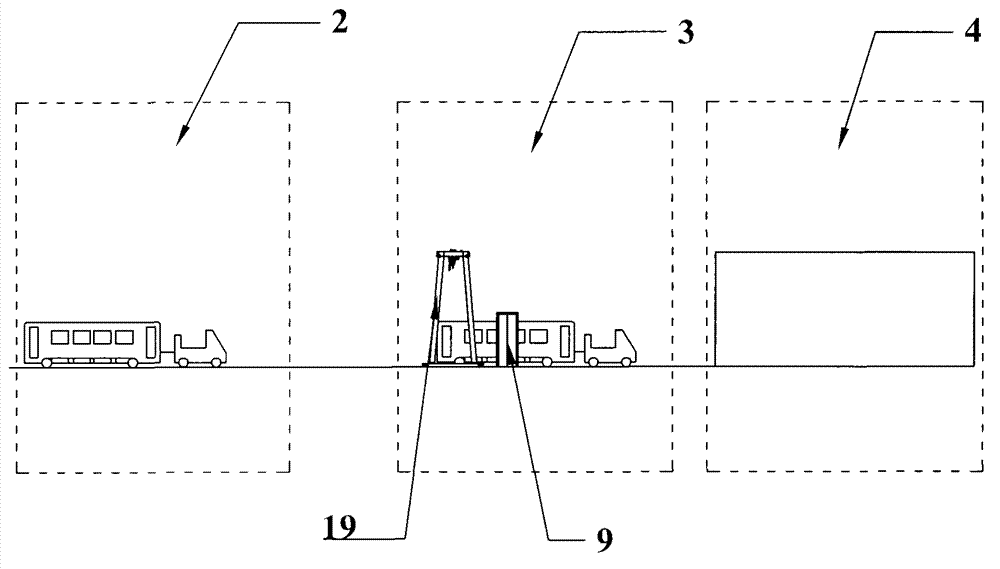

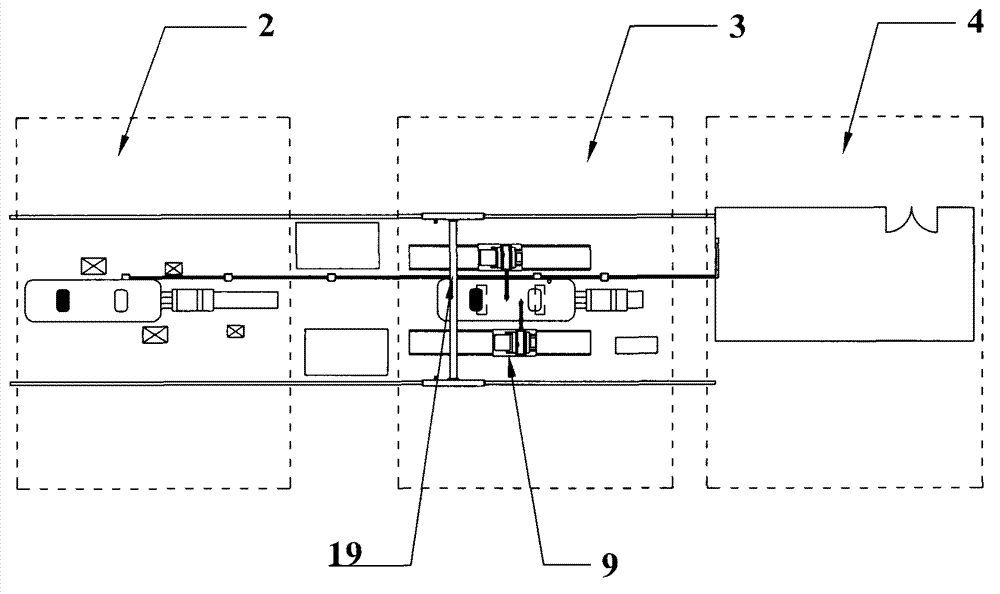

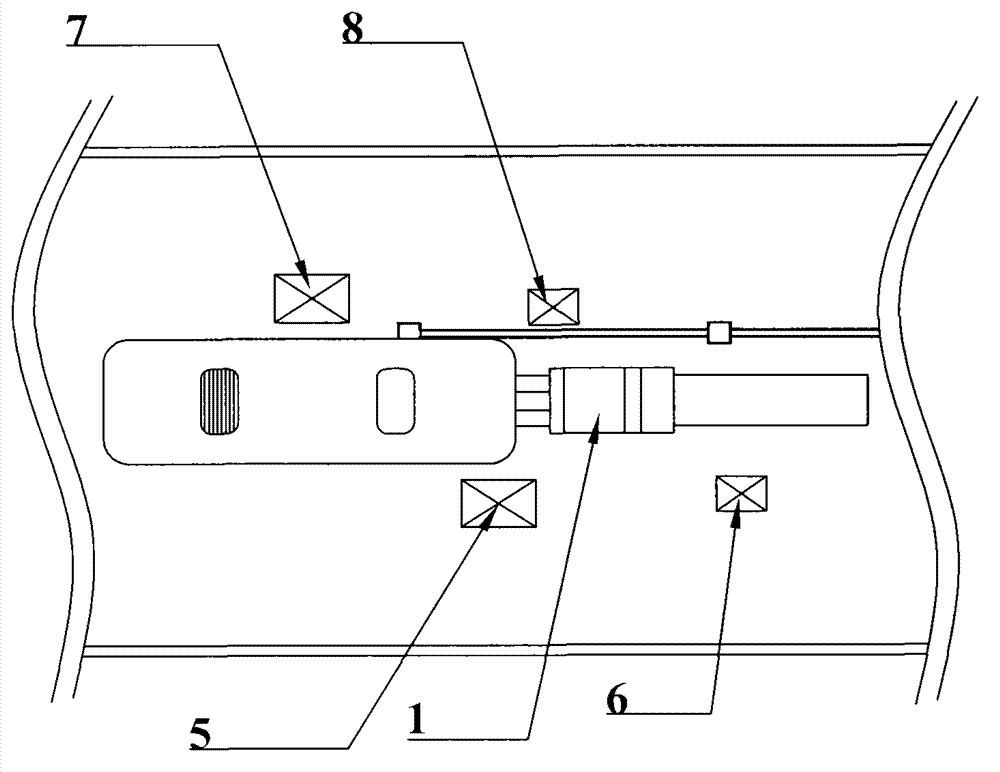

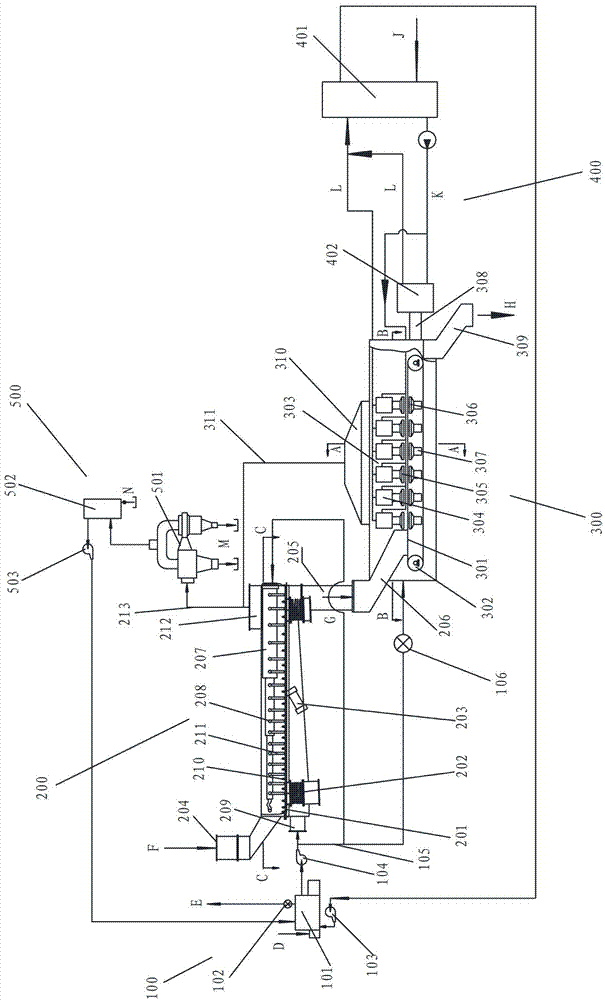

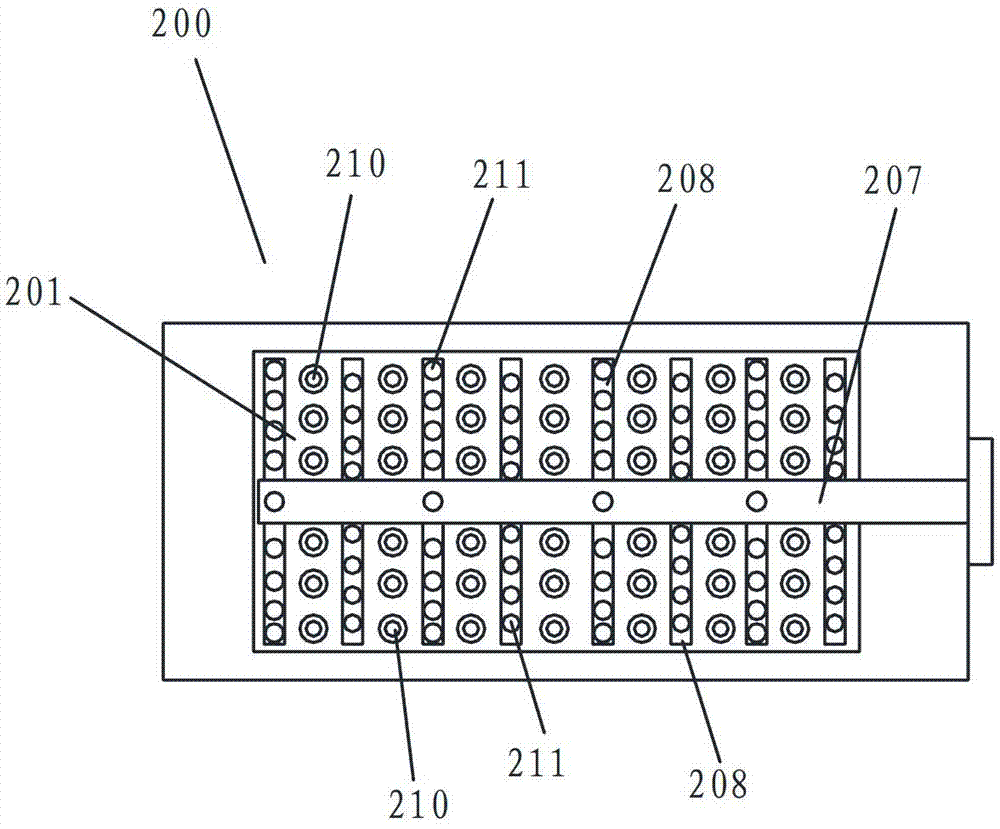

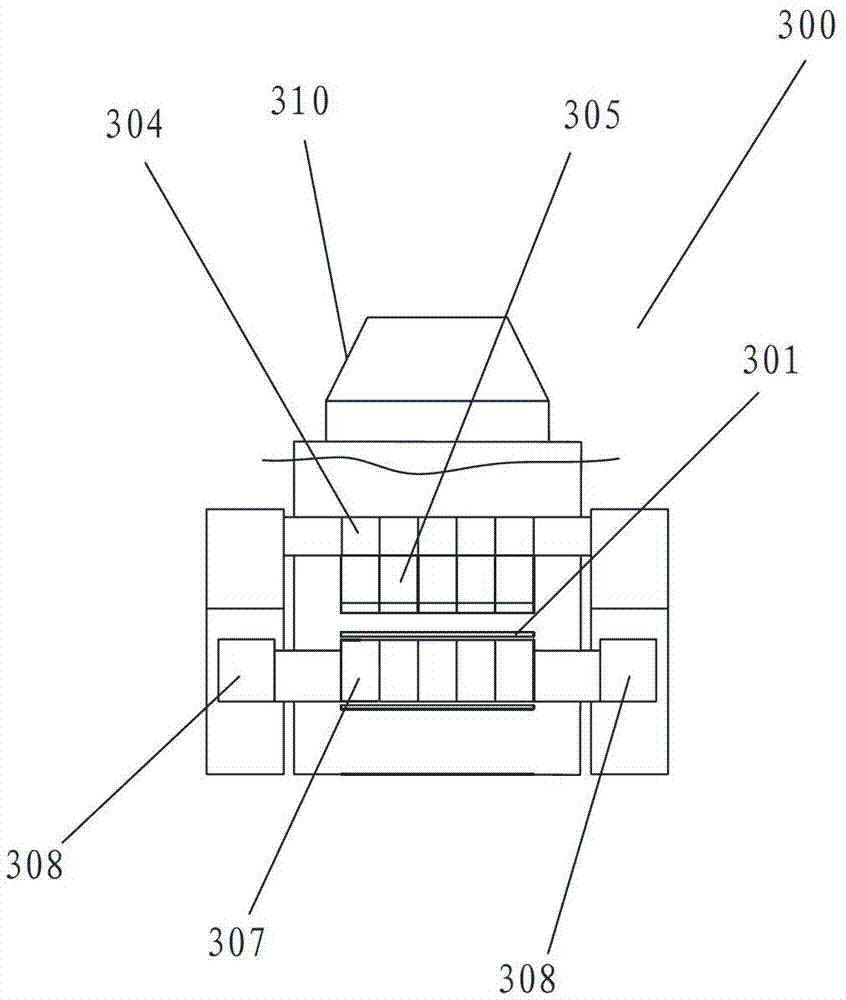

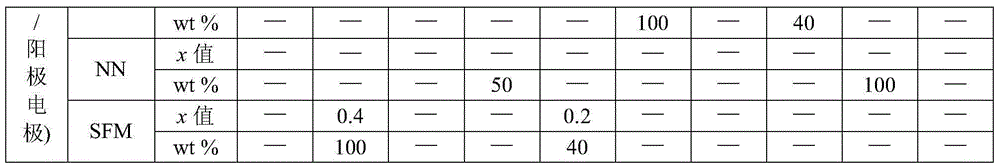

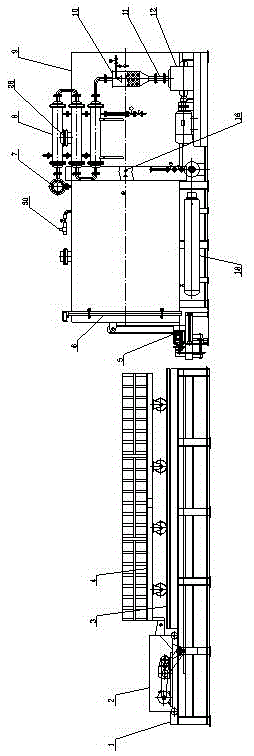

Waste vehicle disassembly production line and corresponding process

InactiveCN103112519AReduce labor intensityLess investmentVehicle dissasembly recoverySolid waste disposalProduction lineRefrigerant reclamation

The invention relates to a waste vehicle disassembly production line and corresponding process. Nowadays, a relatively complete disassembly method for waste vehicles does not exist at both home and abroad. The waste vehicle disassembly production line comprises a pretreatment area and a semi-automatic disassembly area, the pretreatment area comprises a waste oil fluid extracting work station, a refrigerant recycling work station, a windshield, an electrical equipment circuit disassembly work station and an inner trim and tyre disassembly work station, wherein a waste oil fluid extracting device is arranged in the waste oil fluid extracting work station, a refrigerant extracting device is arranged in the refrigerant recycling work station, and an air gun sleeve and an air gun unit are arranged on the inner trim and tyre disassembly work station. The semi-automatic disassembly area is arranged on a downstream position of the pretreatment area, and a semi-automatic disassembly device and a material taking and carrying device are arranged in the semi-automatic disassembly area. Not only do the waste vehicle disassembly production line and the corresponding process achieve transformation from manual disassembly to mechanical disassembly, but also the size of cut material can be adjusted according to requirements, and the waste vehicle disassembly production line and the corresponding process are widely used for disassembly of various vehicles and particularly suitable for disassembling of oversize vehicles.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

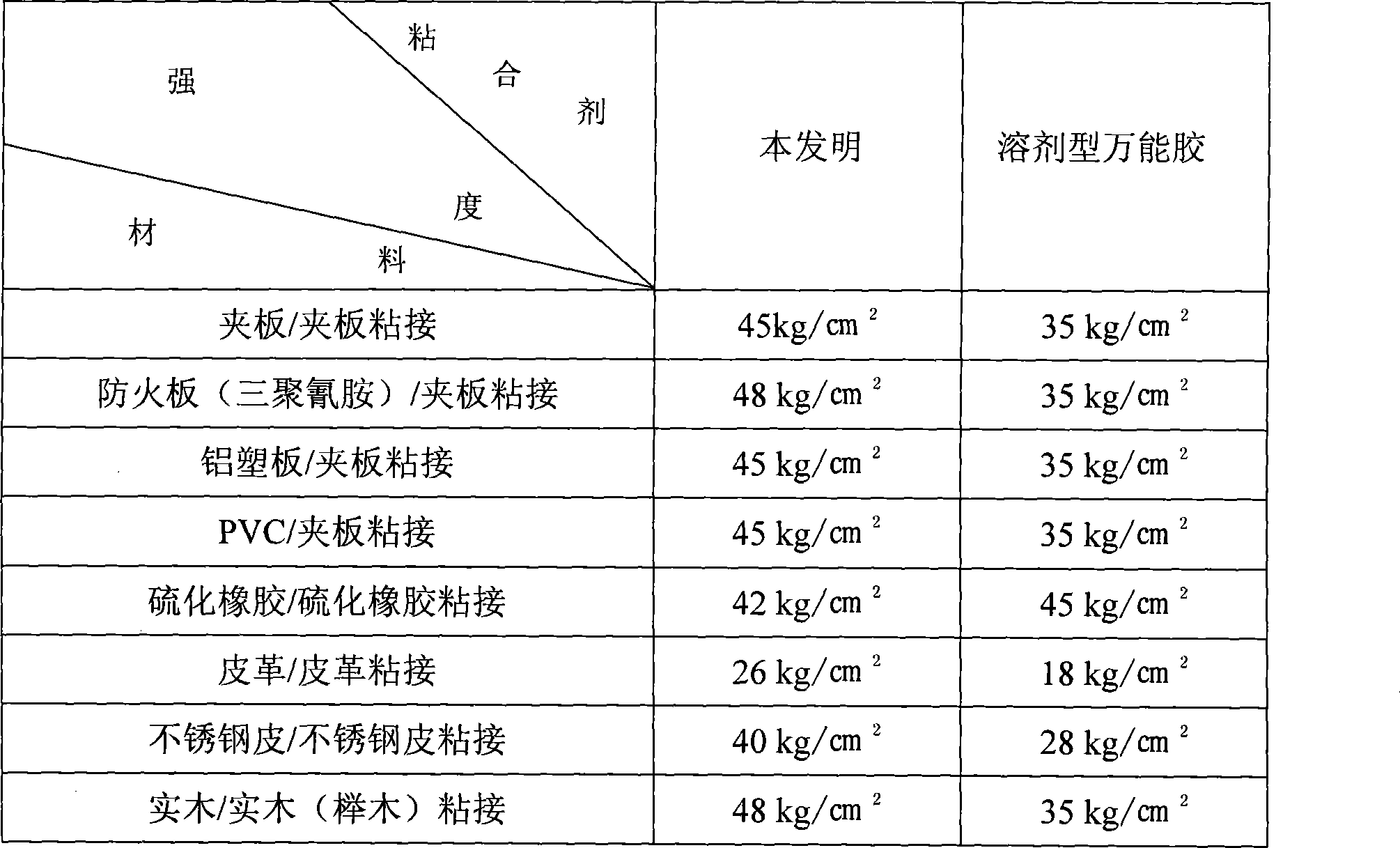

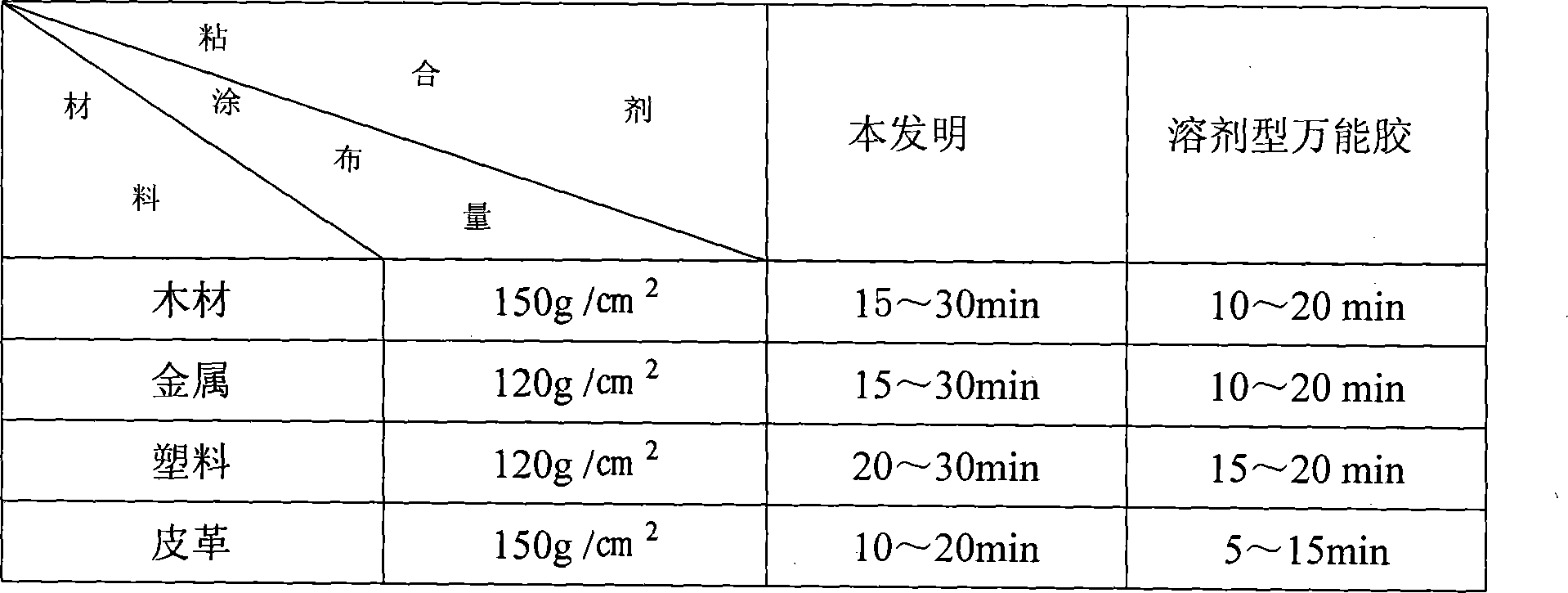

Water-based all-purpose adhesive and method for preparing same

InactiveCN101225271AWith adhesive strengthImprove stabilityInksCoatingsIsooctyl acrylatePolymer science

The invention discloses a water-based all purpose adhesive and the preparation method, which belongs to the field of water-based adhesive, the technical proposal is a copolymer emulsion of 120 to 300 portions of vinyl acetate, 15 to 50 portions of organic silicon monomer with unsaturated double bond, 60 to 150 portions of ethylene tertiary carbonate, 80 to 120 portions of butyl acrylate, 90 to 150 portions of iso-octyl acrylate, 5 to 15 portions of acrylic acid; the emulsion also comprises 20 to 80 portions of tackifying resin, 3 to 8 portions of sodium salt decocting mixture, 50 to 150 portions of plasticizer, 15 to 50 portions of polyvinyl alcohol, 2 to 8 portions of silane coupling agent, 8 to 12 portions of hydrochloric acid, 3 to 15 portions of anionic emulsifier and 3 to 12 portions of nonionic emulsifier. The preparation method is that the mixed monomer is dropped by the manner of emulsion polymerization, and should be completed in three to five hours; warming up to 85 to 95 DEG C to cure for 40 to 60 minutes; then discharging and filtering and packaging after cooling down to 45 to 35 DEG C. The water-based all purpose adhesive has the advantages of convenient use, wide applicability, and can be used for the manufacturing of furniture, luggage and construction decoration.

Owner:唐浩

Production method of environmental straw

InactiveCN104287579ANo pollution in the processPromote decompositionStarch coatingsTablewaresPlant stalkHuman mouth

The invention provides a production method of an environmental straw. The production method includes the steps of (1) taking, cutting and drying a hollow plant stalk; (2) spraying coating to the inner and the outer surfaces of the dried hollow plant stalk and drying the same; (3) performing sterilization on the dried hollow plant stalk. The plant stalk is high polymer material with fragility and flexibility. According to the arrangement, after physical and chemical processing, the hollow plant stalk is made into the high polymer material with toughness and hardness, and the straw is acquired and made of the plant stalk and sticky rice. The production method has the advantages that green and zero-pollution effect and environmental friendliness are realized; immediate contact with human mouth cavity causes no side effect; after utilization, the straw is prone to dissolving with green burning; the production method is easy to operate and low in cost.

Owner:GUANGXI DINGJIAN PLASTIC PROD CO LTD

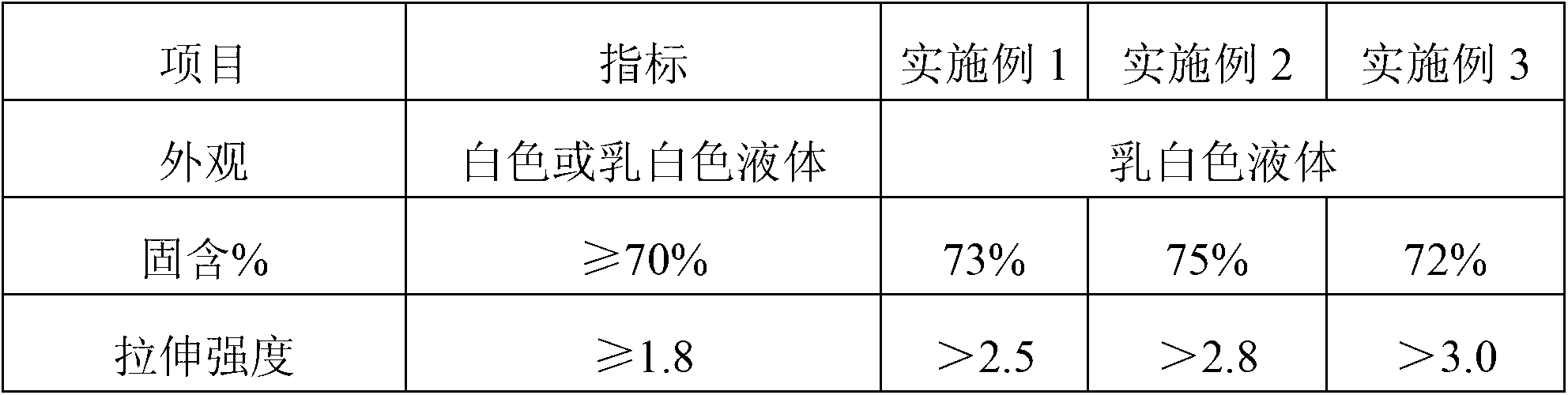

Waterproof glue for building and preparation method thereof

InactiveCN103074010AWide range of applicationsExtended service lifeMonocarboxylic acid ester polymer adhesivesButyl methacrylateDouble bond

The invention provides waterproof glue for a building and a preparation method thereof. The waterproof glue for the building comprises the raw materials in parts by weight: 200-250 parts of vinyl acetate, 25-30 parts of organic silicone monomers containing unsaturated double bonds, 100-120 parts of vinyl versatate, 90-100 parts of butyl acrylate, 120-130 parts of butyl methacrylate, 70-85 parts of crylic acids, 40-60 parts of tackifying resins, 5-7 parts of sodium chelating agents, 200-250 parts of non-phthalic plasticizers, 25-45 parts of polyvinyl alcohol, 4-6 parts of silane coupling agents, 6-12 parts of anionic emulsifiers, 6-9 parts of nonionic emulsifiers, 450-550 parts of de-ionized water, 1-5 parts of corrosion removers and 1.3-3.3 parts of initiators. The waterproof glue for the building has the advantages that the product is wide in application scope, long in service life and high in stability; the storage period at 5-35 DEG C exceeds 12 months; and the waterproof glue for the building is convenient during a construction period.

Owner:FOUR CHUANNUO BUILDING MATERIALS

Agent for dirt-removing and antifogging

InactiveCN1418787ANo pollution in the processNo pollutionOther chemical processesVehicle cleaningSolventSURFACTANT BLEND

The detersive antifogging agent for glass is made of (wt%) 10-20% of anhydrous ethanol as solvent, 5-15% of propylene glycol 5-15% of isopropanol as dispersing agent, 5-20% of cocoanut oil fatty acid diethanol acylamide as non-ionic surfactant, 1-1.5% of essence and 40-60% of pure clean water as raw material through the processes of uniformly stirring them and filling. It is simple in productionprocess and is obvious in detersive antifogging effect, and has extensive application.

Owner:崔长安

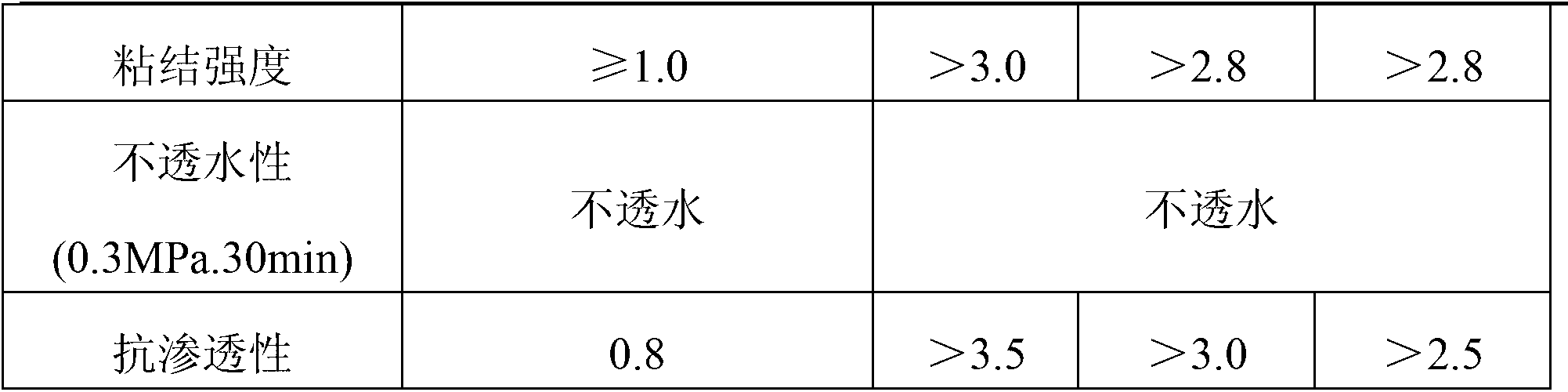

Polyaniline nanometer tube array/graphene composite material electrode and manufacturing method and application thereof

ActiveCN105206430AAchieve synergyImprove performanceHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceFiber

The invention provides a polyaniline nanometer tube array / graphene composite material electrode and a manufacturing method and application thereof, and belongs to the field of new energy products. The composite material electrode comprises a polyaniline nanometer tube array / graphene composite material and a conductive substrate. Graphene is doped in a polyaniline nanometer tube array to form a fiber-slice coexisting structure, the diameter of polyaniline nanometer tubes ranges from 150 nm to 300 nm, and the pipe spacing of the polyaniline nanometer tubes ranges from 300 nm to 400 nm. The conductive substrate is coated with the composite material to form the polyaniline nanometer tube array / graphene composite material electrode. The composite material electrode is high in conductivity and excellent in circulating performance and capacitance performance; the method for preparing the composite material electrode is easy to operate and friendly to the environment; a super capacitor with the composite material electrode is high in capacitance and good in circulating performance.

Owner:南京绿索电子科技有限公司

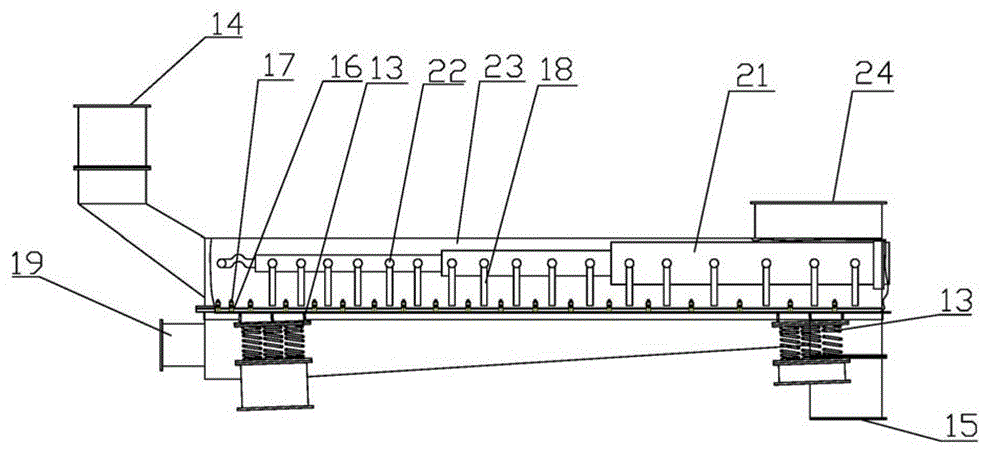

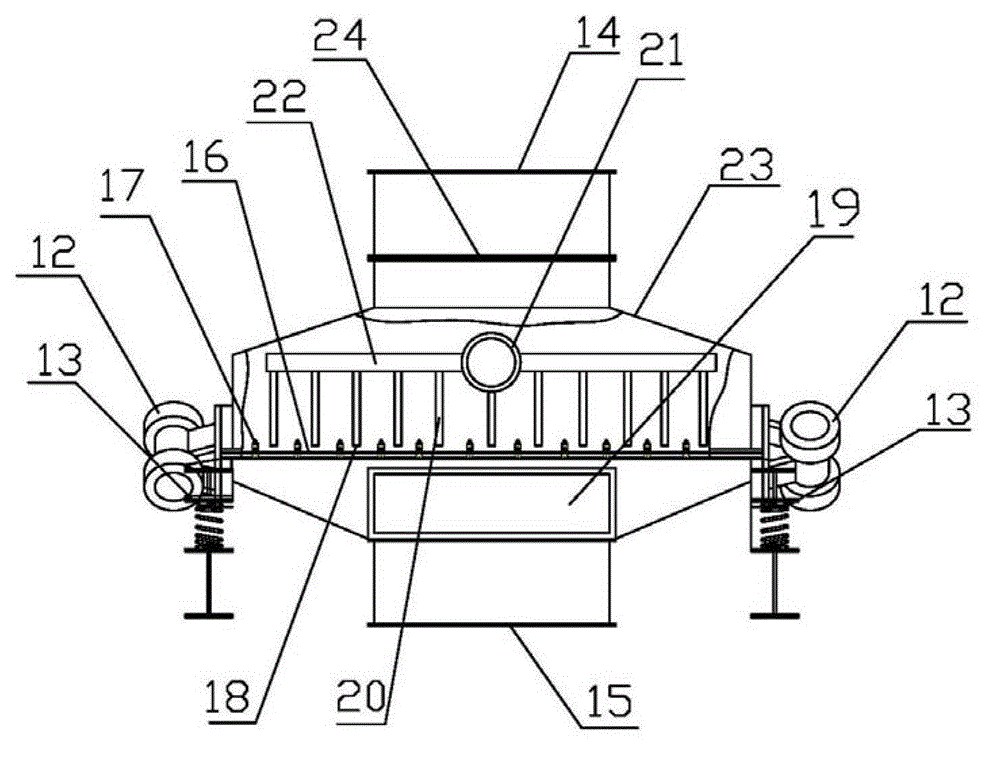

Drying equipment

ActiveCN103115478AReduce moisture contentNo burningDrying gas arrangementsPreliminary solid treatment for dryingMicrowaveEngineering

The invention provides drying equipment which comprises an inert gas feeding device, a vibration fluidized drying device and a multichannel microwave drying device. The inert gas feeding device is connected with the vibration fluidized drying device and the multichannel microwave drying device through pipelines and used for inputting inert gases to the vibration fluidized drying device and the multichannel microwave drying device. A wet material feeding valve is for feeing wet materials is arranged on the vibration fluidized drying device, and the vibration fluidized drying device is further provided with a pre-drying material discharge valve for discharging the wet materials after the wet materials undergo fluidized drying. A discharge port portion of the pre-drying material discharge valve is connected with a material discharge channel for conveying pre-drying materials to the multichannel microwave drying device which is connected with the material discharge channel. The multichannel microwave drying device is further provided with an end product drying material discharge valve for discharging the pre-drying materials after the pre-drying materials undergo microwave drying.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Method for preparing structural material of floors and coaches of high-speed trains

ActiveCN102172792AIncrease the moment of inertiaIncrease stiffnessSoldering apparatusWelding/soldering/cutting articlesSurface oxidationEnergy absorption

The invention discloses a method for preparing a structural material of floors and coaches of high-speed trains. In the method, super light foamed aluminium or foamed aluminum alloy is used as a core layer and aluminum plates with different thicknesses, wherein the aluminum plates are used as upper and lower faceplates to be compounded with the core layer to form the sandwich panels. The method is characterized in that, through mechanically and forcedly paving and spreading the foamed aluminium core layer and the faceplates in a brazing filler metal melt and then carrying out fusion and vibration-assisted coagulation, attached surface oxidation films are removed, and the foamed aluminium core layer and the faceplates are prevented from being oxidized again during welding, and finally, a structural material for floors and coaches of high-speed trains which is compounded by carrying out large-area welding on the foamed aluminium core layer and the upper and lower faceplates. Compared with the material prepared by a traditional cementing method, the material prepared by the method disclosed by the invention has the advantages of high rigidity, long service life, noise isolation, energy absorption, vibration damping, inflaming retarding, corrosion resistance and electromagnetic shielding; meanwhile, the cold and heat processing such as re-welding, surface coating, scraping and thelike and the complete recycling of the material can be realized, and the prepared structural material can replace the structural material for floors and coaches of high-speed trains prepared from honeycomb aluminium sandwich structural slabs, honeycomb paper sandwich structural slabs, organic foamed plastic sandwich panels such as polyurenthane panels and the like, metal-coated wood boards, and other various composite materials.

Owner:UNIV OF SCI & TECH BEIJING

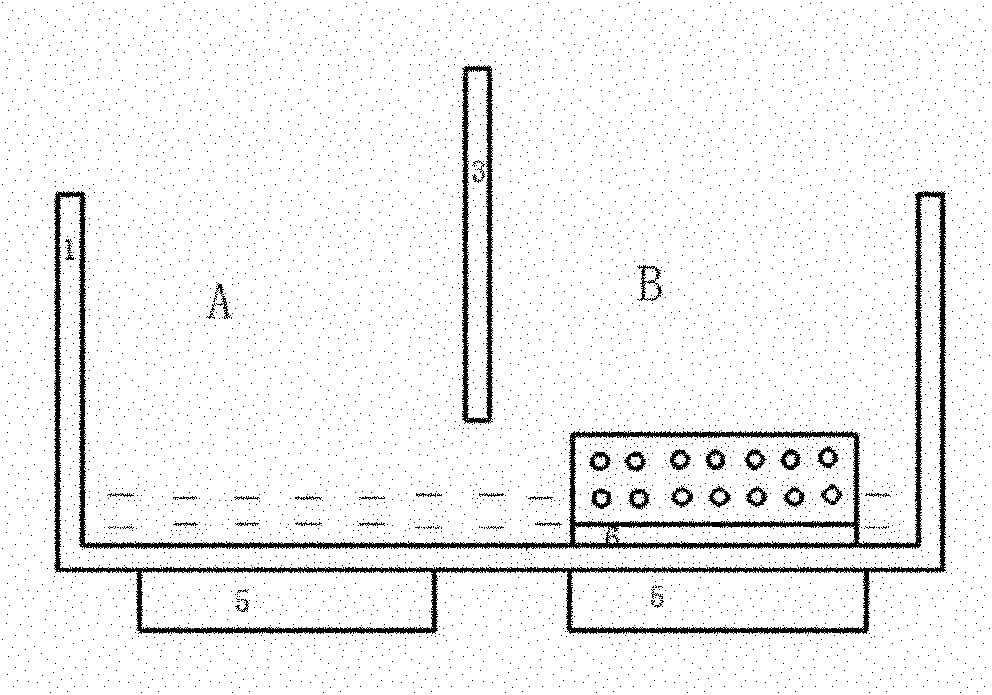

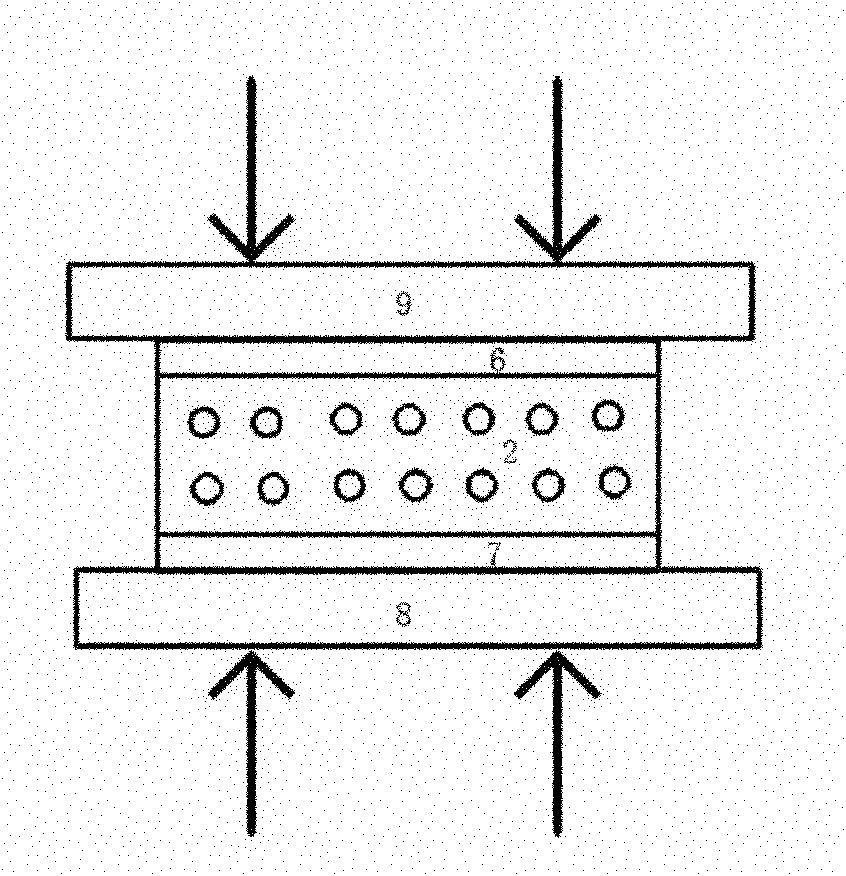

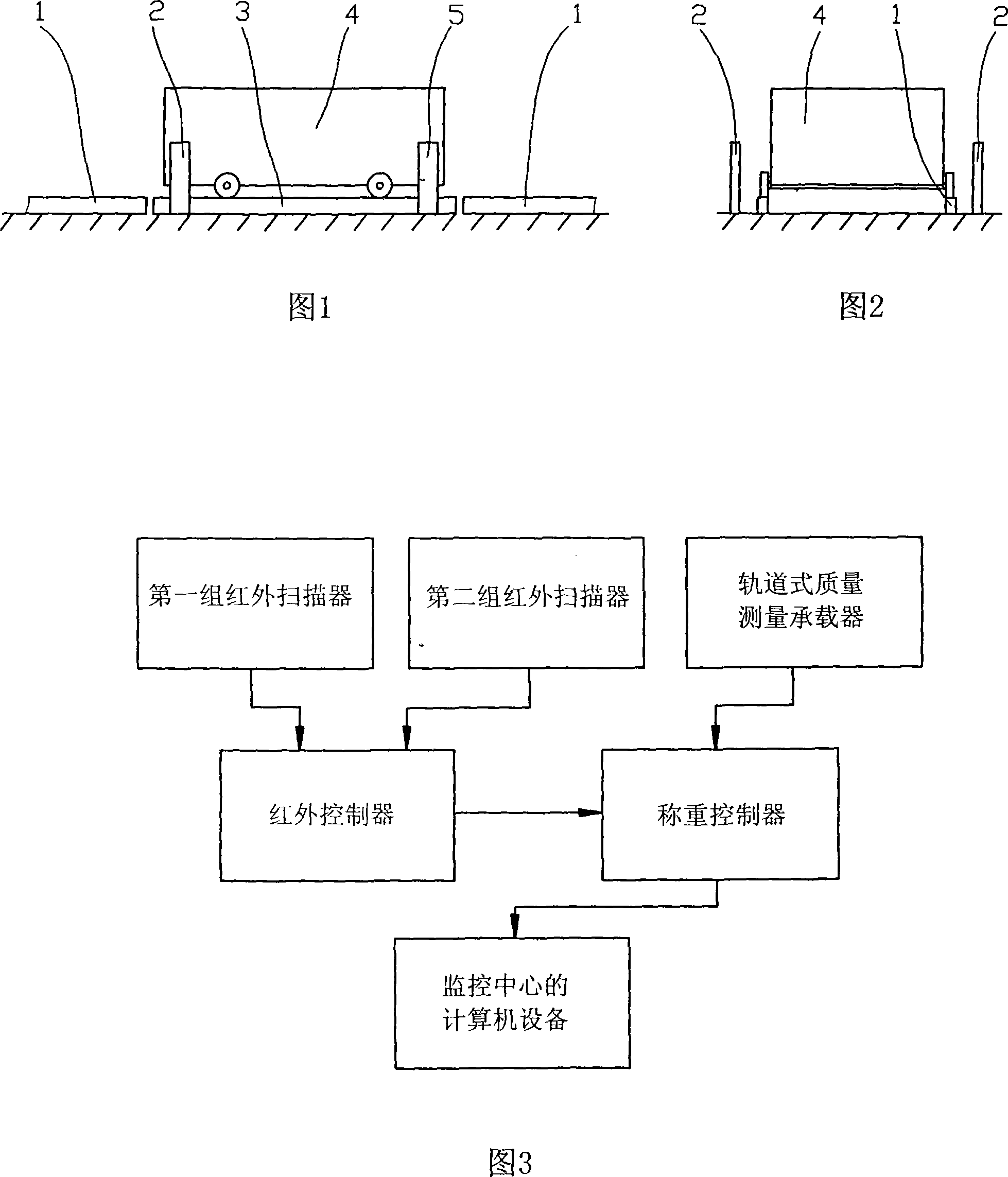

System and method for preventing mine car from evading weighing

InactiveCN101021163AImprove reliabilityDoes not affect normal workMining devicesSpecial purpose weighing apparatusEngineeringTruck

The present invention relates to a system and method capable of preventing miner's truck from evading weighing. Said system is composed of track-type mass measurement loading device, two group of infrared scanners, weighing controller, infrared controller and computer equipment of monitoring centre. Said invention also provides the working principle said system, and also provides the concrete steps of said method.

Owner:重庆大唐科技股份有限公司 +1

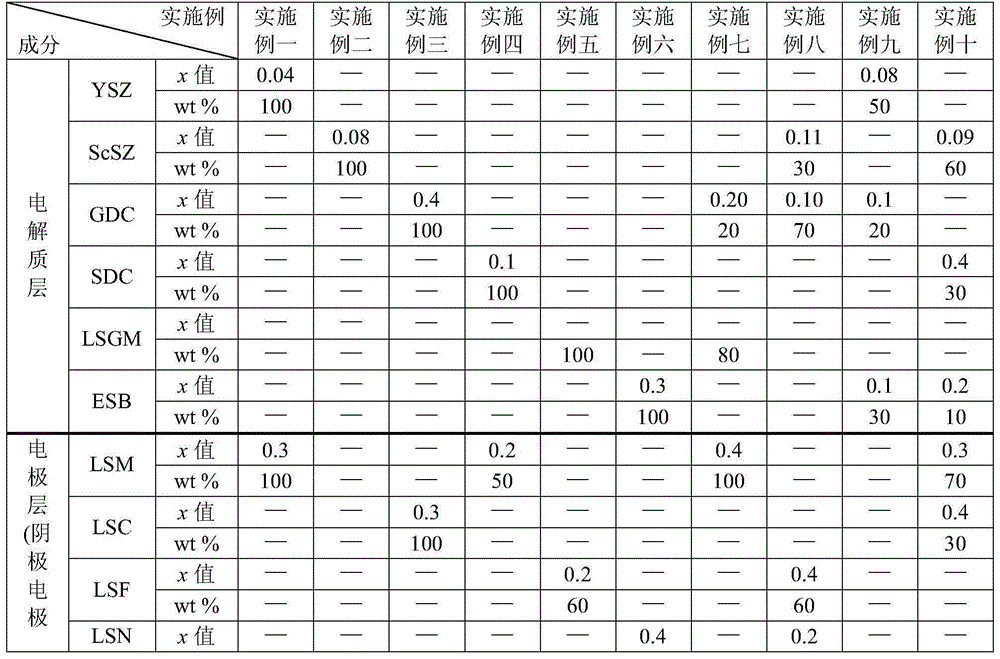

Air-based oxygen-making electrolyte membrane, oxygen-making method and prepared oxygen products

ActiveCN105226295AConvenient and efficient accessSolve the problem that needs to withstand more than 5 times the pressure differenceCell electrodesFinal product manufactureEnergy consumptionElectrolyte

The invention discloses an air-based oxygen-making electrolyte membrane. The electrolyte membrane comprises an electrolyte layer, and a cathode electrode used as an air side electrode layer and an anode electrode used as an oxygen side electrode layer positioned on two sides of the electrolyte layer; and the cathode electrode and the anode electrode have the same compositions. In addition, the invention further discloses an oxygen-making method of the electrolyte membrane and prepared oxygen products. The ionic conductivity of the electrolyte membrane is 100% in selectivity, the electrolyte membrane is dense, and pure oxygen can be obtained conveniently and efficiently; and in addition, the electrolyte membrane is simple in production of device assemblies, high in yield and low in energy consumption, so that breakthrough on the technical bottleneck of demands of most advanced industries on high-purity oxygen is made.

Owner:江西赛瓷材料有限公司

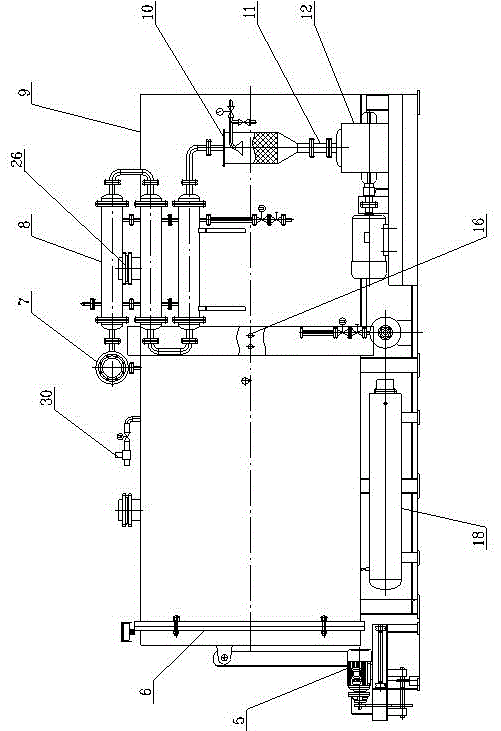

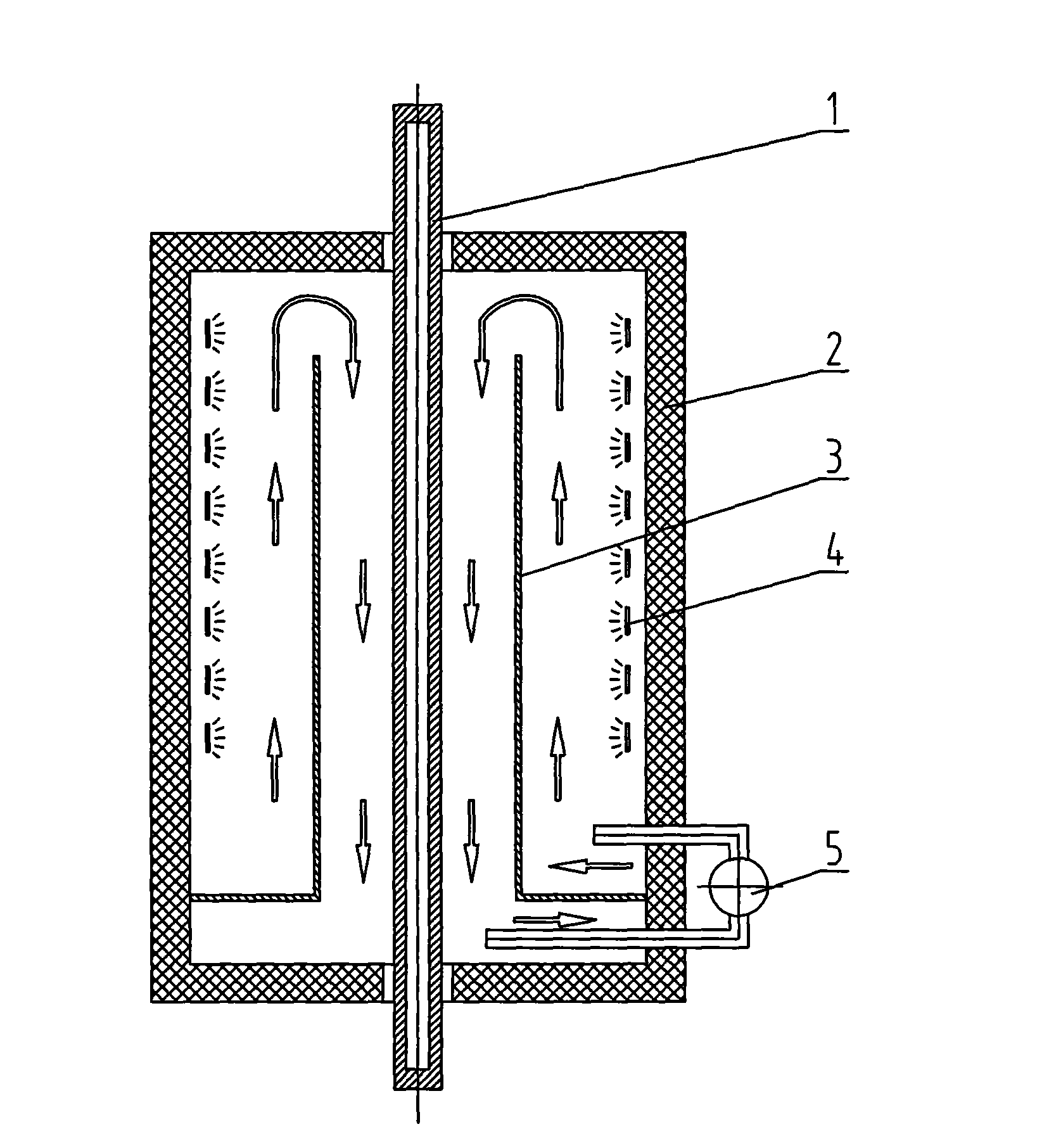

Large-volume vacuum cracking furnace

InactiveCN105617943ASmall temperature fluctuationsEnsure normal dischargeHeat treatmentsPressurized chemical processFiberRecuperator

The invention relates to a large-volume vacuum cracking furnace and belongs to the field of chemical fiber product processing equipment. The large-volume vacuum cracking furnace is characterized in that a track is arranged on a trolley support of the large-volume vacuum cracking furnace; a trolley moves in the extension direction of the track; a trolley driver drives the trolley to move into a furnace shell; a cavity is formed in the furnace shell; an electric heating tube is arranged in the cavity; the furnace shell is connected with a waste gas heater; the waste gas heater is connected with a heat exchanger. The large-volume vacuum cracking furnace provided by the invention has the benefits that gas is supplemented after heating, so that the temperature in the furnace is small in fluctuation, and the cleaning effect is ensured; the gas is exhausted through a vacuum pump after being cooled by two sections of shell and tube type heat exchangers connected in series, so that the use safety of the vacuum pump and the safety of gas exhaust are ensured; as a nitrogen pipeline is arranged in the furnace, when the temperature in the furnace exceeds the standard, a system automatically opens a nitrogen valve and conveys a certain quantity of nitrogen into the furnace, so that a polymer on a cleaning part in the furnace does not burn, that is, the equipment safety is ensured.

Owner:JIANGSU XINLONG CHEM FIBER MACHINERY

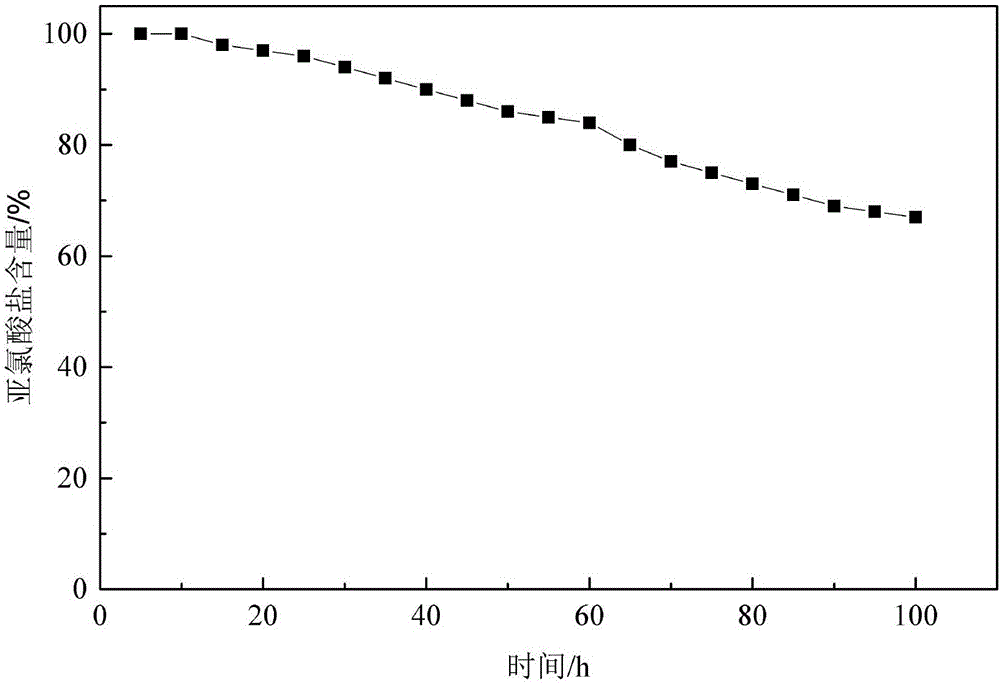

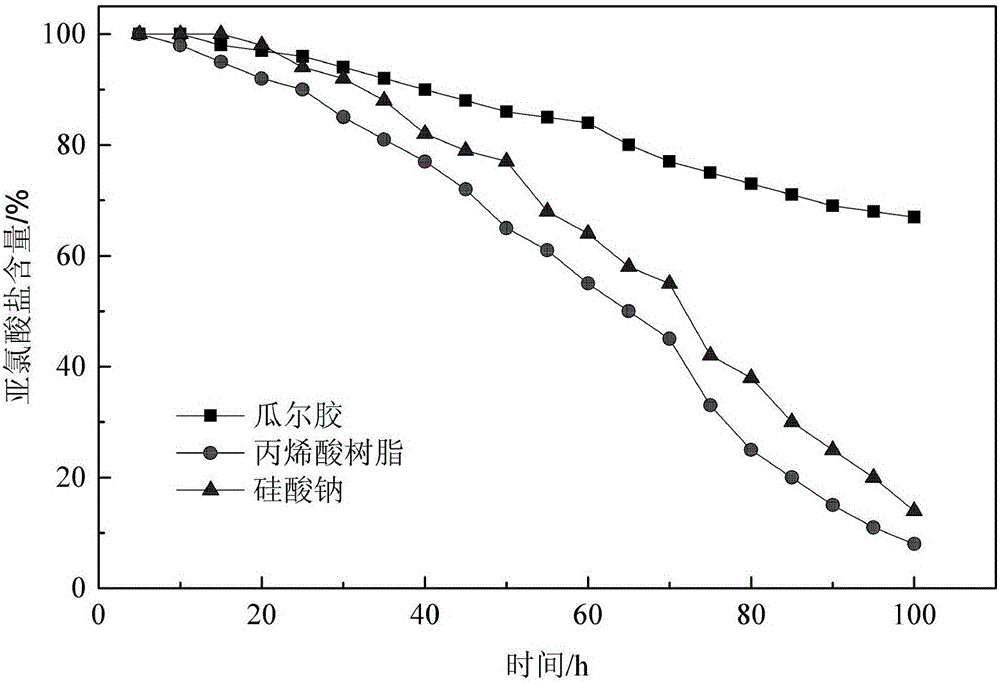

Stable chlorite compound and preparation method thereof

ActiveCN106538599AGood dispersionEasy to transportBiocideDead animal preservationInorganic saltsSolid component

The invention discloses a stable chlorite compound which is prepared from chlorite, guar gum or derivative thereof, a buffer liquid and an inorganic salt. The invention also discloses a preparation method of the stable chlorite compound. In the stable chlorite compound provided by the invention, the chlorite is dispersed and stabilized by the guar gum or derivative thereof, so that the chlorite can be stably stored for a long term under a solid gel state at room temperature. The stable chlorite compound can be conveniently transported and stored, and the safety in storage and transportation processes is promoted; the stable chlorite compound is prevented from explosion and combustion when the stable chlorite compound is mixed with organic matters, is abraded or is impacted; in a use process, when the stable chlorite compound is in contact with activating agents, such as acid, again, the two components can slowly react so as to generate chlorine dioxide; and an acceleration test at 54 DEG C proves that the chlorite content is still more than or equal to 70% after the chlorite solid component is stored for 85 hours at 54 DEG C.

Owner:世倍安生态科技有限公司

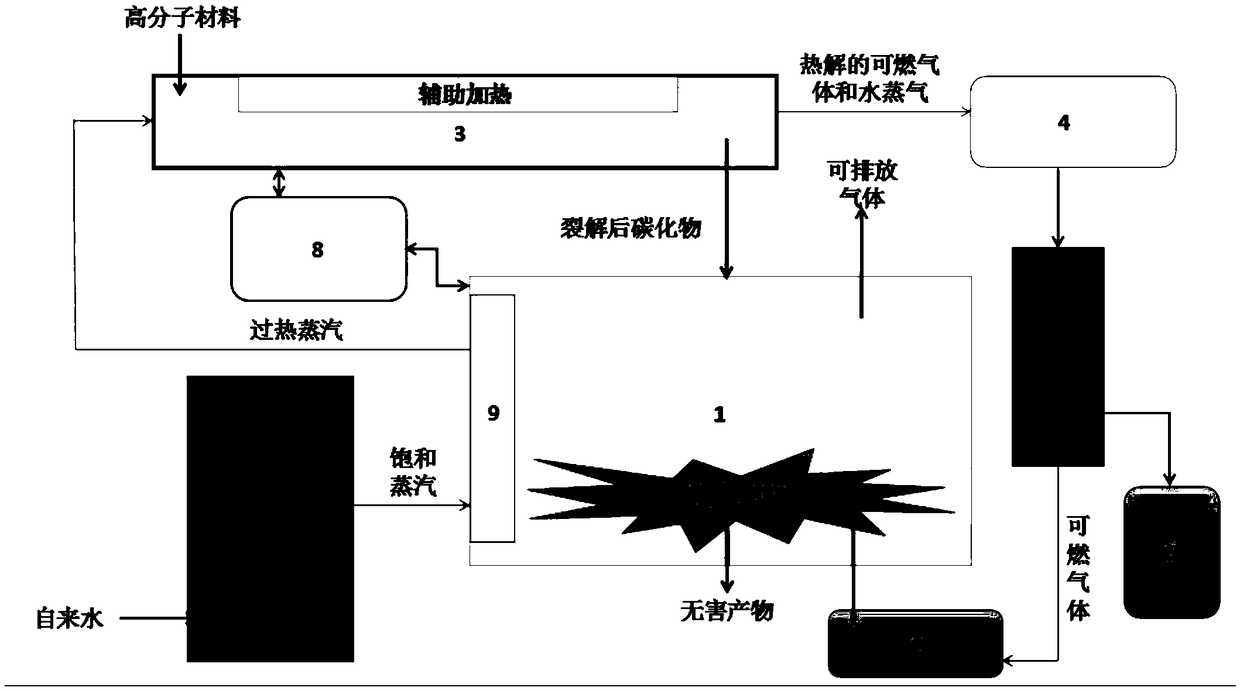

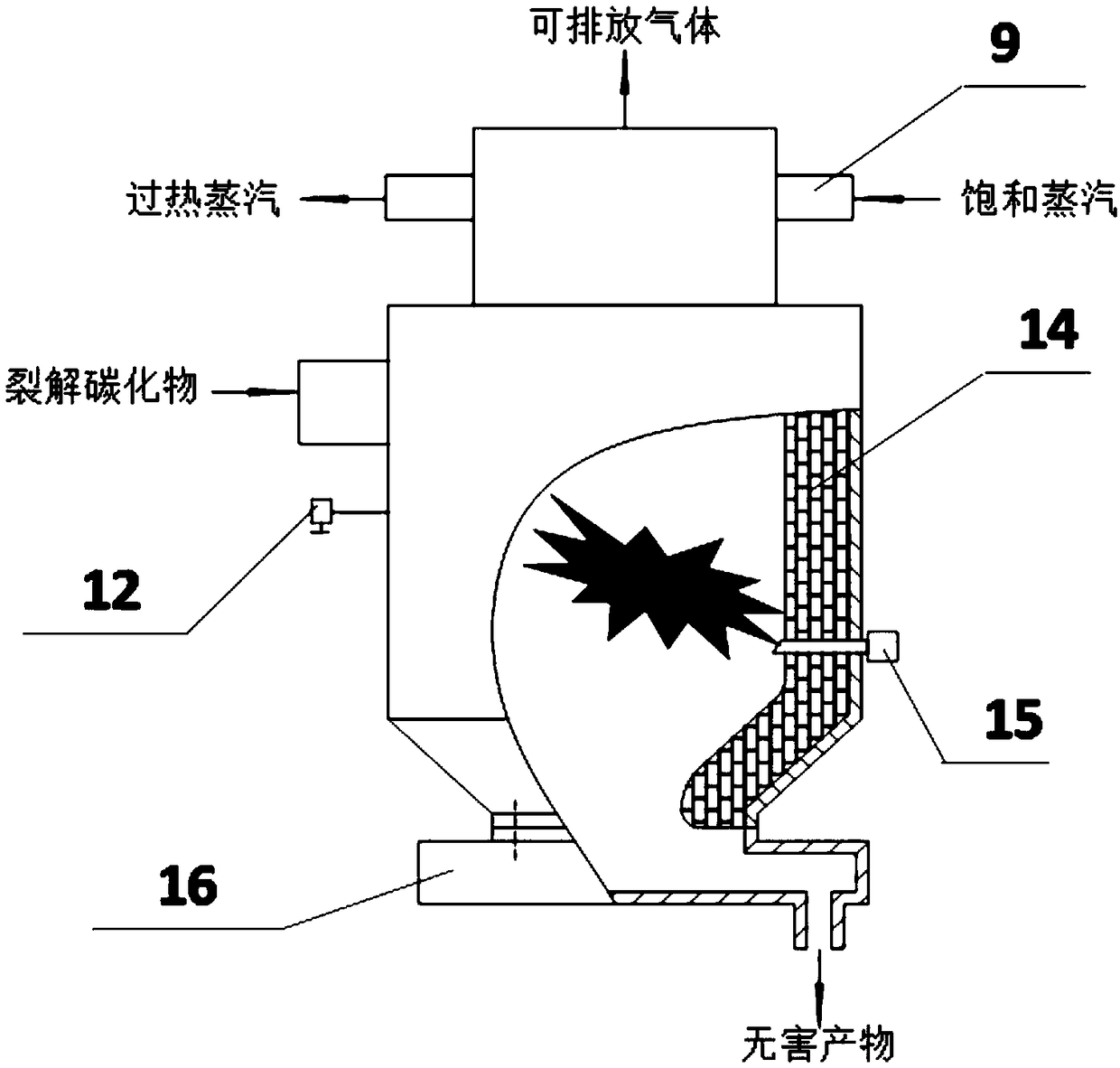

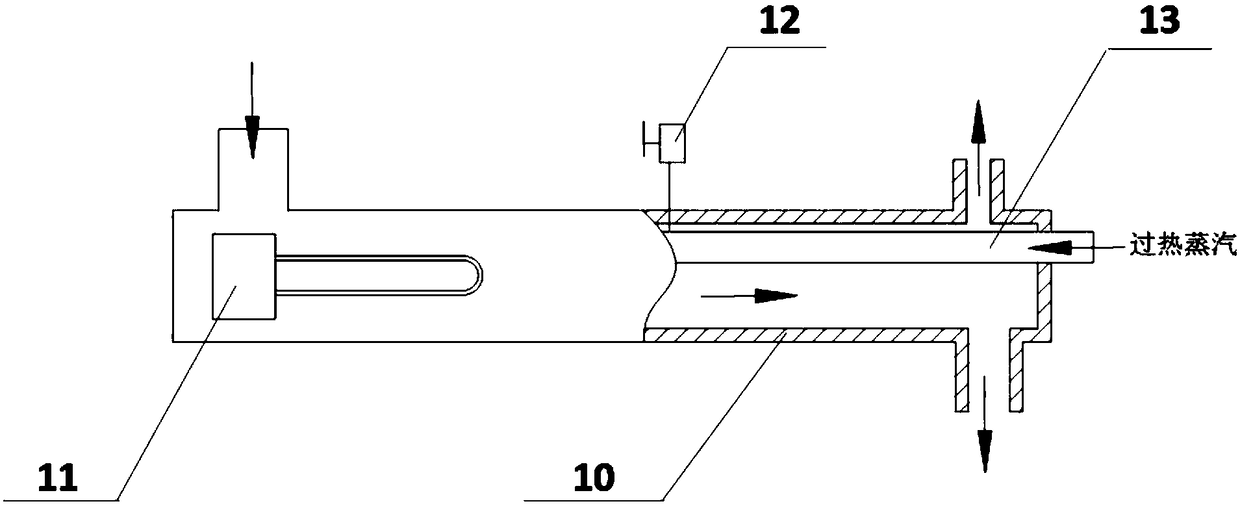

High polymer material continuous treatment method and device

The invention relates to a high polymer material continuous treatment method and device. Overheat steam is utilized as a high polymer material pyrolysis heat source and a fire retardant, the high temperature in a treatment furnace is utilized for heating saturated steam to generate overheat steam at the temperature ranging from 400 DEG C to 900 DEG C, and the oxygen content of the generated overheat steam does not exceed 0.3%; the overheat steam is led into a conveying mechanism, the whole conveying mechanism is kept with the micro negative pressure through an air draft system, it is ensured that in the high polymer material conveying and pyrolysis process, the overheat steam does not leak, the oxygen-free state is kept in the equipment, and the oxidation reaction of the high polymer material in the high-temperature decomposition state is effectively restrained. When the equipment works, the equipment is in the micro negative pressure state, and the system is safe and reliable. The treatment furnace and a steam generator are connected through a pipeline, the overheat steam generated by the equipment provides a necessary heating medium for high polymer material pyrolysis and also becomes the fire retardant for isolating air; and meanwhile, combustible gas and water vapor generated by high polymer material pyrolysis can be recycled and circularly used by the equipment, and accordingly zero emission and zero pollution are achieved.

Owner:上海治实合金科技有限公司

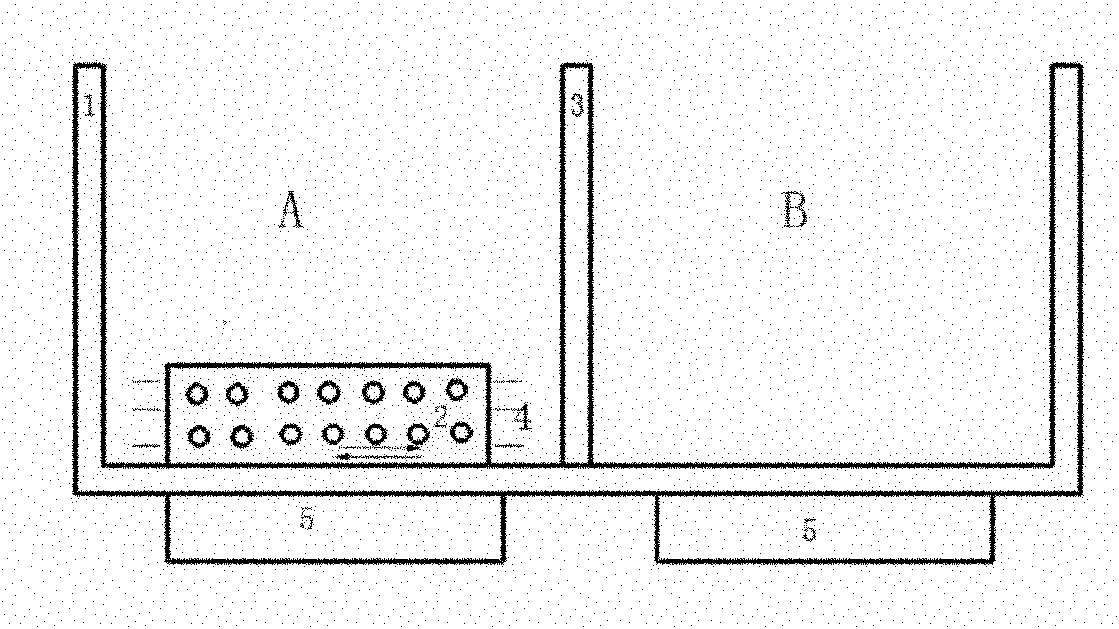

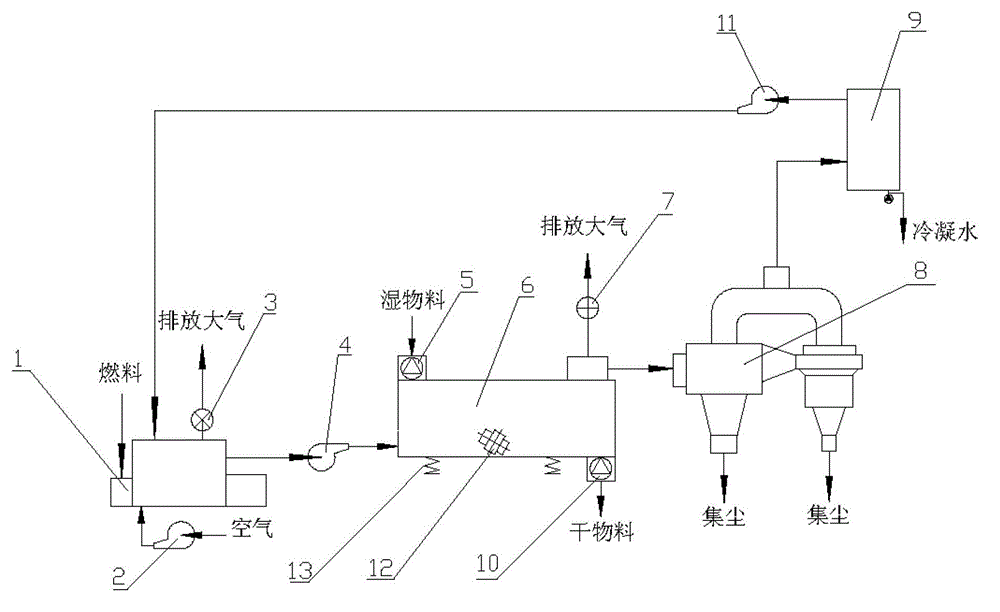

Semi-closed self-inert-type vibrating fluidized drying system

ActiveCN102748922AImprove securityNo burningDrying solid materials with heatDrying gas arrangementsHigh energyProcess engineering

The invention relates to a semi-closed self-inert-type vibrating fluidized drying system, which comprises an inert gas generation device, a vibrating fluidized drying device, a tail gas dust removal purification device and a tail gas condensation purification device which are connected through pipes, wherein the gas outlet of the tail gas condensation purification device is communicated with the inert gas generation device through a pipe. The safety performance of the drying system provided by the invention is good and the problem of burning or explosion is avoided during drying. Besides, the drying system provided by the invention can solve the problems of high energy consumption, poor drying effect, poor dust removing effect and environmental pollution of the existing drying system.

Owner:CHINA SHENHUA ENERGY CO LTD +1

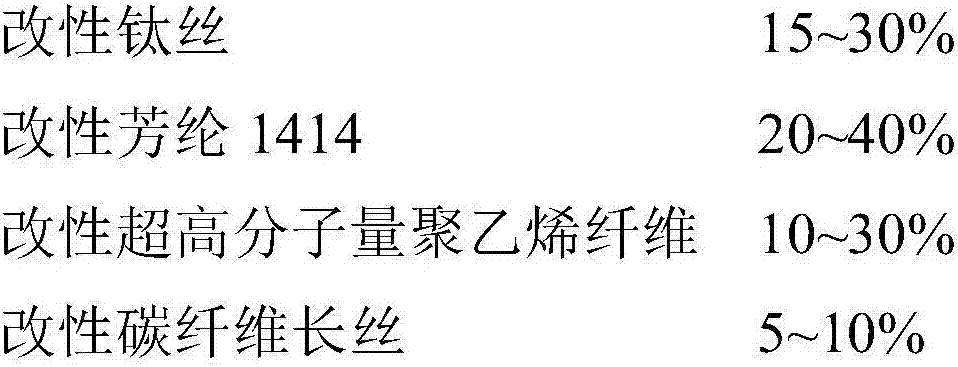

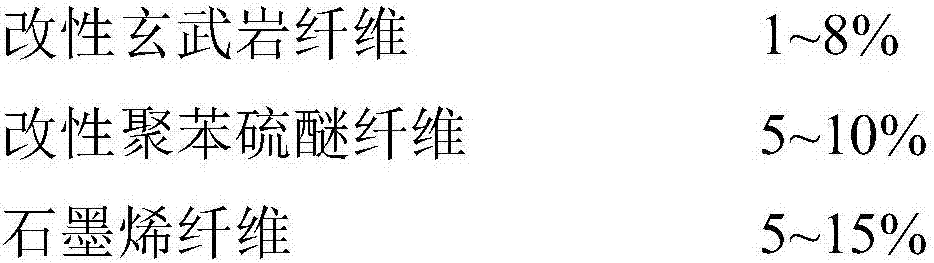

Non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric and preparation method thereof

ActiveCN107059201AHigh strengthSynergistic bulletproofProtective fabricsHeat resistant fibresYarnPolymer science

The invention relates to a non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric and a preparation method thereof, and belongs to the technical field of textile materials and protection materials. Five-strand wires M are prepared from covering yarns A, covering yarns B, covering yarns C and covering yarns D according to the number ratio of the yarns of 1:1:1:2, five-strand wires N are prepared from covering yarns A, covering yarns B, covering yarns C and covering yarns E according to the number ratio of the yarns of 1:1:1:2, the five-strand wires M serve as warp, the five-strand wires N serve as weft, the five-strand wires M and the five-strand wires N are woven to form a fabric, and the fabric is treated to prepare the non-combustible acid-and-alkali-resistant high-temperature-resistant bulletproof fabric. The fabric has collaborative bulletproof function of multiple materials and multiple structures by the aid of yarn structures and special fabric structures, and the fabric is high in strength, good in bulletproof effect and excellent in impact resistance.

Owner:广东军铠防护科技有限公司

Rotary pouring manufacture method of AZ91D magnesium alloy semisolid slurry

The invention relates to a method for preparing AZ91D magnesium alloy semi-solid sizing agent by rotating pouring, which is characterized in that AZ91D magnesium alloy is melted and refined in a smelting maintaining furnace, then cooled to 630-650 DEG C, and insulated for 10-30 minutes; a stainless steel rotating pouring tube is preheated to 60-80 DEG C, with the rotating speed of the pouring tube controlled at 0-105r / min, and the inclination of the rotating pouring tube being 20-30 degrees; then the AZ91D magnesium alloy melt is poured into the rotating tube through a deflection tube; a crystallizer is preheated to 470-500 DEG C; the AZ91D magnesium alloy melt enters the crystallizer through the rotating pouring tube, and insulated for 5-15 minutes. The method for preparing the AZ91D magnesium alloy semi-solid sizing agent by rotating pouring has a simple device, low cost, convenient operation, high practicality; the prepared AZ91D magnesium alloy semi-solid sizing agent has fine grain organization and even distribution; in addition, the process flow is short, the energy consumption is low, the efficiency is high, the equipment is simple, the structure is compact, the applicability is high, and the method is especially applicable to small and medium-sized enterprises of China.

Owner:NANCHANG UNIV

Ash-coke-removal fire-aid anti-corrosion additive for use on fire-side of boiler

The invention is a boiler flame-side dust-cleaning, coke-cleaning, combustion-supporting, corrosion-resistant four-effect additive, belonging to the additive field, and it is a water solution prepared of the following matters: KNO3 5-8wt%, KNO2 2-5wt%, Mg(NO3)2.6H2O 12-15wt%, Cu(NO3)2.3H2O 1.5-2.2wt%, Al(NO3)3.9H2O 2.5-4wt%, H3BO3 0.2-1.3wt% and the rest water. And its advantage is solving the problems of large dosage of coke-cleaning agent, hard to put in, environmental pollution, single effect, etc.

Owner:UNIV OF SCI & TECH BEIJING

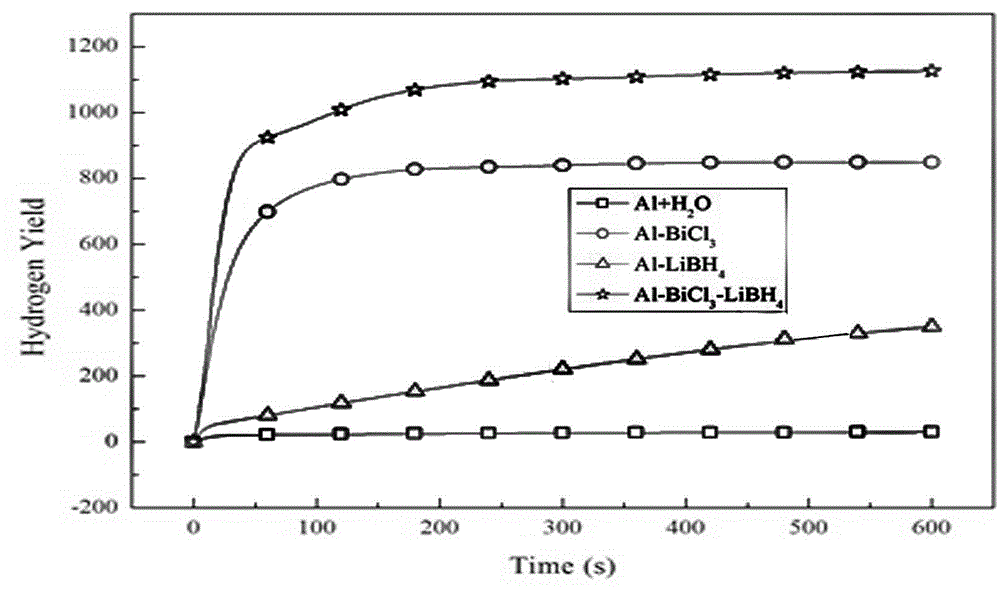

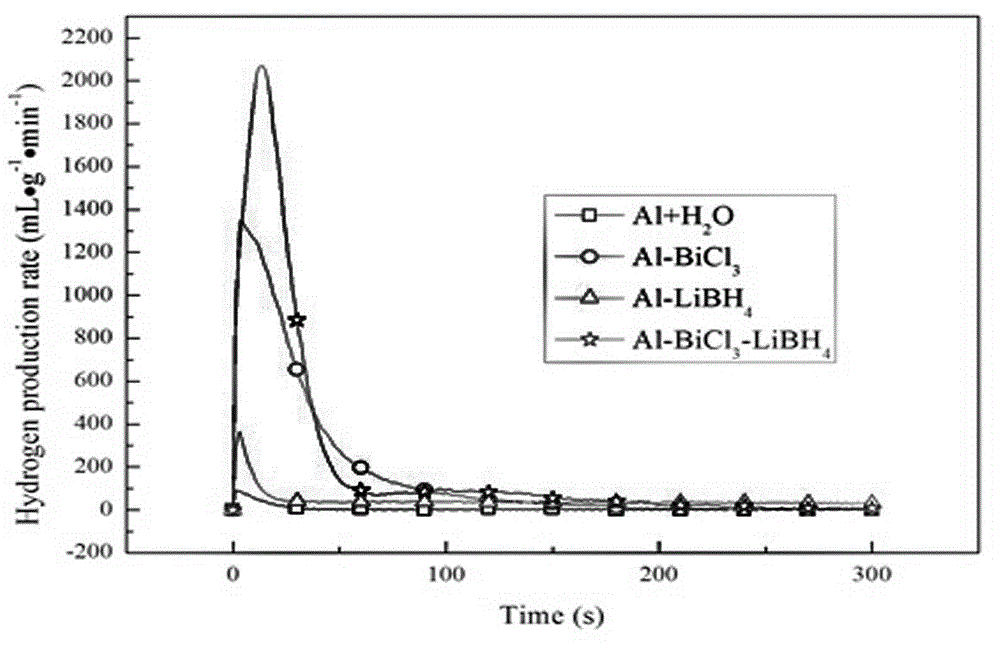

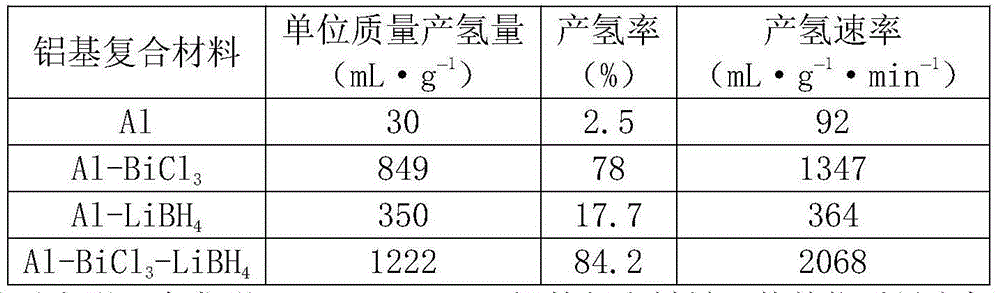

Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material and method for manufacturing same

The invention discloses an Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material and a method for manufacturing the same. The Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material is made of, by weight, 50-95% of aluminum powder and 5-50% of additives by means of ball-milling. BiCl<3> and LiBH<4> are mixed with each other to obtain the additives. The method includes respectively weighing the required aluminum powder, the required BiCl<3> and the required LiBH<4> according to proportions, adding the aluminum powder, the BiCL<3> and the LiBH<4> into a ball-milling tank, adding grinding balls into the ball-milling tank according to a ball-to-material ratio of 20-120:1, sealing the ball-milling tank and filling the tank with argon for protection; placing the ball-milling tank in a ball-milling machine, and carrying out ball-milling for 1-10 hours at the ball-milling rotational speed of 100-500r / min to obtain the Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material. The Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material and the method have the advantages that as proved by tests, the Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material is excellent in hydrogen production performance and low in cost, processes are simple, and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

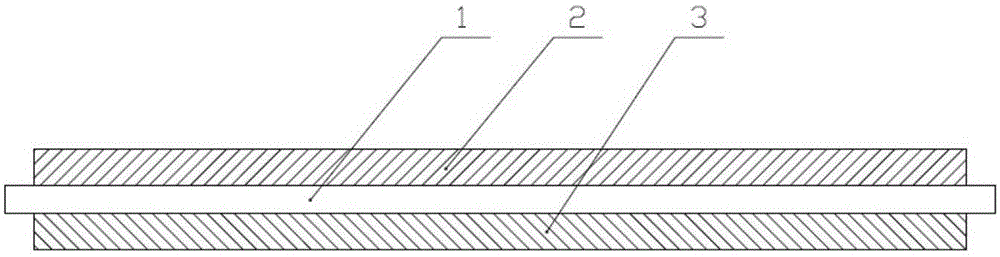

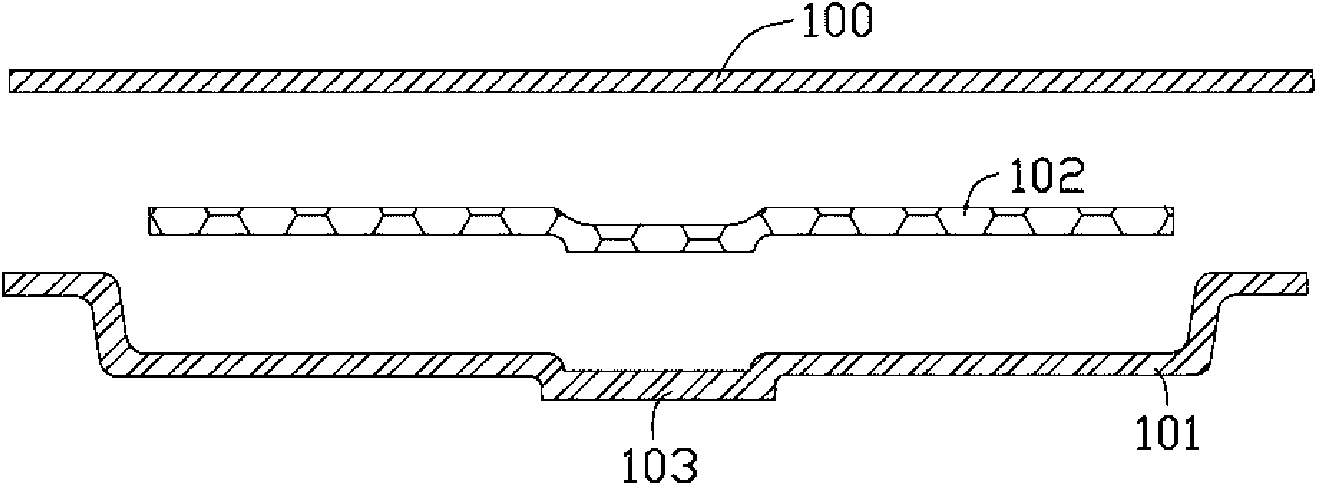

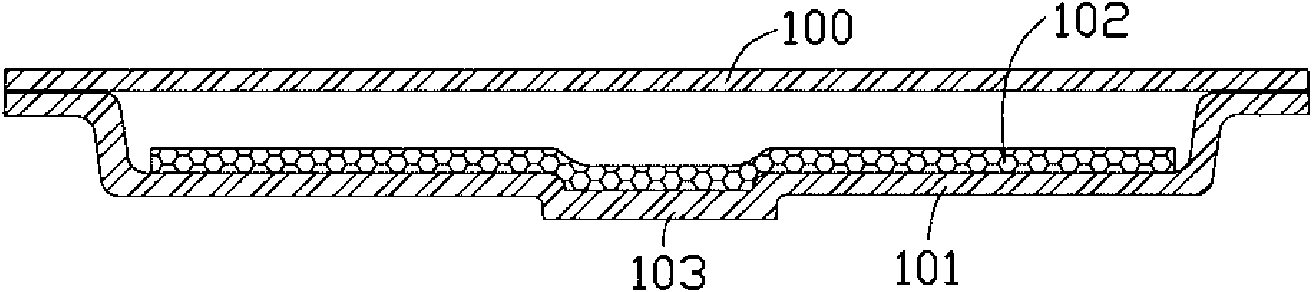

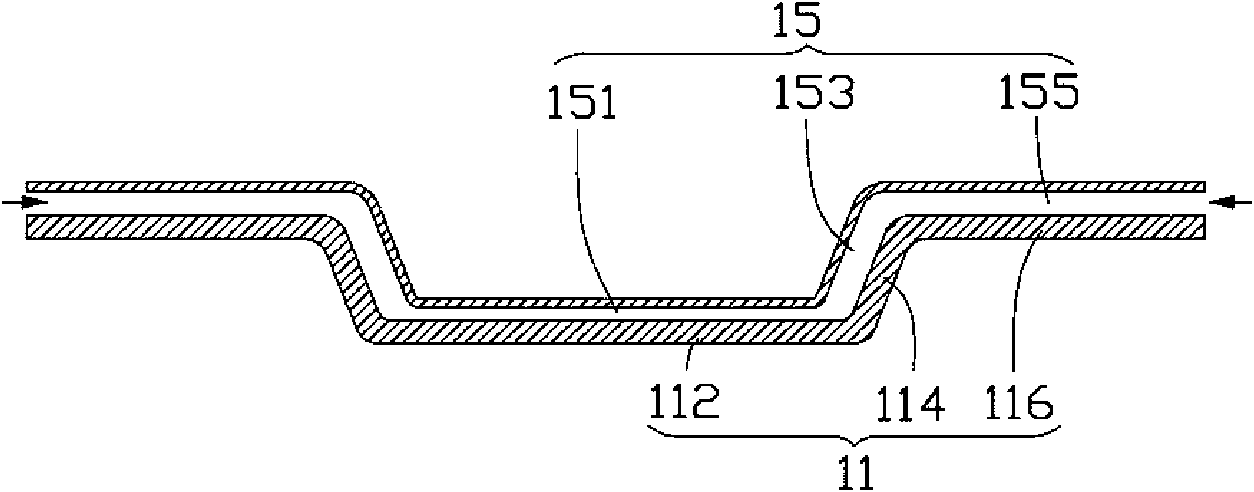

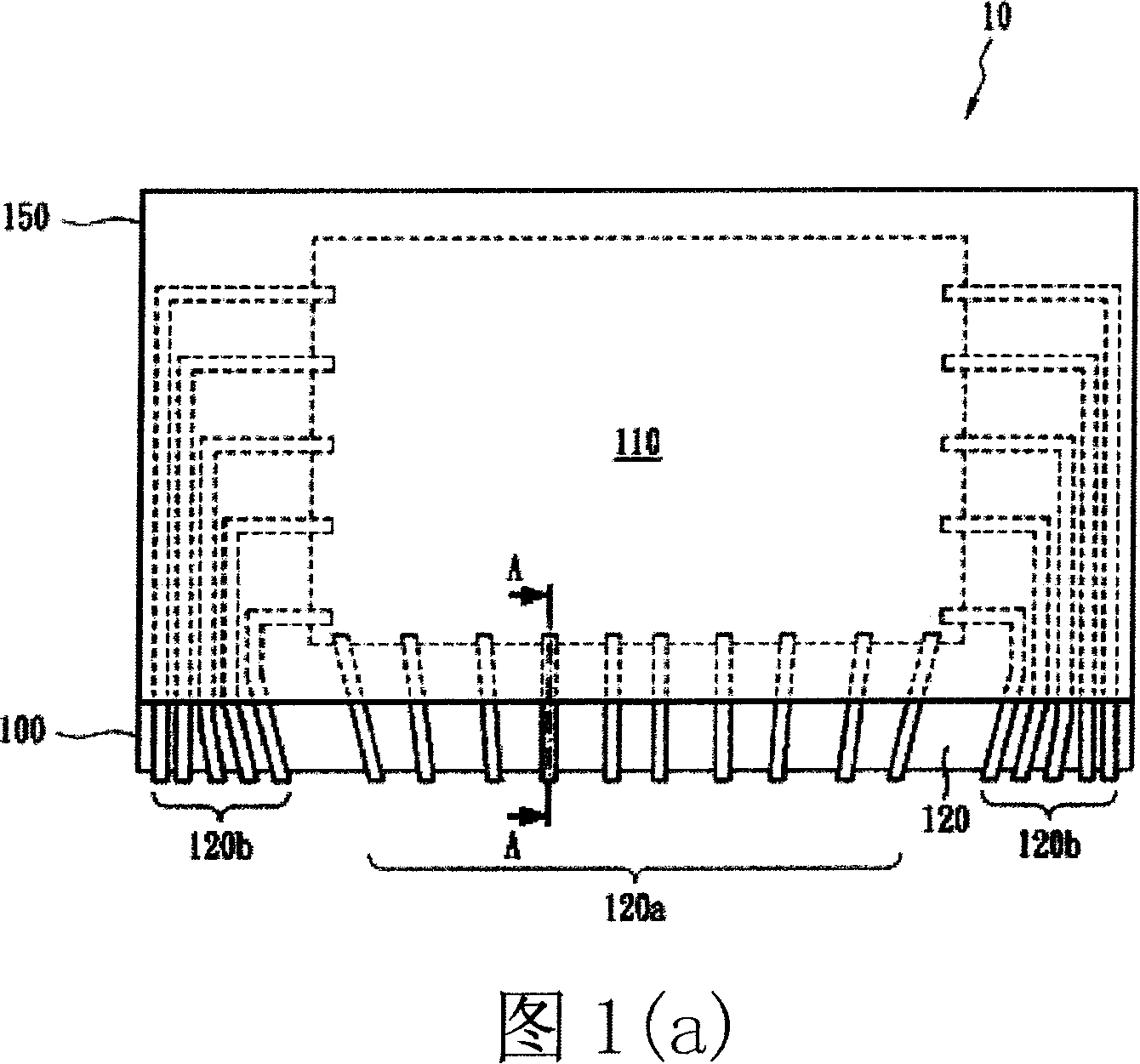

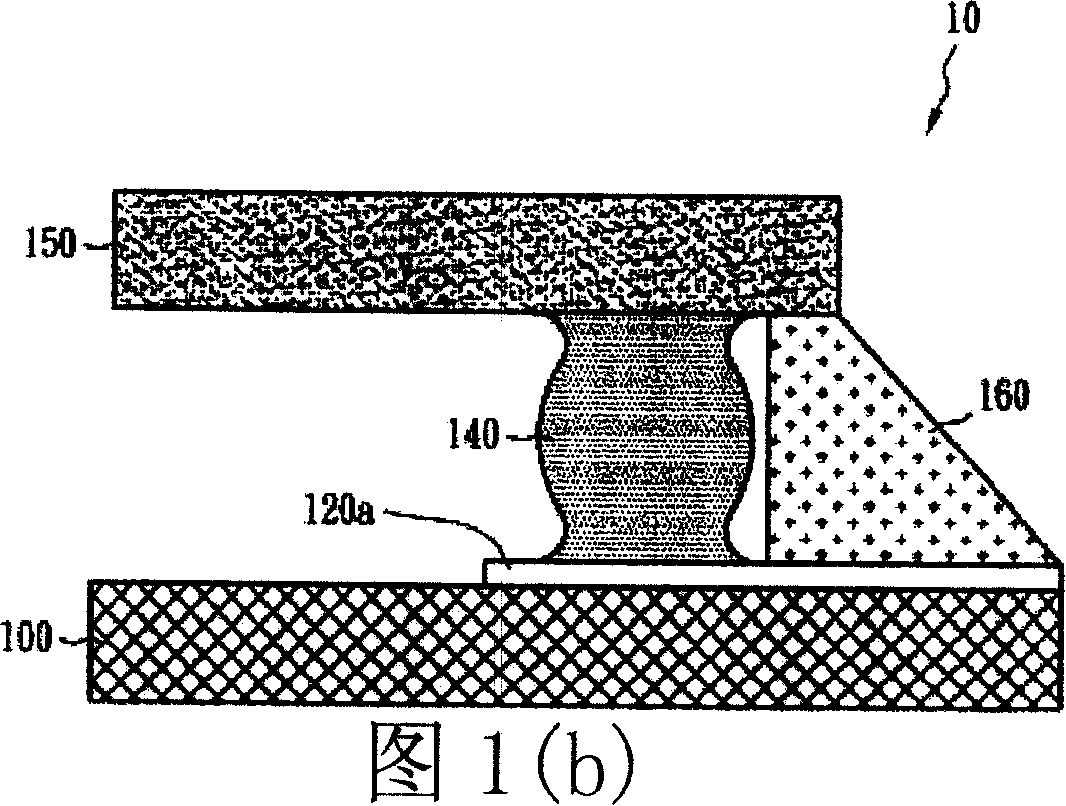

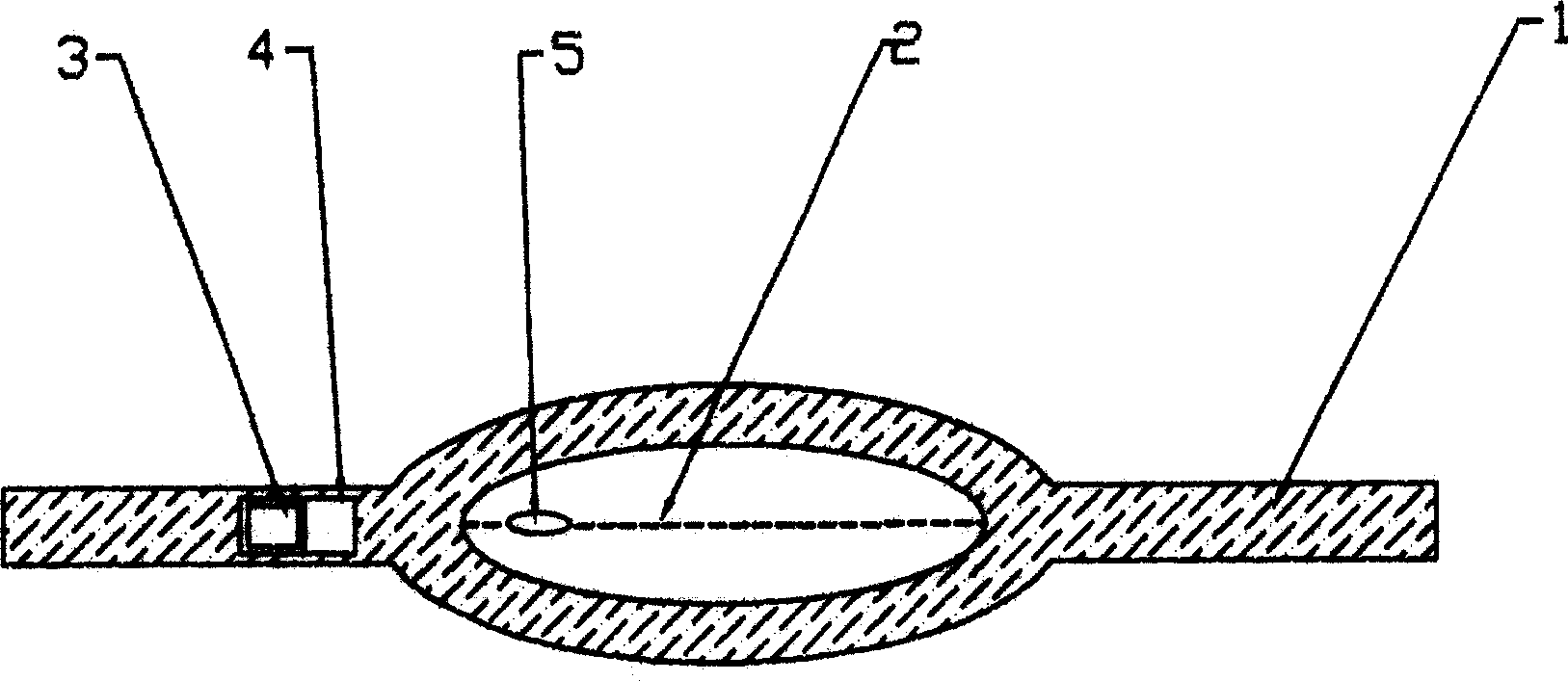

Manufacturing method of capillary structure of flat-sheet heat pipe

InactiveCN101650142AGuaranteed heat transfer performanceNo burningIndirect heat exchangersEngineeringMetal

The invention discloses a manufacturing method of a capillary structure of a flat-sheet heat pipe, comprising the following steps: providing a lower cover board which has a straight heat absorption part and two extension parts extending outwards from the two opposite ends of heat absorption part in a slant way; providing a quantity of metal power; providing a die, which is an inner pore chamber having the outline thereof similar to that of the lower cover board and an opening arranged downwards, and is provided with a first holding section corresponding to the heat absorption part of the lowercover board and a second holding section corresponding to the extension parts with the depth of the first holding section larger than that of the second holding section; filling the metal power intothe die; sintering the lower cover board at high temperature to cause the metal power in the die to be sintered into a continuous capillary structure attached on the upper surface of the lower cover board, wherein the capillary structure comprises a first capillary section attached on the heat absorption part of the lower cover board and a second capillary section attached on the extension parts with the first capillary section being thinner than the second capillary section.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

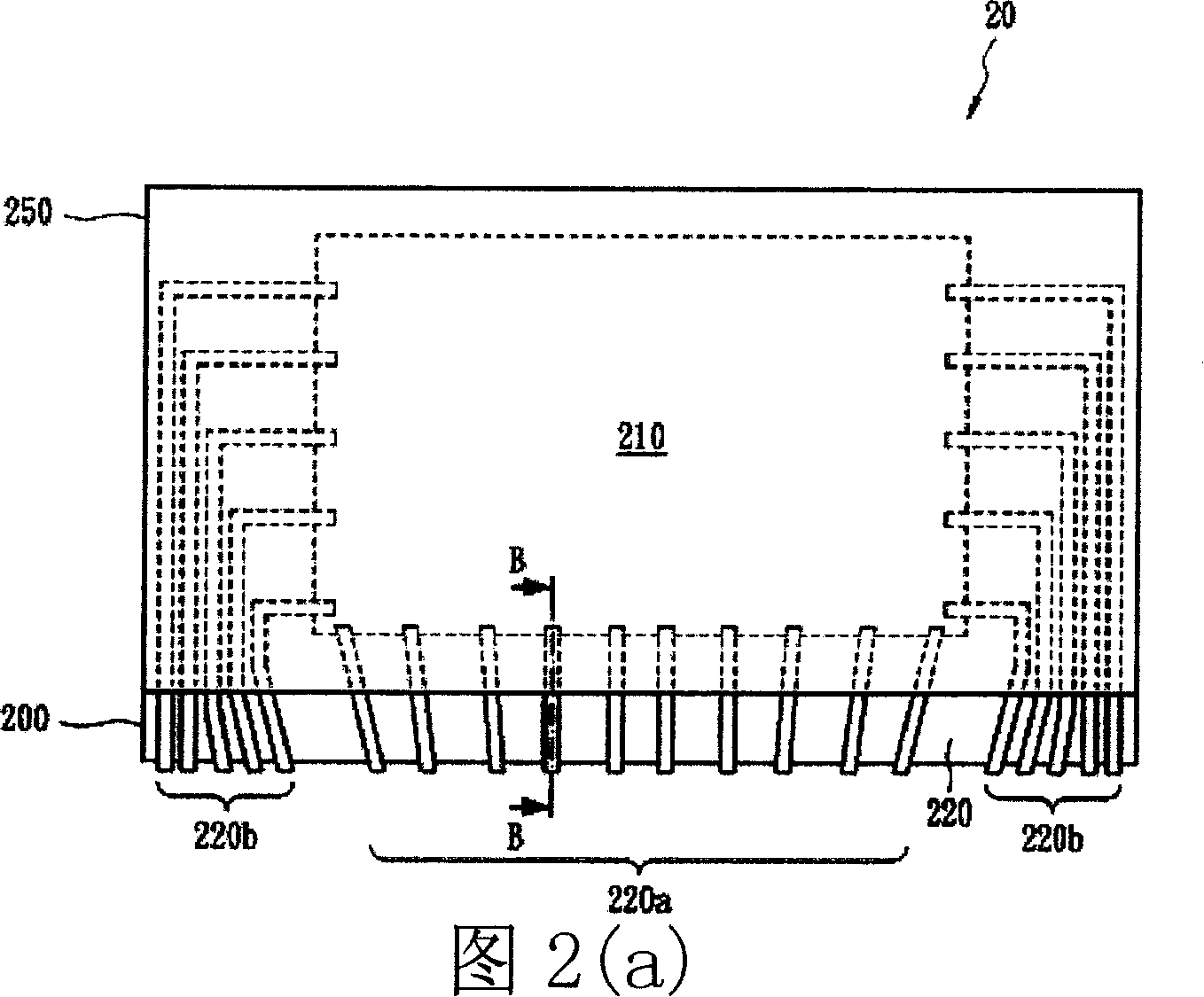

Encapsulation method and structure for OLED device

InactiveCN101154600AStop erosionCorrosion free fromElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

The present invention reveals a packaging method for organic luminescent display device. The packaging method comprises the following steps: firstly, an insulating material layer is covered on part of a conductor area on a substrate so as to coat an anode conductor or a cathode conductor of the conductor area, wherein, the substrate comprises the conductor area and a luminescent area; then the insulating material layer is covered with a first sealing glue layer; subsequently the first sealing glue layer and the luminescent area are covered with an upper cover body; finally, the insulating material layer of the conductor area and the substrate are covered with a second sealing glue layer. As the insulating material layer coats the clad the anode conductor or the cathode conductor, the present invention can completely prevent the inleak of exterior hydrosphere and oxygen, so as to protect the anode conductor or the cathode conductor of the outer conductor area of the first sealing glue layer from oxidative erosion.

Owner:RITDISPLAY

Moulded coal additive

The invention discloses a moulded coal additive, which consists of the following materials with the weight percentage: 0.7 to 1.4 percent of magnesia, 4 to 7 percent of potassium permanganate, 1 to 3 percent of olefin, 2 to 6 percent of potassium chlorate, 2 to 6 percent of potassium nitrate, 2 to 6 percent of sodium nitrate, 3 to 7 percent of manganese dioxide, 0.8 to 2 percent of calcium carbonate, 0.5 to 2 percent of cobalt chloride and the balance of sodium chloride. The adding of the moulded coal additive can lead the moulded coal to be burnt more completely, thereby improving the burning efficiency. The moulded coal additive can lead the sulfur in the moulded coal to participate in burning; while the sulfur which can not be burnt completely can form metallized sulfur and be solidified with soot, deposited with coal slag, and is not discharged with smoke and gas, thus achieving clean burning with non-pollution emission; moreover, all coal boilers do not need to be additionally provided with any attached desulfurizing and dust-removing device and environment-friendly burning can be realized without any limitation.

Owner:唐志刚

High-bonding-strength plate splicing glue and preparation method thereof

InactiveCN106221622AEasy to useImprove stabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl alcoholCarvacryl acetate

The invention discloses high-bonding-strength plate splicing glue and a preparation method thereof. The high-bonding-strength plate splicing glue comprises, by weight, 120-300 parts of vinyl acetate, 60-150 parts of vinyl versatate, 30-120 parts of butyl acrylate, 5-20 parts of acrylic acid, 400-500 parts of deionized water, 50-150 parts of non-phthalate plasticizer, 15-100 parts of polyvinyl alcohol, 2-8 parts of silane coupling agent, 3-5 parts of anionic emulsifier, 3-12 parts of nonionic emulsifier and 1-3 parts of defoamer. The high-bonding-strength plate splicing glue has bonding strength that other binders do not have and is high in adhesiveness and stability, convenient to use and wide in application range. In addition, the high-bonding-strength plate splicing glue has the advantages of being nontoxic, free of peculiar smell, pollution and corrosion, burning-free and free of drawing during coating.

Owner:FOSHAN CITY YONGHENGDA NEW MATERIAL TECH CO LTD

Straw glass fiber fireproof plate section and preparation method thereof

InactiveCN104693829AReduce dosageMake up for the shortcomings of poor wear resistanceSodium PyrithioneSodium pyridinethione

The invention discloses a straw glass fiber fireproof plate section which is characterized by being prepared from the following raw materials in parts by weight: 70-80 parts of crop straws, 3-5 parts of glass fibers, 7-9 parts of a phenolic resin, 4-5 parts of polyurethane, 2-3 parts of zinc borate, 1-2 parts of ammonium polyphosphate, 1-1.5 parts of rosin, 0.4-0.6 part of sodium pyrithione and 10-12 parts of a synergetic filler. The crop straws are taken as a base material of the plate, and the glass fibers, zinc borate and the like are added, so that the fireproof plate section is heat-resistant and flame-retardant; due to the addition of the rosin and sodium pyrithione, insect prevention and rotting protection are realized; due to dual effects of the phenolic resin and polyurethane, the defect that the glass fibers are low in wear resistance is overcome; due to the addition of a modifier prepared by a special process, the flame-retardant property, toughness and wear resistance are further improved; and moreover, the strength of the prepared plate exceeds that of solid wood, fire resistance, moth resistance, rotting protection and moisture prevention are realized, three wastes are avoided in the production process, the amount of the wood is saved, air pollution caused by straw combustion is reduced, and income of the peasants is increased.

Owner:ANHUI JINGLUN HIGH SPEED RAIL EQUIP TECH

Adhesive for textiles and preparation method thereof

InactiveCN106221590AApplicable processingImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCarvacryl acetateTributyl citrate

The invention discloses adhesive for textiles and a preparation method thereof. The adhesive comprises the following components in parts by weight: 120-300 parts of vinyl acetate, 60-150 parts of vinyl versatate, 30-120 parts of butyl acrylate, 5-20 parts of acrylic acid, 400-500 parts of deionized water, 50-150 parts of a non-ortho-benzene plasticizer, and 1-5 parts of an antiseptic. The non-ortho-benzene plasticizer is one of tributyl citrate and diisooctyl sebacate. The adhesive for textiles has bonding strength which is better than the bonding strength of other adhesives, and has the advantages of usage convenience and wide applicability. The adhesive for textiles has the advantages of easily available raw materials, low cost, and simple preparation technology. The adhesive for textiles does not have toxicity, bad smell, pollution corrosion, inflammability, and the like, and gluing of the adhesive does not have wire drawing.

Owner:FOSHAN CITY YONGHENGDA NEW MATERIAL TECH CO LTD

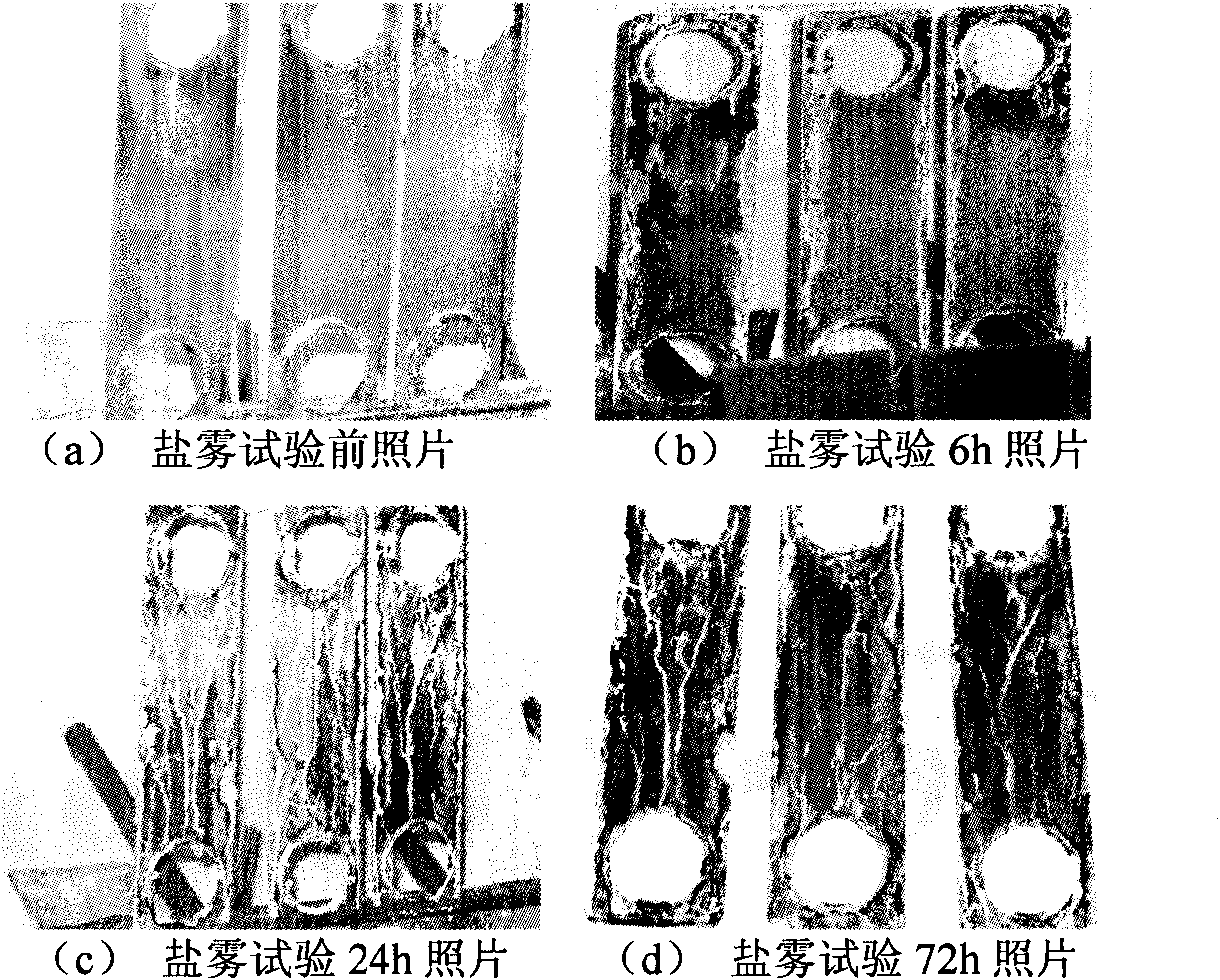

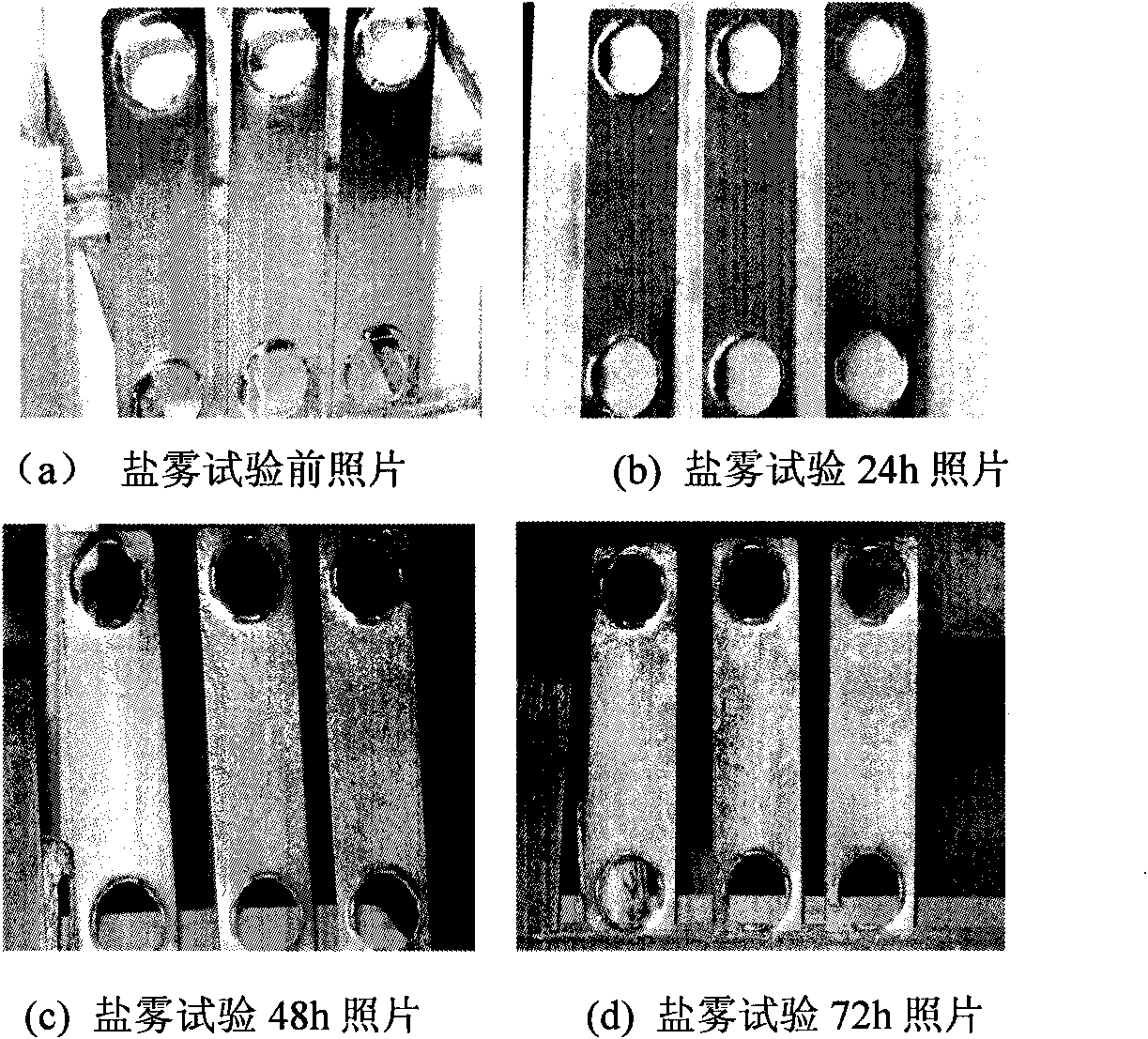

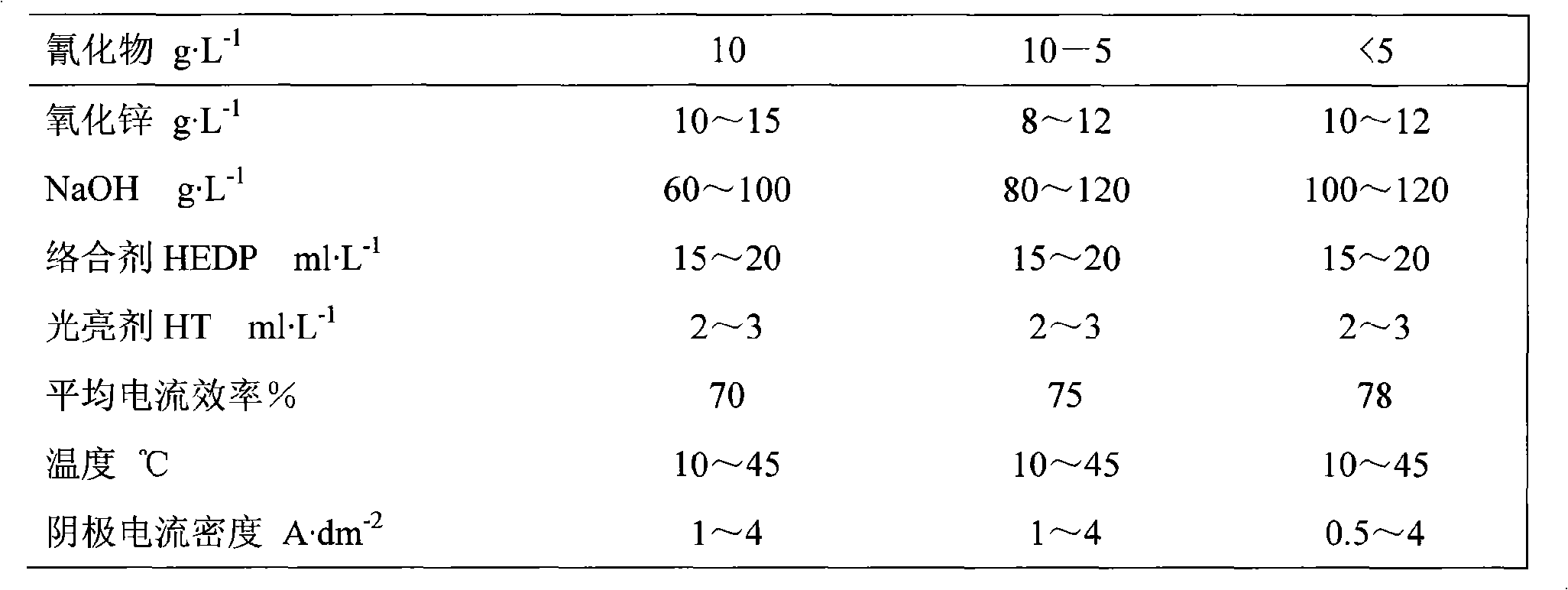

Non-cyanide converting method for cyanide plated zinc

The invention relates to a non-cyanide converting method for cyanide plated zinc. Non-cyanide conversion is as follows: a brightening agent (HT) and a complexing agent (HEDP) are added into plating liquid to carry out zinc plating by stopping adding NaCN and ZnO into the plating liquid. The plating liquid comprises the following components (g*L-1): 10-less than 5 of cyanide, 8-15 of zinc oxide, 60-120 of NaOH, 15-20 of HEDP and 2-3 of HT. The electroplating technical condition comprises the temperature of 10-45 DEG C, the cathode current density (A*dm<-2>) of 0.5-4 and the average current efficiency of 70-78 percent. The corrosion resistance, the bonding capability and the color change resistance of a plating layer completely meet the practical production requirement. The plating liquid has high impurity resistance and is still stable for continuously using for one month. The converted process does not use the cyanide, is easy to process electroplating wastewater and is a more clean production process, thereby replacing a cyanide zinc plating process in a peace way.

Owner:DALIAN MARITIME UNIVERSITY

High-temperature high-pressure kettle air heating device

InactiveCN101664659A⑤ Good temperature uniformityImprove temperature uniformityPressure vessels for chemical processFurnace temperatureInsulation layer

The invention relates to a high-temperature high-pressure kettle air heating device. The prior high-temperature acquisition mode is realized by utilizing the heat convection of conductive oil at homeand abroad and has the following defects of easy leakage, low heat efficiency, poorer controllability, poor furnace temperature evenness, slow temperature increase and decrease and poorer comprehensive performance parameters. The high-temperature high-pressure kettle air heating device comprises a kettle body, a heater, a blower, an insulation layer and an ventilating duct, wherein the insulationlayer comprises an outer layer, a middle insulation cotton layer and an inner layer plate; the kettle body is arranged on the central axis of the device; an air duct is arranged between the kettle body and the external insulation layer and is divided into an inner air duct and an outer air duct by the ventilating duct; the outer air duct is internally provided with the heater; and an air outlet ofthe inner air duct and an air inlet of the outer air duct are arranged at the lower end of one side of the insulation layer and communicated by the blower to form a hot air circulating passage. The invention has little heat loss, low heat efficiency, less repairing points, stronger controllability, good furnace temperature evenness, rapid furnace temperature increase and decrease and favorable comprehensive performance parameters.

Owner:XIAN ELECTRIC FURNACE INST

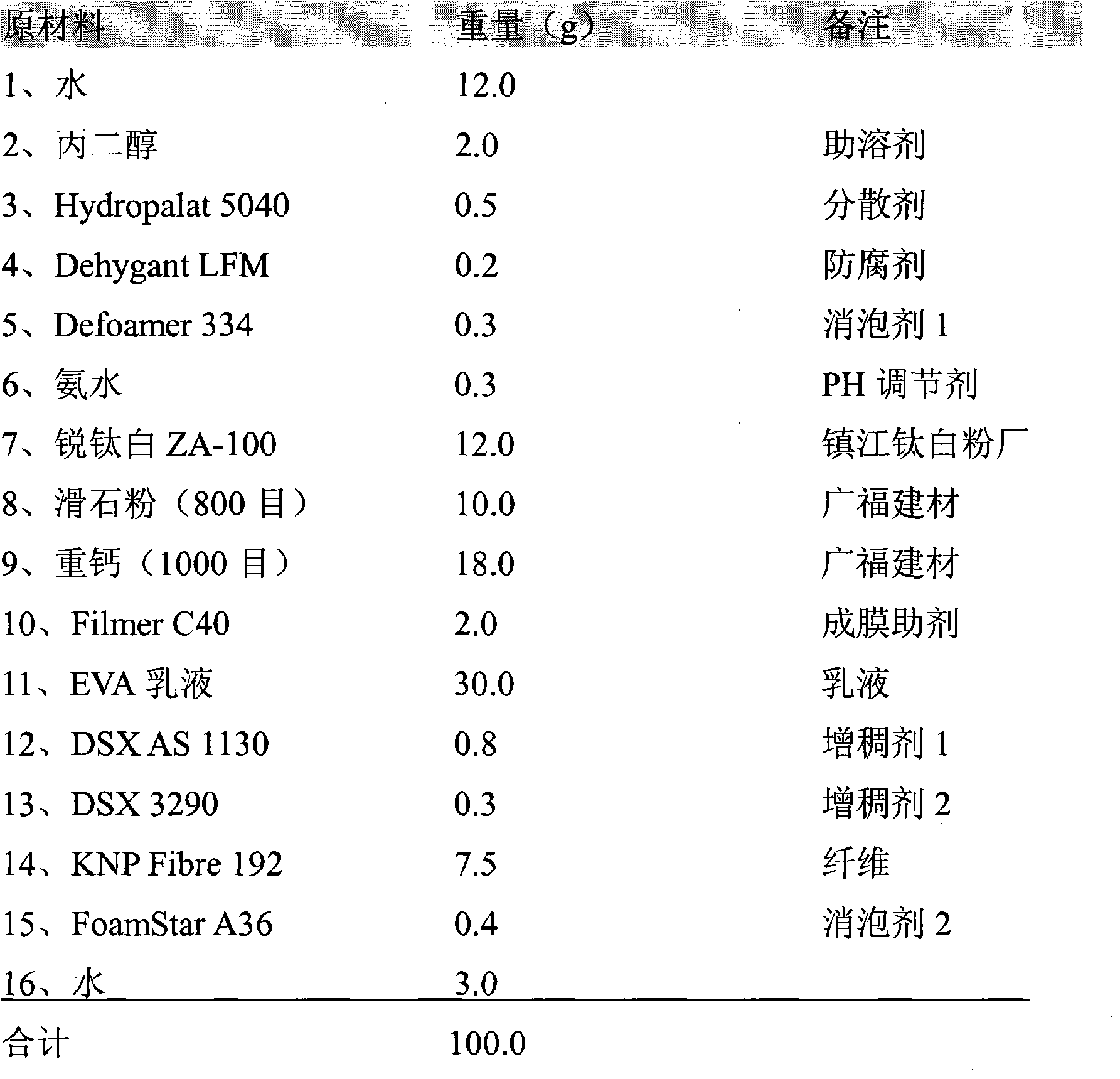

Pasty fibre art designing coating and preparation thereof

InactiveCN101328334AImprove settings stabilitySolve the problem of the stability of the brushed coatingArtist's paintsFiberPolymer science

The invention discloses pasty fiber paint and a preparation method thereof. The pasty fiber paint is prepared from latex, pigment, a filler, antifoaming agents, an anticorrosion agent, a PH regulator, thickeners, a disperser, a film forming auxiliary agent, a flux, fibers and water which are mixed. The preparation method comprises the following steps of: A. mixing and stirring the flux, the disperser, an antifoaming agent 1, the anticorrosion agent and the PH regulator and 80 percent of the water, adding the pigment and the filler into the mixed material during the stirring process, and then carrying out dispersing and grinding at a rotation speed of between 1, 500 and 3, 500rpm to obtain slurry material; B. adding the latex and the film forming auxiliary agent in turn into the slurry material, adding a thickener 1 and a thickener 2 after even agitation, and regulating viscosity to between 115 and 120KU to obtain a paint material; and C adding the fibers into the paint material, adding an antifoaming agent 2 and the rest 20 percent of the water after even agitation, defoaming, and obtaining the product. The pasty fiber paint which is used for interior wall decorating and painting solves the problems that: an elastic hacking film has poor resistance to stain and a rigid hacking film is easy to crack and causes water seepage.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

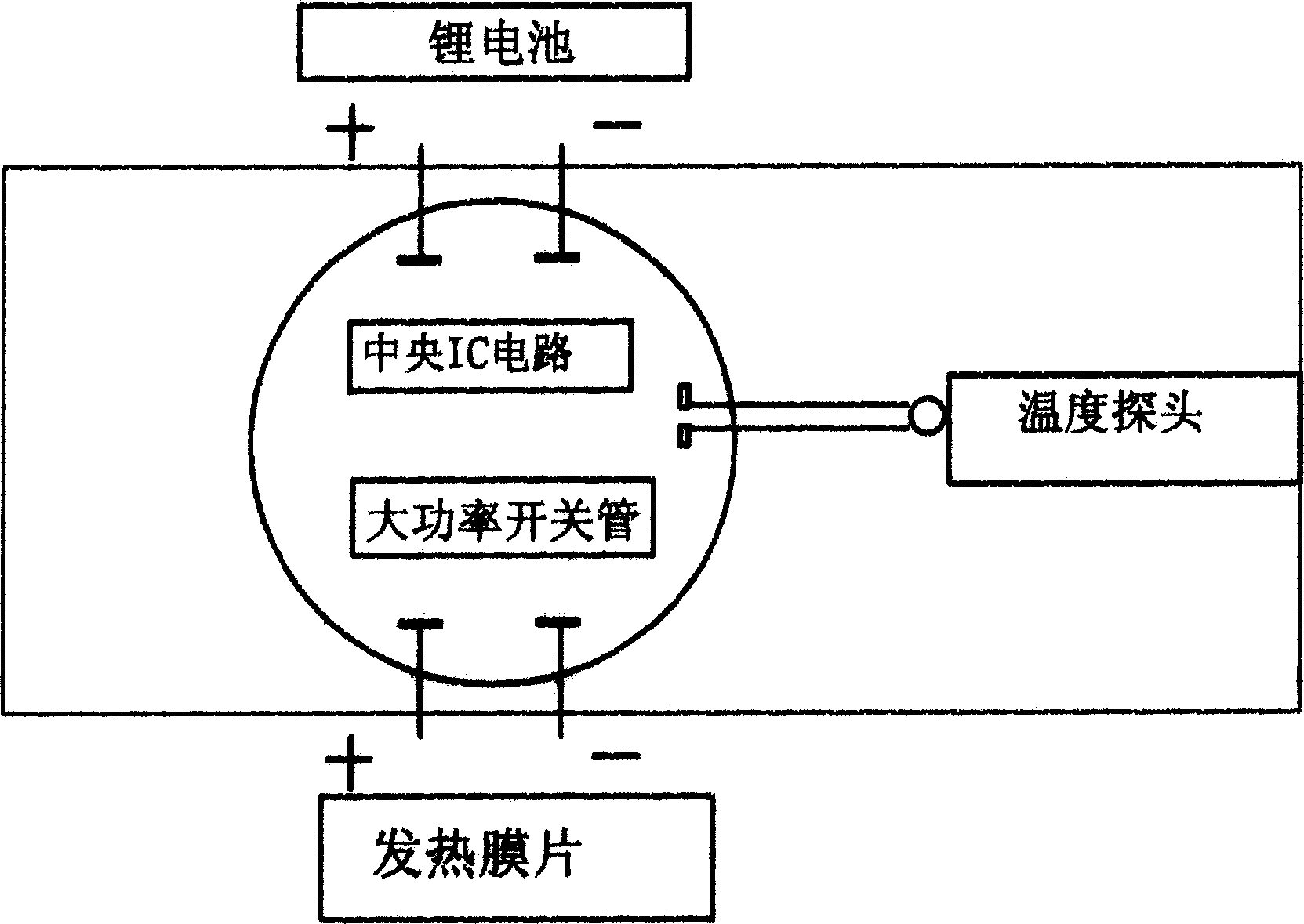

Convenient safety electric heating body heater

InactiveCN1647782ANo deformationIncrease temperatureOhmic-resistance heatingTherapeutic coolingCarbon filmAutomatic control

The convenient and safe electrical heater includes surface cloth layer, inside electric heating layer and rechargeable battery. The electric heating layer has base layer of plastic, heating material of screen printed thin carbon film conducting part of screen printed silver powder. The rechargeable battery is solid lithium-polymer battery with built-in short-circuit protecting circuit. The control circuit board set between the electric heating layer and the battery has temperature probe comprising IC, great power switching transistor and thermistor. The present invention may be produced into waist protecting belt, knee pad or stomach protecting belt. The present invention has the advantages of automatic temperature control, convenient use and safety.

Owner:郑大清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com