Slow release composite fertilizer for high-tower granulation and preparation method thereof

A slow-release compound fertilizer and high-tower granulation technology, which is applied in fertilization devices, fertilizer mixtures, agricultural gas emission reduction, etc., can solve the problem of difficult degradation of molecular polymer-coated slow-release fertilizers, secondary soil pollution, environmental pollution, etc. problem, to achieve the effect of improving disease resistance, enhancing sustained release effect, and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

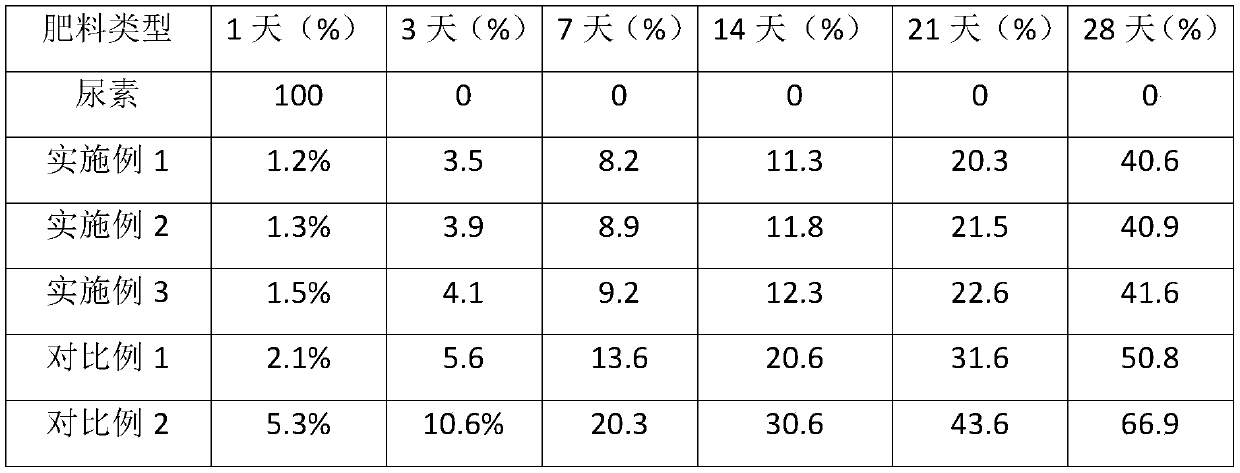

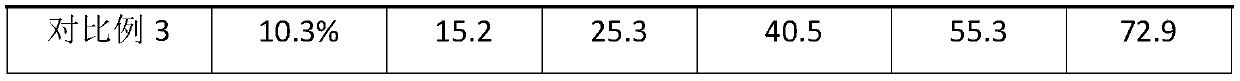

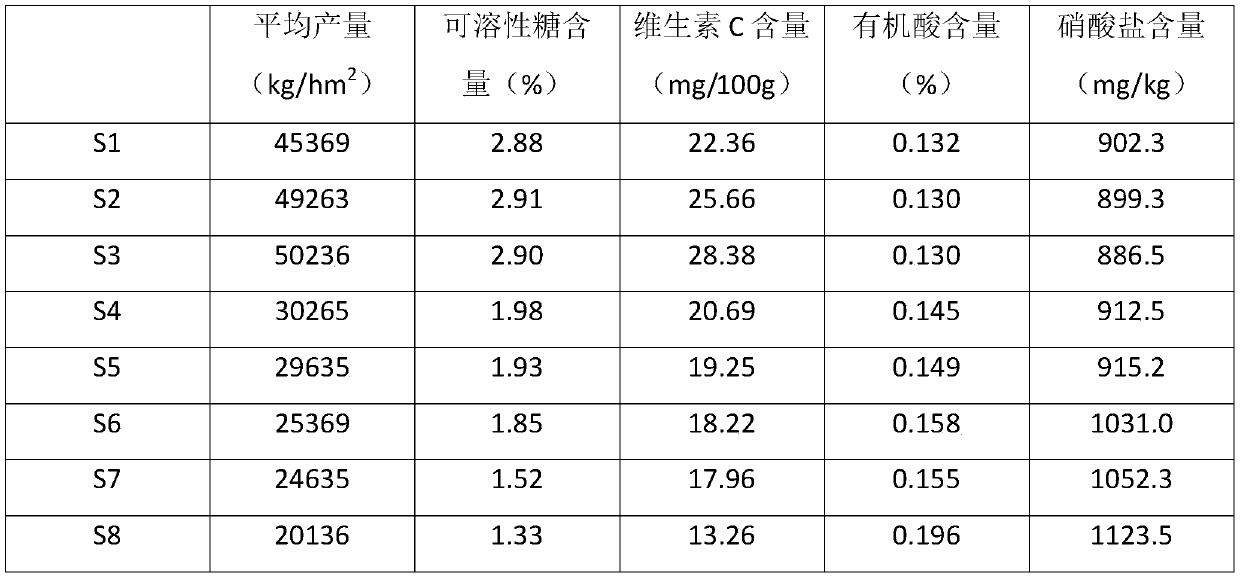

Embodiment 1

[0026] A high-tower granulated slow-release compound fertilizer is prepared from the following raw materials in parts by weight: 100 parts of urea, 80 parts of monoammonium phosphate, 60 parts of potassium chloride, 20 parts of lapis lazuli powder, 10 parts of attapulgite powder, 10 parts of diatomite, 5 parts of medium and trace element mixture, 3 parts of synergist, and 5 parts of outer layer coating agent; the outer layer coating agent is prepared by the following method: (1) take corn stalks, After drying at 70°C, it was pulverized, passed through a 0.5mm sieve, and then calcined in a muffle furnace at a calcination temperature of 500°C for a calcination time of 3 hours. After cooling to room temperature, it passed through a 0.15mm sieve to obtain a powder for use; (2) Dissolve polyvinyl alcohol in 20 times the weight of water, heat the water bath to 90°C to dissolve the polyvinyl alcohol completely, then add 1.5% polyvinylpyrrolidone by weight of the mixture, stir at a con...

Embodiment 2

[0037] A high-tower granulated slow-release compound fertilizer is prepared from the following raw materials in parts by weight: 120 parts of urea, 90 parts of monoammonium phosphate, 70 parts of potassium chloride, 30 parts of lapis lazuli powder, 15 parts of attapulgite powder, 15 parts of diatomite, 10 parts of medium and trace element mixture, 4 parts of synergist, and 8 parts of outer layer coating agent; the outer layer coating agent is prepared by the following method: (1) take corn stalks, After drying at 70°C, it was pulverized, passed through a 0.5mm sieve, and then calcined in a muffle furnace at a calcination temperature of 500°C for a calcination time of 3 hours. After cooling to room temperature, it passed through a 0.15mm sieve to obtain a powder for use; (2) Dissolve polyvinyl alcohol in 20 times the weight of water, heat the water bath to 90°C to dissolve the polyvinyl alcohol completely, then add 1.5% polyvinylpyrrolidone by weight of the mixture, stir at a co...

Embodiment 3

[0048] A high-tower granulated slow-release compound fertilizer is prepared from the following raw materials in parts by weight: 150 parts of urea, 100 parts of monoammonium phosphate, 80 parts of potassium chloride, 40 parts of lapis lazuli powder, 20 parts of attapulgite powder, 20 parts of diatomite, 15 parts of medium and trace element mixture, 5 parts of synergist, and 10 parts of outer layer coating agent; the outer layer coating agent is prepared by the following method: (1) take corn stalks, After drying at 70°C, it was pulverized, passed through a 0.5mm sieve, and then calcined in a muffle furnace at a calcination temperature of 500°C for a calcination time of 3 hours. After cooling to room temperature, it passed through a 0.15mm sieve to obtain a powder for use; (2) Dissolve polyvinyl alcohol in 20 times the weight of water, heat the water bath to 90°C to dissolve the polyvinyl alcohol completely, then add 1.5% polyvinylpyrrolidone by weight of the mixture, stir at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com