Al-BiCl<3>-LiBH<4> aluminum-based composite hydrogen production material and method for manufacturing same

An al-bicl3-libh4, aluminum-based composite technology, applied in hydrogen production and other directions, can solve the problems of large hydride addition, complex preparation process, easy combustion and other problems, improve hydrogen production performance, overcome cold welding, The effect of increasing the hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Under the protection of argon, put 90g of grinding balls and 3g of raw materials into the ball mill jar at a ball-to-material ratio of 30:1. The raw materials are 2.4g Al, 0.3g BiCl 3 , 0.3g LiBH 4 ; The ball milling speed is set to 250r / min, and the ball milling time is 5h, then Al-BiCl can be prepared 3 -LiBH 4 Aluminum matrix composite hydrogen production material.

[0028] The prepared different aluminum-based composite materials were reacted with water at 25°C as 1g (sample): 0.1L (water), that is, about 0.1g of the aluminum-based composite material was weighed, and 10mL of water was added to measure its hydrogen production performance.

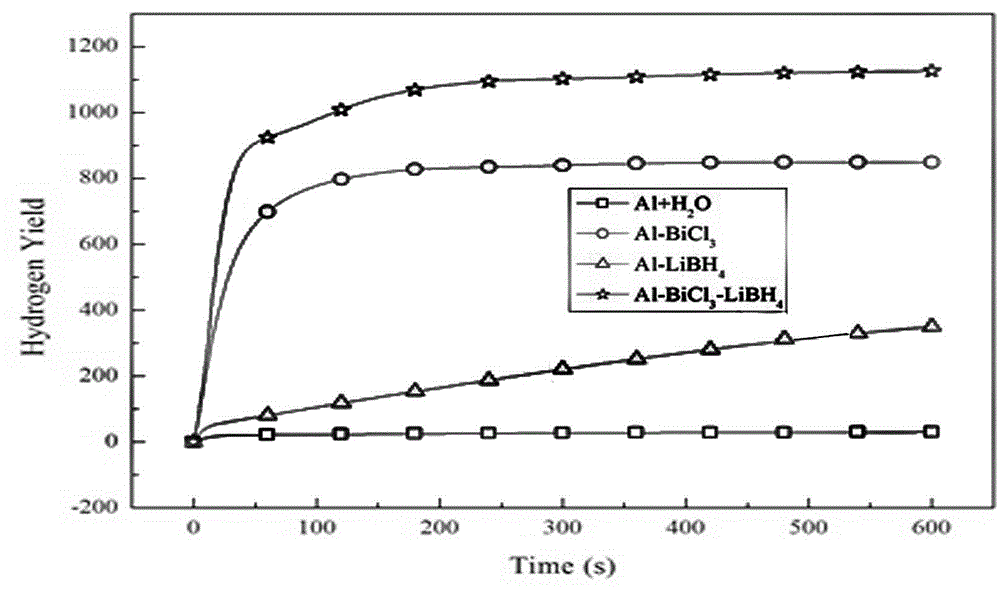

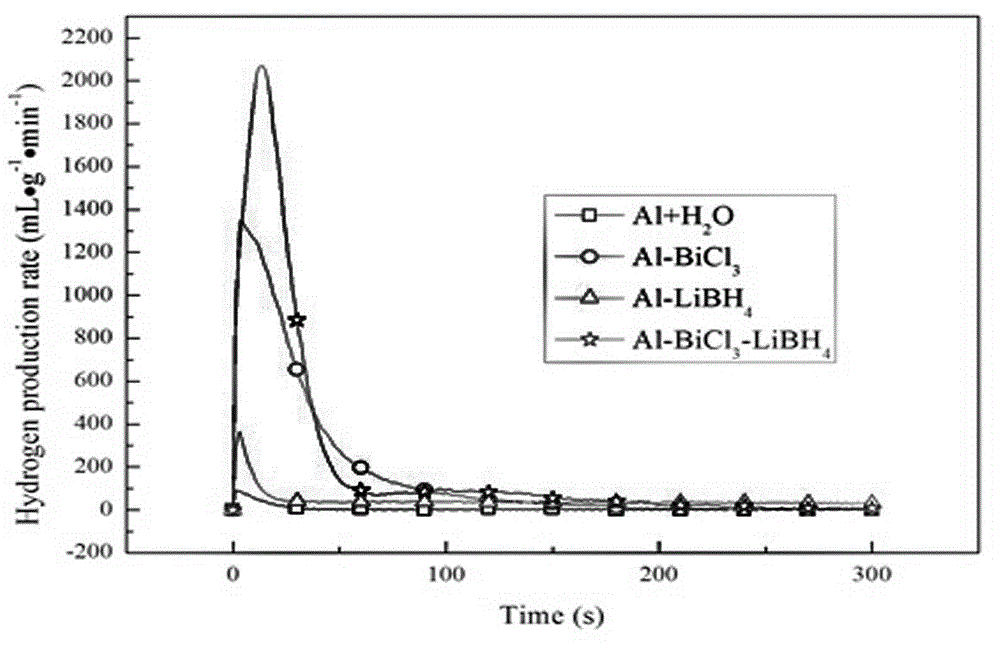

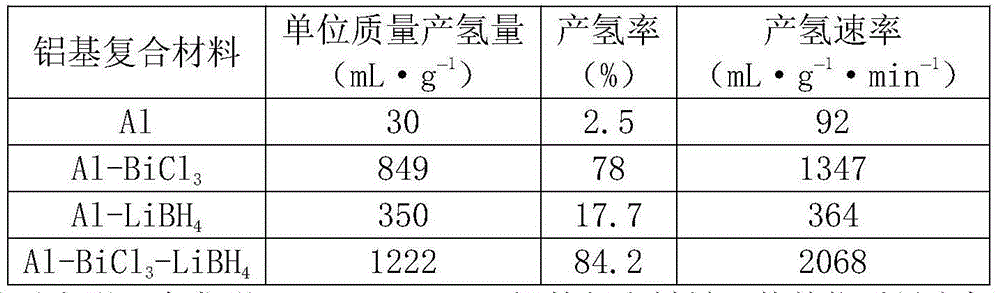

[0029] The experimental results were compared with the pure aluminum powder, Al-BiCl 3 Aluminum Matrix Composites and Al-LiBH 4 Aluminum matrix composite materials were compared and analyzed, and some results are shown in figure 1 , figure 2 and Table 1.

[0030] Table 1. Comparison table of hydrogen production performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com