Preparation method of anti-oxidizing coating

A technology of anti-oxidation coating and silicon carbide layer, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problem of crack-prone hydrogen chloride inhibition, multi-layer SiC coating gap increase, deposition Conditions are not easy to control and other problems, to achieve the effect of overcoming poor high temperature oxidation resistance, avoiding cracks and partial shedding, and improving high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of anti-oxidation coating, described method comprises the steps:

[0029] (1) Place the base material in a deposition reaction chamber (such as a deposition furnace), for example, cut the base material into samples of different specifications and shapes (for example, a flat sample with a length of 100 mm, a width of 100 mm, and a height of 5 mm or An outer diameter of 60mm, an inner diameter of 30mm and a ring sample of 10mm in height), and then the sample is supported in a deposition furnace (CVD furnace);

[0030] (2) Adjust the temperature in the deposition reaction chamber to 1000-1200°C (for example, 1000°C, 1020°C, 1050°C, 1080°C, 1100°C, 1120°C, 1150°C, 1180°C or 1200°C), and make the The deposition reaction chamber is kept warm under the condition that the degree of vacuum is 1-3kPa (for example, 1, 1.5, 2, 2.5 or 3kPa);

[0031] (3) Introduce silicon carbide source gas into the deposition reaction chamber (fo...

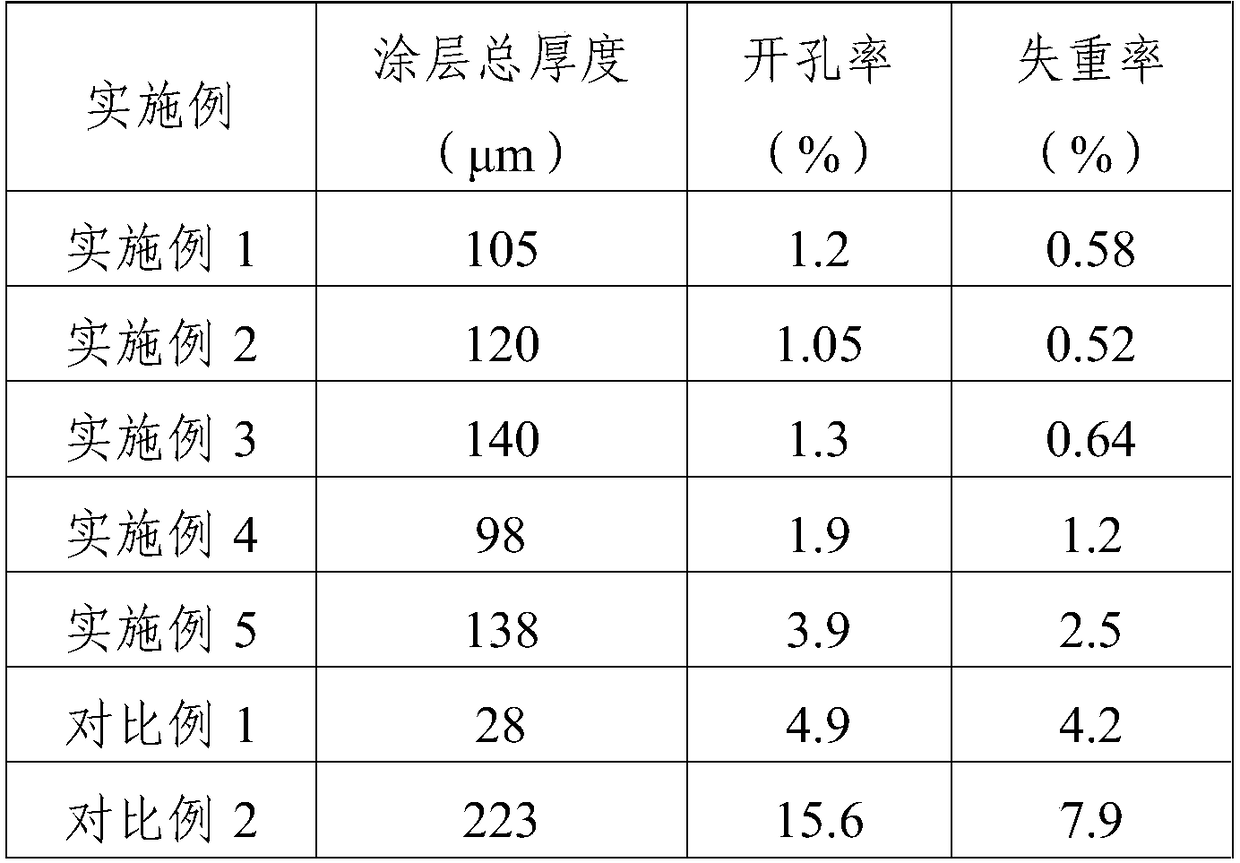

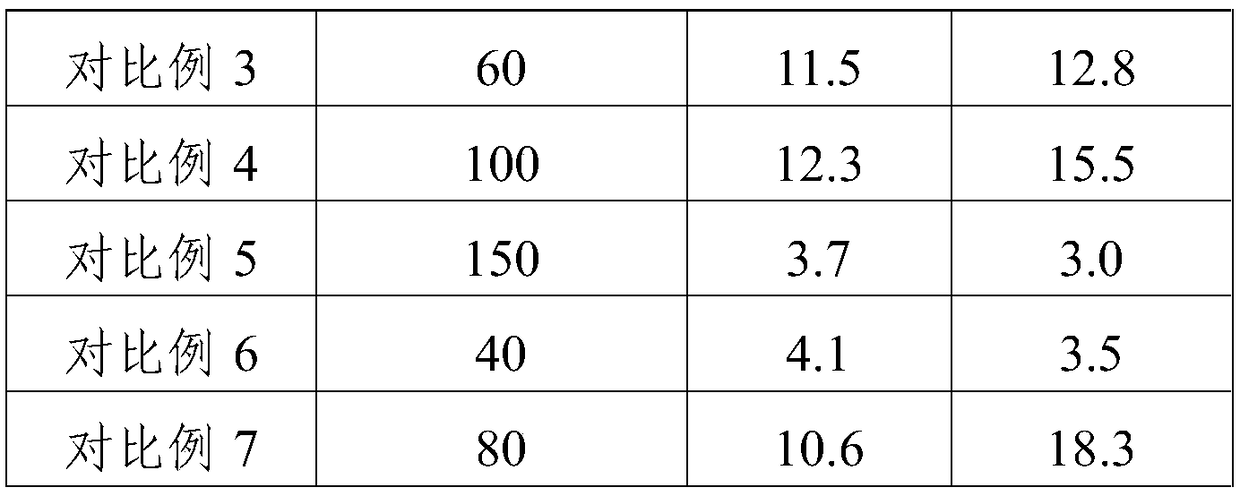

Embodiment 1

[0061] Put a C / SiC composite flat sample with a length of 100mm, a width of 100mm and a height of 10mm (100*100*10mm) into a deposition furnace (CVD furnace); raise the temperature of the deposition furnace to 1020°C, Insulation under a negative pressure of 3kPa; under the stable conditions of a temperature of 1020°C (deposition temperature) and a negative pressure of 3kPa (deposition pressure) in the deposition furnace, the SiC source gas is introduced to deposit the SiC layer three times, and the deposition time of each layer is After 4 hours, the SiC / SiC / SiC anti-oxidation coating was finally obtained; wherein, the silicon carbide source gas contained trichloromethylsilane, argon and hydrogen; the flow rate of the argon was 0.6m 3 / h, the flow rate of the hydrogen is 0.1m 3 / h, the mol ratio of the hydrogen to the trichloromethylsilane is 11:1.

[0062] Perform performance test on the sample prepared with anti-oxidation coating in this embodiment: perform SEM characterizat...

Embodiment 2

[0064] Put a 100mm long, 100mm wide and 5mm high (100*100*5mm) C / SiC composite flat sample into the CVD furnace; raise the temperature of the deposition furnace to 1050°C, Insulation under the state; under the stable conditions of temperature of 1050 ℃ and negative pressure of 2kPa in the deposition furnace, the SiC source gas was introduced, and the SiC layer was deposited three times, and the deposition time of each layer was 4 hours, and finally the SiC / SiC / SiC resist Oxide coating; wherein, the silicon carbide source gas contains trichloromethylsilane, argon and hydrogen; the flow rate of the argon is 0.8m 3 / h, the flow rate of the hydrogen is 0.15m 3 / h, the mol ratio of the hydrogen to the trichloromethylsilane is 13:1.

[0065]Perform performance test on the sample prepared with anti-oxidation coating in this embodiment: perform SEM characterization on the sample with anti-oxidation coating prepared in this embodiment, and obtain the anti-oxidation coating prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com