Duct piece assembling and grouting integrated machine for shield underground butt joint

A segment assembling machine and segment assembling technology are applied in the field of shield tunneling machines, which can solve problems such as segment loosening, and achieve the effects of reducing processing and manufacturing costs, reducing the amount of opening, and preventing stress relaxation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

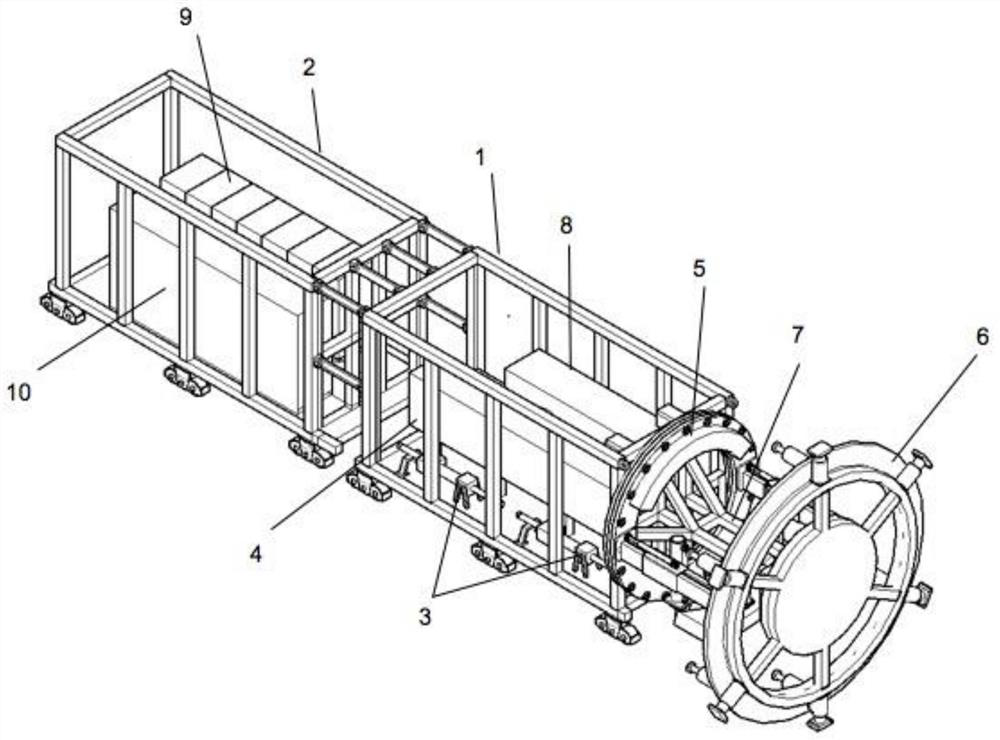

[0033] A segment 573 assembling and grouting integrated machine for shield underground docking, refer to Figures 1 to 8 , including a segment assembly machine 5, a first trolley 1, a second trolley 2, a grouting device, a power unit and an anti-loosening device 6; the two ends of the first trolley 1 are respectively connected to the second trolley 2 and a segment assembly machine 5; the first trolley 1 is provided with the grouting device, and the second trolley 2 is provided with the moving device; the segment assembly machine 5 is connected to the On the front-end frame of the first trolley 1, the assembly machine moves forward and backward along the tunnel axis.

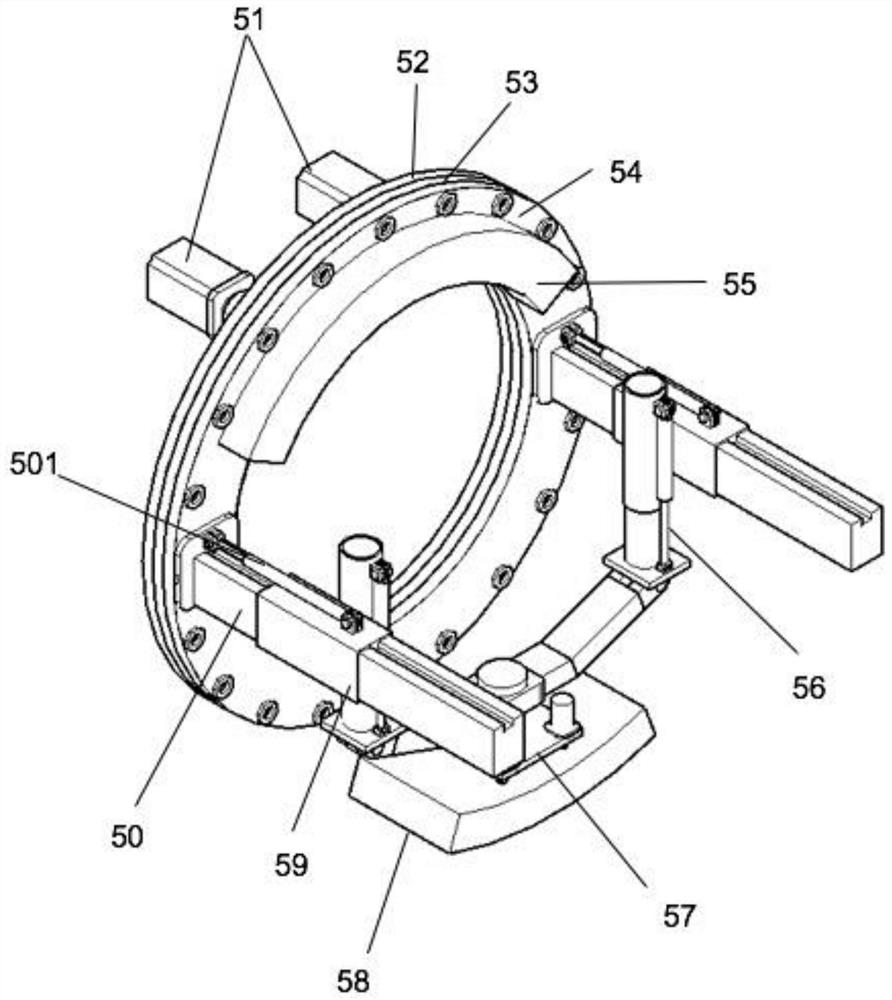

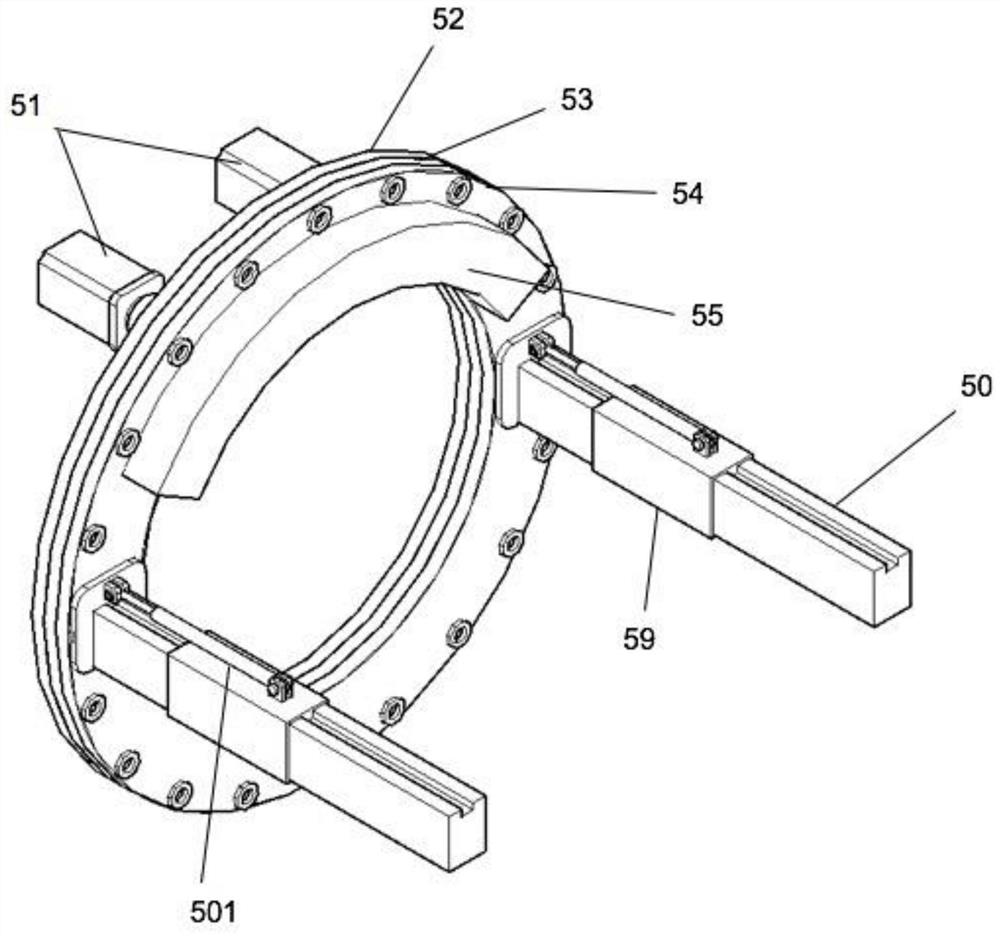

[0034] The segment assembly machine 5 includes a circular rotation device, an axial translation device, a radial lifting device 56 and a grabbing device 57; the circular rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com