Air-based oxygen-making electrolyte membrane, oxygen-making method and prepared oxygen products

A technology of electrolyte membrane and oxygen production method, which is applied in the field of solid-state ionics, can solve the problems of high difficulty in reconciliation, high energy consumption, and high energy consumption, and achieve the effects of reduced design difficulty, dense electrolyte membrane, and reduced strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiment of the present invention is an electrolyte membrane based on air oxygen generation, such as figure 1 As shown, it includes an electrolyte layer 1, and a cathode electrode 2 as an air-side electrode layer and an anode electrode 3 as an oxygen-side electrode layer located on both sides of the electrolyte layer. Wherein, the composition of the cathode electrode 2 and the anode electrode 3 of the electrode layer is the same.

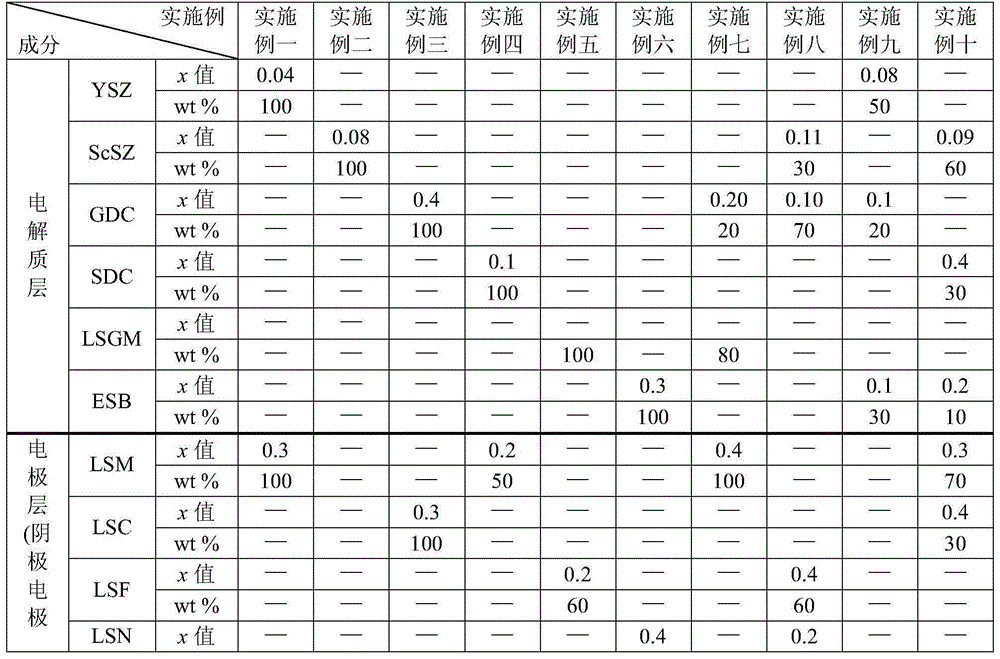

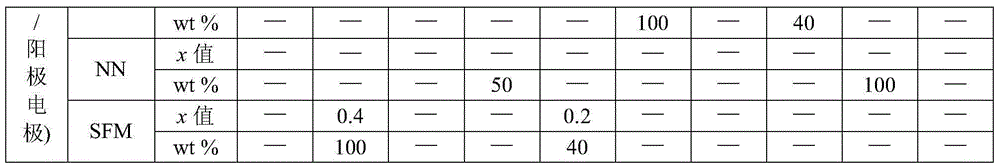

[0035] Table 1 shows the composition of the electrolyte layer and the electrode layer of the electrolyte membrane of each embodiment of the present invention.

[0036] Table 1 Composition of the electrolyte layer and the electrode layer of the electrolyte membrane of each embodiment of the present invention

[0037]

[0038]

[0039] The wt% of each material component is the content in the electrolyte layer / electrode layer.

[0040] The present invention adopts the oxygen production method of the electrolyte membrane of the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com