Soffit-type ultra-high performance concrete precast shield tunnel segment structure and design method

An ultra-high performance, tunnel segment technology, used in tunnels, earth-moving drilling, tunnel lining, etc., can solve the problems of stress relaxation bolt joints between annular joints, concrete damage, poor crack resistance and water leakage, etc. The effect of reducing the amount of concrete used, improving the bearing capacity and alleviating serious water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

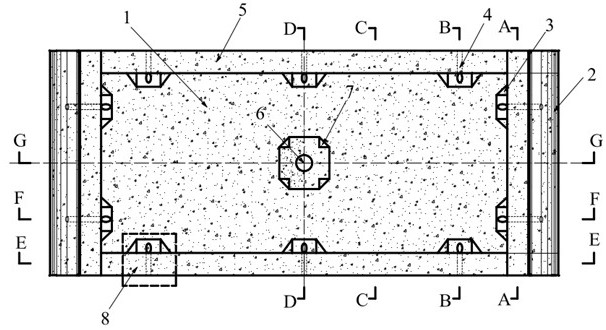

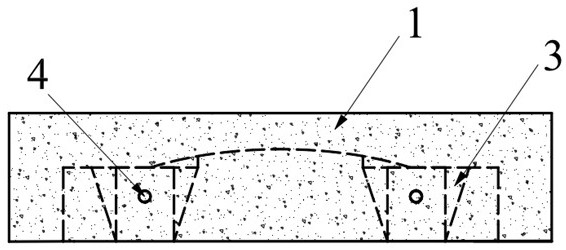

[0154] Such as Figure 1-11 As shown, a soffit type ultra-high performance concrete prefabricated shield tunnel segment, including:

[0155] Soffit 1, located in the soffit area of the main body of the ultra-high performance concrete segment;

[0156] Segment seam groove 2;

[0157] Straight bolt reserved hole 4;

[0158] The first reinforcing rib 3 is located at the reserved hole 4 for straight bolts;

[0159] The local reinforcement band 5 is located at the edge of the main body of the segment;

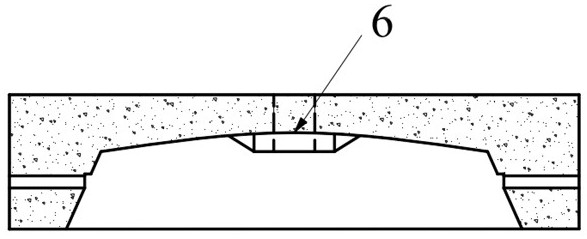

[0160] Segment grouting hole 6;

[0161] The second reinforcing rib 7 is located at the grouting hole 6 of the segment;

[0162] Hand hole 8, near the hand hole 8 is the concrete reinforcement area;

[0163] Local reinforcement with steel bars 9;

[0164] The soffit steel bar 10 is located in the soffit area of the main body of the segment;

[0165] The spiral steel bar 11 is located at the grouting hole 6 of the segment.

[0166] 1) The soffit area of the main body o...

Embodiment 2

[0179] A shield tunnel segment has an outer diameter of 6000mm and a ring width of 1500mm. The overall tunnel segment is made of ultra-high performance concrete material, the concrete grade is UC120, the steel bar type is HRB400, the thickness of the concrete cover layer is 20mm, the design load of the minimum reinforcement ratio is the maximum positive bending moment design value of 277.0kN·m, and the corresponding axial force design Value - 1867.5kN.

[0180] The design method of the main soffit area of the soffit ultra-high performance concrete shield tunnel segment is as follows:

[0181] 1. According to the strength of the ultra-high performance concrete material used, the type of steel bar and the internal force generated by the external load calculated according to the code, the longitudinal normal section size of the segment is determined, and the thickness h of the vault is determined 1 and arch foot thickness h 2 .

[0182] Preliminary drafting of vault thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com