Encapsulation method and structure for OLED device

A technology of light-emitting display and packaging method, which is applied to lighting devices, electroluminescent light sources, light sources, etc., and can solve problems such as short circuits, circuit burnout of organic light-emitting display devices, and wire erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

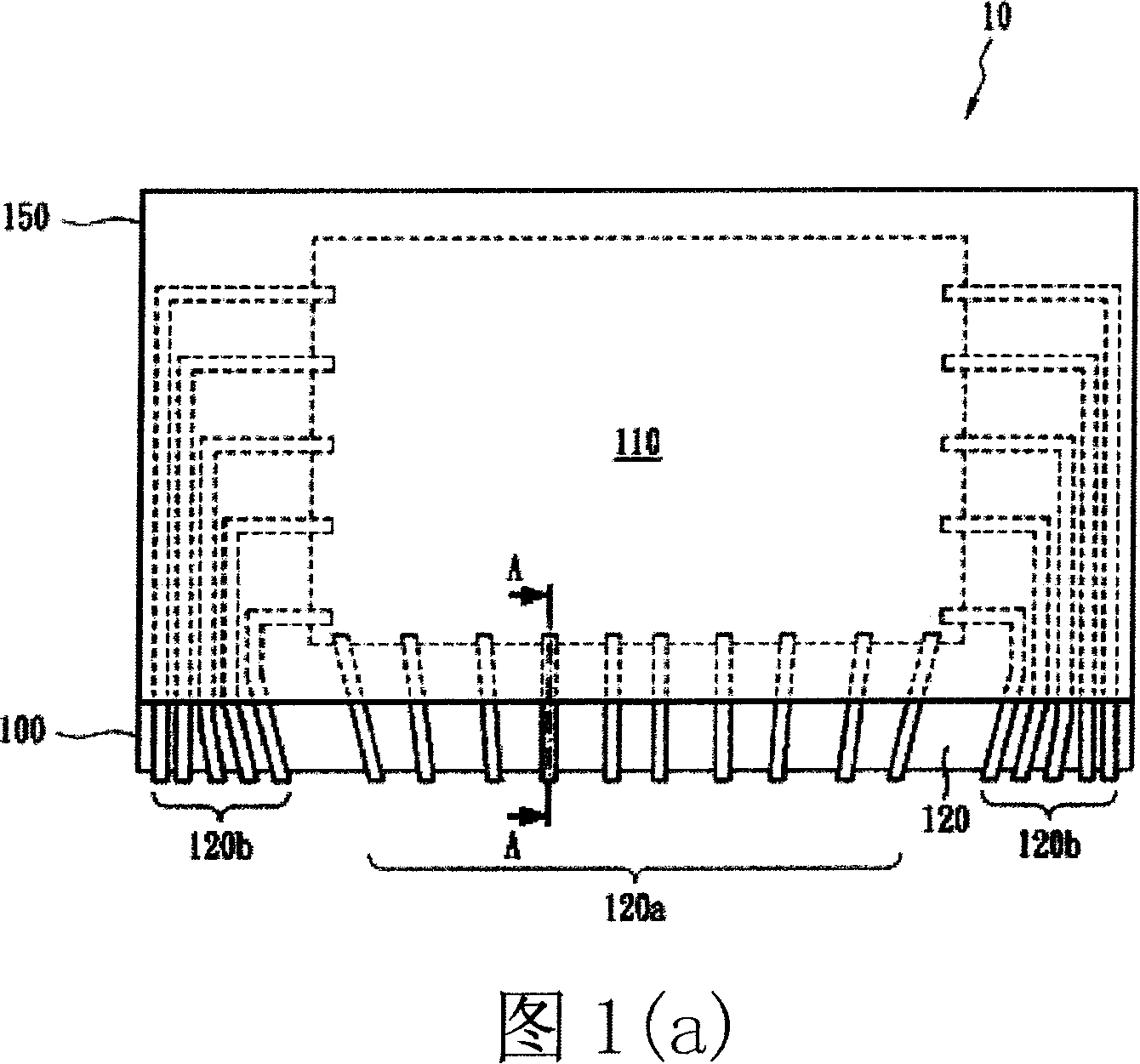

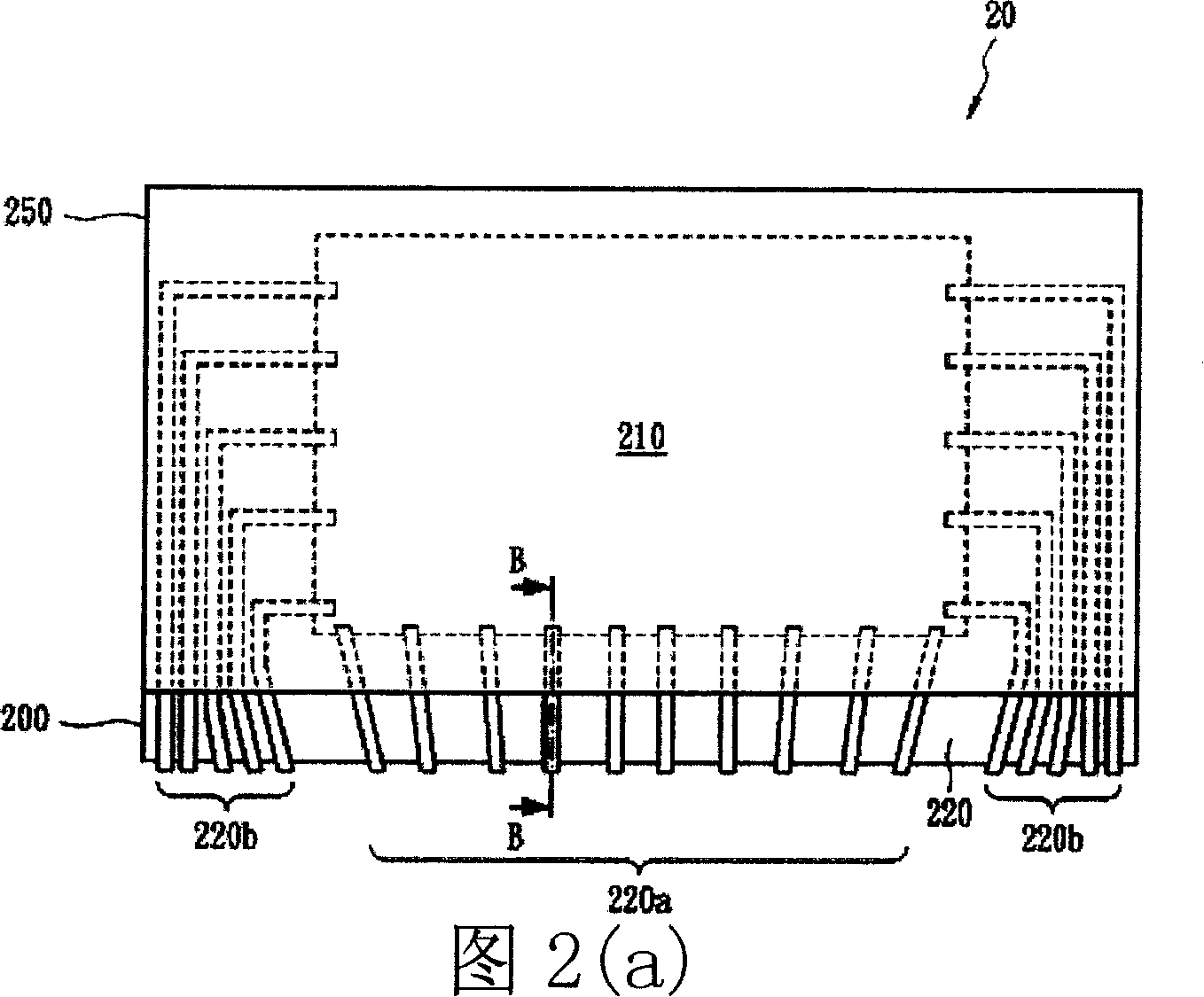

[0058] FIG. 2( a ) is a schematic top view of the organic light emitting display device packaging structure 20 according to the first embodiment of the present invention. The organic light emitting display device packaging structure 20 includes a light emitting region 210 and a wire region 220 formed on a substrate 200 . The light-emitting area 210 contains a plurality of anode lines and a plurality of cathode lines (not shown) stacked on the substrate 200, and the lines in the light-emitting area 210 are sealed in the light-emitting area 210 by the upper cover 250 and the substrate 200. within a space. The wire region 220 includes a plurality of anode wires 220a connected to the anode wires and a plurality of cathode wires 220b connected to the cathode wires, which are respectively stacked on the substrate 200 outside the light emitting region 210 . The anode wires 220 a and the cathode wires 220 b are gathered together on the same side of the substrate 200 .

[0059] Fig. 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com