Patents

Literature

44results about How to "Reduce the amount of opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

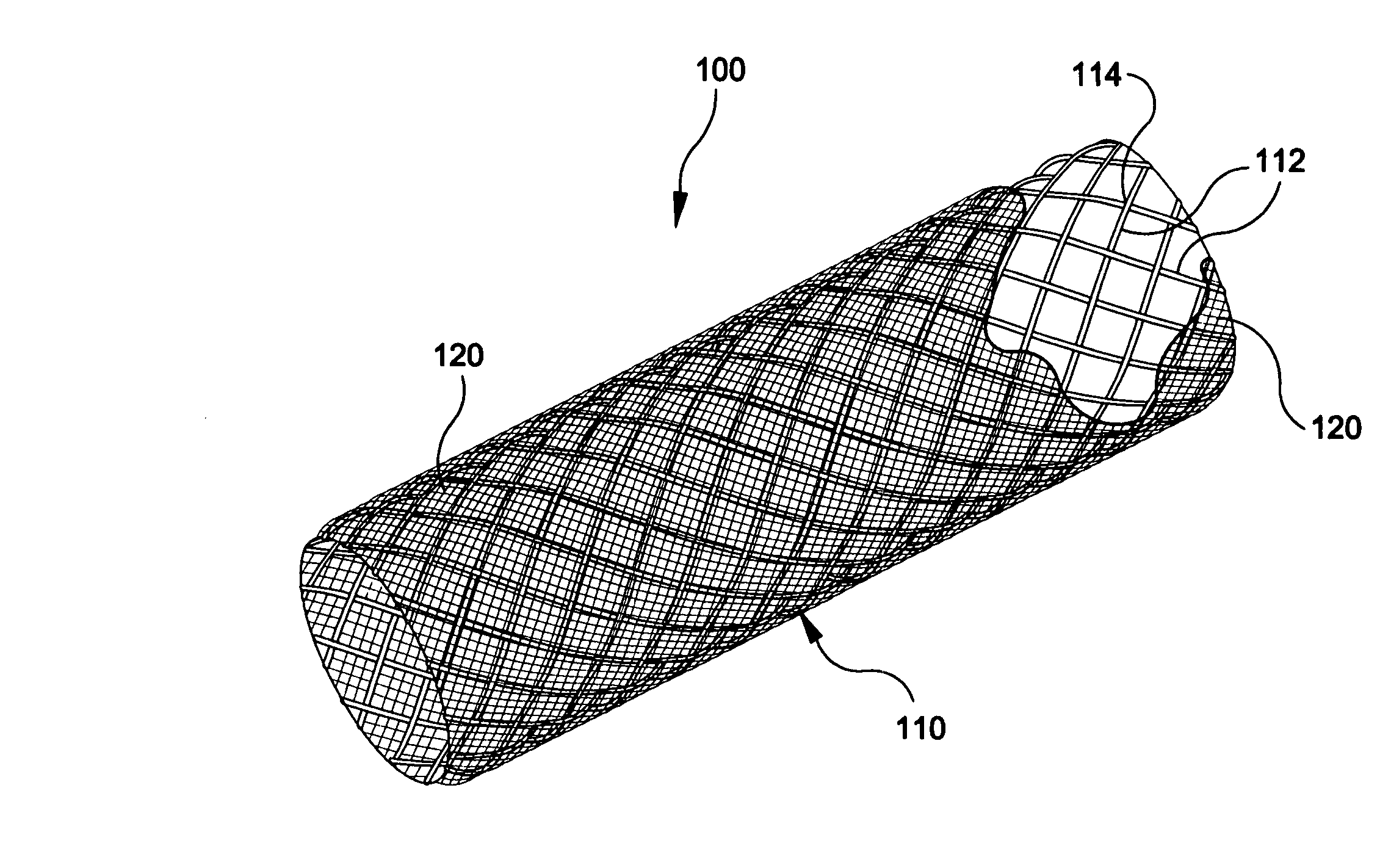

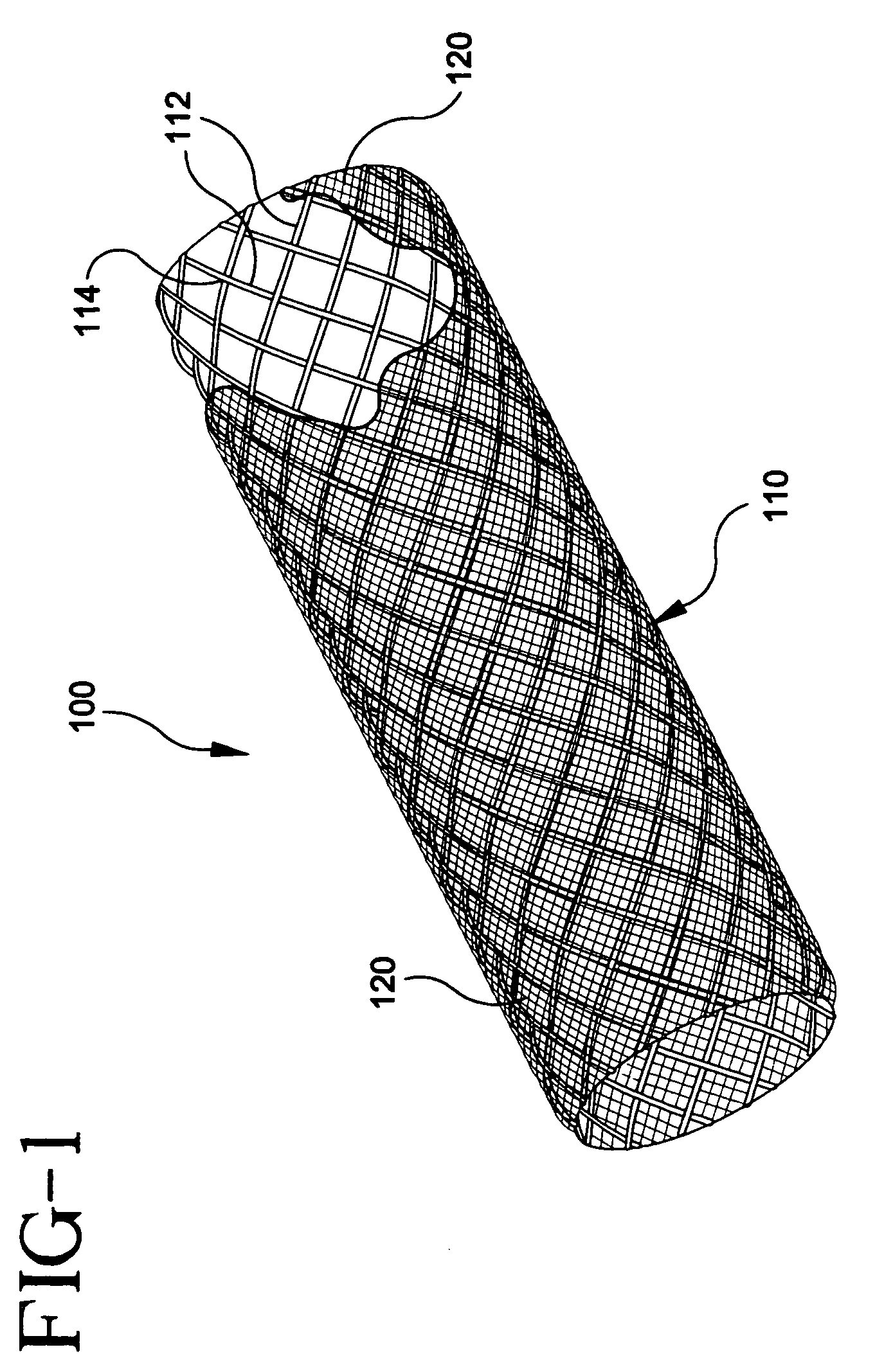

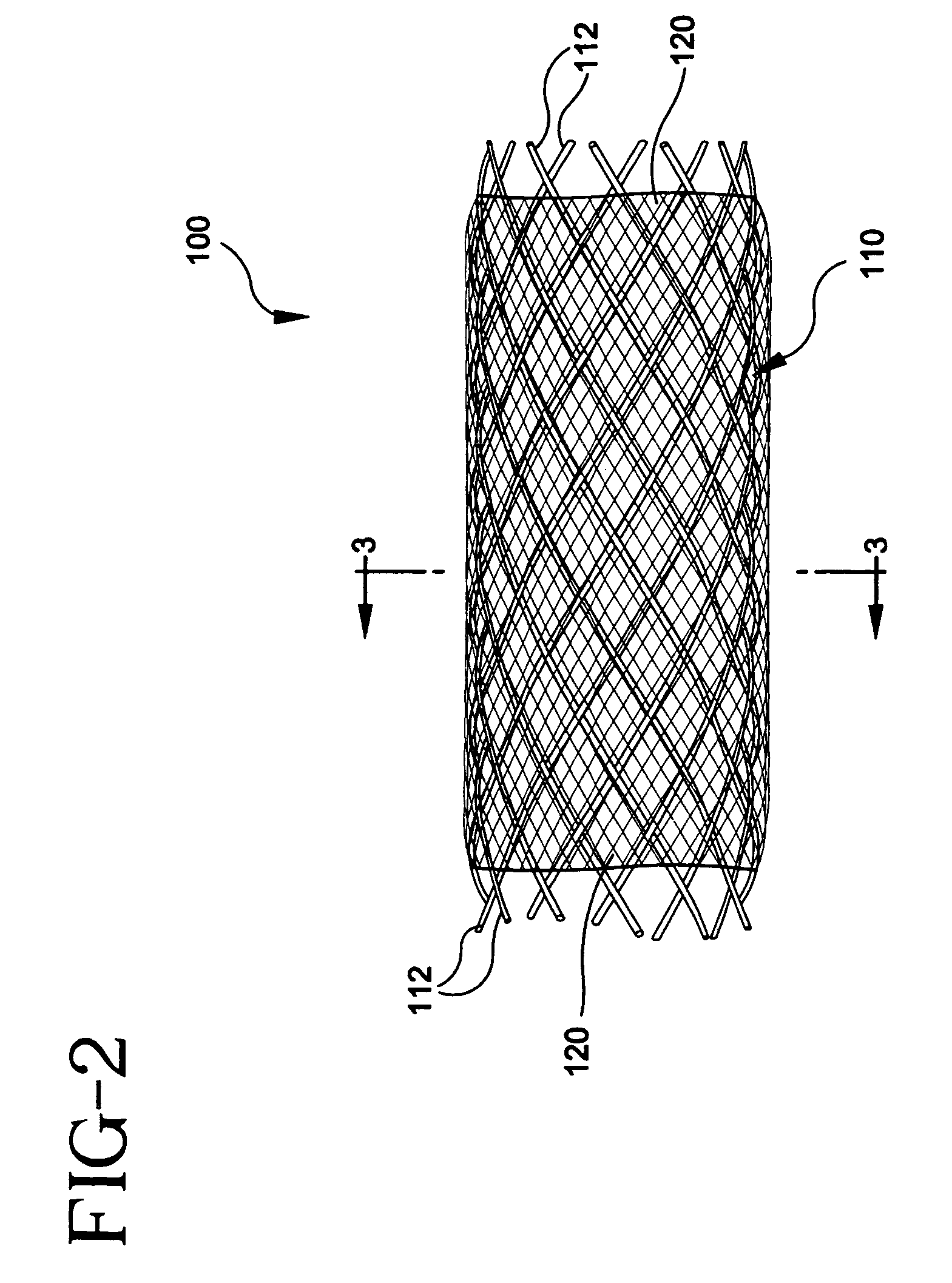

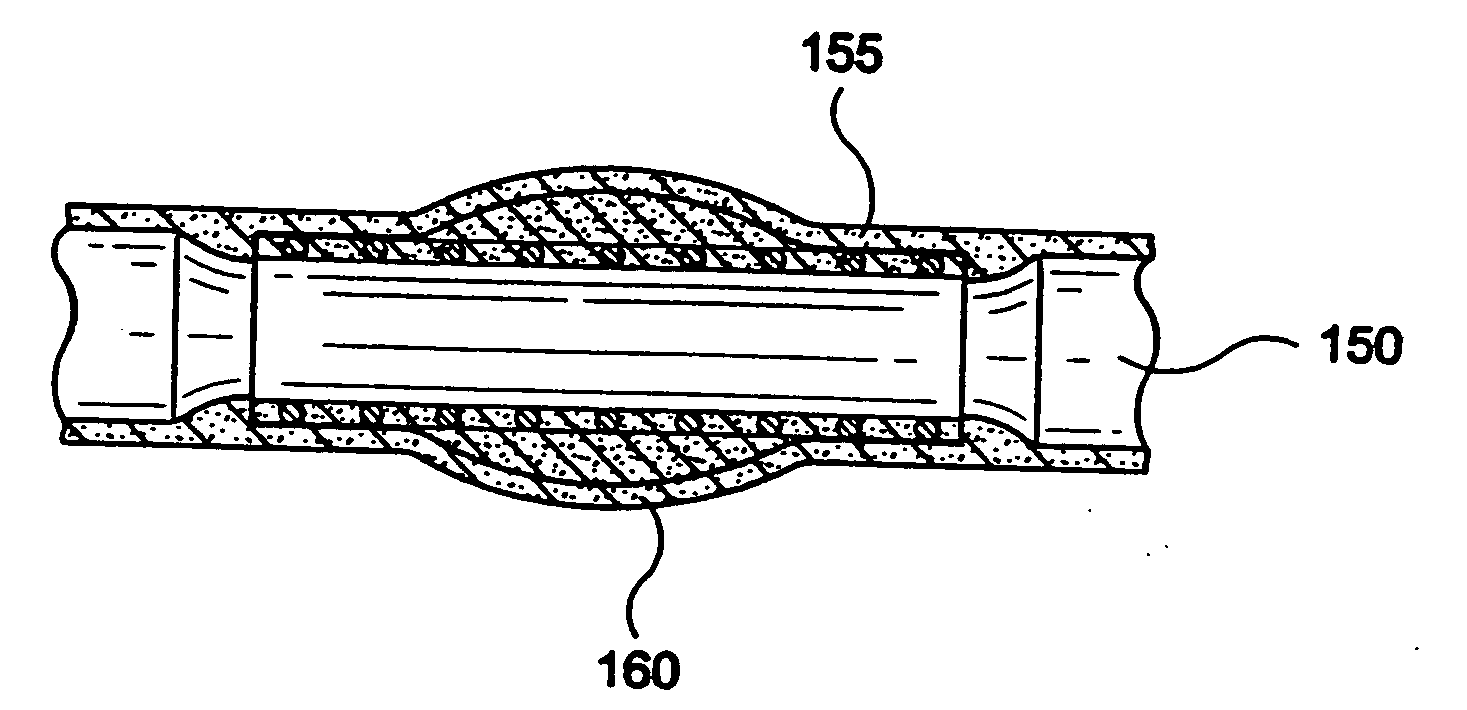

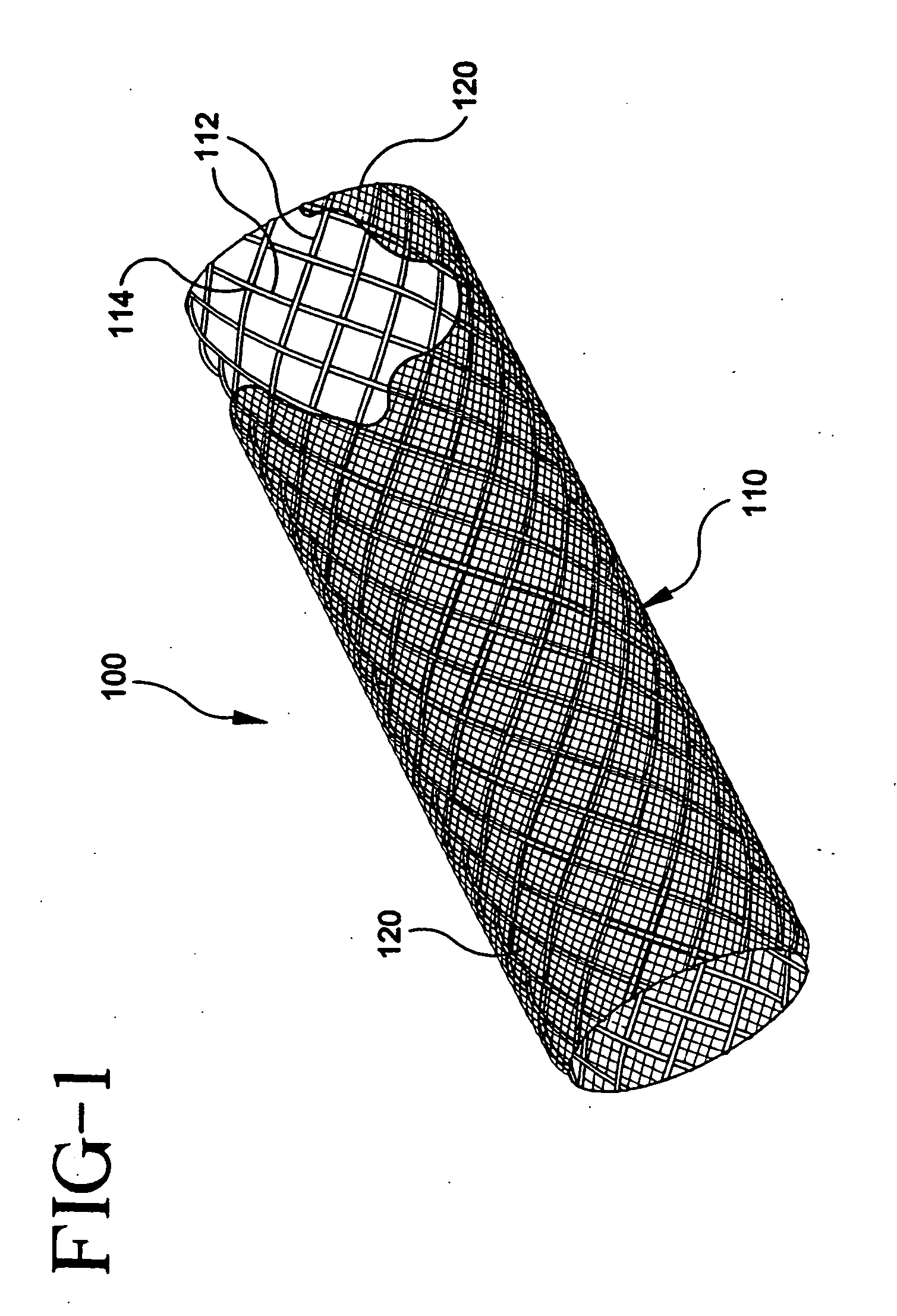

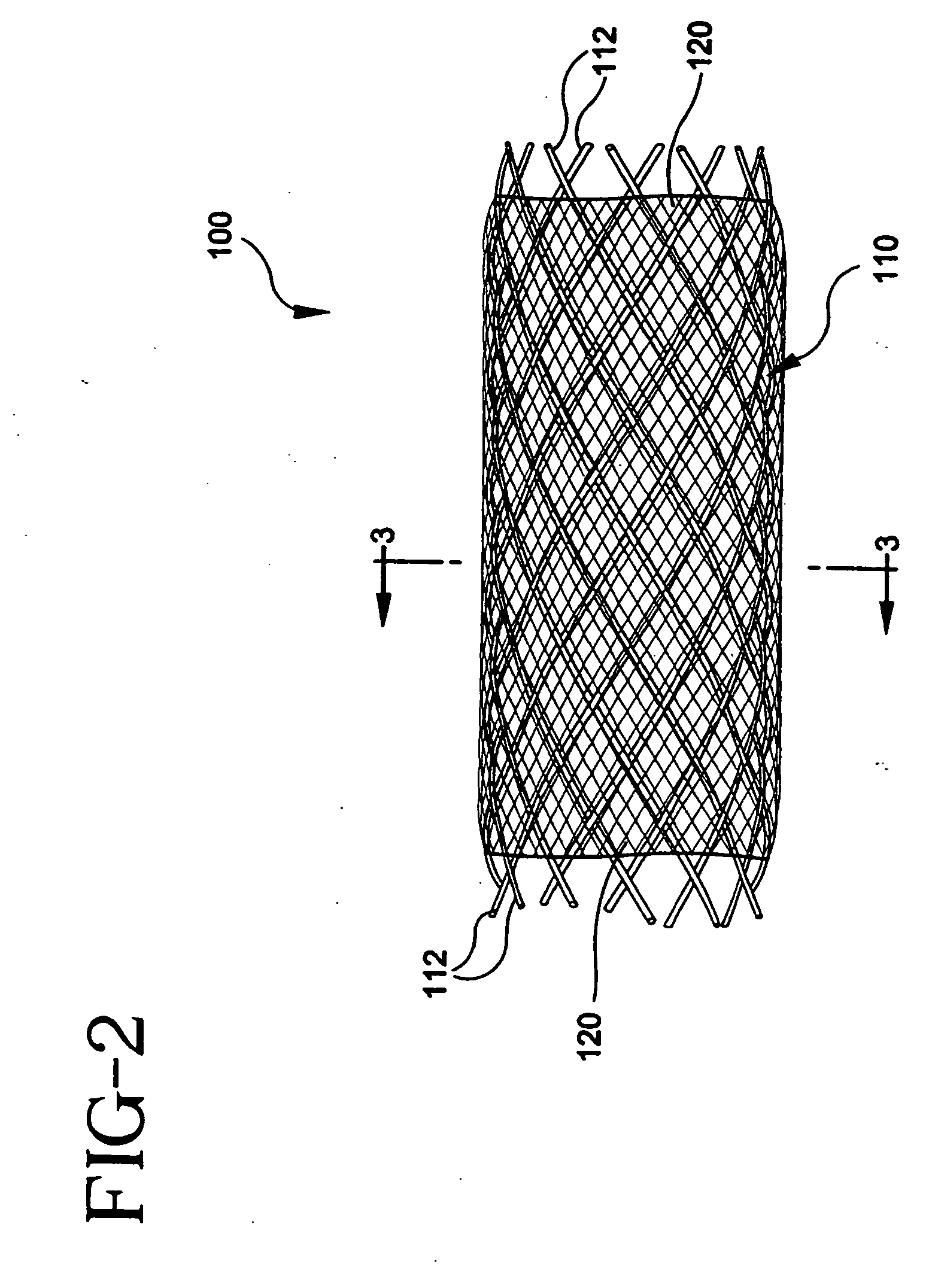

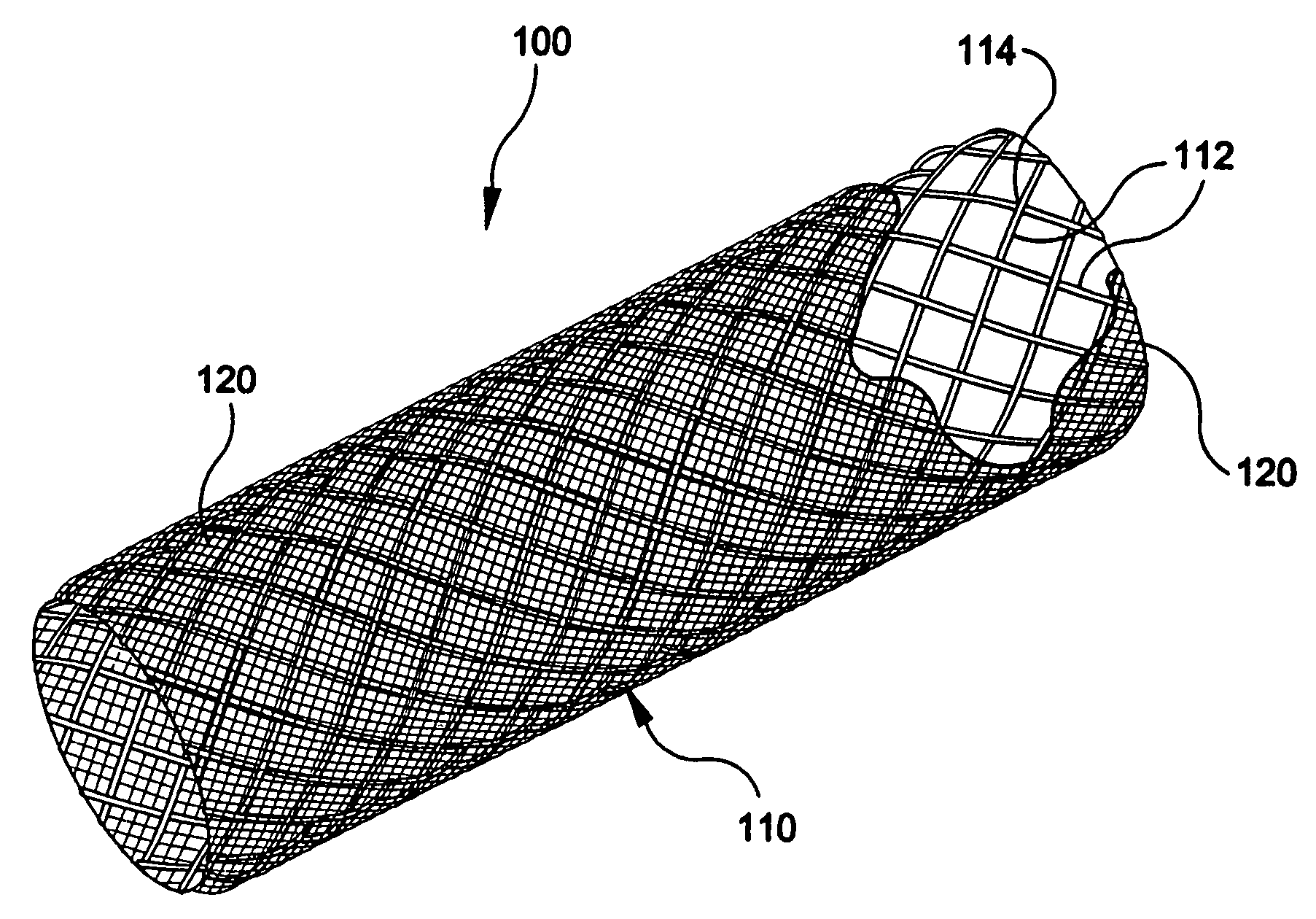

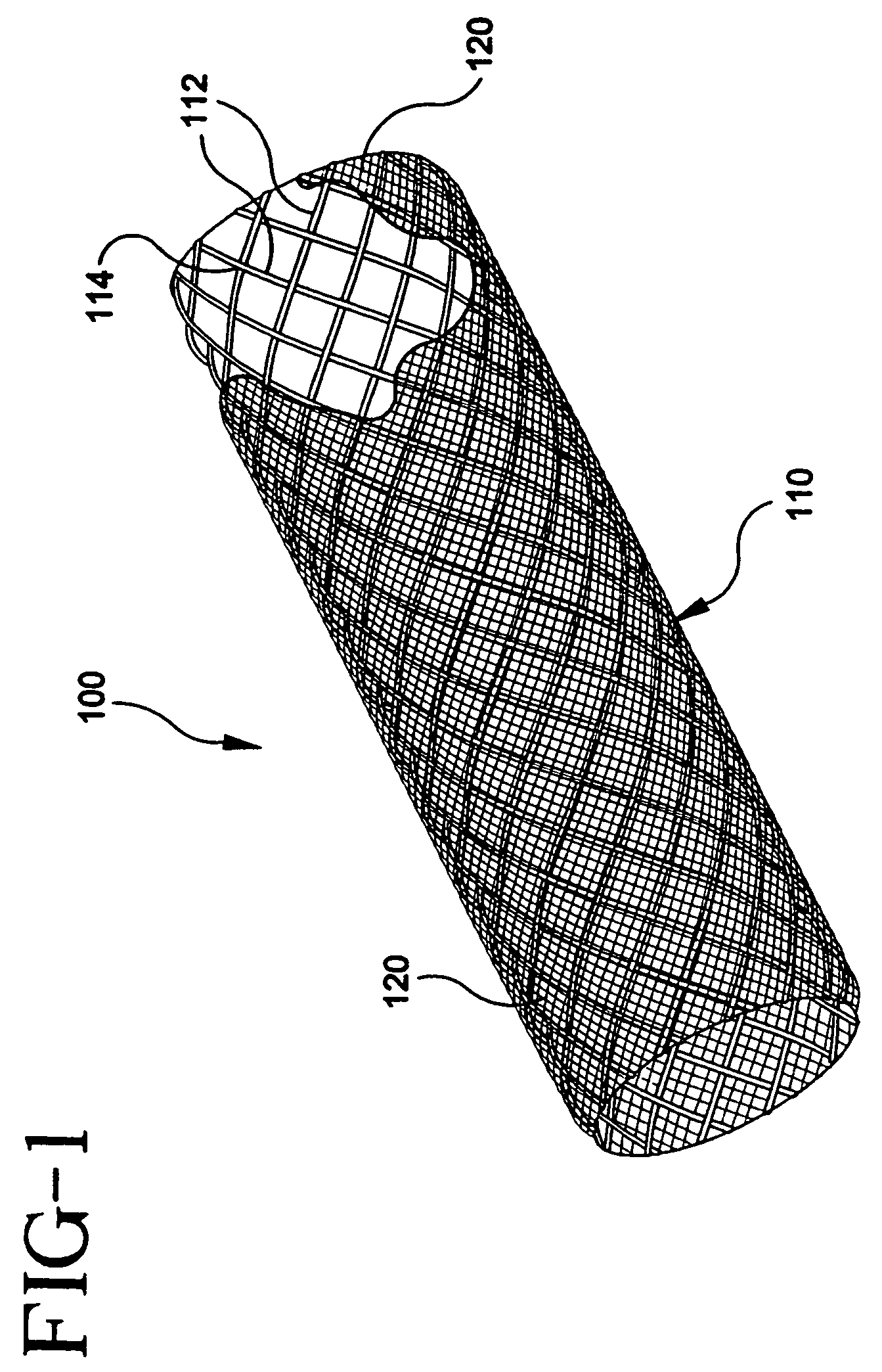

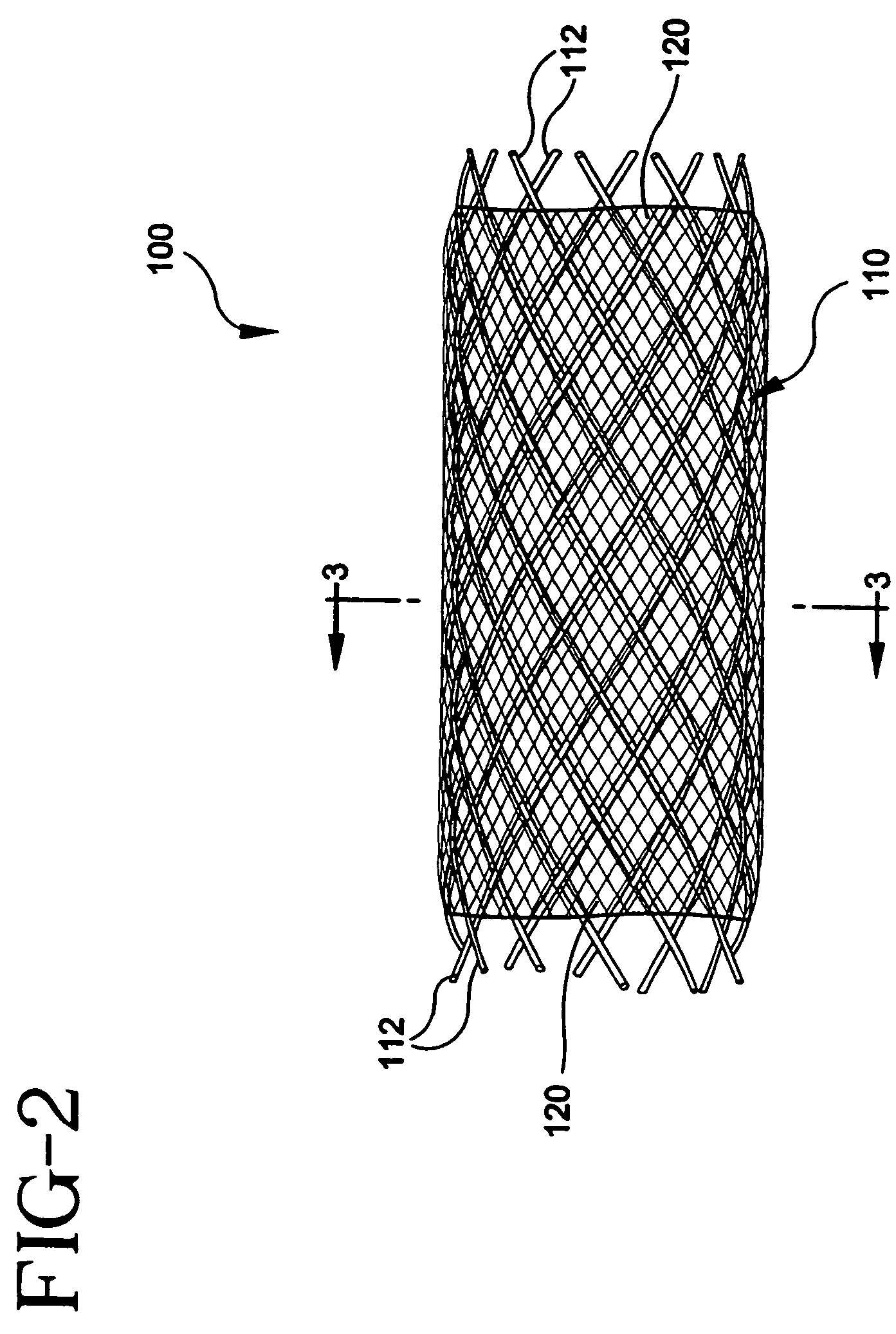

Stent-graft with bioabsorbable structural support

InactiveUS7108716B2Less open spacePrevent and limit tissue ingrowthStentsSurgeryStent graftingArterial fistula

The invention relates to a stent-graft with a bioabsorbable structure and a permanent graft for luminal support and ‘treatment of arterial fistulas, occlusive disease, and aneurysms. The bioabsorbable structure is formed from braided filaments of materials such as PLA, PLLA, PDLA, and PGA and the graft is formed from materials such as PET, ePTFE, PCU or PU.

Owner:SCHNEIDER (USA) INC

Stent-graft with bioabsorbable structural support

InactiveUS20060266474A1Less open spacePrevent and limit tissue ingrowthStentsSurgeryStent graftingCompanion animal

The invention relates to a stent-graft with a bioabsorbable structure and a permanent graft for luminal support and treatment of arterial fistulas, occlusive disease, and aneurysms. The bioabsorbable structure is formed from braided filaments of materials such as PLA, PLLA, PDLA, and PGA and the graft is formed from materials such as PET, ePTFE, PCU or PU.

Owner:BOSTON SCI SCIMED INC

Stent-graft with bioabsorbable structural support

InactiveUS7699887B2Less open spacePrevent and limit tissue ingrowthStentsSurgeryStent graftingArterial fistula

The invention relates to a stent-graft with a bioabsorbable structure and a permanent graft for luminal support and treatment of arterial fistulas, occlusive disease, and aneurysms. The bioabsorbable structure is formed from braided filaments of materials such as PLA, PLLA, PDLA, and PGA and the graft is formed from materials such as PET, ePTFE, PCU or PU.

Owner:BOSTON SCI SCIMED INC

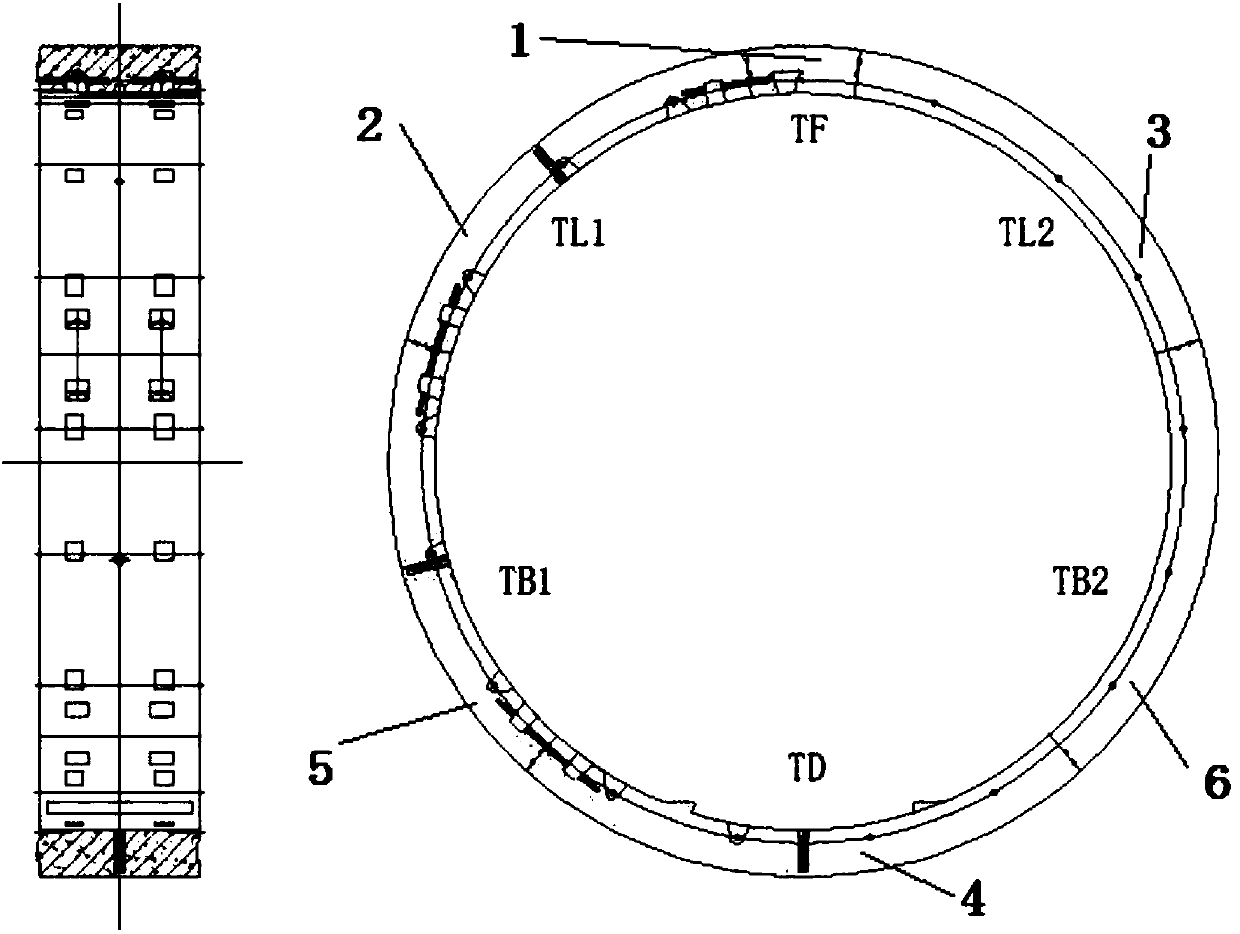

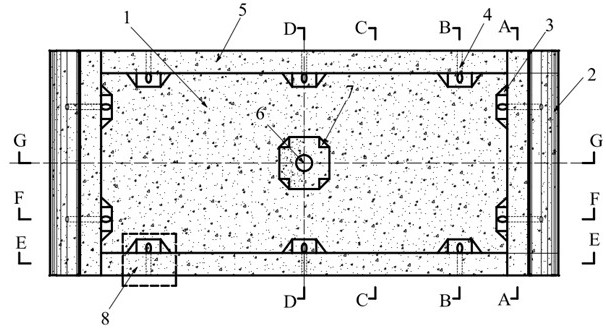

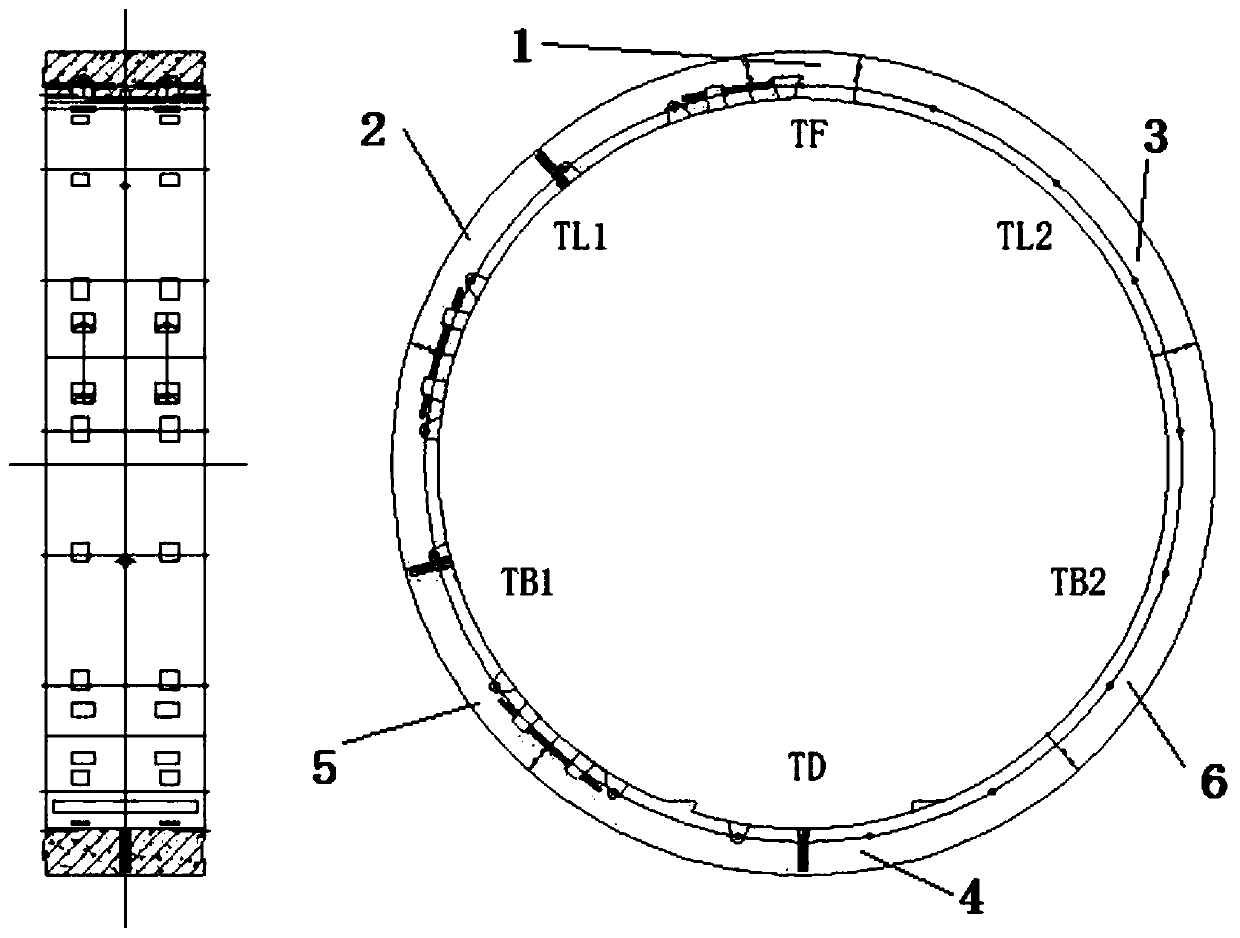

Shield tunnel lining segment and reinforcing method thereof

ActiveCN107620598AImprove integrityIncrease stiffnessUnderground chambersTunnel liningStress conditionsEngineering

The invention discloses a shield tunnel lining segment and further discloses a reinforcing method of the shield tunnel lining segment. An existing structure comprises a top-sealing block, a first adjoining block, a second adjoining block, a bottom-sealing block, a first standard block and a second standard block, wherein the first adjoining block and the second adjoining block are located at the two ends of the top-sealing block, and the first standard block and the second standard block are located at the two ends of the bottom-sealing block. The first adjoining block is connected with the first standard block, and the second adjoining block is connected with the second standard block. Steel strand hole passages are formed in the existing first adjoining block and first standard block, steel strands are arranged in the steel strand hole passages, and steel strand outlets are formed in the inner sides of the first adjoining block and the first standard block. The second adjoining blockand the second standard block are also treated in the same way. The reinforcing method comprises the steps that (1) the lining segment is prefabricated according to the borne load of a tunnel structure; (2) the stress condition of the lining segment is judged, and the reinforcing method of the lining segment is determined; and (3) the lining segment is reinforced. According to the shield tunnel lining segment and the reinforcing method, the overall rigidity and the deformation harmony of the tunnel structure are improved, and tunnel operation safety can be ensured.

Owner:TONGJI UNIV

Air-conditioning device for vehicle

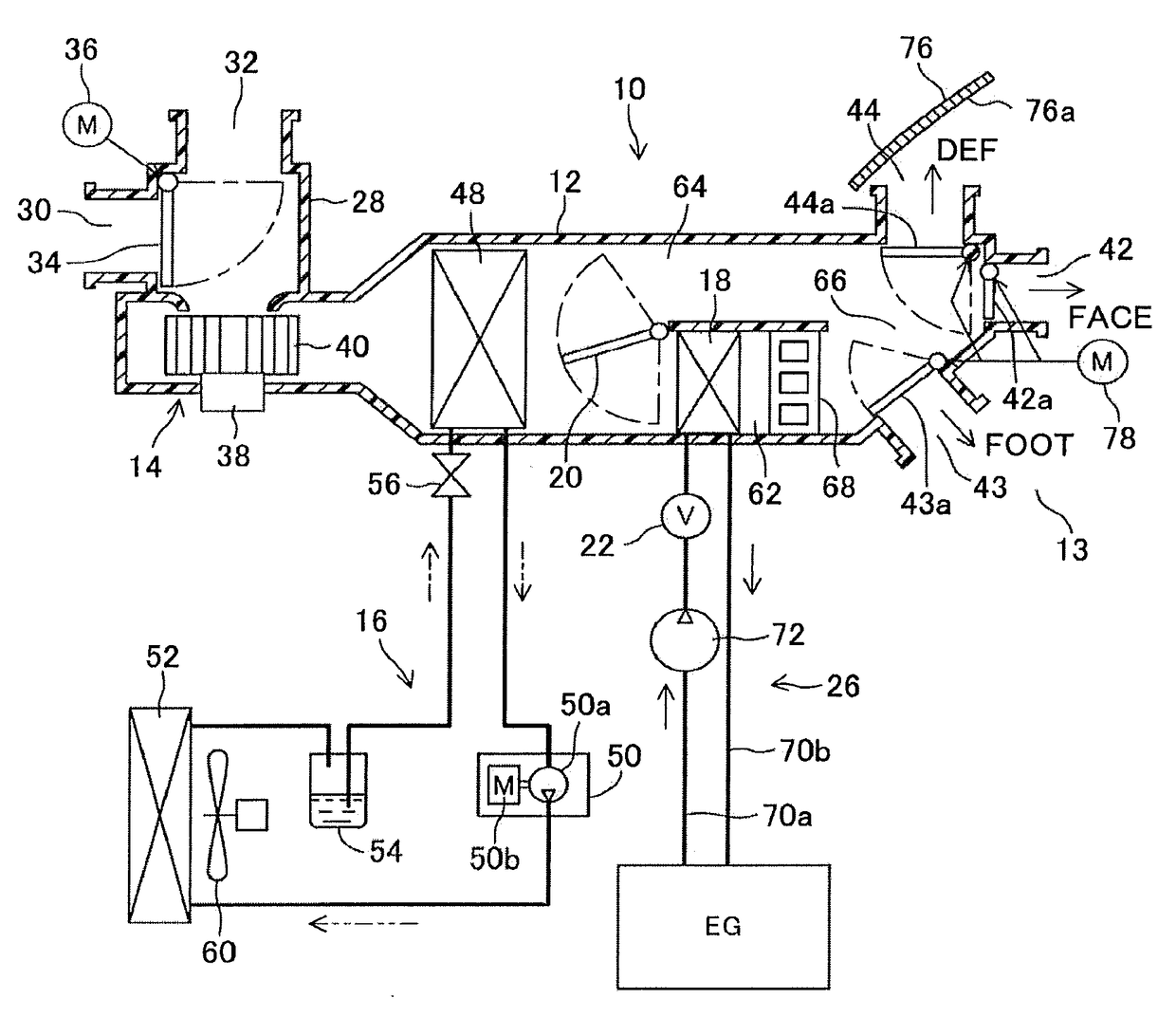

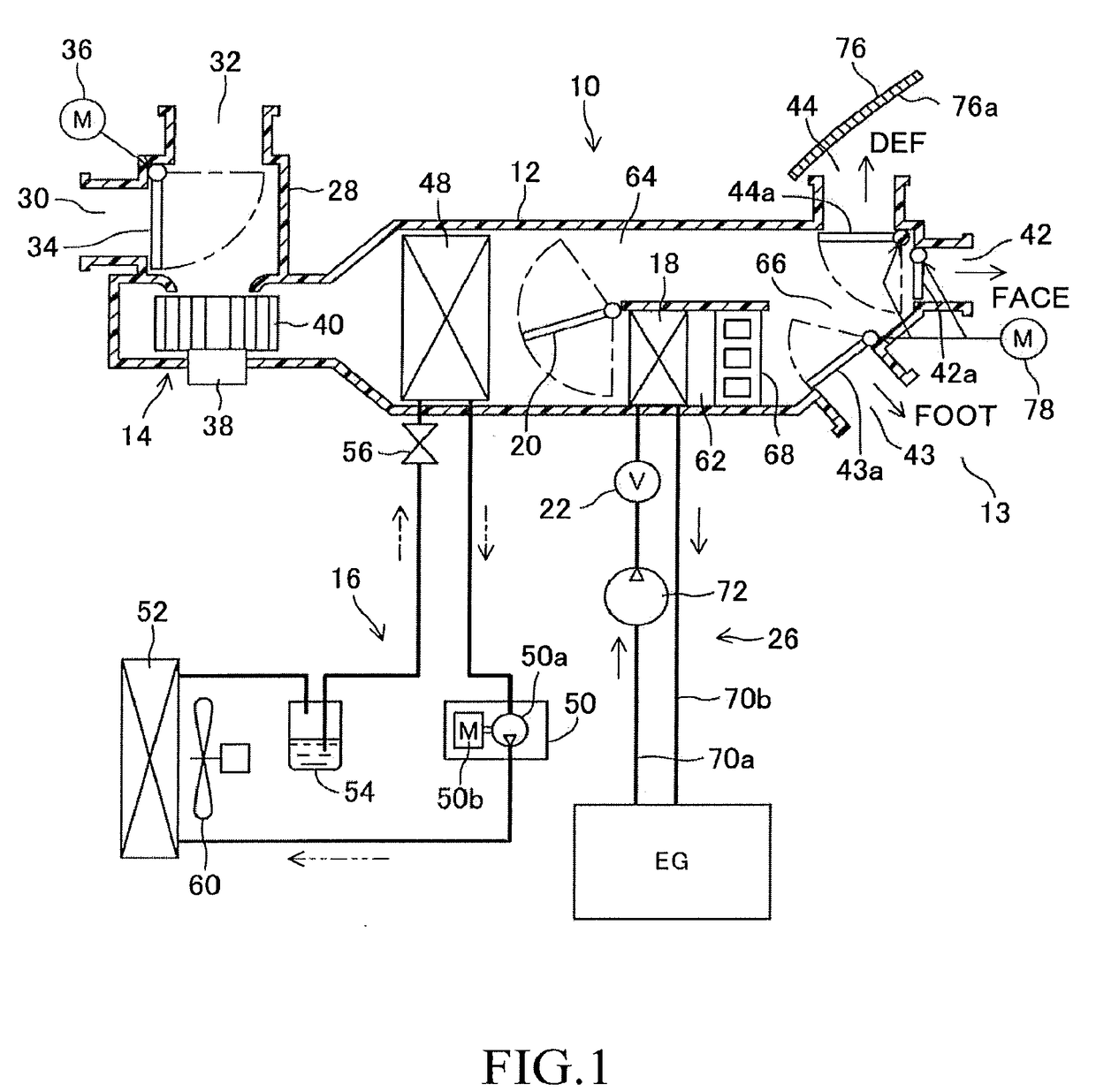

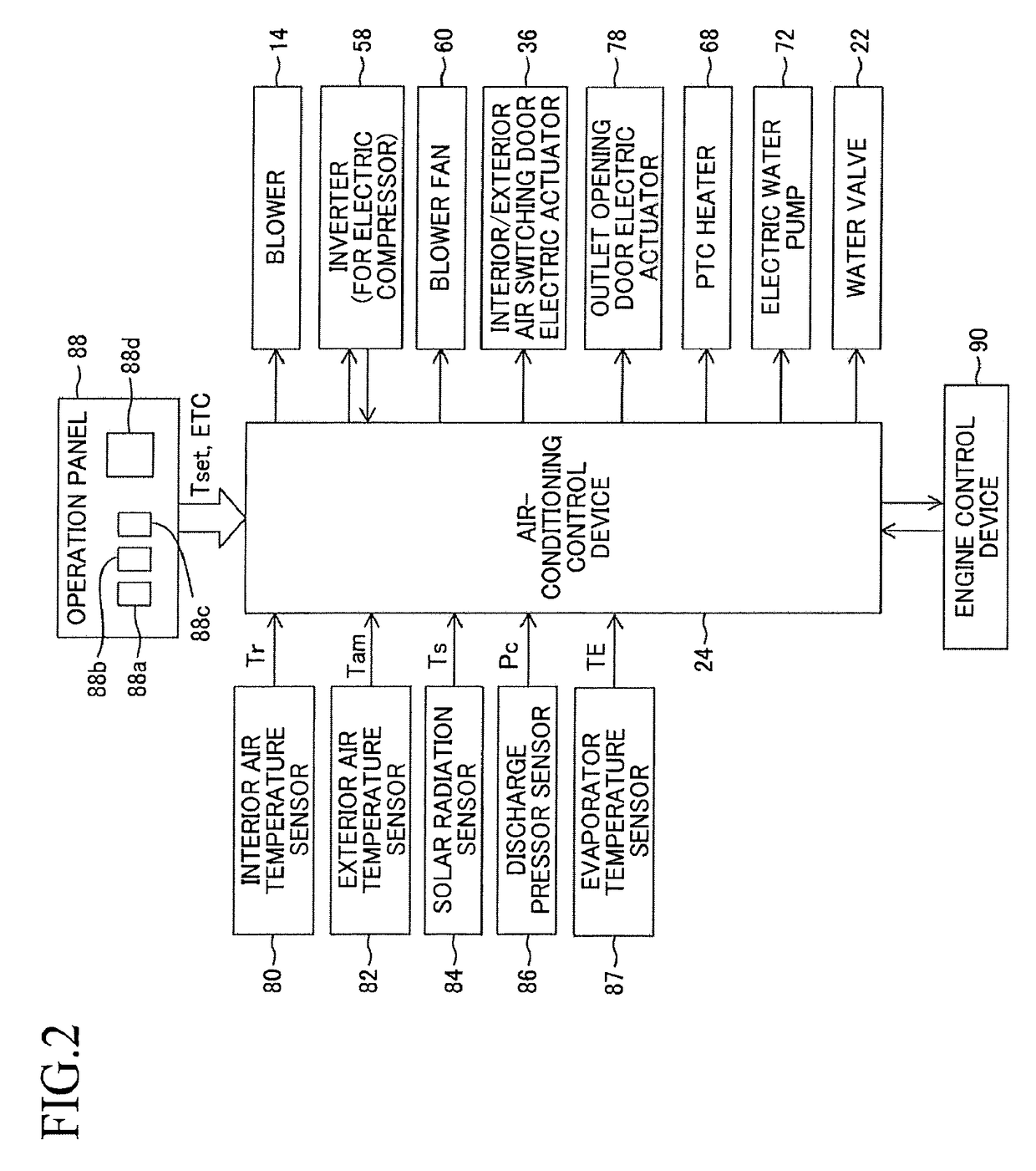

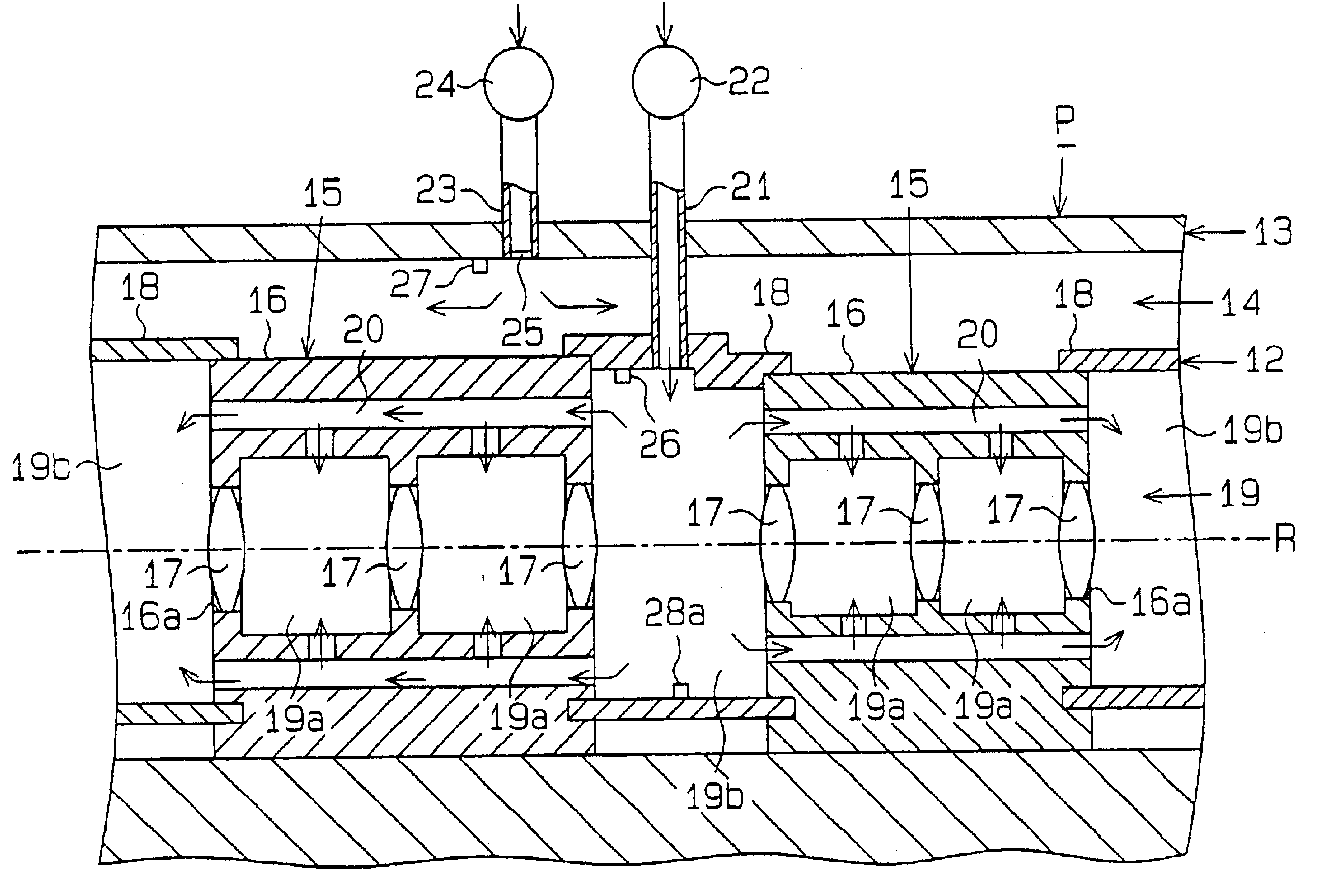

ActiveUS20170174045A1Reduce rotation speedIncreasing target temperatureAir-treating devicesVehicle heating/cooling devicesEvaporatorAirflow

Provided is an air-conditioning device for a vehicle, including: a cooling device configured to cool air passing through a duct; a heater core, which is arranged in the duct on a downstream side of airflow with respect to the cooling device, and is configured to use an engine coolant as a heat source to heat the air; a water valve provided in a coolant circulation system on an upstream side of the heater core; and a controller configured to control those components, in which the controller is configured to decrease an opening amount of the water valve in a predetermined cooling mode. The control is configured to, when the opening amount of the water valve is decreased, decrease a rotational speed of a compressor of the cooling device, and increase a target evaporator temperature of an evaporator of the cooling device, thereby decreasing cooling performance of the cooling device.

Owner:TOYOTA JIDOSHA KK

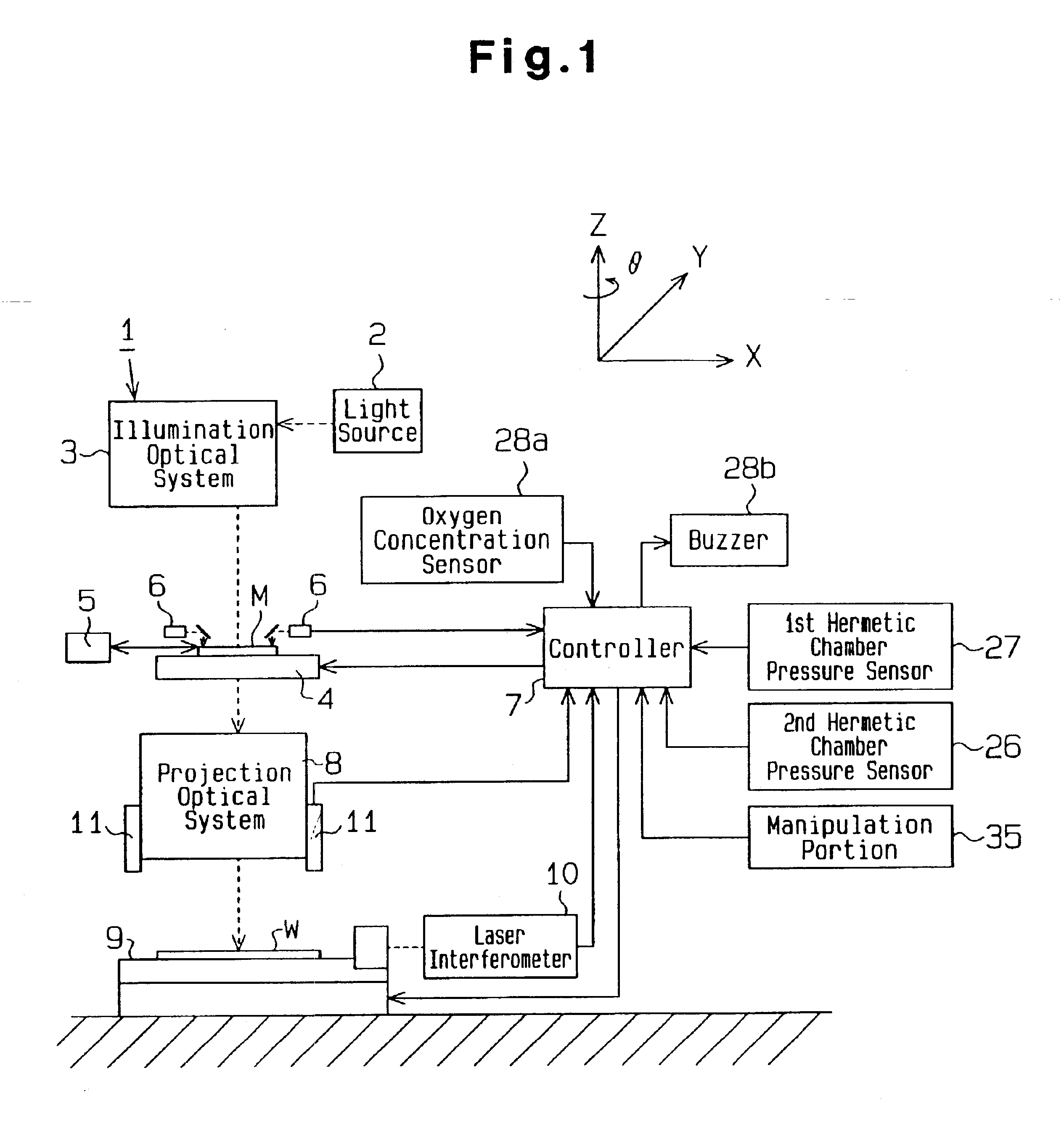

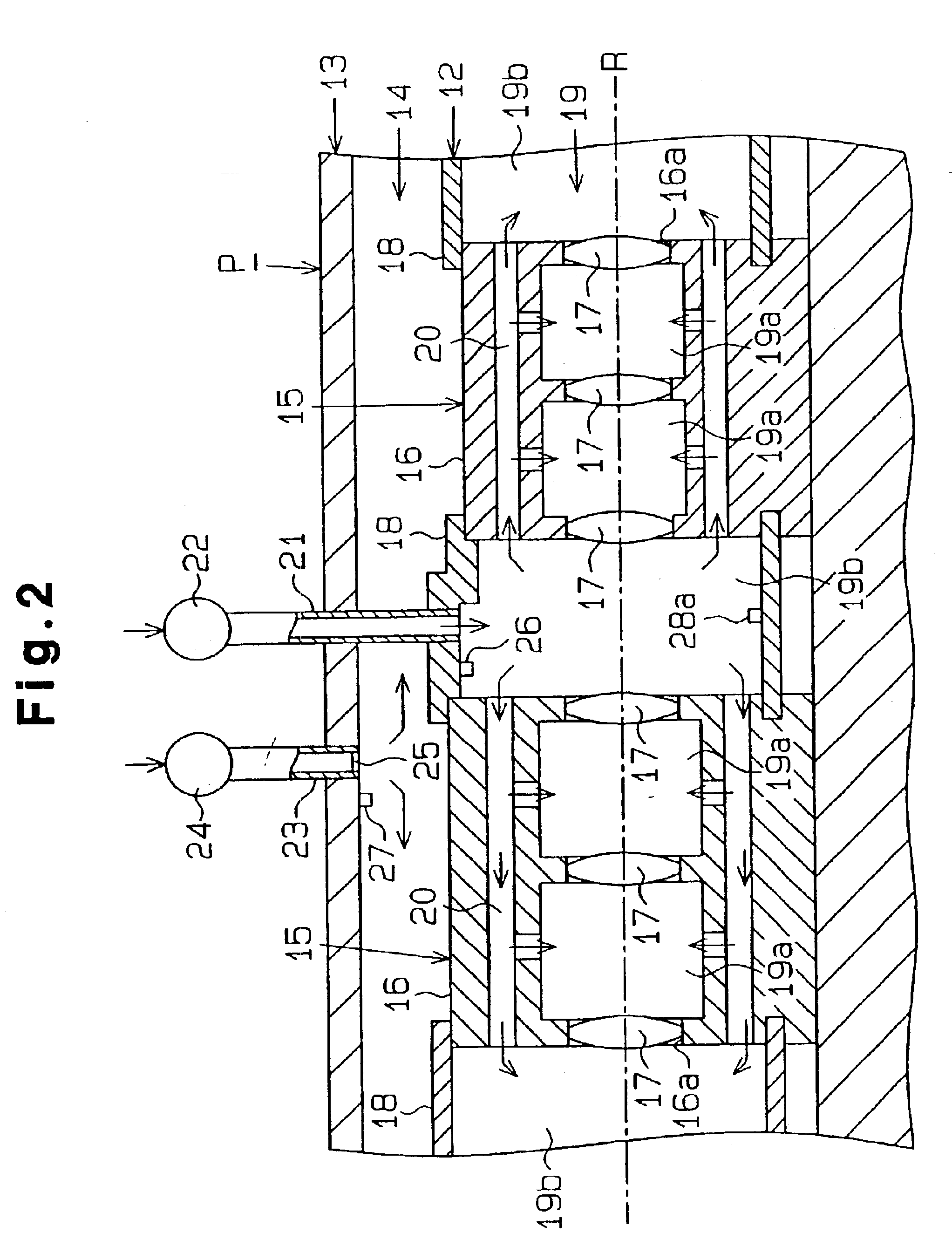

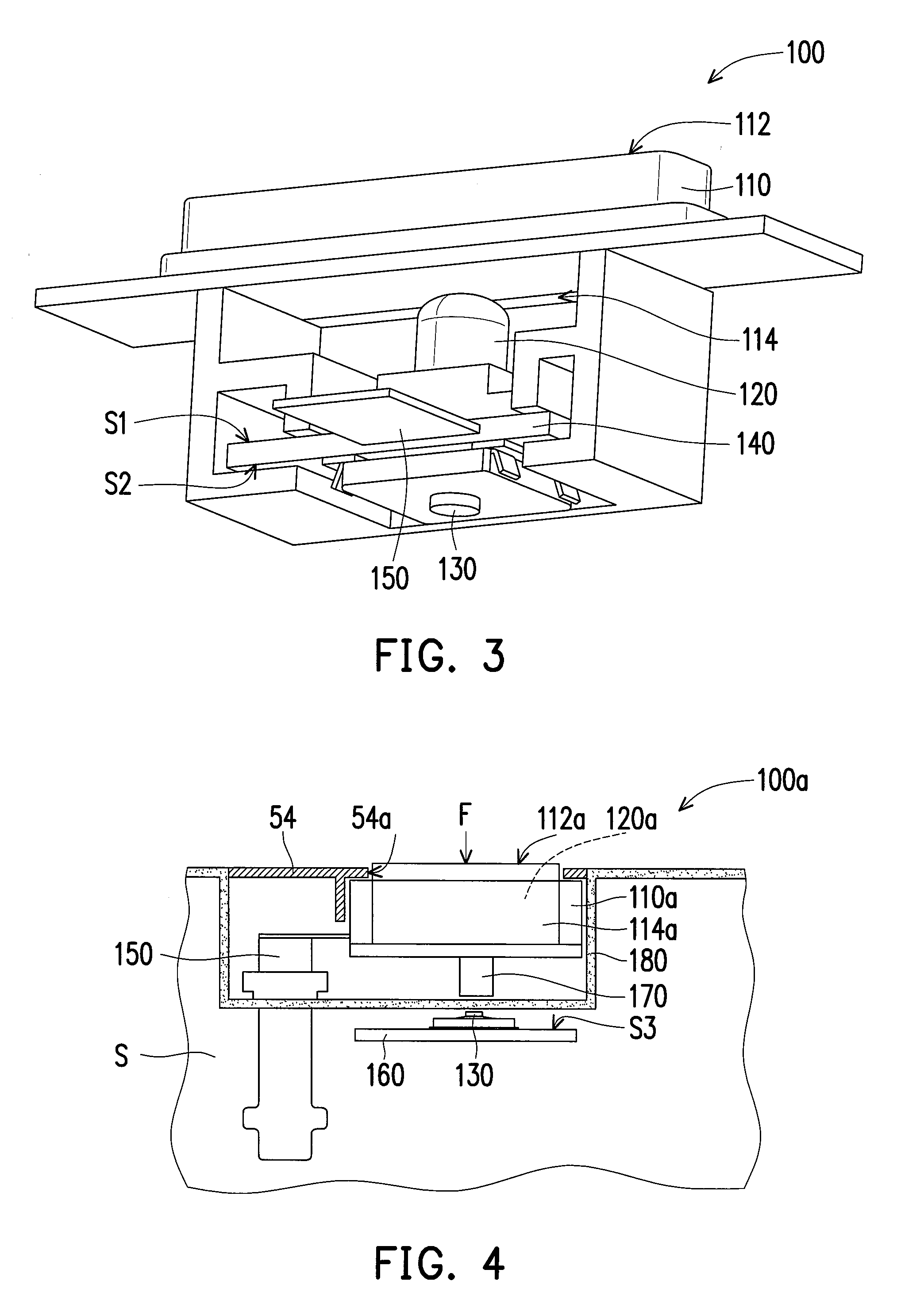

Optical apparatus and exposure apparatus incorporating the apparatus

InactiveUS6961114B2Function increaseImprove the optical apparatusPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical pathAmbient air

An optical apparatus having at least one optical element arranged along an optical path of an irradiation light. A first hermetic chamber is defined along the optical path separating the optical path from ambient air and charged with a predetermined gas. A second hermetic chamber is located in the first hermetic chamber separating the optical path from the gas in the first hermetic chamber and retaining the optical elements.

Owner:NIKON CORP

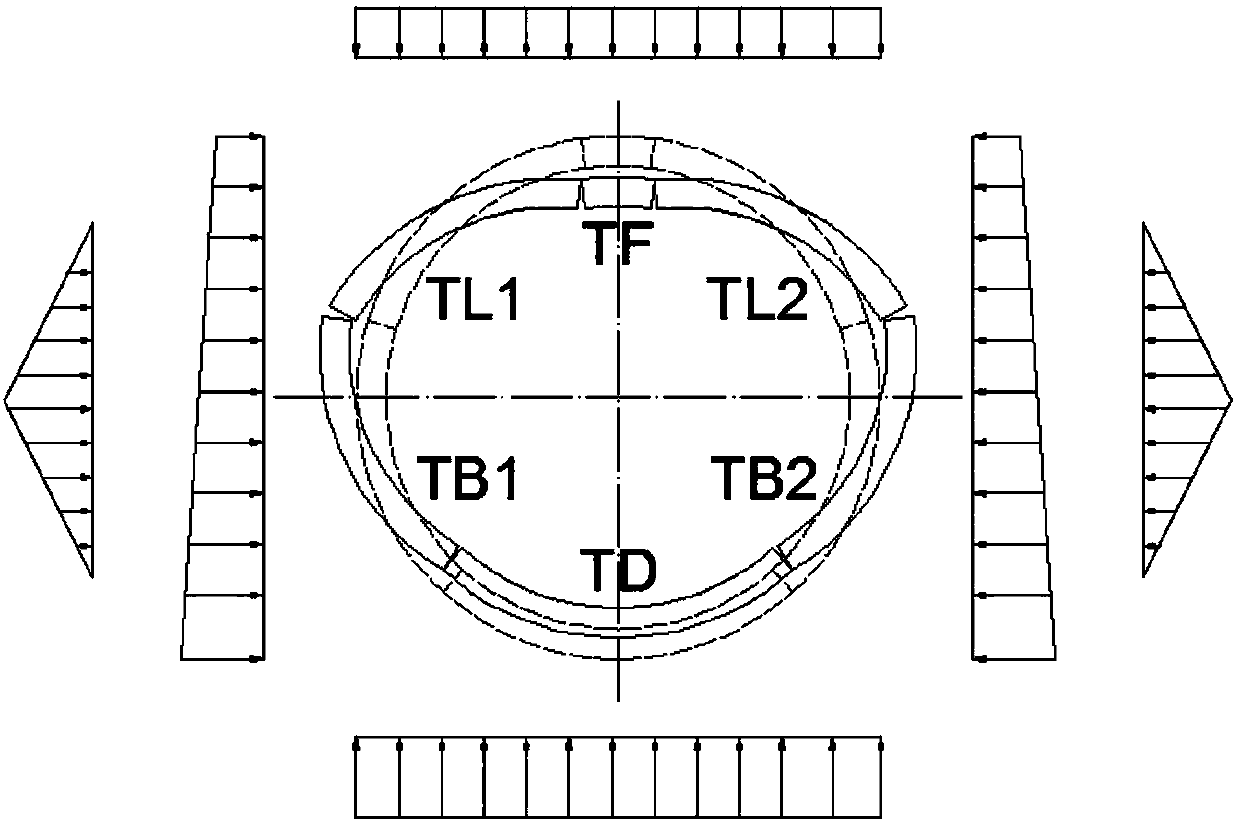

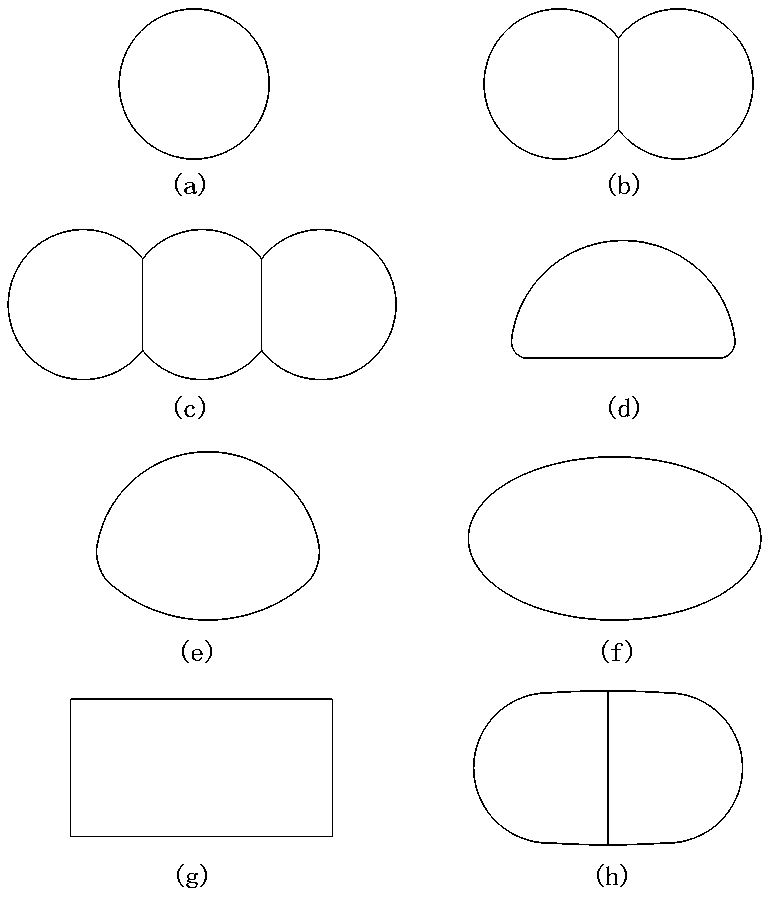

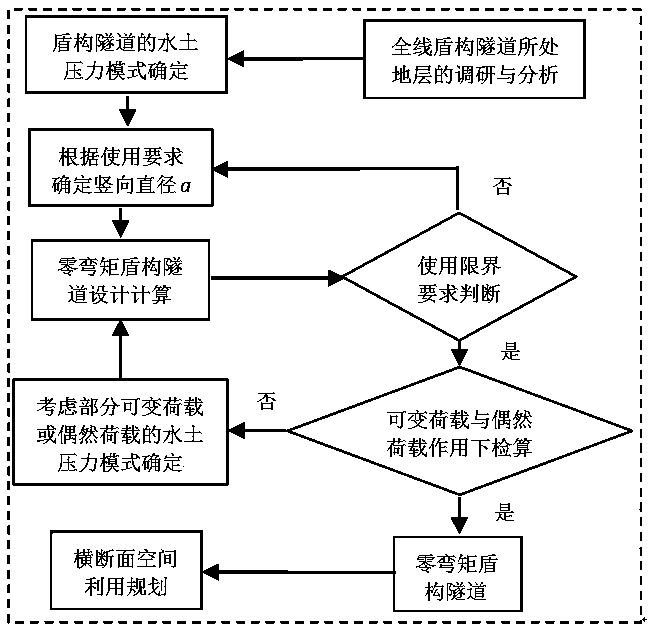

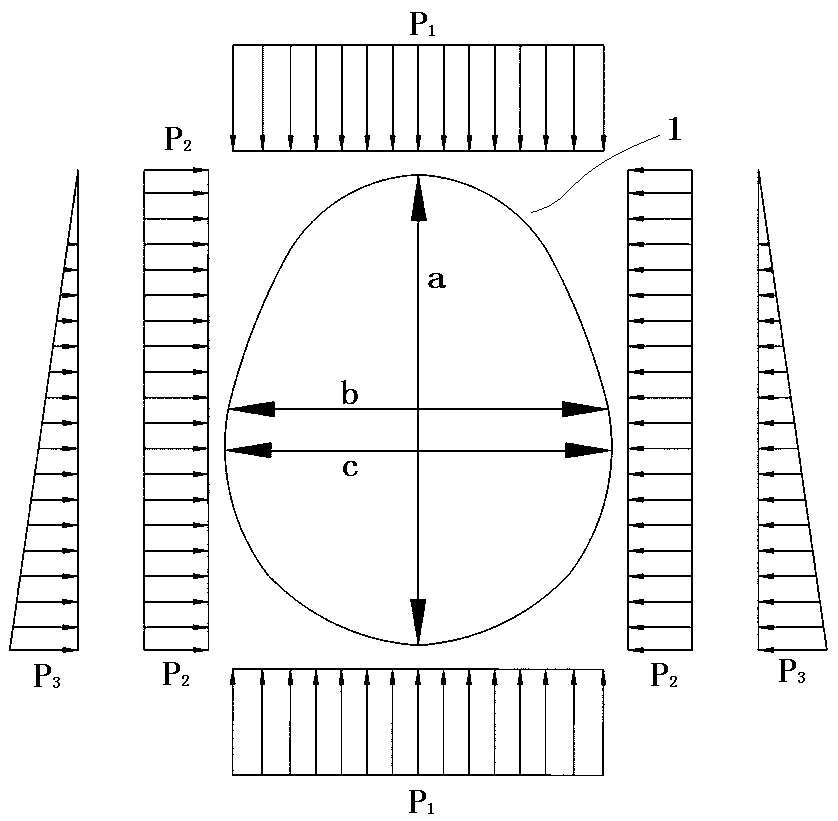

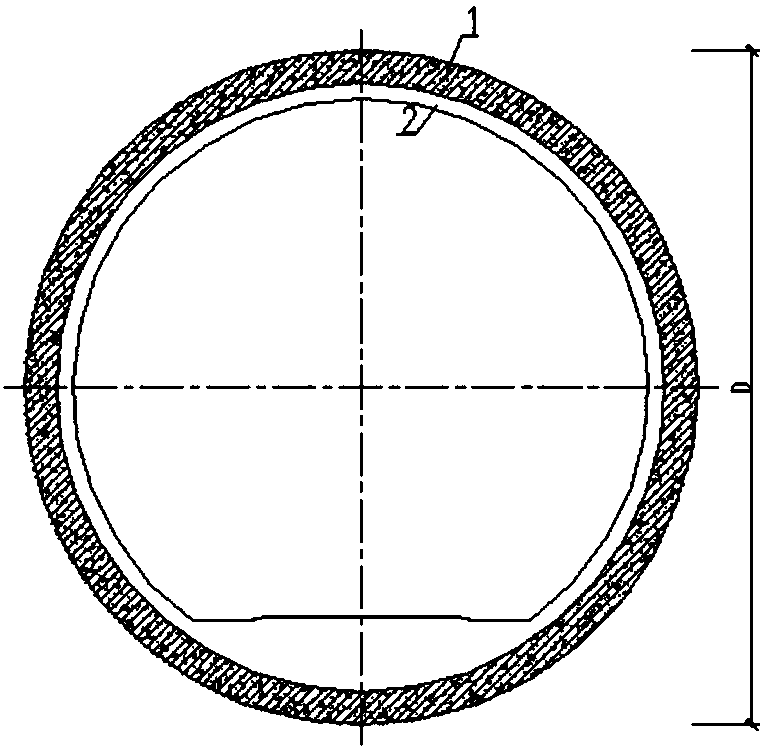

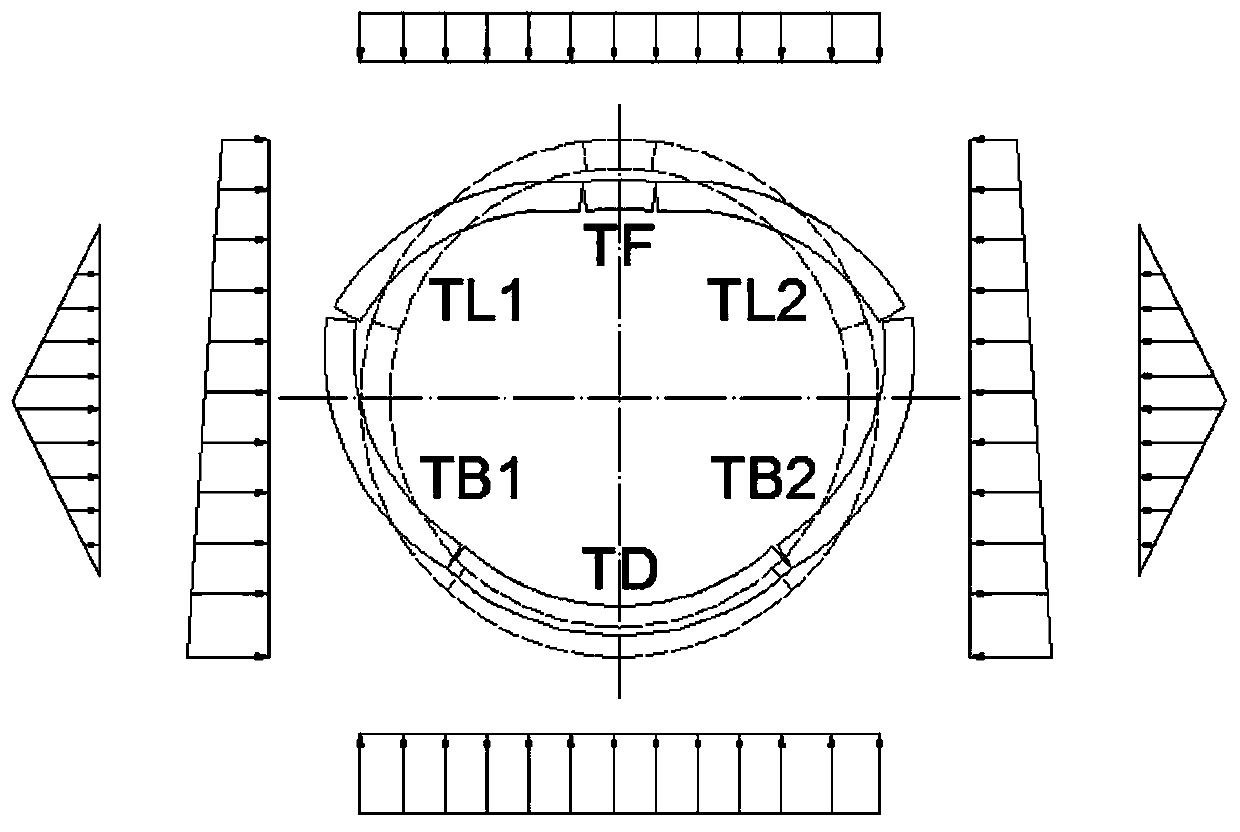

Design and calculation method of zero bending moment shield tunnel cross section

ActiveCN107247851AReduce bending momentReduce lateral deformationGeometric CADDesign optimisation/simulationWater tableWater level

The invention discloses a design and calculation method of a zero bending moment shield tunnel cross section. In the method, overall buried depth conditions, surrounding water and soil mechanical properties, underground water level conditions and the like of the top of a shield tunnel are analyzed according to formation conditions of the shield tunnel, the designed water and soil pressure mode of the shield tunnel is determined after comprehensive analysis, in this way, the rational axis and key parameters of shield tunnel cross section are designed, the cross section of the shield tunnel is of an egg-shaped structure which is small in the top and big in bottom, and the cross section theoretical bending moment of the shield tunnel cross section is zero under the effect of the designed water and soil pressure. The design and calculation method of the zero bending moment shield tunnel cross section has the advantages that the design and calculation method is simple and easy to operate, compared with a traditional shield tunnel, on the condition that the project cost is not basically increased, the bending moment of the designed zero bending moment shield tunnel is reduced to the greatest extent, therefore the cross section deformation of the shield tunnel and the expansion deformation of a pipe sheet longitudinal joint connector are avoided, breakage and water seepage of the pipe sheet longitudinal joint connector are prevented, and the using quantity of steel bars in a pipe sheet is reduced.

Owner:EAST CHINA JIAOTONG UNIVERSITY

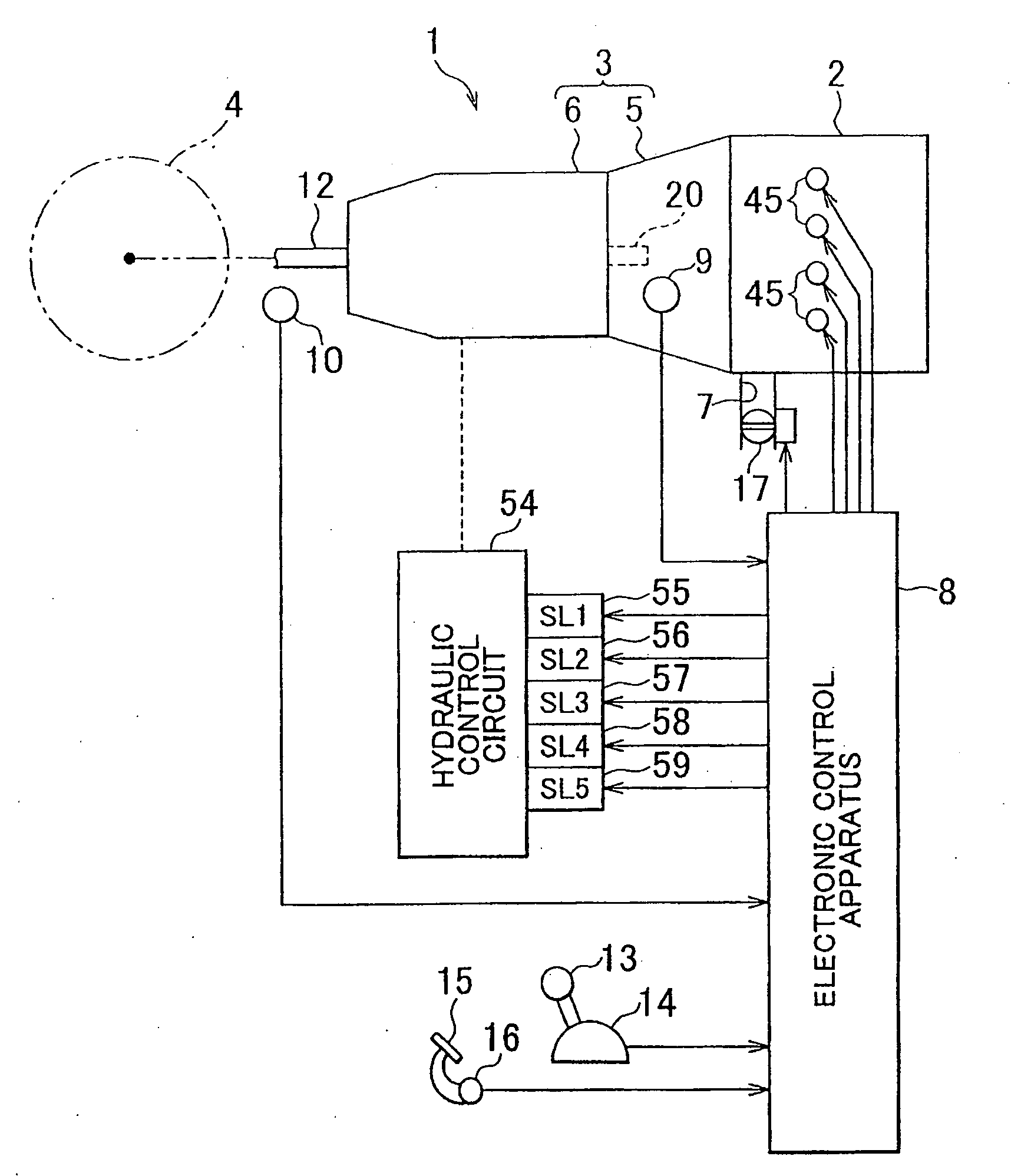

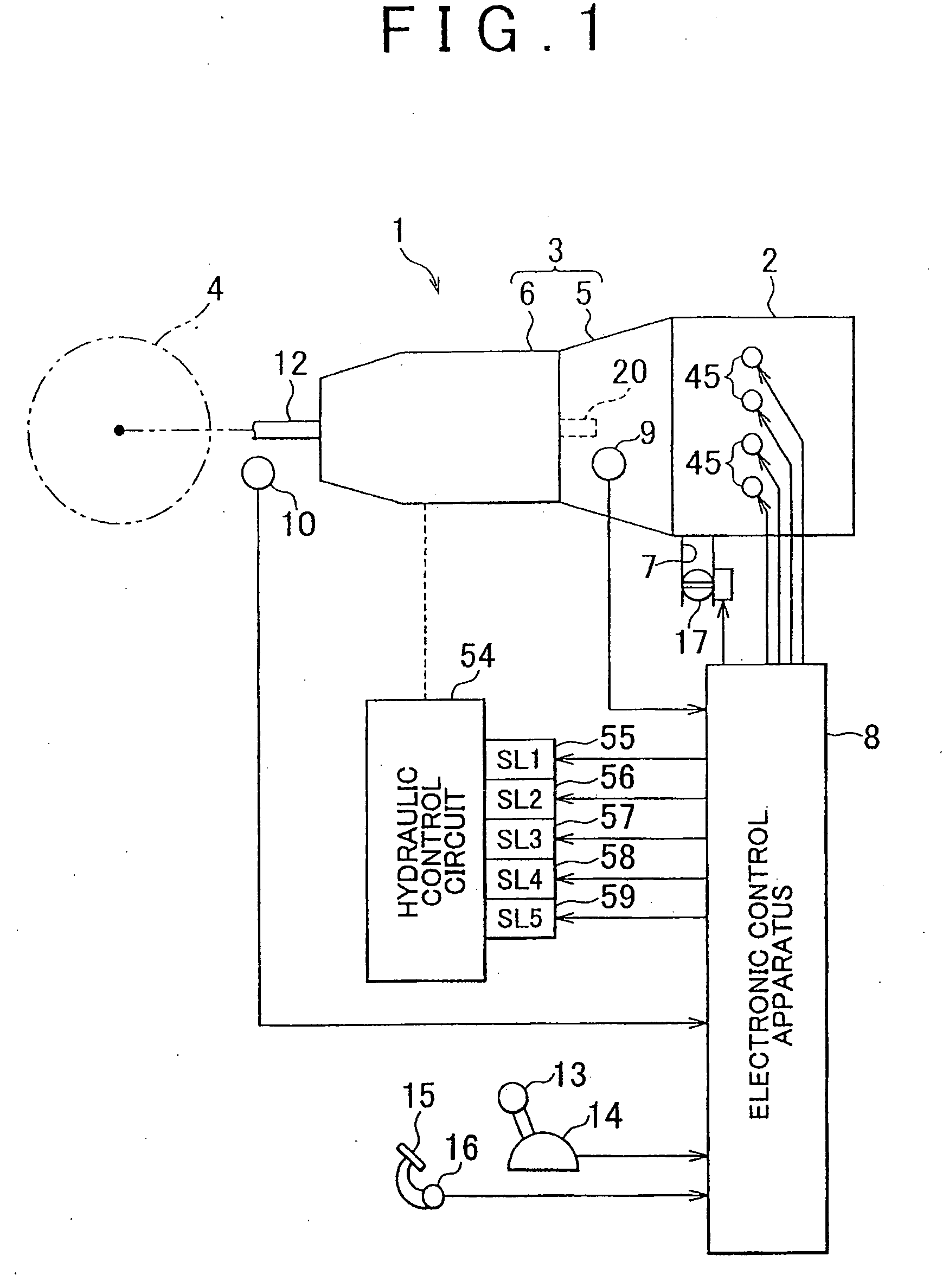

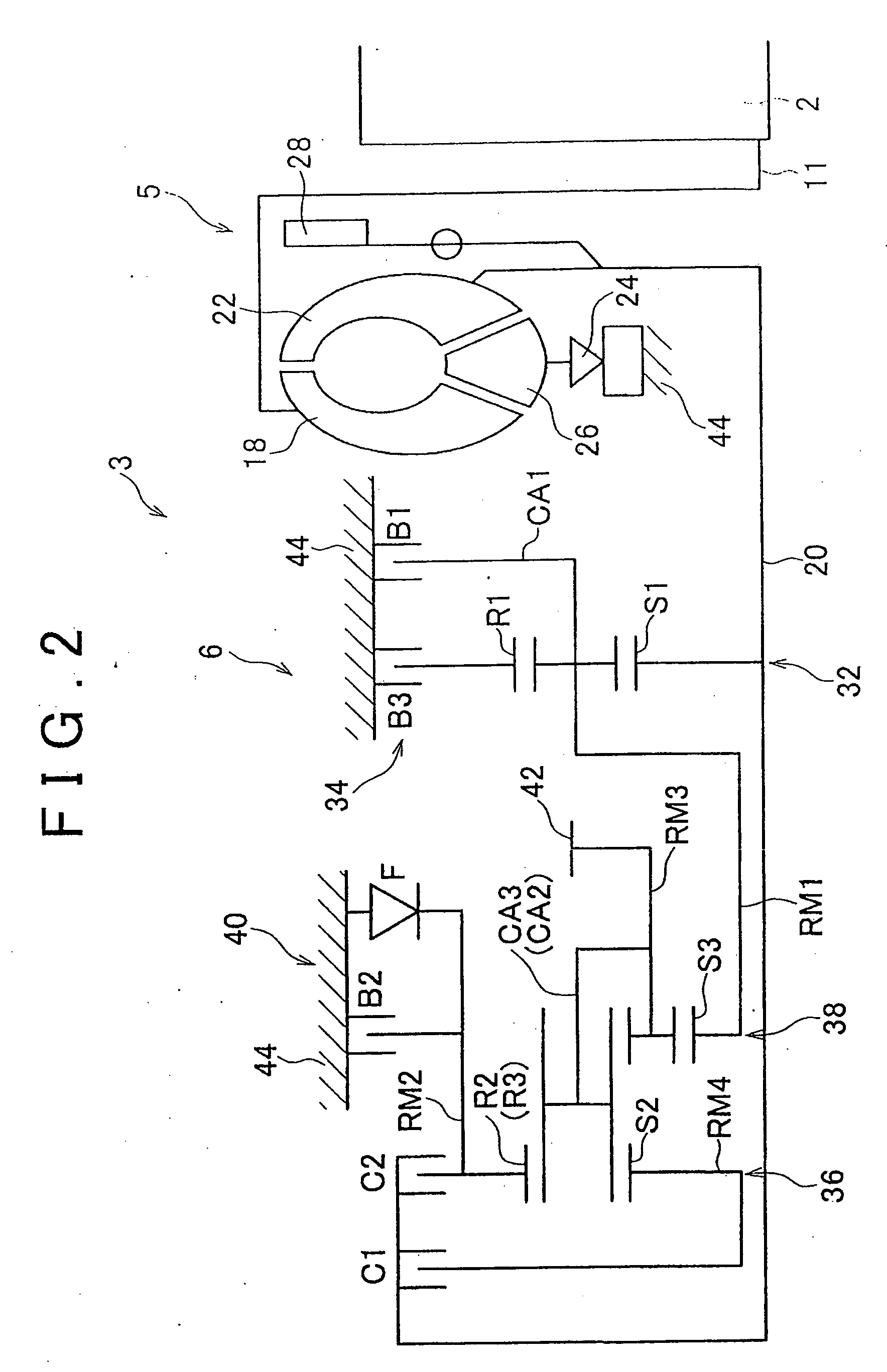

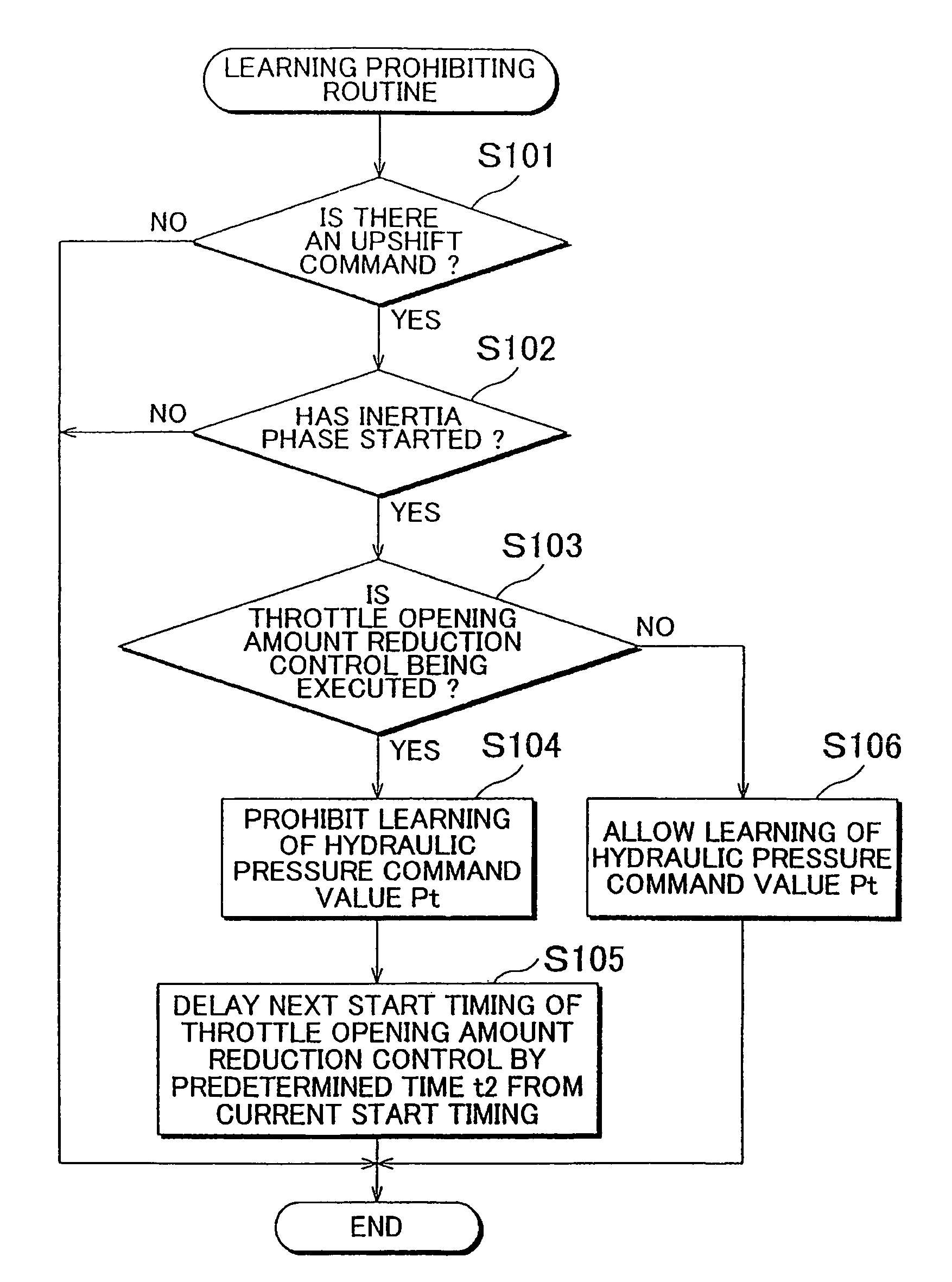

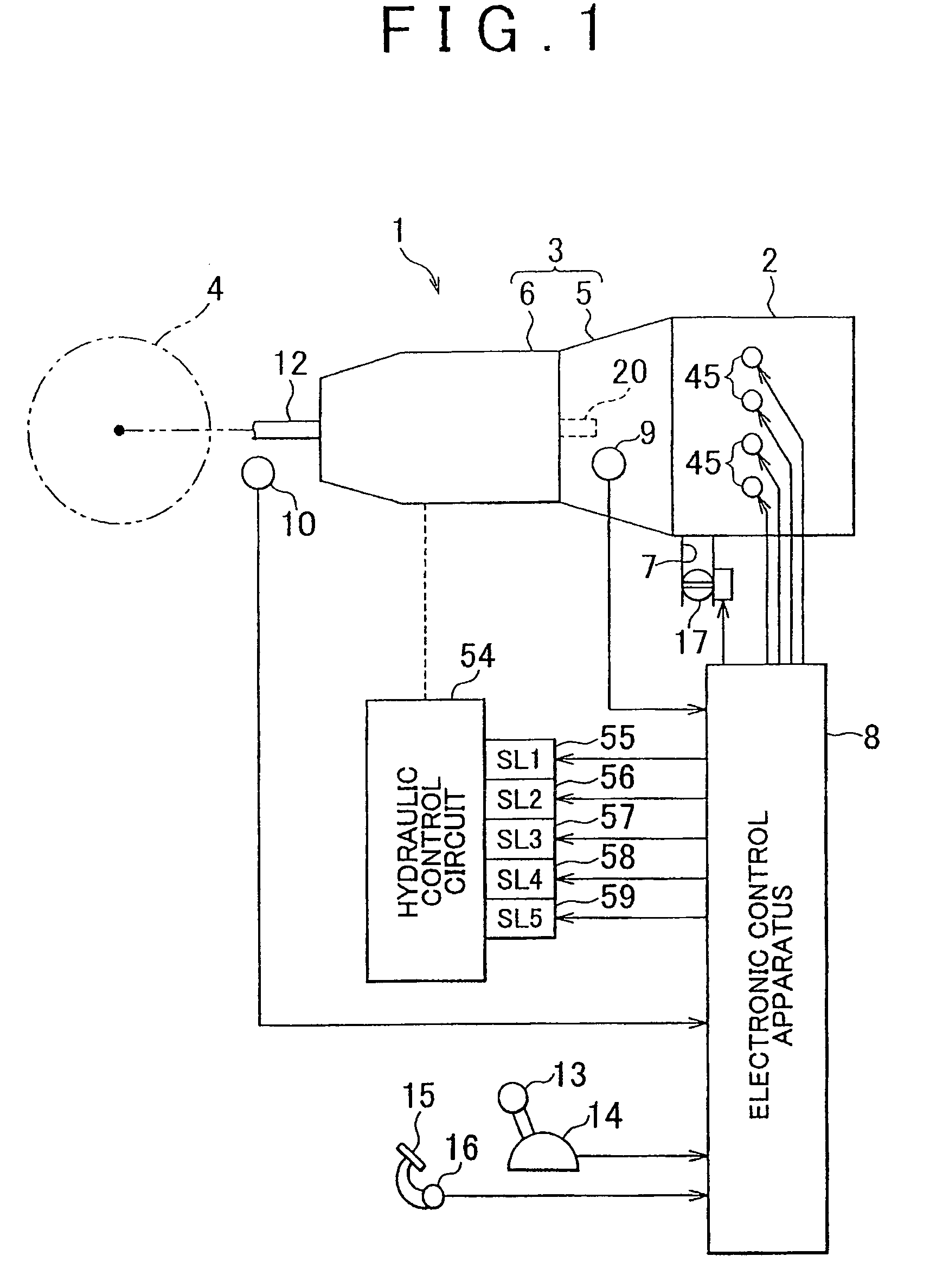

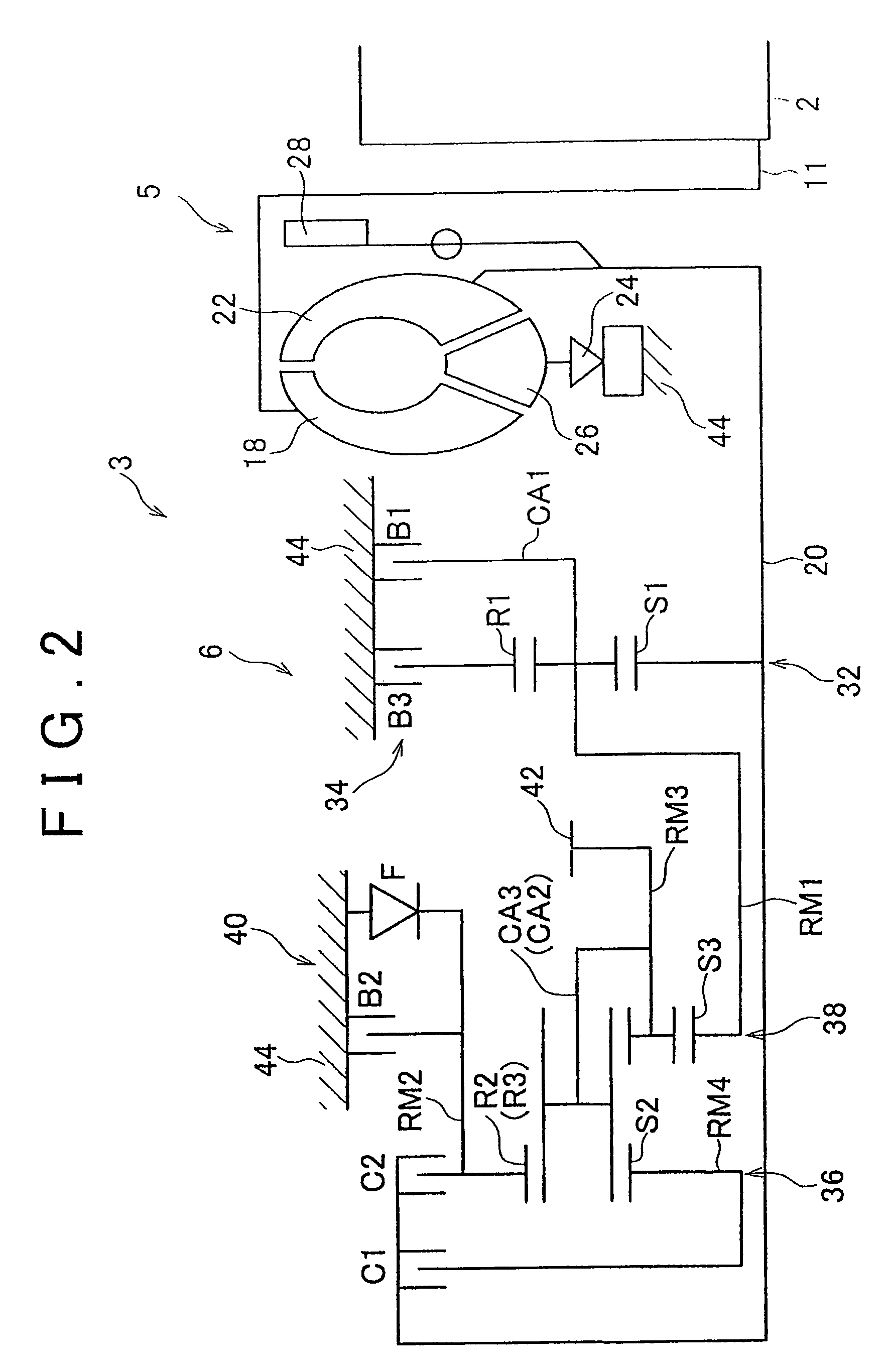

Vehicular control apparatus and vehicular control method

ActiveUS20100056332A1Reduce output torqueDecrease in learning frequencyDigital data processing detailsGearing controlAutomatic transmissionControl theory

When shifting an automatic transmission (3) into a higher gear, it is determined that an inertia phase has started when an input rotation speed of the automatic transmission (3) has started to decrease. Here, if throttle opening amount reduction control is being performed to reduce the output torque of the engine (2) when it is determined that the inertia phase has started, it is highly likely that that determination is erroneous because that control causes the input rotation speed of the automatic transmission (3) (i.e., the engine speed) to decrease. When it is highly likely that the determination that the inertia phase has started is erroneous in this way, learning of a hydraulic pressure command value (Pt) is prohibited. As a result, erroneous learning of the hydraulic pressure command value (Pt) can be prevented.

Owner:TOYOTA JIDOSHA KK

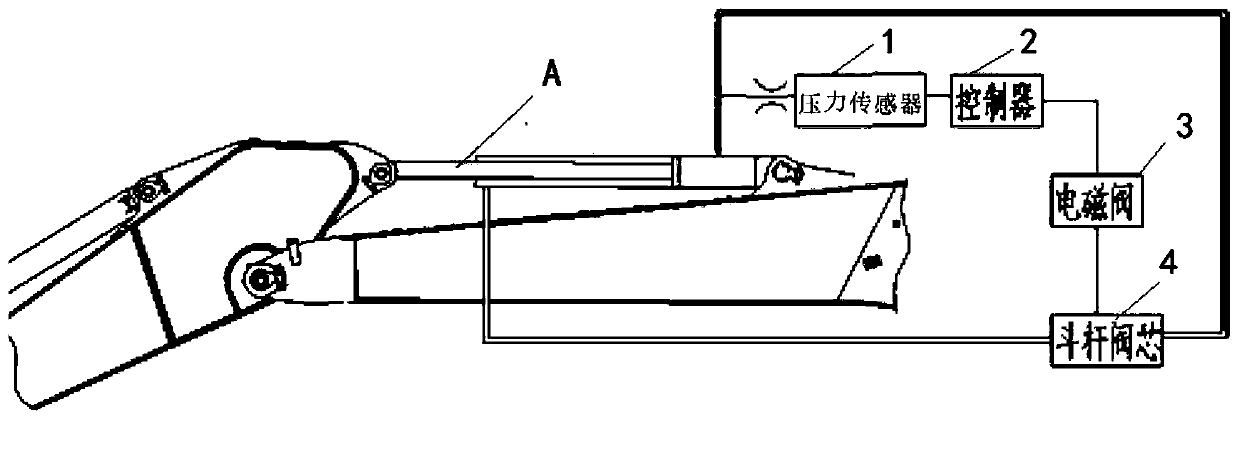

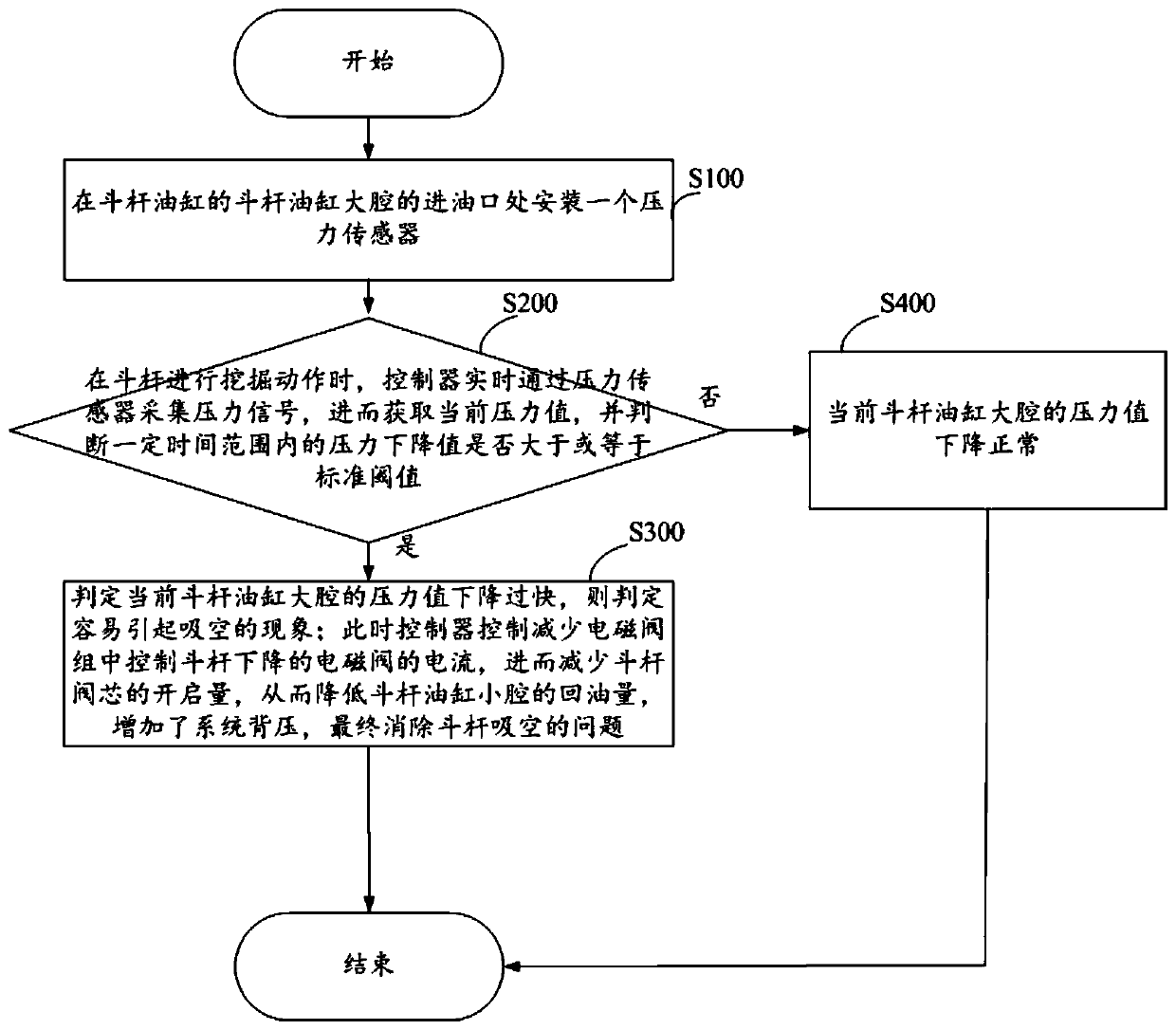

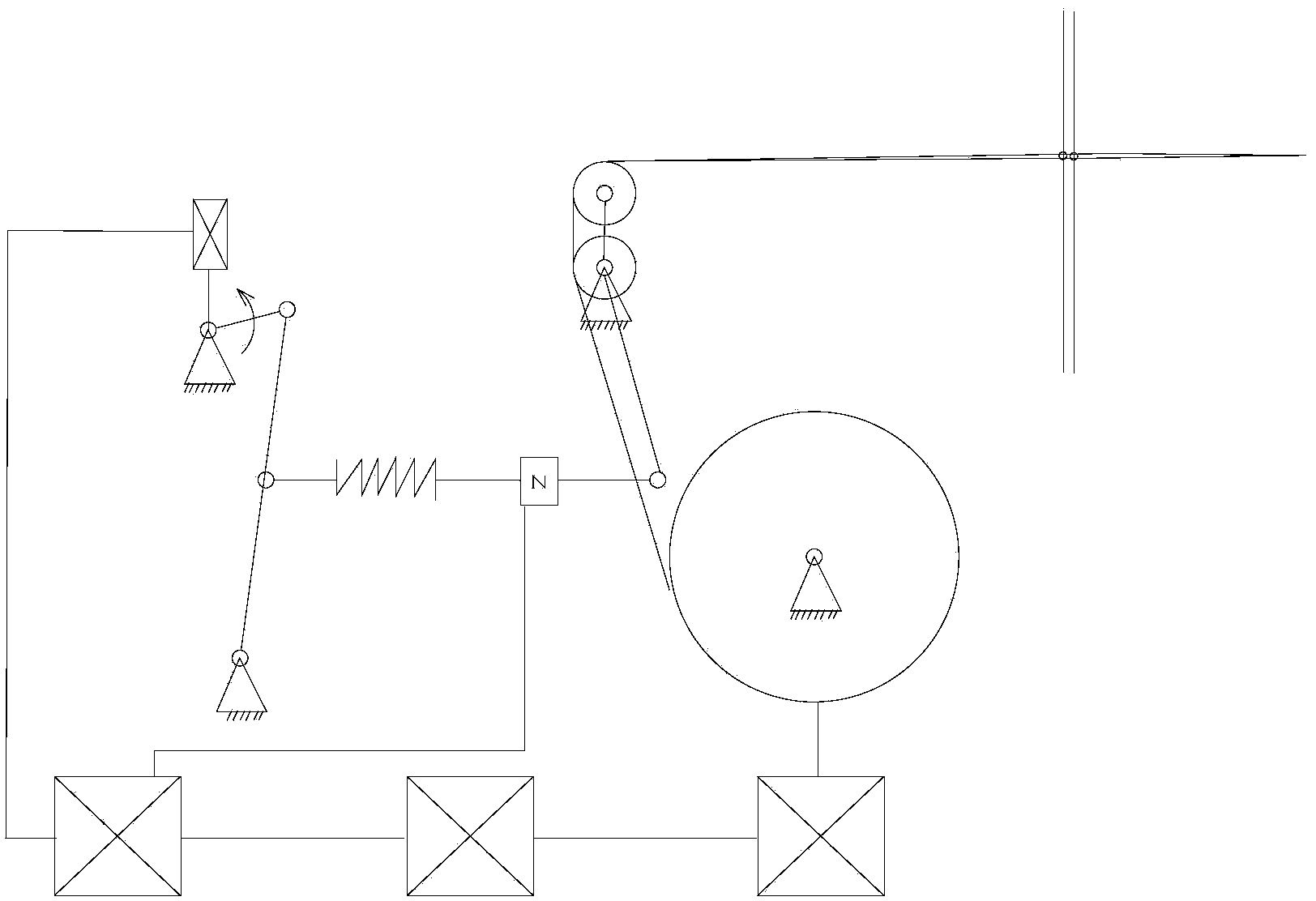

Energy-saving control device and control method for controlling bucket rod of excavator to descend

InactiveCN109736373ASolve the problem of suctionSmall currentMechanical machines/dredgersTime rangePower flow

The invention relates to an energy-saving control device and control method for controlling a bucket rod of an excavator to descend. The energy-saving control device for controlling the bucket rod ofthe excavator to descend comprises a pressure sensor, a controller, an electromagnetic valve for controlling the bucket rod to descend, and a bucket rod valve core. The controller is used for collecting pressure signals in real time through the pressure sensor when the bucket rod carries out excavation action, then the current pressure value is obtained, and whether the pressure descending value within the preset time range is larger than or equal to the standard threshold value or not is judged; if the pressure descending value within the current preset time range is larger than or equal to the standard threshold value, it is judged that the pressure value of a large cavity of a current bucket rod oil cylinder is descended too fast, and it is determined that the phenomenon of air suctionis caused easily; and at the moment, the controller controls to reduce currents of the electromagnetic valve for controlling the bucket rod to descend in an electromagnetic valve set, then the openingamount of the bucket rod valve core is reduced, thus the oil amount of a small cavity of the bucket rod oil cylinder is reduced, the system back pressure is increased, and finally the problem of airsucking of the bucket rod is eliminated.

Owner:SHANGHAI SANY HEAVY IND

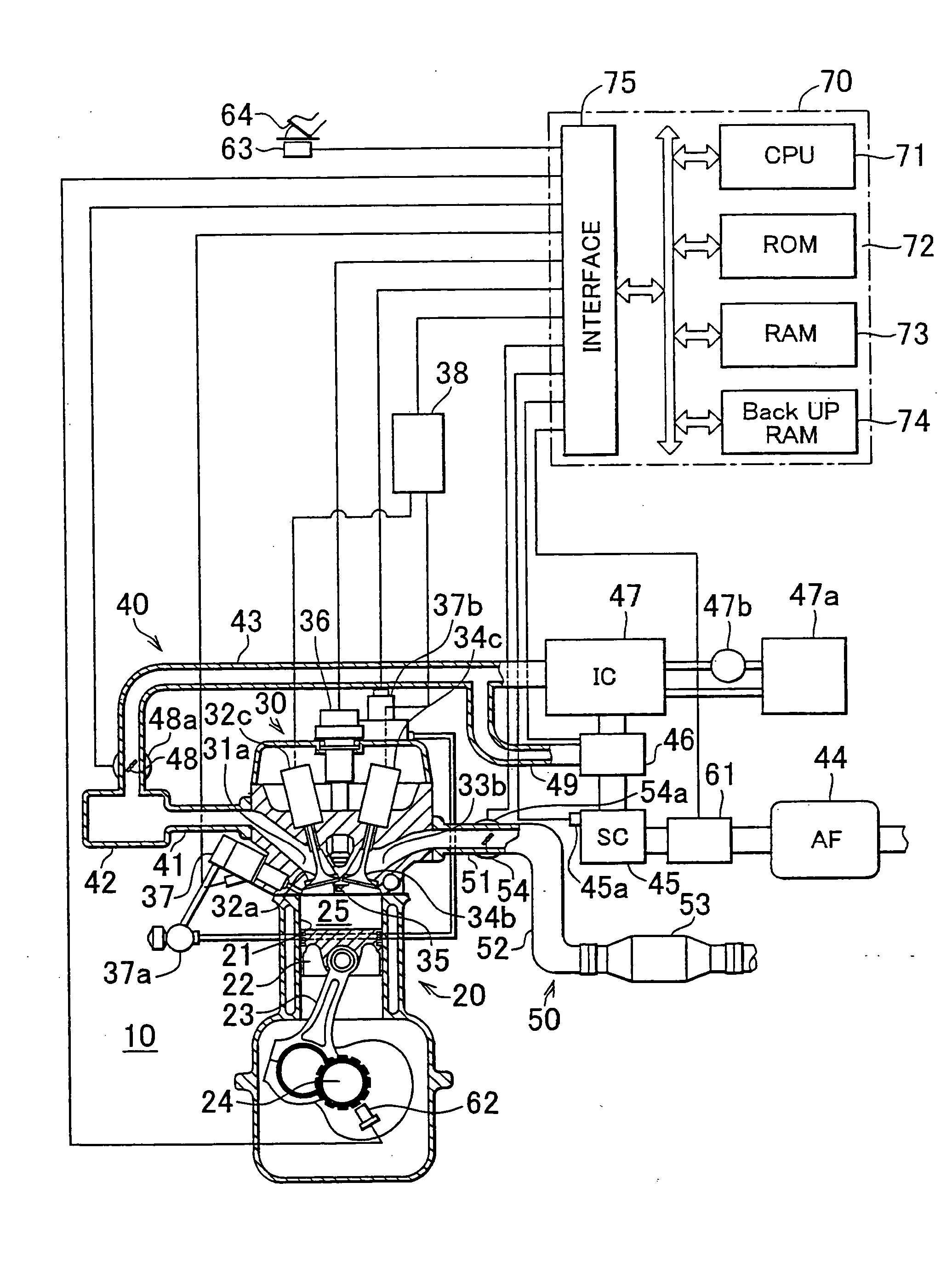

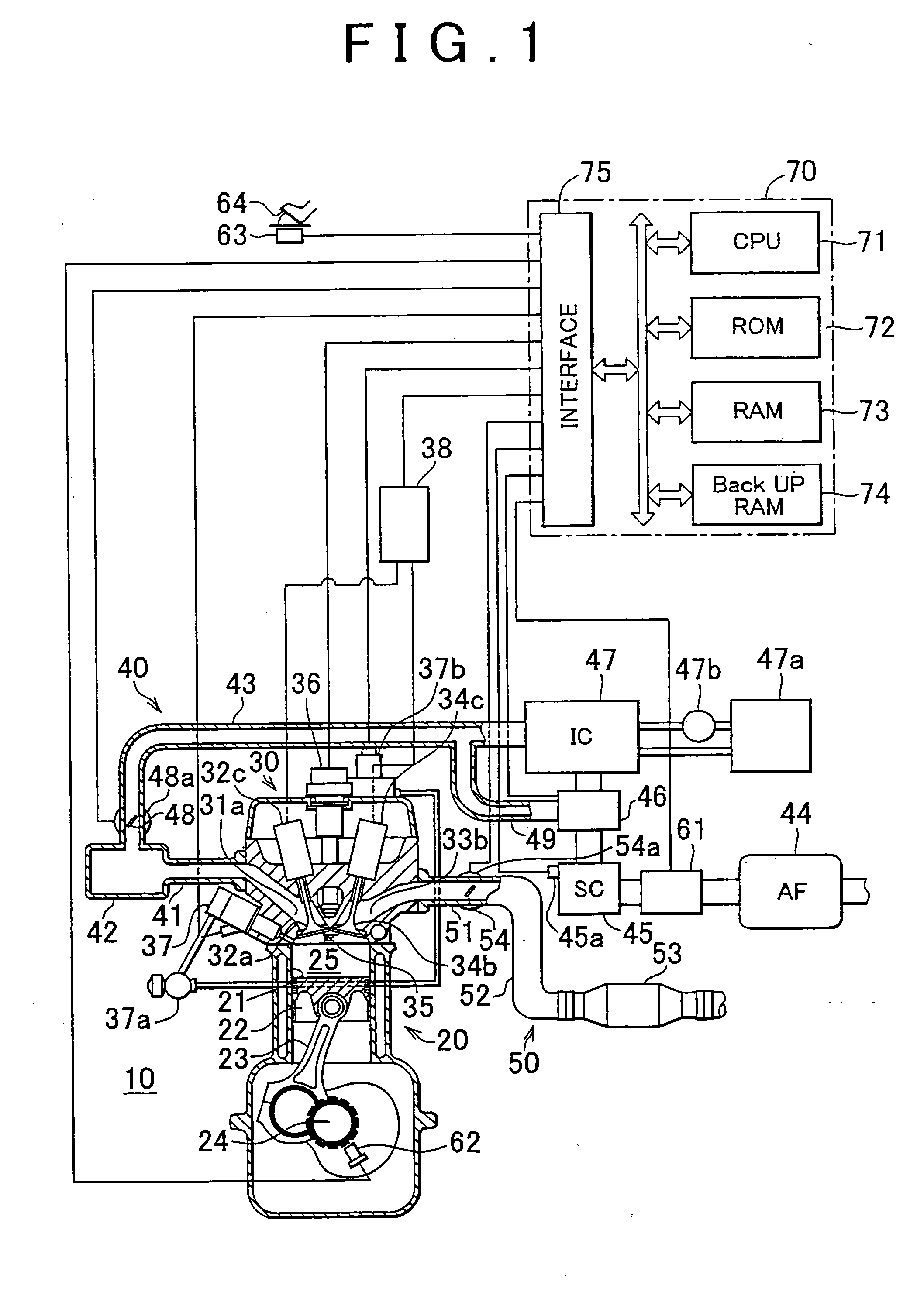

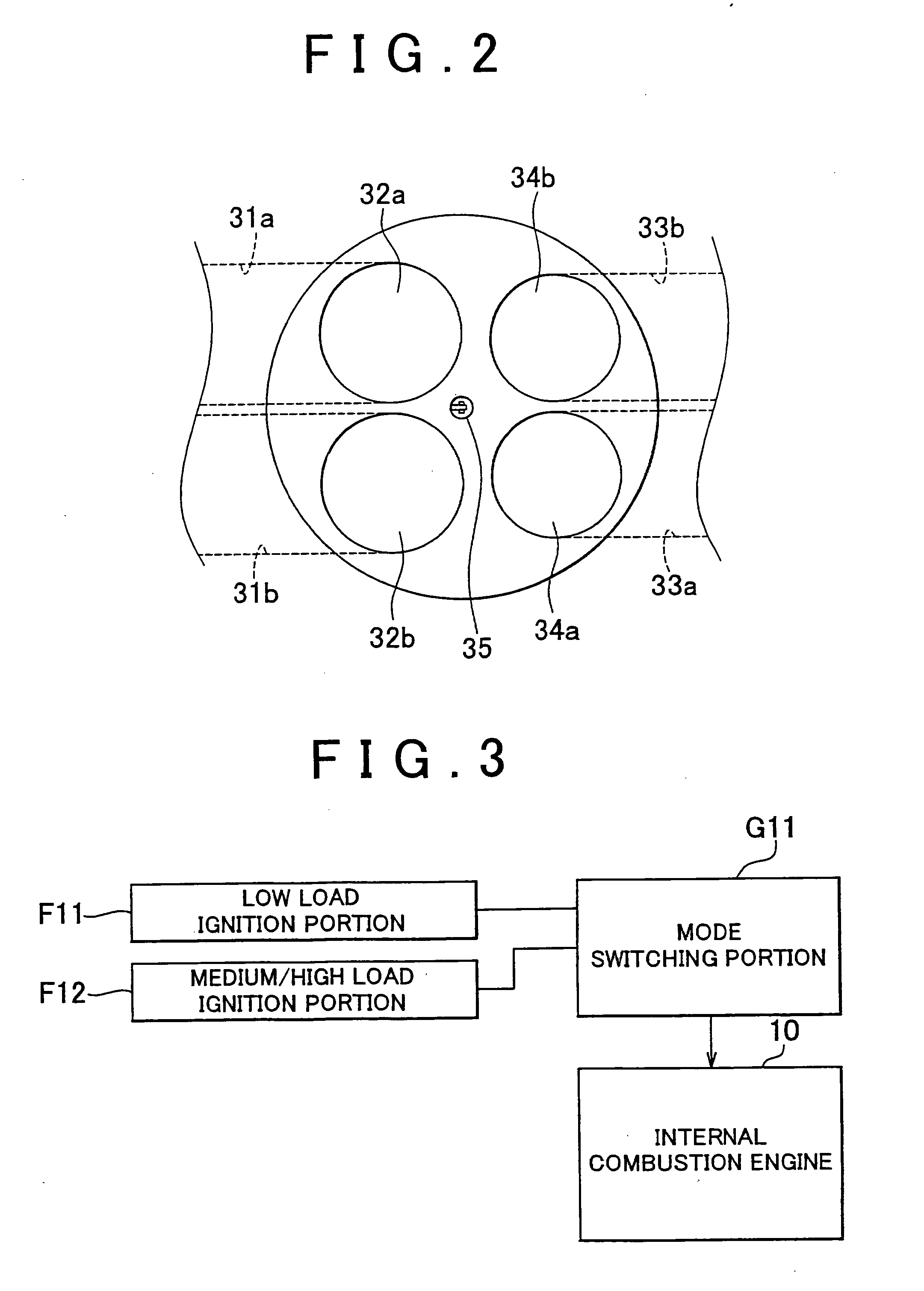

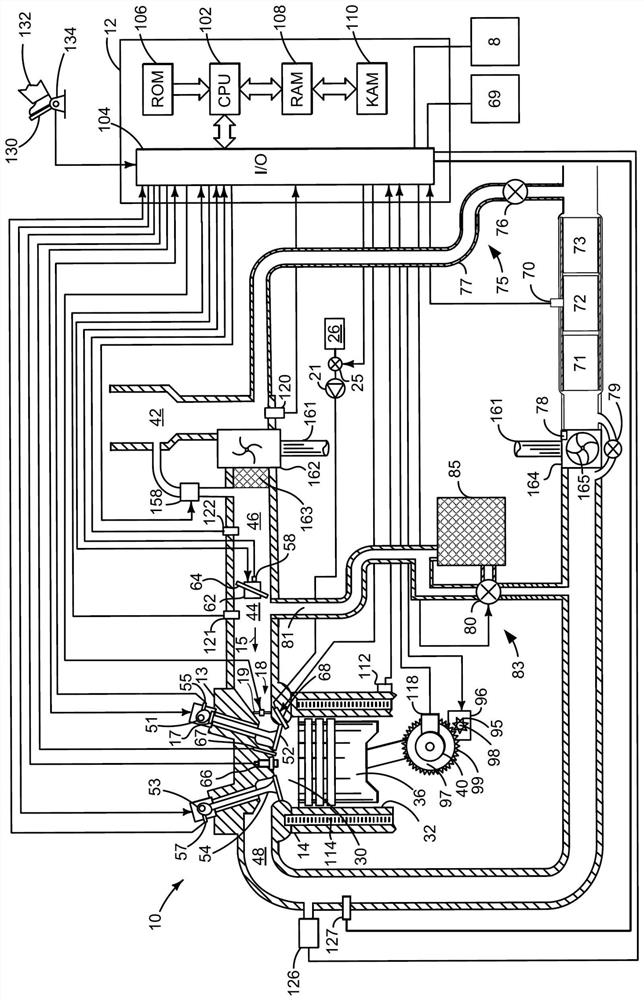

Control apparatus and method for four-stroke premixed compression ignition internal combustion engine

ActiveUS20070107680A1Increase temperatureReduce the amount of openingValve arrangementsElectrical controlCombustion chamberExhaust valve

A control apparatus for a four-stroke premixed compression ignition internal combustion engine opens an exhaust valve to discharge burned gas from a combustion chamber at a first exhaust-valve opening timing, and reopens the exhaust valve at a second exhaust-valve opening timing that is retarded with respect to the intake-valve opening timing. Thus, burned gas discharged from the combustion chamber flows back into the combustion chamber through the exhaust port. The control apparatus retards the second exhaust-valve opening timing as the load on the engine increases. This obviates the need to decrease the lift of the exhaust valve to decrease the amount of burned gas that is reintroduced into the combustion chamber and prevents increases in the resistance against the flow of burned gas into the combustion chamber.

Owner:TOYOTA JIDOSHA KK

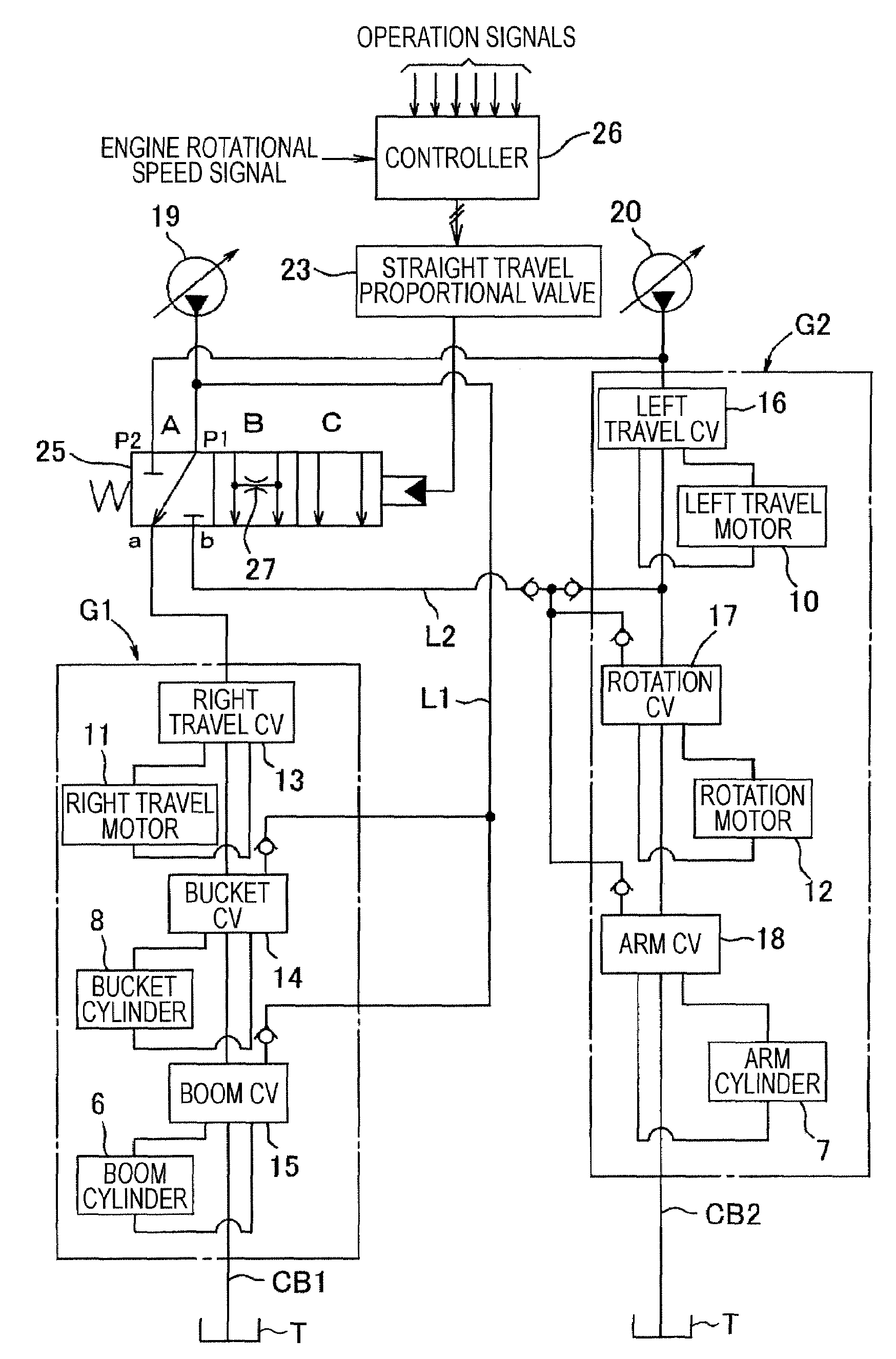

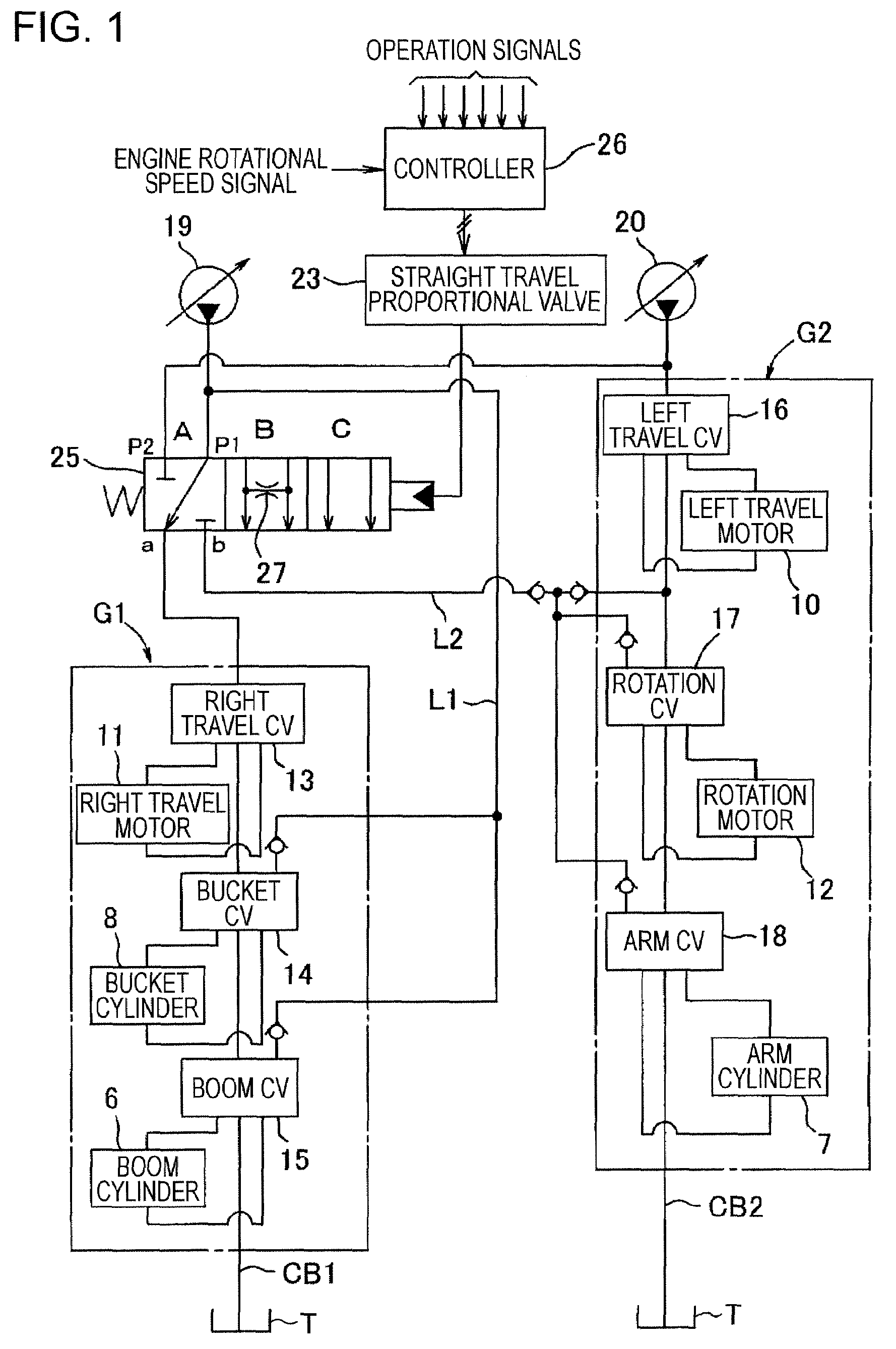

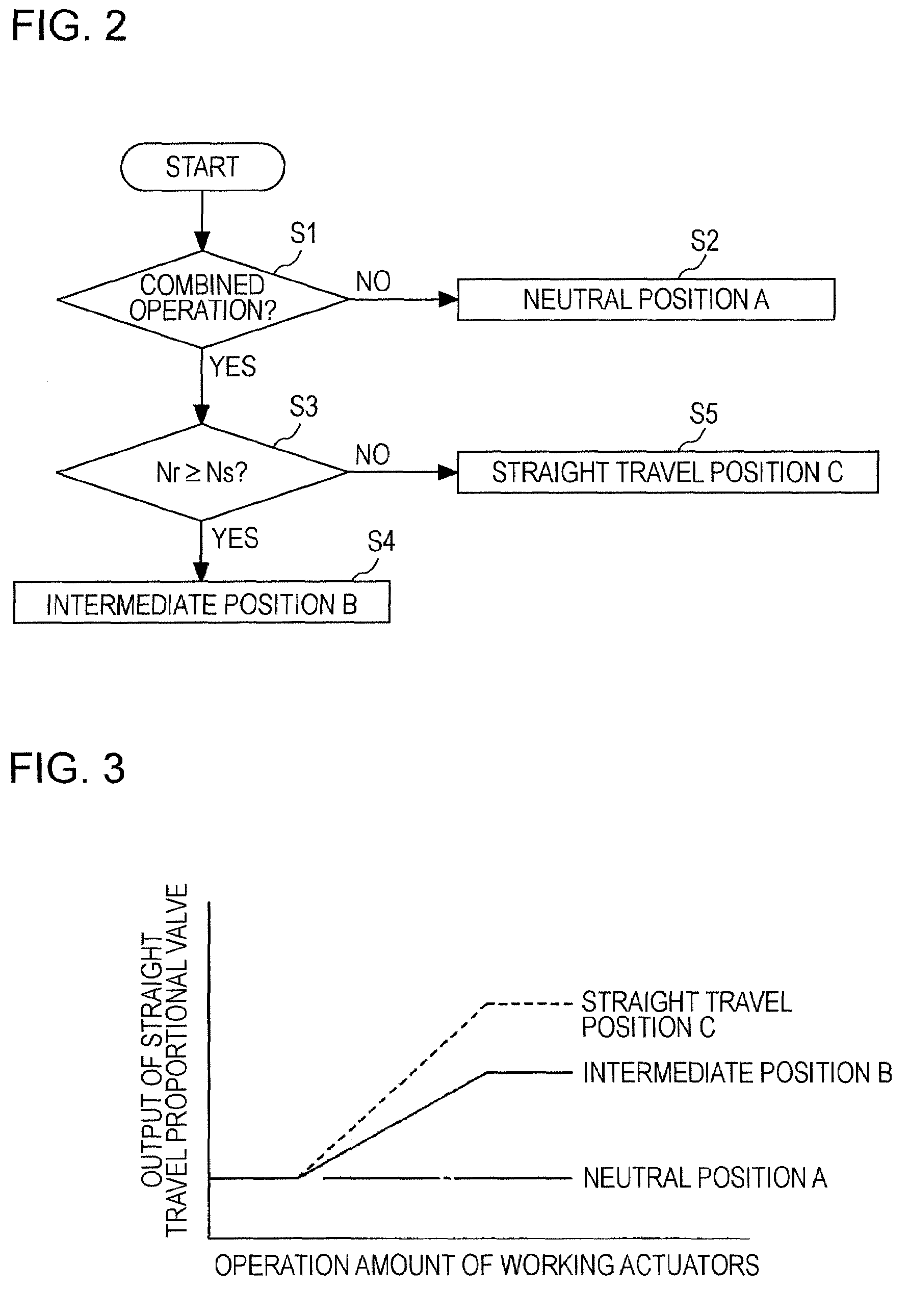

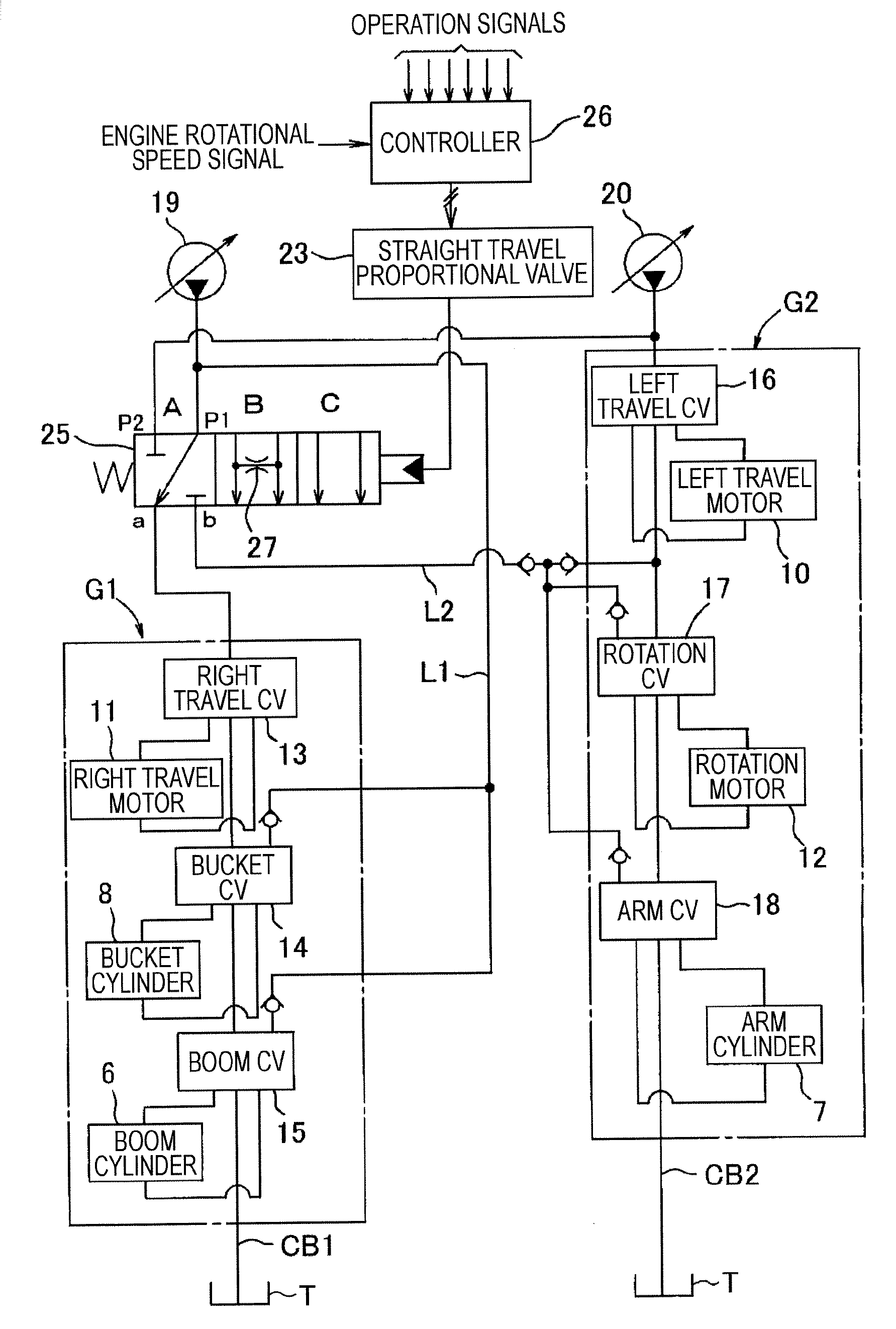

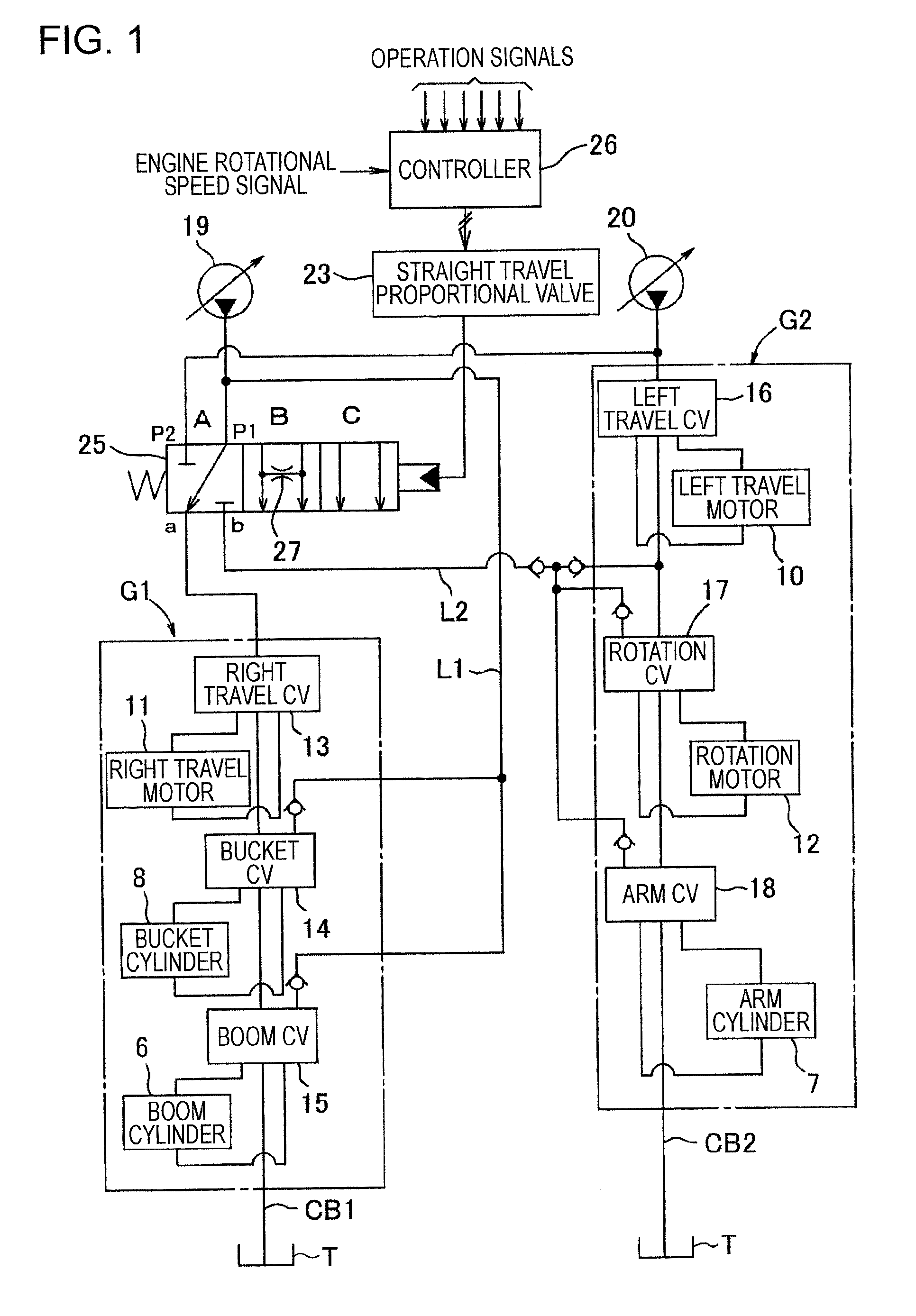

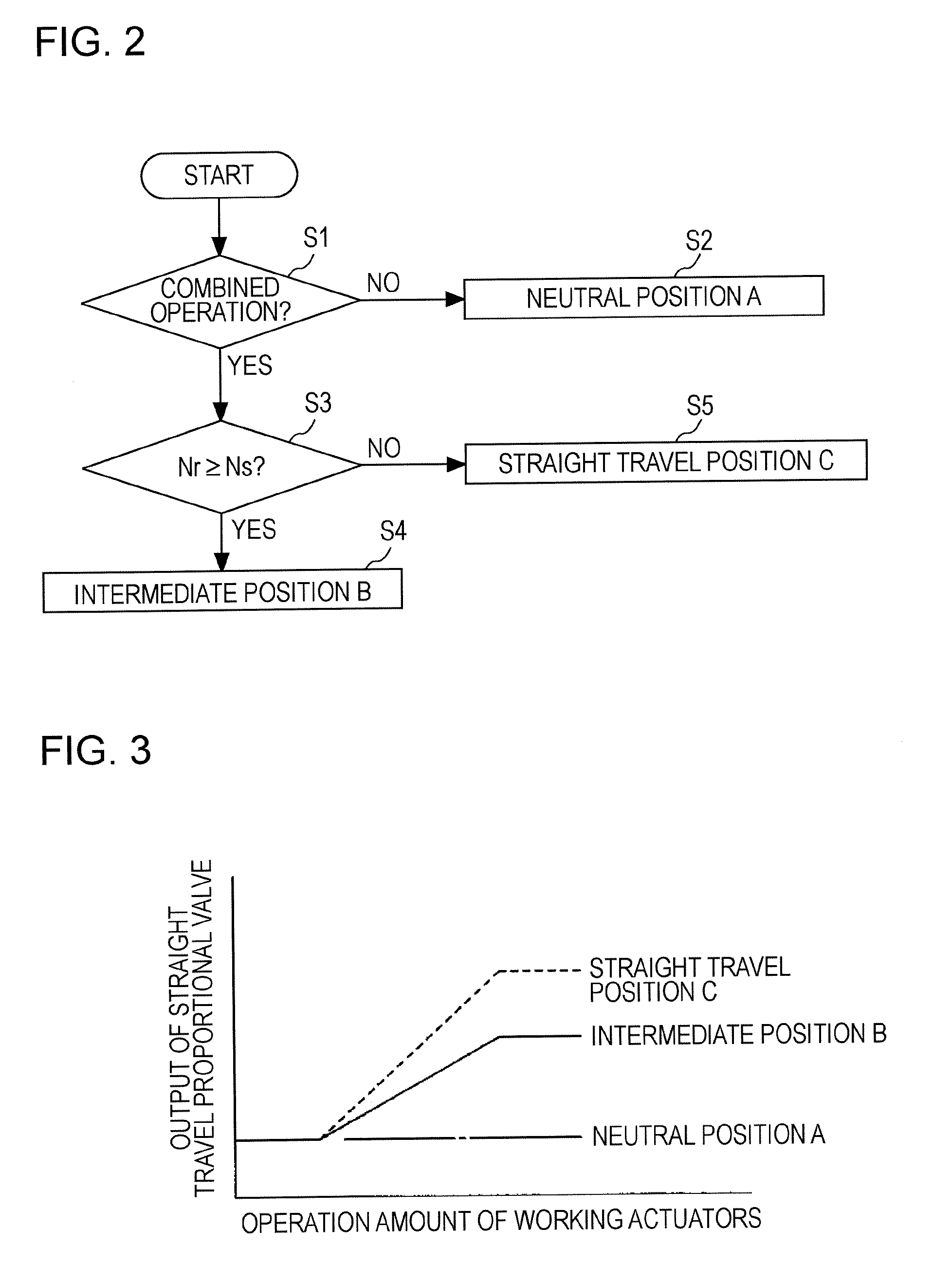

Hydraulic controlling device of working machine

ActiveUS7497080B2Avoid interferenceShorten speedFluid couplingsSoil-shifting machines/dredgersEngineeringActuator

A hydraulic controlling device in which, when performing a combined operational process, a position of a straight travel valve is switched to a straight travel position to drive both a travel motor and a working actuator by separate pumps. In this case, to prevent a sudden reduction in travel speed resulting from a reduction in a flow amount at a travel side, pump lines of both pumps are connected to each other at an intermediate position by a connection path, so that a portion of oil at a working side is sent towards the travel side. With such a structure, when a rotational speed of an engine is less than a set rotational speed, an opening amount of the connection path is reduced through a straight travel proportional valve by a controller, thereby preventing pressure interference causing, for example, the working actuator to no longer move.

Owner:KOBELCO CONSTR MASCH CO LTD

Vehicular control apparatus and vehicular control method

ActiveUS8287431B2Prevent pressureReduce speedDigital data processing detailsGearing controlAutomatic transmissionError prevention

Owner:TOYOTA JIDOSHA KK

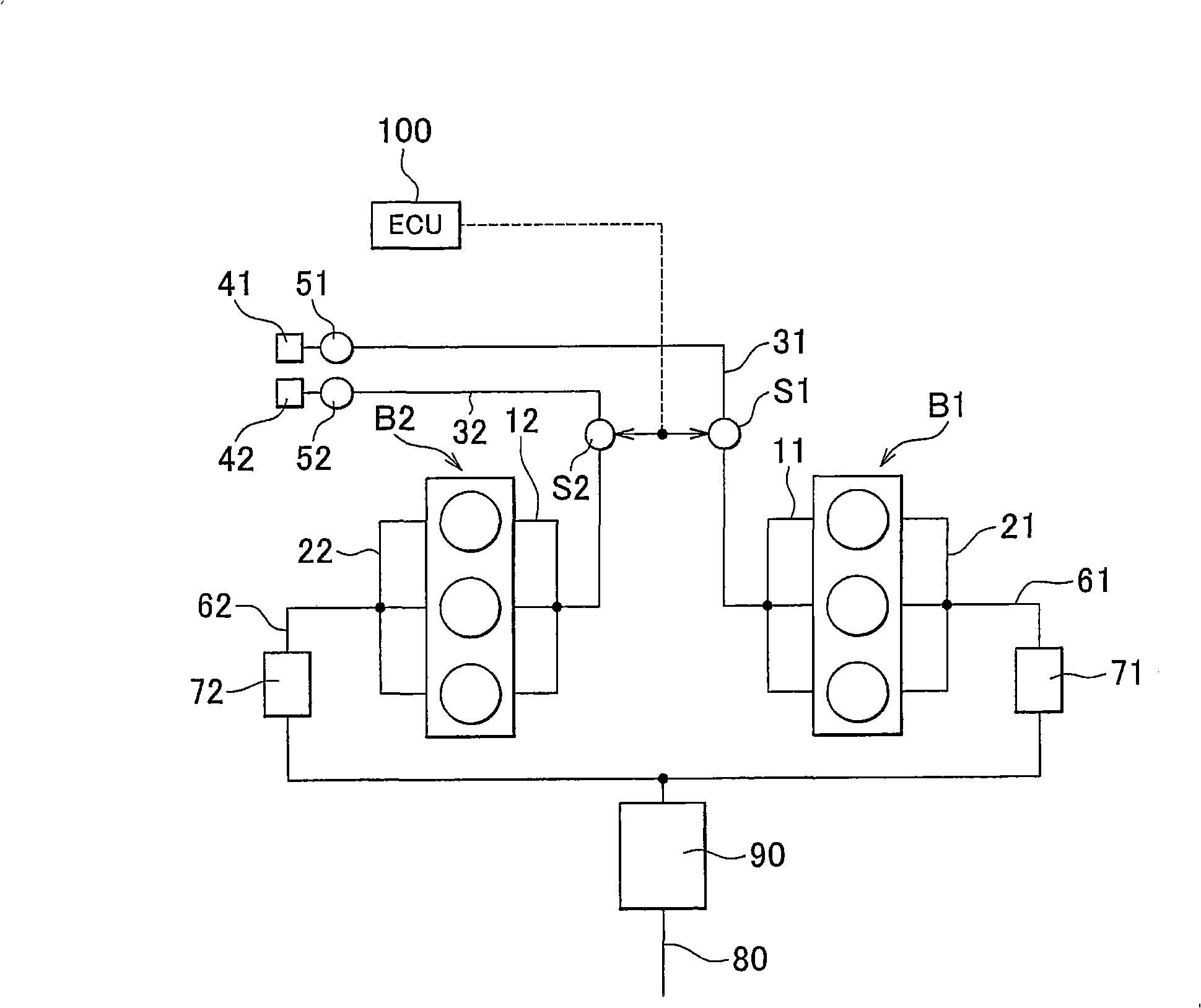

Throttle valve control apparatus of an internal combustion engine

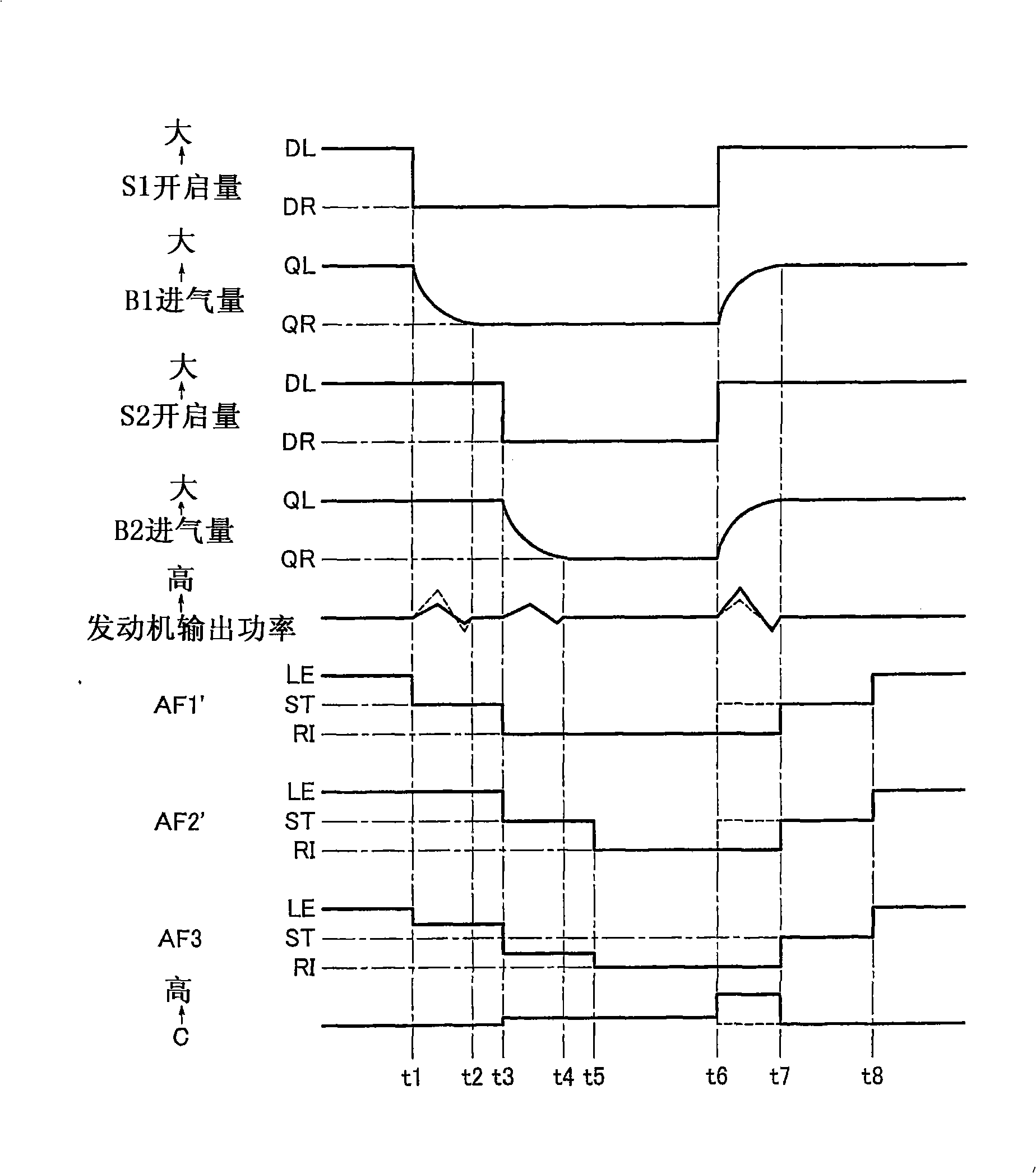

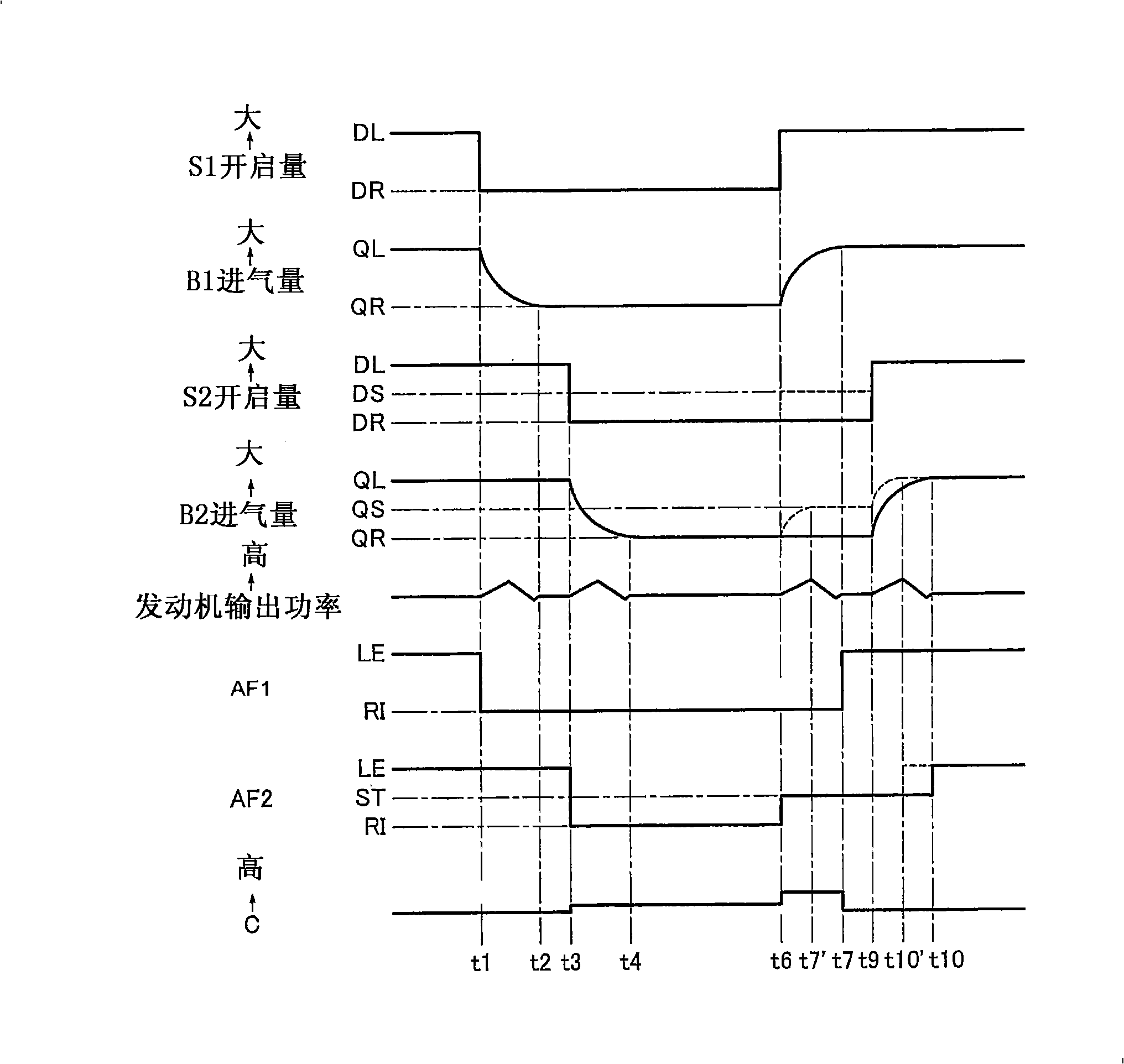

InactiveCN101405498AReduce the amount of openingElectrical controlInternal combustion piston enginesControl theoryAir–fuel ratio

The invention provides a throttle valve control apparatus of an internal combustion engine having at least a first cylinder group (Bl) and a second cylinder group (B2). A first throttle valve (Sl) is arranged in an intake passage (31) of the first cylinder group and a second throttle valve (S2) is arranged in an intake passage (32) of the second cylinder group. The throttle valve control apparatus includes a controller that, when there is a demand to switch a combustion air-fuel ratio of the internal combustion engine without changing engine output, first changes an opening amount of the first throttle valve, and then changes an opening amount of the second throttle valve.

Owner:TOYOTA JIDOSHA KK

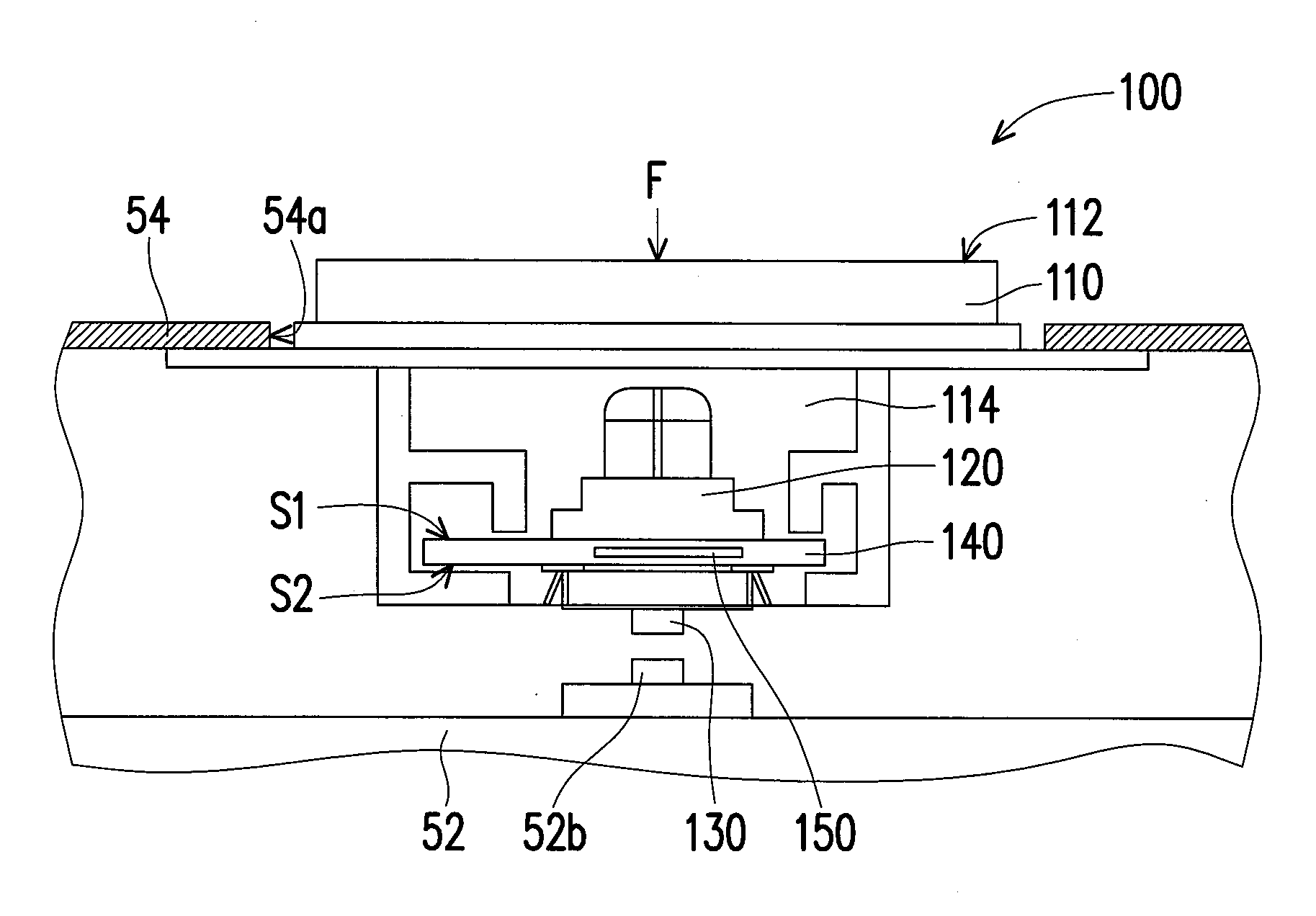

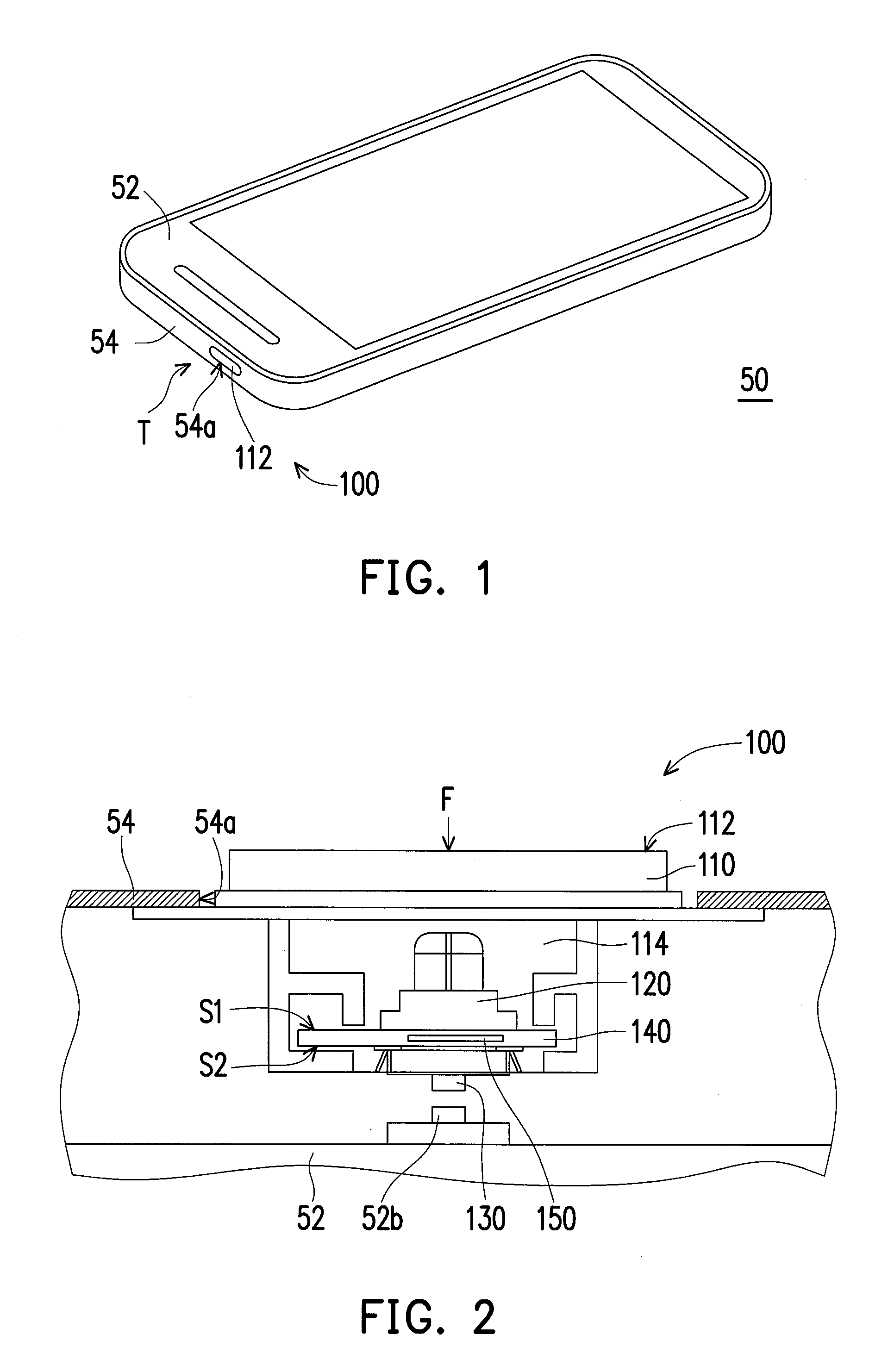

Button assembly and handheld electronic device

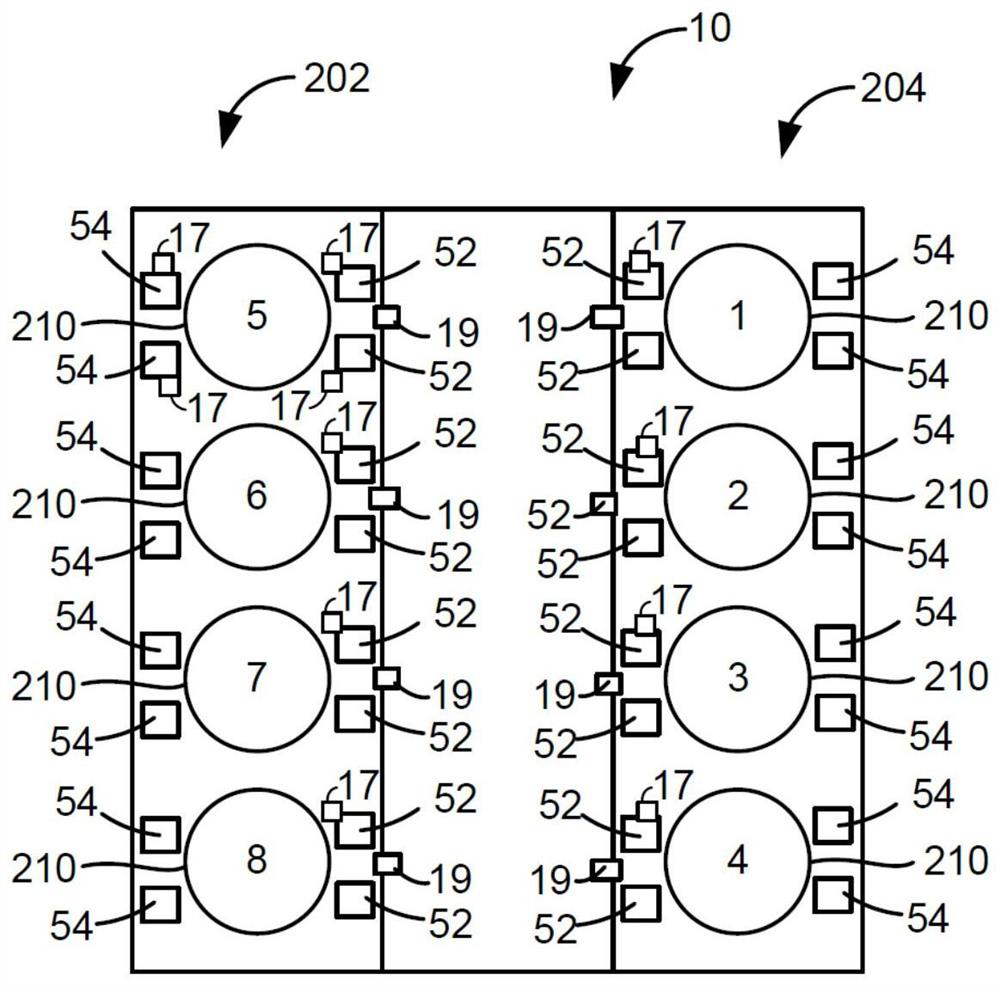

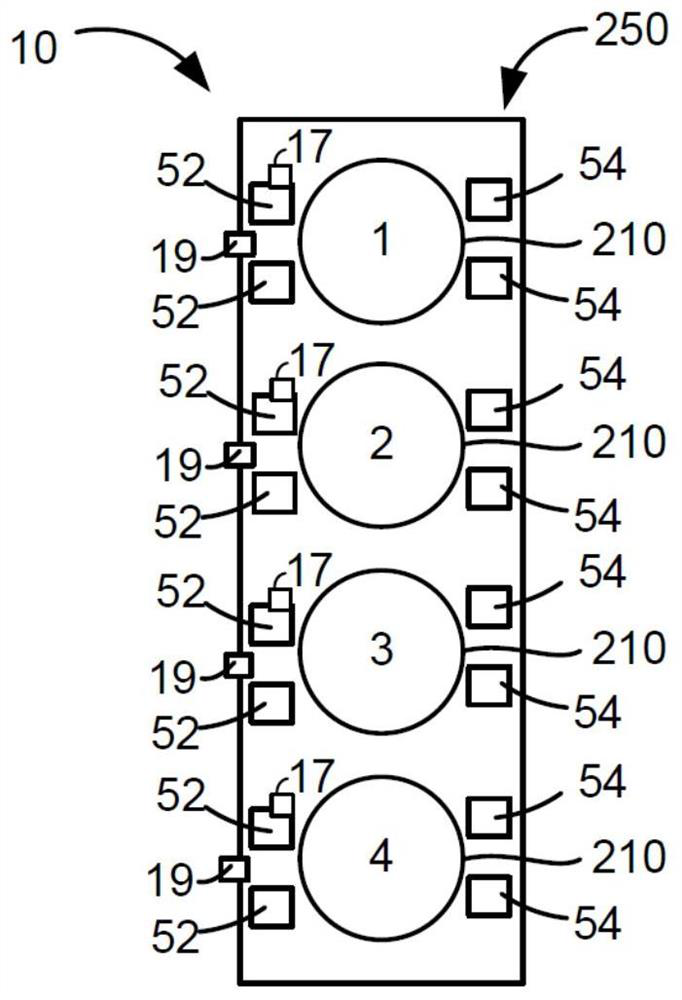

InactiveUS20140168924A1Reduce the amount requiredReduce the amount of openingContact operating partsCasings/cabinets/drawers detailsEngineeringElectronic equipment

A button assembly suitable for being disposed at an opening of a housing of a handheld electronic device is provided. The button assembling includes a button, a signal-receiving-and-transmitting component and a switch. The button is movably disposed at the opening, and the button has a pressing portion exposed by the housing. The signal-receiving-and-transmitting component is disposed in the housing and corresponds to the pressing portion, wherein the signal-receiving-and-transmitting component is suitable for transmitting or receiving a wireless signal passing through the pressing portion. The switch is disposed in the housing and coupled to the button, so that the switch is adapted to be actuated by pressing the pressing portion of the button. A handheld electronic device including a body, a housing and a button assembly is also provided. The housing covers the body and has an opening. The button assembly is disposed at the opening.

Owner:HTC CORP

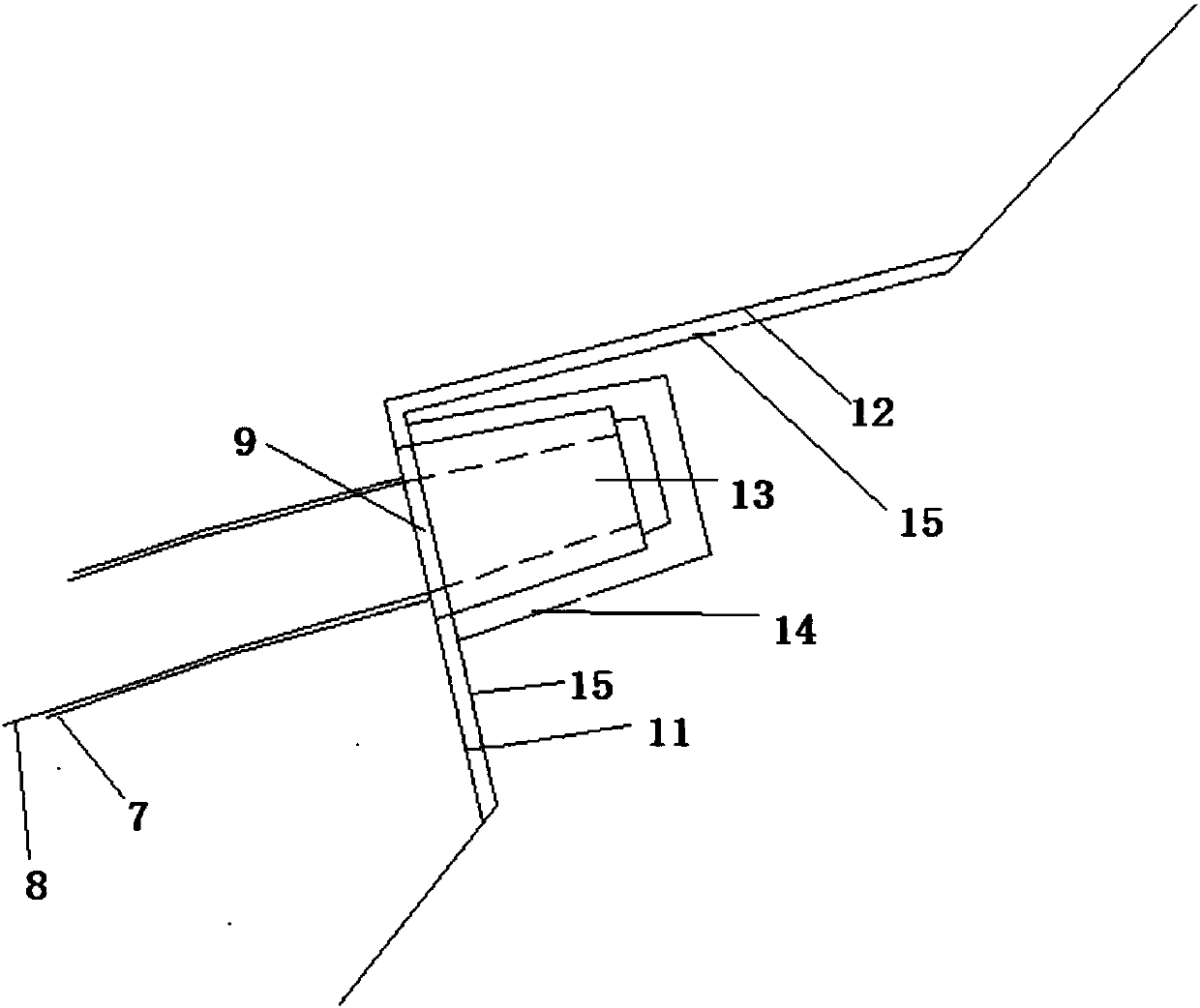

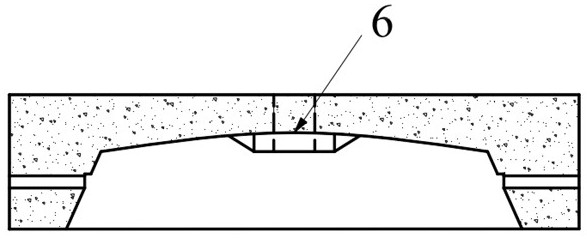

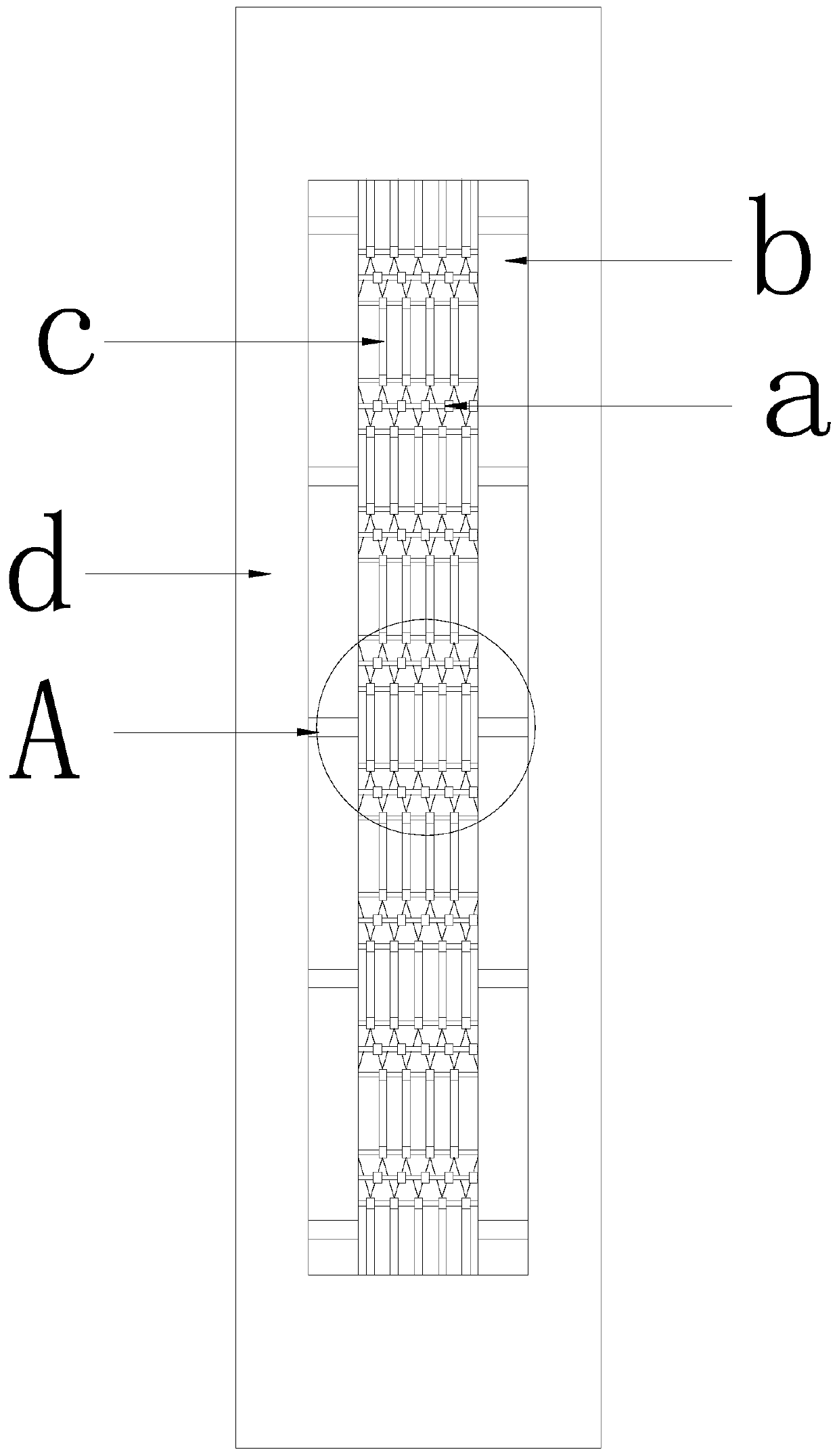

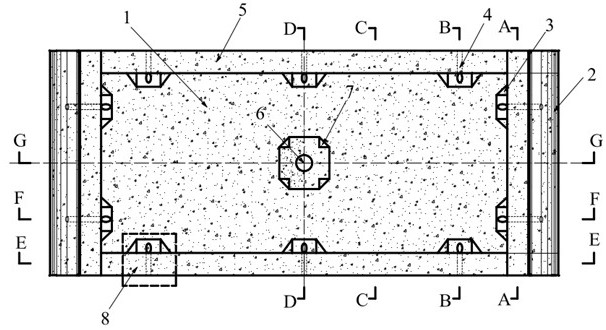

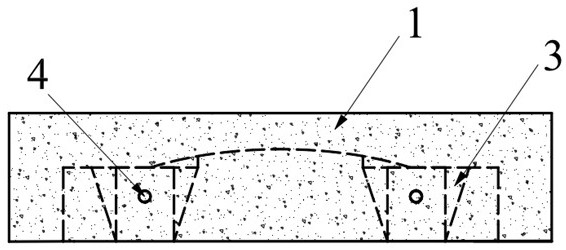

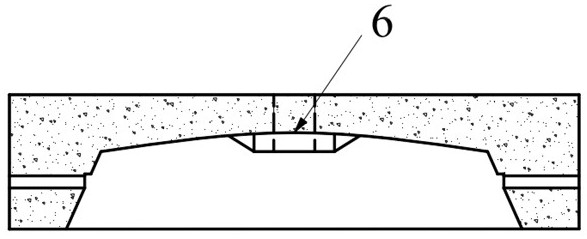

Arch web type ultra-high performance concrete prefabricated shield tunnel segment structure and design method

ActiveCN112727500AExcellent stress relaxationReduce mis-stationGeometric CADUnderground chambersCrack resistanceArchitectural engineering

The invention relates to an arch web type ultra-high performance concrete prefabricated shield tunnel segment structure and a design method. The segment structure comprises a segment main body, wherein the segment main body comprises an arch crown, an arch web, an arch foot, a reinforcing mesh in concrete, a segment grouting hole and a segment joint groove, wherein the cross section of the arch web is of a cambered surface sheet-shaped structure, and the arch web has an arched longitudinal section. The method specifically comprises the following steps of 1), determining the thickness h1 of the arch crown and the thickness h2 of the arch foot; 2), calculating the bearing capacity of the normal section of the arch web area of the ultra-high performance concrete segment main body, and enabling the normal section of the arch web area to be equivalent to a rectangular section for reinforcement calculation; 3), rechecking of internal force of segment main body arch web area; and 4), comparing reinforcement results calculated according to the bearing capacity of the normal section of the flexural member with reinforcement results calculated according to the bearing capacity of the normal section of the large eccentric compression member, and selecting a scheme with a large reinforcement area for reinforcement. The method can solve the problem of poor crack resistance of the segment structure.

Owner:HUNAN UNIV

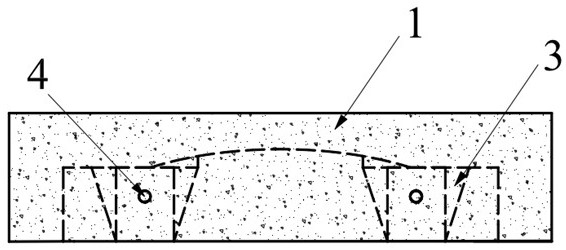

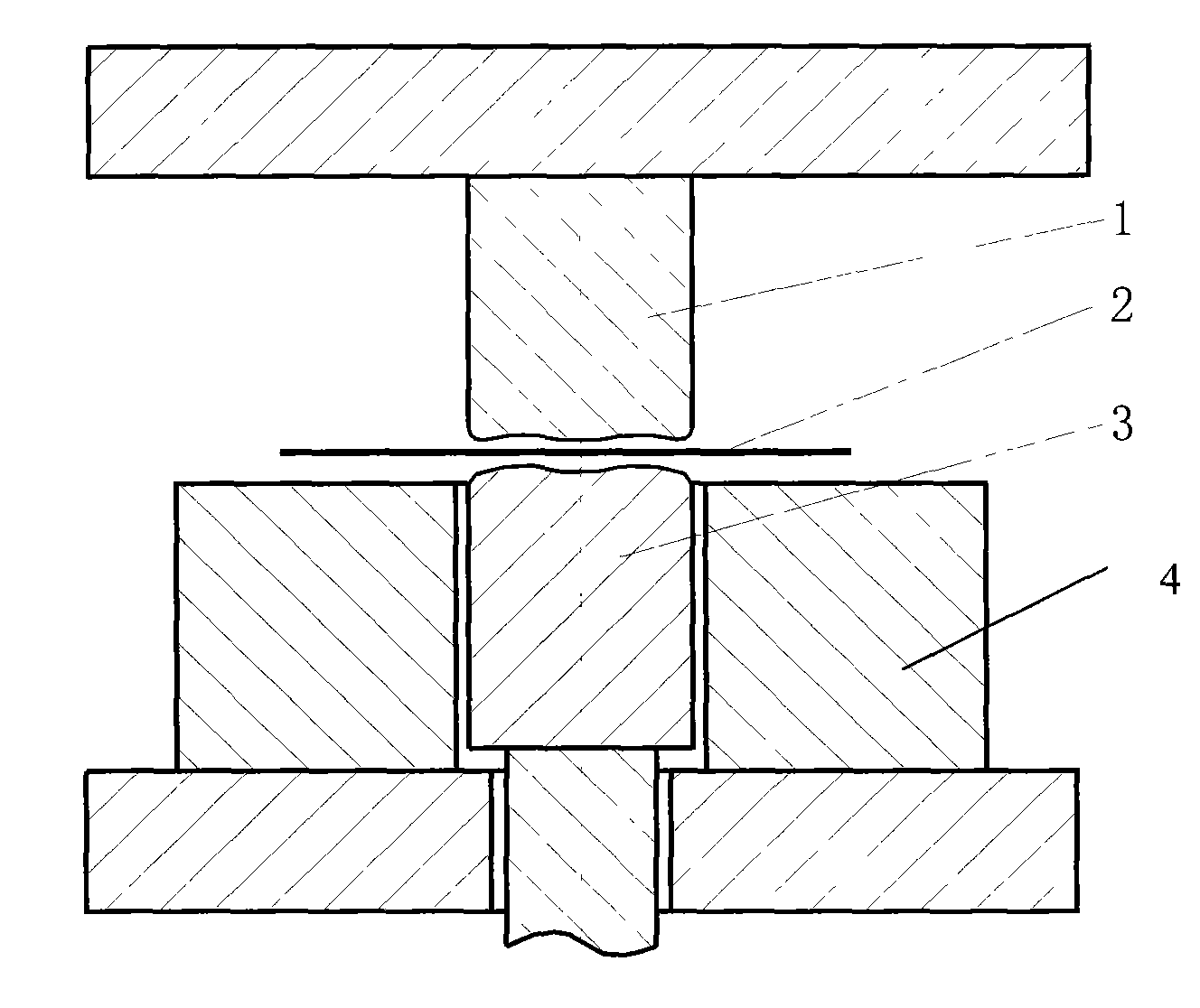

Ultrahigh strength steel stamping part rebound control method

InactiveCN101653800AEffective positioningPrevent cascadingShaping toolsUltimate tensile strengthMaterials science

The invention provides an ultrahigh strength steel stamping part rebound control method, belonging to the stamping forming technical field. The mould in the method is mainly composed of a terrace die,a die and a top plate, the bottom surface of the terrace die and the upper surface of the top plate are made into dual circular arc surface, when in forming, the terrace die moves down, plates are compacted on the bottom surface of the terrace die by the top plate, so as to cause the plates to generate elastic deformation along the circular arc of the terrace die; and when in discharging, the bent dual circular arc surface generates inverse rebound deformation to compensate rebound deformation of the two sidewalls of a stamping part, and rebound is reduced or even eliminated by control on circular arc radian. Meanwhile the dual circular arc structure can realize reliable location in plate forming, thus improving the integral forming quality of the formed part.

Owner:JILIN UNIV

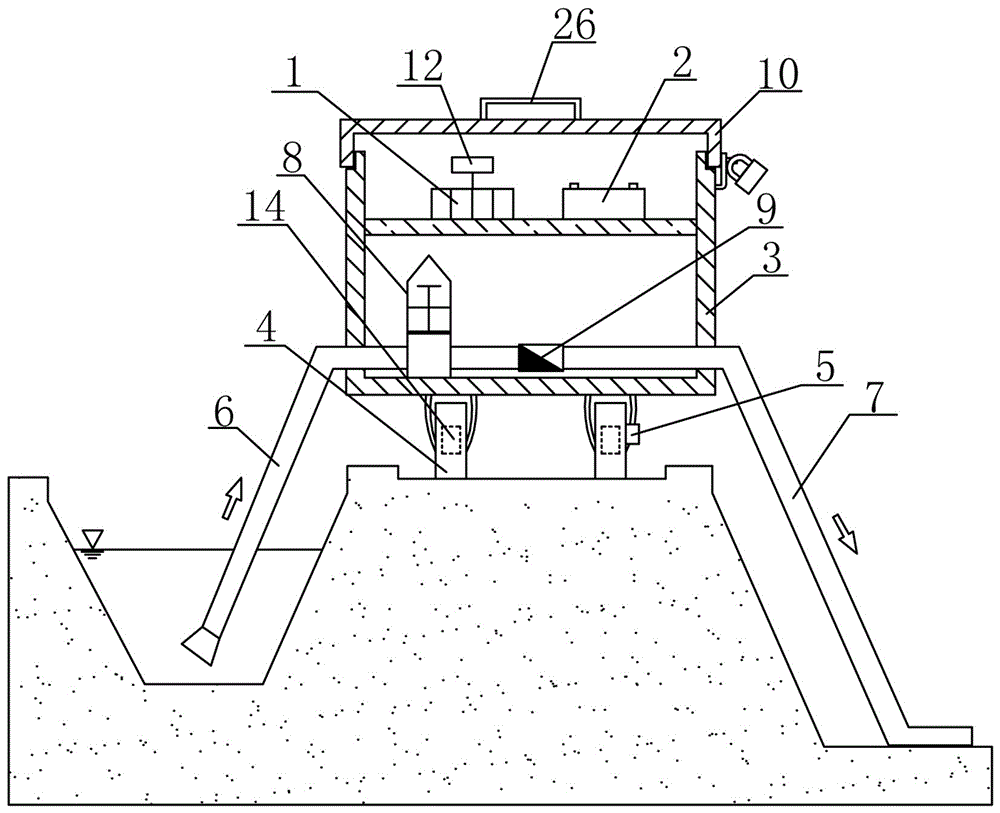

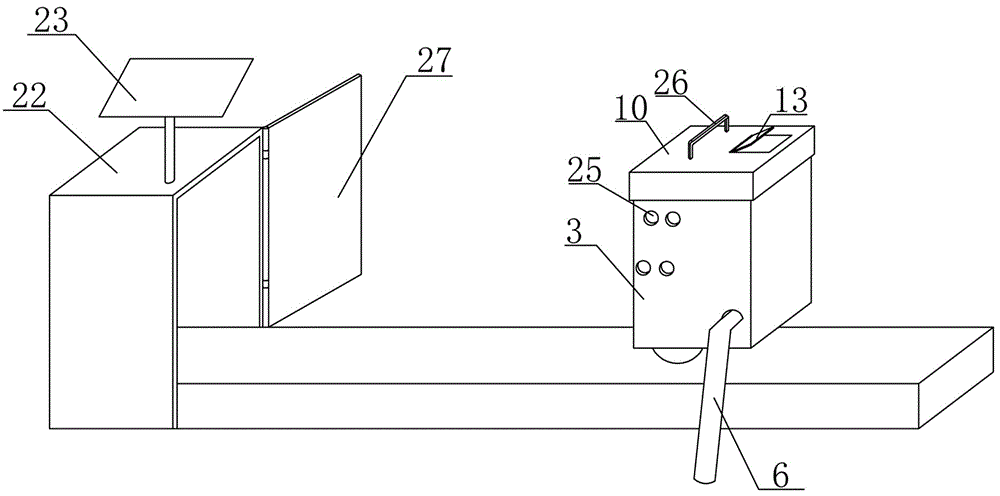

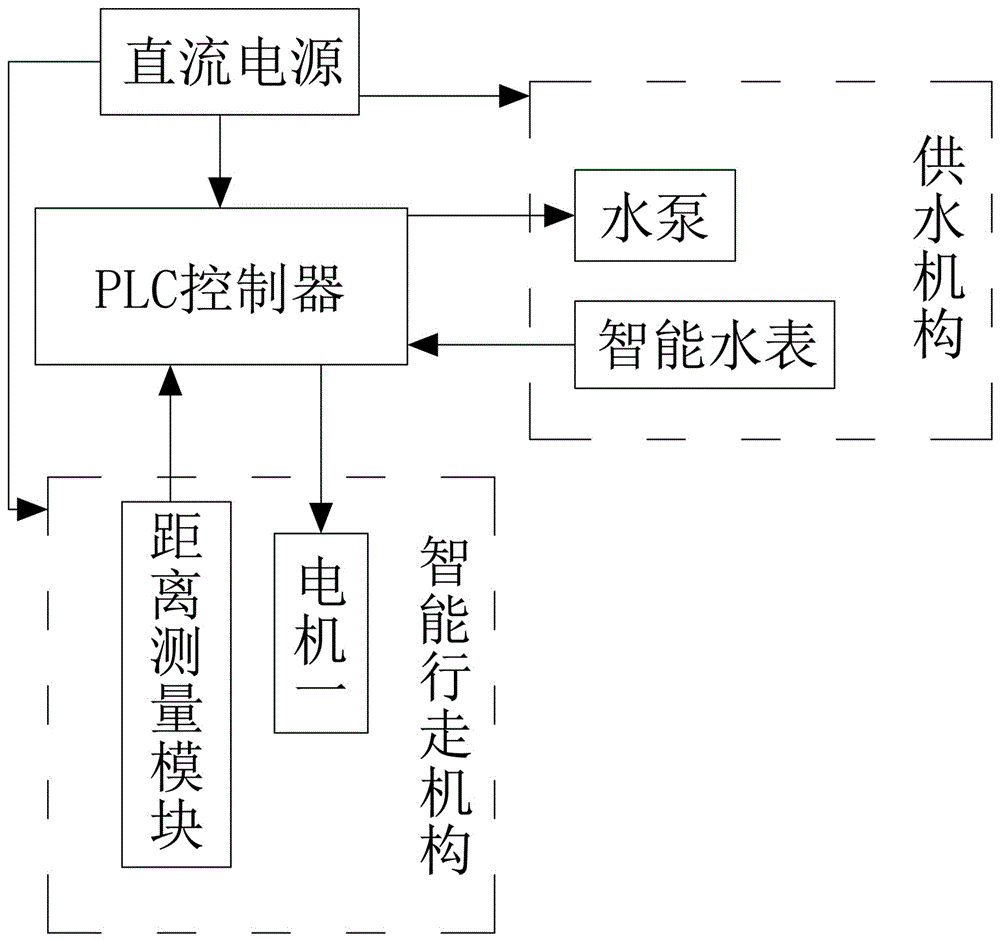

Self-propelled canal irrigation device and irrigation method for same

ActiveCN106305367AExtended service lifePrevent drag phenomenonWatering devicesCultivating equipmentsAutomatic controlEngineering

The invention discloses a self-propelled canal irrigation device. The self-propelled canal irrigation device comprises an intelligent walking mechanism, a water supplying mechanism, a PLC (Programmable Logic Controller) and a direct current power supply, wherein the direct current power supply provides a power supply for the intelligent walking mechanism, the water supplying mechanism and the PLC; the intelligent walking mechanism comprises a frame, moving wheels arranged at the bottom of the frame, distance measuring modules arranged on the corresponding moving wheels and a motor I for driving the corresponding moving wheels to operate; the water supplying mechanism comprises a water inlet pipe, a water outlet pipe and a water pumping device; a smart water meter is arranged on the water outlet pipe; the PLC controller is electrically connected with the distance measuring modules, the motors I and the smart water meter. The device can replace a traditional water outlet of a channel and is low in cost; the service life of the channel can be prolonged, automatic control is facilitated, automatic irrigation can be realized, manpower is saved, and water is saved.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

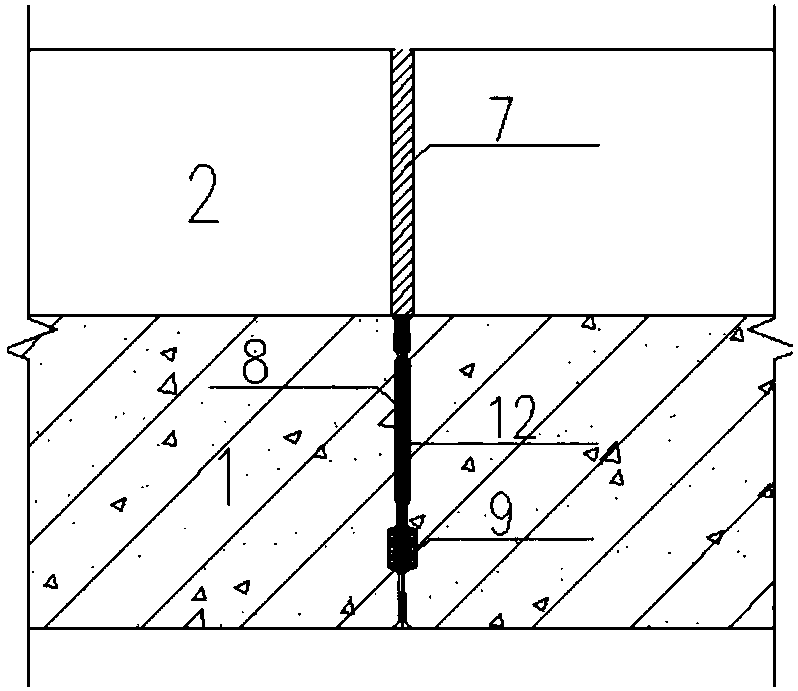

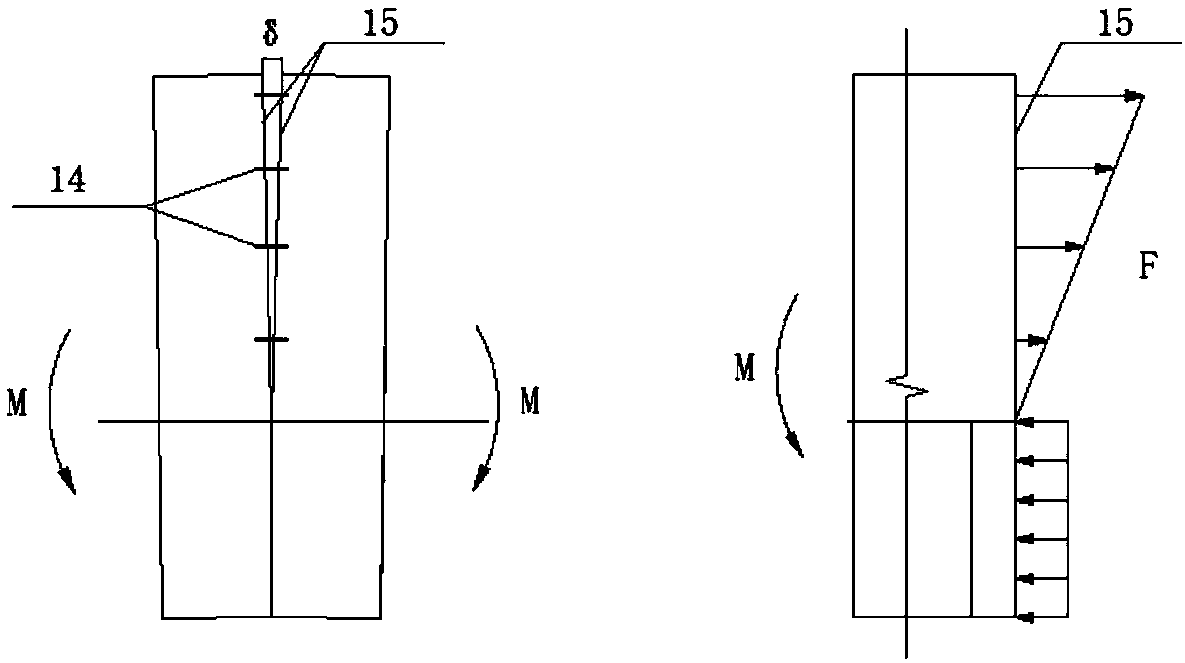

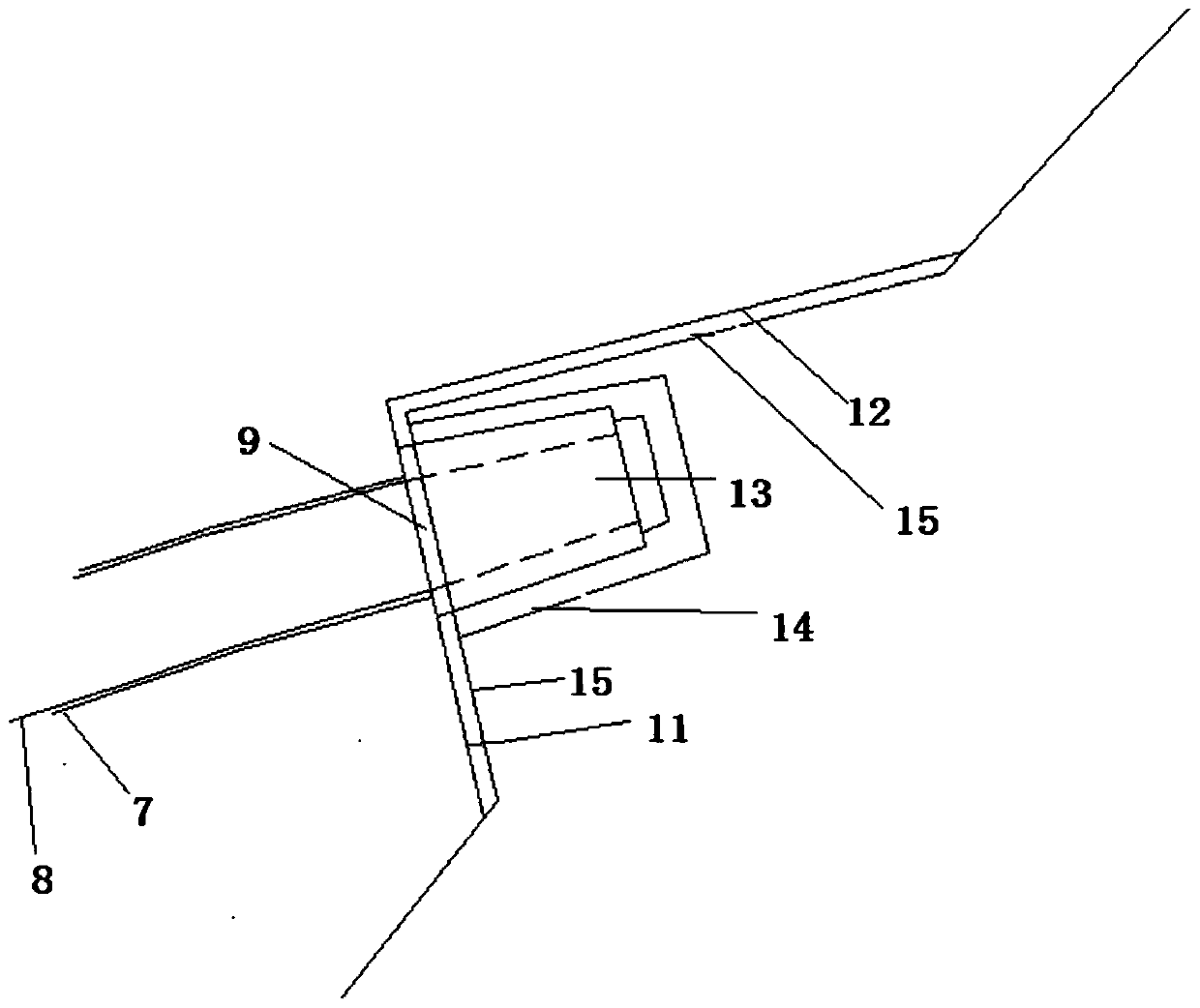

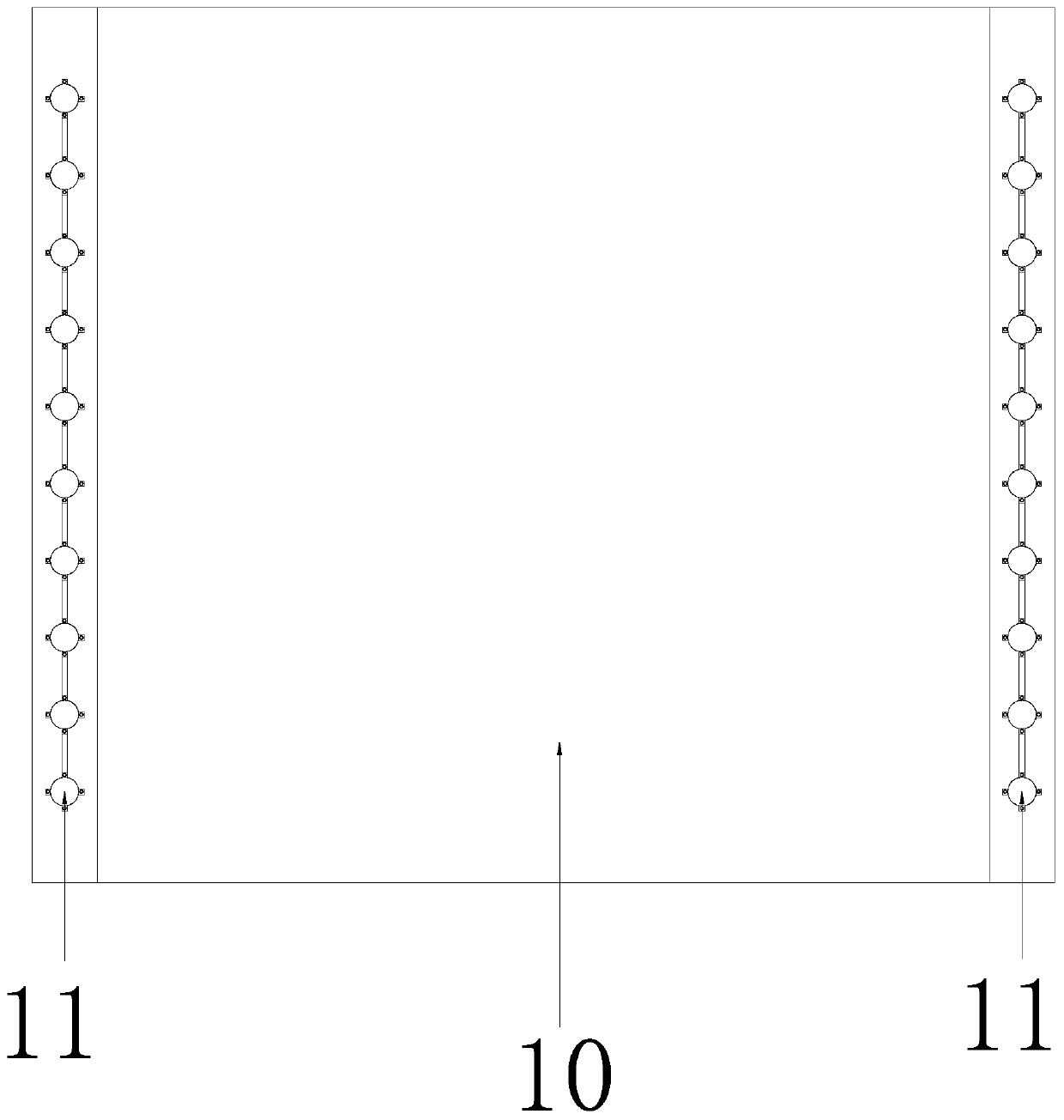

Double-layer lining shield tunnel deformation joint structure and shield tunnel

PendingCN108150192AReduce the amount of openingImprove waterproof effectUnderground chambersTunnel liningTransverse shearEngineering

The invention discloses a semi-flexible and semi-rigid double-layer liner shield tunnel deformation joint structure. The structure comprises segments and linings, and laminated structural connection is formed between the segments and the linings in a non-deformation joint section; in a deformation joint section, the segments is continuously provided with N segment deformation joints at a predetermined length L at each interval, and N is an integer greater than or equal to 1; in positions corresponding to deformation joints of the segments, the linings are provided with lining small sections, lining deformation joints are arranged at the junction of the lining small sections and adjacent non-deformation joint sections, and the lining deformation joints and the segment deformation joints arearranged longitudinally in a staggered mode; and the invention further discloses a shield tunnel. According to the semi-flexible and semi-rigid double-layer liner shield tunnel deformation joint structure and the shield tunnel, the longitudinal rigidity of the deformation joints is higher than that of conventional flexible deformation joints, the opening amount of the segment joints can be reduced effectively, and the waterproof effect of a double-layer lining structure is improved; N segment deformation joints are arranged at the deformation joint sections to jointly share the opening amountof the segment joints; and the segments and the lining deformation joints are staggered in space, and the transverse shear can be resisted effectively to prevent slab staggering.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

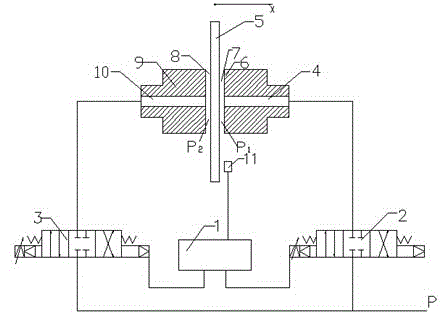

Saw blade guiding device and regulation method thereof

InactiveCN104400114AReduce the amount of openingReduce air pressureMetal sawing devicesEngineeringActive vibration control

The invention discloses a saw blade guiding device and a regulation method thereof. Air-static guiding discs are arranged on the two sides of a saw blade to form a clearance; a stable-pressure air source P is used for providing compressed air; the compressed air is respectively conveyed to the guiding discs by pneumatic servo valves and then enters the clearance between the two sides of the saw blade so that pressure p1and pressure p2 are formed to apply a thrust to the saw blade. The pneumatic servo valves can control the size of the openings thereof according to signals sent from a controller so as to control the size of the pressure of outlets of the servo valves; vibration displacement and speed of the saw blade are measured by a displacement sensor and sent to the controller; the controller is used for controlling the pneumatic servo valves according to the signals of the displacement sensor. According to the device, a pneumatic force is used for controlling initiative vibration of guidance of the saw blade, and the air on the two sides of the saw blade are used for generating thrust, so that the vibration of the saw blade is controlled stably, the control precision can be increased, and the stability of the saw blade can be improved.

Owner:TAIYUAN UNIV OF TECH

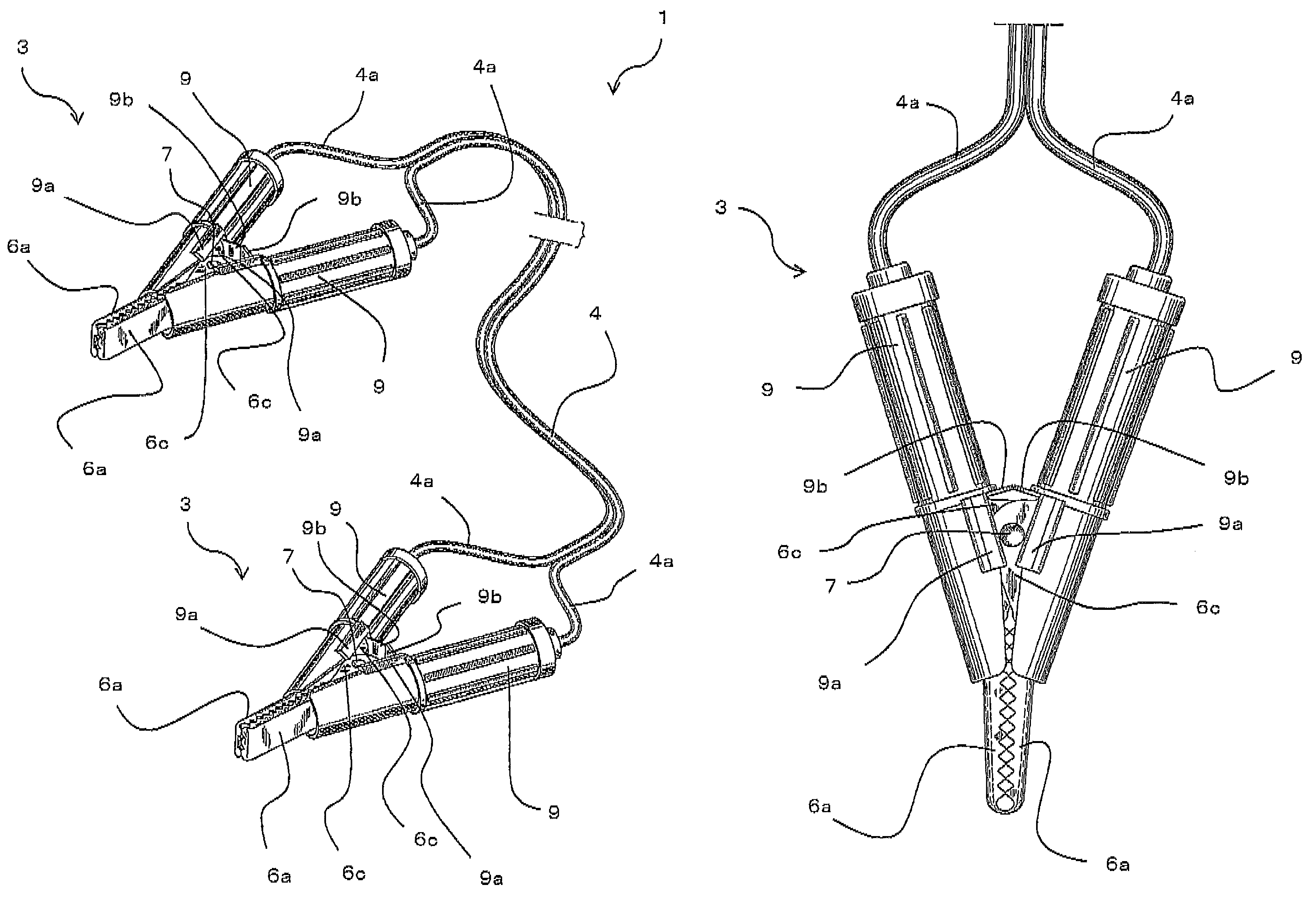

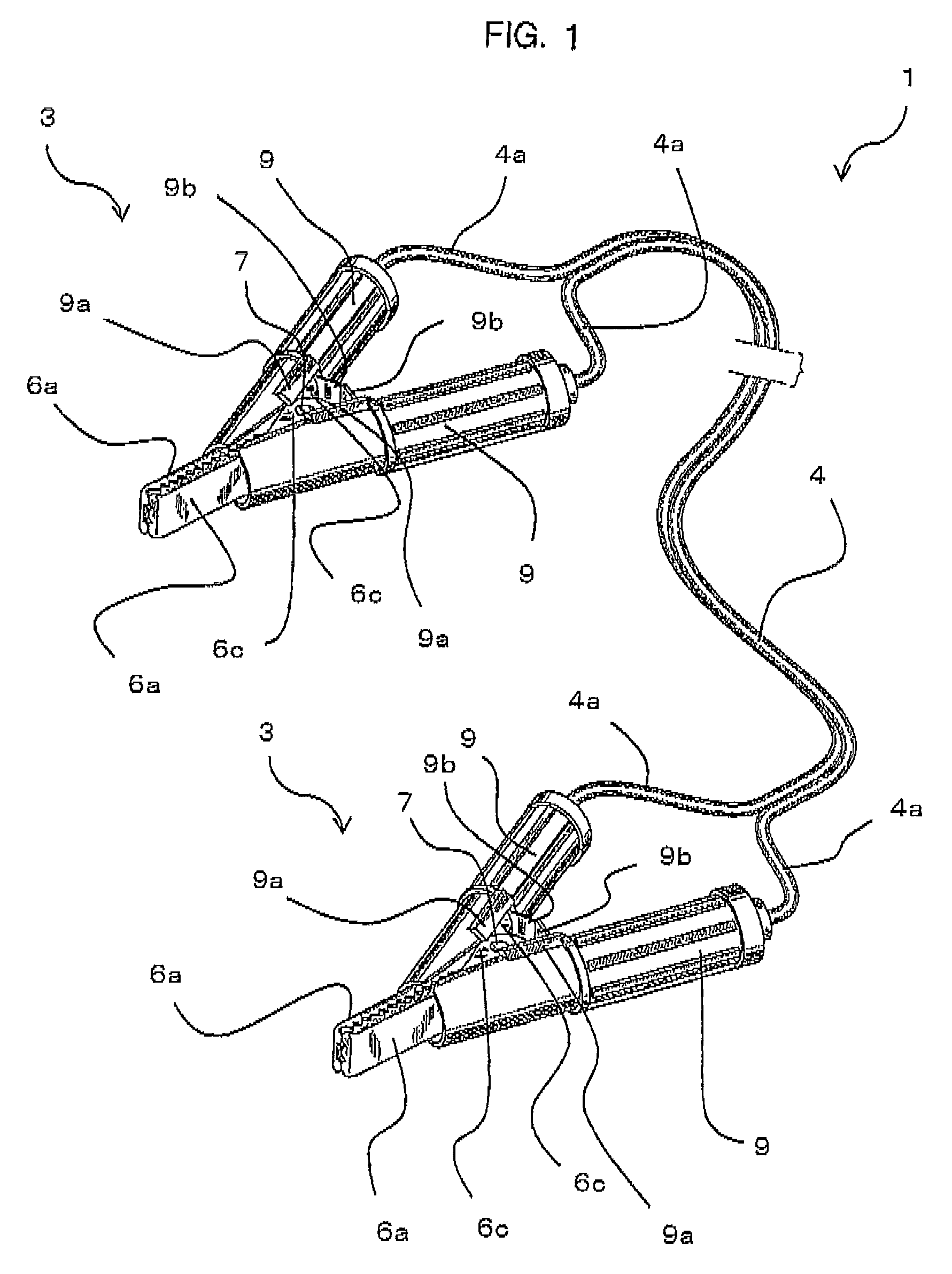

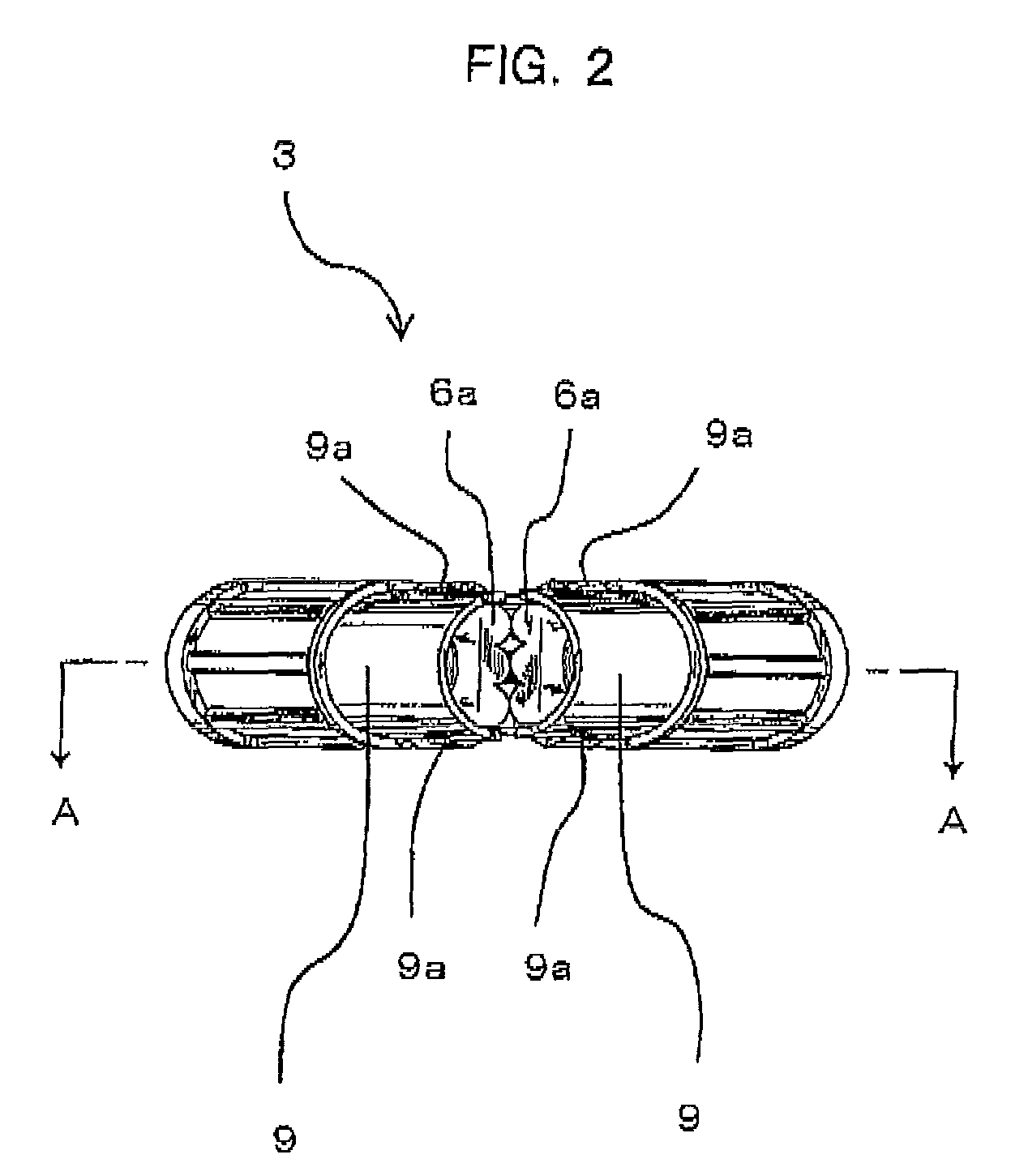

Booster cable

InactiveUS8210869B2High strengthImprove rigidityCoupling device connectionsElectric connection basesClosed state

The present invention provides a booster cable capable of reliably being connected to a terminal that is provided in a limited space. Specifically, a connecting clip 3 is attached to both ends of a cable main body 4. Clamping sections 6a of the connecting clip 3 are set to be wide and outer surfaces of the pair of clamping sections 6a are set to be substantially in parallel in a closed state so that the clamping sections 6a are set to have approximately same thickness up to root portions. The root portions of the clamping sections 6a do not interfere so that the clamping sections 6a are able to be inserted into a limited space up to the root portions. It is thereby possible to sufficiently clamp and reliably connect the assisting terminal 5 that is provided in a limited space.

Owner:SEIWA IND SEIWA KOGYO

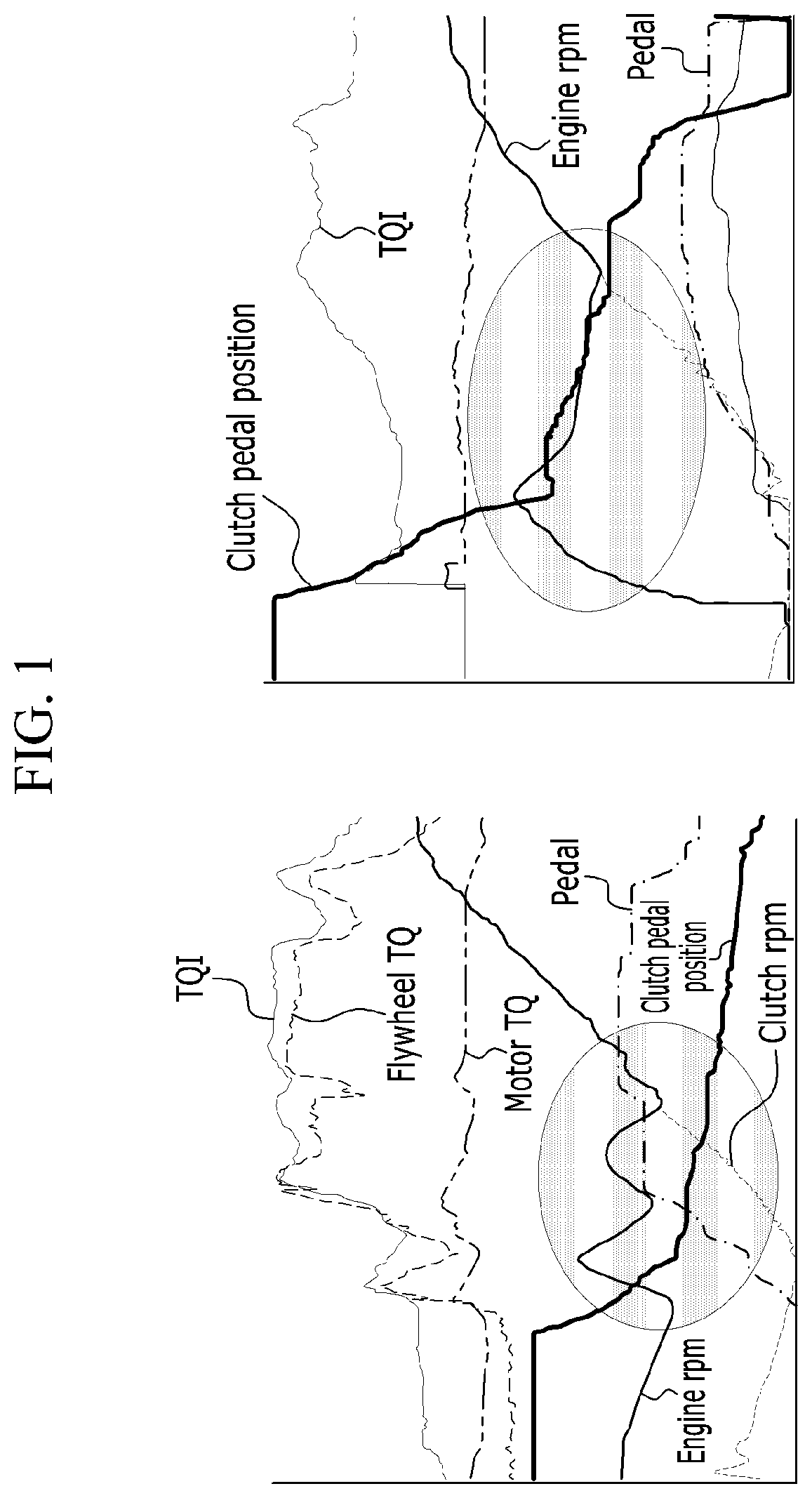

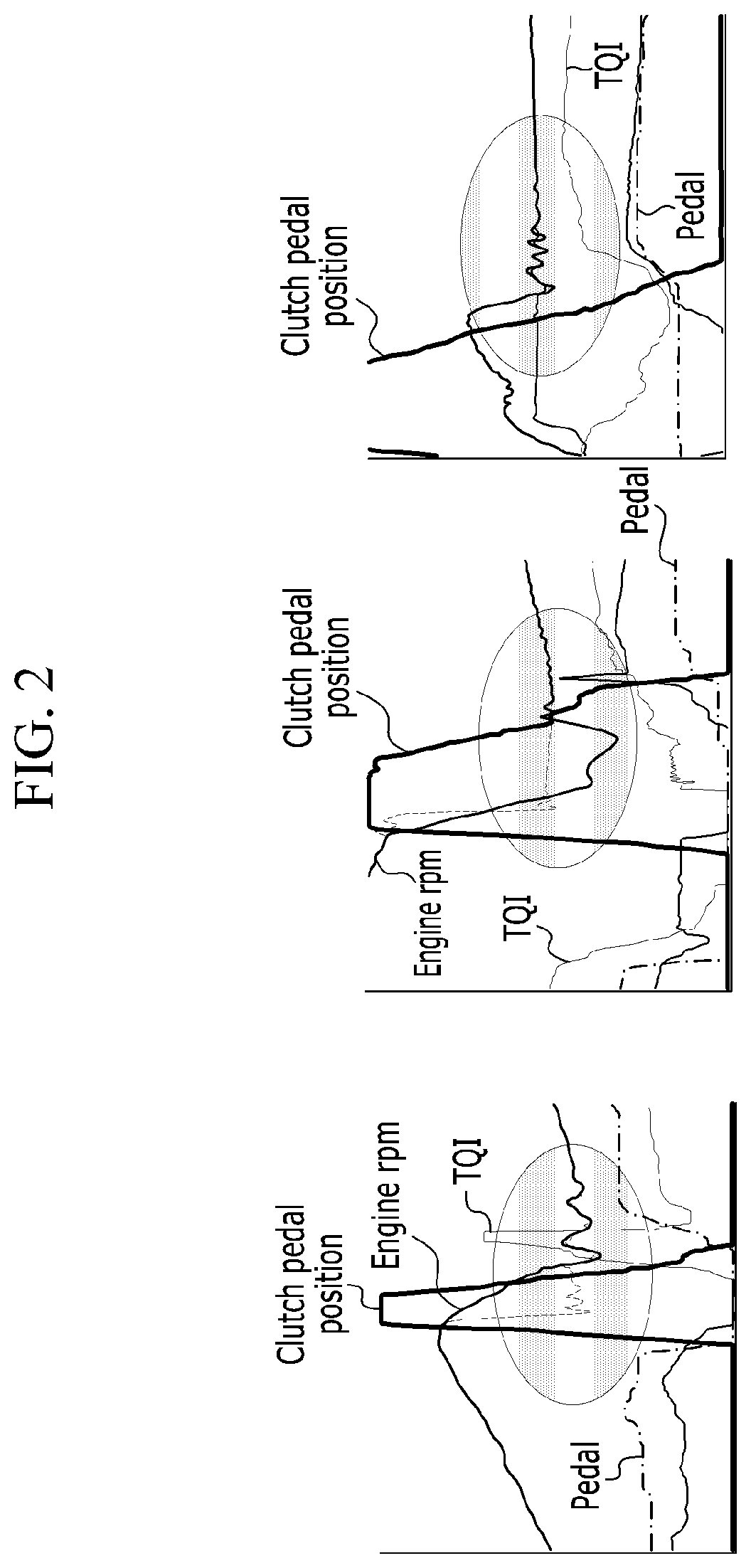

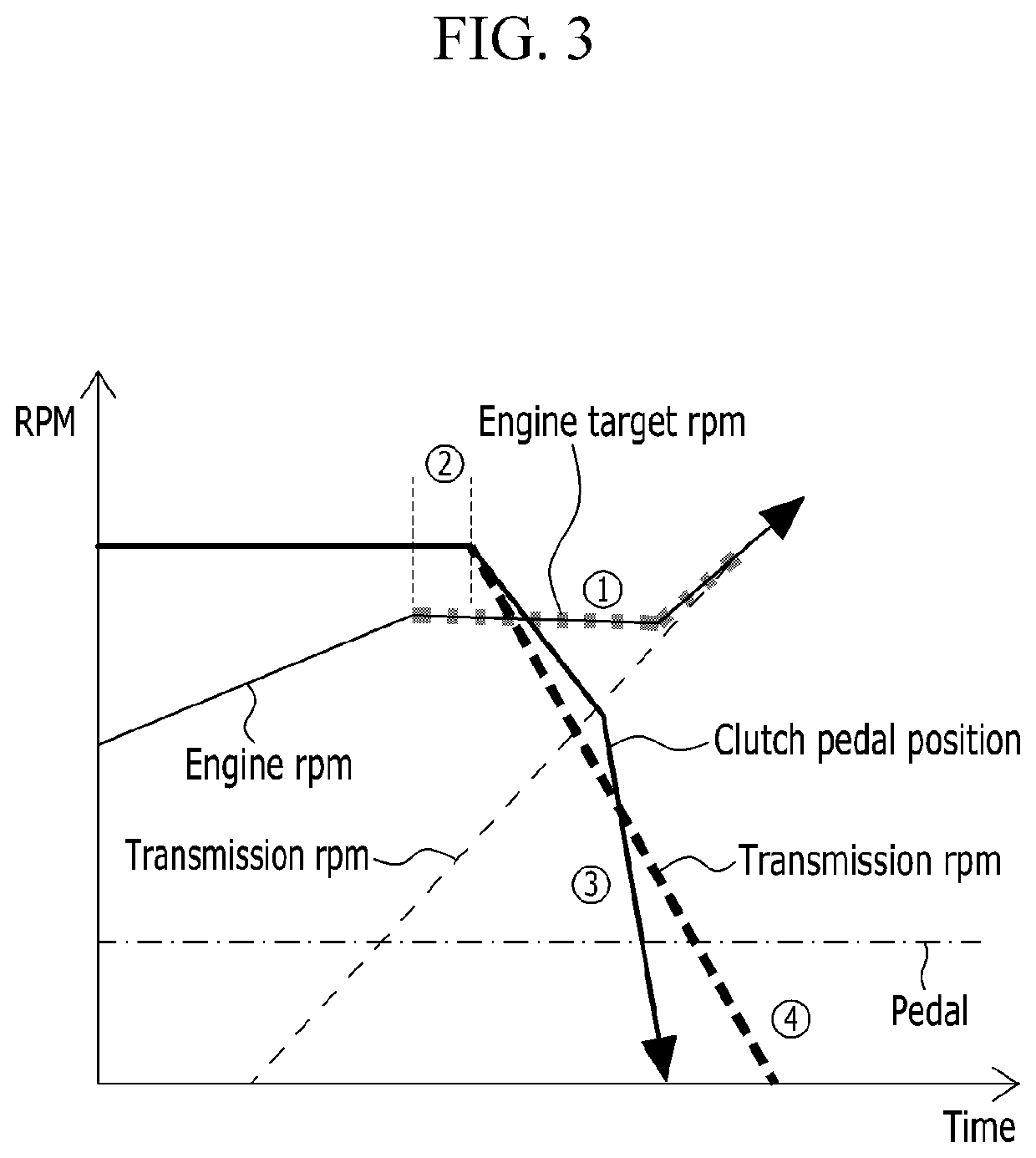

Method of controlling engine and transmission of hybrid vehicle

ActiveUS20220025971A1Smoothly improve ride comfortReduce the amount of openingHybrid vehiclesElectrical controlControl engineeringHybrid electrical vehicle

A method of controlling an engine and a transmission of a hybrid vehicle includes steps of: determining whether the vehicle starts, determining an engine RPM and a gear stage of a transmission if the vehicle has started, determining whether the engine RPM has reached an engine speed control point, determining an engine target RPM and an engine target RPM slope of the vehicle when it is determined that the engine RPM has reached the engine speed control point, controlling the engine RPM of the vehicle to follow the engine target RPM and the engine target RPM slope, determining whether the engine RPM has slipped compared to the target engine RPM, and performing PID control to follow the engine target RPM if the engine RPM slips compared to the engine target RPM.

Owner:HYUNDAI MOTOR CO LTD +1

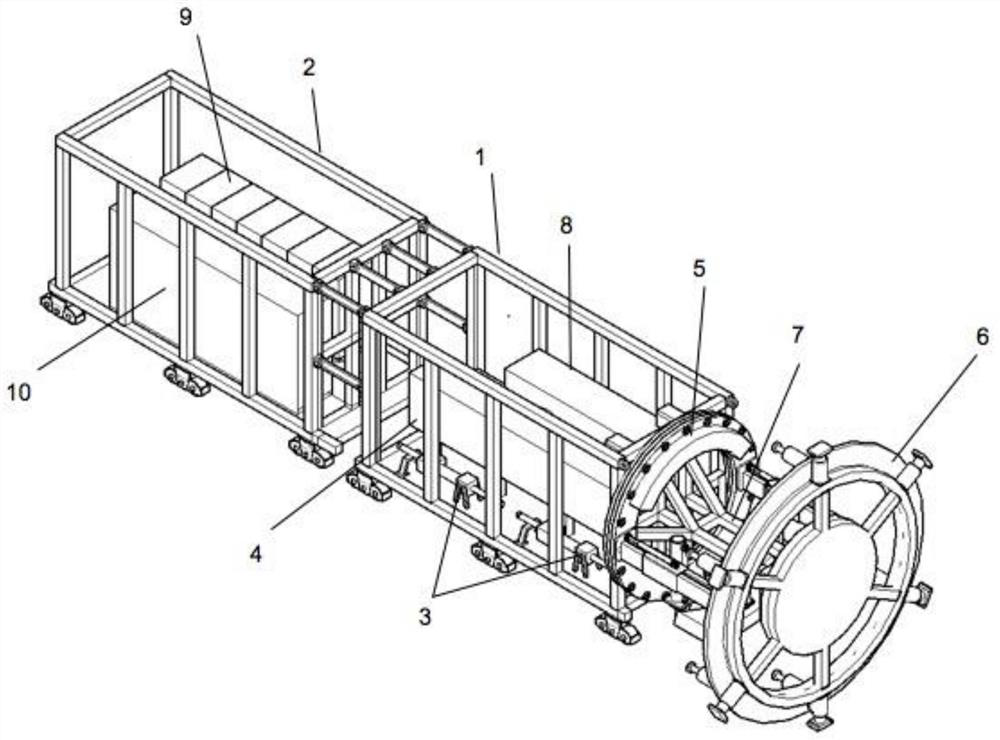

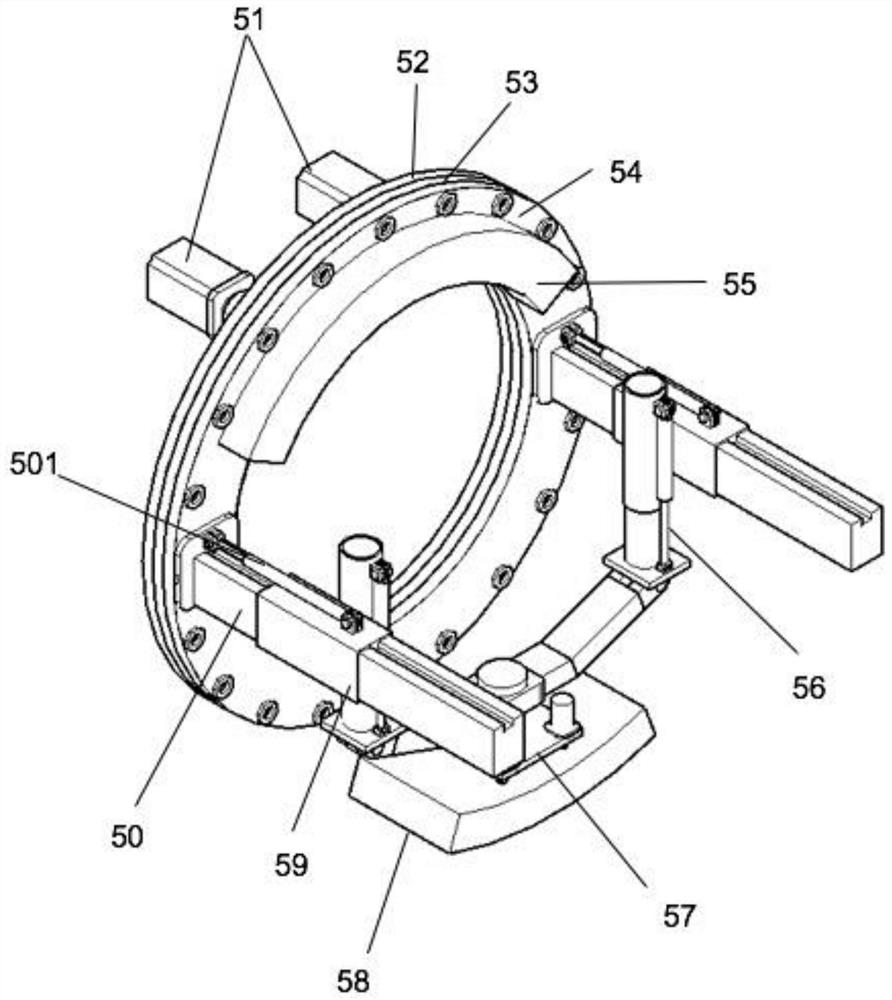

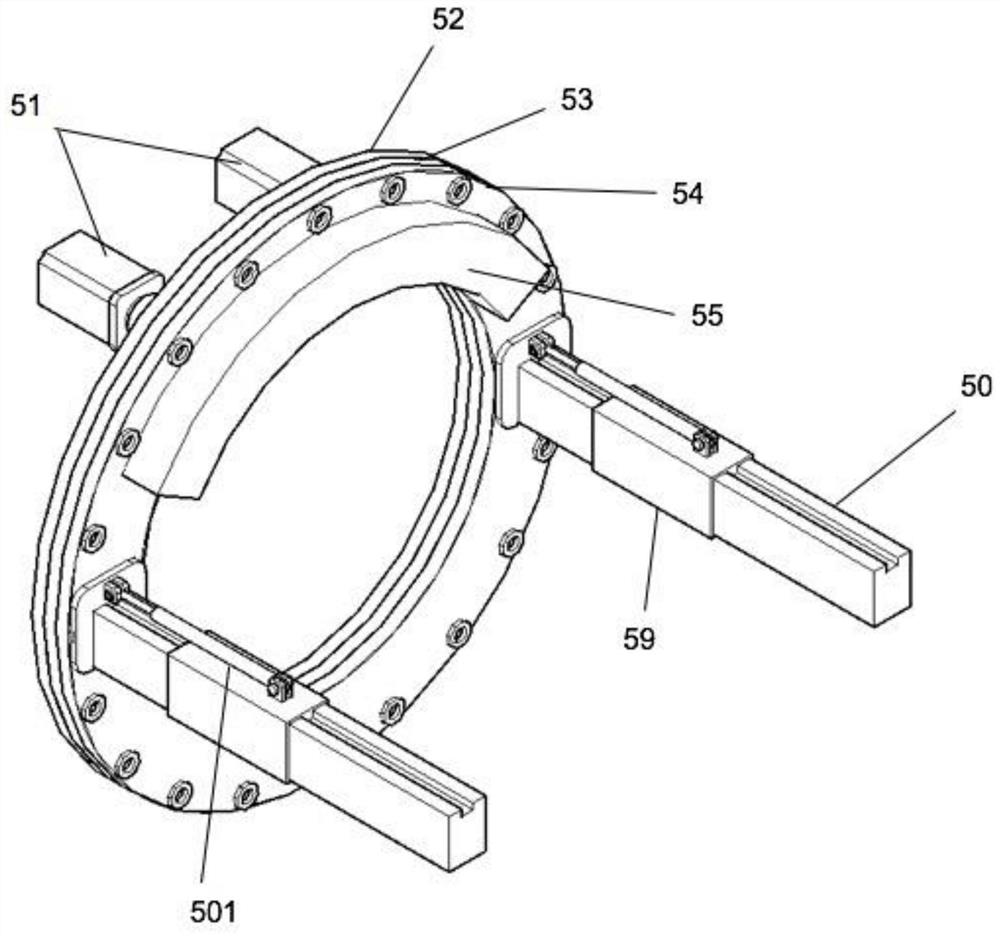

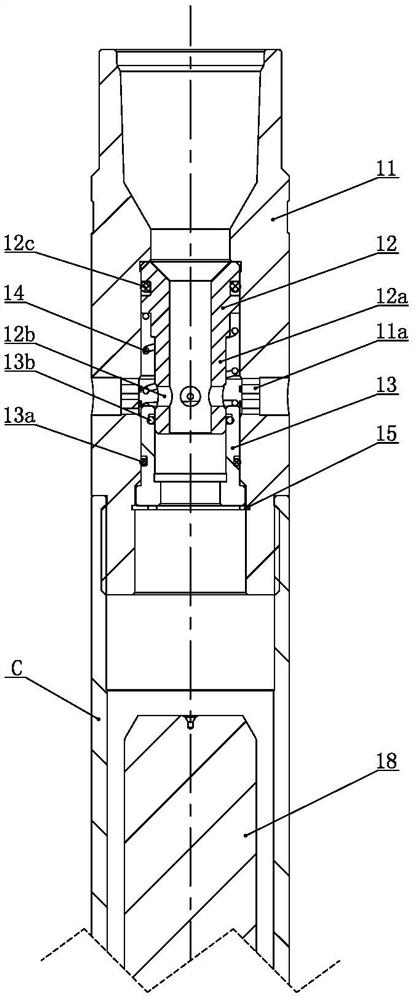

Duct piece assembling and grouting integrated machine for shield underground butt joint

PendingCN113790069AGuaranteed accuracyNot occupying spaceUnderground chambersTunnel liningStructural engineeringMachine

The invention provides a duct piece assembling and grouting integrated machine for shield underground butt joint. The machine comprises a duct piece assembling machine, a first trolley, a second trolley, a grouting device, a power device and an anti-loosening device. Two ends of the first trolley are respectively connected with the second trolley and the duct piece assembling machine; the grouting device is arranged in the first trolley; the power device is arranged in the second trolley; and the duct piece assembling machine comprises an annular rotation device, an axial translation device, a radial lifting device and a grabbing device. By the adoption of the technical scheme, the problems of shield underground butt joint prefabricated duct piece assembling, synchronous grouting behind a wall, duct piece loosening and the like can be solved.

Owner:CHINA CONSTR COMM ENG GRP UNITED +1

Hydraulic controlling device of working machine

ActiveUS20070193261A1Preventing pressure interferenceEngine speed to decreaseFluid couplingsSoil-shifting machines/dredgersActuatorControl theory

A hydraulic controlling device in which, when performing a combined operational process, a position of a straight travel valve is switched to a straight travel position to drive both a travel motor and a working actuator by separate pumps. In this case, to prevent a sudden reduction in travel speed resulting from a reduction in a flow amount at a travel side, pump lines of both pumps are connected to each other at an intermediate position by a connection path, so that a portion of oil at a working side is sent towards the travel side. With such a structure, when a rotational speed of an engine is less than a set rotational speed, an opening amount of the connection path is reduced through a straight travel proportional valve by a controller, thereby preventing pressure interference causing, for example, the working actuator to no longer move.

Owner:KOBELCO CONSTR MASCH CO LTD

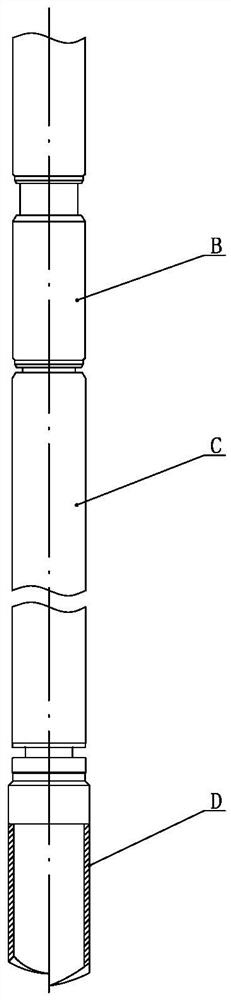

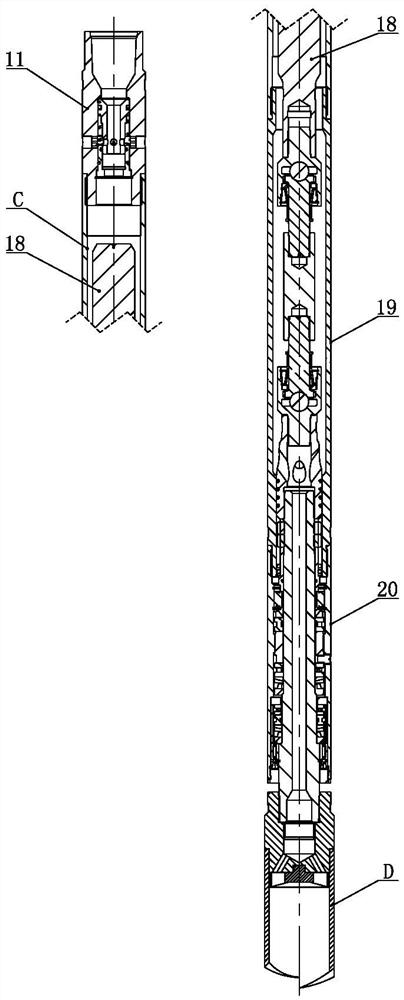

Casing leakage plugging small workover operation method

ActiveCN112360389ALow costShorten workover periodWell/borehole valve arrangementsSealing/packingCement pasteWorkover

The invention relates to a casing leakage plugging small workover operation method. The method sequentially comprises the following steps that (1) a position of a casing leakage breaking section is determined; (2) a bridge plug is arranged below the casing leakage breaking section; (3) the position above a rubber plug is filled with a quartz sand protective layer; (4) an oil pipe is run and cementpaste is injected to the position above the leakage breaking section; (5) after the tubing string is tripped out to a safe distance, a wellhead, is closed, pressing is performed to squeeze the cementpaste into a leakage layer, and it is guaranteed that the cement paste is still higher than the top of a leakage section; (6) a well is closed under pressure, and waiting on the cement paste is performed for 36 hours or longer; (7) the tubing string is tripped out, and a cement drilling tubular column runs in hole to drill and grind a cement section; (8) oil pipes are additionally connected one by one, and the cement drilling tubular column is downwards advanced until the cement section is completely drilled off; (9) pressure testing is performed to confirm whether a leakage point is successfully blocked or not, and then the oil pipe is detached one by one until the cement drilling tubular column is completely tripped out of the wellhead; and (10) if the leakage point is not successfullyblocked, the step (4) is re-executed. And if the leakage point is successfully blocked, a quartz sand protection layer is flushed, and the rubber plug is fished out. According to the operation method,a casing can be repaired under the condition that a small casing is not hung.

Owner:CHINA PETROCHEMICAL CORP +2

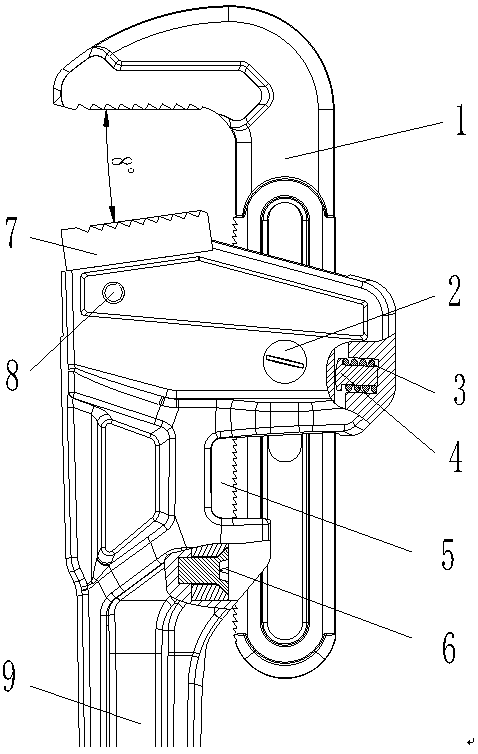

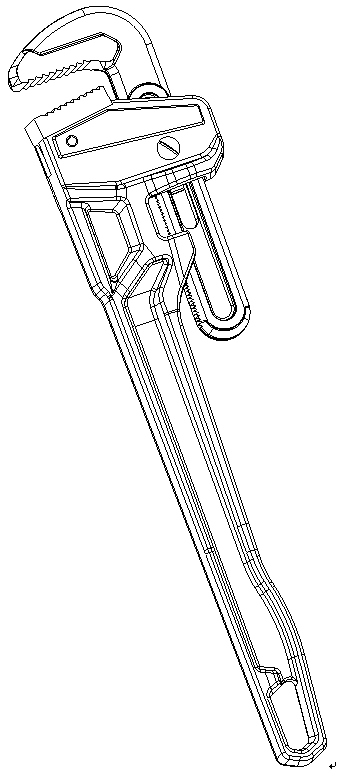

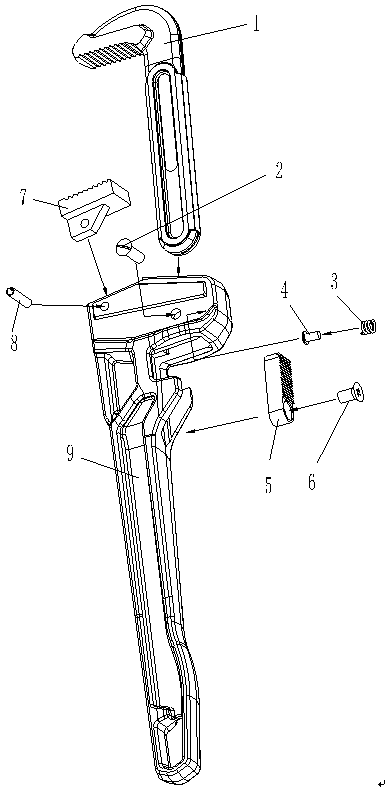

Quick pipe wrench

The invention discloses a quick pipe wrench which comprises a wrench handle body, a movable jaw and a fixed jaw, a front-back through rectangular long groove used for installing the movable jaw is formed in the upper half part of the front end of the wrench handle body, an adjusting strip body is arranged at the tail end of the movable jaw, the adjusting strip body is inserted into the rectangularlong groove, the fixed jaw is arranged at the lower half part of the front end of the wrench handle body, the fixed jaw is corresponding to the head part of the front end of the movable jaw, lower stop teeth are arranged on the lower end surface of the adjusting strip body of the movable jaw, a small stop block is arranged on the upper end face of the wrench handle body, upper stop teeth are arranged on the upper end face of the small stop block, the lower stop teeth of the adjusting strip body are correspondingly meshed with the upper stop teeth of the small stop block, an upper round hole is formed in the inner wall of the top of the rectangular long groove, a spring pin is arranged in the upper round hole, and the lower end of the spring pin abuts against the upper end surface of the adjusting strip body. The quick pipe wrench has the function of quickly adjusting the opening, the function of continuously and rapidly repeating the ratchet screwing on pipe fittings with different diameters can be realized, and the working efficiency of an operator are greatly improved.

Owner:威海市力钰实业有限公司

A shield tunnel lining segment and its reinforcement method

ActiveCN107620598BImprove integrityIncrease stiffnessUnderground chambersTunnel liningStress conditionsEngineering

The invention discloses a shield tunnel lining segment and further discloses a reinforcing method of the shield tunnel lining segment. An existing structure comprises a top-sealing block, a first adjoining block, a second adjoining block, a bottom-sealing block, a first standard block and a second standard block, wherein the first adjoining block and the second adjoining block are located at the two ends of the top-sealing block, and the first standard block and the second standard block are located at the two ends of the bottom-sealing block. The first adjoining block is connected with the first standard block, and the second adjoining block is connected with the second standard block. Steel strand hole passages are formed in the existing first adjoining block and first standard block, steel strands are arranged in the steel strand hole passages, and steel strand outlets are formed in the inner sides of the first adjoining block and the first standard block. The second adjoining blockand the second standard block are also treated in the same way. The reinforcing method comprises the steps that (1) the lining segment is prefabricated according to the borne load of a tunnel structure; (2) the stress condition of the lining segment is judged, and the reinforcing method of the lining segment is determined; and (3) the lining segment is reinforced. According to the shield tunnel lining segment and the reinforcing method, the overall rigidity and the deformation harmony of the tunnel structure are improved, and tunnel operation safety can be ensured.

Owner:TONGJI UNIV

System and method for warming exhaust device of engine exhaust system

PendingCN113294250AEmission reductionIncrease exhaust temperatureElectrical controlExhaust apparatusExhaust gasAutomotive engineering

The invention provides a system and a method for warming an exhaust device of an engine exhaust system. Methods and systems for increasing exhaust gas temperatures of an engine are described. In one example, engine exhaust gas temperatures may be increased via deactivating cylinders and flowing exhaust gases through deactivated cylinder. Engine pumping losses may be reduced via the exhaust gases that flow through the deactivated cylinder so as to reduce engine fuel consumption while heating an exhaust gas after treatment device.

Owner:FORD GLOBAL TECH LLC

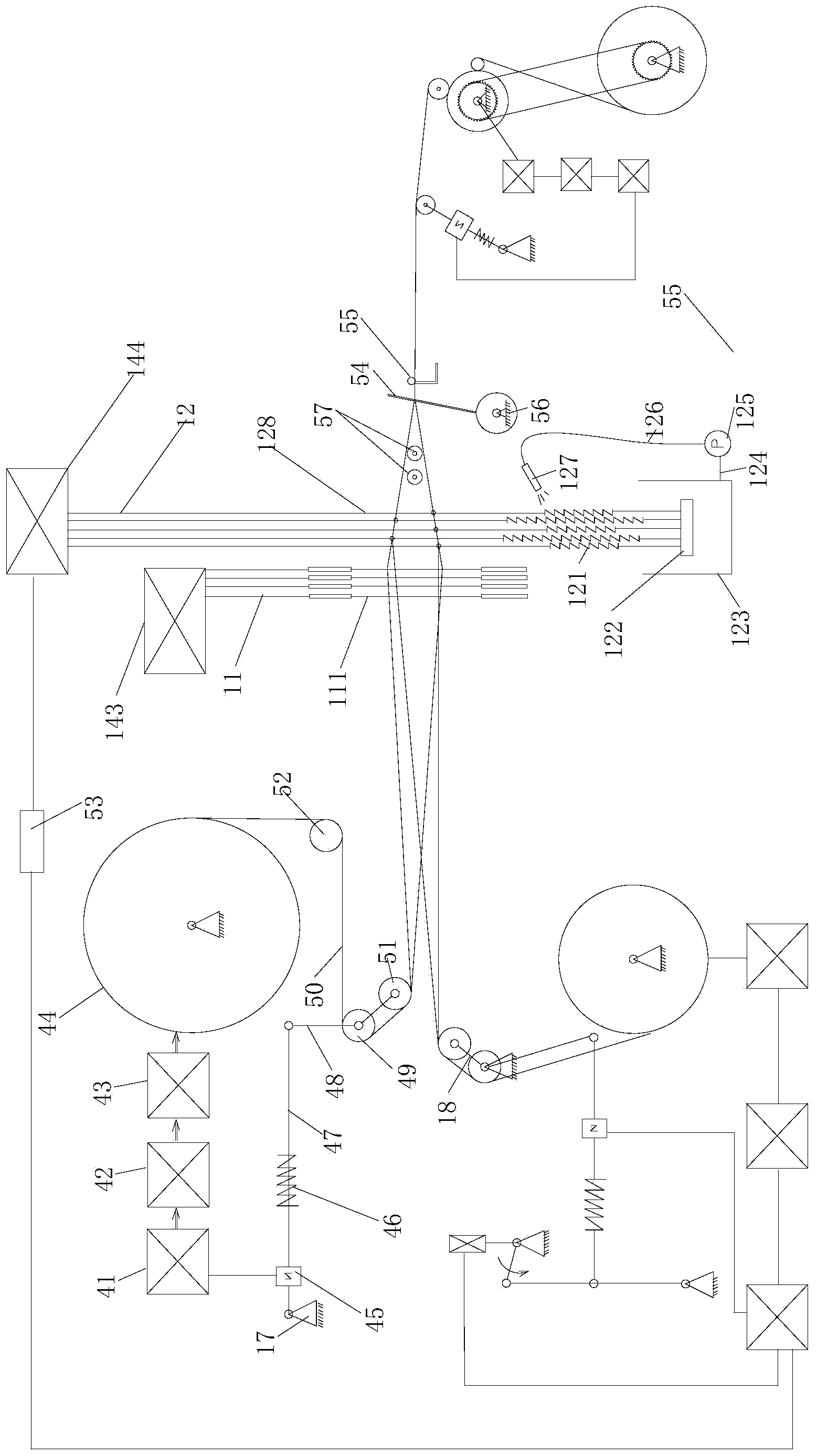

Double-let-off type composite shed water jet loom

InactiveCN103215733BGuaranteed stabilityAccurate and stable weft densityLoomsOther shedding mechanismSpray nozzleEngineering

The invention discloses a double-let-off type composite shed water jet loom, which comprises an active electronic let-off device, a passive electronic let-off device, a main shaft coder, a dobby, a jacquard machine, a reed, a shed stabilization device, a beating-up shaft, a nozzle and a passive take-up device. An active servo control system is actively adapted to the requirements of load variations of a shed according to pattern tissues, so that the stability of the shed is ensured; an active let-off take-up system is matched with a sensing device, so that responses to the requirements of tension variations of warps can be quickly made, positive compensation is realized, and the accuracy and the stability of weft density of cloth are ensured; due to the adoption of a composite shed time sequence difference manner, the problems of warp breakage and shed unclearness, which are caused by high warp density and excessive resistance, are solved; and beating-up stroke is improved, so that a shedding amount is reduced, the fluctuation range of the warps is narrowed, the warp breakage frequency is reduced, and the weaving efficiency and the quality of the cloth are effectively improved.

Owner:ZHEJIANG SANZHI TEXTILES +2

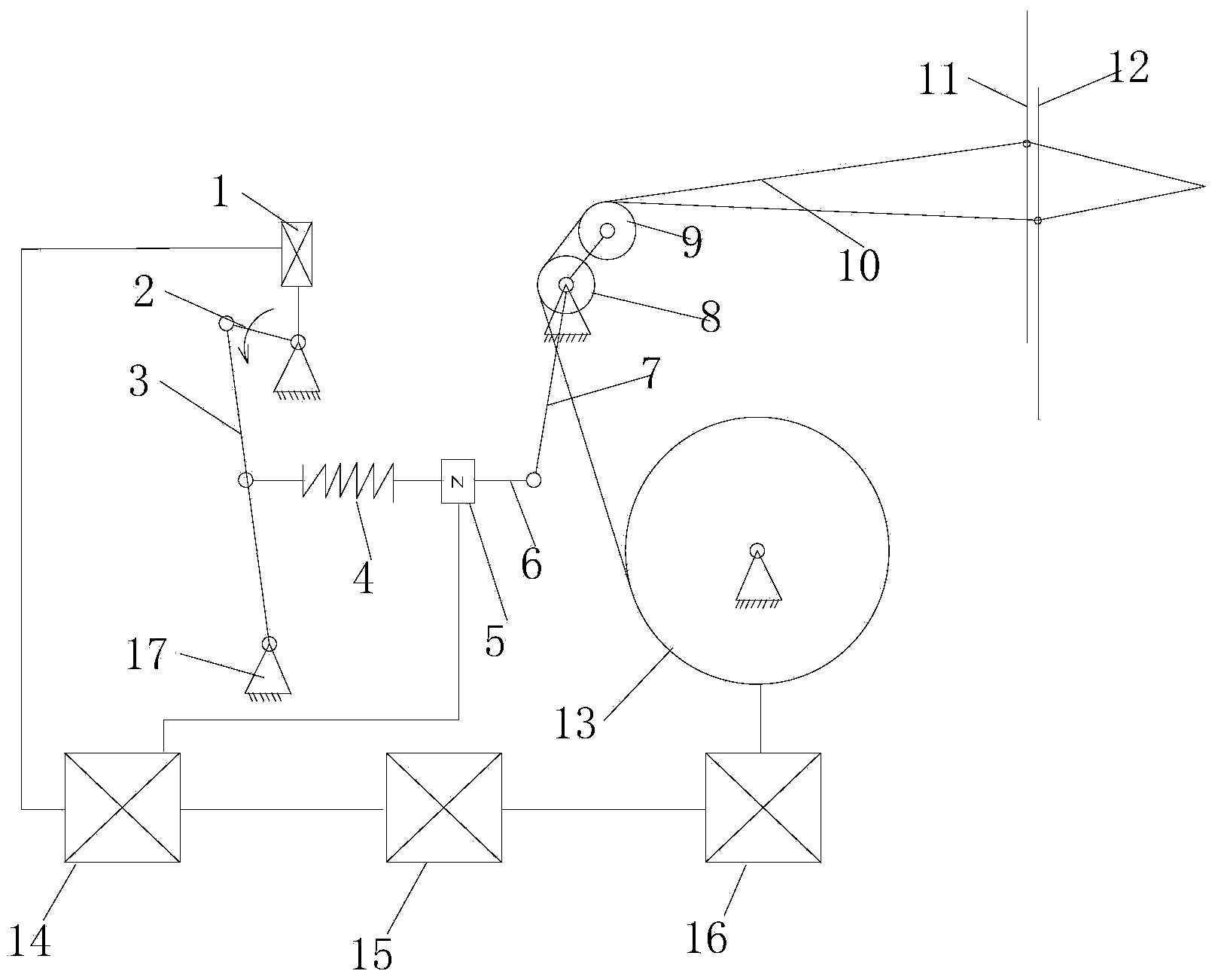

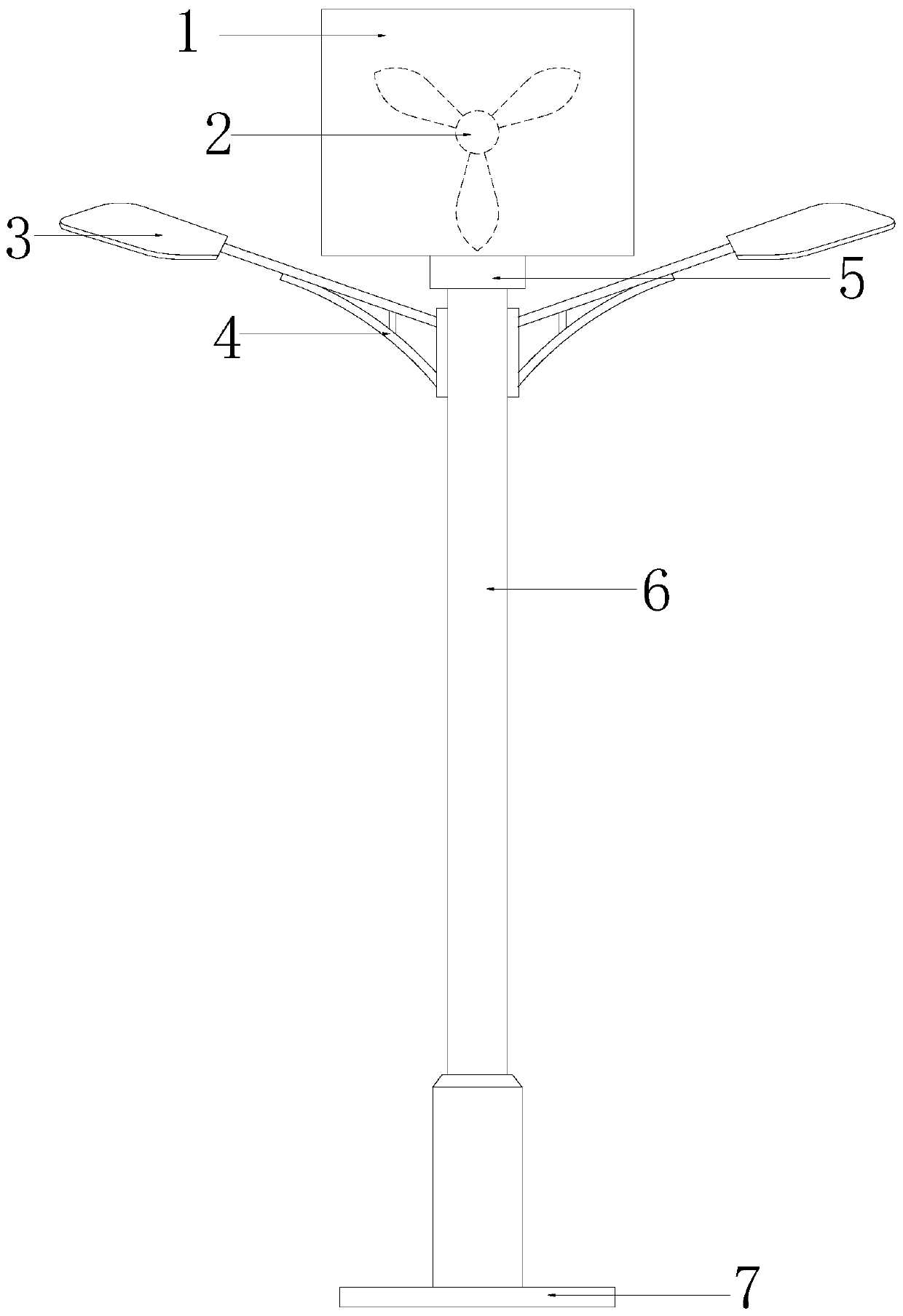

Wind-inlet-volume-adaptive-adjustment wind energy LED lighting street lamp

InactiveCN110131656AHinder entryReduce the entry wind speedElectric circuit arrangementsOutdoor lightingEngineeringDynamo

The invention discloses a wind-inlet-volume-adaptive-adjustment wind energy LED lighting street lamp. The wind-inlet-volume-adaptive-adjustment wind energy LED lighting street lamp structurally comprises a wind-volume adaptive device, a wind power generation device, lighting lamps, lamp stands, a wind direction trace device, a vertical column and a base, wherein the base is perpendicularly connected to the bottom of the vertical column; compared with the prior art, the wind-inlet-volume-adaptive-adjustment wind energy LED lighting street lamp has the advantages that the wind-volume adaptive device is additionally arranged on the wind energy street lamp, and by combining a protection cover, wind-volume self-adjusting mechanisms and spring groups, the lamp can self-adapt to the wind speed; when wind power is small, a wind inlet can be enlarged, and contains much wind, and power generation of a wind energy power generator is facilitated; when the wind power is large, the wind speed is detected by a wind speed sensor and is delivered to the wind-volume self-adjusting mechanisms to self-adjust the size of the wind inlet, the wind inlet volume and the wind inlet speed are decreased accordingly, and it is effectively avoided that as wind power is over large, the wind power generation device is damaged.

Owner:尤德逢

Soffit-type ultra-high performance concrete precast shield tunnel segment structure and design method

ActiveCN112727500BExcellent stress relaxationReduce mis-stationGeometric CADUnderground chambersCrack resistanceArchitectural engineering

Arch feet, steel mesh inside the concrete, pipe pipe grouting holes, tube seam grooves, and the horizontal cross section of the arched abdomen is a arc -surface structure; the arched abdomen also has an arched vertical cross section.For the design method of the present invention, the specific steps are as follows: 1) Determine the thickness H 1 And the thickness of the arch feet H 2 ; 2) Ultra -high -performance concrete pipes The main body of the arched belly area of the main cross -section bearing capacity calculation, the positive cross section of the arched belly area is equivalent to the rectangular section for reinforcement calculation;Calculation capacity calculation of the positive cross -section bending of the bending component and calculated by the carrier capacity of the positive cross bearing capacity of the positive cross -section of the compression component.The invention can solve the problem of poor cracking resistance of the tube.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com