Large-volume vacuum cracking furnace

A cracking furnace and large-volume technology, applied in the method of using atmospheric pressure to chemically change substances, dispersing particle filtration, using liquid separation agent, etc., can solve the problem of poor cooling effect, failure to achieve the effect, and high defective rate of products and other problems, to achieve the effect of small temperature fluctuation, ensure equipment safety, and ensure cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

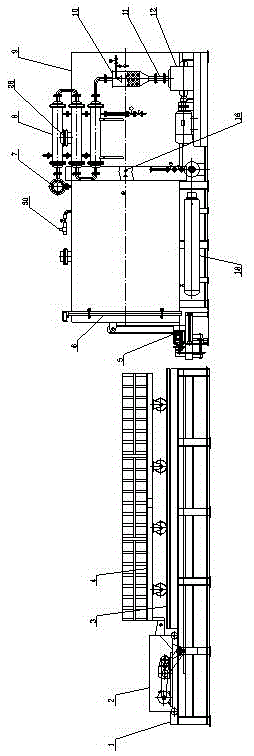

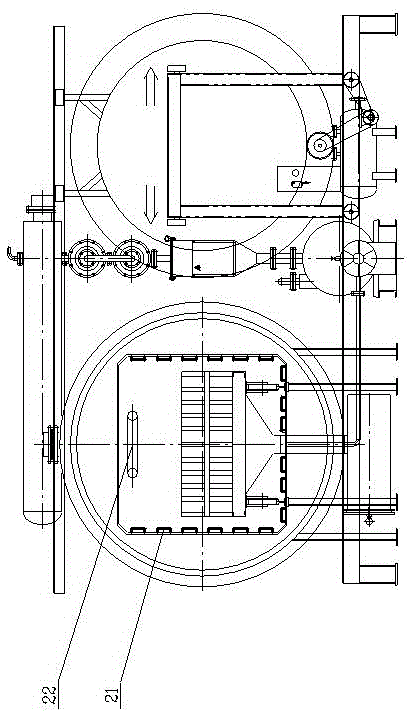

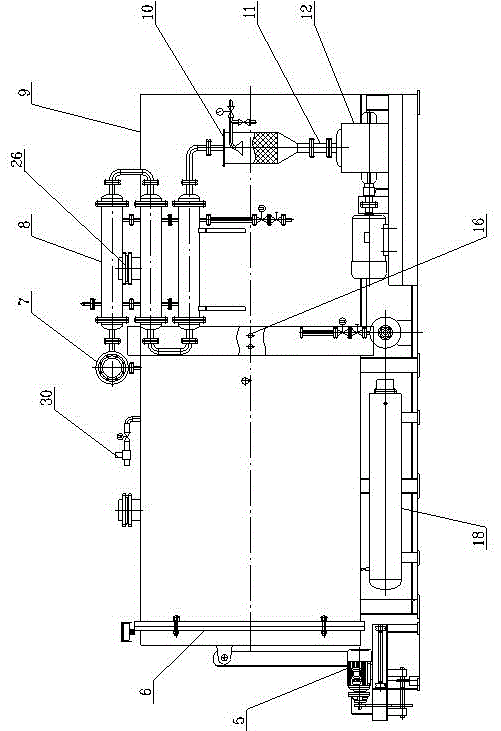

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: a large-volume vacuum cracking furnace, including a trolley support 1, a trolley driver 2, a track 3, a trolley 4, a furnace door 6, an exhaust gas heater 7, a heat exchanger 8, a furnace shell 9, and an electric heating tube 21 ; The trolley support 1 is provided with a track 3; the trolley 4 moves along the extension direction of the track 3; the trolley driver 2 drives the trolley 4 to move into the furnace shell 9; the furnace shell 9 is provided with a cavity, and in the cavity The electric heating tube 21 is arranged; the furnace shell 9 is connected with the exhaust gas heater 7 , and the exhaust gas heater 7 is connected with the heat exchanger 8 .

[0021] The furnace shell 9 is provided with a nitrogen gas inlet 30 , and the nitrogen gas inlet 30 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com