Patents

Literature

91results about How to "Adequate adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly diatom ooze wall material powder and wall material and preparation method thereof

InactiveCN101700965AImprove adsorption capacityAdequate adsorptionMoisture absorptionAir purification

The invention discloses environment-friendly diatom ooze wall material powder and a wall material as well as a preparation method and application thereof. The diatom ooze wall material with macromolecule sieve structure is prepared by taking a plurality of natural environment-friendly non-metal material having strong adsorbability and good plasticity as main materials through a simple process. The environment-friendly diatom ooze wall material powder has the advantages of low cost, air purification, moisture absorption, deodorization, inflaming retarding, heat insulation, easy popularization,and the like.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

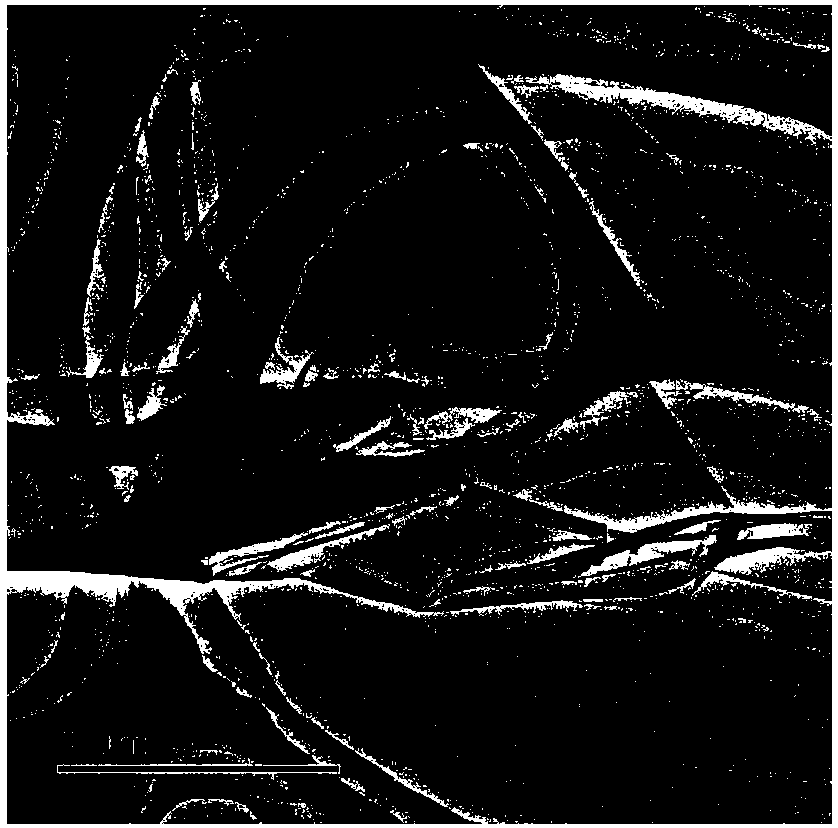

PAN (Polyacrylonitrile)-based porous carbon nanofiber for removing NOx from air, and preparation method and application thereof

ActiveCN102517692ALarge specific surface areaRich in microporesPhysical/chemical process catalystsOther chemical processesPorous carbonReaction temperature

The invention relates to a PAN (Polyacrylonitrile)-based porous carbon nanofiber for removing NOx from air. The PAN-based porous carbon nanofiber has the diameter range of 50-1000 nm, the specific surface area of 200-1200 m<2> / g, a micropore-based porous structure and the micropore volume of 0.3-1.0 cm<3> / g. The PAN-based porous carbon nanofiber can remove the low-concentration NOx from air at room temperature through flowing air containing the low-concentration NOx through the PAN-based porous carbon nanofiber, wherein the low-concentration NOx means the concentration, less than 50 ppm, of NO in air, and in order to ensure a removal effect, the flow velocity of the air containing the low-concentration NOx is 100-400 SCCM, and the reaction temperature is the room temperature. The invention further provides a preparation method of the PAN-based porous carbon nanofiber, and the preparation method is simple and controllable in process.

Owner:TSINGHUA UNIV

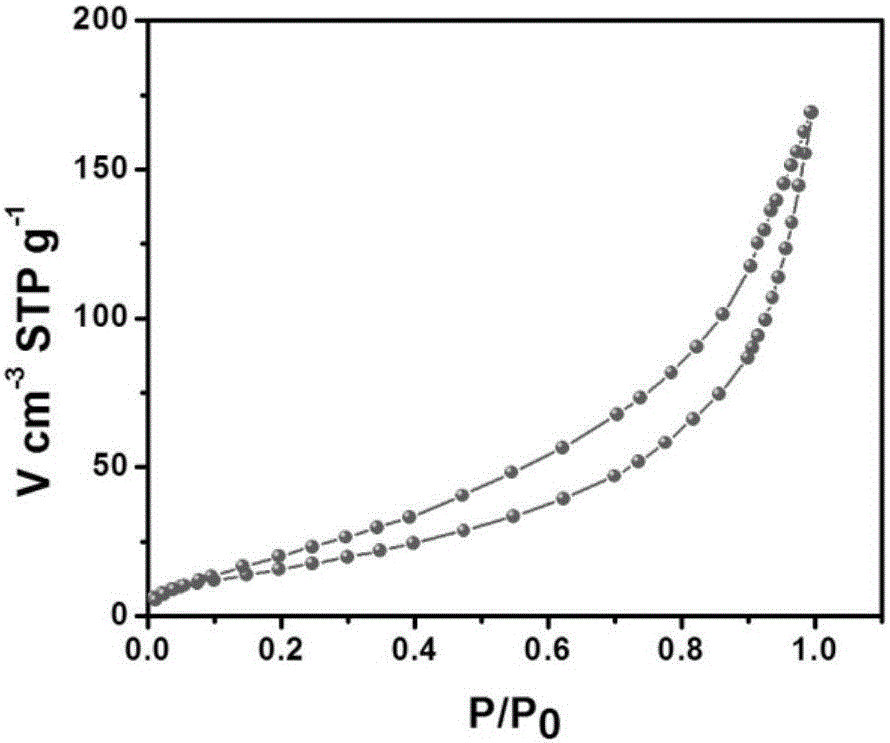

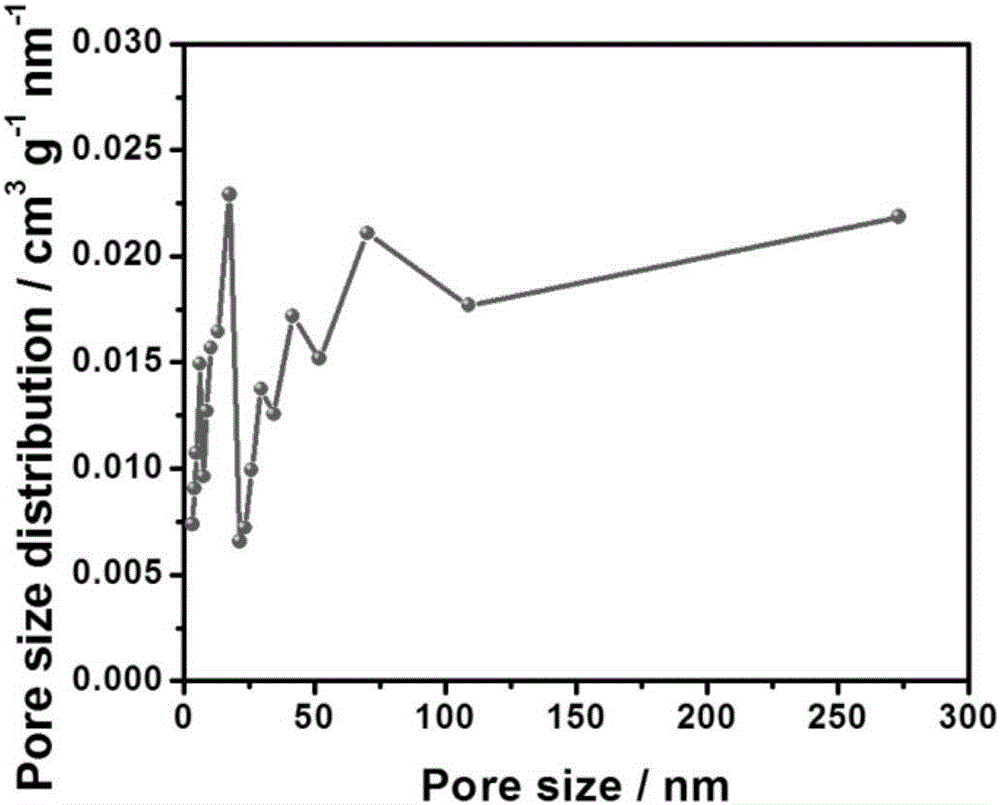

A metal-organic framework compound @ mesoporous material composite, a preparing method thereof and applications of the composite

ActiveCN106861634ASlow down decompositionExtended service lifeGas treatmentOther chemical processesChemical compoundDecomposition

A metal-organic framework compound @ mesoporous material composite, a preparing method thereof and applications of the composite are provided. According to the composite, a metal-organic framework compound is distributed in pore passages of a mesoporous material, CO2 adsorbability of the metal-organic framework compound is fully utilized, a developed network pore passage structure of the mesoporous material also facilitates CO2 gas molecular diffusion, the metal-organic framework compound distributed in the pore passages can be in full contact with CO2 gas, and the mesoporous material can effectively delay decomposition and degeneration of the metal-organic framework compound in a flue gas environment and prolongs the service life time of an adsorption material, and therefore the composite can have excellent high-temperature resistance and water tolerance. The preparing method is simple in process, and suitable for large-scale production. The composite can be adopted as a CO2 adsorbent, is particularly used for adsorbing CO2 in flue gas, and can be used stably for long time in the flue gas environment.

Owner:WEIFANG UNIVERSITY

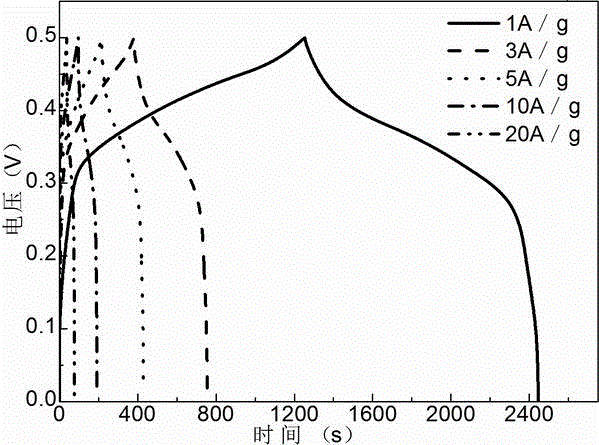

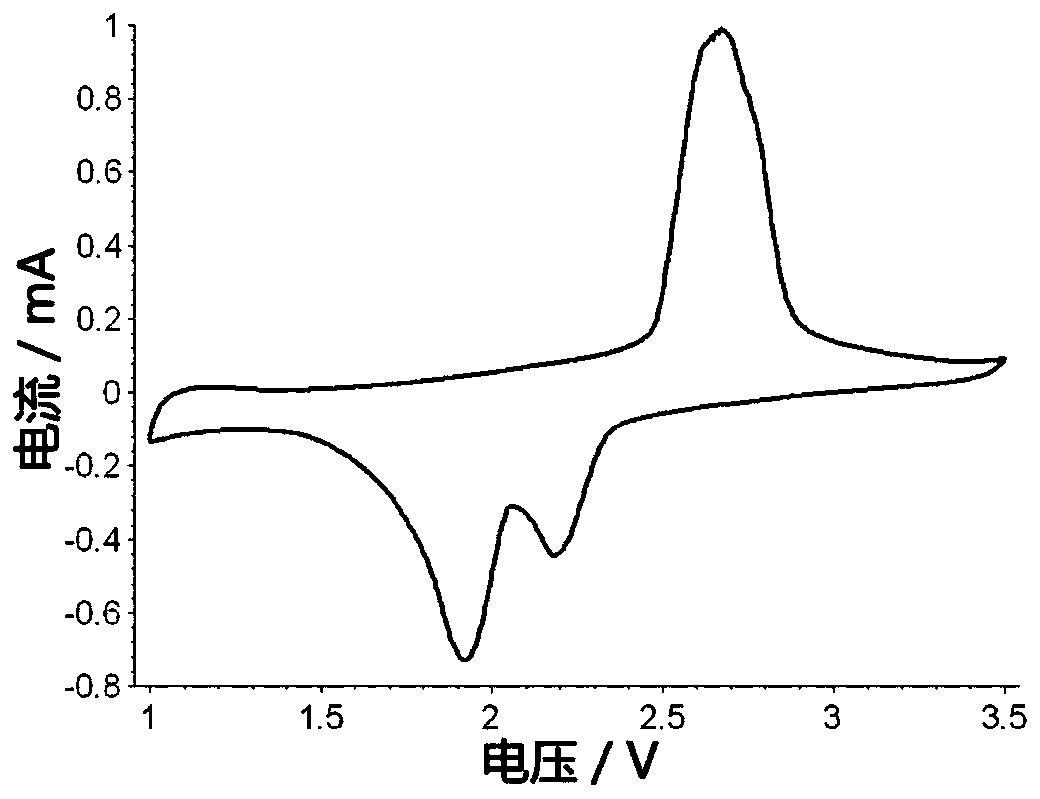

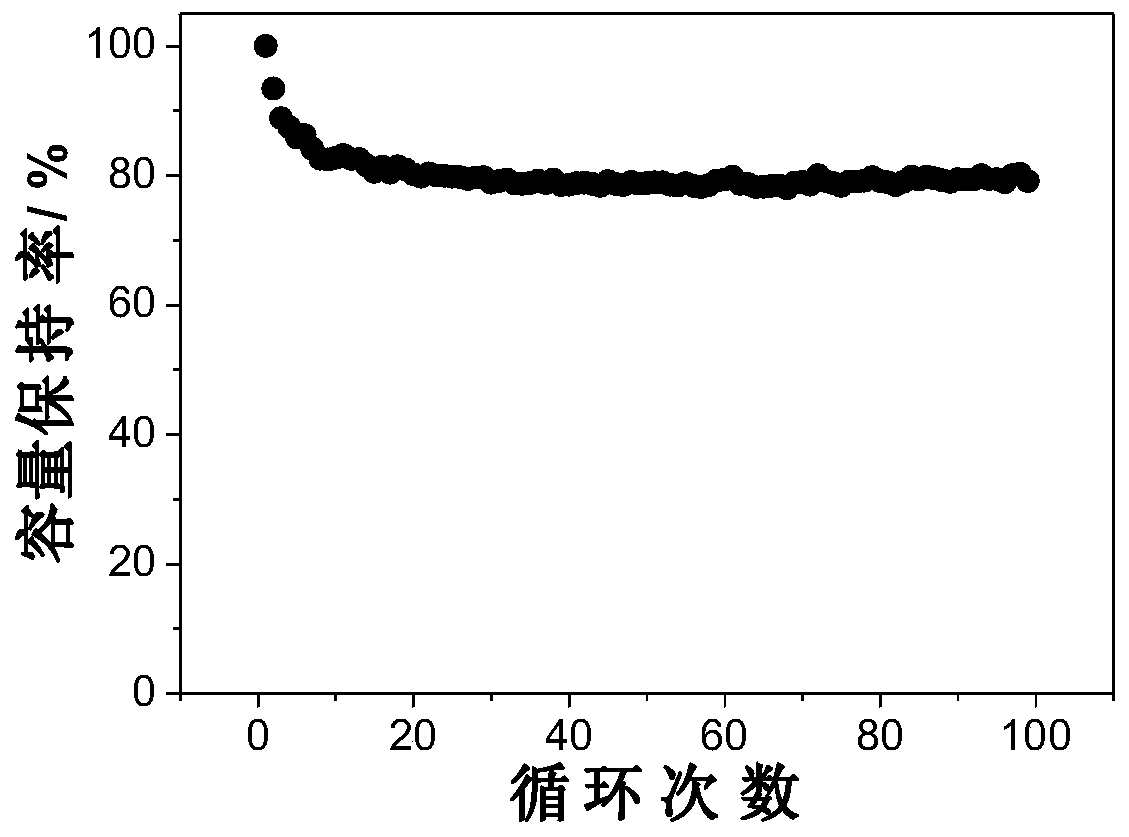

Preparation method of layered cobalt-zinc double hydroxide-graphene compound supercapacitor electrode

InactiveCN106206055ALarge specific surface areaAdequate adsorptionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceZinc hydroxide

The invention relates to a preparation method of a layered cobalt-zinc double hydroxide-graphene compound supercapacitor electrode. The preparation method comprises the following steps of firstly, dispersing graphene oxide and a surfactant in an urea aqueous solution with ultrasound to form a graphene oxide suspension liquid; secondly, adding cobalt nitrate hexahydrate and zinc acetate dehydrate to the graphene oxide suspension liquid, and stirring the liquid to form a uniform precursor solution; and finally, transferring the precursor solution to a hydrothermal reaction kettle, simultaneously placing a foamed nickel current collector in the precursor solution in the hydrothermal reaction kettle for hydrothermal reaction at 120-180 DEG C, depositing a hydrotalcite layered cobalt-zinc hydroxide-graphene compound on the surface of the foamed nickel current collector, and drying the foamed nickel current collector after ultrasonic washing to form the compound active electrode. The preparation method is simple, is easy to control and is low in cost, and the prepared compound active electrode is endowed with relatively high special capacitance and rate performance.

Owner:HENAN NORMAL UNIV

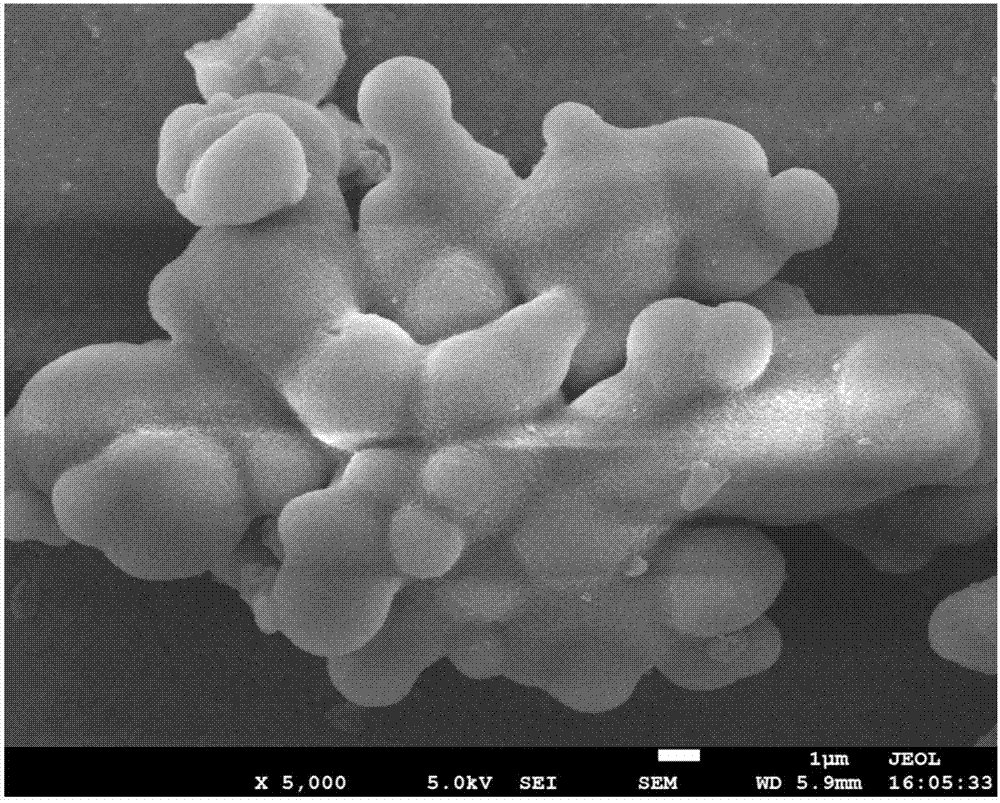

Technique for preparing porous ceramicite loaded Ag/N-TiO2 nano film

InactiveCN101209422AAchieve hybrid dopingLess adulteratedWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsMicrowaveExpanded clay aggregate

The invention provides a preparation technique for porous porcelain granules loaded with Ag / N-TiO2 nanometer film, which comprises the preparation of the porous porcelain granules and the manufacture of film on the porous porcelain granules, and is characterized in that: (1) -100 meshes of fly ash and quicklime and -200 meshes of kaolin and glass powder are adopted as raw materials, which are mixed according to the weight ratio of 70: 6: 10:14; TiO2 that accounts for 0.5-1 percent of the total weight of the raw materials, NH4HCO3 that accounts for 20-30 percent of the total weight of the raw materials and water that accounts for 60-65 percent of the total weight of the raw materials, are all added into the mixture mixed by the four raw materials; the new mixture is stirred uniformly to prepare granules with the particle size of 1-2cm, which is immediately placed under microwave for foaming and drying for 1-5min so as to prepare porous porcelain granule billets with the diameter of 2-5cm, and then the billets are sintered for 1h under 1100DEG C to prepare the porous porcelain granules; (2) Ag / N-TiO2 sol is prepared by adopting sol-gel method and the sol is coated on the porous porcelain granules by adopting dipping method, thus obtaining the porous porcelain granules loaded with Ag / N-TiO2 nanometer film after drying and calcining. The sol is evenly coated on the porous porcelain granules, so active constituent does not lose effectiveness under low temperature, thus having good visible light degradation and relatively strong bactericidal effect.

Owner:SHANDONG UNIV OF TECH

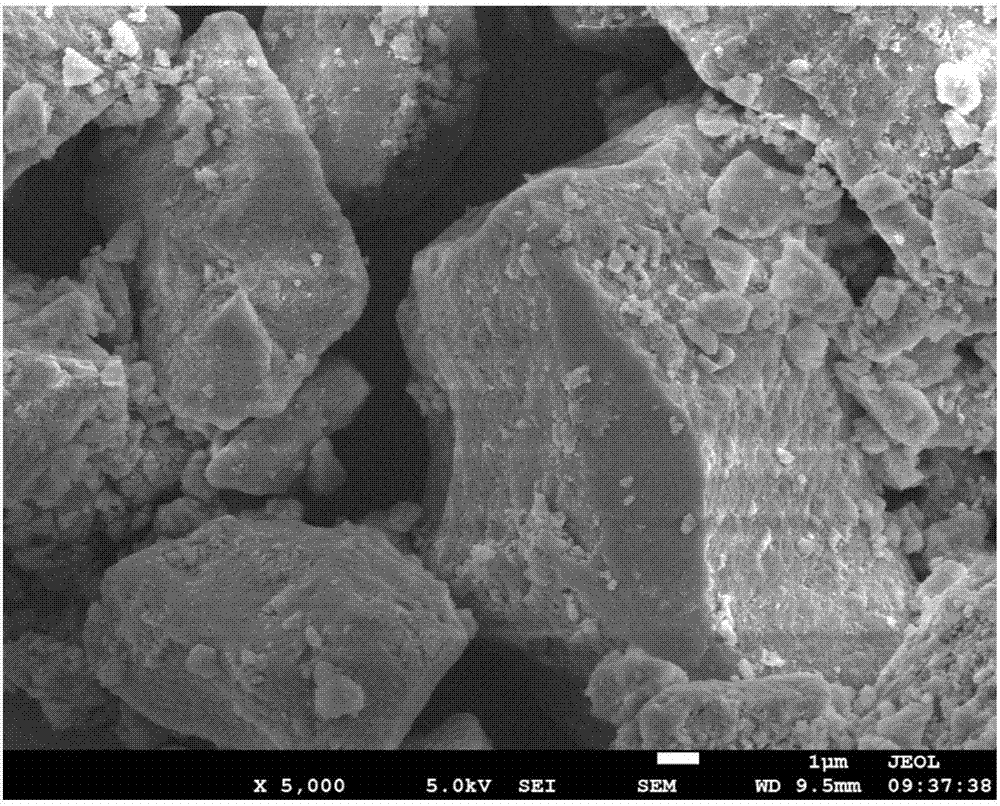

Sensitizing type expanded ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN101591210ALarge specific surface areaLow oil leakageExplosive working-up apparatusFuel oilParaffin oils

The invention discloses a sensitizing type expanded ammonium nitrate fuel oil explosive and a preparation method thereof. The explosive is prepared by blending expanded ammonium nitrate and nitromethane, and the mass percentages are 66.3%-80% and 20%-33.7%; or the explosive is prepared by blending expanded ammonium nitrate, nitromethane and composite oil phase, and the mass percentages of expanded ammonium nitrate, nitromethane and composite oil phase are 84%-95%:1%-11%:4%-5%; or the explosive is prepared by blending expanded ammonium nitrate, nitromethane, composite oil phase and aluminium powder, wherein the composite oil phase is prepared by melting diesel oil and paraffin, and the mass ratio of diesel oil and paraffin is 6:4, and the mass percentages of expanded ammonium nitrate, nitromethane, composite oil phase and aluminium powder are 91%-94.5%:1%-3%:4-5%:0.5-1%. The invention adopts self-sensitizing expanded ammonium nitrate with multiple micropores, large specific surface area and high oil adsorption ratio as an oxidant, and nitromethane or aluminium powder as a combustible agent to prepare the expanded ammonium nitrate fuel oil explosive which has good detonation sensitivity and is capable of being reliably detonated by a single detonator.

Owner:NANJING UNIV OF SCI & TECH

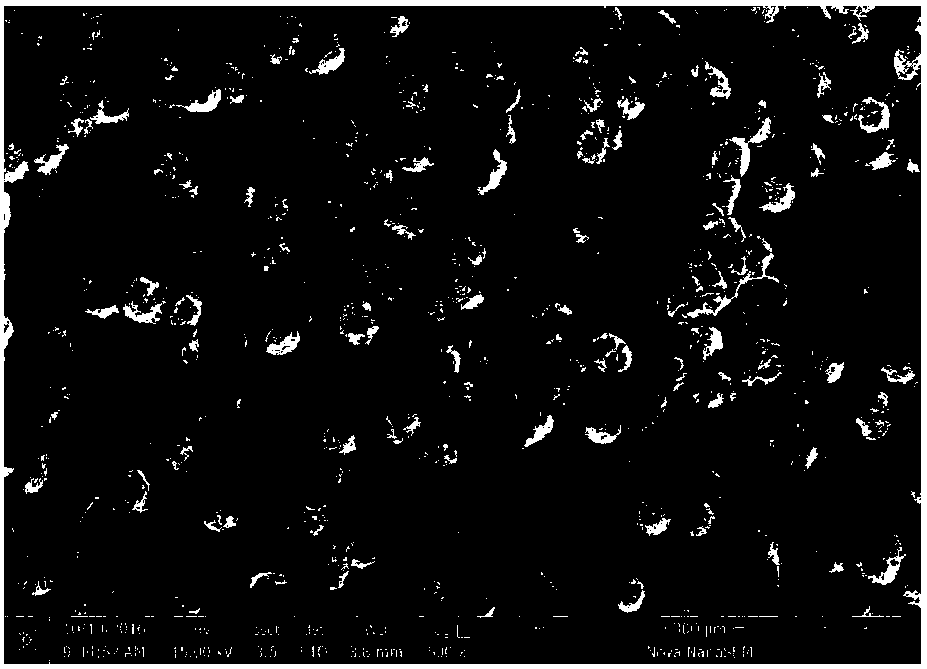

Method of using graphene sheet and carbon nano tube three-dimensional compound for adsorbing heavy metal in water

InactiveCN106277172APlay a supporting roleAvoid reunionOther chemical processesWater contaminantsAdsorption equilibriumOrganic solvent

The invention discloses a method of using a graphene sheet and carbon nano tube three-dimensional compound for adsorbing heavy metal in water. The method includes the following steps that a, under the condition of continuous stirring, a graphene sheet and carbon nano tubes are fully mixed in organic solvent to form a graphene sheet and carbon nano tube three-dimensional compound solution; b, the graphene sheet and carbon nano tube three-dimensional compound is added into sewage containing heavy metal ions and are continuously stirred under room temperature until the formed mixed reaction system reaches an adsorption equilibrium state, and then the mixed reaction system is still standing; c, the graphene sheet and carbon nano tube three-dimensional compound is separated through an applied magnetic field to purify the sewage. Compared with the prior art, the method has the advantages of being simple, environmentally friendly, free of pollution and capable of treating multiple kinds of heavy metal ions, many kinds of heavy metal ions can be treated, and the removal rate is 98% or more; the graphene sheet and carbon nano tube three-dimensional compound can be recovered through the magnetic field and used repeatedly and is low in cost.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

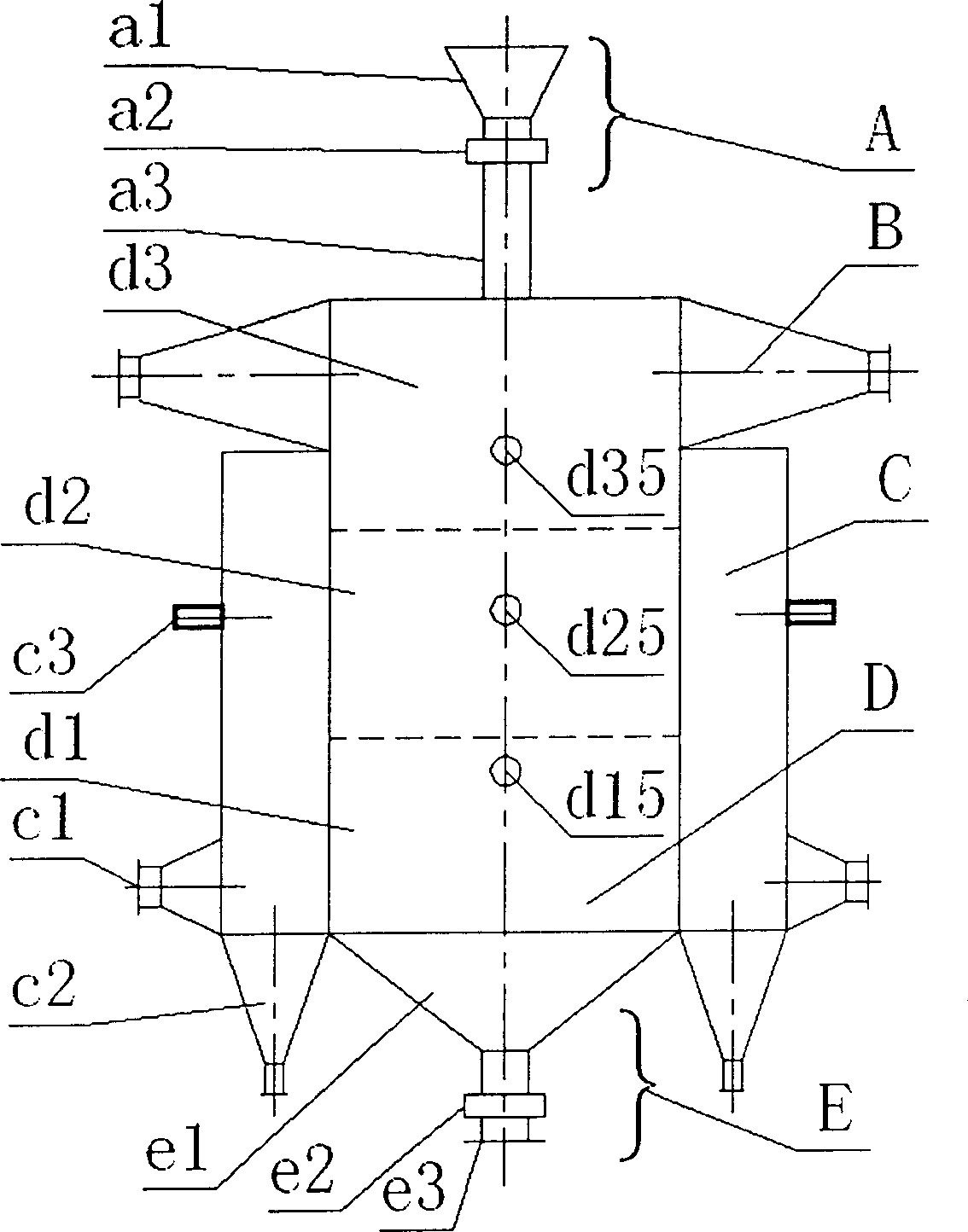

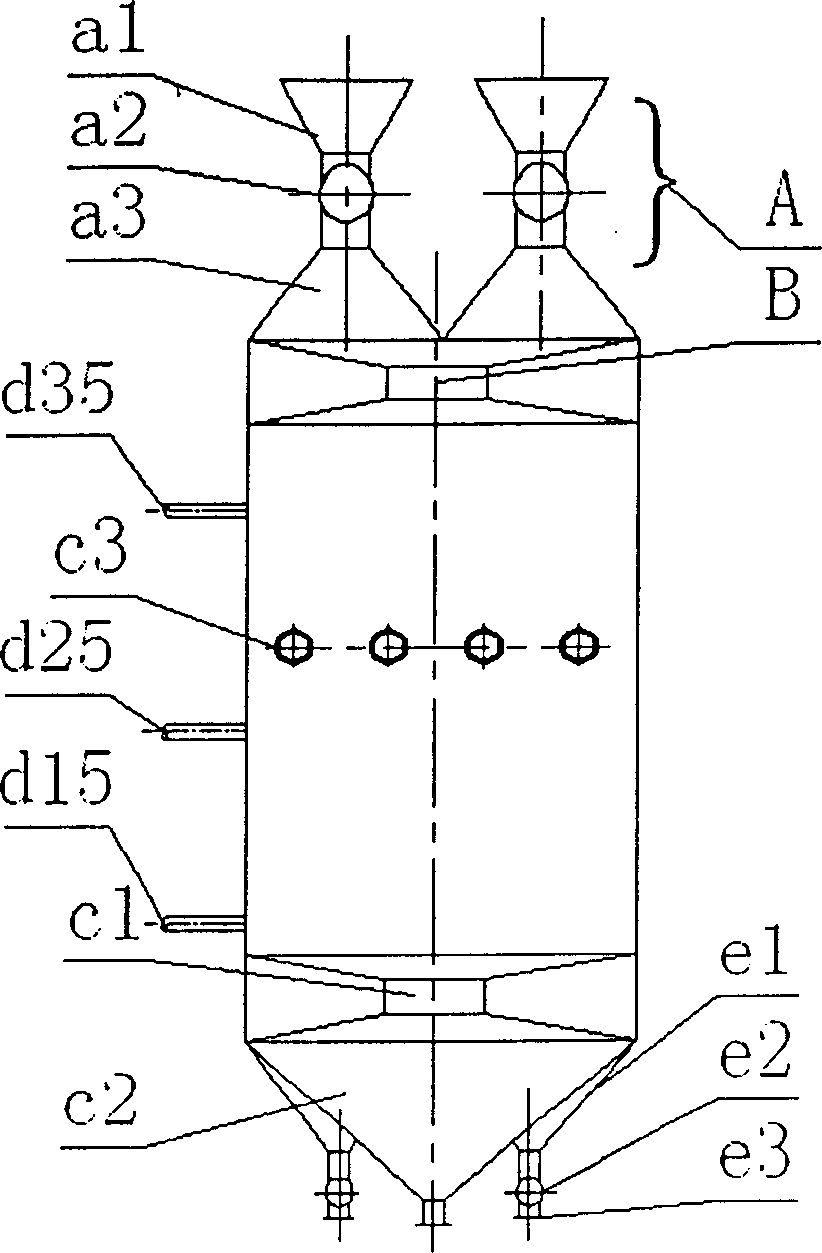

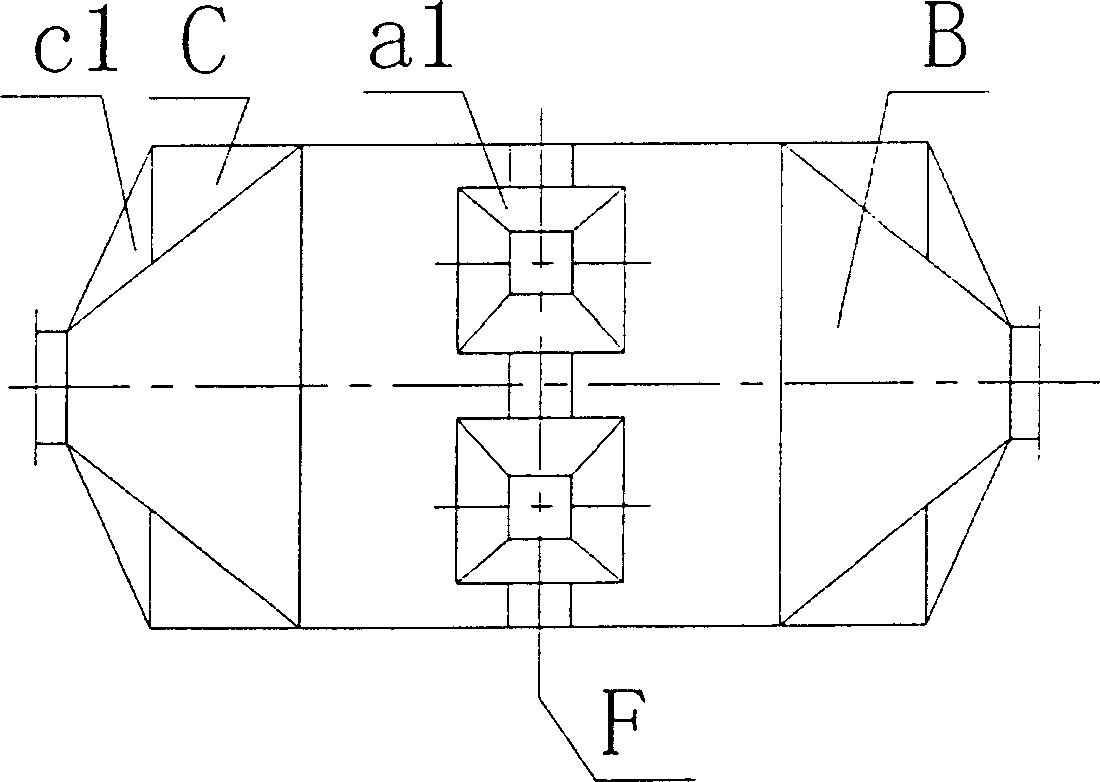

Coupling multistage device with active carbon purifying waste gas

InactiveCN1820819ATake advantage ofCompact structureDispersed particle separationActivated carbonMaterial distribution

The present invention provides coupling multistage apparatus with active carbon to purify waste gas, and the apparatus is used in desulfurizing, denitrating, dedusting, eliminating heavy metal and eliminating organic compound of waste gas. It consists of pre-purifying room, movable adsorption bed, purified gas outlet, material feeding mechanism, and discharging mechanism. Each of the material feeding mechanism and the discharging mechanism consists of material bin, material guide pipe and gas trap valve. The movable adsorption bed consists of one or several adsorption sections superposed sequentially, the material feeding mechanism is set on the top, the discharging mechanism is set in the bottom, and the pre-purifying room and the purified gas outlet are set in the side. The apparatus has compact structure, simple material distribution, complete functions, less resistance, high purifying effect, fully use of active carbon, long service life and low running cost.

Owner:史鱼海

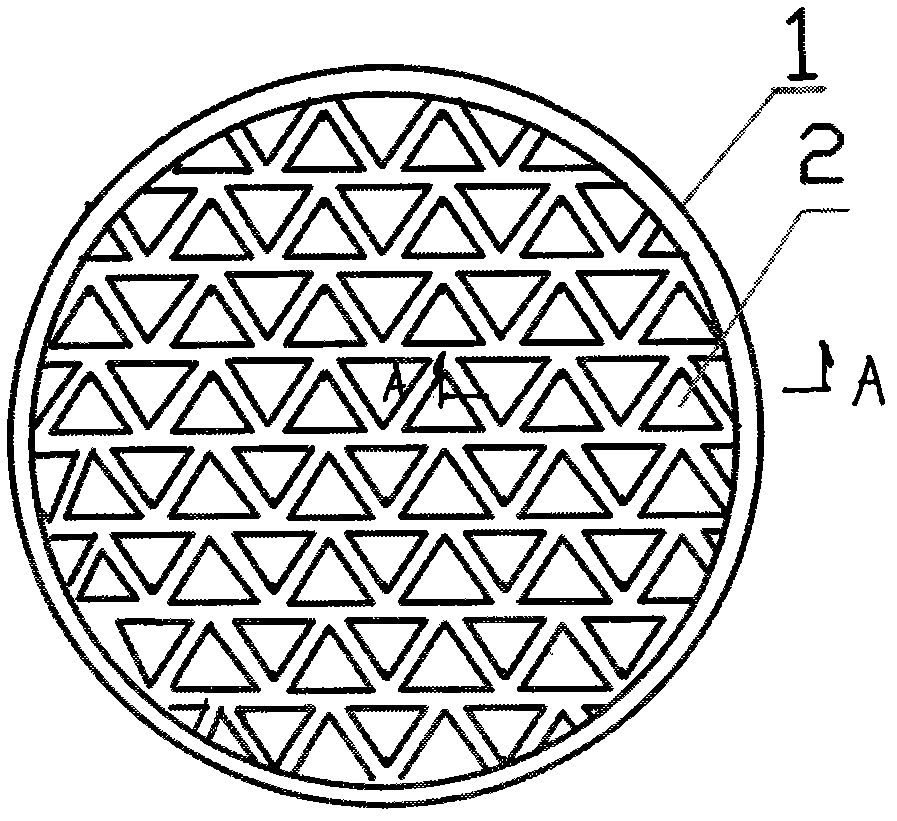

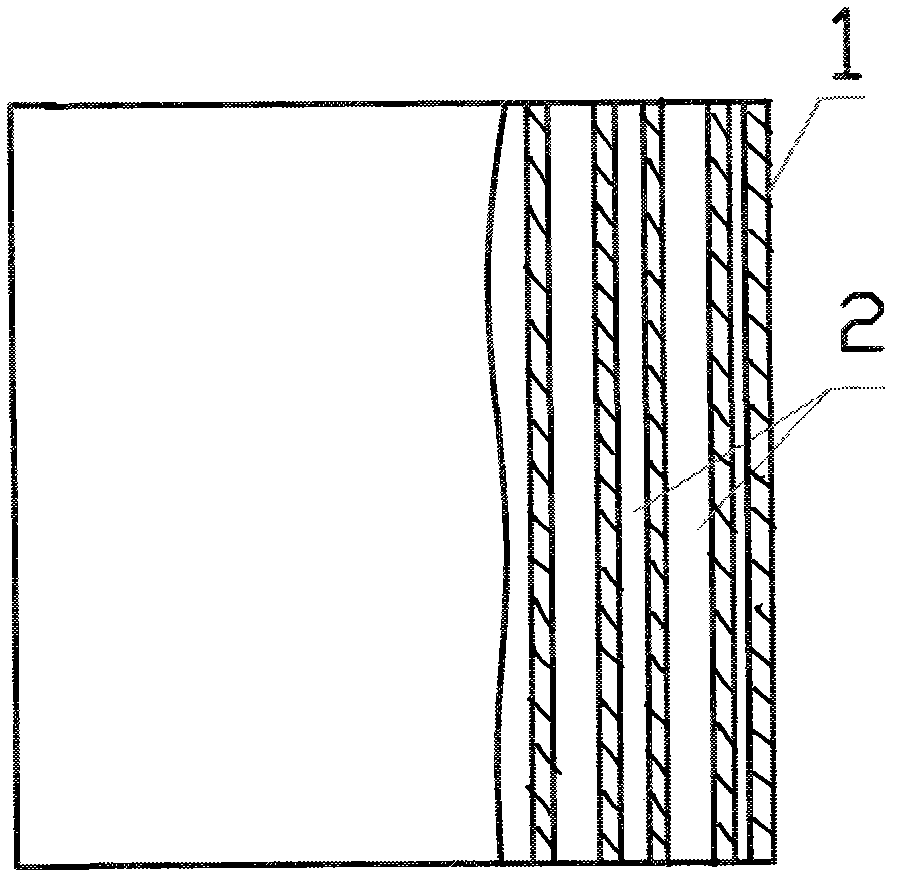

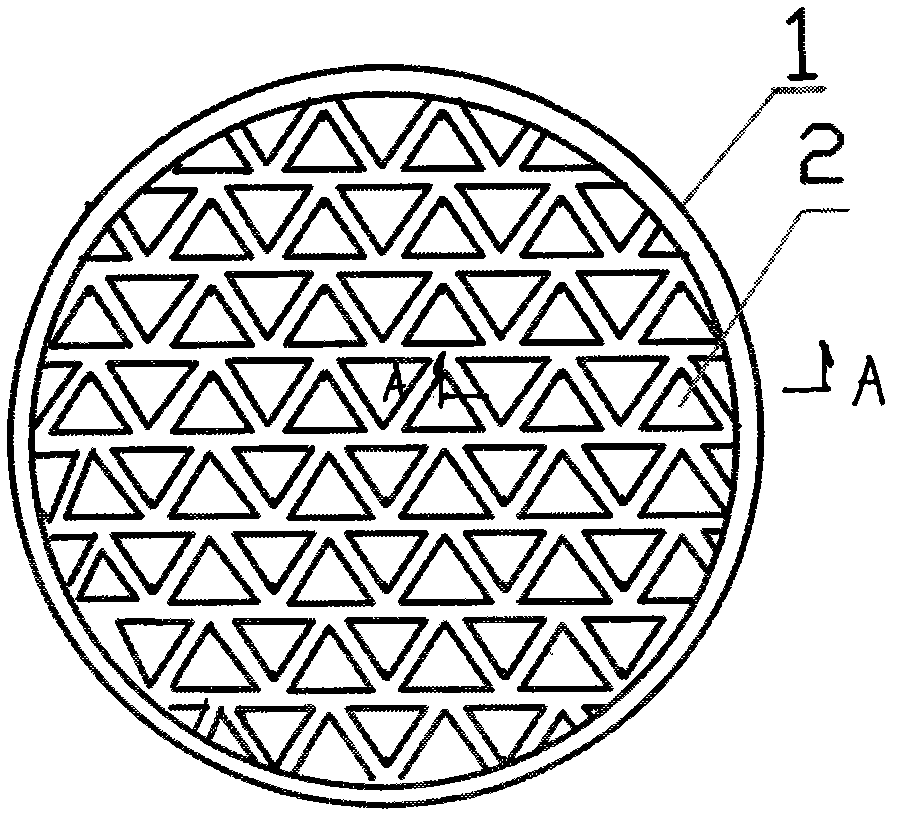

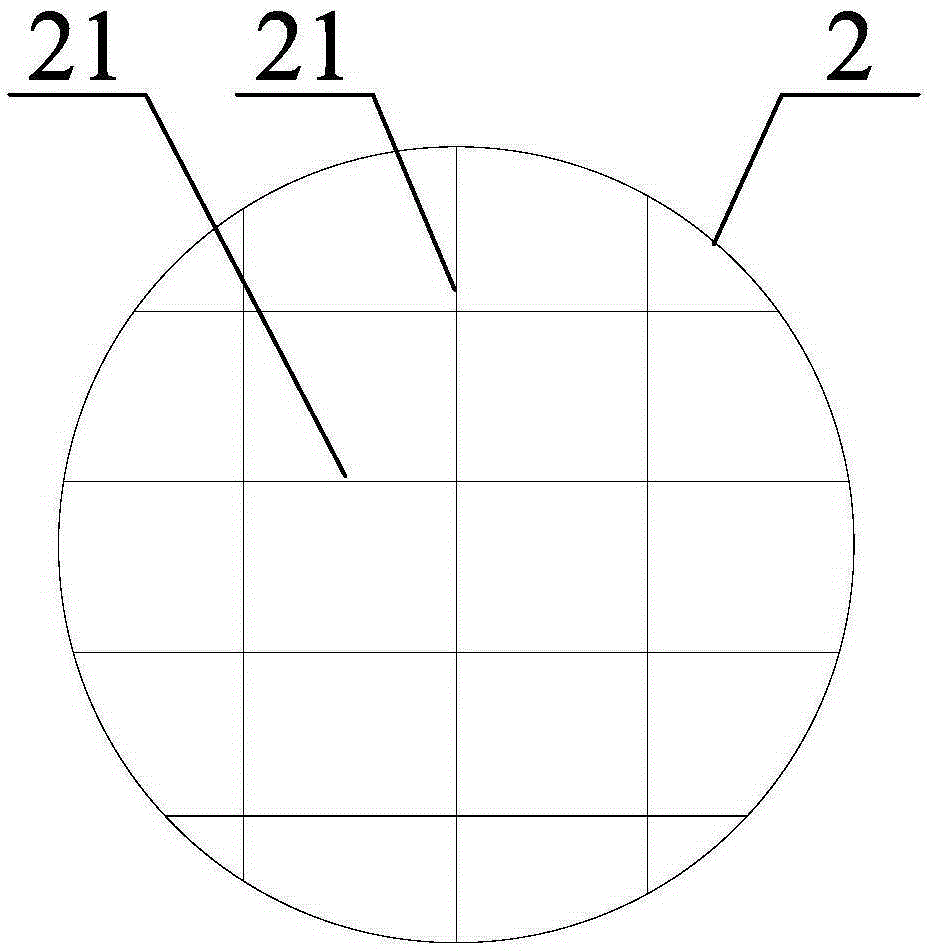

Bird-nest catalyst carrier

The invention discloses a bird-nest catalyst carrier, which comprises a body (1). The body is cylindrical or cuboid; and honeycomb holes (2) which are uniformly distributed, and parallel or staggered vertically and staggered or parallel horizontally are formed in an inner cavity of the body. One or a mixture of more of activated aluminium oxide, zirconium oxide, magnesium oxide, silicon carbide, titanium dioxide and natural clay is taken as a main raw material, is added with an adhesive, a fusing agent and a proper amount of water, and is subjected to ball milling, kneading, ageing, mixing, molding, drying, shaping, cutting and low-temperature sintering to form the bird-nest catalyst carrier. Due to large specific surface area and void ratio, large internal through pore diameter and large pore volume, the bird-nest catalyst carrier can improve the total effective contact quantity to the greatest extent and shorten the flowing path of raw oil in the catalyst, so that the catalyst in the carrier can fully achieve the effect, and the raw oil flowing through the catalyst is fully separated, adsorbed, purified and filtered.

Owner:姚光纯

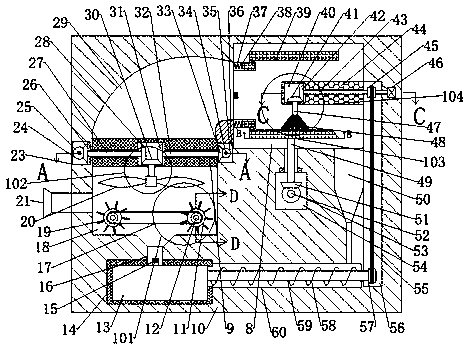

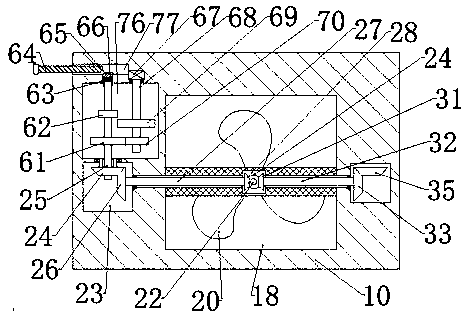

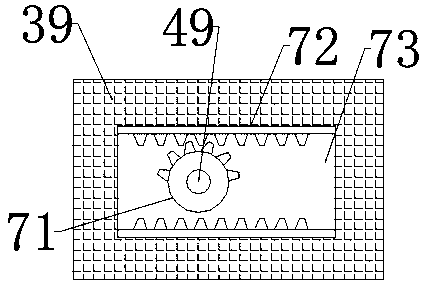

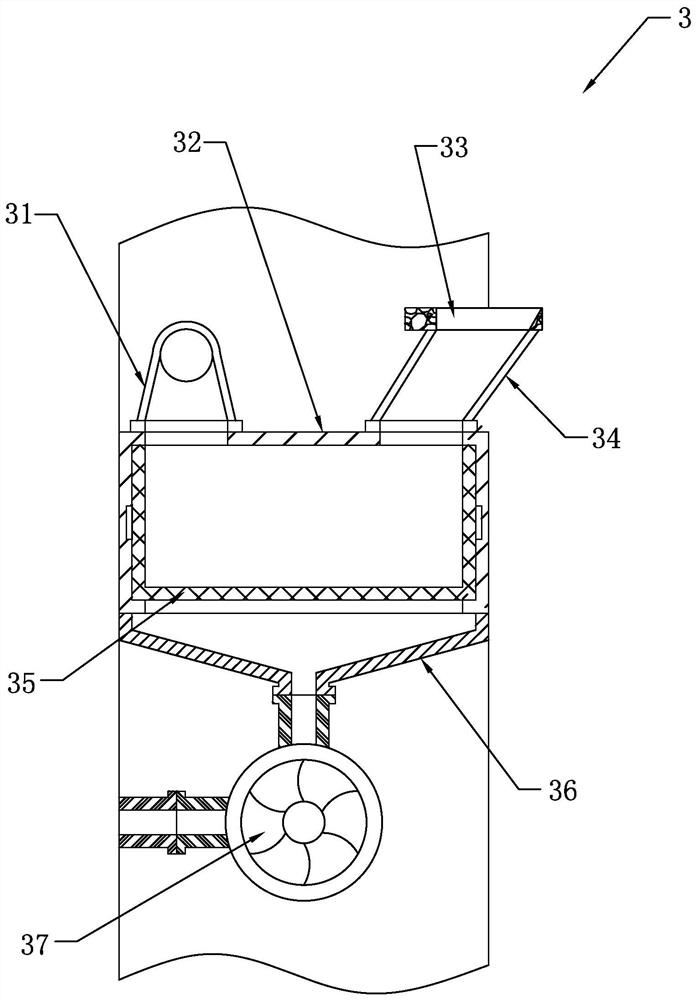

Automatic dust removal device of distribution box

InactiveCN111013824APlay a cooling roleAdequate adsorptionUsing liquid separation agentCleaning using gasesWater storageThermodynamics

The invention discloses an automatic dust removal device of a distribution box. The automatic dust removal device comprises a device body, wherein the left end wall of the device body is provided withan ash suction port communicated with the outside, the right end of the ash suction port is communicated with a filtering cavity, the filtering cavity penetrates through the device body front and back, a belt transmission cleaning device is arranged on the inner bottom wall of the filtering cavity, and comprises a driving belt wheel and a driven belt wheel, the driving belt wheel and the driven belt wheel are fixedly mounted through a belt wheel shaft and are in transmission connection through a first belt, and hair brushes are arranged on the driving belt wheel and the driven belt wheel. According to the device, the automatic dust removal device is placed at the air blowing opening in the side wall of a distribution box, an electric air discharge device sucks the dust in the distributionbox and plays a role in heat dissipation of the distribution box, large-particle dust is precipitated through atomization of water, small-particle dust enters an adsorption cavity, the dust can be well and sufficiently adsorbed through an electrostatic adsorption method, the small-particle dust is gathered together, the dust is swept and conveyed into a water storage tank through a sweeping device and is collected, it is guaranteed that the dust is sufficiently adsorbed in the device through two treatments, and operation is easy and convenient.

Owner:兰溪米雪电子科技有限公司

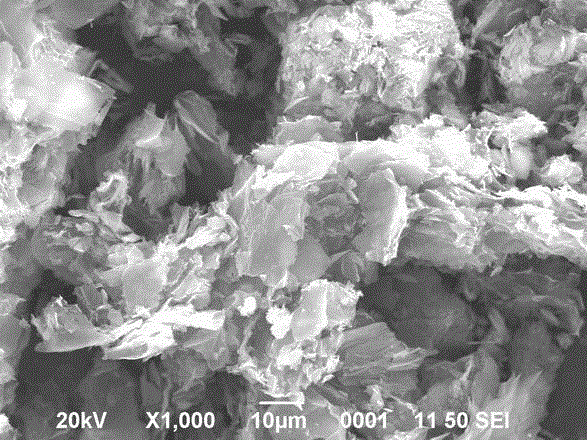

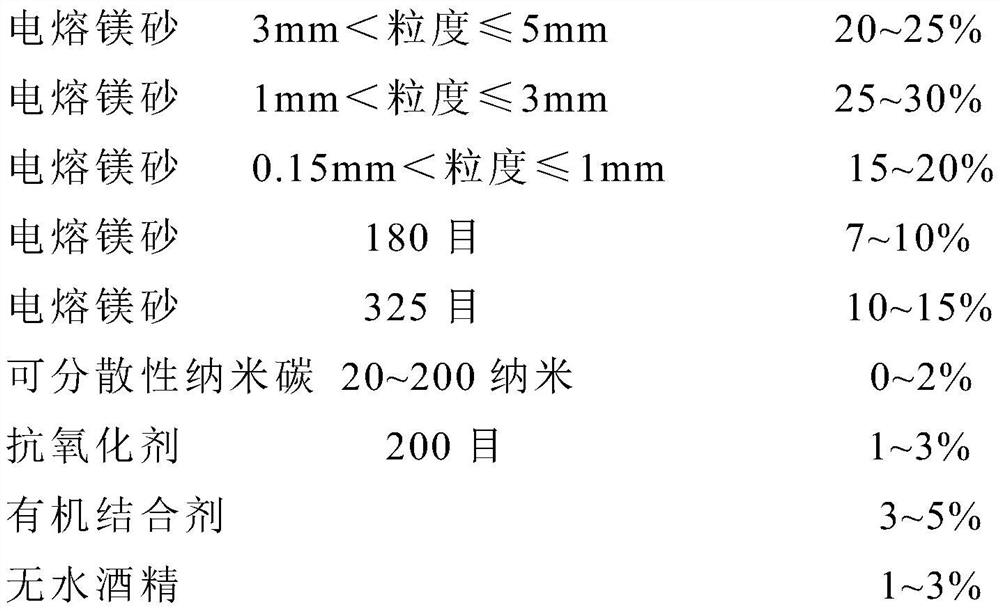

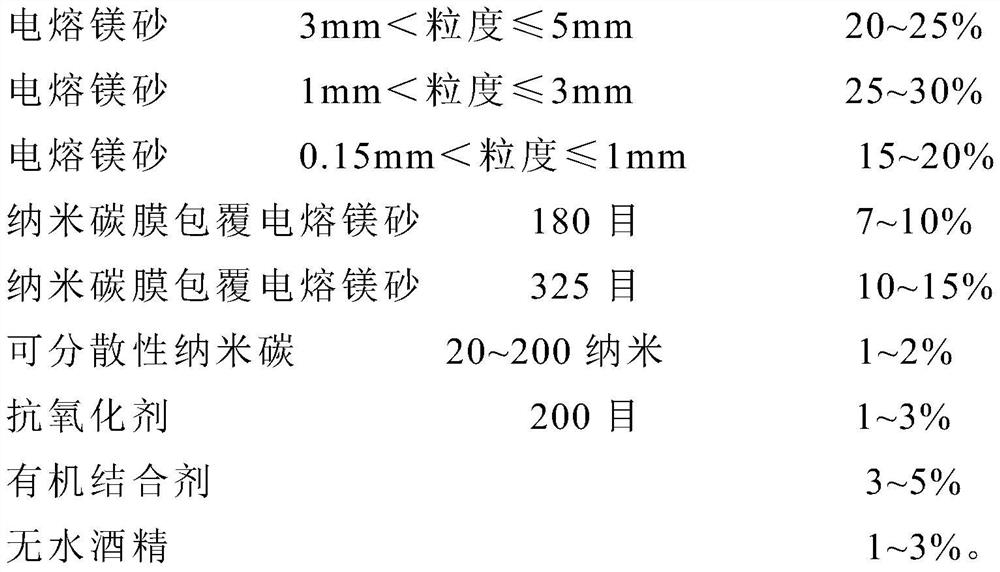

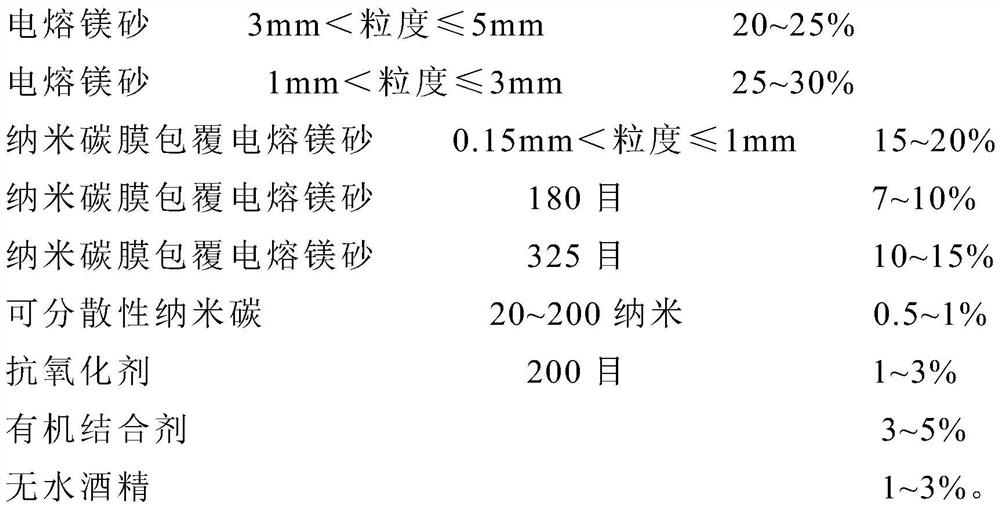

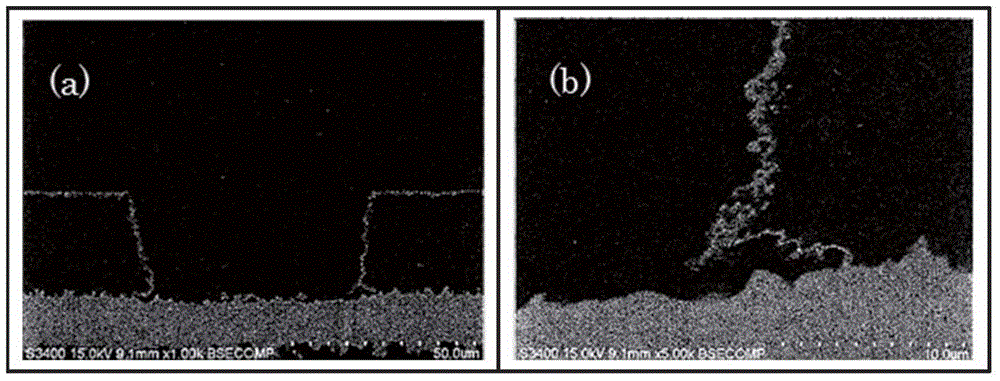

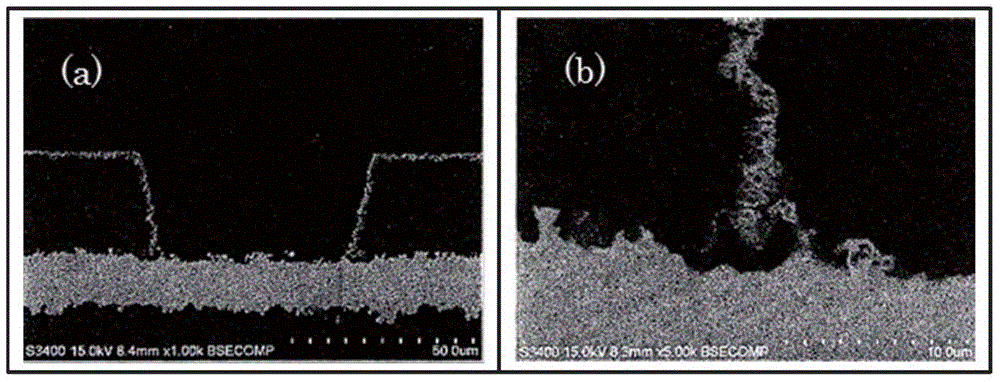

Nano-carbon low-carbon magnesia carbon brick for ladle slag line and preparation method

The invention discloses a nano-carbon low-carbon magnesia-carbon brick for ladle slag lines and a preparation method, wherein the magnesia-carbon brick comprises fused magnesia with five particle sizes, dispersible nano-carbon and an antioxidant, and through coating of nano-carbon films on the surfaces of fused magnesia particles with different particle sizes and application of the dispersible nano-carbon, the nano-carbon low-carbon magnesia-carbon brick can be used for ladle slag lines. By utilizing the characteristics that the nano carbon film and the dispersible nano carbon are mainly amorphous carbon, contain a small amount of graphite young crystals, can be infiltrated by a solvent and the like, infiltration and adsorption of the nano carbon film and the dispersible nano carbon to anorganic binding agent are improved, and uniform dispersion of the nano carbon in the magnesia carbon brick is realized; in addition, the size of carbon particles in the magnesia carbon brick is greatly reduced by controlling the sizes of the nanocarbon film and the dispersible nanocarbon with the thickness of 20-200 nanometers, the contact frequency of a refractory raw material of the magnesia carbon brick and the carbon particles is remarkably improved, the performance of the carbon particles is exerted under the condition of low carbon content, and the anti-erosion permeability of the magnesia carbon brick is improved.

Owner:武汉钢铁有限公司

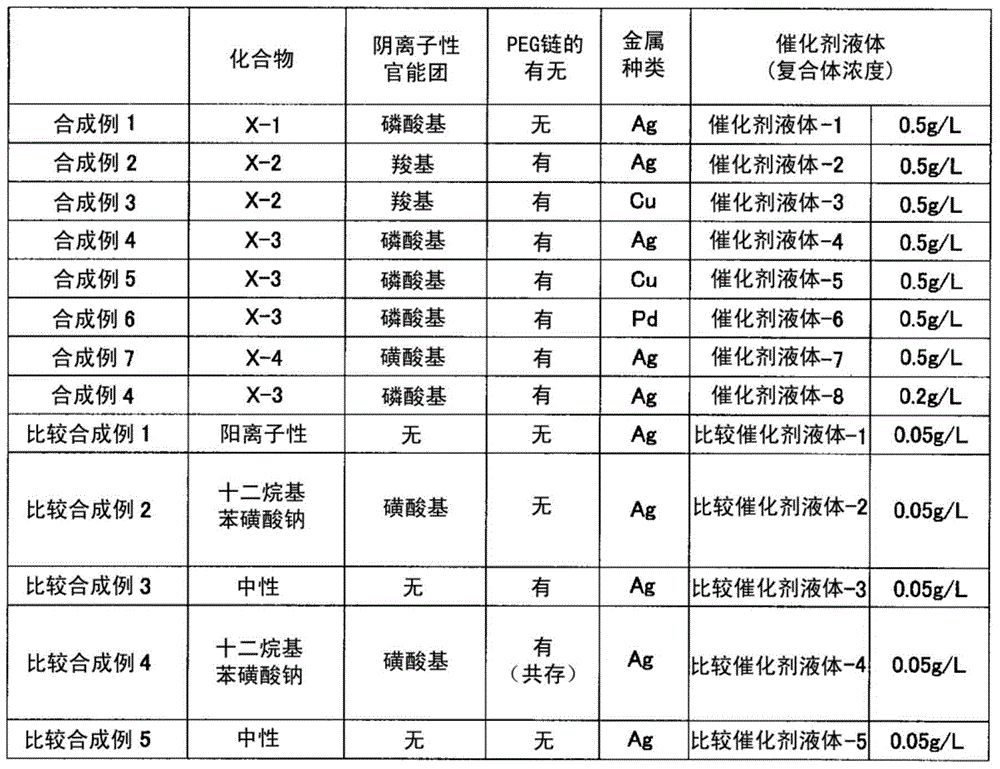

Catalyst for electroless plating, metallic coating film produced using same, and method for producing said metallic coating film

ActiveCN104903492ALess risk of price changesImprove economyOrganic-compounds/hydrides/coordination-complexes catalystsLiquid/solution decomposition chemical coatingPhosphoric acidElectroless plating

The present invention provides: a catalyst for electroless plating, which is characterized by being a complex of a compound (X) and metal nanoparticles (Y), wherein the compound (X) is produced by polymerizing a monomer mixture (I) that contains a (meth)acrylic acid-type monomer having at least one anionic functional group selected from the group consisting of a carboxy group, a phosphoric acid group, a phosphorous acid group, a sulfonic acid group, a sulfinic acid group and a sulfenic acid group; a metallic coating film produced using the catalyst; and a method for producing a metallic coating film using the catalyst.

Owner:DIC CORP

Marinated beancurd skins

InactiveCN106578112AGreat tasteAdds a sweet flavorCheese manufactureFood scienceReady to eatHigh pressure

The invention relates to marinated beancurd skins, and belongs to the technical field of food processing. The marinated beancurd skins disclosed by the invention are made by a method including the following steps of grinding soaked soybeans into soybean milk, boiling over the soybean milk, heating the boiled-over soybean milk for heat preservation, extracting beancurd skins formed on the end surface of a soybean milk tank, and baking the extracted beancurd skins until the water content of the baked beancurd skins is 20-25wt%; uniformly spreading the baked beancurd skins on a grid baking layer frame, and performing secondary baking until the baked beancurd skins are golden, dried and crisp; and placing the beancurd skins after secondary baking into a steaming basket, performing softening with steam, quickly moving the softened beancurd skins into a marinating pot, sprinkling seasoning fluid, performing uniform stirring, bagging the marinated beancurd skins, and performing high-pressure sterilization and vacuum packaging. The invention provides a making method of the selenium-enriched pulp-coated beancurd skins, the technology is simple, the number of times for baking is small, cost and energy resources are greatly saved, the pipeline operation can be realized, and the marinated beancurd skins can be suitable for being put into production; the beancurd skins are soaked in marinade seasoning fluid, so that the taste of the marinated beancurd skins can be notably improved; and the marinated beancurd skins disclosed by the invention are moderate in soft and hard degrees, good in mouth feel, rich in nutrition, ready-to-eat after being unpacked, simple in technology and few in nutrition losses.

Owner:青岛力天宏泰新能源科技有限公司

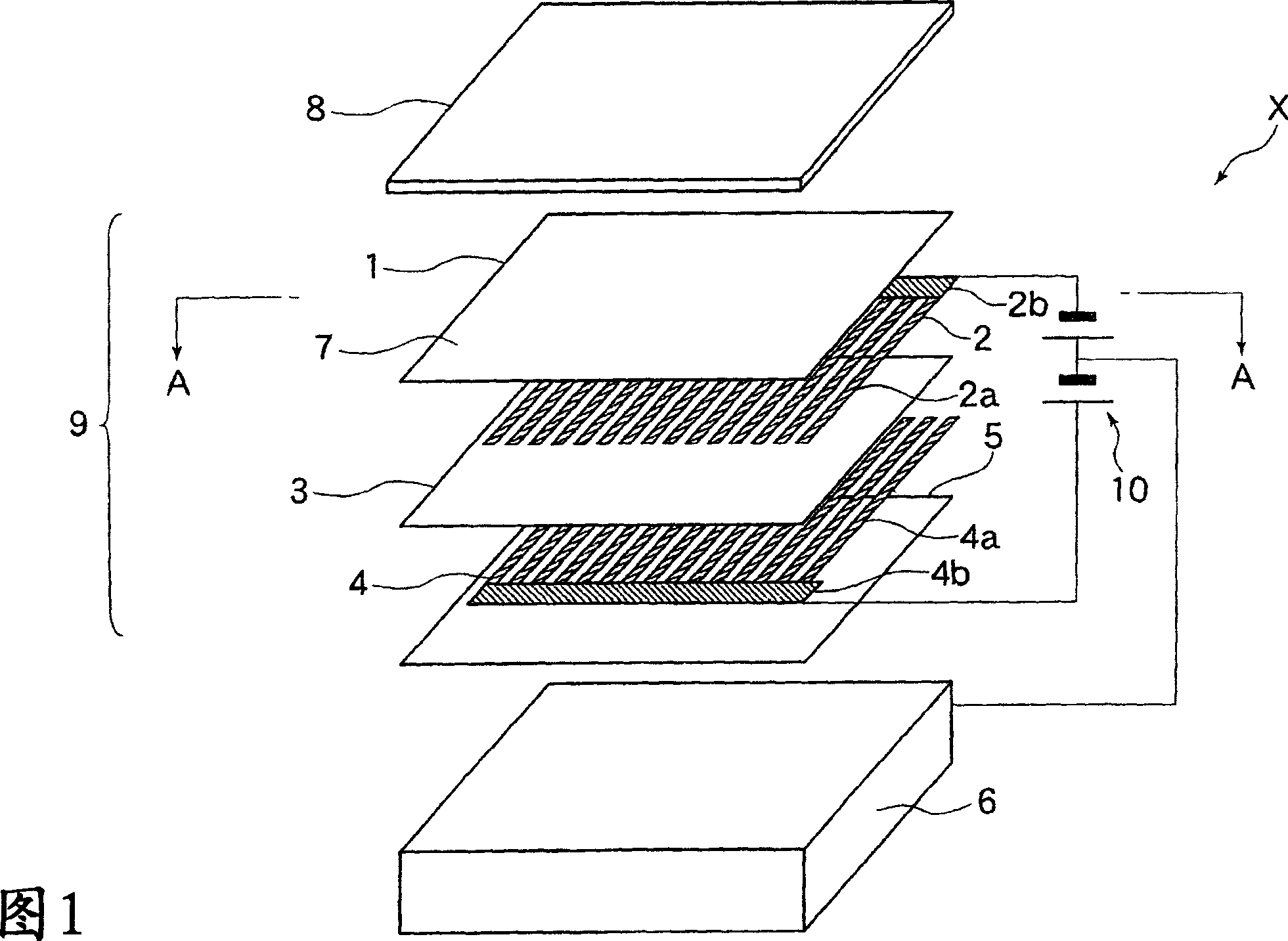

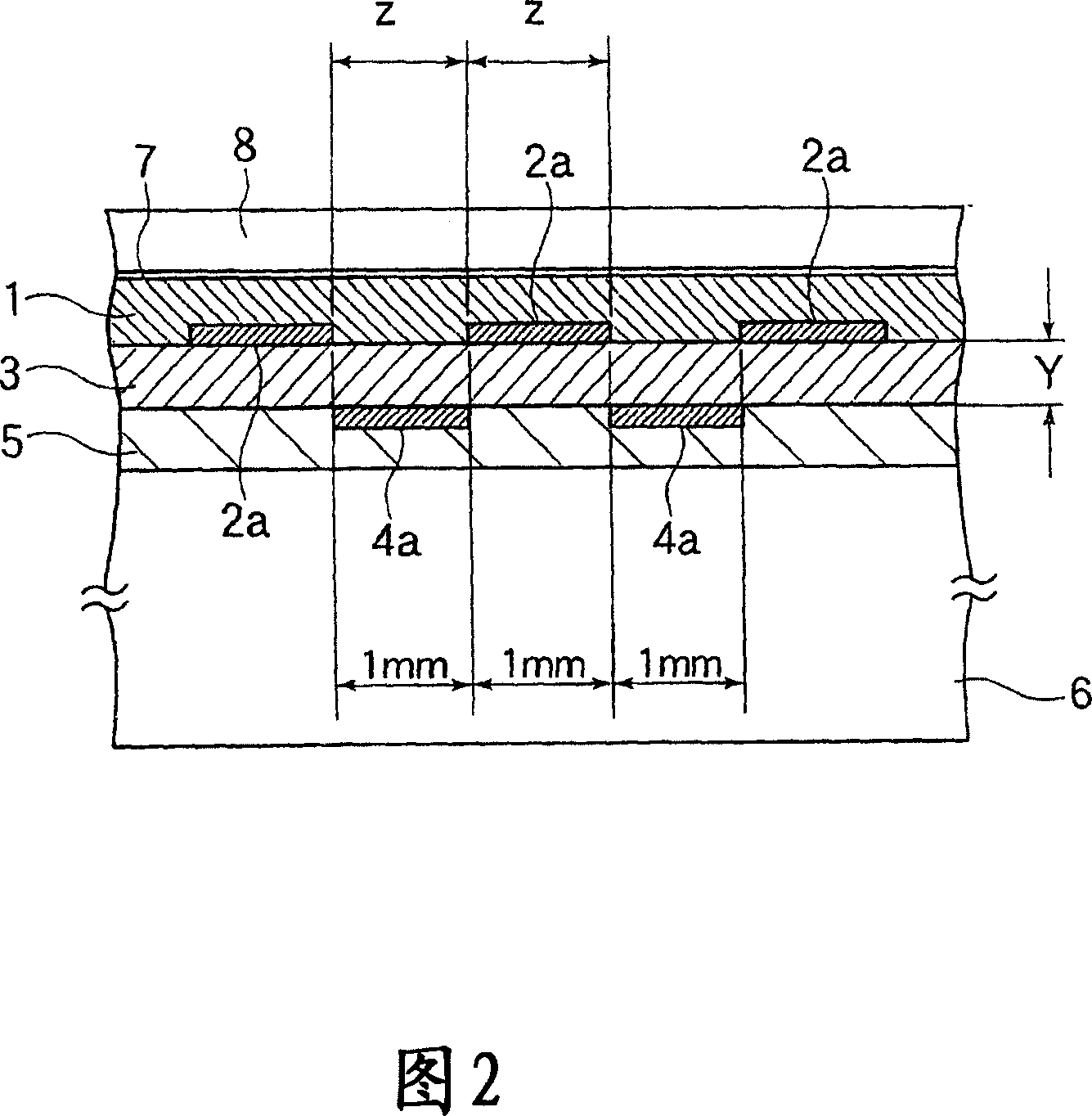

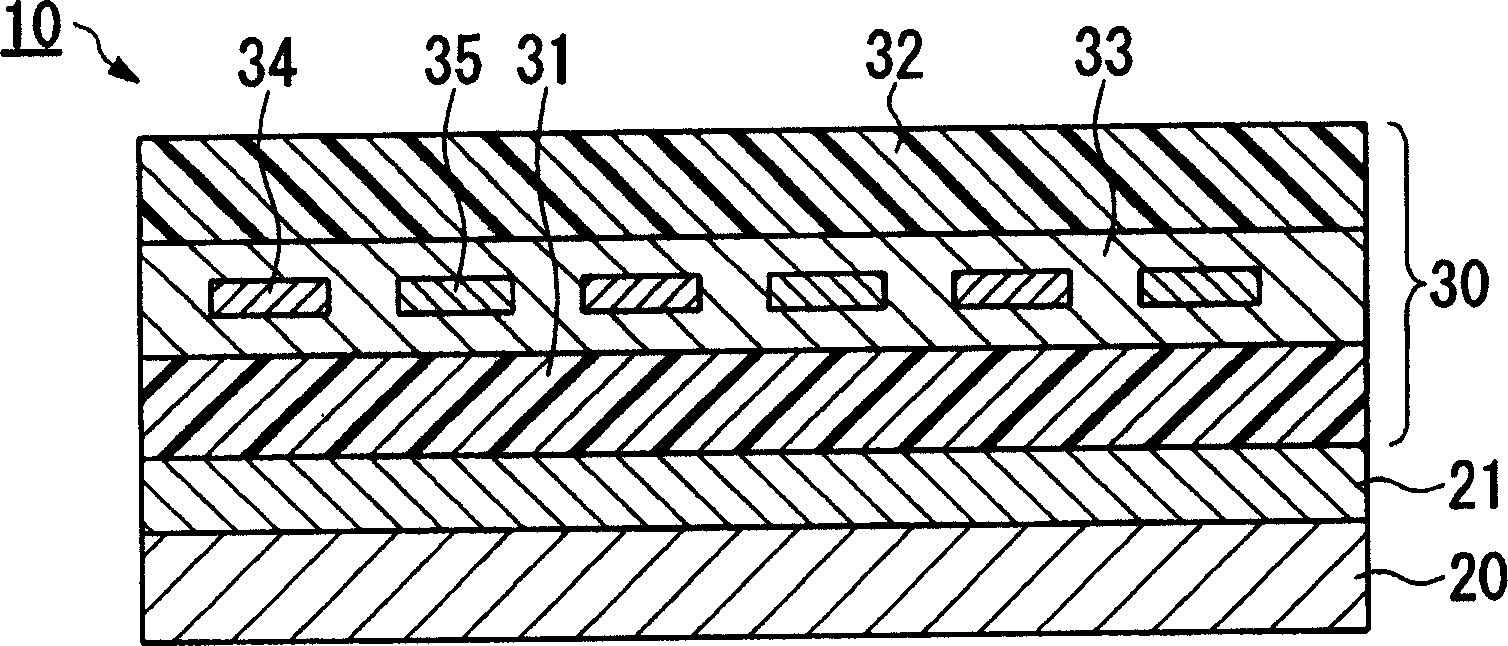

Bipolar electrostatic chuck

InactiveCN1934693AImprove insulation stabilityImprove reliabilitySemiconductor/solid-state device manufacturingElectrostatic holding devicesPhysicsVoltage

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in peeling off a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

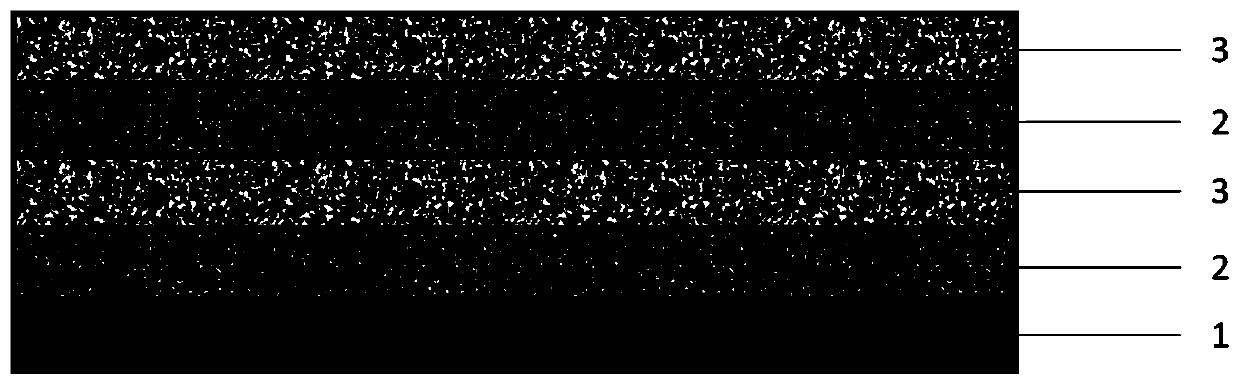

Positive electrode of lithium sulfur secondary battery

ActiveCN109888176AInhibition of the shuttle effectExpand the electrochemical reaction areaNon-aqueous electrolyte accumulator electrodesTotal thicknessLithium sulfide

The purpose of the invention is to provide a positive electrode of a lithium sulfur secondary battery. The positive electrode of the lithium sulfur secondary battery comprises 1 to 5 layers of sulfur-containing positive electrode material layers and 1 to 5 layers of lithium-stored material layers containing a transition metal element; and the sulfur-containing positive electrode material layers and the lithium-stored material layers are alternately coated. The total thickness of the positive electrode is 50 to 800 microns, the thickness of each sulfur-containing positive electrode material layer is 1 to 500 microns, and the thickness of each lithium-stored material layer is 1 to 200 microns. The electrode provided by the invention can suppress the shuttle effect, has a lithium storage performance, and can provide partial capacity; and the positive electrode of the lithium sulfur secondary battery can provide more active sites for lithium sulfide and improve the utilization of sulfur.

Owner:ZHEJIANG UNIV OF TECH

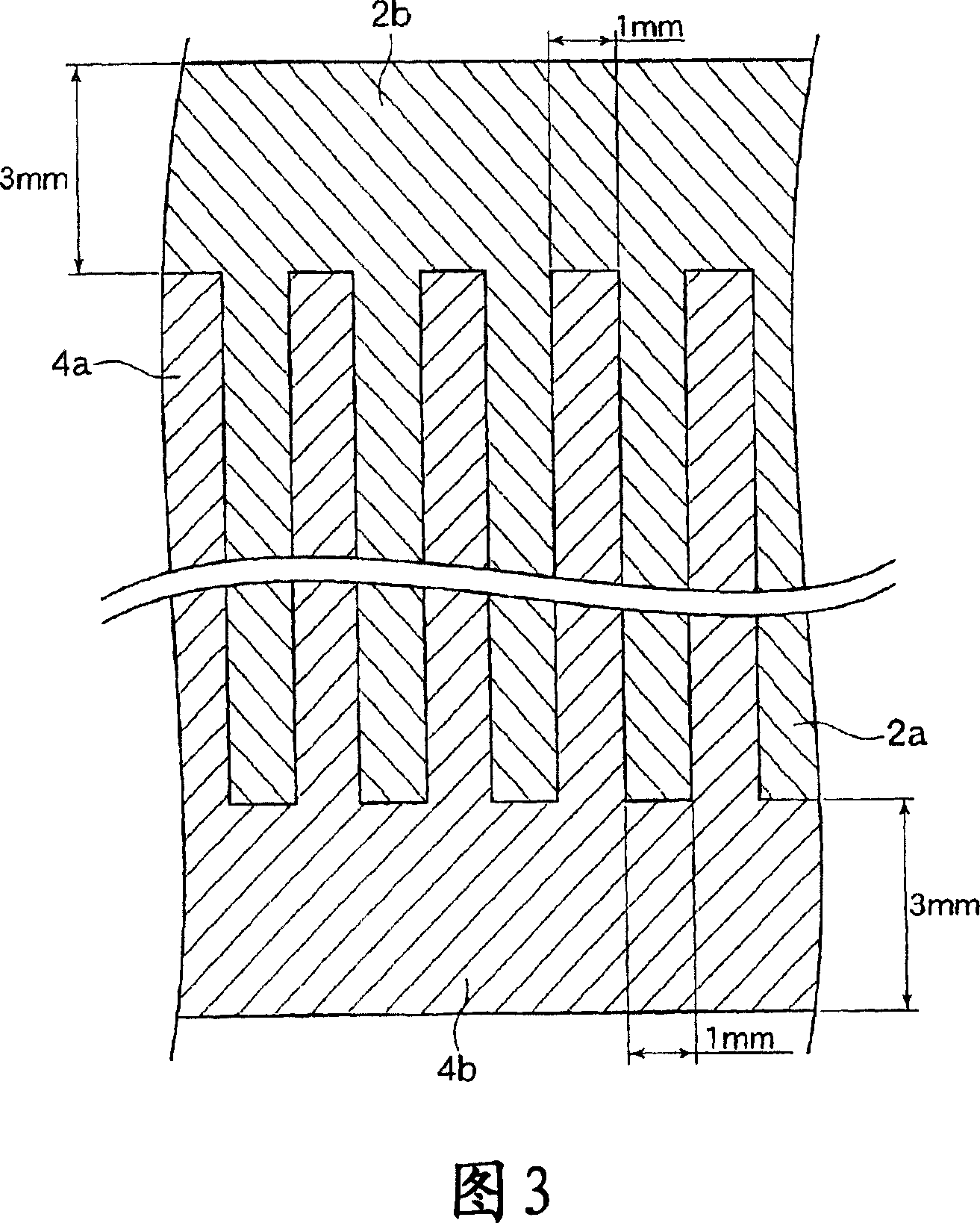

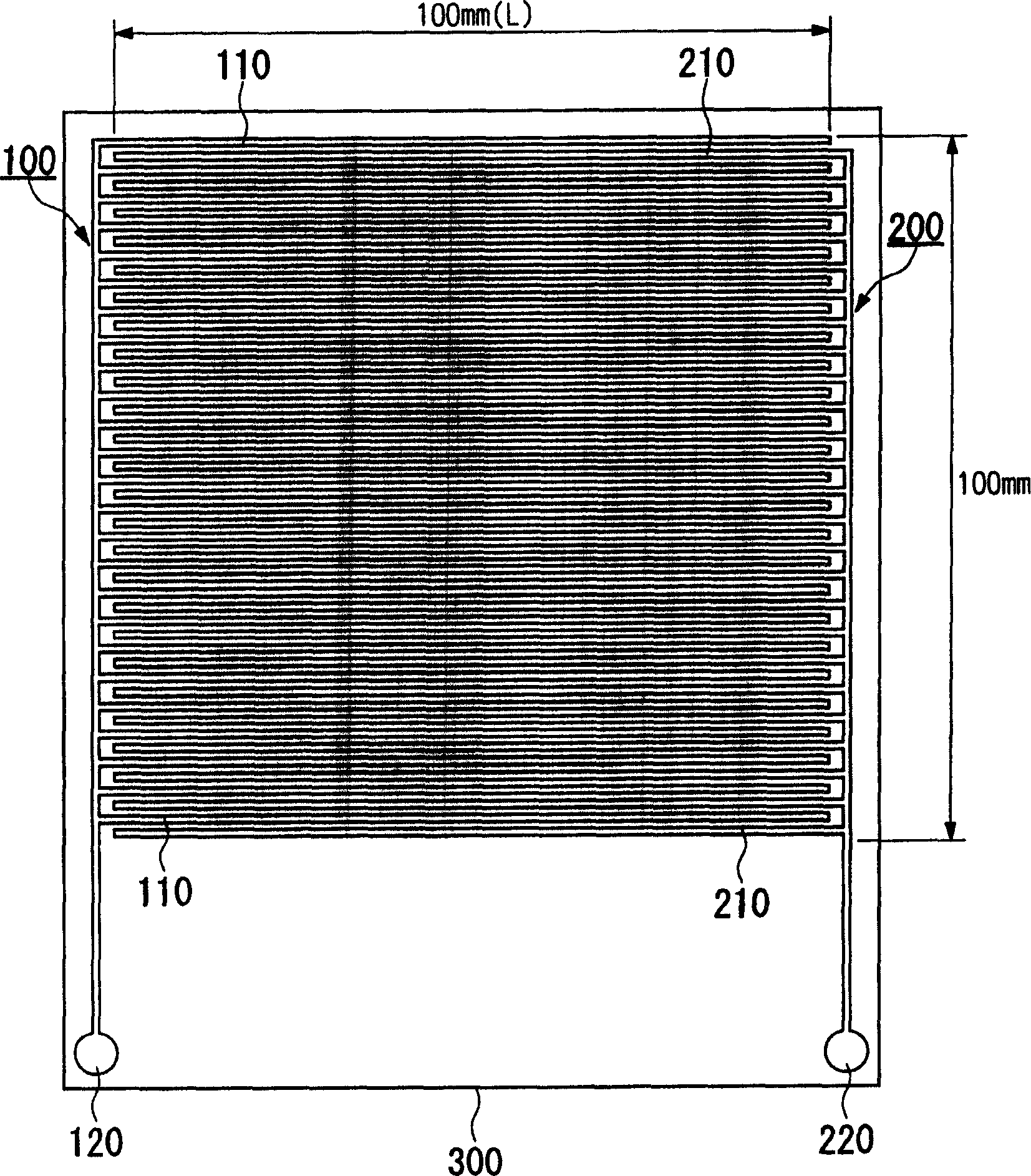

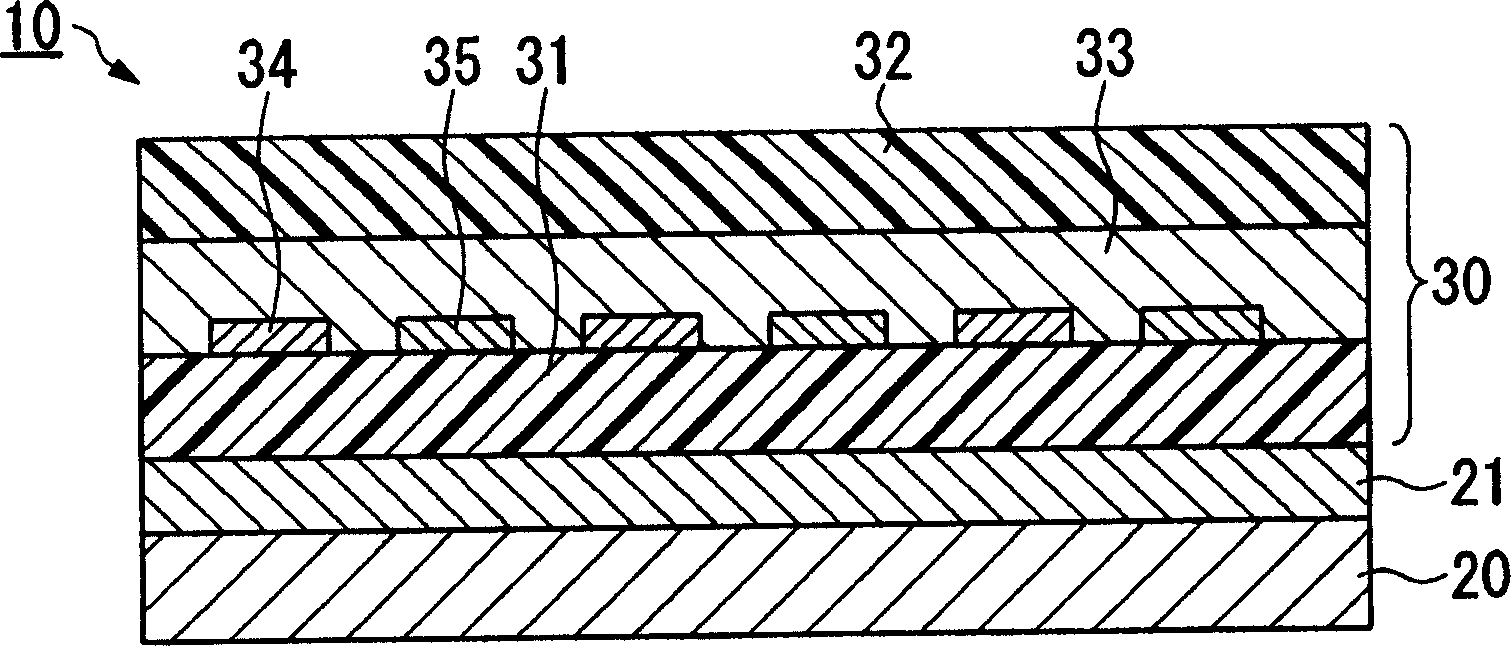

Plate electrode for static electricity sucking disk devices and static electricity sucking disk device using the same

ActiveCN1525547AAdequate adsorptionContainer filling methodsSemiconductor/solid-state device manufacturingOrganic filmStatic electricity

The object of the present invention is to provide an electrode sheet for electrostatic chuck devices which has sufficient adsorption power to insulating materials. In order to achieve the object, the present invention provides an electrode sheet for electrostatic chuck devices (30) comprising a pair of insulating organic films (31) and (32), which are adhered by an insulating adhesive layer (33), and electrodes (34) and (35), which are present in the insulating adhesive layer (33), wherein the thickness of the insulating adhesive layer (33) is larger than that of the electrodes (34) and (35).

Owner:TOMOEGAWA PAPER CO LTD

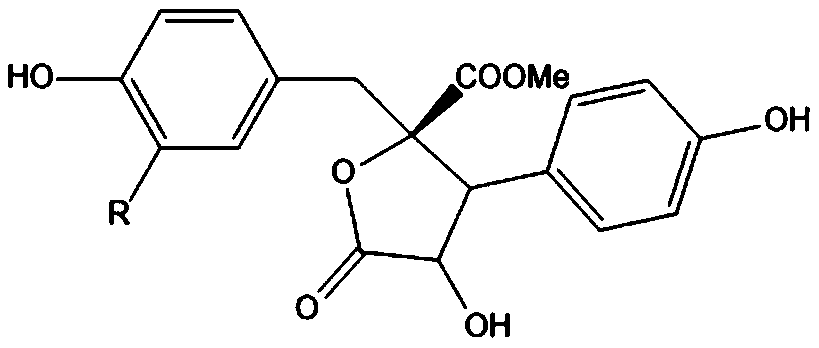

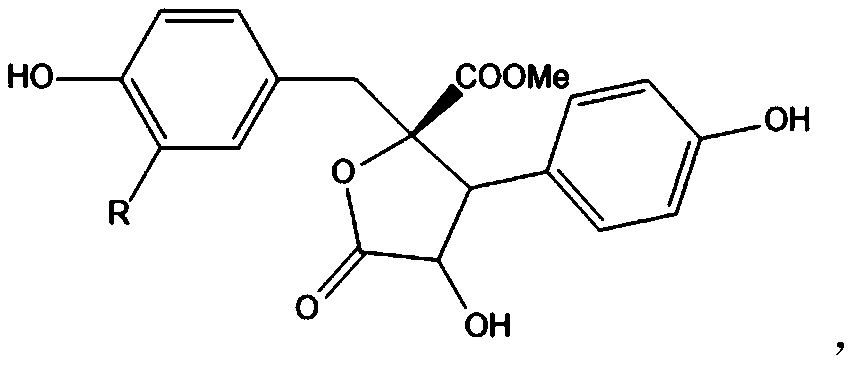

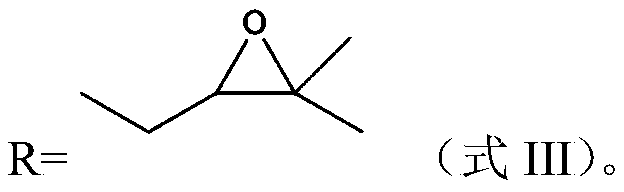

Application of aspergillus terreus secondary metabolite-butyrolactone in preparation of medicament for treating diabetes

InactiveCN109999024AImprove inflammationReduce generationOrganic active ingredientsMetabolism disorderSecondary metaboliteEthyl acetate

The invention provides an application of aspergillus terreus secondary metabolite-butyrolactone in preparation of a medicament for treating diabetes, and belongs to the technical field of microbial medicaments. The aspergillus terreus secondary metabolite-butyrolactone comprises butyrolactone I, wherein the butyrolactone I is extracted according to the following method: fermenting aspergillus terreus OUCMDZ-2739 inoculated in fermentation broth for 25-35 days at 20-30 DEG C; filtering the fermentation broth after fermentation with denim to separate filtrate and mycelium, respectively extracting with ethyl acetate, mixing the obtained ethyl acetate extracts, and concentrating to obtain ethyl acetate solution extract; and further purifying the ethyl acetate solution extract to obtain the butyrolactone I. By the adoption of the application of the aspergillus terreus secondary metabolite-butyrolactone in the preparation of the medicament for treating diabetes, the medicament can inhibit activity of alpha-glucosidase, regulate a composition of intestinal flora, metabolize more short-chain fatty acids, reduce a uric acid level, maintain synthesis of insulin, avoid rising of a blood sugarlevel, and achieve the purpose of relieving type 2 diabetes.

Owner:嘉兴市爵拓科技有限公司

Dyeing process of active dye

InactiveCN104532614AProlonged Adsorption Diffusion ProcessHigh salt concentrationDyeing processAcetic acidFiber

The invention discloses a dyeing process of active dye. The process comprises the following steps: drying active dye, and then standing at room temperature for 5 minutes; adding a dye leveler; adding a dispersing agent; heating to 40 DEG C; soaking the dye which is processed with clear water for 30 minutes; keeping the temperature for 20 minutes; adding 30% of mirabilite and soaking for 20 minutes; adding 60% of mirabilite and soaking for 10 minutes; heating to 60 DEG C; keeping the temperature for 10 minutes; adding 2% of sodium carbonate and soaking for 20 minutes; adding 8% of sodium carbonate and soaking for 20 minutes; adding 15% of sodium carbonate and soaking for 2 0 minutes; keeping the temperature for 40 minutes; flushing with cold water for 10 minutes; adding glacial acetic acid; flushing with hot water of 80 DEG C for 15 minutes; soaping twice; flushing with hot water for 15 minutes; neutralizing; carrying out fixation; softening; carrying out post-treatment; and discharging the cloth. According to the dyeing process of the active dye disclosed by the invention, after the dye is added, the dye is uniformly attached to the fabric; the mirabilite is added in batches; the salinity in the dye liquid is not too high; color points are prevented from being separated out on the fabric surface; the time interval of adding an additive is prolonged; the adsorption diffusion process of the dye is prolonged; dye molecules in the dye bath can be relatively fully diffused and adsorbed into the fiber; the dye concentration in the dye bath is lowered; the trend of agglomeration of the dye molecules is lowered; and high color fastness is ensured.

Owner:SUZHOU CITY WUZHONG DISTRICT GUOXIANG XUYU WOOLENSWEATER PROCESSING PLANT

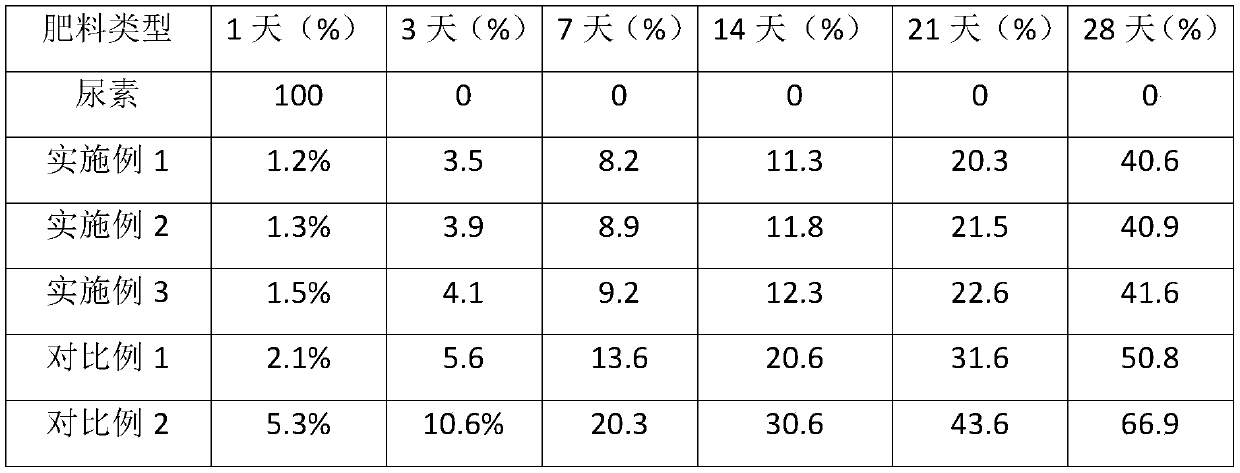

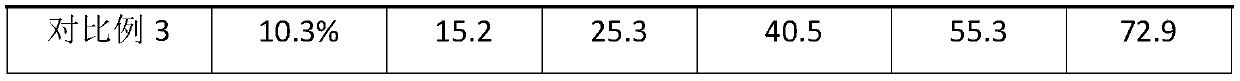

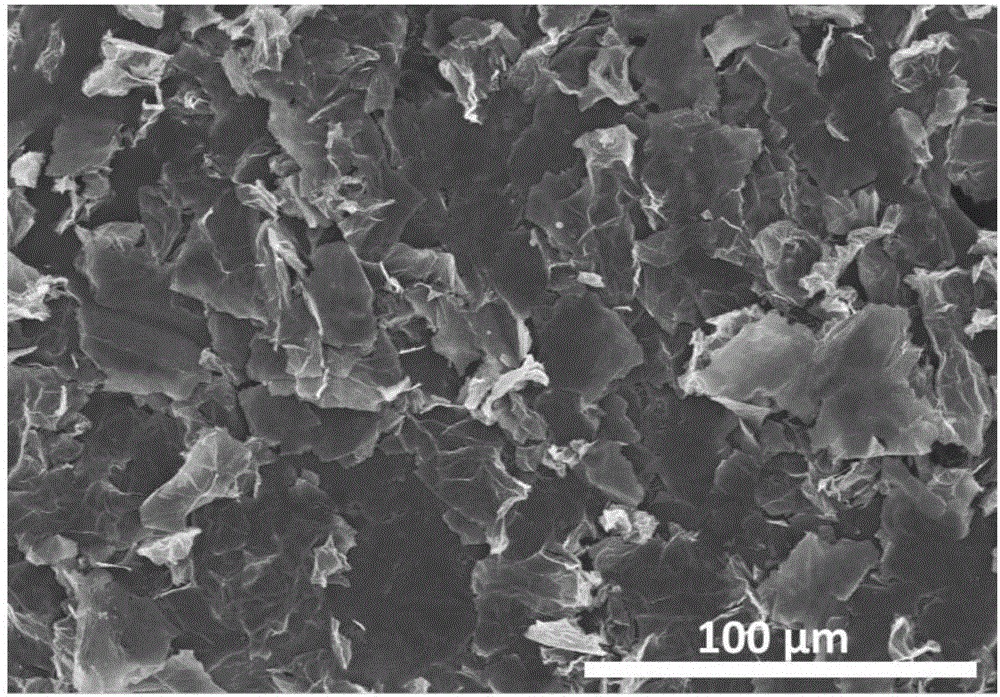

Slow release composite fertilizer for high-tower granulation and preparation method thereof

InactiveCN109776221AImprove disease resistancePromote crop growthClimate change adaptationAgriculture gas emission reductionPolyvinyl alcoholPhosphate

The invention discloses a slow release composite fertilizer for high-tower granulation and a preparation method thereof and belongs to the technical field of fertilizer. The fertilizer is prepared from, by weight, 100-150 parts of urea, 80-100 parts of monoammonium phosphate, 60-80 parts of potassium chloride, 20-40 parts of celestite powder, 10-20 parts of attapulgite powder, 10-20 parts of kieselguhr, 5-15 parts of a medium trace element mixture, 3-5 parts of a synergist and 5-10 parts of an outer-layer coating agent; the outer-layer coating agent is prepared in the mode that polyvinyl alcohol and polyvinylpyrrolidone are subjected to copolymerization, and then biomass charcoal is added. According to the slow release composite fertilizer, nanosilicon dioxide is added as the synergist, and through cooperation of the synergist and a coating material, an obvious slow release effect of the fertilizer is achieved. The prepared fertilizer is safe, environmentally friendly, has an obvious fertilizer efficiency, capable of achieving high tower granulation, low in cost and high in efficiency and has high market application potential.

Owner:GARSONI FERTILIZER MEISHAN

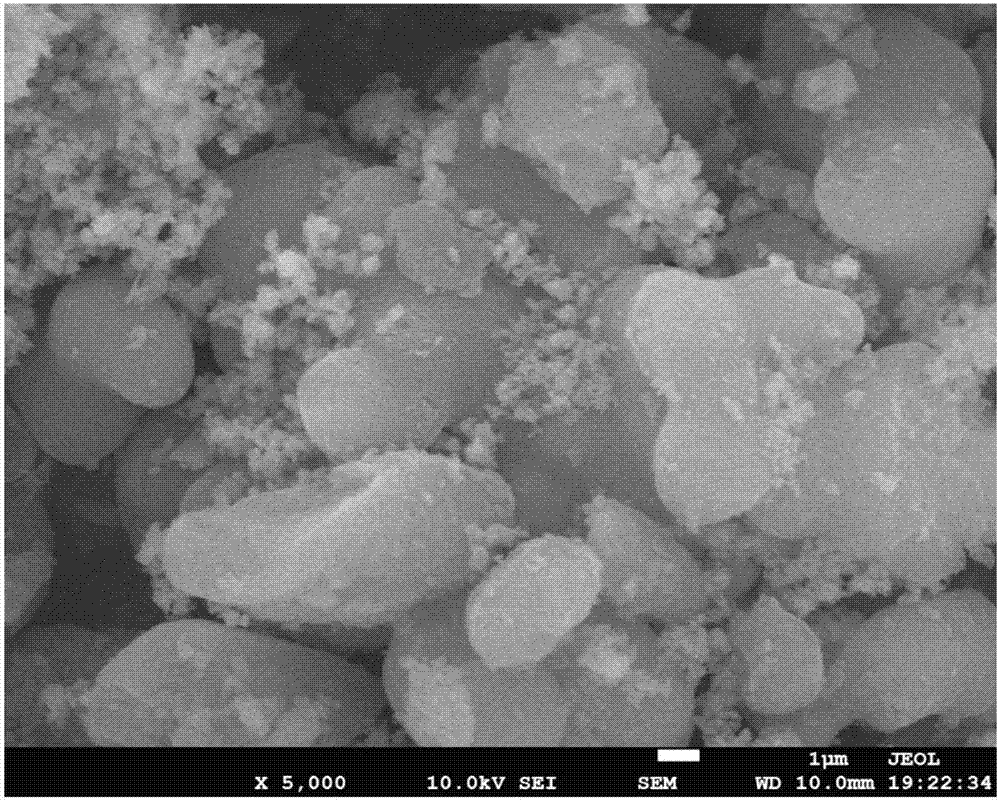

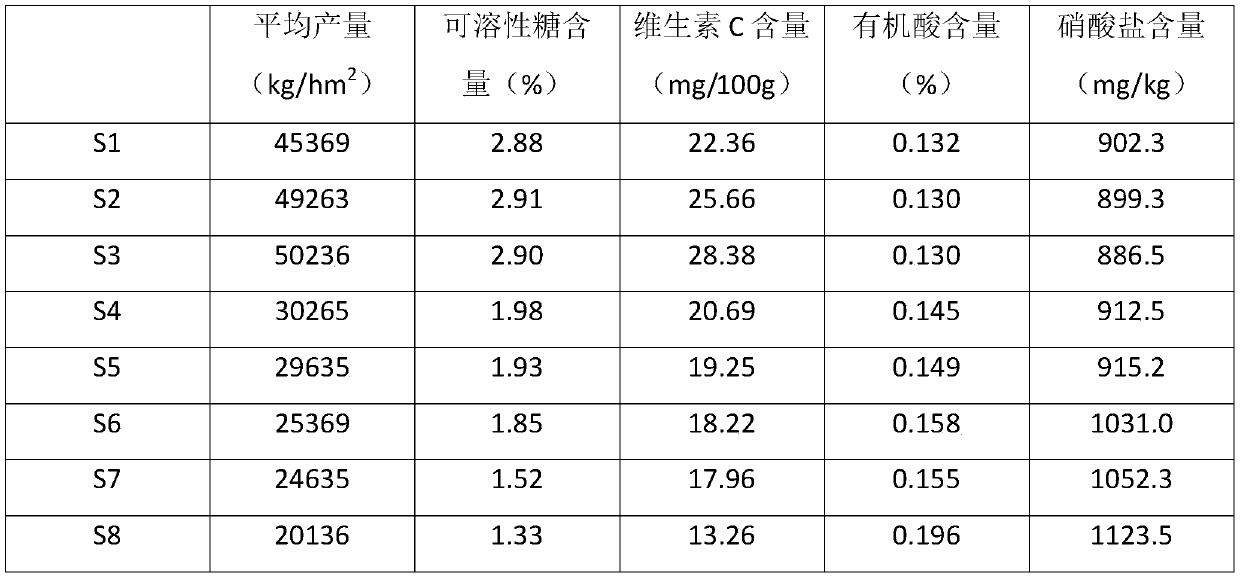

Magnetic ferroferric oxide nano particle and graphene composite, as well as preparation method and application thereof

InactiveCN106179230AImprove adsorption capacityTo achieve the purpose of water purificationLight-sensitive devicesOther chemical processesCvd grapheneIon

The invention discloses a magnetic ferroferric oxide nano particle and graphene composite. The specific surface area of the composite is 60-65m<2> / g, in the composite, ferroferric oxide particles are 10-35nm in size, and ferroferric oxide supports graphene flaky materials, so as to ensure that the flaky materials are stacked up to form gaps, and the gaps are 20 to 100 nm. The composite provided by the invention is used for wastewater treatment, the ferroferric oxide in the composite not only can be used for effectively removing chrome in wastewater, but also cannot produce sludge and cause secondary pollution. Moreover, due to the strong adsorbability of graphene, nano particles and suspended solids can be removed and waste water can be purified well. The invention provides a method which can control sewage in a cheap, reliable and recycling way. A hexavalent chromium ion absorbed composite is taken as an electrocatalyst for being applied to counter electrodes of a dye-sensitized solar cell, therefore, refuse reclamation is achieved, waste is reduced, and resources are saved.

Owner:LIAOCHENG UNIV

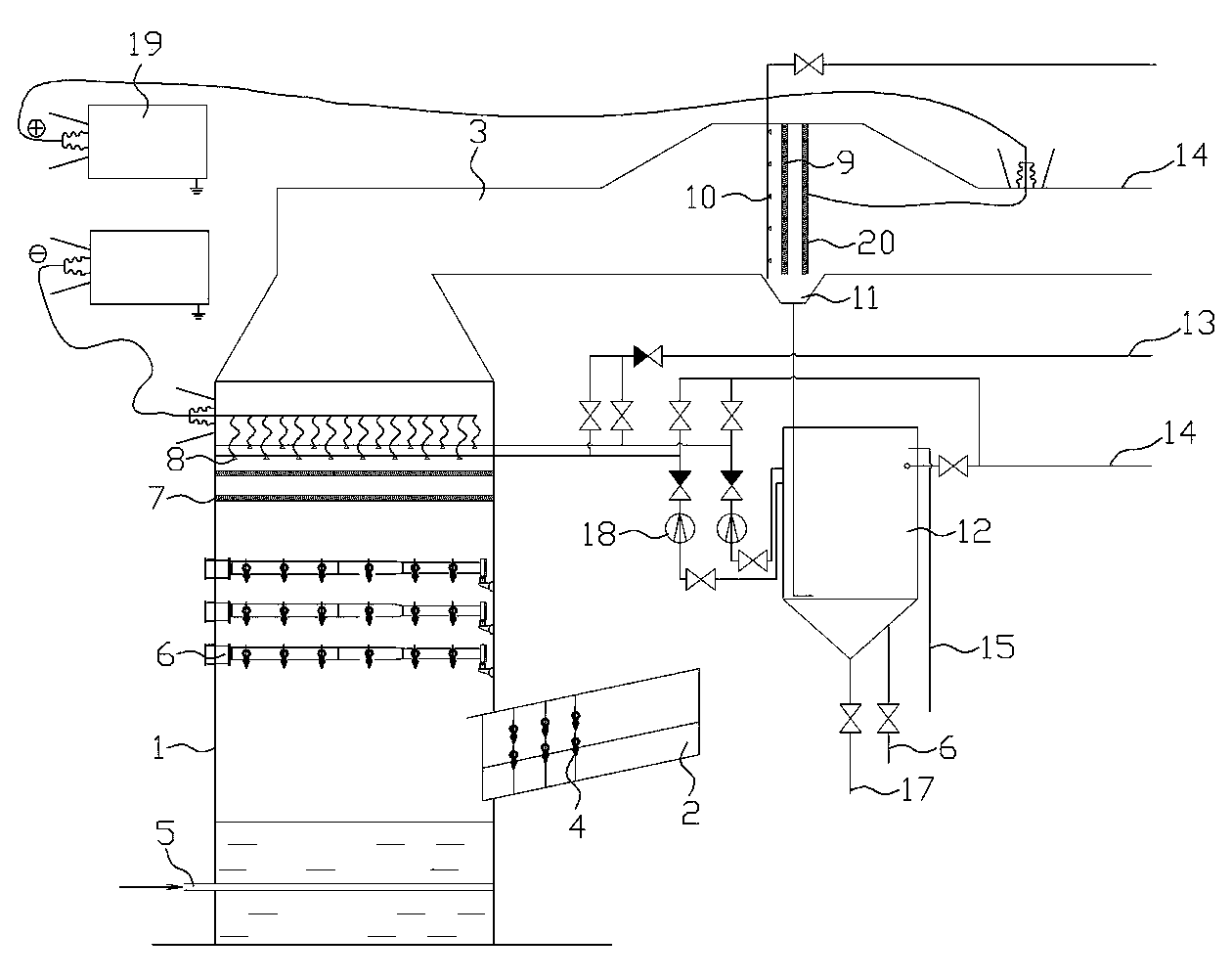

Wet desulfurization system with electrostatic humidifier and anode demister

ActiveCN103446837AEfficient collectionEmission reductionCombination devicesHigh pressureDevice failure

The invention provides a wet desulfurization system with an electrostatic humidifier and an anode demister, which relates to a purification apparatus in a thermal power plant, particularly an apparatus for lowering dust content in spray-type desulfurization absorption tower wet desulfurization fume. The wet desulfurization system comprises an absorption tower, wherein a spray layer and a demister are arranged in the tower; a humidification sprayer is arranged 0.3-1.0m behind the demister; the humidification sprayer is connected with a high-voltage electrostatic power supply; a last stage demister is arranged in a flue which is 4-10m behind the humidification sprayer; a flush sprayer for flushing the last stage demister is arranged in front of the last stage demister; an electrostatic demister is arranged behind the last stage demister and connected with the high-voltage electrostatic power supply. The wet desulfurization system effectively lowers the smoke dust discharge amount of the thermal power plant chimney, has the advantages of low energy consumption, lower investment, convenient maintenance of equipment, long service life, short construction cycle, extremely low equipment failure rate, simple operation regulation and high equipment safety, and can effectively collect fine particles, escape ammonia, heavy metal, organic pollutants and the like.

Owner:王利国 +2

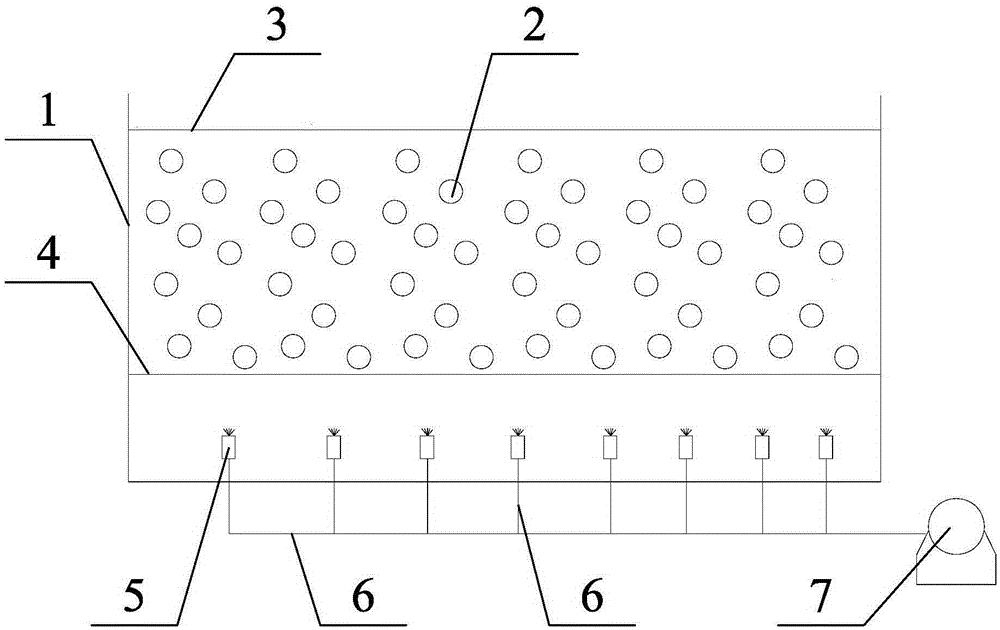

Sewage treatment tank

InactiveCN105254013AImprove effectivenessIncrease varietyTreatment with aerobic and anaerobic processesSewageOxygen

The invention relates to the technical field of equipment for sewage treatment and provides a sewage treatment tank. The sewage treatment tank comprises an aeration tank and a plurality of biological stuffing filling the aeration tank, wherein the microorganism is attached to the biological stuffing to decompose the pollutants in the sewage; air can be blown into the aeration tank from bottom to top; the biological stuffing is arranged, so that the biology species in the aeration tank are increased; when the biological stuffing is under the driving of air, the air bubble in the sewage can be impacted, so that the air bubble is smaller and thinner, the quantity of the air bubble is increased and the use ratio of oxygen is increased; through the arrangement, the pollutants in the sewage can be thoroughly removed.

Owner:JIANGSU ONE WATER IND CO LTD

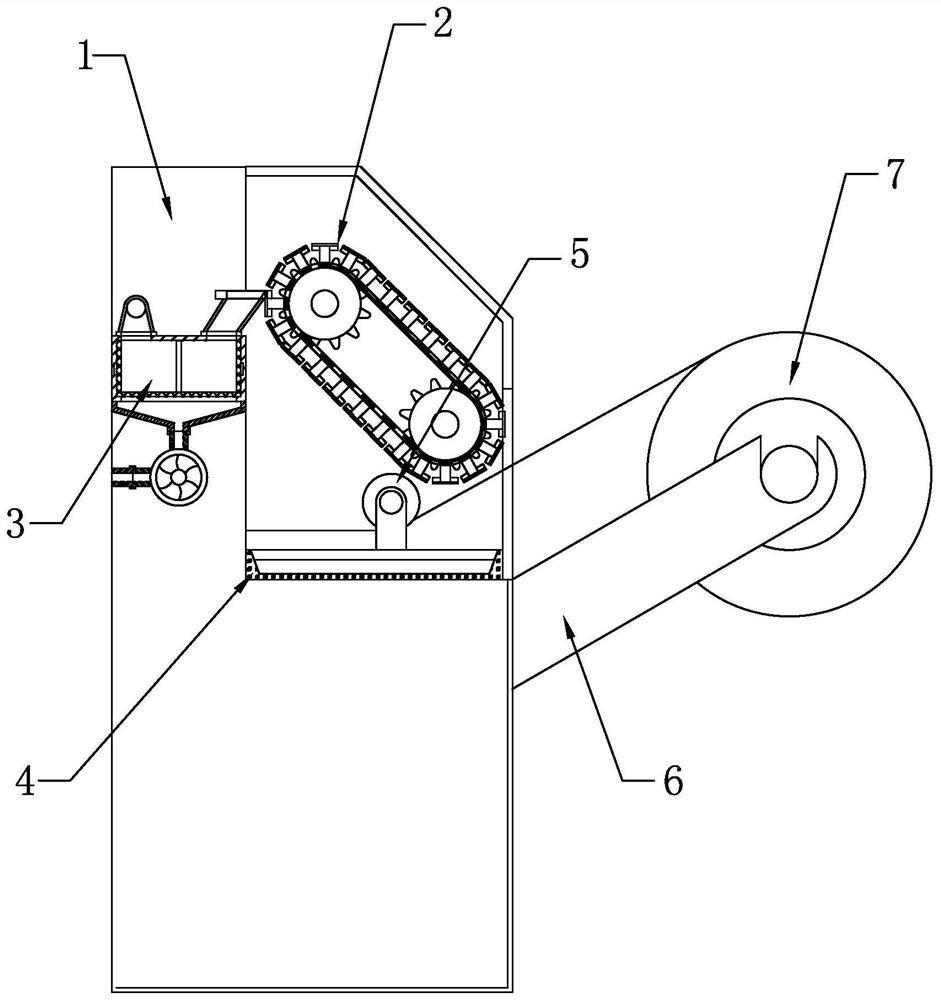

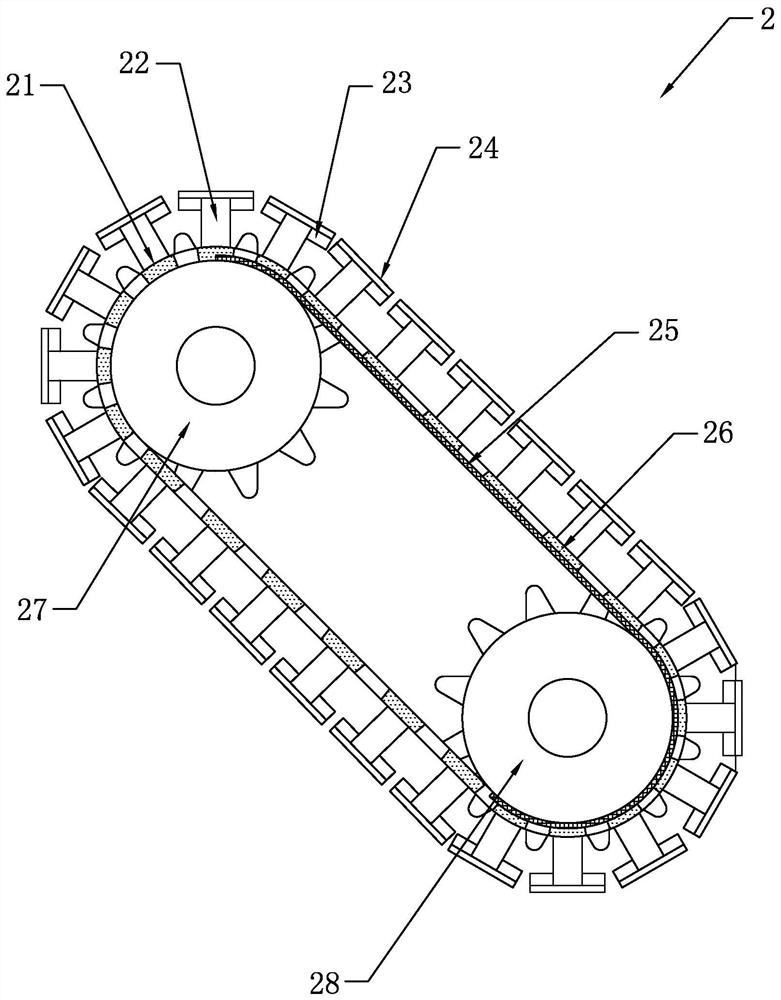

Broken thread cleaning device of textile equipment and application method thereof

InactiveCN111889456AAdequate adsorptionReduce flyingElectrostatic cleaningDirt cleaningStructural engineeringMechanical engineering

The invention discloses a broken thread cleaning device of textile equipment and an application method thereof, and belongs to the technical field of textile cleaning equipment. The broken thread cleaning device comprises a textile frame, a discharge guide roller, a fixing frame and a spool, and further comprises an electrostatic adsorption mechanism, a storage mechanism and a storage disc; the electrostatic adsorption mechanism is located directly above the discharge guide roller, the storage mechanism is located at the end, away from the spool, of the discharge guide roller, and the storagedisc is located under the discharge guide roller; the electrostatic adsorption mechanism comprises a transmission chain, a plurality of groups of conductive rods, a plurality of groups of adsorption plates, two conductive rails, a driving wheel and a driven wheel, the driving wheel is connected with the driven wheel through the transmission chain, the conductive rails are fixed between the drivingwheel and the driven wheel on both sides of the transmission chain, the multiple groups of conductive rods are arranged on the transmission chain, and the multiple groups of adsorption plates are correspondingly fixed to the conductive rods; and conductive sheets are arranged on the adsorption plates, and the conductive sheets are connected with the conductive rods. According to the technical scheme, broken threads and dust can be adsorbed and collected, the broken threads and dust flying are reduced, and the environmental pollution is reduced.

Owner:JIANGSU JINDA TEXTILE IND

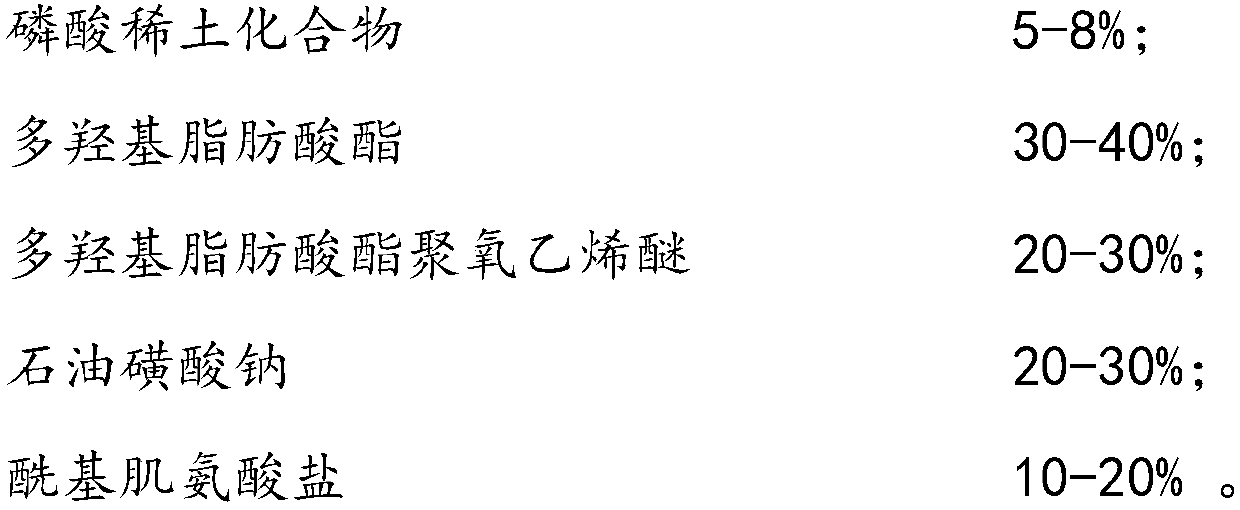

Fire-resistant hydraulic fluid composition, preparation method of fire-resistant hydraulic fluid composition and hydraulic fluid prepared by using composition

InactiveCN107603713AImprove friction and wear resistanceAdequate adsorptionAdditivesPhosphoric acidPhosphate

The invention provides a fire-resistant hydraulic fluid composition, which is characterized by being prepared from a raw material comprising 5 to 8 percent by mass of phosphate rare earth compound. The prepared fire-resistant hydraulic fluid composition can obviously improve frictional wear resistance and rust protection of hydraulic fluid; meanwhile, both swelling and shrinkage of the prepared fire-resistant hydraulic fluid composition for sealing materials, such as chemigum, accord with related standard requirements.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Preparation and use methods of magnesium hydrate/reduced graphene oxide composite material

ActiveCN108295829AEfficient photocatalytic performanceEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationOxide compositeSewage

The invention provides a preparation method of a magnesium hydrate / reduced graphene oxide composite material with efficient photocatalytic performance. Another aim of the invention is to provide efficient application of the material in photodegradation of organic pollutants in dyeing wastewater. The composite material is extremely strong in photocatalytic degradation effect and is still relativelyhigh in photocatalytic degradation capacity under a plurality of circulations. Furthermore, as magnesium hydrate has a relatively large density, the composite material is easy to be separated from sewage, thereby providing convenience for recycling of a catalyst.

Owner:FUJIAN UNIV OF TECH

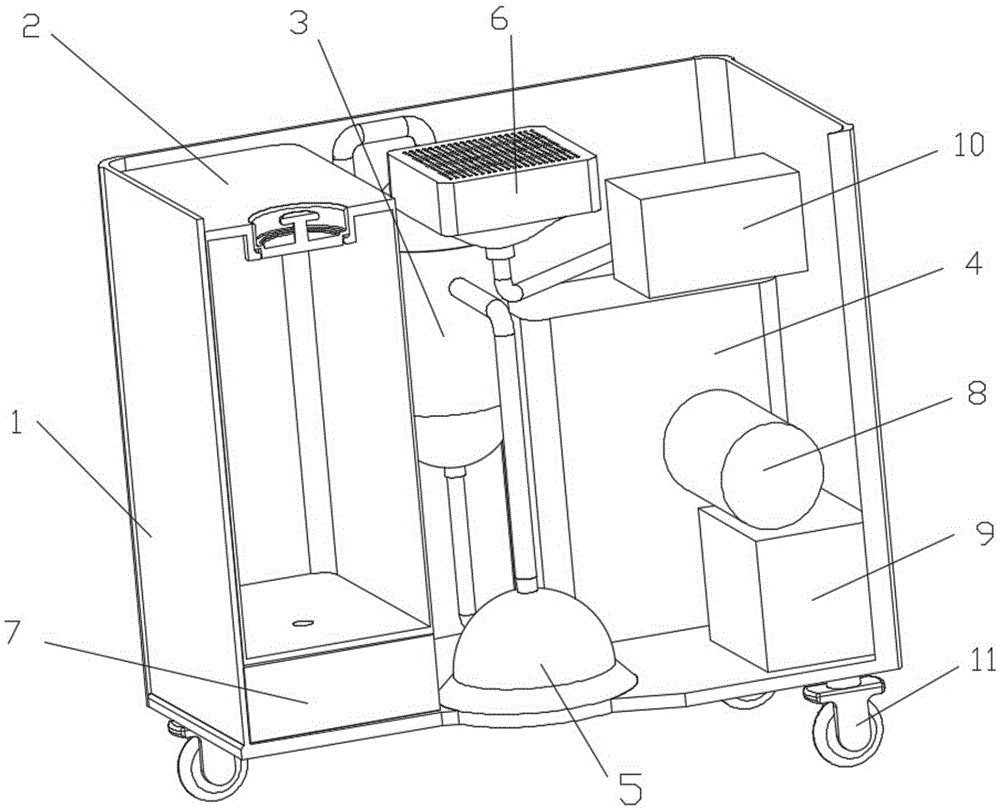

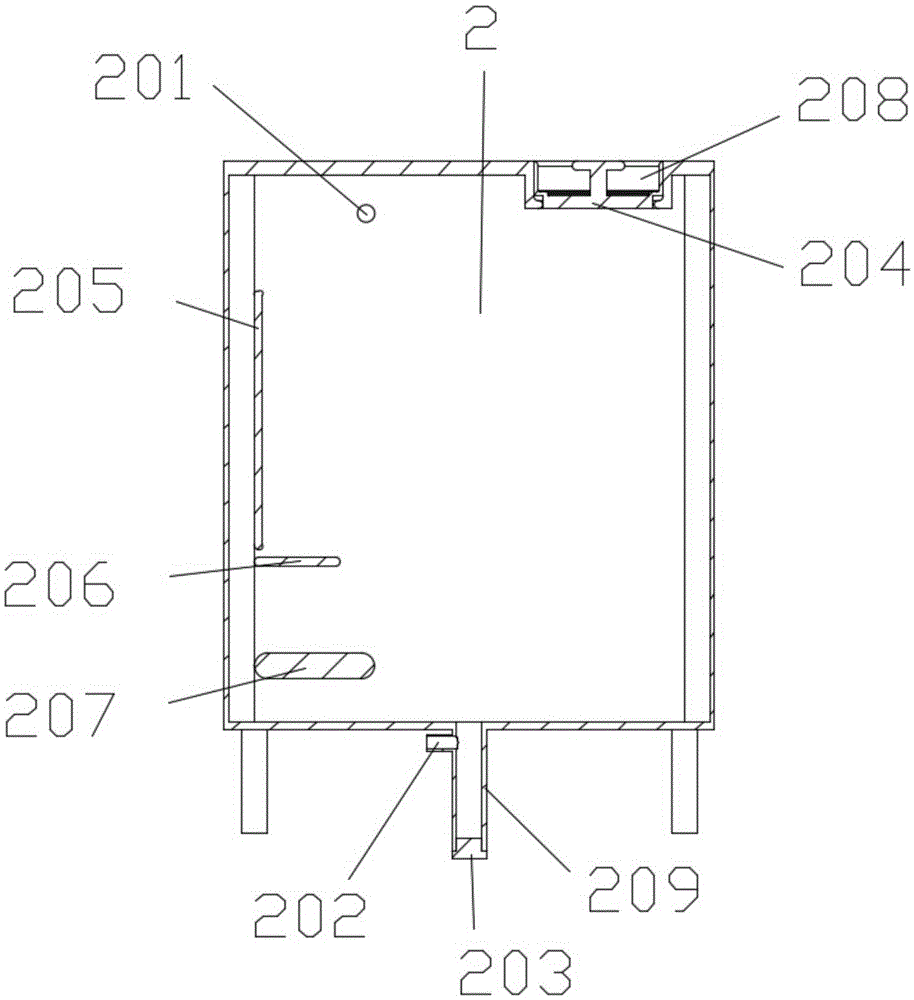

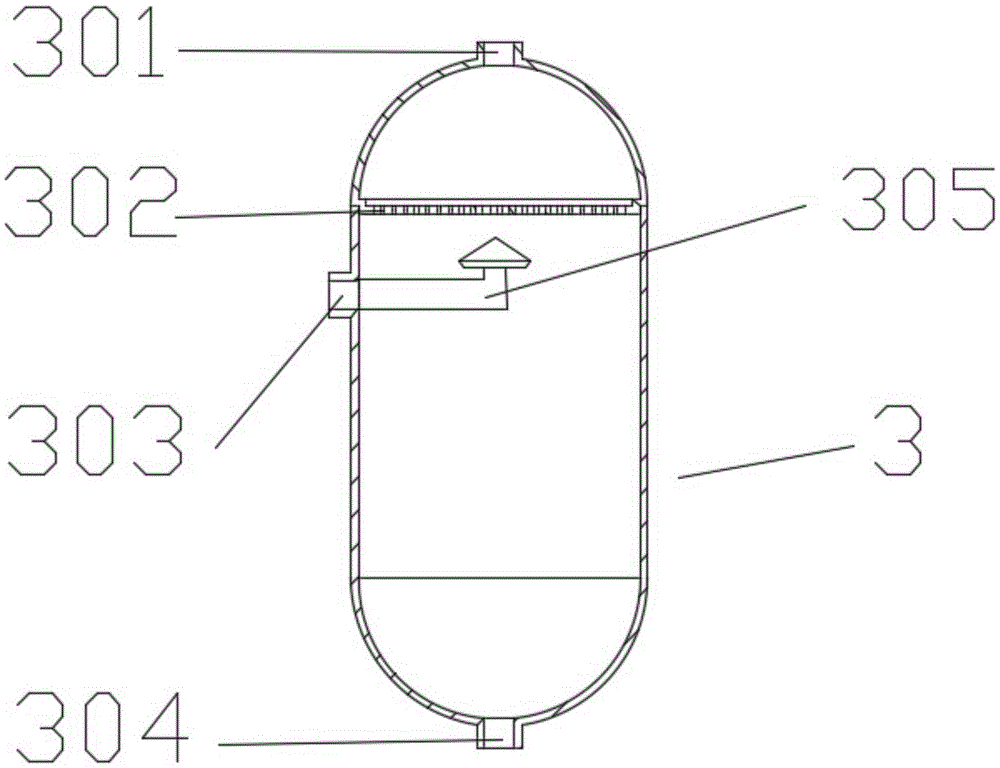

Harmful gas purifier

InactiveCN105477946AEasy to handleCause secondary pollutionGas treatmentDispersed particle filtrationChemical reactionPhysisorption

The invention discloses a harmful gas purifier. The harmful gas purifier is characterized by comprising a case-like frame (1), and a liquid storage device (2), a spraying device (3), a reaction device (4), a dust collector (5), an adsorption device (6), a water pump (7), a blower fan (8), a power supply (9) and a controlling device (10) arranged in the frame (1). The harmful gas purifier provided by invention is portable and highly efficient; a reaction solution is cyclically utilized; reasonable layout enables physical adsorption and chemical reaction to be adequate; different reaction solutions can be prepared according to main harmful gas pollution sources in the air; and the flow of the reaction solution is adjustable, and the harmful gas purifier is convenient to move.

Owner:HOHAI UNIV

Internal and external hydrophobic xonotlite type calcium silicate board as well as manufacturing method and application thereof

PendingCN114751707AAvoid loss of strength and insulation effectImprove waterproof effectHeat proofingBuilding insulationsChemistryEmulsion

The invention discloses a xonotlite type calcium silicate board with hydrophobic inside and outside as well as a manufacturing method and application thereof. The manufacturing method comprises the following steps: 1) mixing a siliceous material and a calcareous material in water, and uniformly stirring; wherein the molar ratio of silicon atoms to calcium atoms in the siliceous material and the calcium material is 1: (0.8-1.2); (2) injecting the uniformly mixed raw material slurry into a dynamic synthesis reaction kettle, introducing high-temperature steam to enable the temperature in the reaction kettle to reach 180-250 DEG C and the pressure to reach 1.5 MPa or above, and then keeping the temperature and the pressure; (3) adding reinforcing fibers accounting for 1-8% of the total mass of solids into xonotlite slurry obtained in the step (2), then adding oily organic silicon emulsion, and fully stirring to enable the solids in the slurry to be fully contacted and mixed with the oily organic silicon emulsion; and (4) carrying out extrusion forming on the slurry prepared in the step (3) in a mold by using a hydraulic machine, and drying to obtain the xonotlite type calcium silicate board with hydrophobic inside and outside.

Owner:LAIZHOU MINGGUANG THERMAL INSULATION MATERIALS

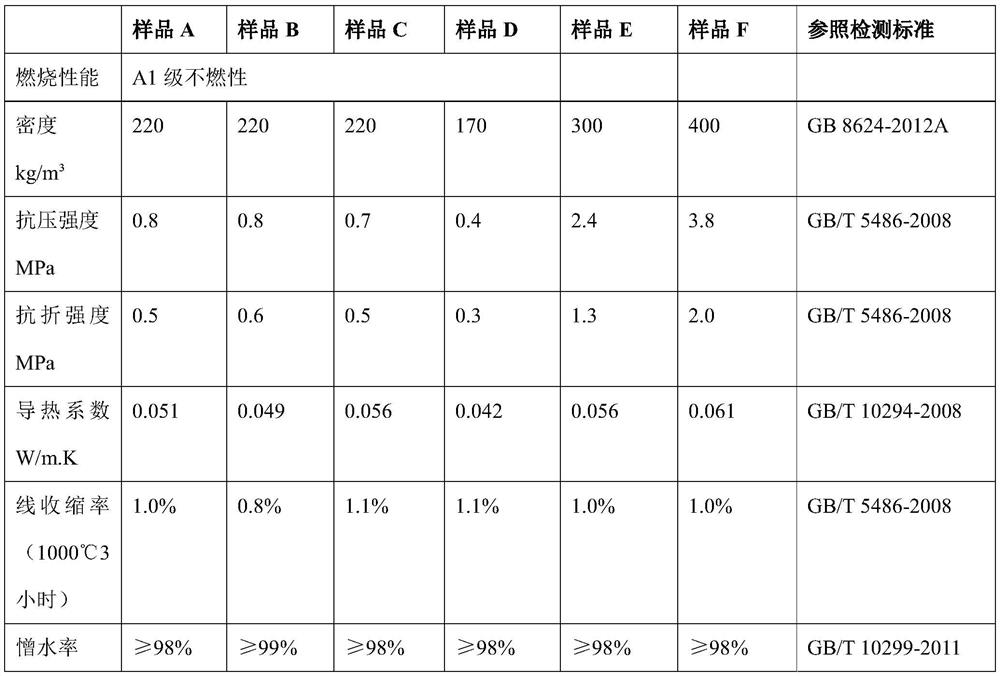

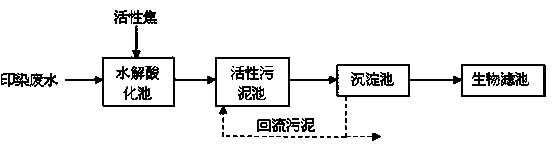

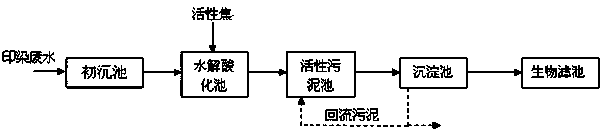

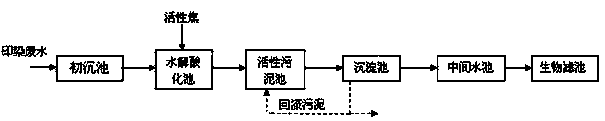

System for treating printing and dyeing wastewater with activated coke adopted and process thereof

ActiveCN103058455BExtended stayImprove removal efficiencyMultistage water/sewage treatmentActivated sludgeBiological filter

The invention provides a system for treating printing and dyeing wastewater with activated coke adopted. The system comprises a hydrolytic acidification device, an activated sludge pool, a settling pool and a biological filter pool, wherein the hydrolytic acidification device, the activated sludge pool, the settling pool and the biological filter pool are arranged in a sequentially connected mode, activated coke is added into the hydrolytic acidification device, and discharging water with the activated coke and from the hydrolytic acidification device enters the activated sludge pool again. According to the system, the activated coke is added into the hydrolytic acidification device, the activated coke is fully mixed with the wastewater in the hydrolytic acidification device, so that standing time of recalcitrant molecules in the wastewater on the hydrolytic acidification device is improved, and efficiency of hydrolytic acidification is improved. The wastewater with the activated coke and from the hydrolytic acidification device enters the activated sludge pool again, the activated coke continues to have the function of absorption and degradation, and removal efficiency on sludge concentration and organic matter in the activated sludge pool is improved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

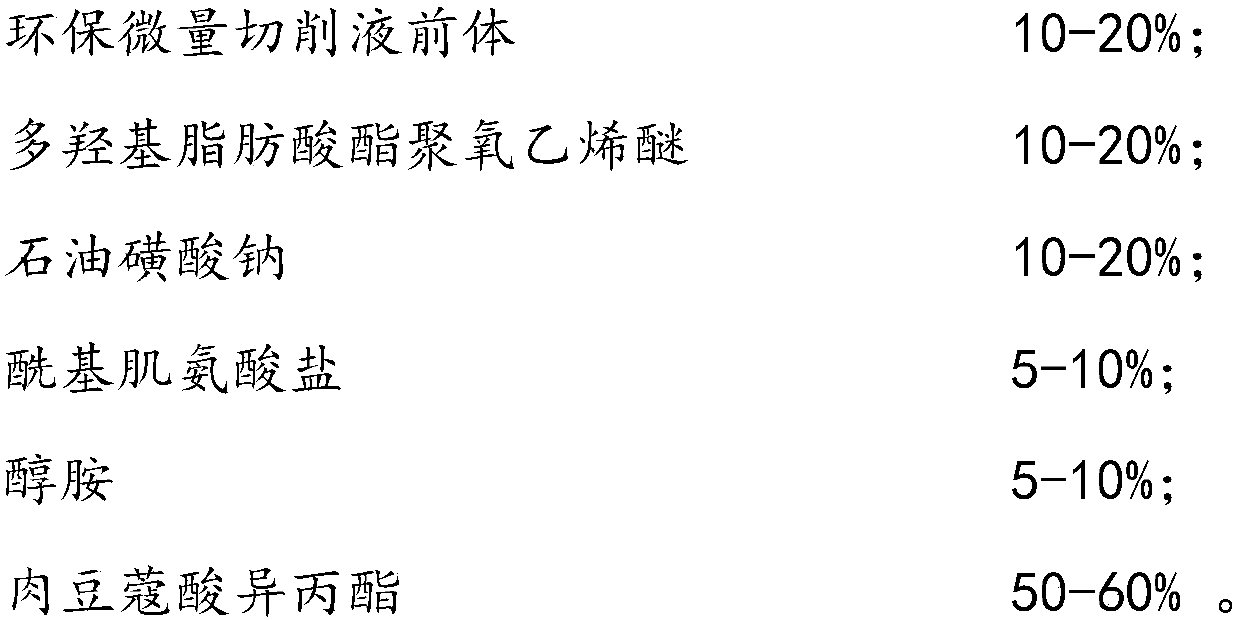

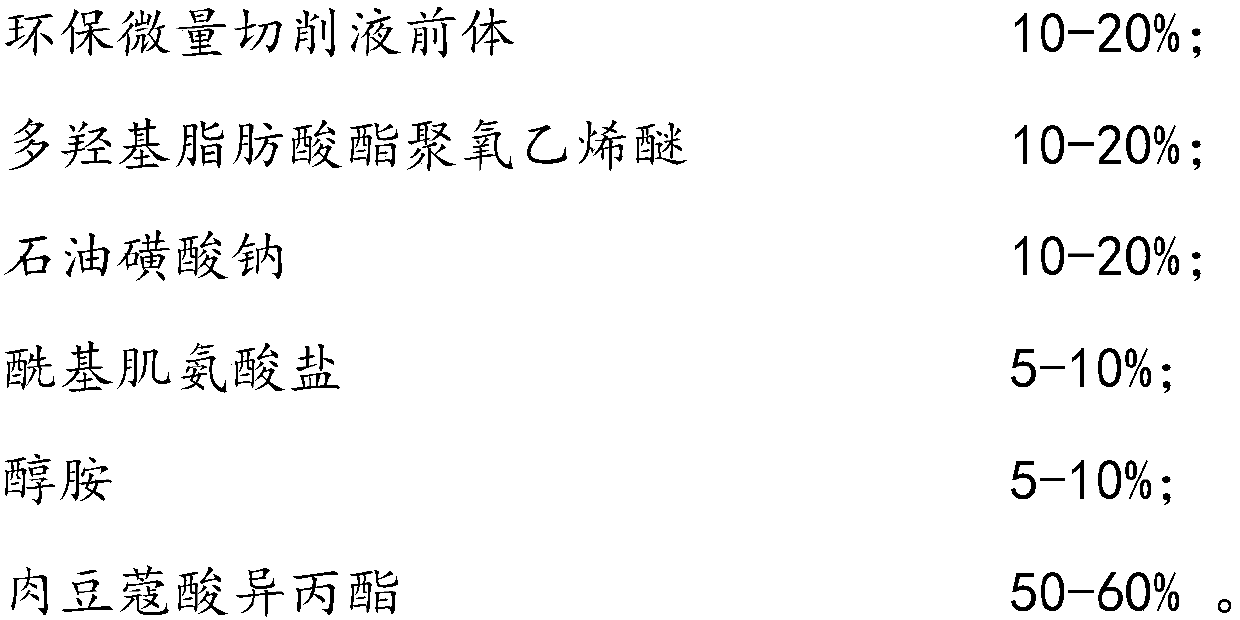

Environment-friendly microscale cutting fluid and preparation method thereof

InactiveCN107699313AGood extreme pressure and anti-wear propertiesRepair wearAdditivesSulfonateSODIUM COCOYL SARCOSINATE

The invention provides environment-friendly microscale cutting fluid. The environment-friendly microscale cutting fluid is characterized in that components are mixed and blended at 40-60DEG C to be completely transparent, and the components include, by weight, 10%-20% of an environment-friendly microscale cutting fluid precursor, 10%-20% of polyhydroxy fatty acid ester polyoxyethylene ether, 10%-20% of petroleum sodium sulfonate, 5%-10% of sodium cocoyl sarcosinate, 5%-10% of alkylol amine and 50%-60% of isopropyl myristate. The environment-friendly microscale cutting fluid is used cooperatively with a microscale lubricating device, usage can be reduced to less than original 5%; good lubrication and cooling effects are achieved, and energy conservation and emission reduction and environment protect effects are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

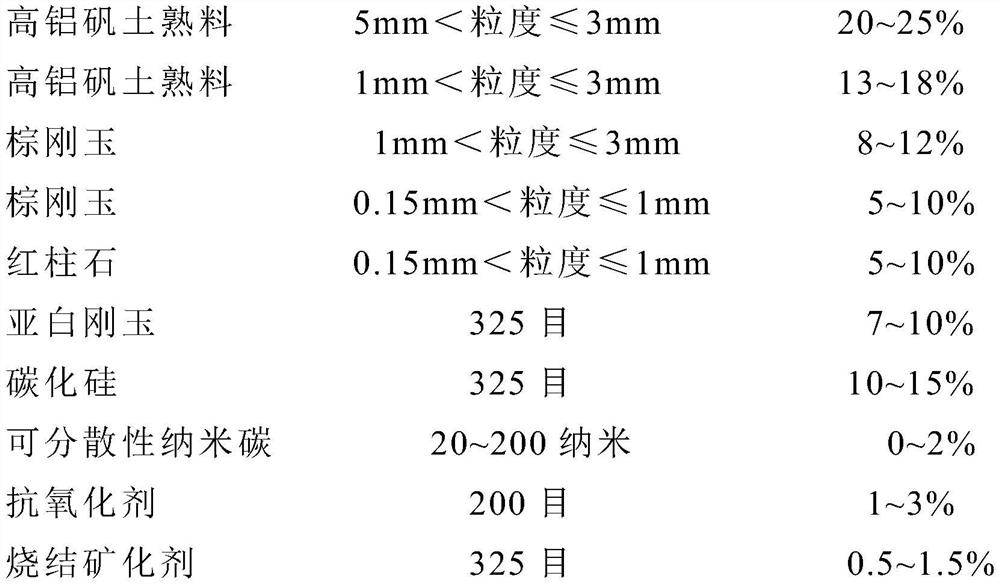

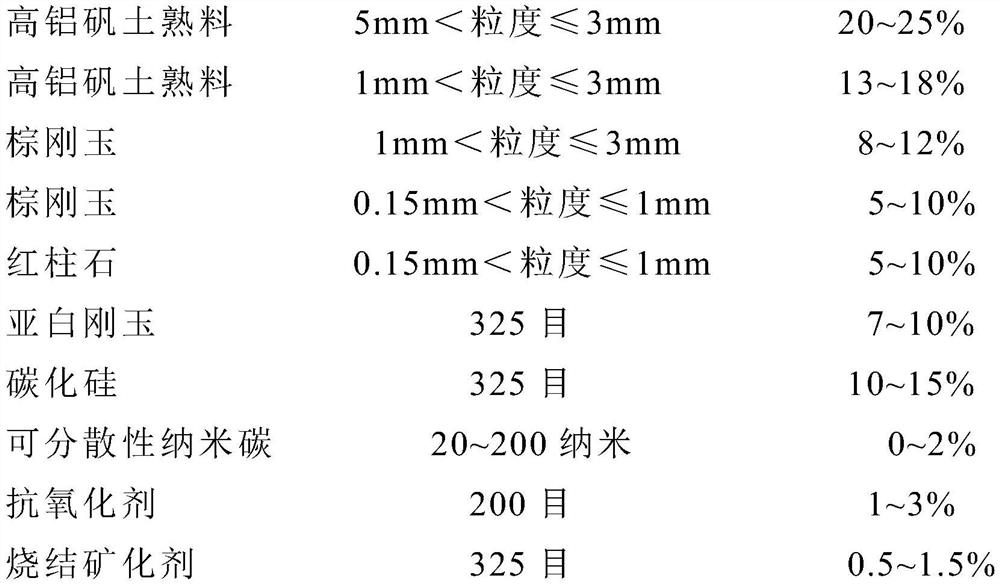

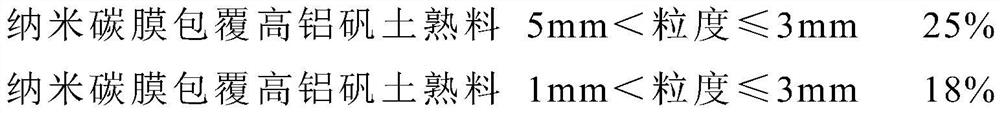

Low-carbon aluminum silicon carbide carbon brick containing nanocarbon and preparation method thereof

The invention discloses a nanocarbon-containing low-carbon aluminum silicon carbide carbon brick and a preparation method thereof. The brick comprises high bauxite clinker with two granularities, brown fused alumina with two granularities, sub-white fused alumina, dispersible nanocarbon and the like. Through the application of the nano-carbon film and the dispersible nano-carbon, which are none, partially or completely coated on the surfaces of particles of three raw materials, comprising high-alumina bauxite clinker, brown fused alumina and sub-white fused alumina; the oxidation resistance ofthe nano-carbon is improved by utilizing the characteristics that the nano-carbon film and the dispersible nano-carbon are mainly amorphous carbon, contain a small amount of graphite chicks, can be infiltrated by a solvent and the like; therefore, infiltration and adsorption of the nano carbon film and the dispersible nano carbon to the organic binding agent are improved, the uniform dispersion of the nano carbon in the magnesia carbon brick is realized; finally, the size of carbon particles in the aluminum silicon carbide carbon brick is greatly reduced through the size control of the thickness of the nano carbon film and the dispersible nano carbon, so that the contact frequency of the refractory raw material of the aluminum silicon carbide carbon brick and the carbon particles is obviously improved, and the performance of the carbon particles under the condition of low carbon content is ensured.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com