Epitaxial structure of semiconductor and growth method of epitaxial structure

A technology of epitaxial structure and growth method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as device performance impact, achieve stress regulation, save time, and avoid the effect of crystal quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

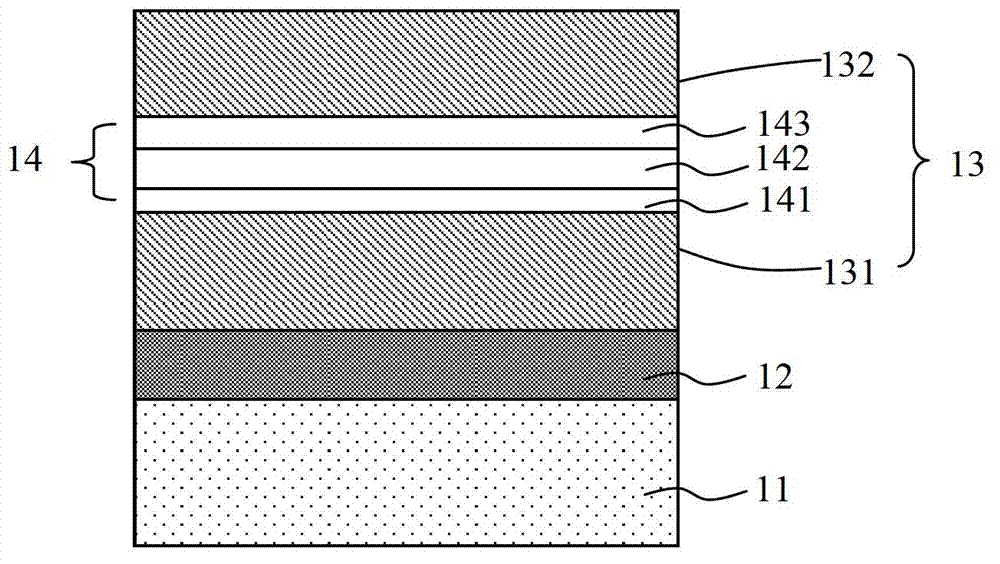

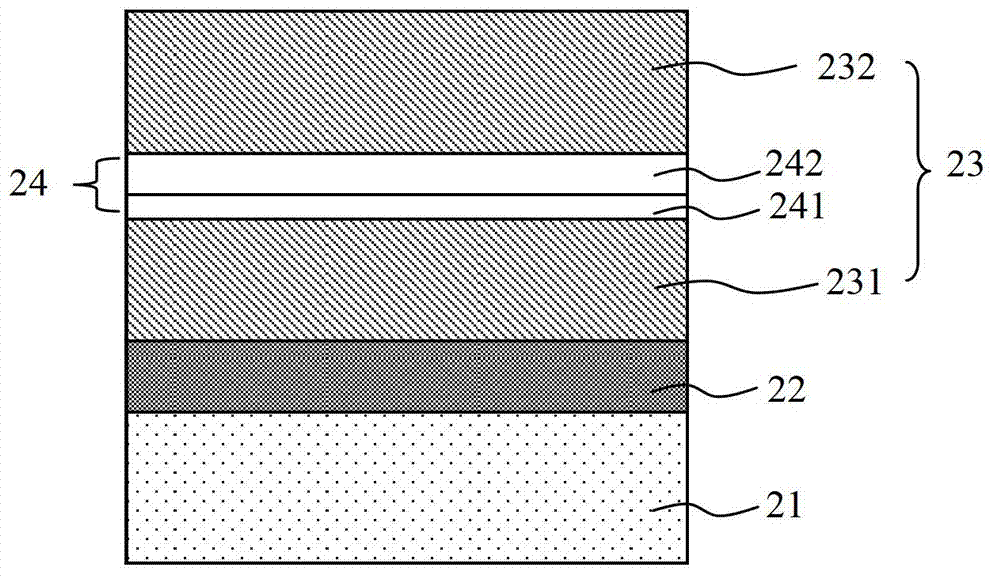

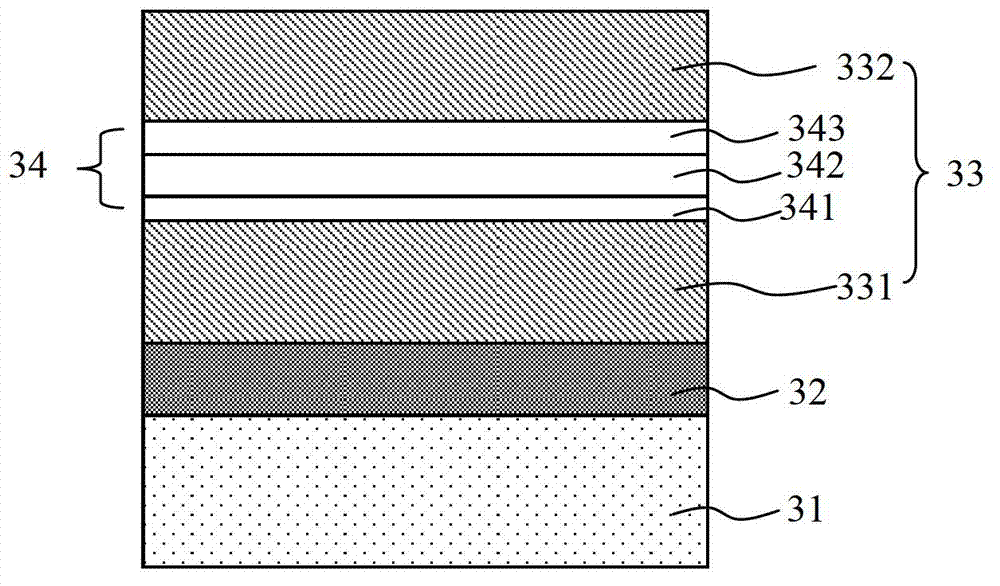

[0039] The embodiment of the present invention discloses a semiconductor epitaxial structure, including:

[0040] a nitride nucleation layer formed on a silicon or silicon carbide substrate;

[0041] a nitride layer formed on the nitride nucleation layer, the nitride layer comprising a first nitride layer and a second nitride layer;

[0042] an insertion layer between the first nitride layer and the second nitride layer, the insertion layer includes a first insertion layer and a second insertion layer above the first insertion layer, the first insertion layer The first insertion layer is an aluminum gallium nitride layer, the second insertion layer is an aluminum gallium nitride layer or an aluminum nitride layer, and the average content of aluminum in the first insertion layer is lower than the average content of aluminum in the second insertion layer.

[0043] Correspondingly, the embodiment of the present invention also discloses a method for growing a semiconductor epitax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com