Binder composition for semiconductor device and binder sheet for semiconductor device

A composition, semiconductor technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc., can solve the problems of large operation volume and cost, electrical corrosion, insulation reduction, etc., to improve Reliability, labor reduction, and excellent reflow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

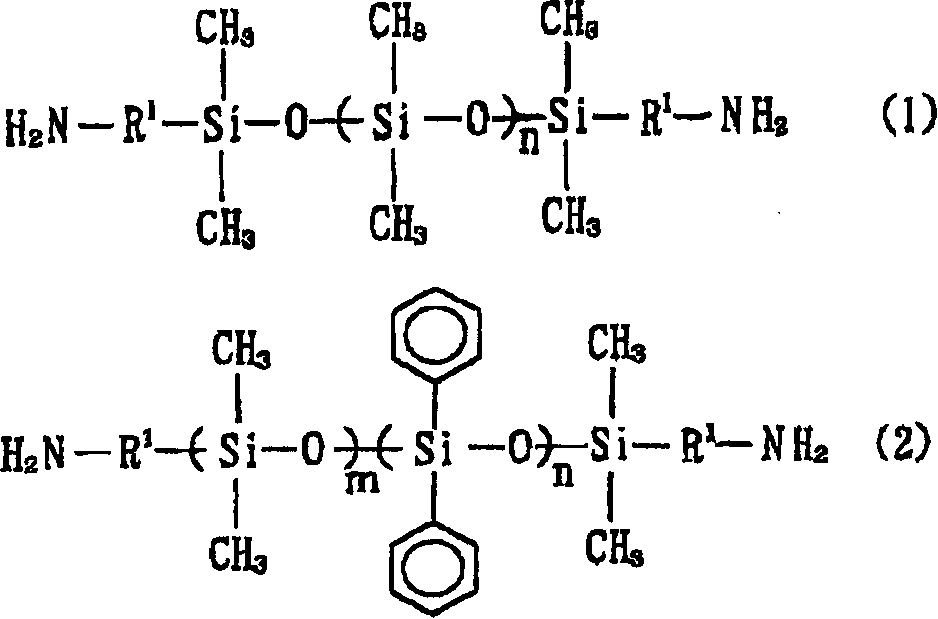

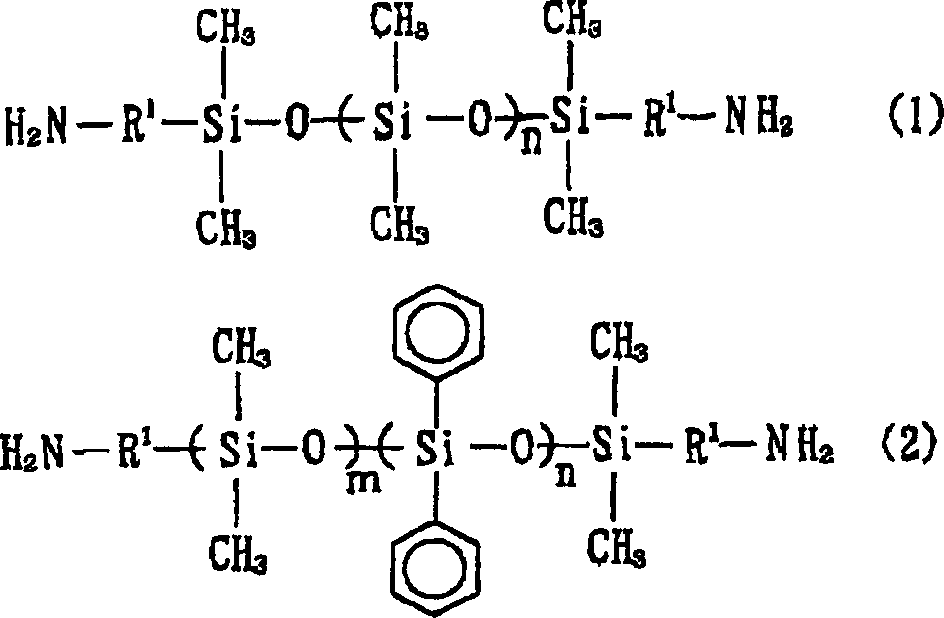

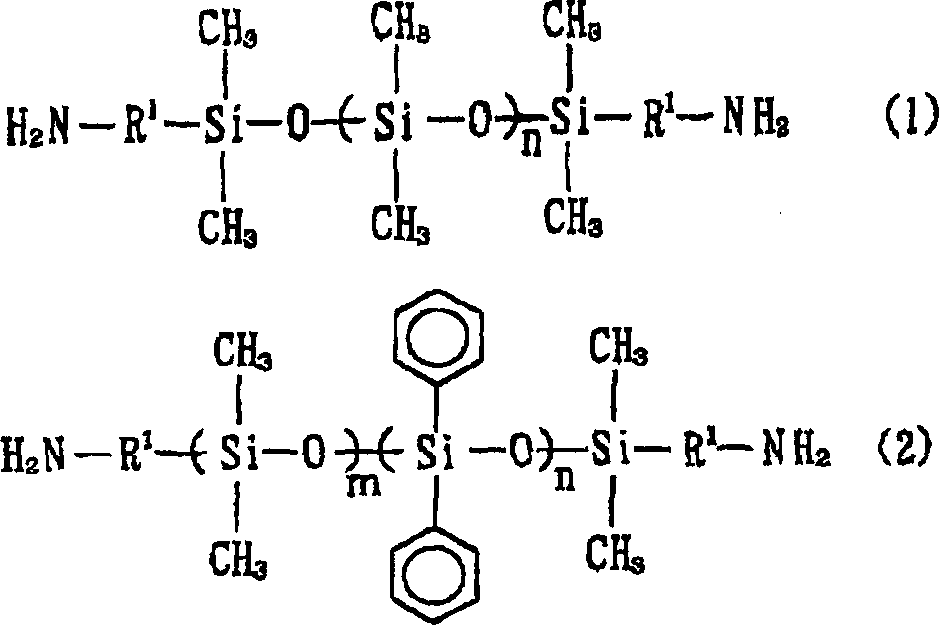

Method used

Image

Examples

Embodiment 1~28、 comparative example 1~7

[0197] Examples 1-28, Comparative Examples 1-7 [Preparation of coating material of adhesive composition]

[0198]The (A) component, (B) component, (C) component or (C') component, (D) component, silane coupling agent, epoxy curing agent, filler, and diene-containing compound represented by symbols in Table 1 The copolymers were dissolved in toluene at room temperature to about 80° C. in the compounding amounts shown in Table 1 (mass % relative to the total solid content) to obtain coatings containing the adhesive composition (solid content concentration: 35% by mass %).

[0199] In addition, content of a filler is the part by mass (mass part) with respect to the sum total of 100 mass parts of (A) component, (B) component, (C) component or (C') component, and (D) component.

[0200] Moreover, the meaning of the symbol in Table 1 which shows the kind of each component used in Examples 1-28 and Comparative Examples 1-7 is shown in Table 2.

[0201] (quality%)

(p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com