Semi-closed self-inert-type vibrating fluidized drying system

A drying system, vibration fluidization technology, applied in drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of low drying rate, poor air tightness, uneven airflow distribution, etc., to achieve good safety , Solve the effect of large energy consumption and poor dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

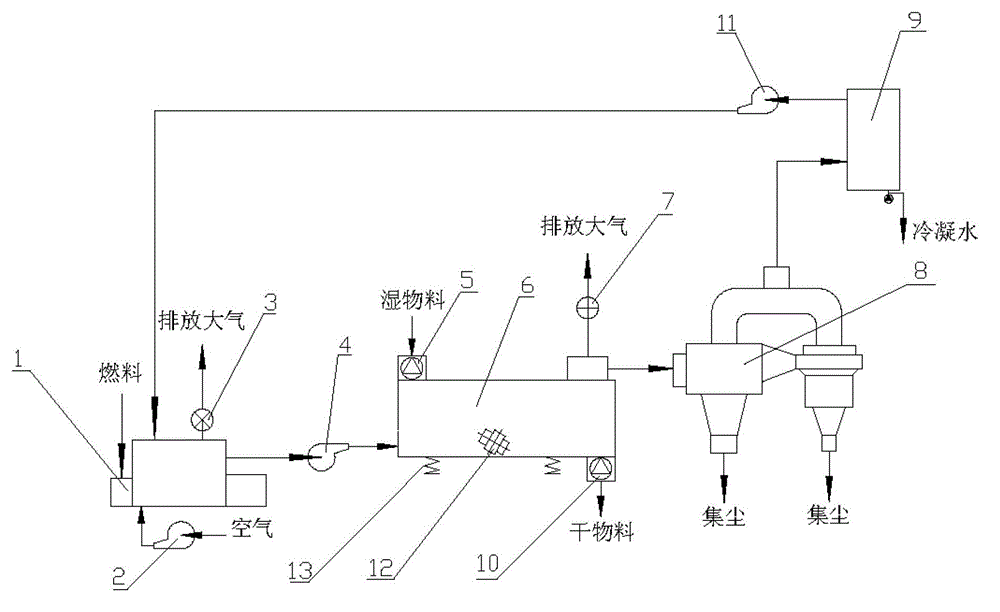

[0090] The semi-closed self-inert vibrating fluidized drying system includes a blower 2, an inert gas generating device 1, an induced draft fan 4, a vibrating fluidized drying device 6, an exhaust gas dust removal and purification device 8, an exhaust gas condensation purification device 9 and An induced draft fan 11, and the outlet of the induced draft fan 11 communicates with the inert gas generating device 1 through a pipeline. The vibrating fluidized drying device 6 is purchased from Qianjiang Drying Co., Ltd., and its model is GZQ.

[0091] The fuel (specifically, coal) entering the inert gas generating device 1 (hot stove) is combusted together with the air input into the inert gas generating device 1 through the blower 2, thereby generating dry gas. When the oxygen content in the dry gas is lower than 8% through the monitoring device for measuring the oxygen content inside the hot blast stove 1, the dry gas at this moment is a qualified inert gas, which contains a large...

Embodiment 2

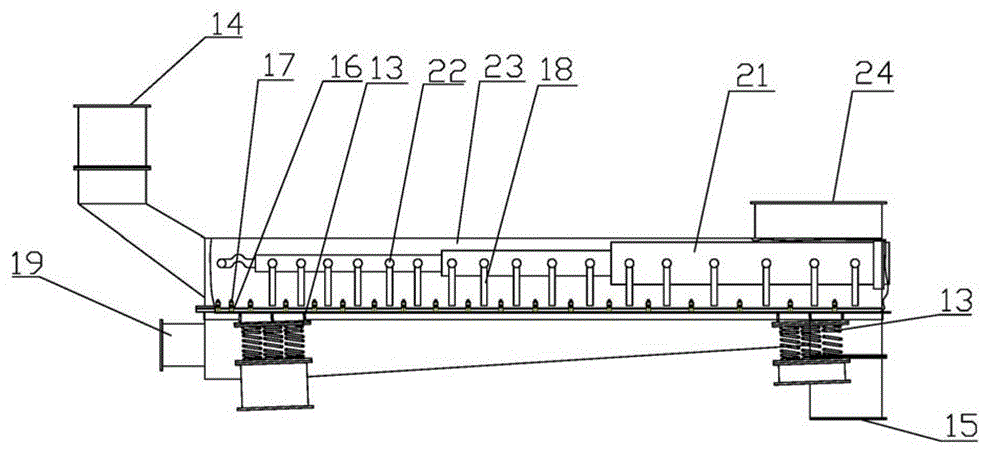

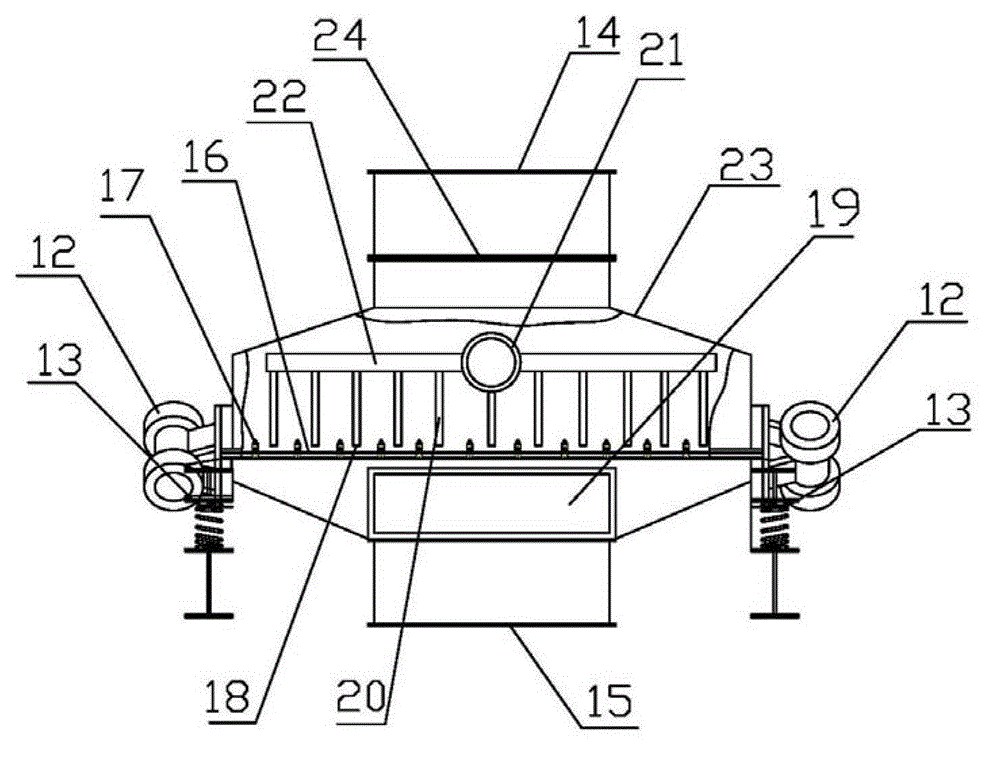

[0094] The semi-closed self-inert vibrating fluidized drying system includes a blower 2, an inert gas generating device 1 (with a vent valve 3), an induced draft fan 4, a vibrating fluidized drying device 6 (with an explosion relief device) connected in sequence through pipelines 7) Tail gas dust removal and purification device 8, tail gas condensation purification device 9 and induced draft fan 11, and the outlet of induced draft fan 11 communicates with the inert gas generating device 1 through a pipeline. The vibrating fluidized drying device includes: a bed body 23 with a shell and a drying bed 16 placed therein; an exciting motor 12 is arranged at its center of gravity, and vibration isolation springs 13 are arranged at its four corners; the bed One end of body 23 is provided with material inlet 14, and is provided with the material inlet feed valve 5 that can isolate air; The other end of described bed body 23 is provided with material outlet 15, and is provided with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com