Internal and external hydrophobic xonotlite type calcium silicate board as well as manufacturing method and application thereof

A kind of tombstone and calcium silicate board technology, applied in the direction of heat preservation, fire prevention, building components, etc., can solve the problems of weakened waterproof effect, weakened heat preservation effect, freezing damage, etc., so as to improve the waterproof effect and avoid the change of strength and heat preservation effect. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

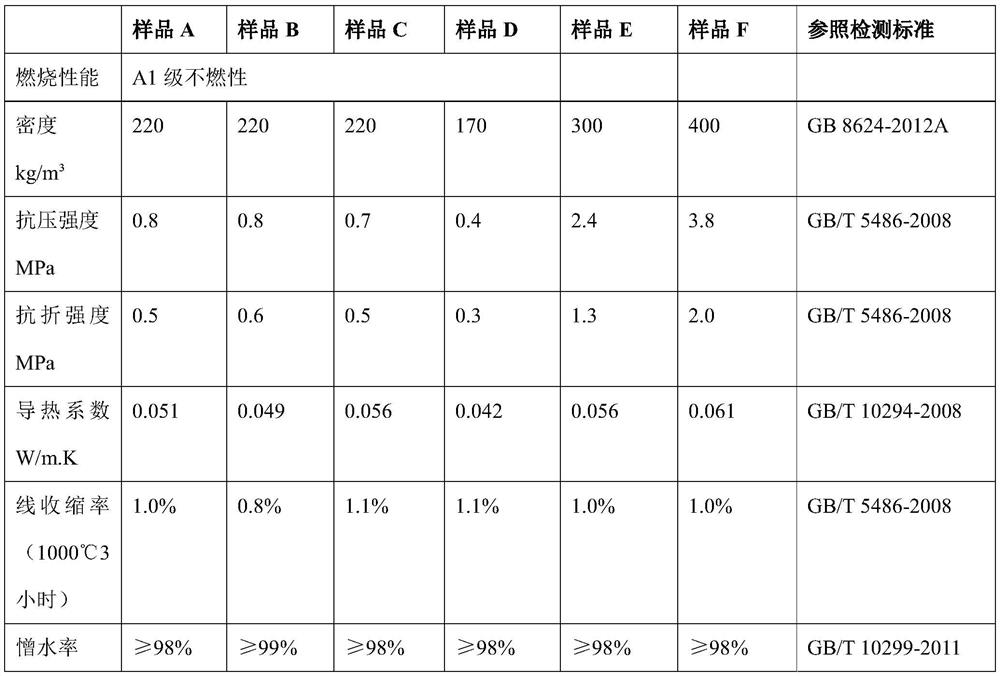

Examples

Embodiment 1

[0029] A method for making a tobermorite type calcium silicate board with internal and external water repellency, the specific steps are:

[0030] (1) Prepare quartz powder with a silica content of 98% and a 400-mesh sieve balance of no more than 5%; prepare slaked lime powder with a calcium hydroxide content of 90% and a 325-mesh sieve balance of no more than 5%.

[0031] (2) Mix quartz powder and slaked lime powder in water according to the molar ratio of silicon atom to calcium atom 1:1 and stir evenly.

[0032] (3) The uniformly mixed raw materials are injected into the dynamic synthesis reactor, and high-temperature steam is introduced to make the temperature in the reactor reach 220 ° C and the pressure to reach 1.8 MPa, and then keep the temperature and pressure for 6 hours to obtain the tombstone crystal as the main component. slurry.

[0033] (4) Adding 3% of the total mass of the tobermorite slurry obtained in the step (3) to the glass fiber, then adding the oily si...

Embodiment 2

[0036] A method for making a tobermorite type calcium silicate board with internal and external water repellency, the specific steps are:

[0037] (1) Prepare silica fume with a silica content of 98% and a 400-mesh sieve balance of no more than 5%; prepare slaked lime powder with a calcium hydroxide content of 90% and a 325-mesh sieve balance of no more than 5%.

[0038] (2) Mix quartz powder and slaked lime powder in water according to the molar ratio of silicon atom to calcium atom 0.9:1 and stir evenly.

[0039] (3) The uniformly mixed raw materials are injected into the dynamic synthesis reaction kettle, and high-temperature steam is introduced to make the temperature in the reaction kettle reach 250 ° C and the pressure to reach 2.3 MPa, and then keep the temperature and pressure for 4 hours, so that the main component is tombstone crystals. slurry.

[0040] (4) adding the tombstone slurry obtained in step (3) into polyester fibers accounting for 4% of the total mass, th...

Embodiment 3

[0043] A method for making a tobermorite type calcium silicate board with internal and external water repellency, the specific steps are:

[0044] (1) Prepare rice husk ash with a silica content of 98% and a 400-mesh sieve balance of no more than 5%; prepare slaked lime powder with a calcium hydroxide content of 90% and a 325-mesh sieve balance of no more than 5%.

[0045] (2) Mix quartz powder and slaked lime powder in water according to the molar ratio of silicon atom to calcium atom 1.1:1 and stir evenly.

[0046] (3) The uniformly mixed raw materials are injected into the dynamic synthesis reactor, and high-temperature steam is introduced to make the temperature in the reactor reach 200 ° C and the pressure to reach 1.6 MPa, and then keep the temperature and pressure for 12 hours to obtain tombstone crystals as the main component. slurry.

[0047] (4) Adding 1% of the total mass of carbon fiber to the tombstone slurry obtained in step (3), then adding 5% of the total mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com