Preparation method of fluoride-free waterproof agent and product thereof

A fluorine-free water repellent and catalyst technology, applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., can solve the problems that fluorine-free water repellents are difficult to achieve waterproof effect, limited application, and the waterproof effect is not durable enough, etc. Achieve the effect of improving waterproof effect, high market prospect and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

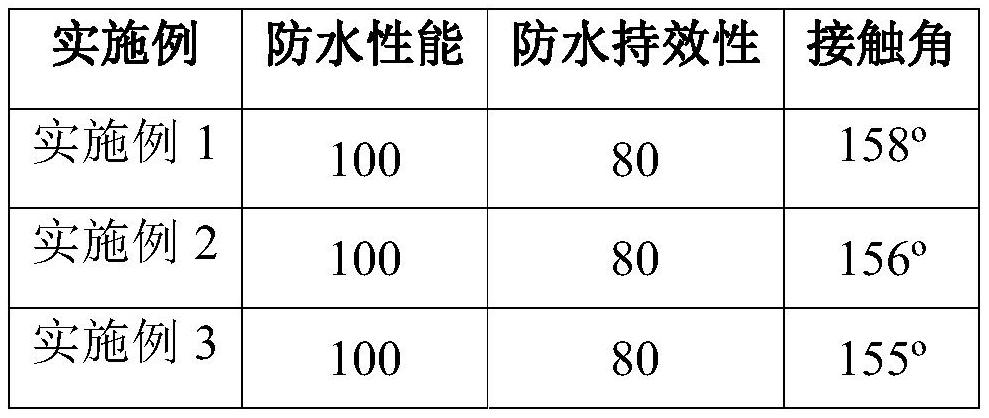

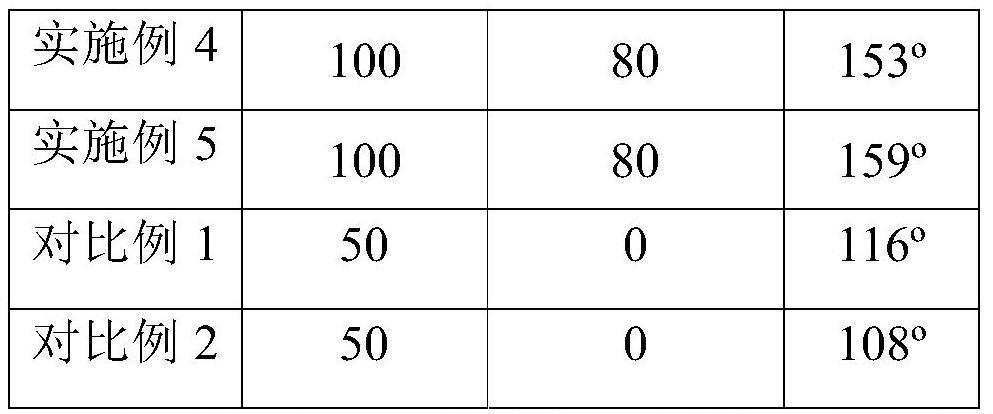

Examples

preparation example Construction

[0019] In order to solve the above problems, the first aspect of the present invention provides a kind of preparation method of fluorine-free waterproofing agent, comprises the following steps:

[0020] a. Mix organic solvent, catalyst and water, add tetraethyl orthosilicate and silane to obtain mixed solution;

[0021] b. Mix the above mixed solution, an alkane derivative with a carbon number ≥ 10, an emulsifier, an initiator, and water to obtain a fluorine-free waterproofing agent.

[0022] Step a in this application is the preparation of the modified nano silicon dioxide mixed solution.

[0023] From the perspective of increasing the reaction rate, in some preferred embodiments, the organic solvent is selected from a mixture of one or more of ethanol, ether, methanol, acetone, isopropanol, and tetrahydrofuran; further preferably, the The organic solvent is selected from one or more mixtures of ethanol, ether, and methanol.

[0024] In some preferred embodiments, the catal...

Embodiment 1

[0053] Embodiment 1 provides a kind of preparation method of fluorine-free waterproofing agent, comprises the following steps:

[0054] a. Mix 900g of absolute ethanol and 320g of water, adjust the pH to 3 with hydrochloric acid, stir at 55°C for 25min, and add dropwise 360g of tetraethyl orthosilicate and 10g of 3-glycidyl etheroxypropylmethyldiethoxy base silane, stirred at 60°C for 60 min to obtain a mixed solution.

[0055] b. Under nitrogen protection, mix 100g of the mixed solution in step a, 15g of dodecanol, 10g of cardanol polyoxyethylene polyoxypropylene ether (purchased from Shandong Youso Chemical Technology Co., Ltd., brand BGF-6), 2g Mix ammonium persulfate and 30g of water, and react at 80°C for 2 hours to obtain a fluorine-free waterproofing agent.

Embodiment 2

[0057] Embodiment 2 provides a kind of preparation method of fluorine-free waterproofing agent, comprises the following steps:

[0058] a. Mix 900g of absolute ethanol and 320g of water, adjust the pH to 10 with ammonia water, stir at 55°C for 25min, and add dropwise 360g of tetraethyl orthosilicate and 10g of 3-glycidyloxypropyltriethoxysilane , and stirred at 60°C for 60 min to obtain a mixed solution.

[0059] b. Under the protection of nitrogen, the mixed solution in 100g step a, 15g methyl octadecanoate, 10g linear fatty alcohol polyoxyethylene ether (purchased from Jiangsu Haian Petrochemical Plant, brand OE-2), 2g over Mix ammonium sulfate and 30g of water, adjust the pH to 8, and react at 80°C for 2 hours to obtain a fluorine-free waterproofing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com