Patents

Literature

76results about How to "Excellent stress relaxation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

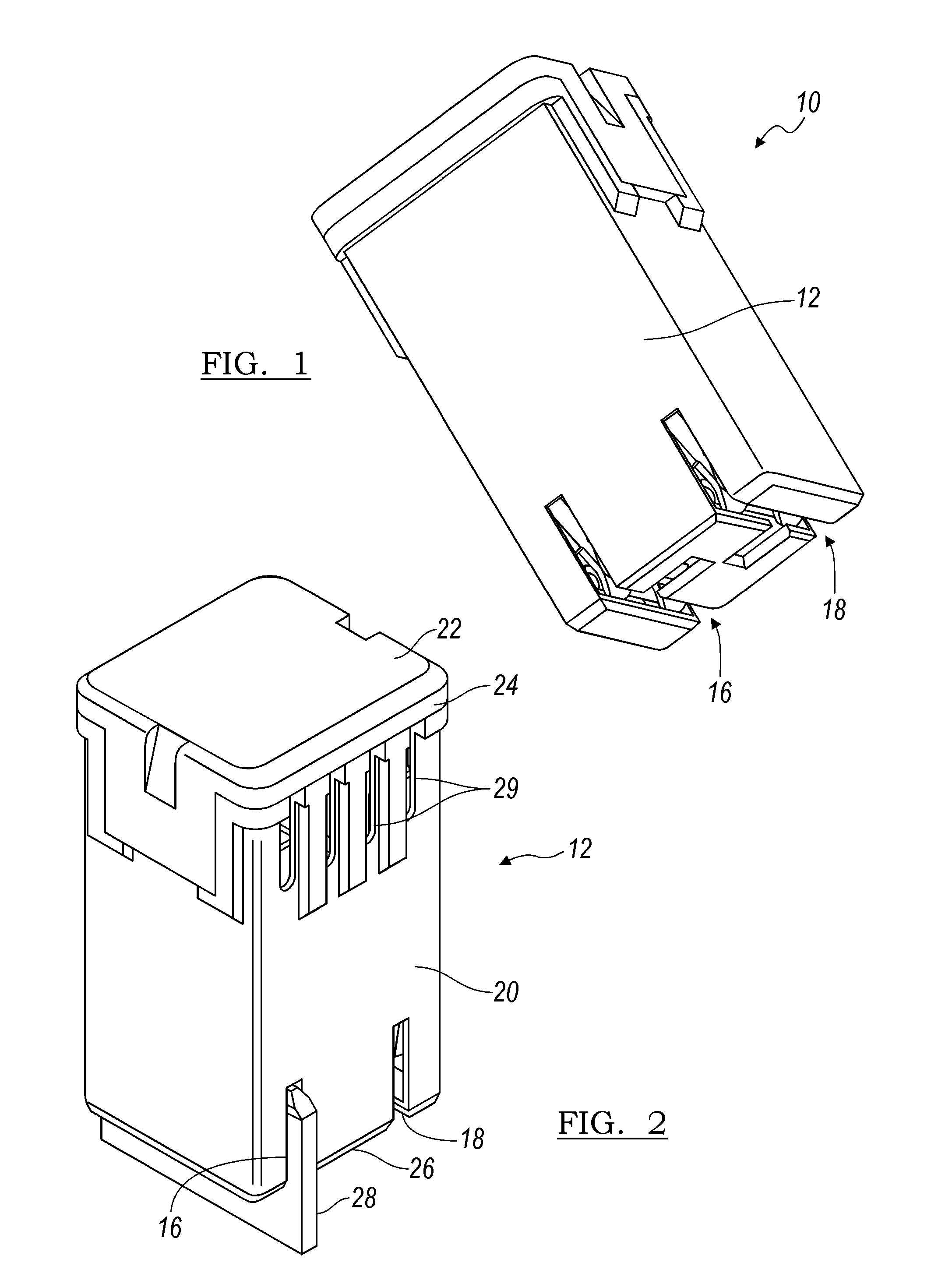

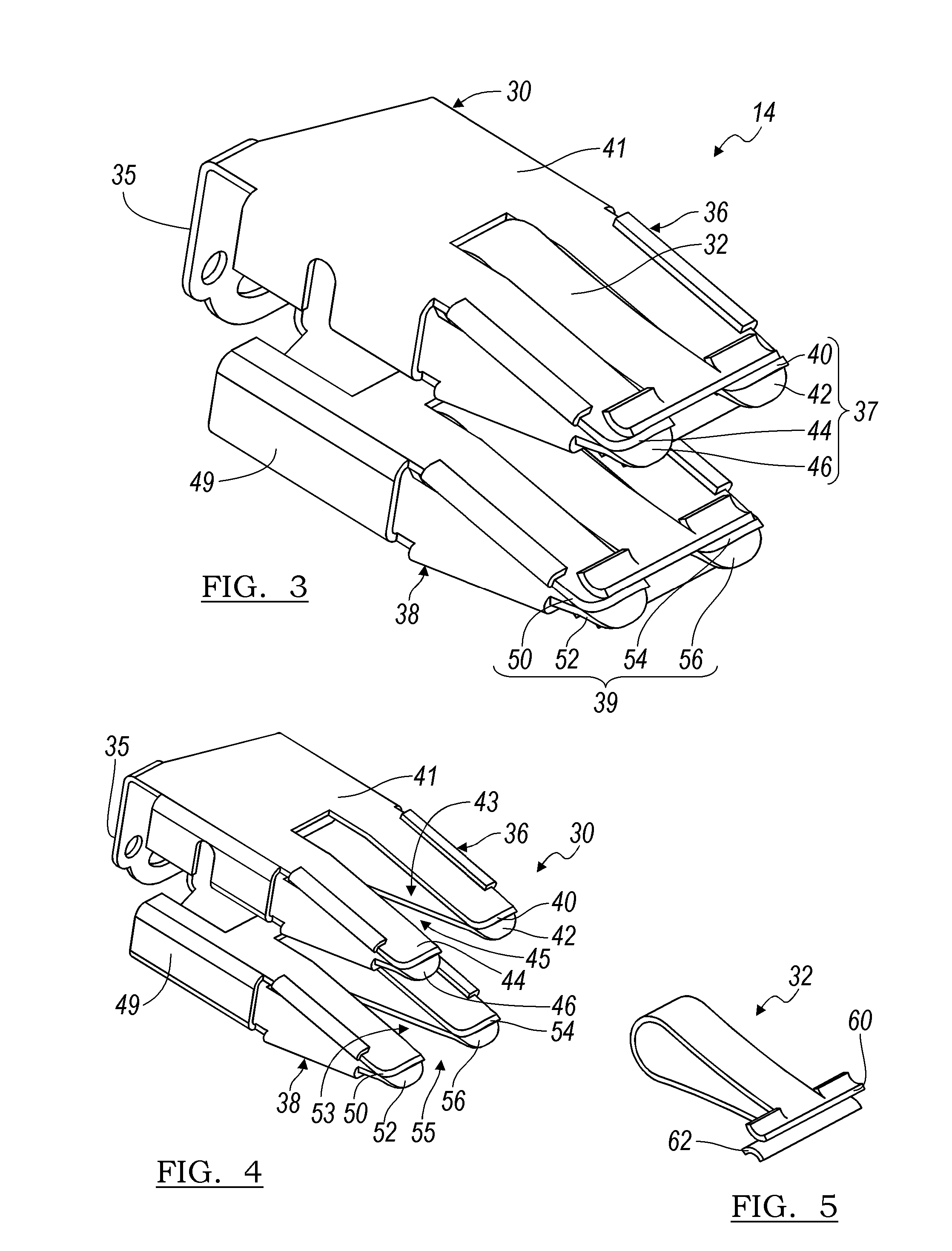

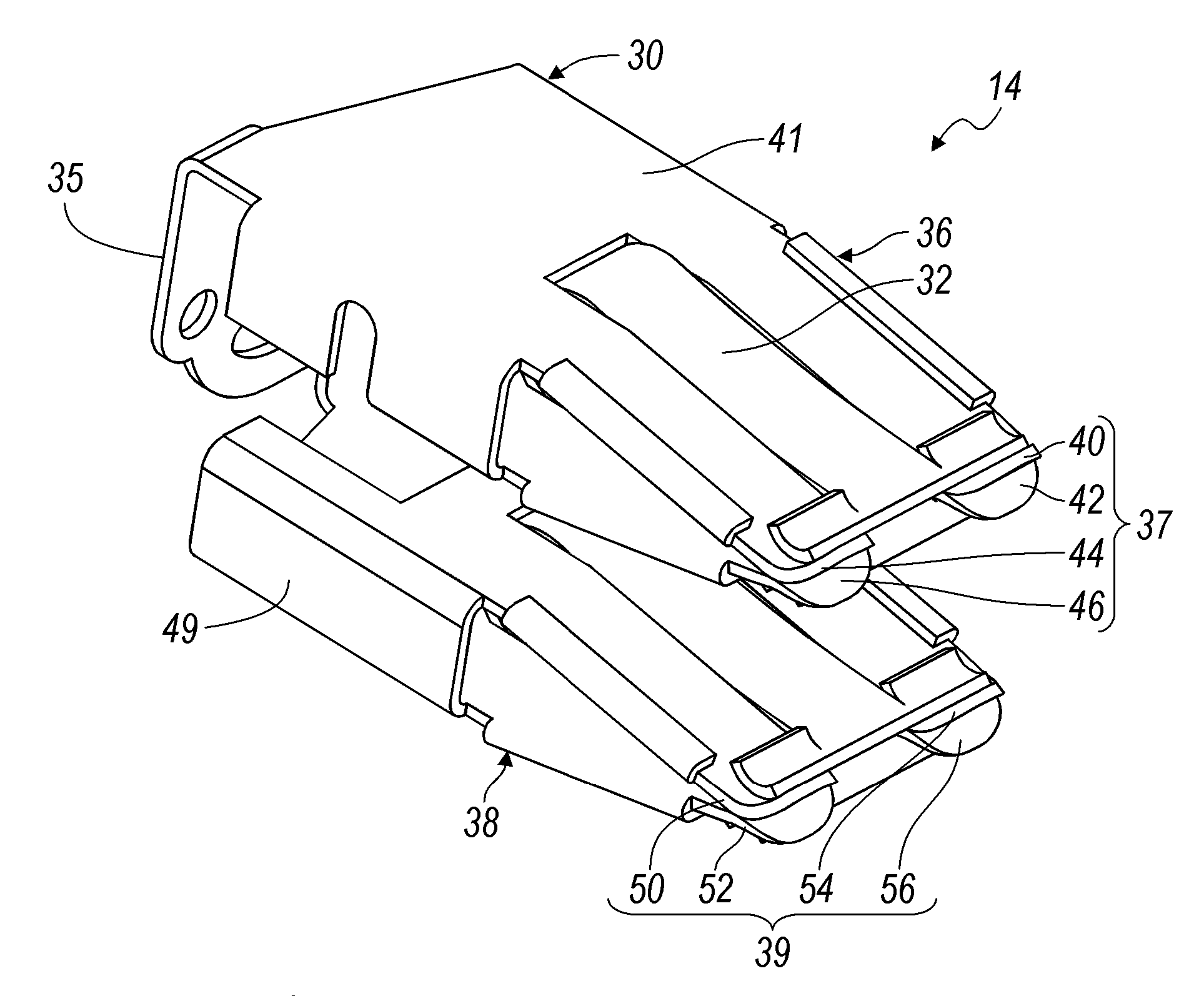

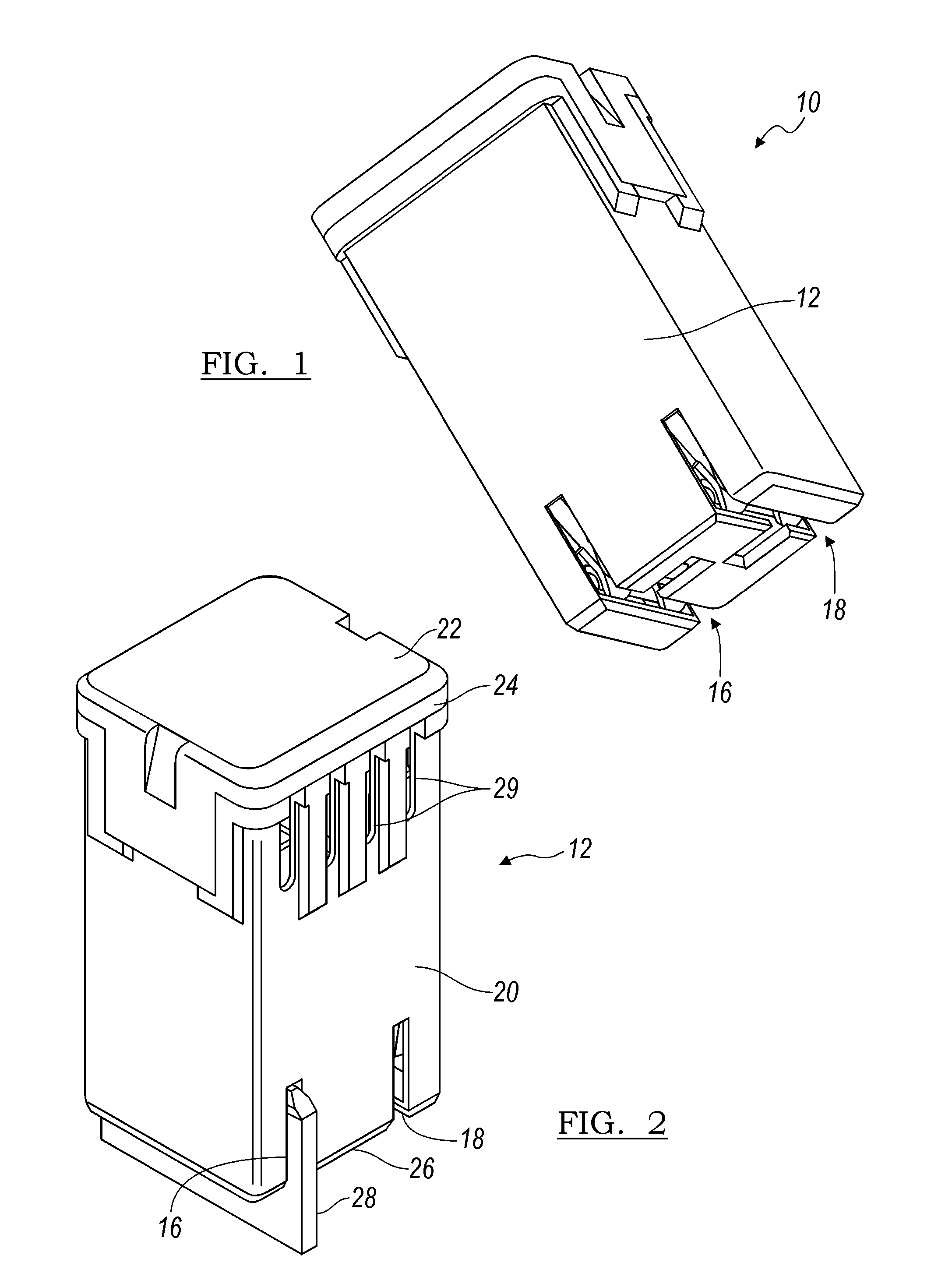

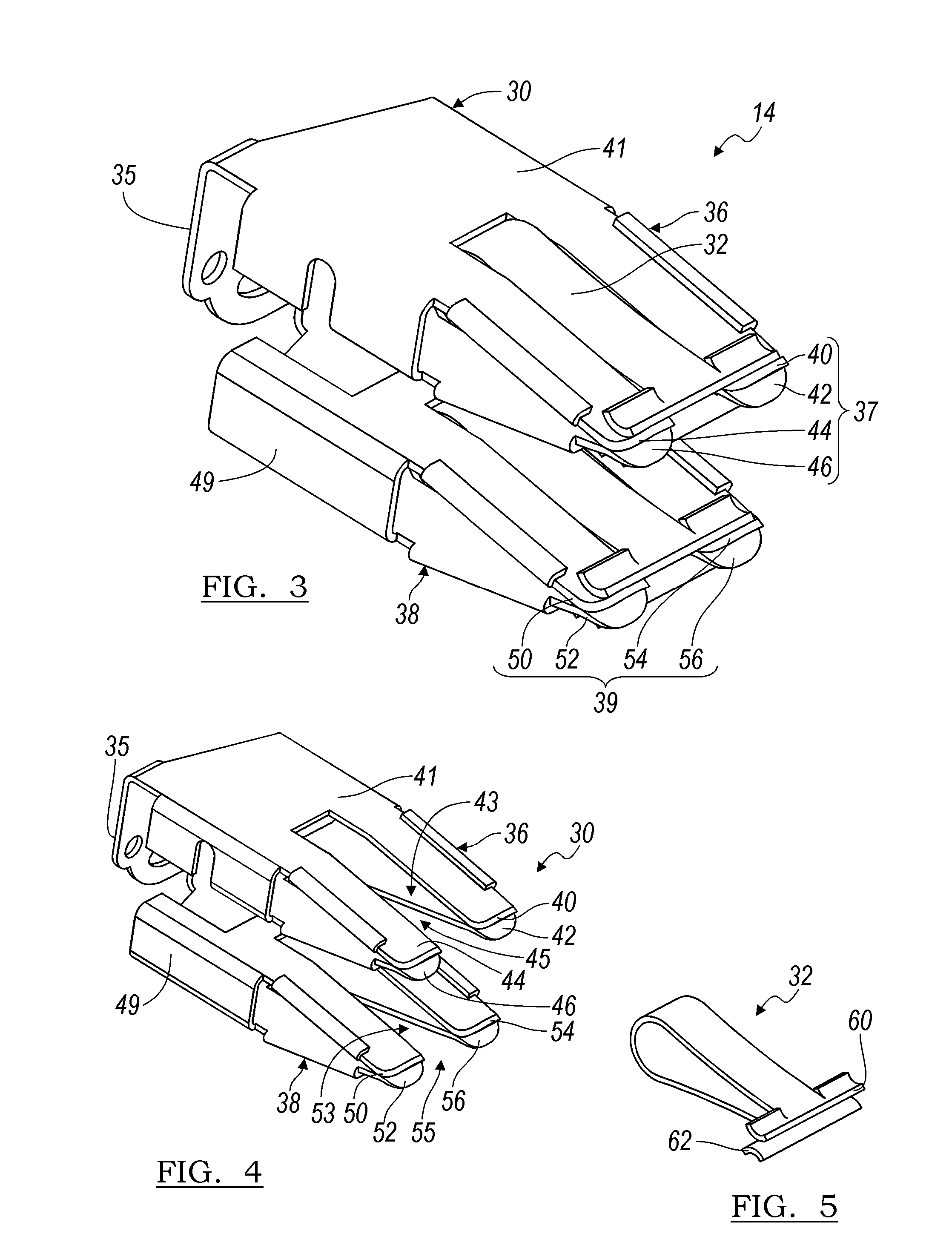

High power case fuse

InactiveUS7595715B2Increase powerGreat mechanical stress propertyIncorrect coupling preventionCoupling contact membersElectrical and Electronics engineeringFuse cutout

A high power fuse includes a fuse body having a first terminal receptor including a first set of terminal legs and a second terminal receptor in spaced relation to the first terminal receptor. The second terminal receptor includes a second set of terminal legs. A fuse element is disposed between the first terminal receptor and the second terminal receptor. A first clamp-like member is mounted to the fuse body for applying a predetermined compression force against the first set of terminal legs and is configured to secure a first male terminal between the first set of terminal legs. A second clamp-like member is mounted to the fuse body for applying a predetermined compression force against the second set of terminal legs and is configured to secure a second male terminal between the second set of terminal legs.

Owner:LEAR CORP

Copper alloy having bendability and stress relaxation property

InactiveUS20060137773A1Improve bendabilityImprove stress relaxation propertyMetallic pattern materialsStress relaxationMaterials science

A copper alloy contains 0.01% to 1.0% of Fe, 0.01% to 0.4% of P, and 0.1% to 1.0% of Mg with the remainder being copper and inevitable impurities and has a volume fraction of dispersoids having a particle diameter exceeding 200 nm of 5% or less, in which dispersoids having a particle diameter of 200 nm or less and containing Mg and P have an average particle diameter of 5 nm or more and 50 nm or less. The copper alloy preferably has an average particle diameter of dispersoids containing Fe and P of 20 nm or less. The copper alloy has improved bendability and stress relaxation property.

Owner:KOBE STEEL LTD

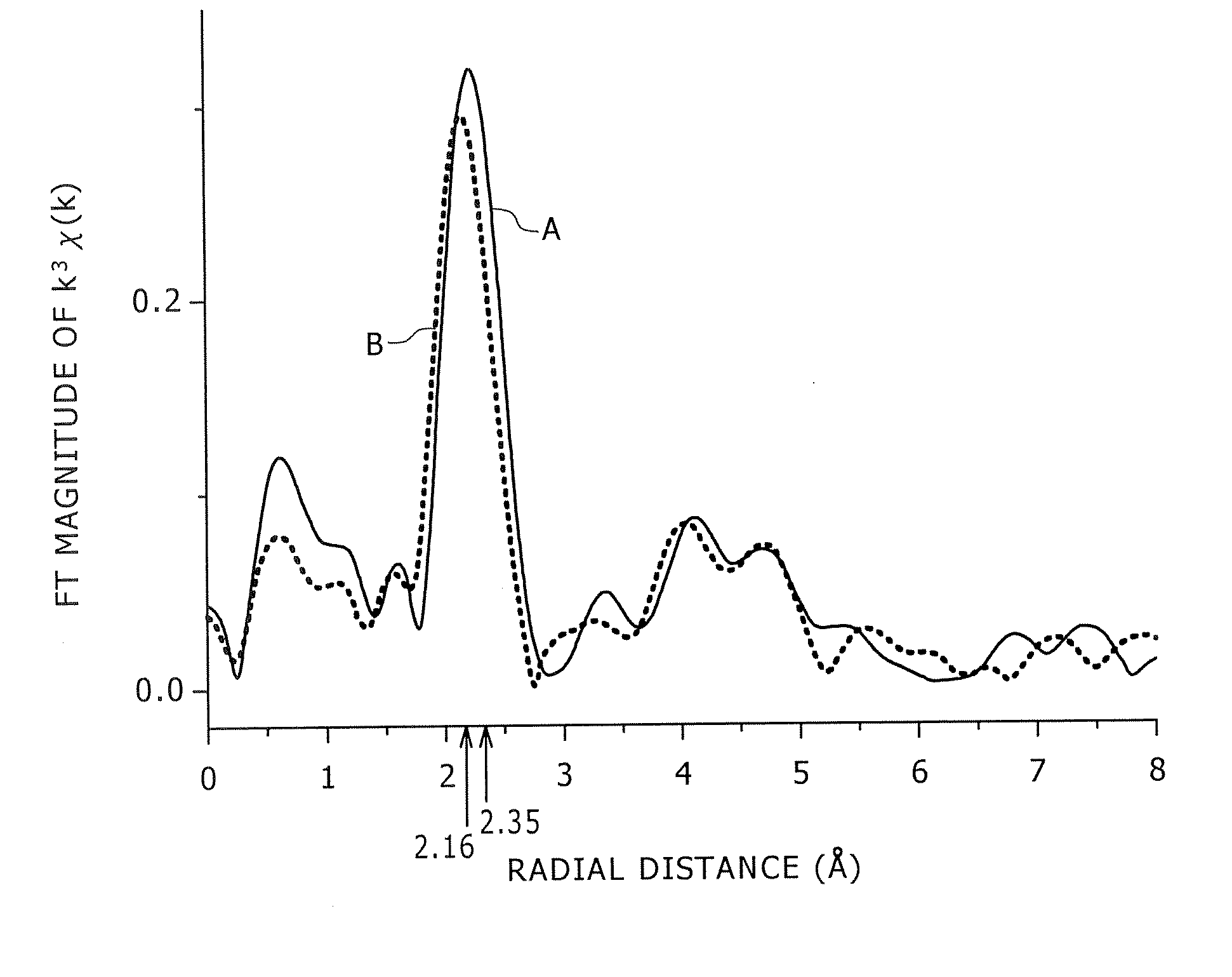

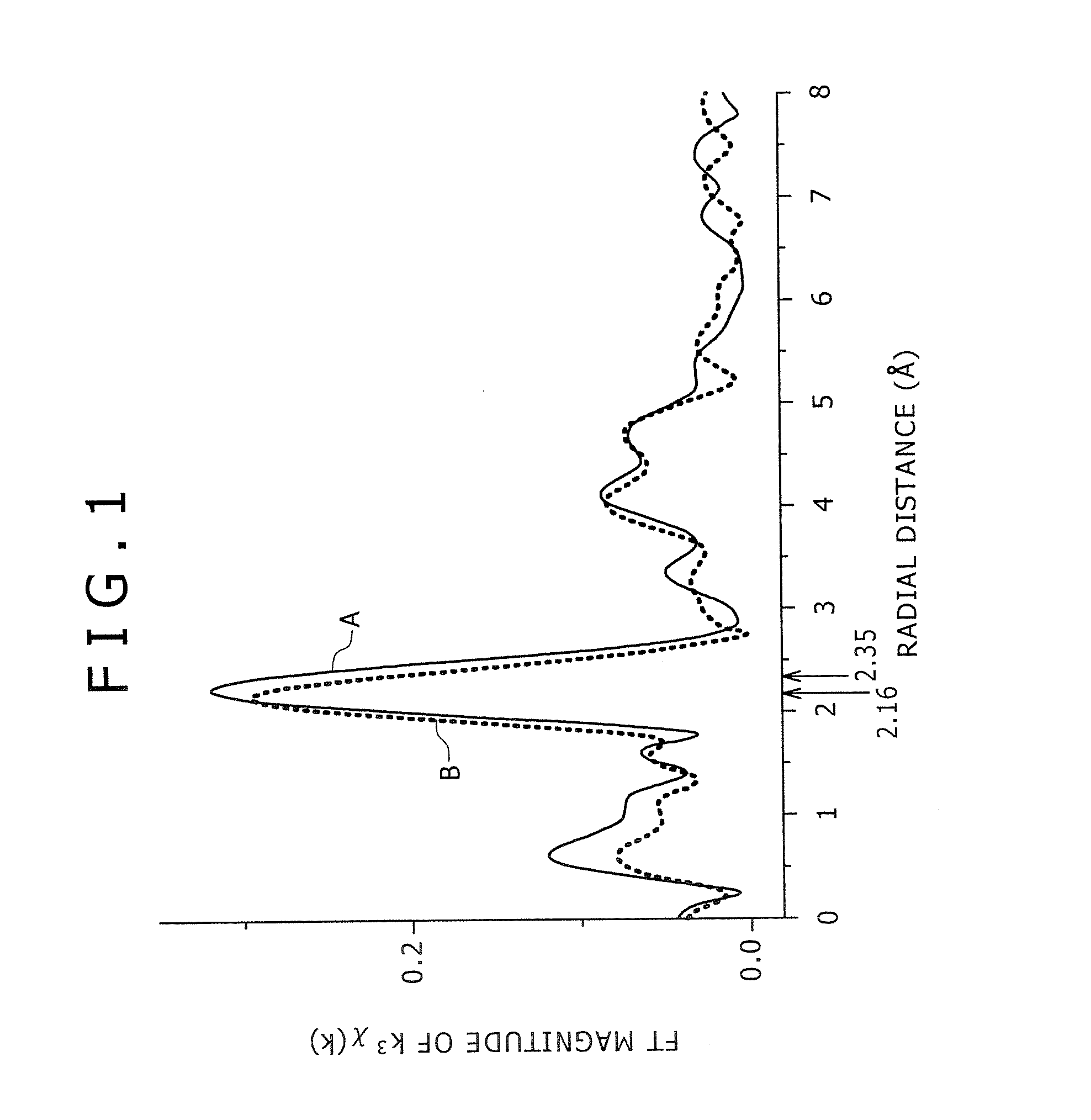

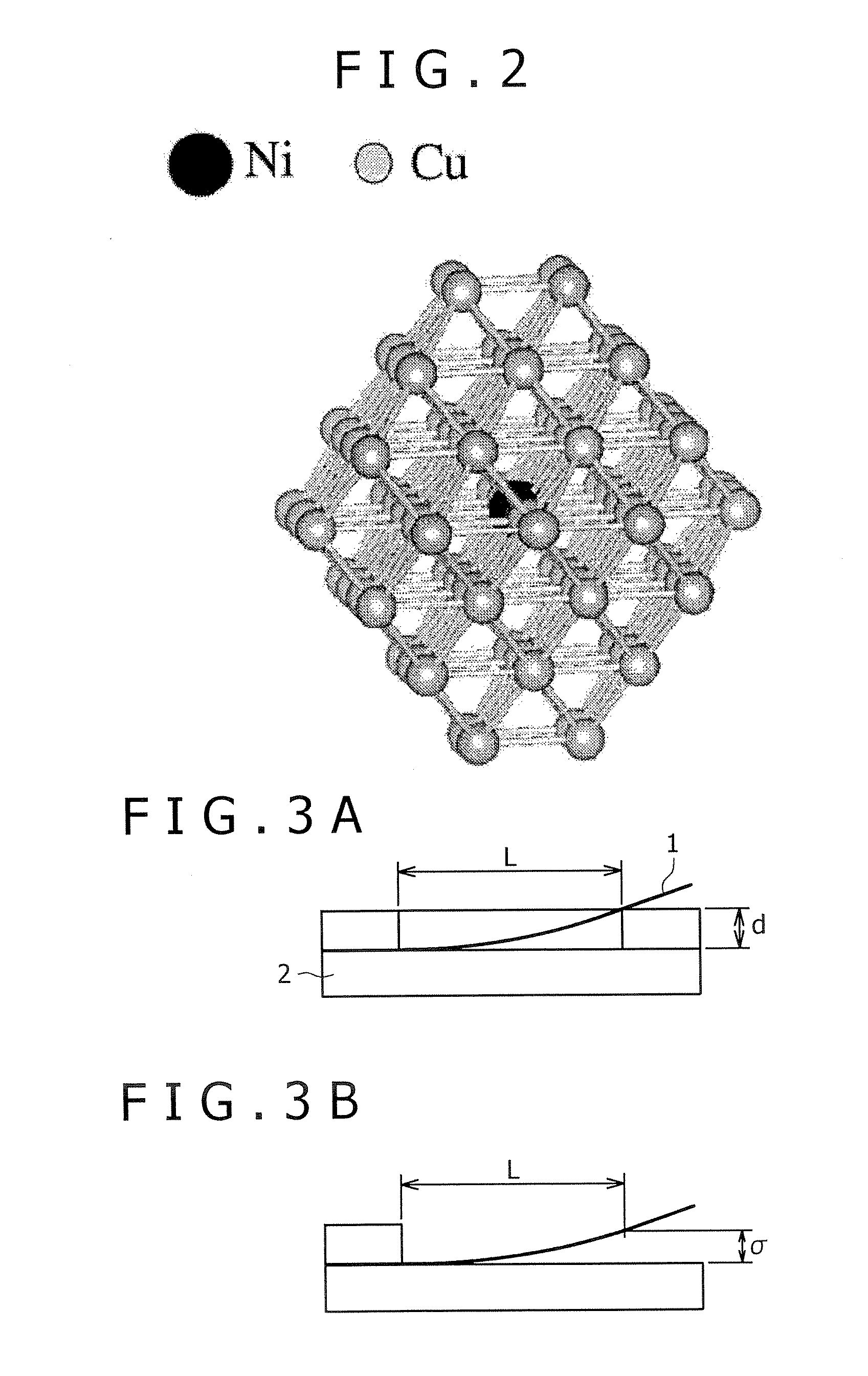

Copper alloy having excellent stress relaxation property

A Cu—Ni—Sn—P alloy is provided, which is excellent in stress relaxation property in a direction perpendicular to a rolling direction, and has any of high strength, high conductivity, and excellent bendability. A copper alloy contains 0.1 to 3.0% of Ni, 0.1 to 3.0% of Sn, and 0.01 to 0.3% of P in mass percent respectively, and includes copper and inevitable impurities as the remainder; wherein in a radial distribution function around a Ni atom according to a XAFS analysis method, a first peak position is within a range of 2.16 to 2.35 Å, the position indicating a distance between a Ni atom in Cu and an atom nearest to the Ni atom. Thus, distances to atoms around the Ni atom in Cu are comparatively increased, so that the stress relaxation property in a direction perpendicular to the rolling direction of the copper alloy is improved.

Owner:KOBE STEEL LTD

Pressure-Sensitive Adhesive and Method for Producing Same, and Pressure-Sensitive Adhesive Sheet

InactiveUS20080248299A1Good optical performanceImprove adhesionLayered productsEster polymer adhesivesVitrificationPolymer science

A pressure-sensitive adhesive, comprising a polymer (A), which is formed by polymerization of a radical polymerizable monomer, contains carboxyl groups, and has a glass transition temperature within a range from −80 to 0° C. and a weight average molecular weight within a range from 500,000 to 1,500,000, a tricyclic diterpene carboxylic acid (B), and a curing agent (C) capable of reacting with a carboxyl group, wherein the total acid value of the combination of the polymer (A) and the tricyclic diterpene carboxylic acid (B) is within a range from 5 to 50 (mgKOH / g).

Owner:TOYO INK SC HOLD CO LTD

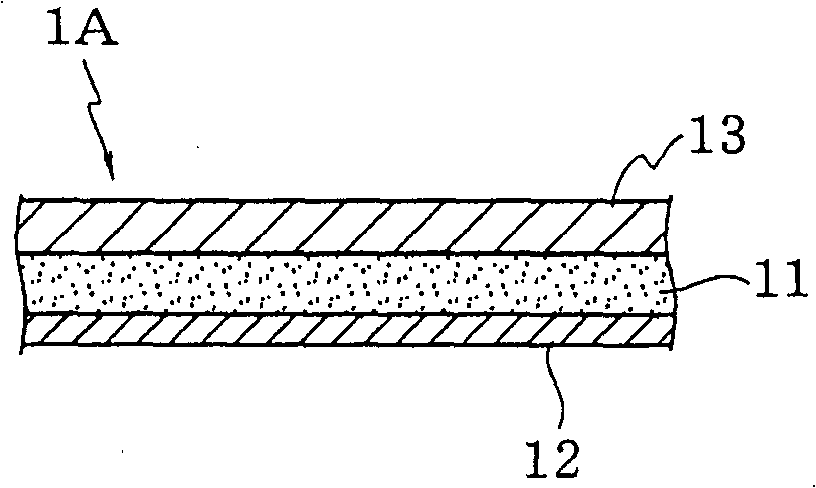

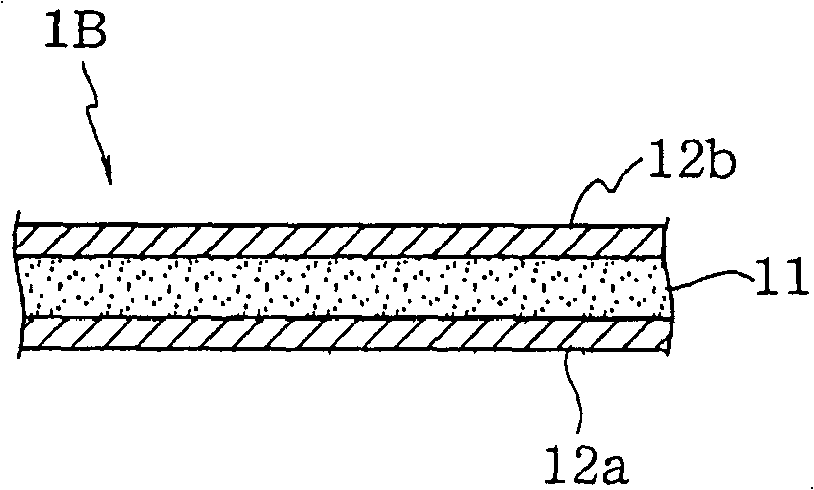

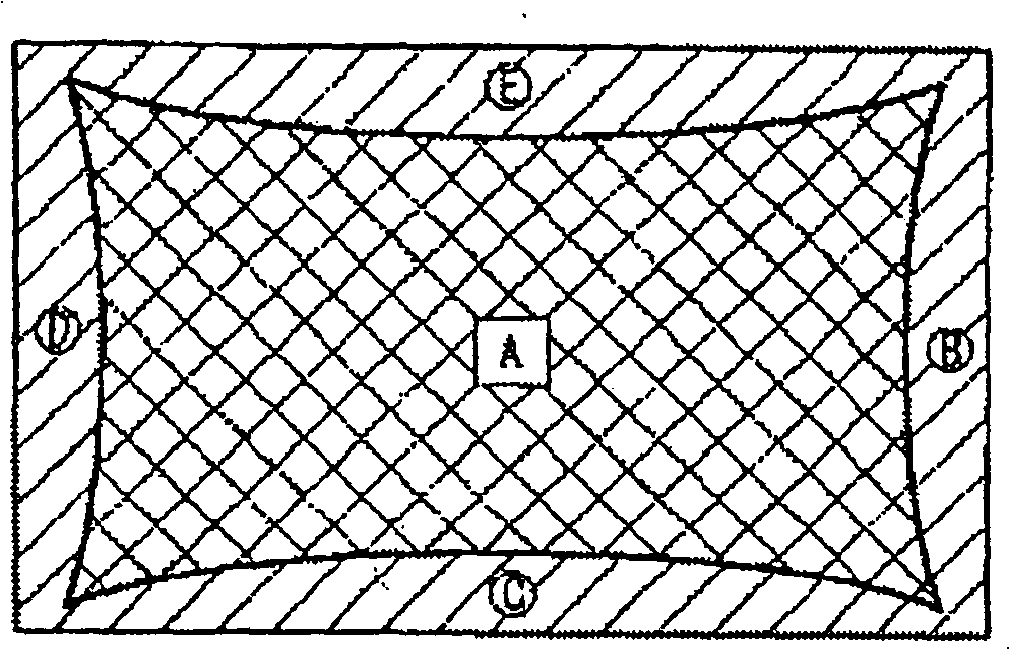

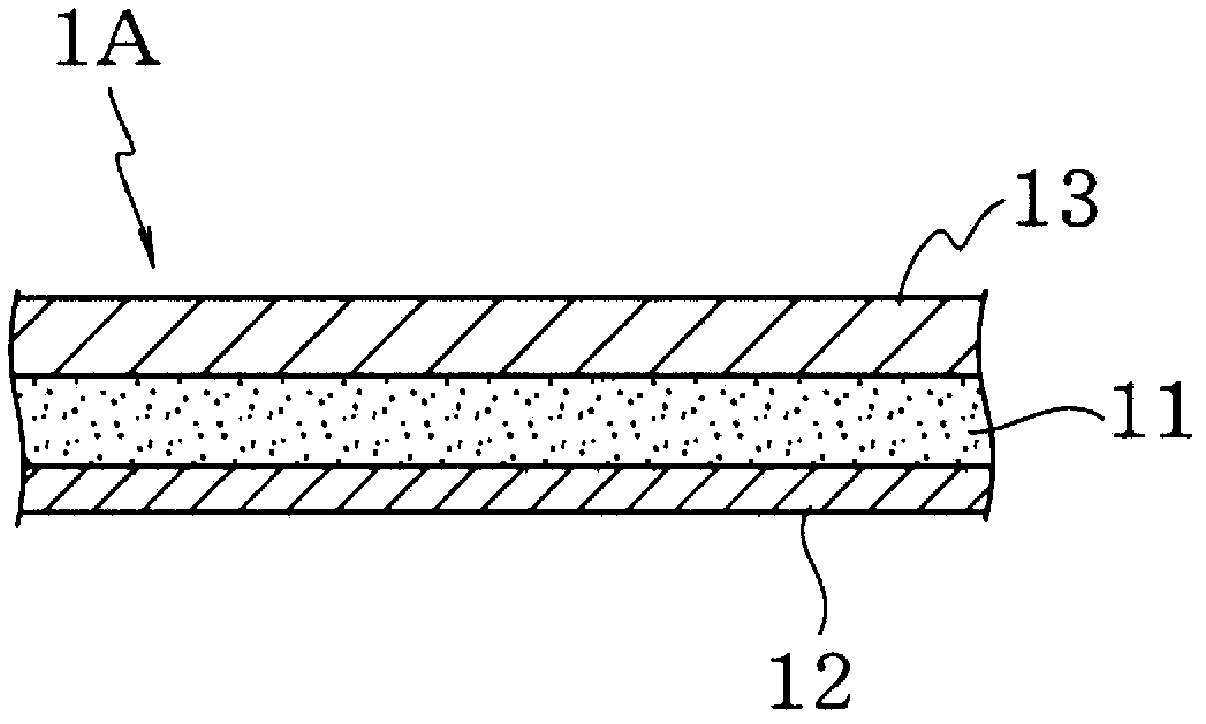

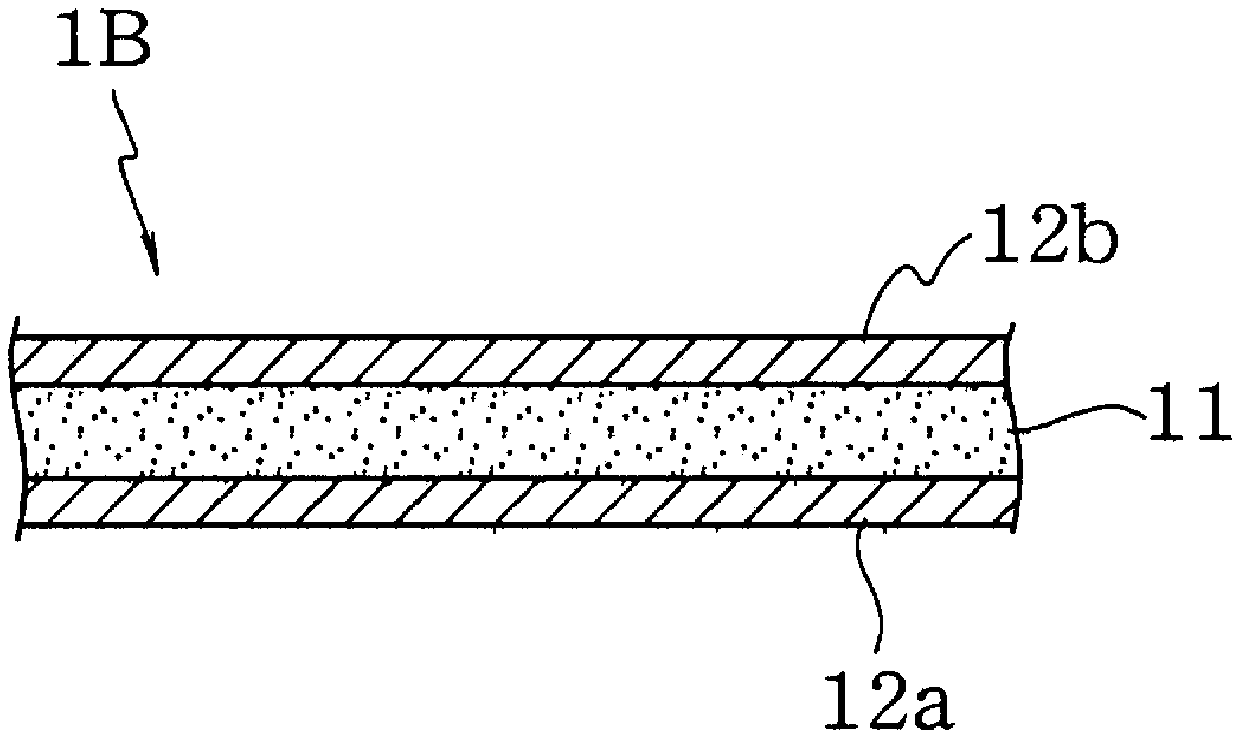

Conformable multi-layer sheet materials

InactiveUS6869496B1Easy to operatePromote softeningStampsLamination ancillary operationsPolyesterPhysical property

A multi-layer sheet material comprises a film, and adhesive layer and an optional release liner. The film is a polyester blend comprising first and second polyesters that are substantially amorphous and possess certain physical properties including softening temperature, E-modulus, elongation and residual stress.

Owner:3M INNOVATIVE PROPERTIES CO

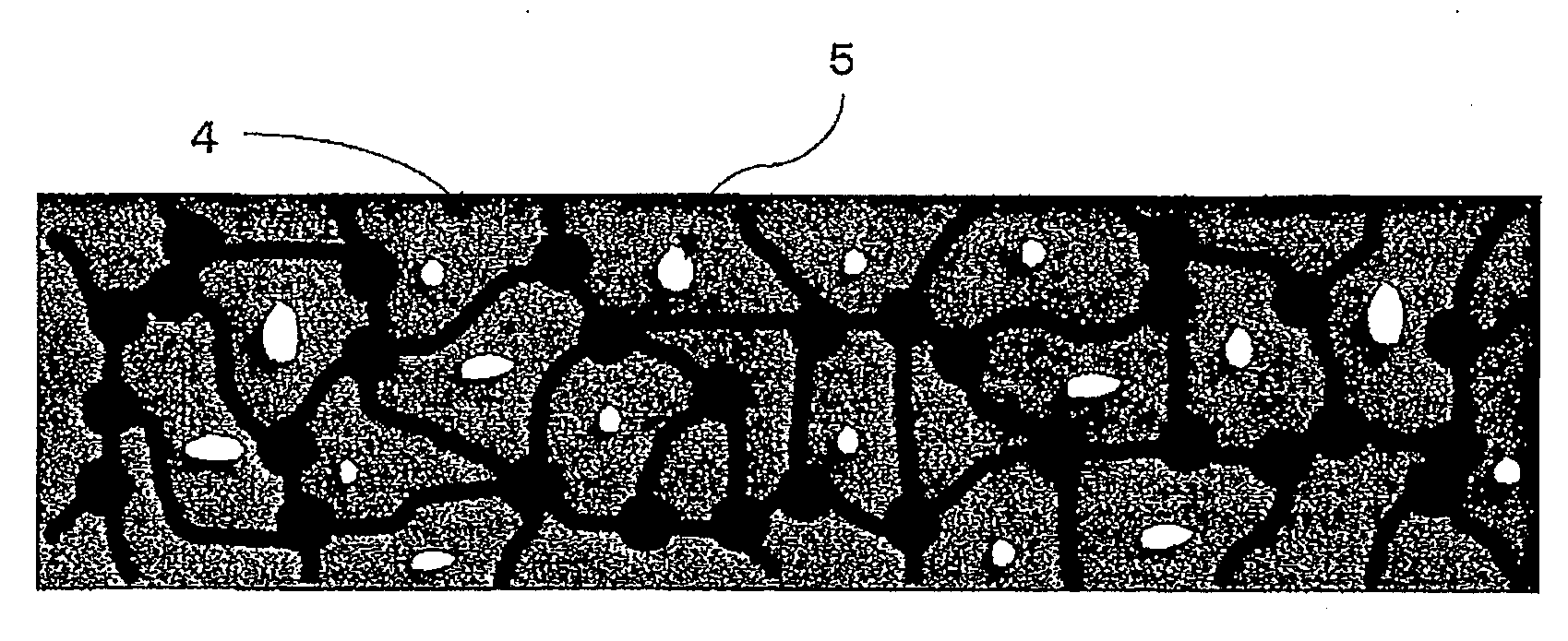

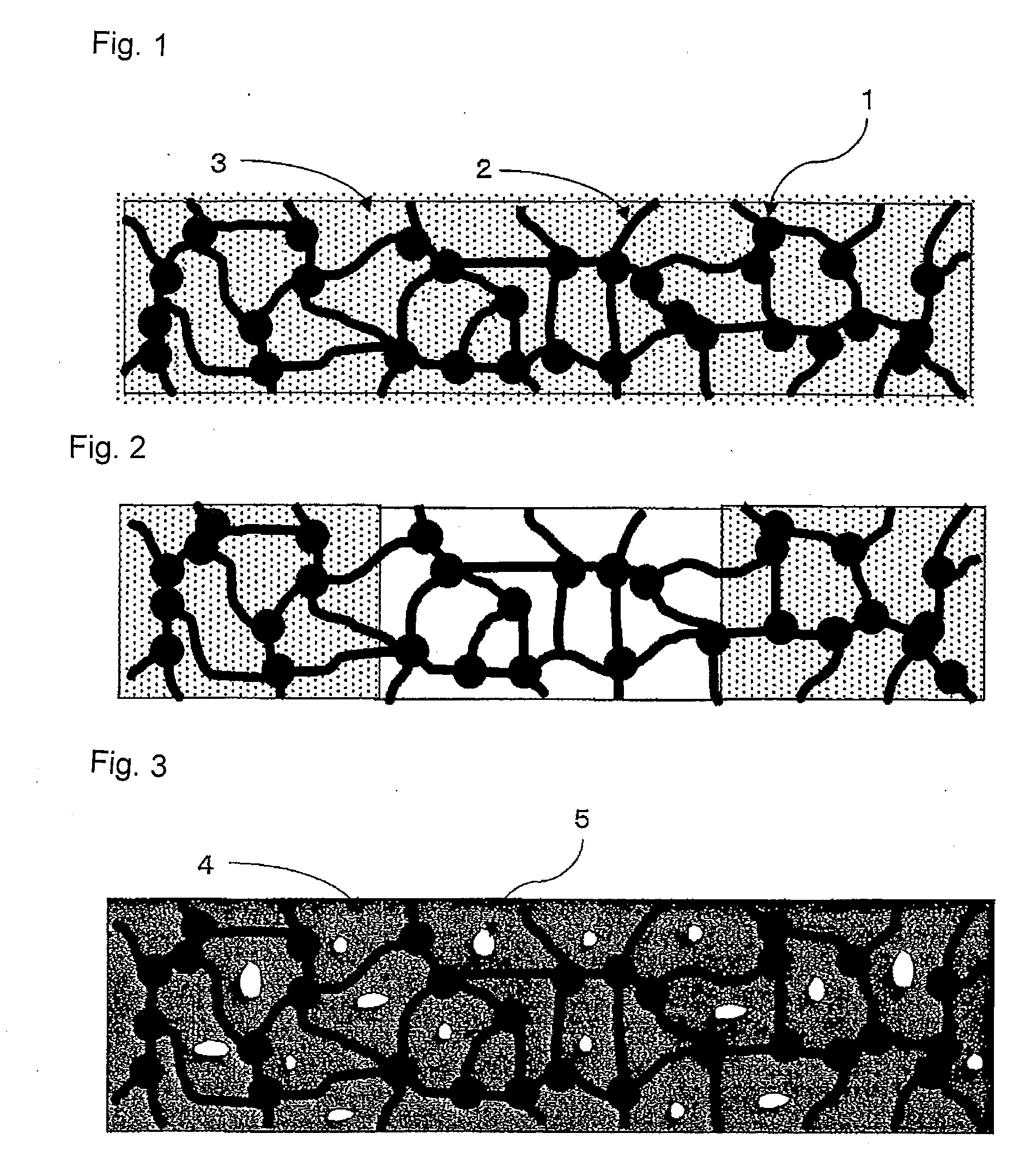

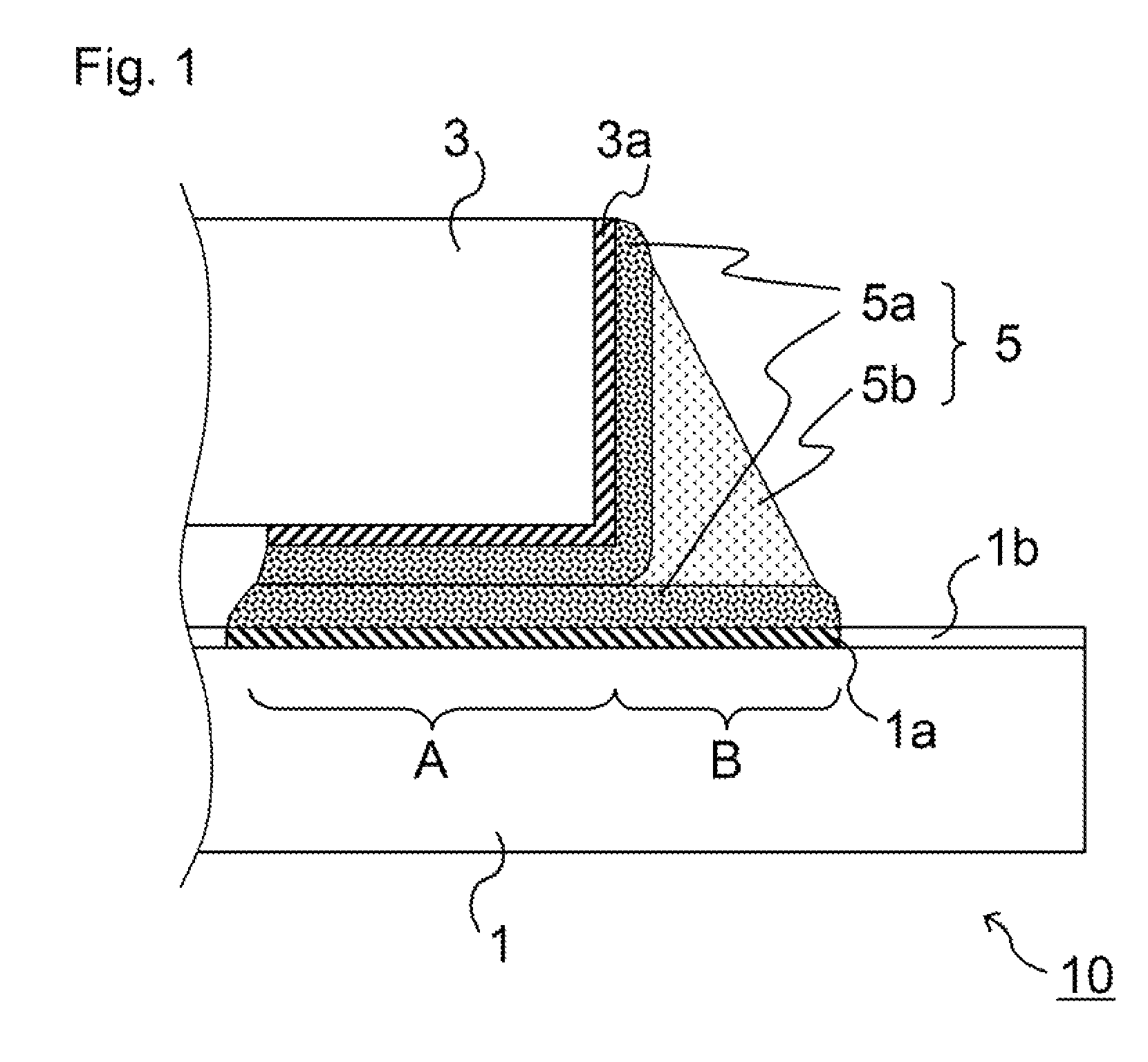

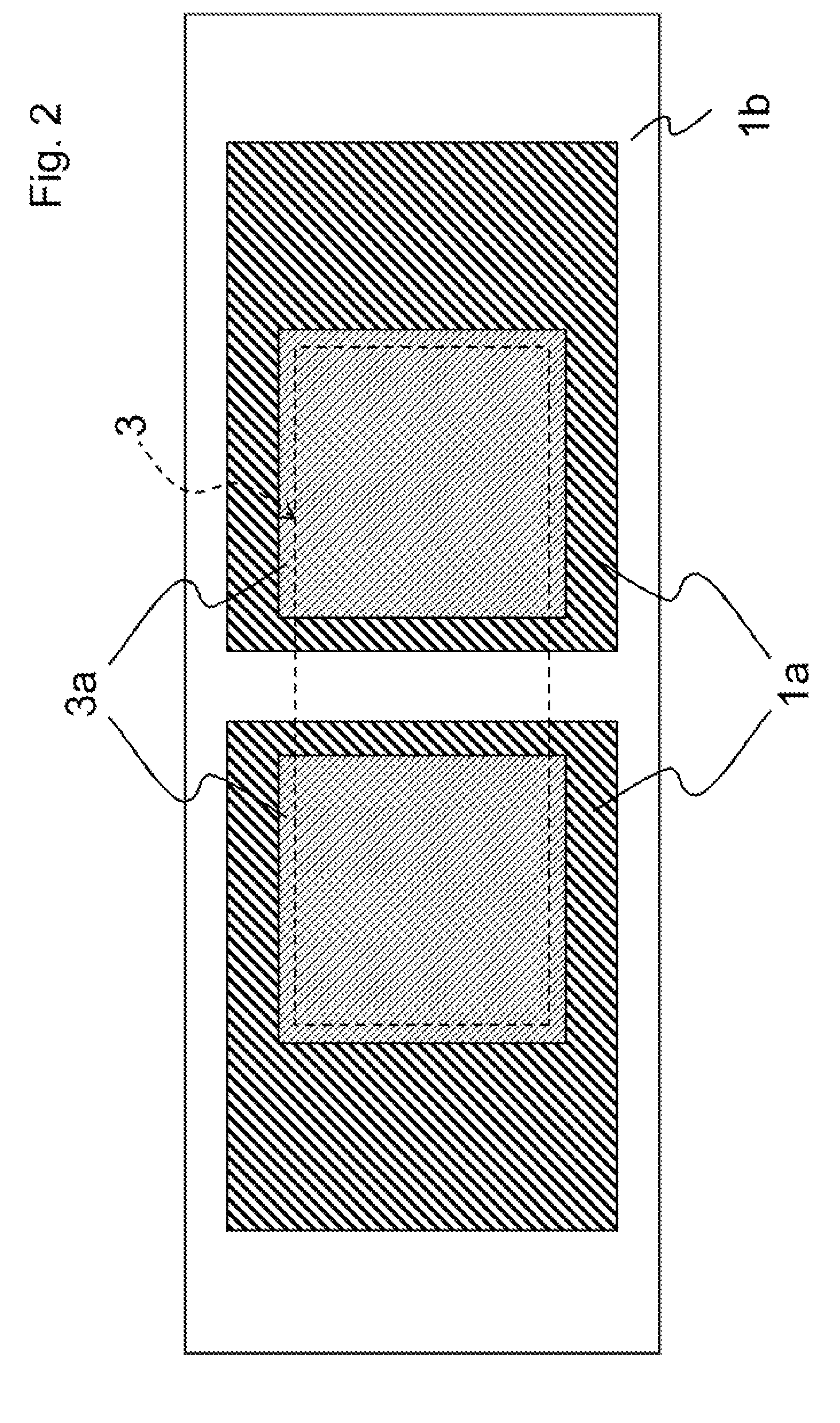

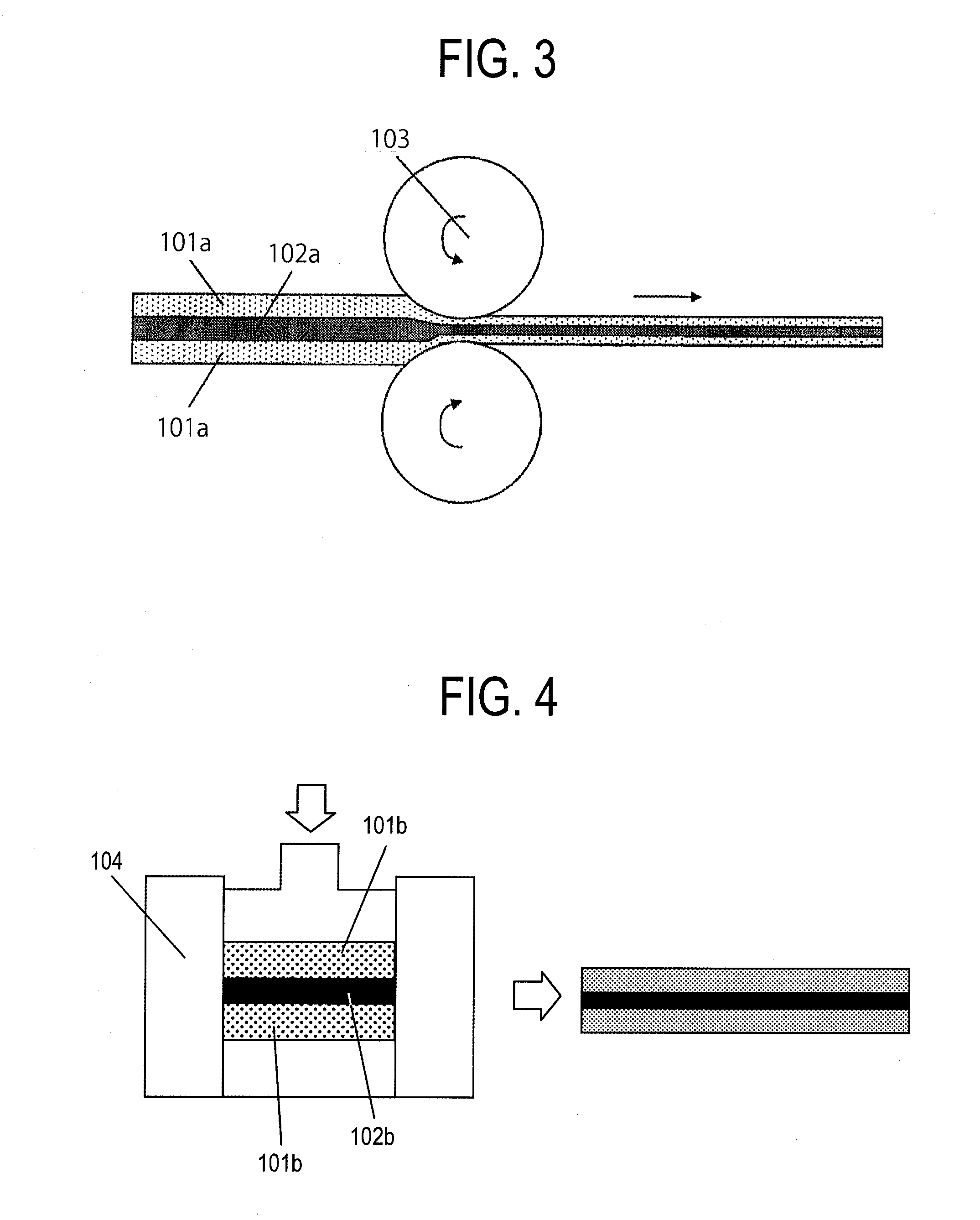

Composite Sheet and Production Method Thereof

InactiveUS20120169016A1Sufficient compressibilityHigh tensile strengthEngine sealsOther chemical processesMetallurgyCompressibility

It is an objective of the present invention to provide a composite sheet and a production method thereof, which composite sheet has excellent sealing ability, since the sheet exhibits high compressibility and yet low stress relaxation, as well as high strength and excellent pressure resistance. The objective of the present invention is also to provide a sheet gasket having the above-mentioned properties. The composite sheet according to present invention is characterized in that pores of an expanded porous PTFE sheet are filled with silica gel; and a ratio of remaining pores is not less than 5% and not more than 50%.

Owner:W L GORE & ASSOC GK

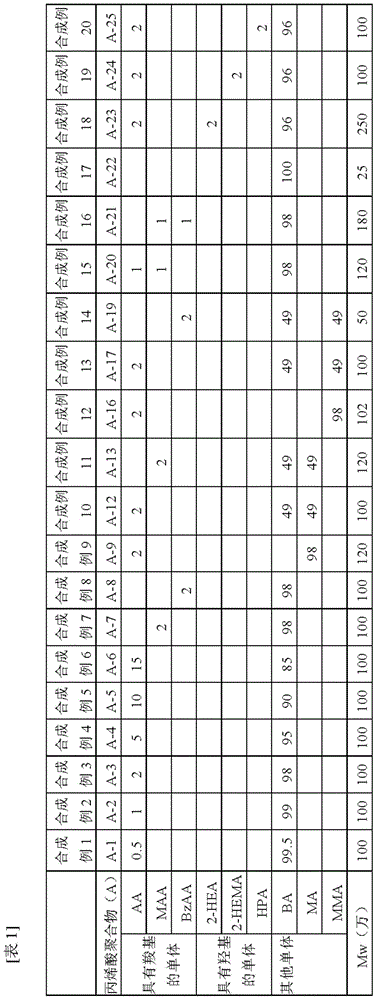

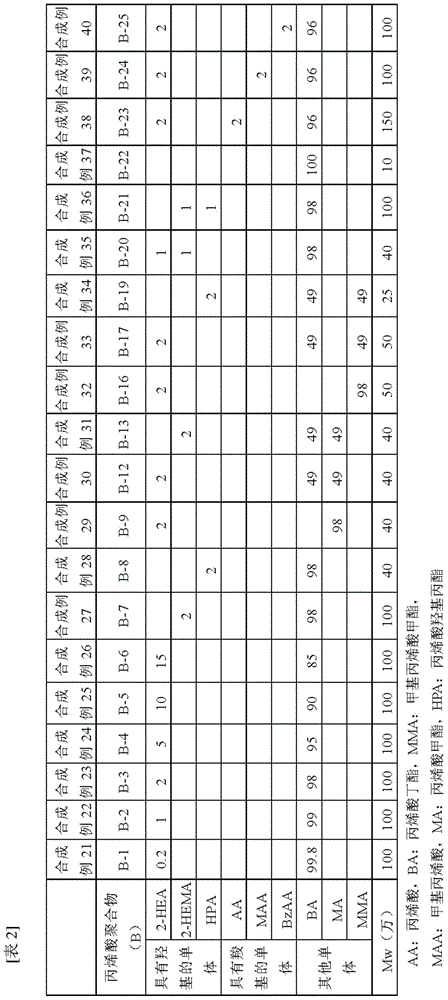

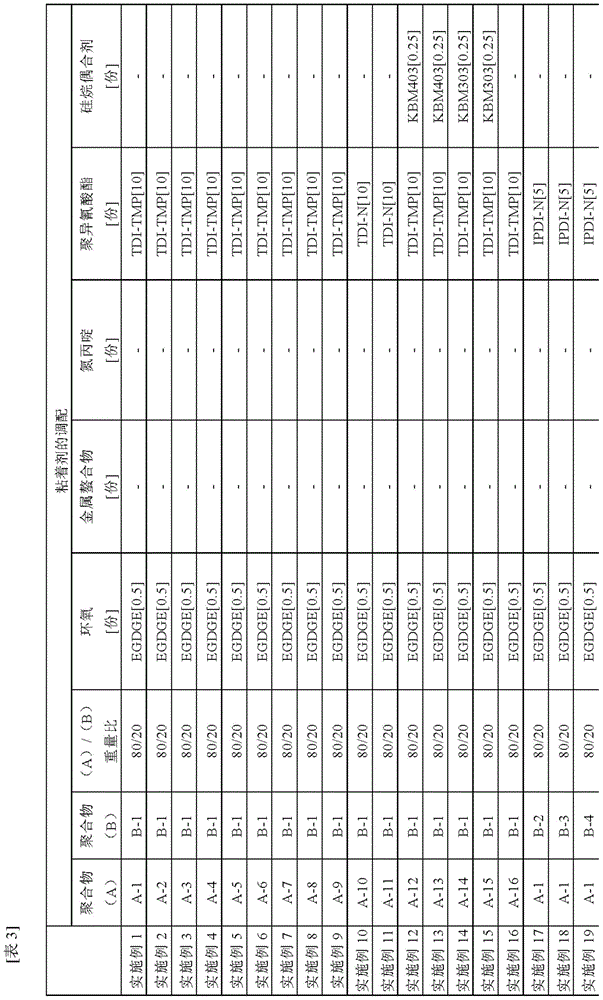

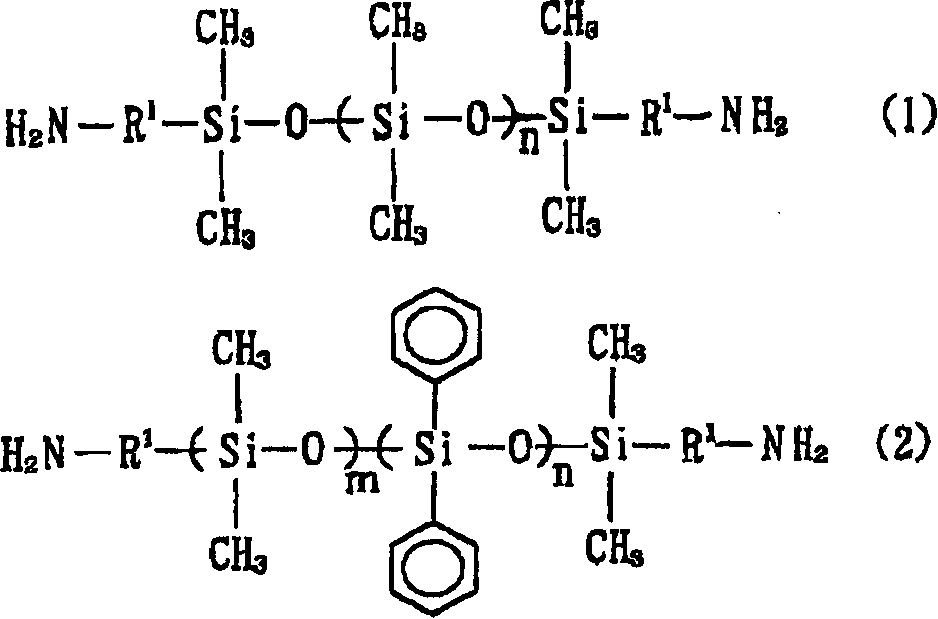

Pressure sensitive adhesive composition, pressure sensitive adhesive and pressure sensitive adhesive sheet

ActiveCN102108272AExcellent pressure sensitive adhesionExcellent resistance to light leakageNon-macromolecular adhesive additivesFilm/foil adhesivesPolarizerMethyl group

The invention provides a pressure sensitive adhesive composition with both excellent light-leak resistance and durability when applicable to optical components such as polarizer and the like, a manufacturing method of the pressure sensitive adhesive composition, a pressure sensitive adhesive and a pressure sensitive adhesive sheet. The pressure sensitive adhesive composition comprises a first (methyl) acrylate copolymer (A) with a weight average molecular weight of 700-2500 thousands, a second (methyl) acrylate copolymer (B) with a weight average molecular weight of 8-250 thousands, and a crosslinking agent (C), wherein the content of the second (methyl) acrylate copolymer (B) with respect to 100 parts by weight of the first (methyl) acrylate copolymer (A) is 5-50 parts by weight; the second (methyl) acrylate copolymer (B) contains a monomer which has a functional group (b1) with high reactivity with the crosslinking agent (C) and is used as a component element, and furthermore the content of the monomer in the second (methyl) acrylate copolymer (B) is more than 1 wt%; the first (methyl) acrylate copolymer (A) does not contain a monomer which has a functional group with reactivity with the crosslinking agent (C) and is used as a component element, or contains a monomer which has a functional group (a1) with lower reactivity with the crosslinking agent (C) than the functional group (b1) of the second (methyl) acrylate copolymer (B) and is used as a component element.

Owner:LINTEC CORP

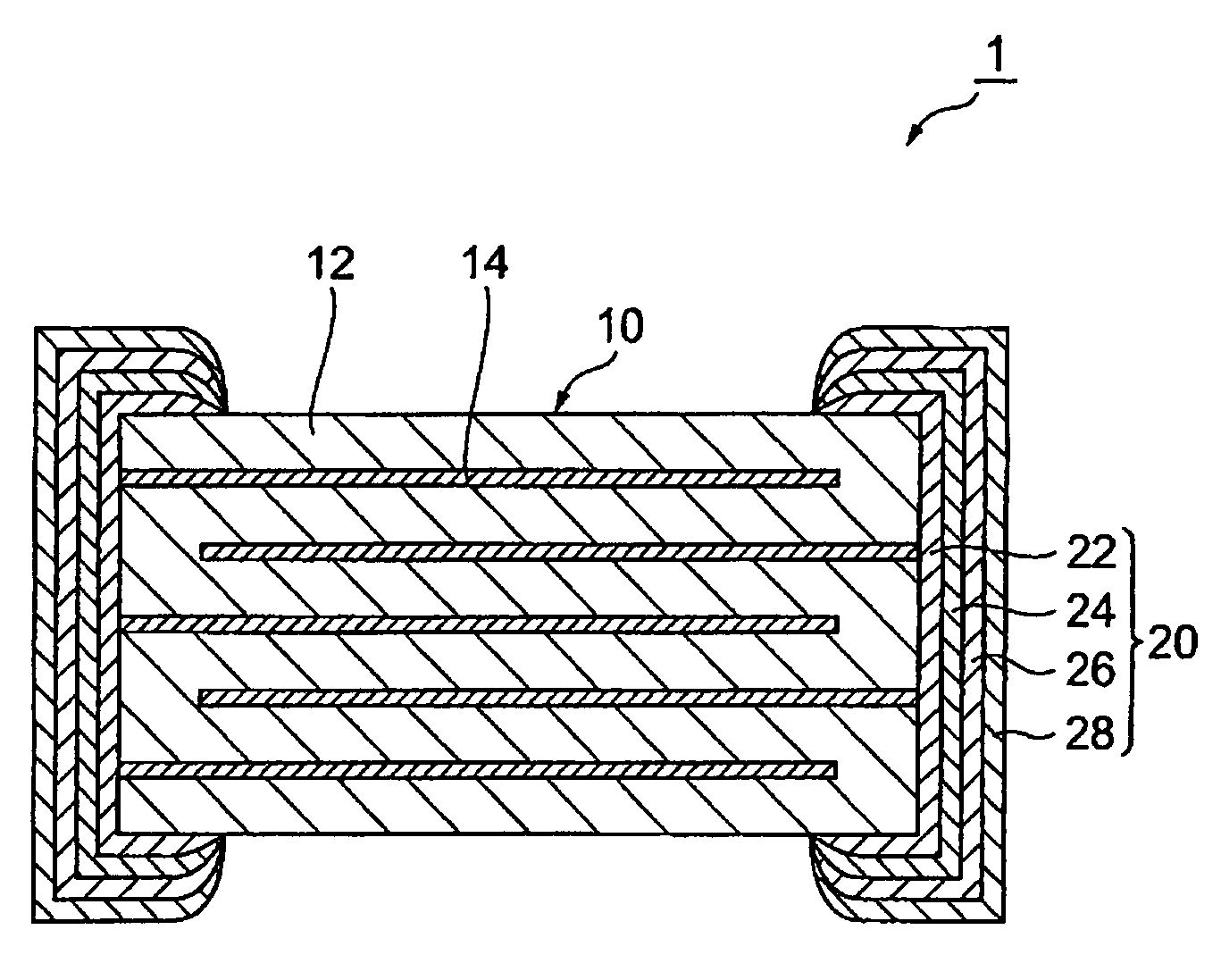

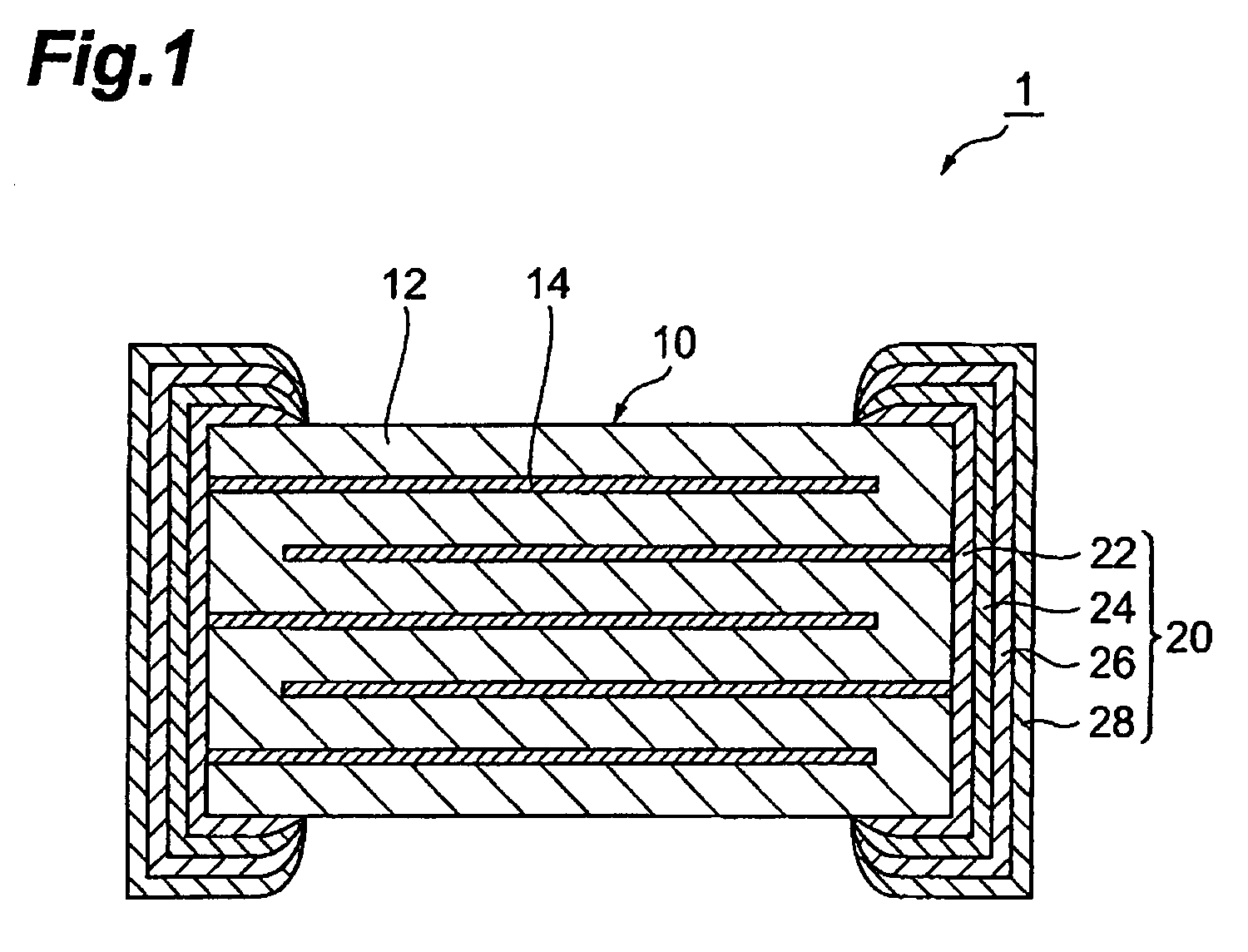

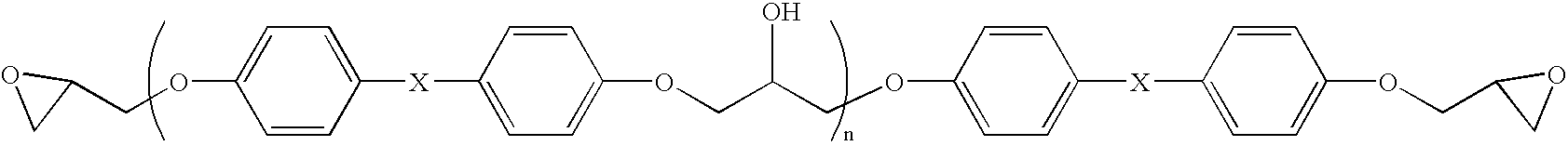

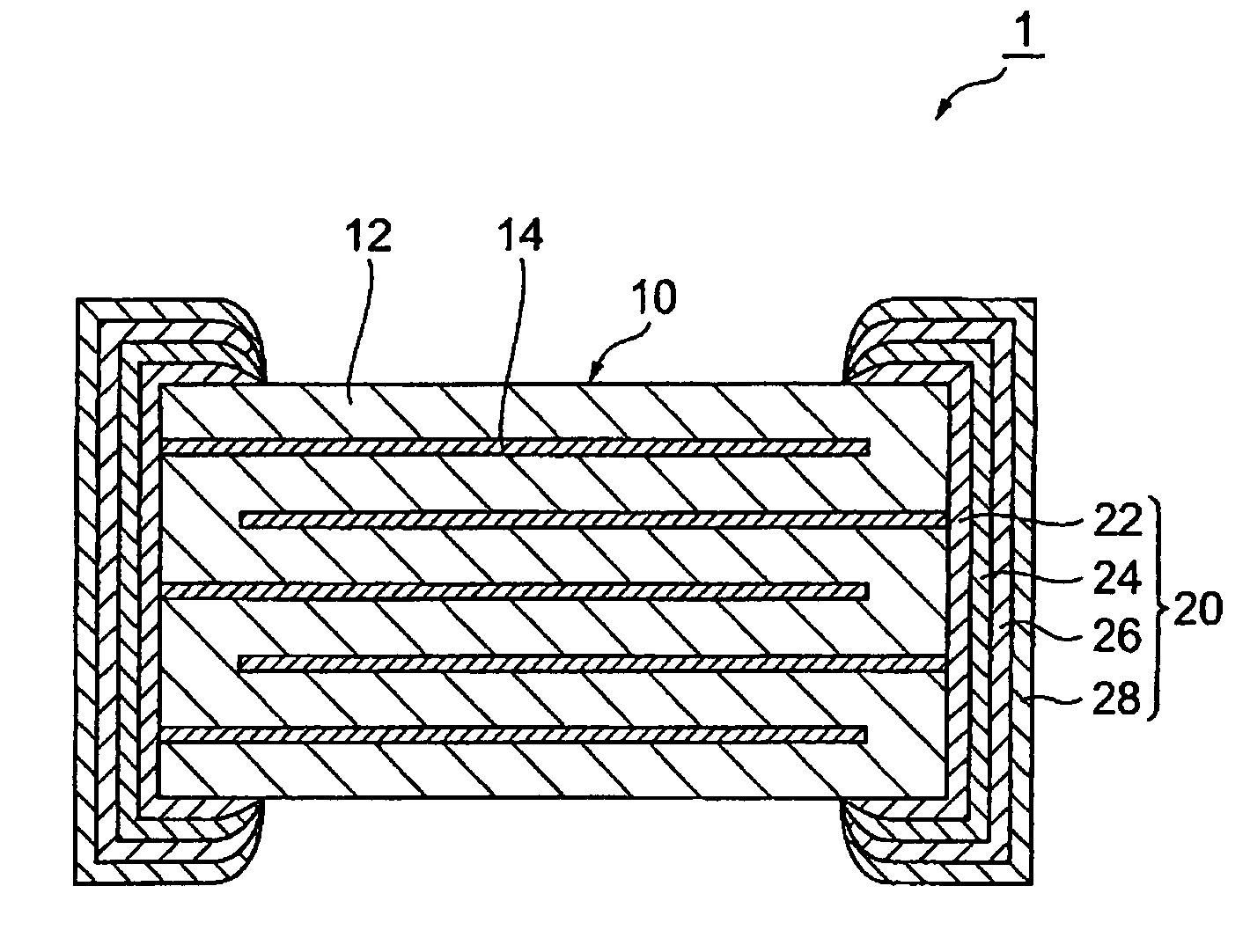

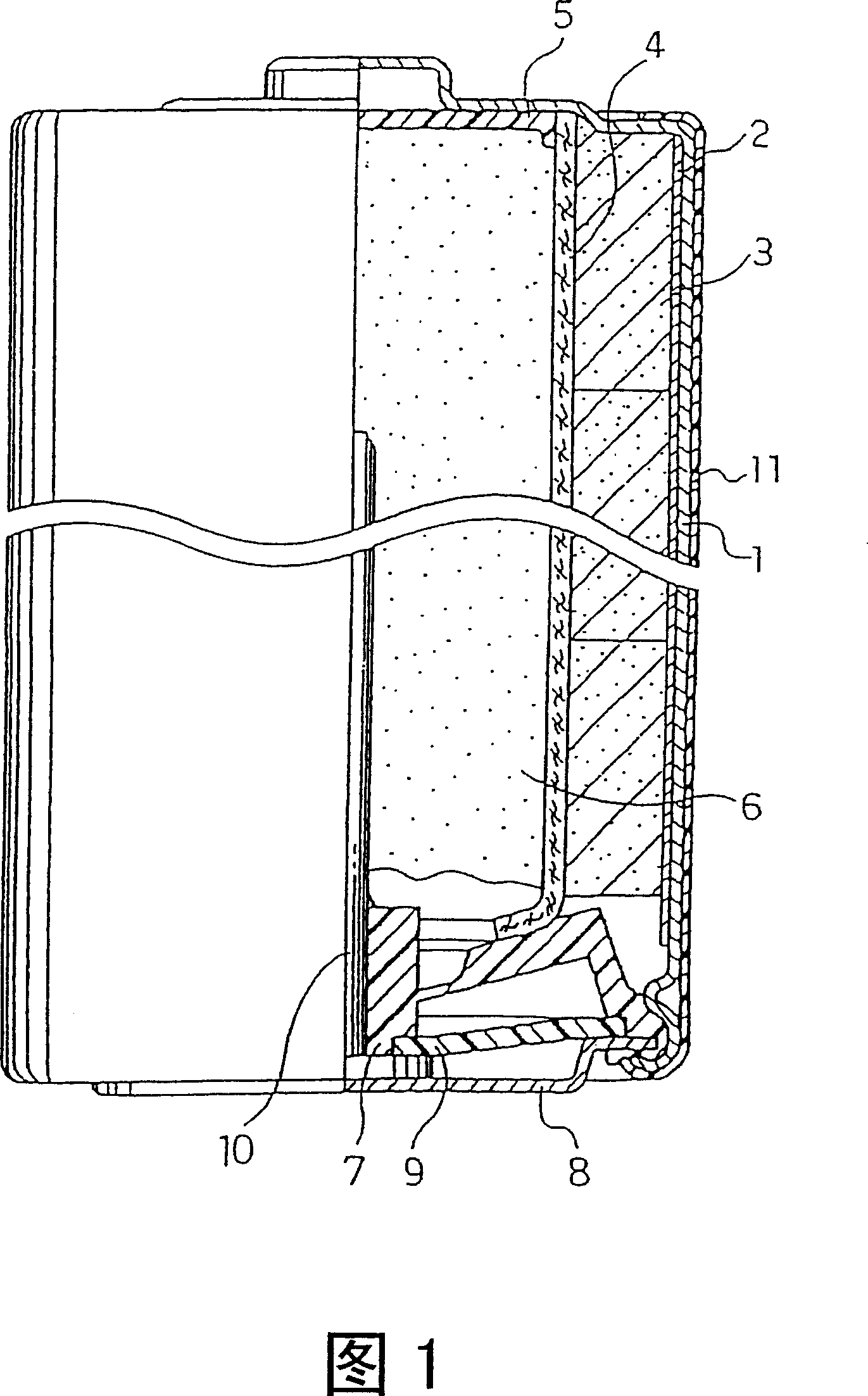

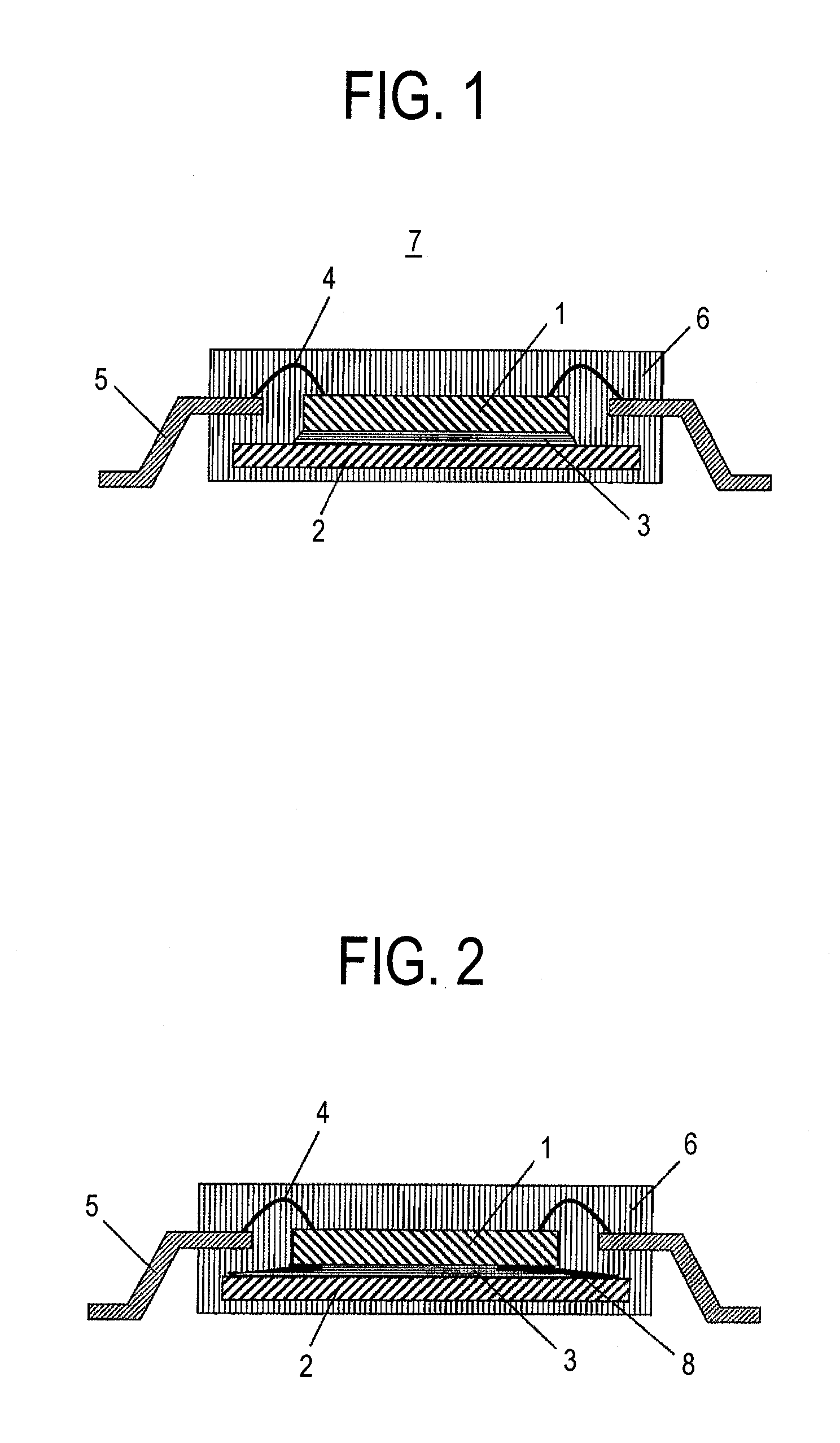

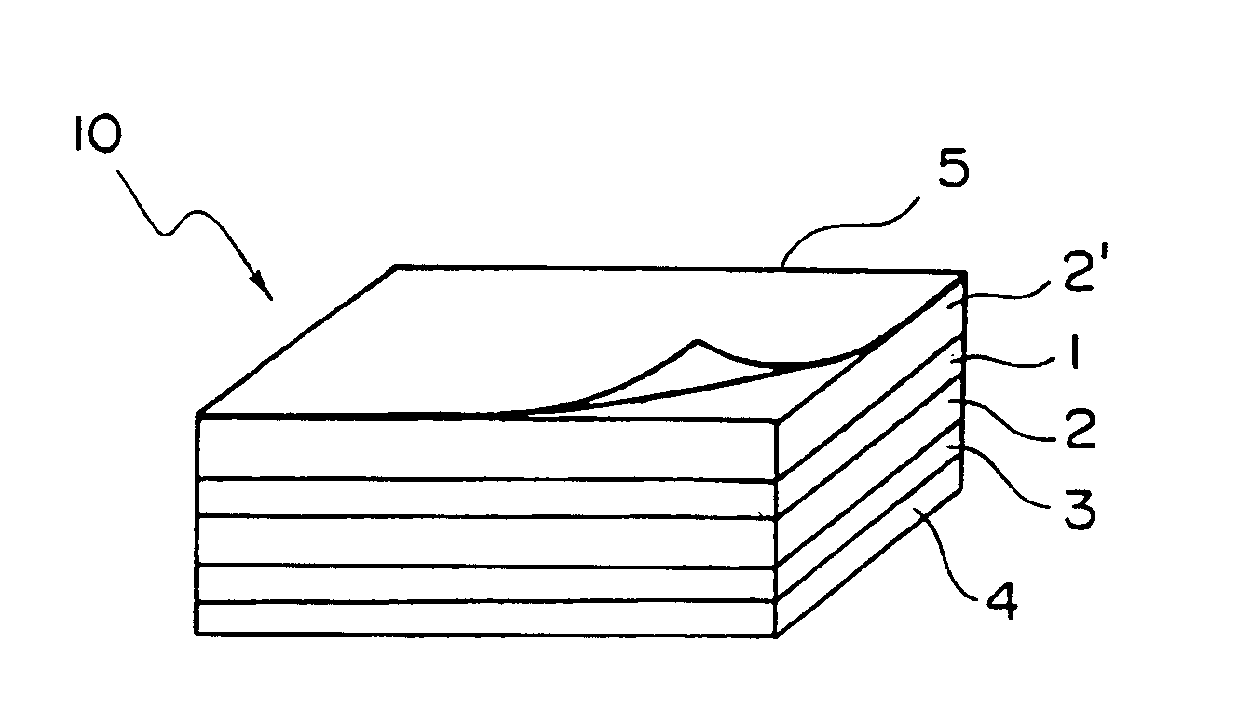

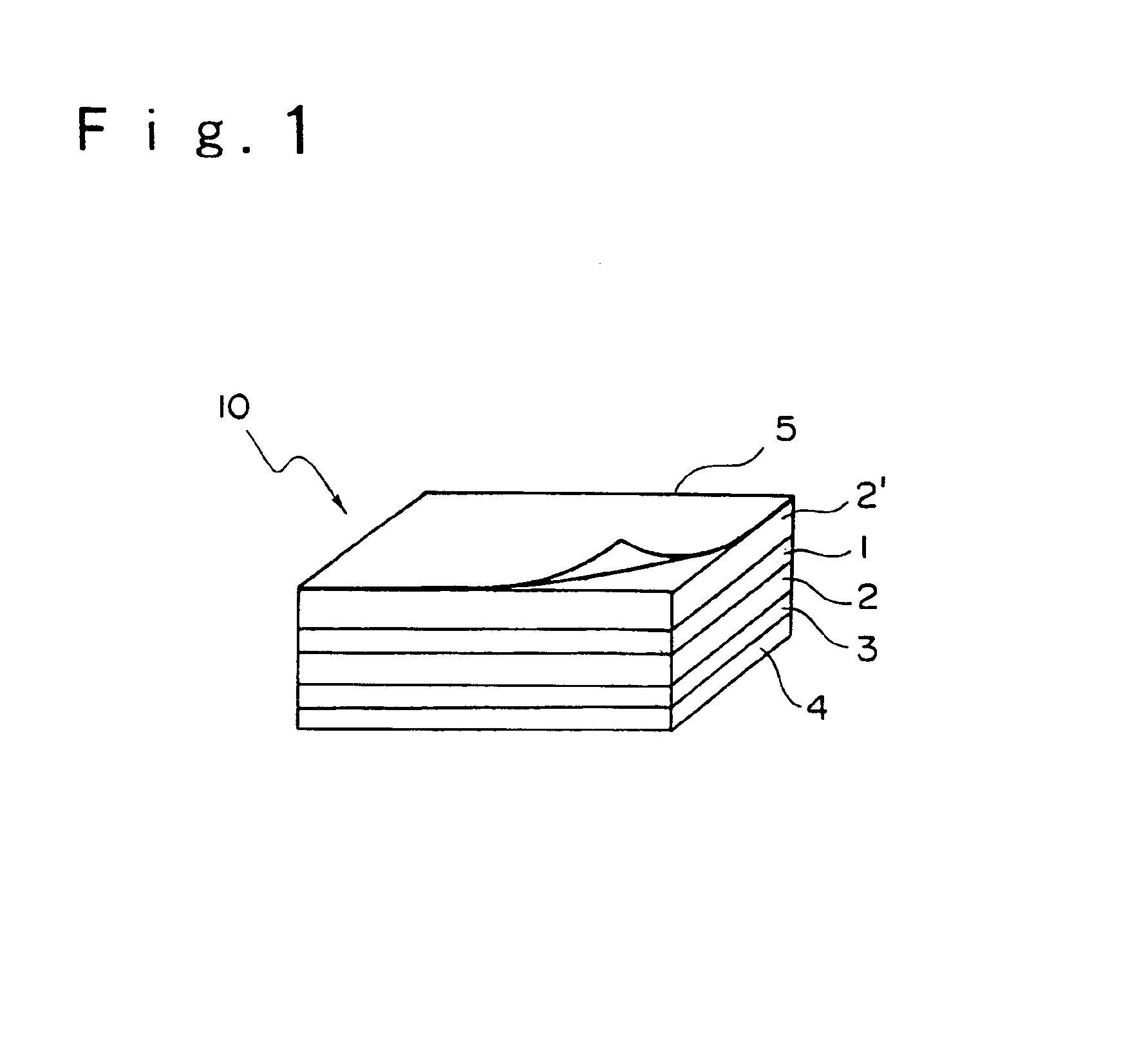

Electronic component

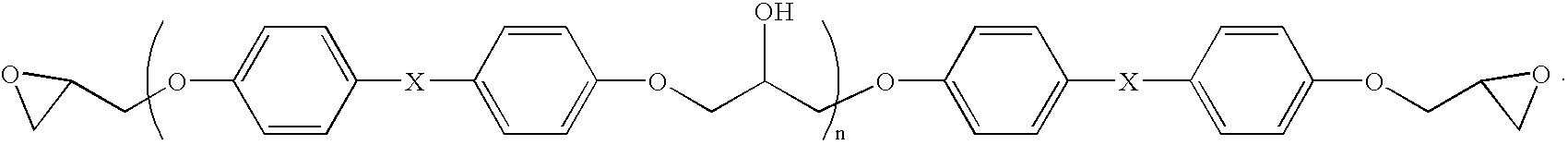

ActiveUS20070215379A1Reduce generationRatio is smallMemory architecture accessing/allocationStacked capacitorsEpoxyCeramic capacitor

The present invention aims to provide an electronic component capable of reducing the occurrence of cracks at the joining portion with a board etc. A capacitor 1 (laminated ceramic capacitor) being one example of the electronic component of the present invention is provided with an element assembly 10 (ceramic) and a pair of external electrodes 20 formed on both side surfaces of the element assembly. In the element assembly 10, a dielectric layer 12 and an internal electrode 14 are laminated alternately. The external electrode 14 has such constitution that a first electrode layer connected with the internal electrode 14, a second electrode layer (electroconductive resin layer) including a hardened product of epoxy resin containing an epoxy compound having a molecular weight of 2000 or more and plural epoxy groups as the base compound, a third electrode layer composed of Ni and a fourth electrode layer composed of Sn are formed in this order from the element assembly side.

Owner:TDK CORPARATION

Electronic component

ActiveUS7847371B2Reduce generationRatio is smallMemory architecture accessing/allocationFixed capacitor dielectricEpoxyCeramic capacitor

Owner:TDK CORPARATION

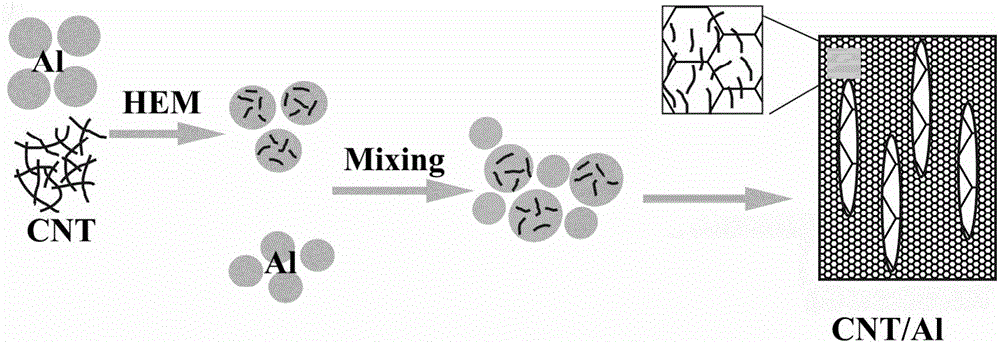

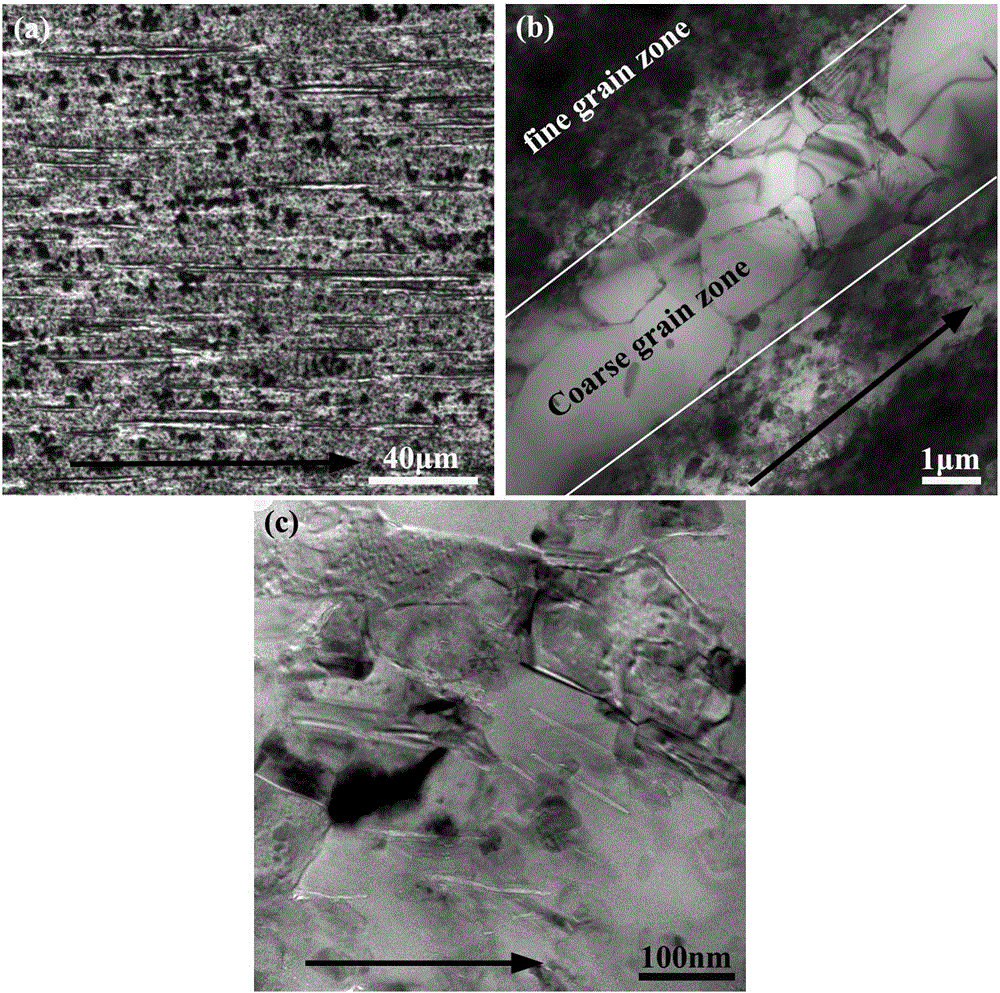

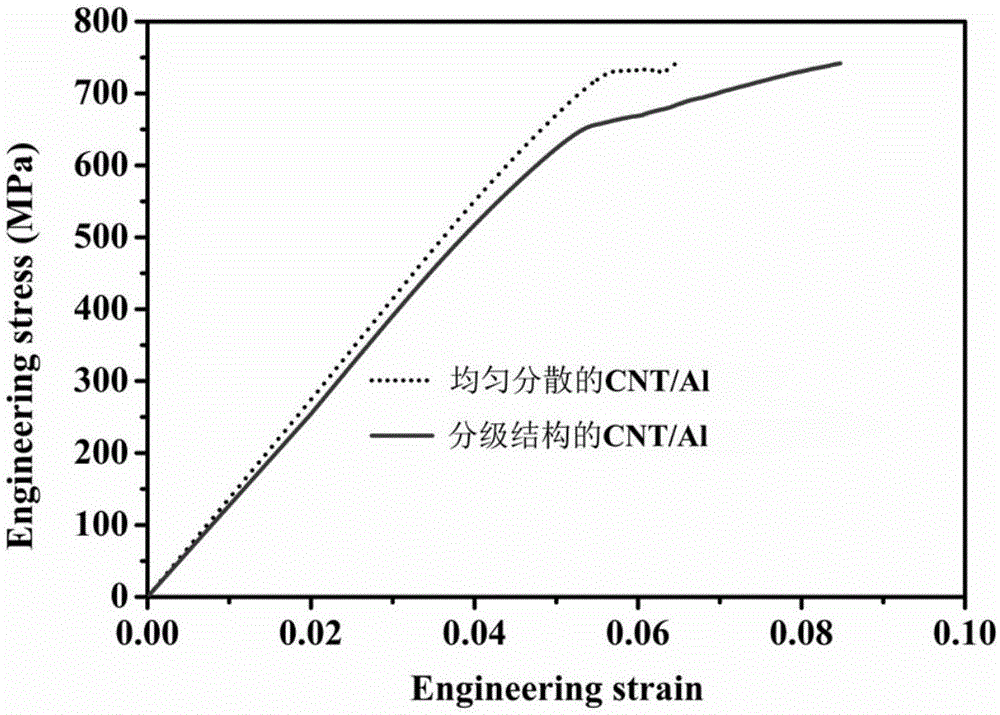

Preparing method of high-toughness carbon nanotube enhanced metal-based composite

The invention belongs to the technical field of composites, and particularly relates to a preparing method of a high-toughness carbon nanotube enhanced aluminum-based composite of a grading structure. Due to the fact that the small and fine toughness area is introduced in the carbon nanotube enhanced aluminum-based composite prepared through the method to form the grading structure, the more excellent toughness is shown compared with that of a homogeneous composite. Through high-energy ball milling, uniformly-dispersed carbon nanotube enhanced aluminum-based composite powder is prepared, micron aluminum powder is added in the composite powder secondarily, through mixing, final carbon nanotube enhanced aluminum-based composite powder is obtained, and through subsequent compactness and secondary processing, the final composite is obtained. The method has the beneficial effects that the process is simple and efficient, and large-scale production capacity is achieved; the prepared composite of the grading structure has the small and fine toughness area, and therefore the excellent strong toughness is shown.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

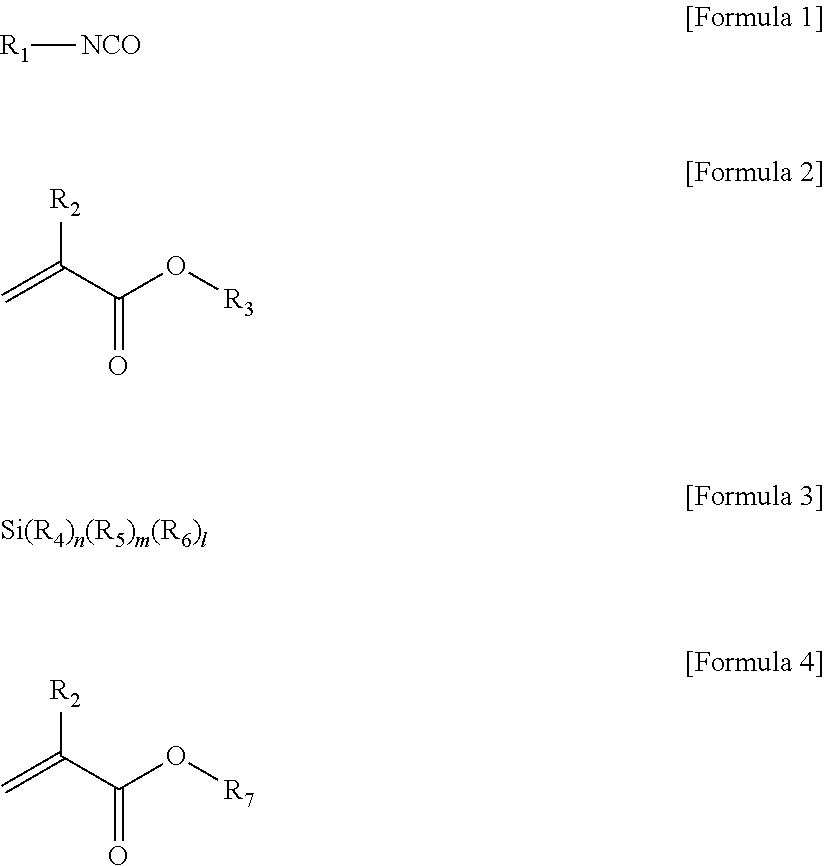

Photocurable resin composition and cured product of same, resin sheet and production method for same, and display device

InactiveUS20120114953A1Excellent reliabilityExcellent stress relaxation propertyPolyureas/polyurethane adhesivesSynthetic resin layered productsChemistryIsocyanate compound

A photocurable resin composition including: (A) a urethane (meth)acrylate oligomer having a polyoxyalkylene structure, (B) a (meth)acrylic polymer, (C) a (meth)acrylic monomer, and (D) a photopolymerization initiator, wherein the component (A) is produced using monomer components including (a1) a polyoxyalkylene polyol, (a2) a polyisocyanate, and (a3) a hydroxyl group-containing mono(meth)acrylate compound, a relationship N (=n1 / n2) between the total mass n1 of the monomer components and the total equivalent weight n2 of acryloyl groups within the all monomer components is 4,000 or greater, and the component (A) is substantially free of unreacted isocyanate groups.

Owner:HITACHI CHEM CO LTD

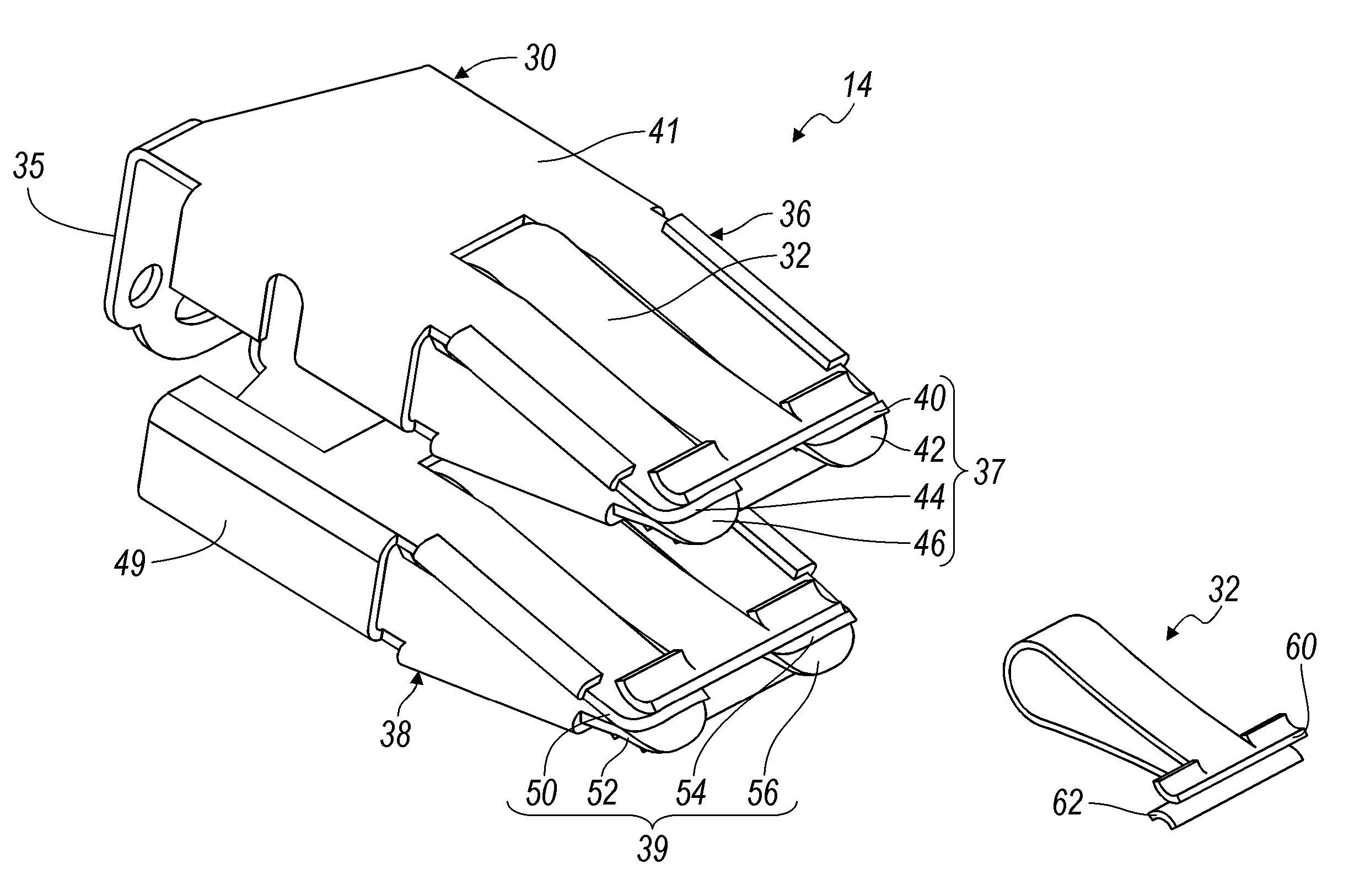

High Power Case Fuse

InactiveUS20090085712A1Increase powerGreat mechanical stress propertyIncorrect coupling preventionCoupling contact membersEngineeringElectrical and Electronics engineering

A high power fuse includes a fuse body having a first terminal receptor including a first set of terminal legs and a second terminal receptor in spaced relation to the first terminal receptor. The second terminal receptor includes a second set of terminal legs. A fuse element is disposed between the first terminal receptor and the second terminal receptor. A first clamp-like member is mounted to the fuse body for applying a predetermined compression force against the first set of terminal legs and is configured to secure a first male terminal between the first set of terminal legs. A second clamp-like member is mounted to the fuse body for applying a predetermined compression force against the second set of terminal legs and is configured to secure a second male terminal between the second set of terminal legs.

Owner:LEAR CORP

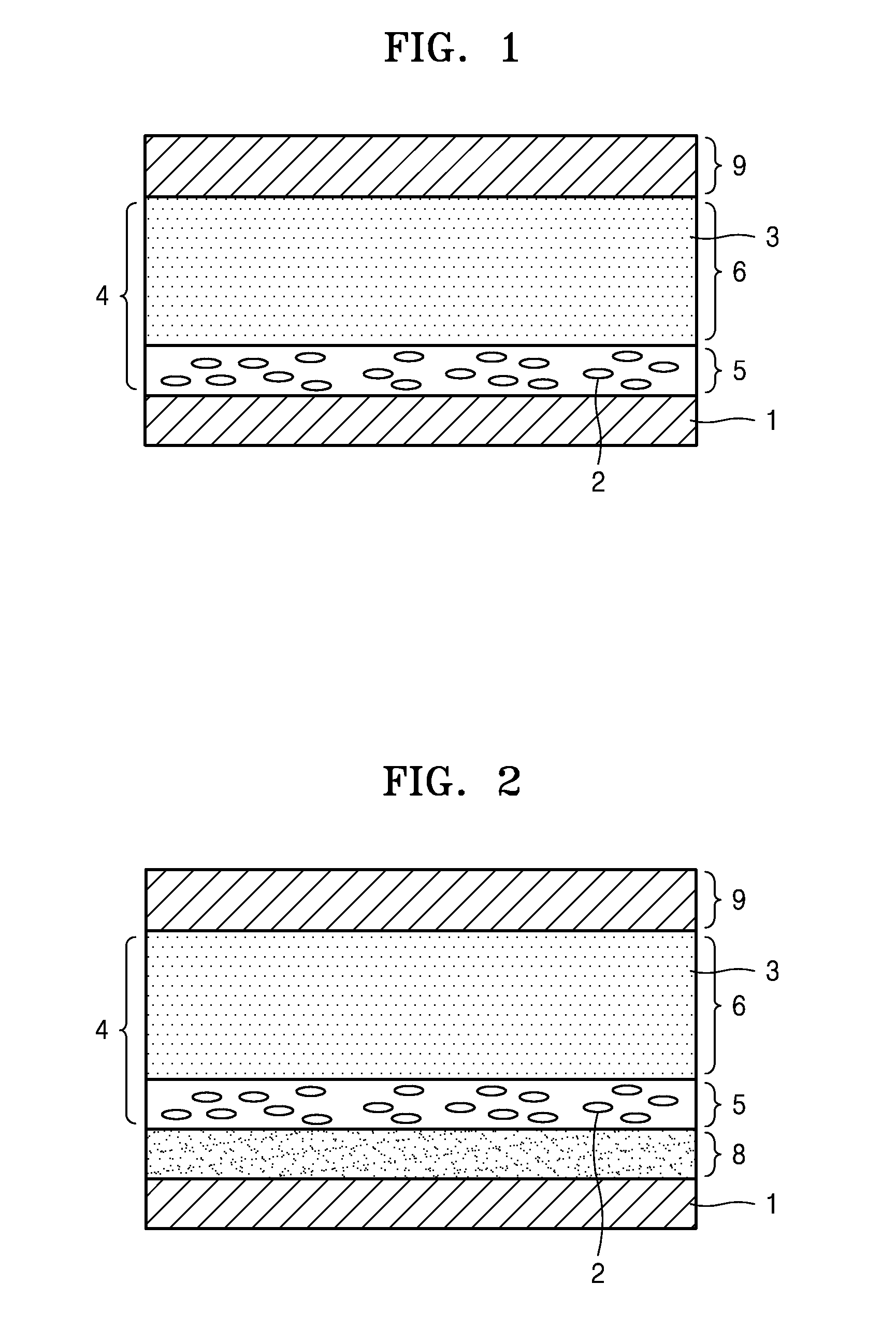

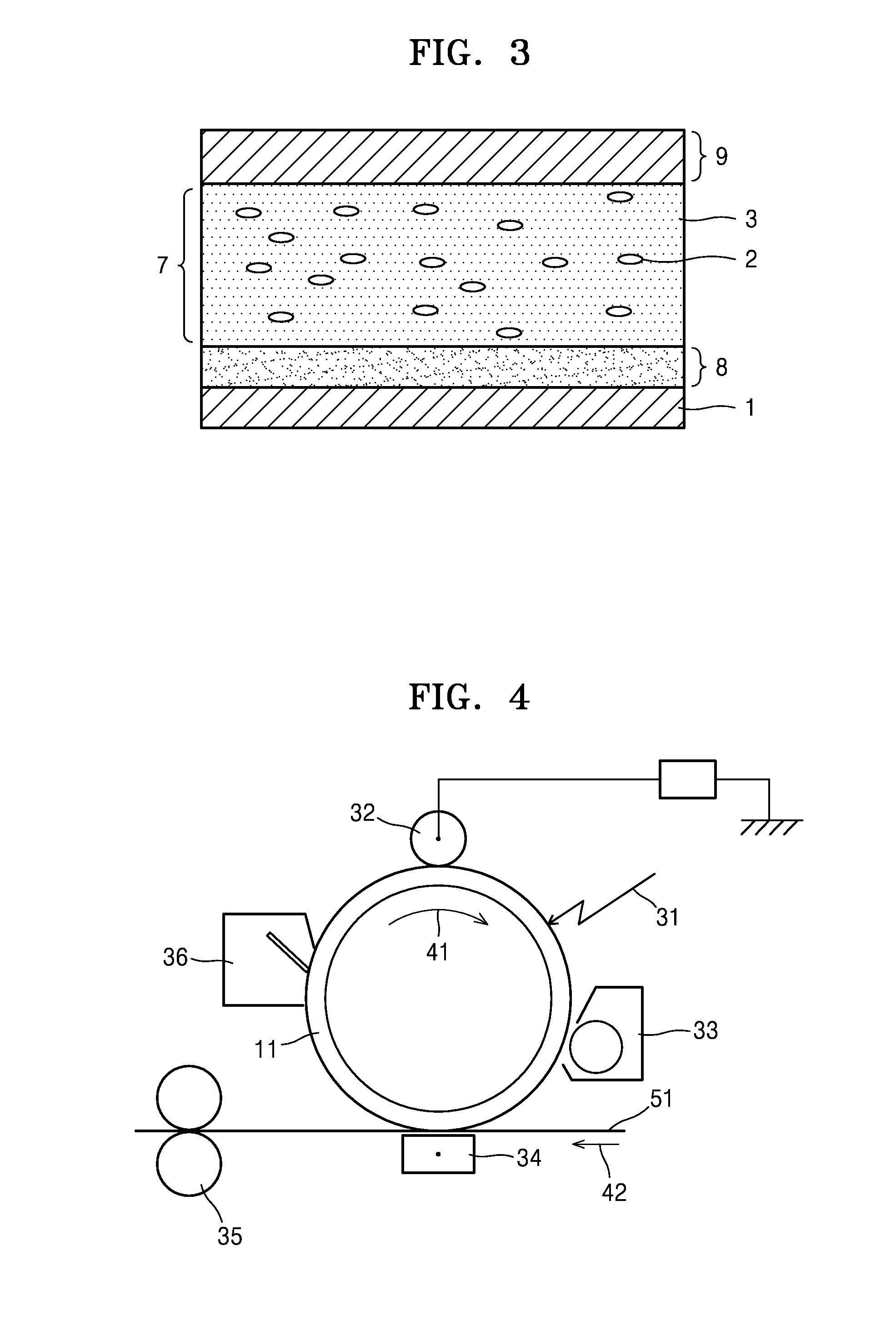

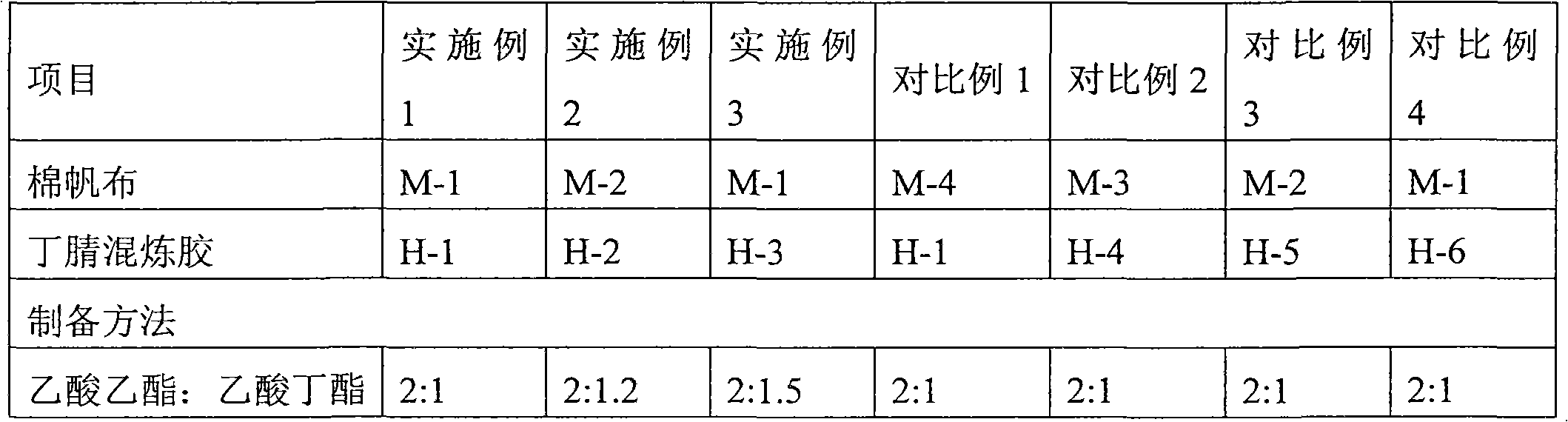

Organic photoreceptor, and electrophotographic cartridge and electrophotographic imaging apparatus including the same

ActiveUS20150192869A1High hardnessIncrease elasticityElectrographic process apparatusCorona dischargeOligomerImaging equipment

An organic photoreceptor including a photosensitive layer disposed on an electrically conductive substrate; and a protective layer disposed on the photosensitive layer, wherein the protective layer includes a cured product of a multifunctional acrylic oligomer including a urethane group and a multifunctional curable compound including a dendrimeric structure.

Owner:SAMSUNG ELECTRONICS CO LTD

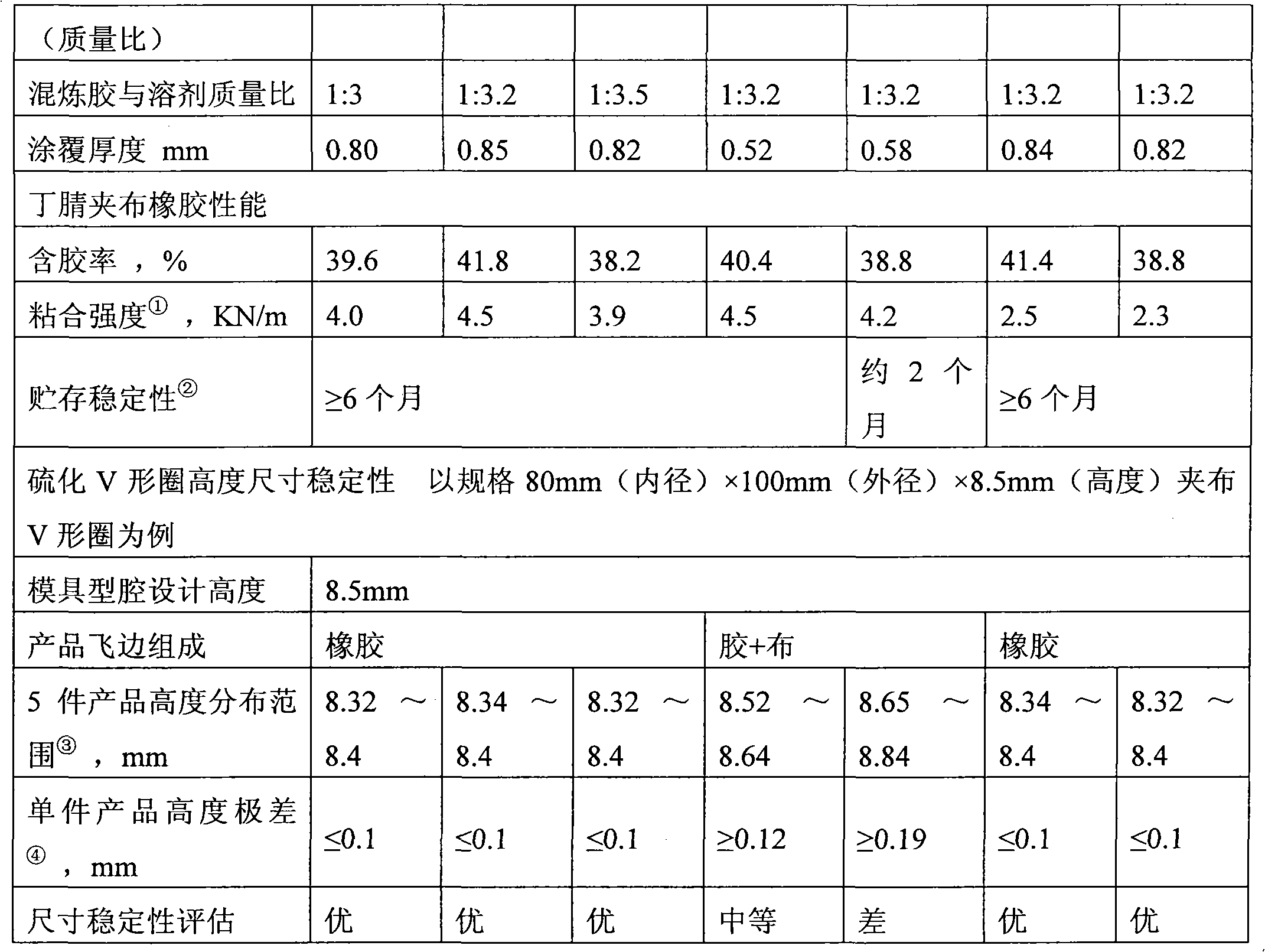

Butyronitrile canvas filler rubber and preparation method and application thereof

InactiveCN101880973AEasy to solveAvoid uniformityEngine sealsFibre treatmentHydraulic cylinderPolymer science

The invention provides butyronitrile canvas filler rubber and a preparation method and application thereof. The butyronitrile canvas filler rubber is prepared by applying butyronitrile rubber mixture onto cotton canvas with the unit area weight of 550 to 600g / m<2> and the thickness of 0.62 to 0.66mm, the thickness of the butyronitrile canvas filler rubber is 0.8 to 0.85mm, and the content of the butyronitrile rubber mixture in percentage by mass is 38 to 42 percent. The method first prepares the butyronitrile rubber mixture, then dissolves the butyronitrile rubber mixture into solvent to prepare glue, and then applies the glue onto the cotton canvas to prepare the butyronitrile canvas filler rubber. The butyronitrile canvas filler rubber has high adhesive strength and good storage stability, and a V-shaped ring prepared form the rubber has the advantages of small single product height range and excellent size stability, and can be used for hydraulic cylinder pistons and piston rods with precise height size.

Owner:GUANGZHOU MECHANICAL ENG RES INST

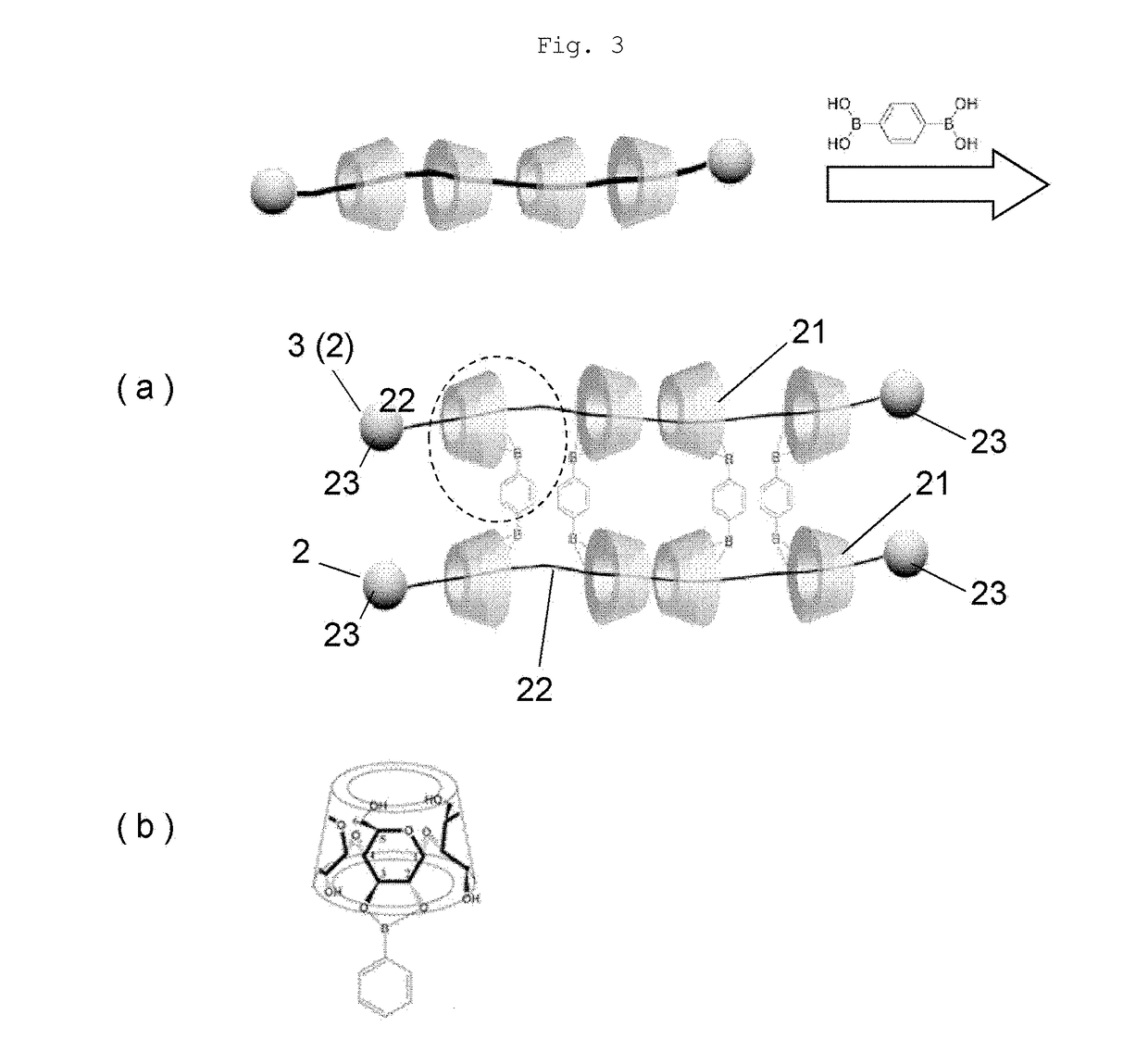

Adhesive composition, adhesive, and adhesive sheet

ActiveCN103360997AFavorable inventory burdenFavorable production efficiencyMacromolecular adhesive additivesEster polymer adhesivesPolymer sciencePolyrotaxane

An adhesive composition, an adhesive, and an adhesive sheet are suitable for optical components such as a polarized sheet and have excellent stress relaxation property. The adhesive composition comprises monomer units which form a polymer, a (methyl) acrylate polymer (A) which has carboxyl-contained monomers and has weight-average molecular weight of being 500,000 to 3 million, and a reactive polyrotaxane compound (B) containing cyclic oligosaccharide having polymerized double bonds.

Owner:LINTEC CORP

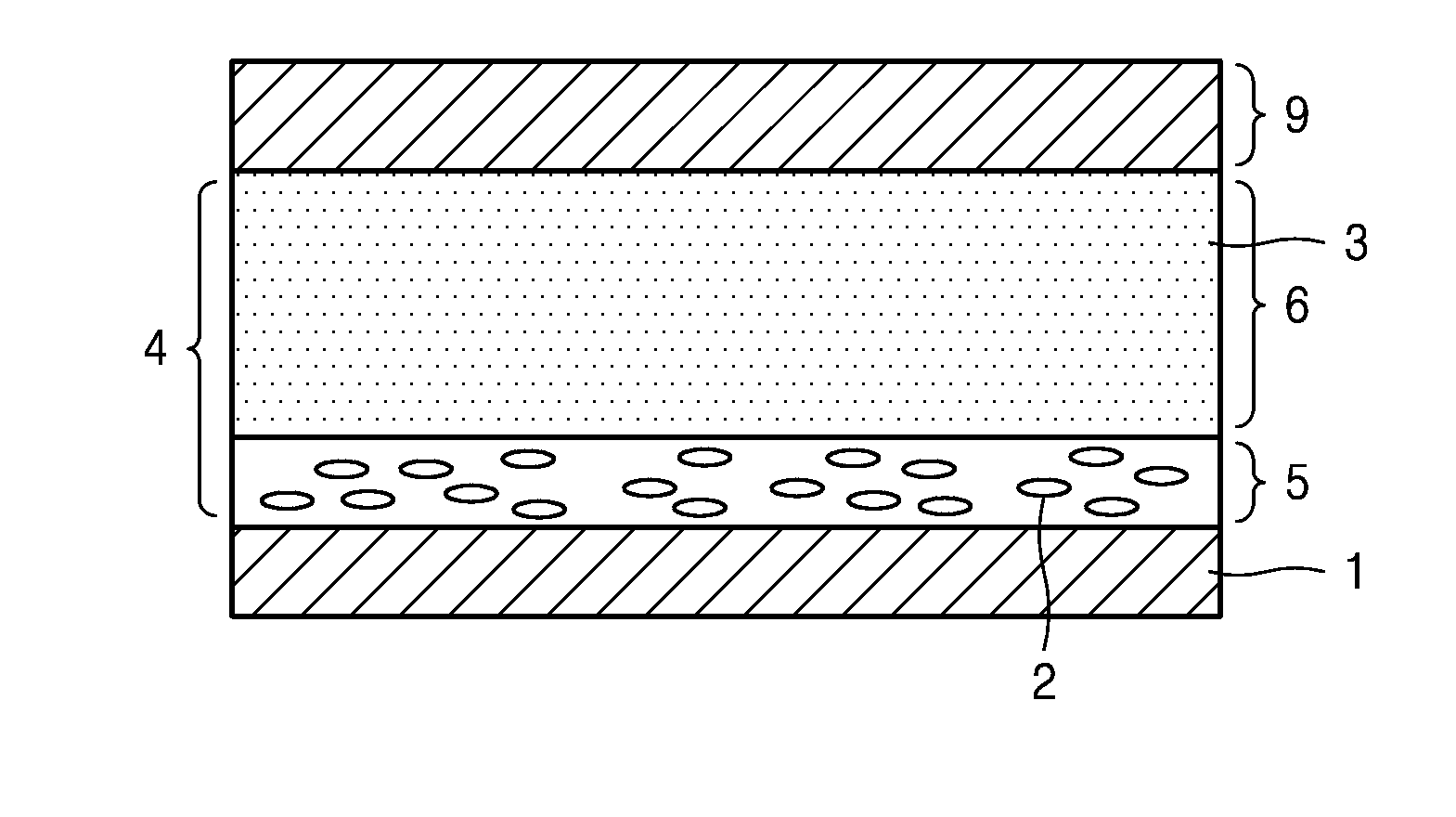

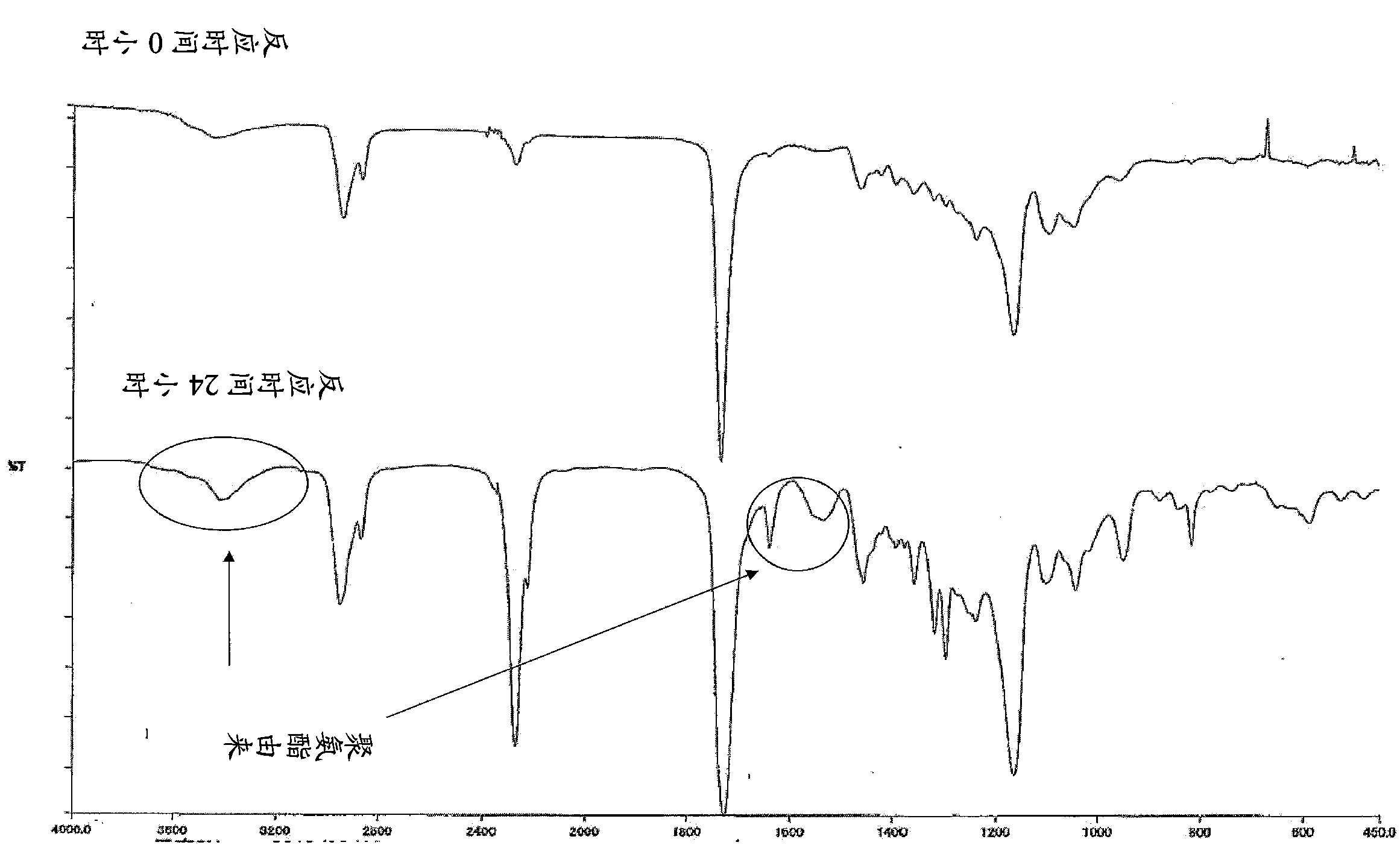

Alkali battery

InactiveCN1969414AImprove electronic conductivityExcellent stress relaxationSecondary cellsAlkaline accumulator electrodesElectrolysisGraphite

An alkali battery comprising a positive electrode, a negative electrode and an alkali electrolyte, wherein the positive electrode contains a positive electrode mixture containing nickel oxyhydroxide, electrolytic manganese dioxide and expanded graphite, this expanded graphite having an average particle diameter on volume basis of 5 to 25 m, a BET specific surface area of 4 to 10 m2 / g and a bulk specific gravity (apparent density), measured by the still standing method, of 0.03 to 0.10 g / cm3, the nickel oxyhydroxide exhibiting an average nickel valence of = 3.05, the content of the expanded graphite being in the range of 3 to 15 wt.% based on the total amount of the nickel oxyhydroxide, electrolytic manganese dioxide and expanded graphite contained in the positive electrode mixture.

Owner:PANASONIC CORP

Thermoplastic elastomer composition

Disclosed is a thermoplastic elastomer composition which is composed of 35-50 parts by mass of a hydrogenated block copolymer (a) having a weight average molecular weight of 70,000-120,000, 30-50 parts by mass of a softening agent (b) for rubber, and 5-25 parts by mass of a polystyrene resin (c) having a weight average molecular weight of 100,000-400,000 (provided that the total of (a), (b) and (c) is 100 parts by mass). The hydrogenated block copolymer (a) is obtained by hydrogenating a block copolymer having at least two polymer block A's mainly containing a vinyl aromatic compound unit and at least one polymer block B mainly containing a conjugated diene unit. In this hydrogenated block copolymer (a), the vinyl aromatic compound unit is contained in an amount of 35-45% by mass, and not less than 50% of carbon-carbon double bonds respectively derived from the conjugated diene in the polymer block B is hydrogenated.

Owner:KURARAY CO LTD

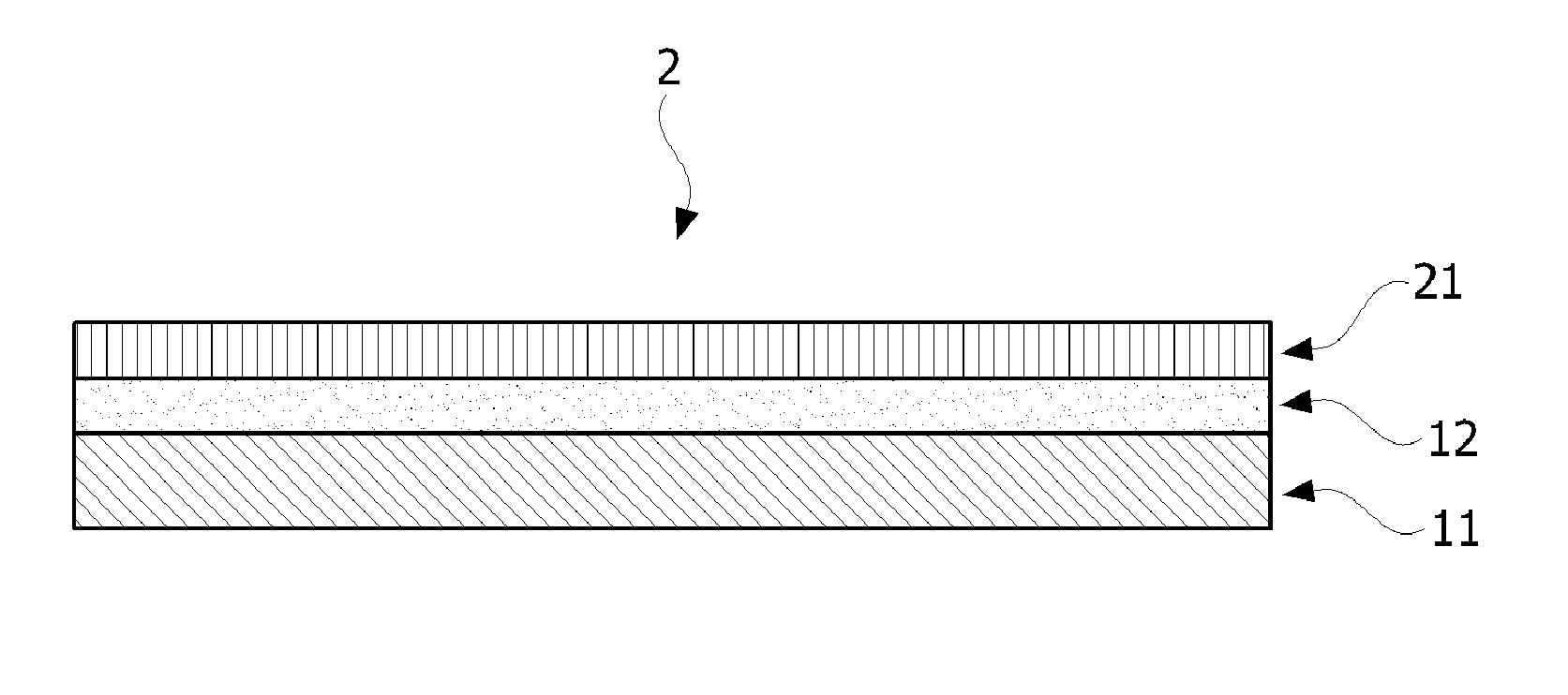

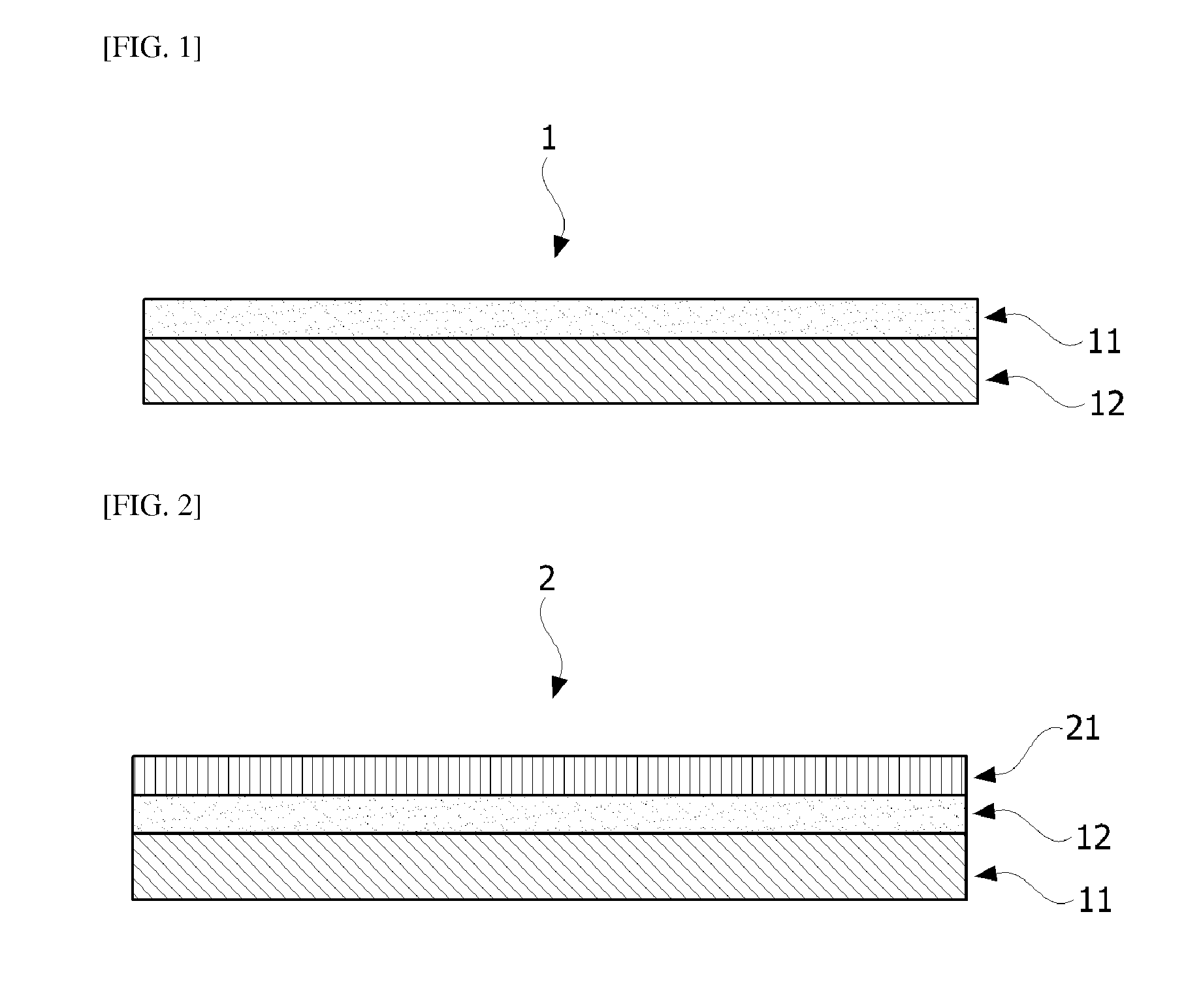

Substrate film and method of manufacturing the same

ActiveUS20140045319A1Increase thermal resistanceGood dimensional stabilityFilm/foil adhesivesPolyureas/polyurethane adhesivesHeat resistanceStress relaxation

Provided are a substrate film and a method of manufacturing the substrate film. The substrate film may have excellent thermal resistance and dimensional stability, has excellent stress relaxation to prevent damage of a wafer caused by remaining stress, inhibits damage to or flying-off of the wafer caused by application of a non-uniform pressure during the processing of the wafer, and has excellent cuttability. Accordingly, the substrate film of the present invention can be effectively used as a processing sheet in a process of processing various kinds of wafers including dicing, back-grinding or picking-up.

Owner:LG CHEM LTD

Silver-coated resin particles, method for manufacturing same, and electroconductive paste using same

ActiveUS20170358384A1Improve heat resistanceReadily availableConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialConductive pasteSilver coating

A silver-coated resin particle including a heat-resistant resin core particle and a silver coating layer formed on the surface of the resin core particle. The average grain diameter of the resin core particle is 0.1 to 10 μm, the amount of silver contained in the silver coating layer is 60 to 90 parts by mass, relative to 100 parts by mass of the silver-coated resin particle, and the exothermic peak temperature of the silver-coated resin particle by differential thermal analysis is 265° C. or higher.

Owner:MITSUBISHI MATERIALS ELECTRONICS CHEM CO LTD

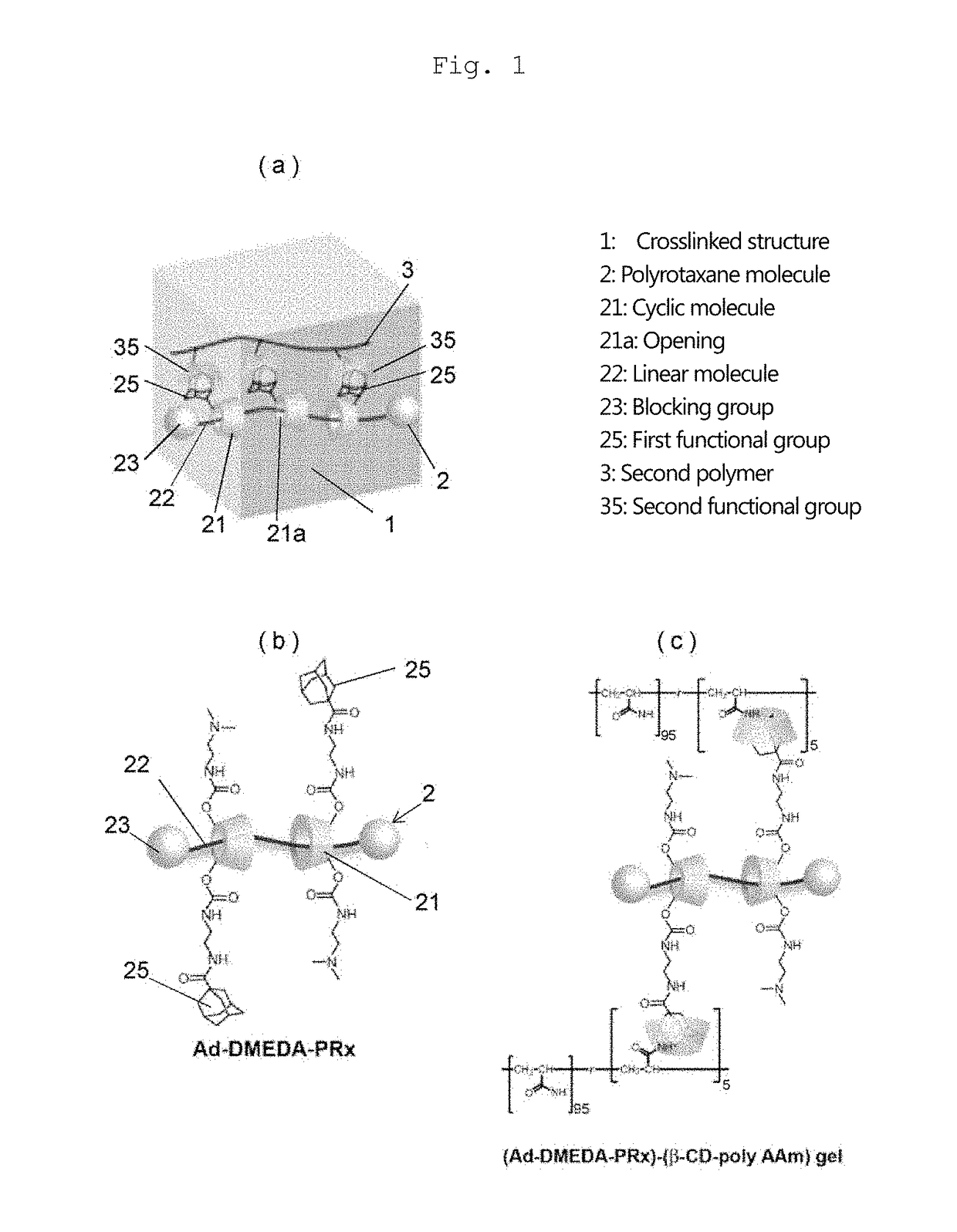

Self-restoring macromolecular material and production method for same

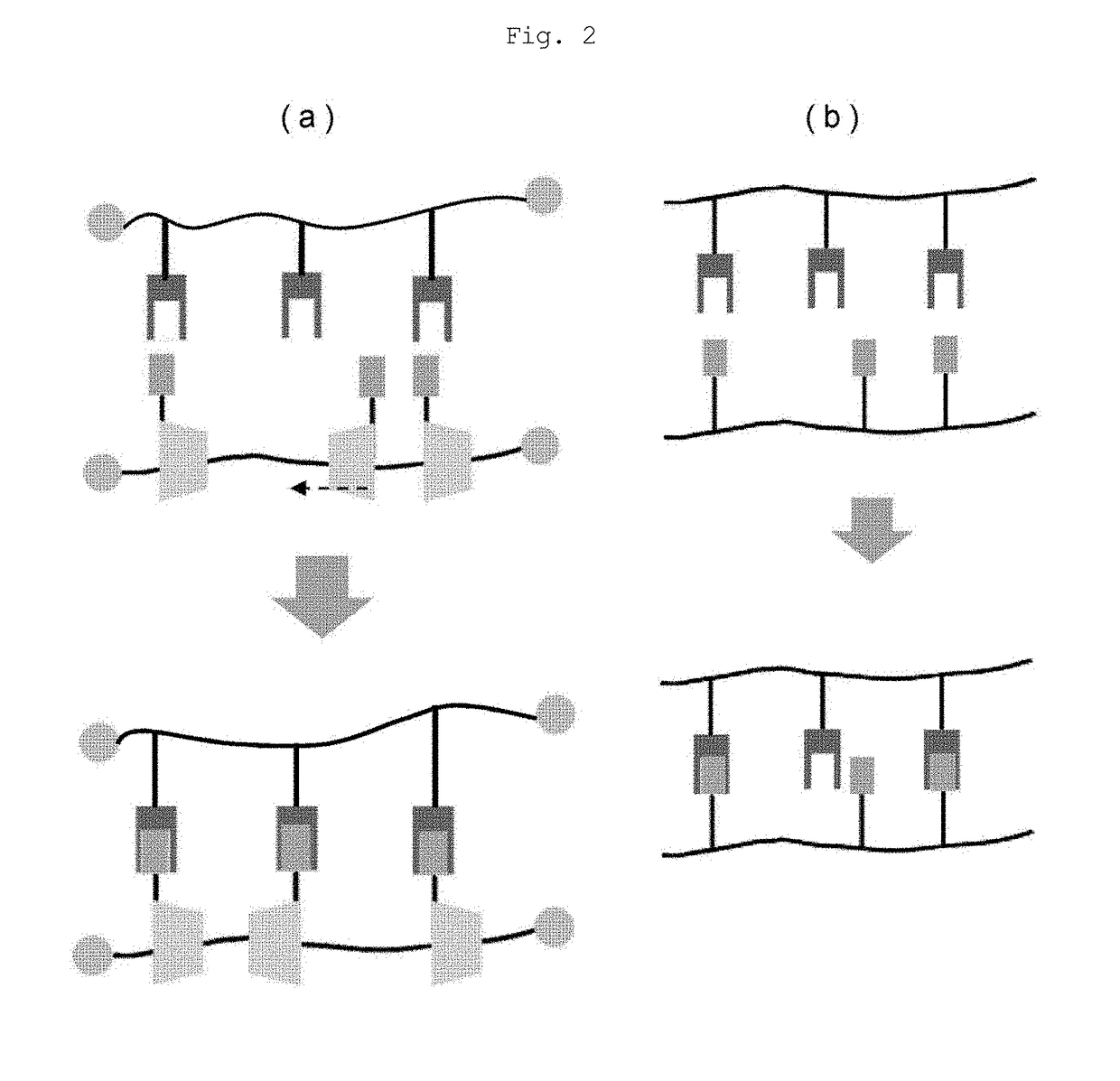

InactiveUS20170233533A1Excellent stress relaxationLoss of material propertyPolyrotaxaneBicyclic molecule

Provided is a self-restoring macromolecular material that not only has excellent stress relaxation but that can also be easily restored to its original state, even when damaged or severed. Also provided is a method for producing the self-restoring macromolecular material. The self-restoring macromolecular material contains a crosslinked structure that is formed by crosslinking a polymer containing at least a polyrotaxane molecule. The polyrotaxane molecule is formed so as to include a cyclic molecule 21 and a linear molecule that passes through an opening 21a of the cyclic molecule. The crosslinked structure 1 is crosslinked via a reversible bond between the cyclic molecule of the polyrotaxane molecule and a polymer molecule other than the polyrotaxane molecule.

Owner:OSAKA UNIV

Adhesive composition, adhesive sheet and adhesive optical component

InactiveUS20050148733A1Improve adhesionSuppresses liftingPolyureas/polyurethane adhesivesEster polymer adhesivesOligomerMeth-

An adhesive composition which is the crosslinked product of components which comprise (C) a copolymer of a (meth)acrylic ester having a weight-average molecular weight of 1,000,000 or greater, (D) 5 to 100 parts by weight per 100 parts by weight of component (C) of an oligomer of (meth)acrylic esters having a weight-average molecular weight of 1,000 to 10,000 and (E) 0.001 to 50 parts by weight per 100 parts by weight of component (C) of a crosslinking component comprising a difunctional crosslinking agent. The adhesive composition exhibits excellent adhesion with adherents, and stress relaxation and follows changes in the dimensions of substrates.

Owner:LINTEC CORP

Soldering material and electronic component assembly

ActiveUS8598464B2Increase thermal fatigueImprove thermal fatigue resistanceFinal product manufacturePrinted electric component incorporationStress relaxationCopper

A solder material includes 1.0-4.0% by weight of Ag, 4.0-6.0% by weight of In, 0.1-1.0% by weight of Bi, 1% by weight or less (excluding 0% by weight) of a sum of one or more elements selected from the group consisting of Cu, Ni, Co, Fe and Sb, and a remainder of Sn. When a copper-containing electrode part of an electronic component is connected to a copper-containing electrode land of a substrate by using this solder material, a part having an excellent stress relaxation property can be formed in the solder-connecting part and a Cu—Sn intermetallic compound can be rapidly grown from the electrode land and the electrode part to form a strong blocking structure.

Owner:PANASONIC CORP

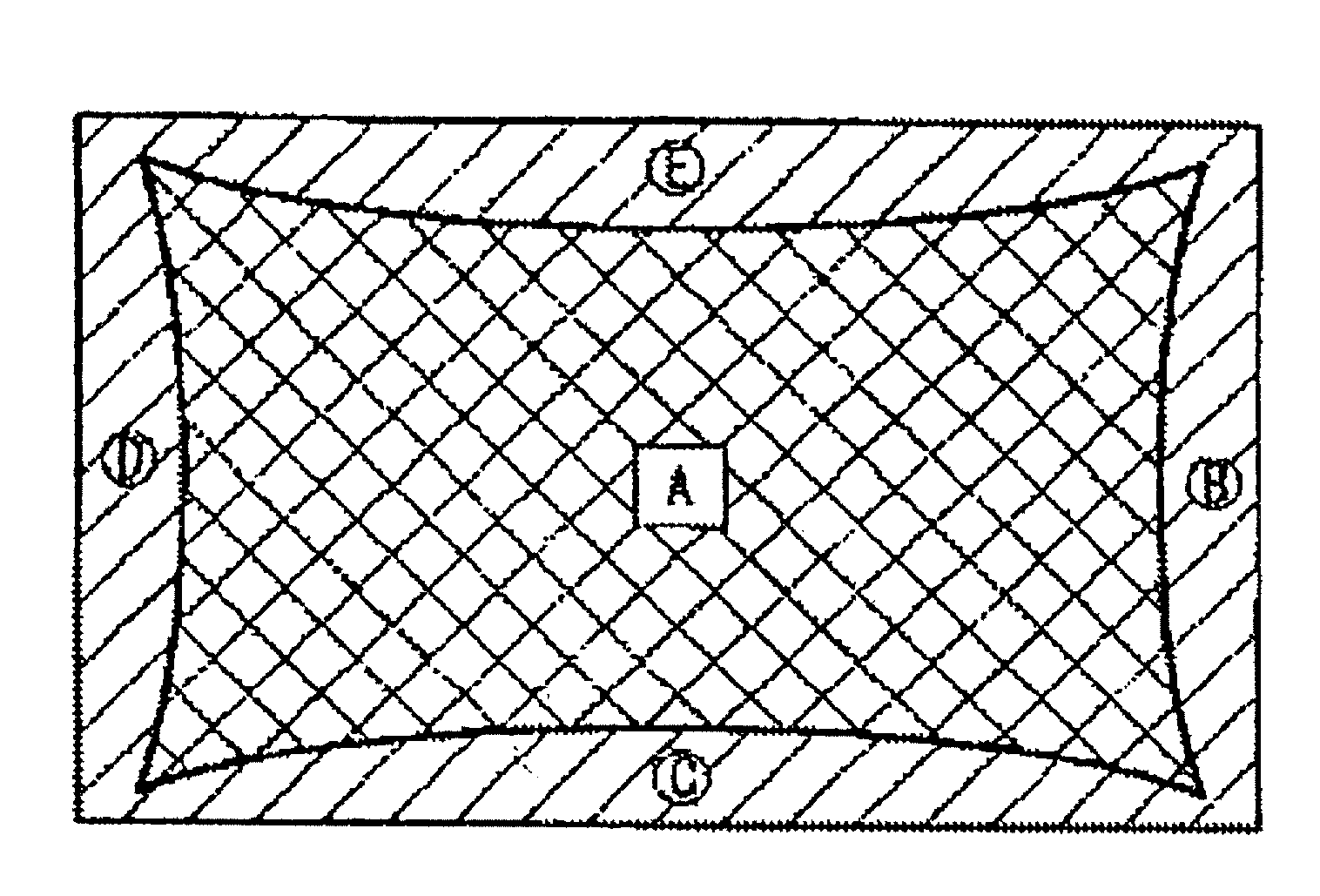

Pressure-sensitive adhesive sheet

InactiveUS20110262746A1Increased durabilitySufficient optical characteristicPolyureas/polyurethane adhesivesThin material handlingPolymer sciencePolyrotaxane

A pressure-sensitive adhesive sheet including: a base material; and a pressure-sensitive adhesive layer formed from a pressure-sensitive adhesive composition that comprises a polyrotaxane (A) having at least two cyclic molecules and a linear-chain molecule passing through opening portions of the cyclic molecules wherein the cyclic molecules have each one or more reactive groups and the linear-chain molecule has blocking groups at both ends thereof, wherein the pressure-sensitive adhesive layer has an elongation at break of not smaller than 300% and a haze value of not greater than 30%, and a holding power of the pressure-sensitive adhesive sheet according to JIS Z0237, but at a measurement temperature of 80° C., is not greater than 1000 μm as the displacement of the pressure-sensitive adhesive sheet after 70,000 seconds.

Owner:LINTEC CORP

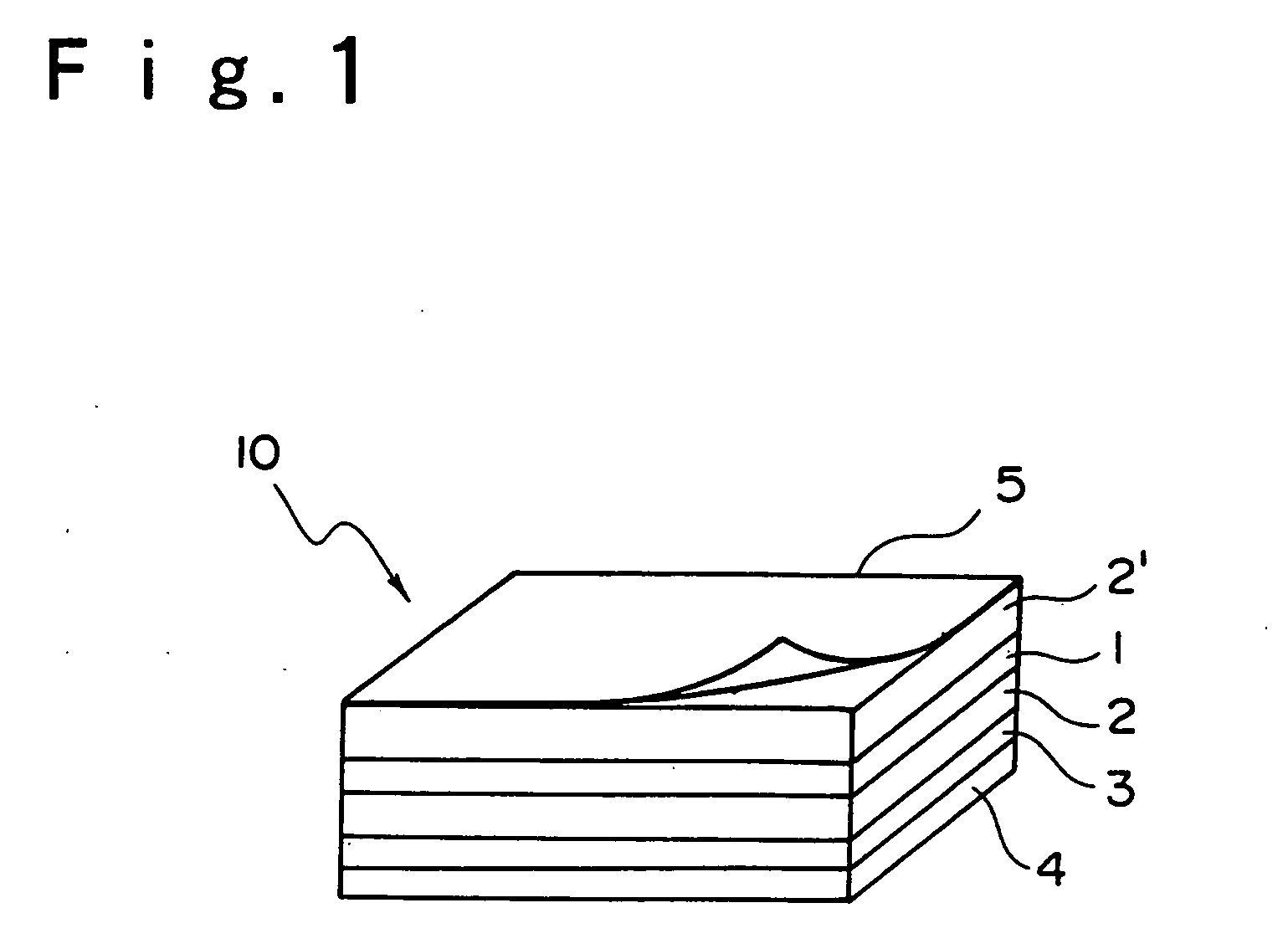

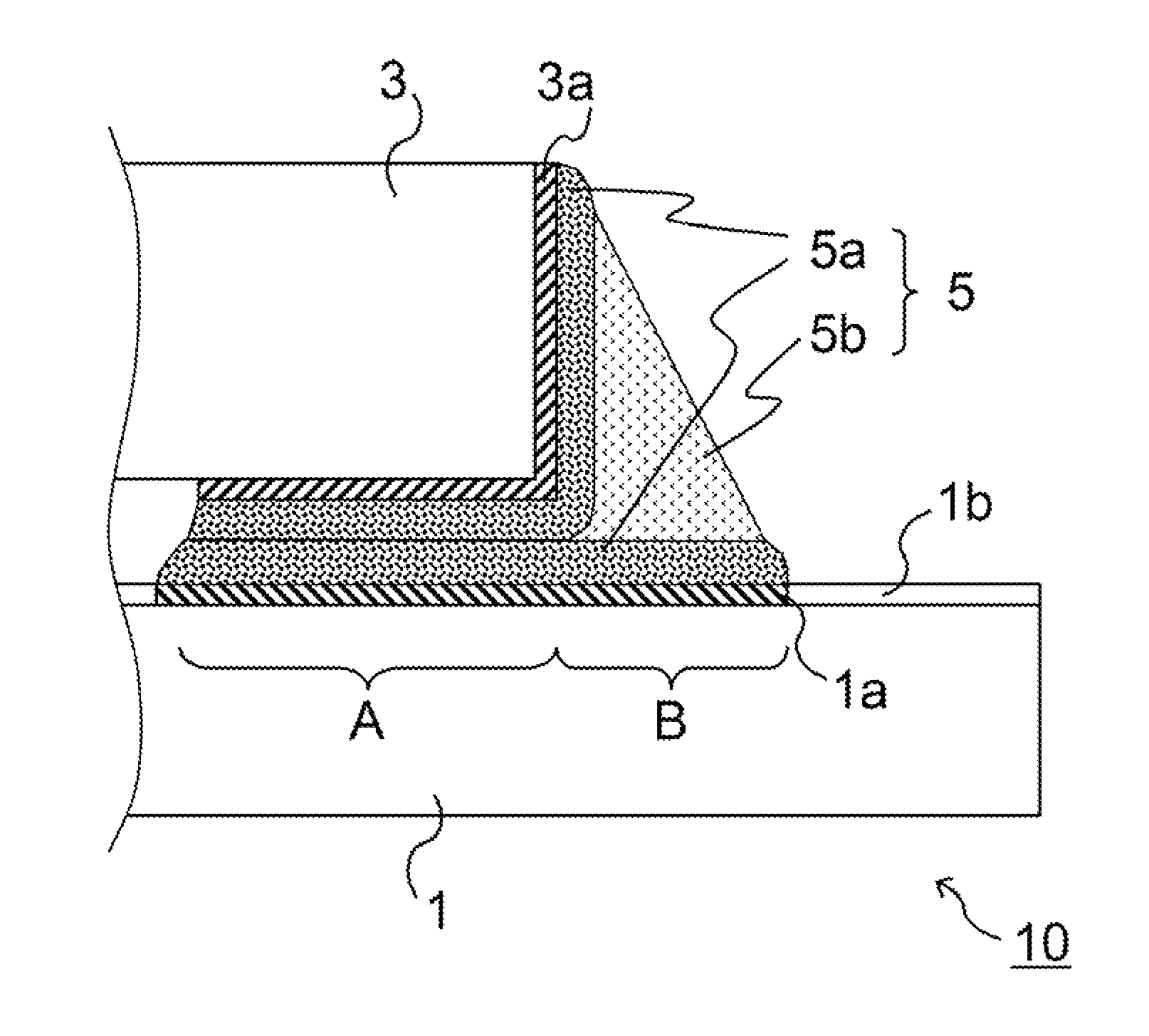

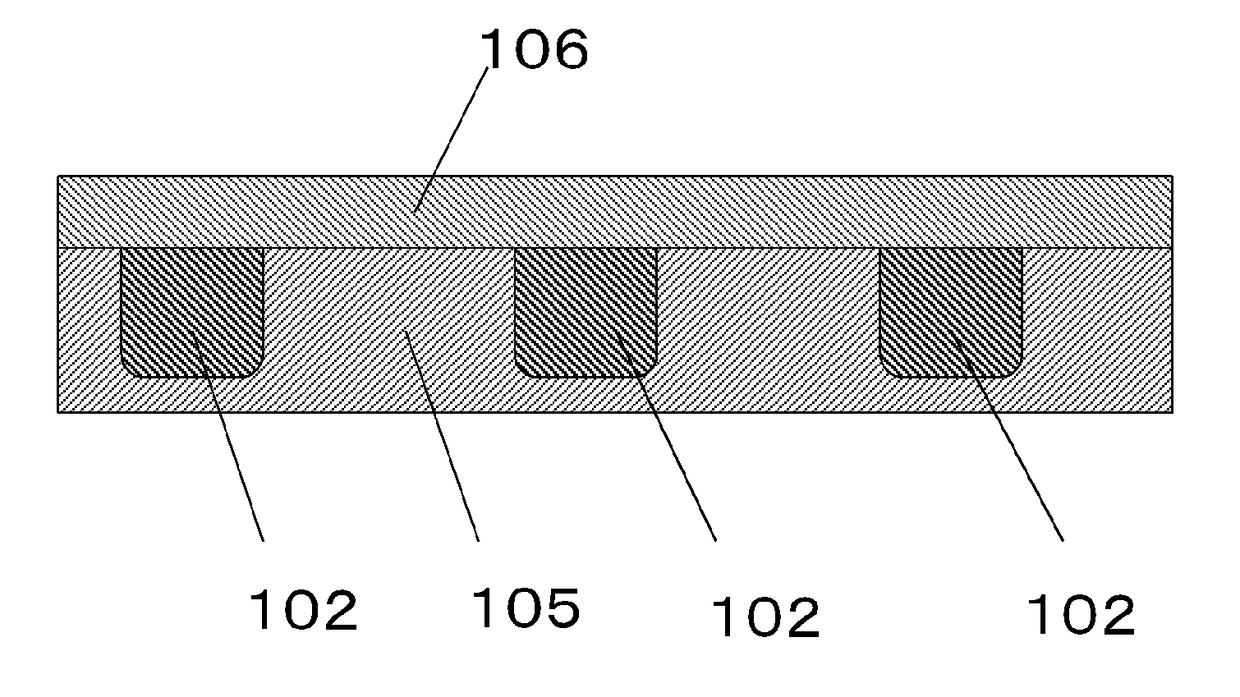

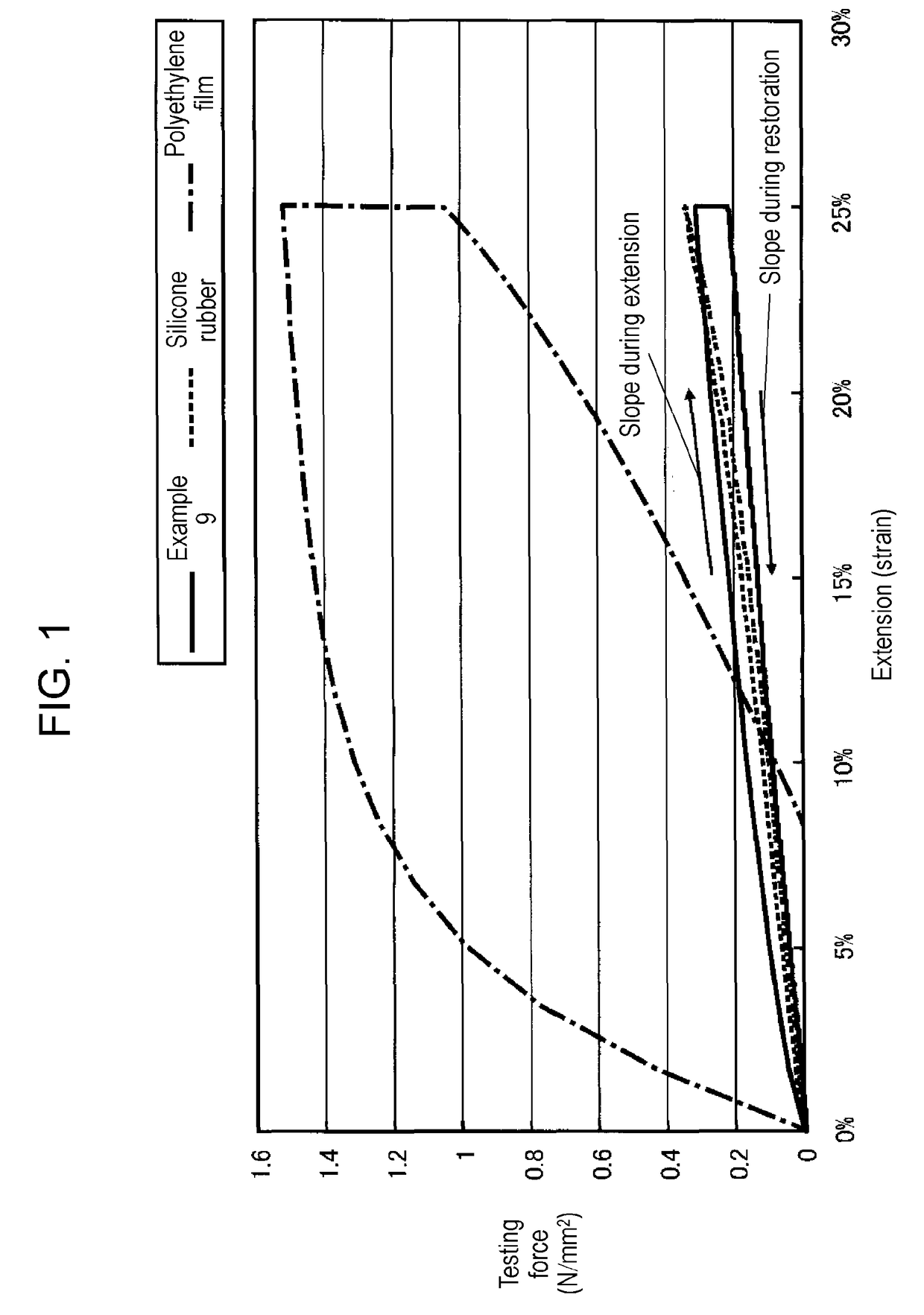

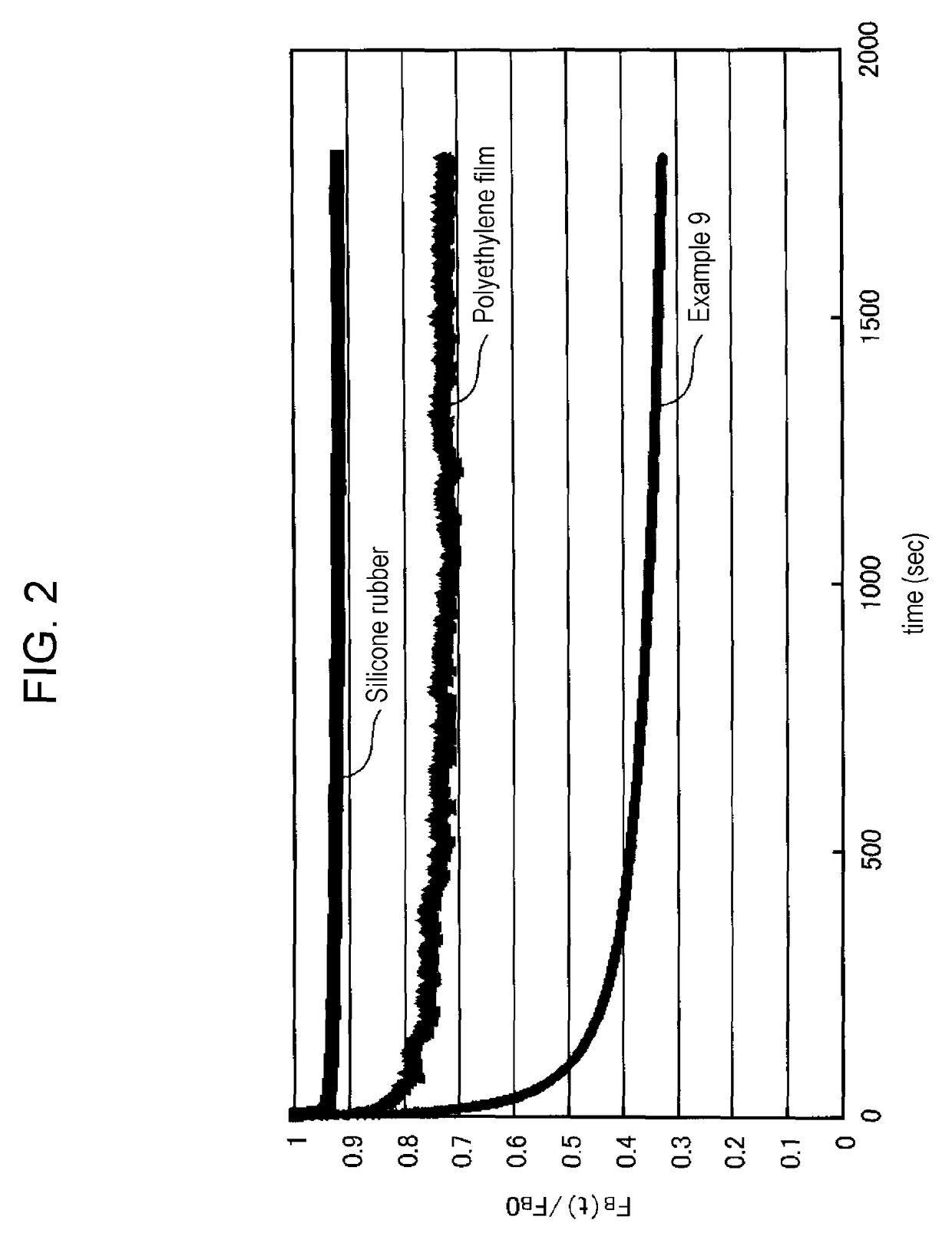

Structural member for electronic devices

ActiveUS9802397B2Improve residual stressReduce the amount of solutionProtective equipmentTransportation and packagingEngineeringStress relaxation

Provided is a structural member for electronic devices which uses a material that is flexible and has excellent restoration properties after extension and stress relaxation properties. The structural member for electronic devices has the following properties A and B: (Property A) In a case where predetermined deformation is applied, stress that applies the deformation is relaxed (reduced) with time: and (Property B) In a case where the stress that applies deformation is 0, the deformation rarely remains while a resin composition is recovered. That is, when stress is 0, residual strain substantially becomes 0 (specifically 3% or lower).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

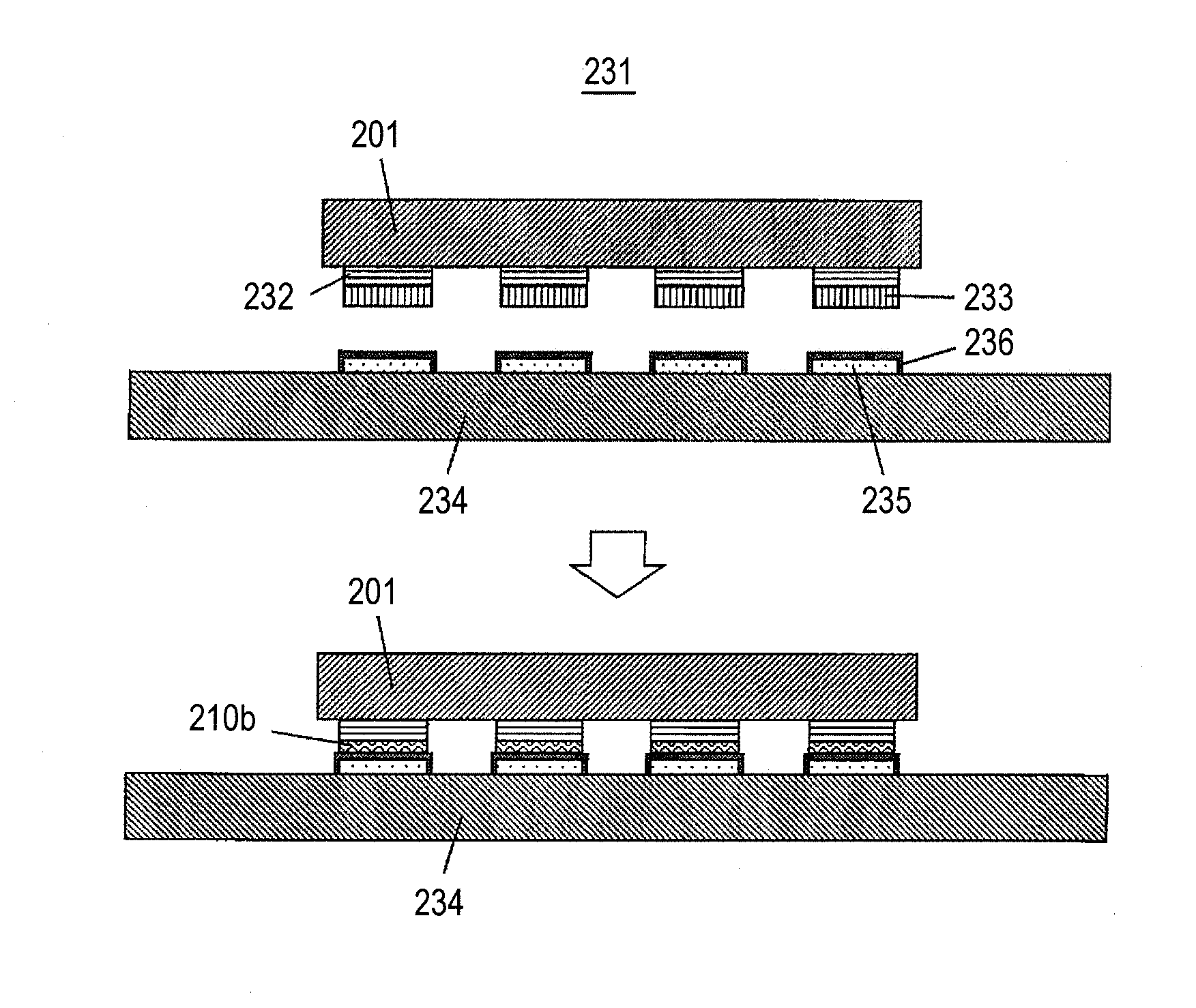

Connecting material, semiconductor device and method for manufacturing semiconductor device

ActiveUS20120098134A1Excellent stress relaxationSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceStress relaxation

When connecting with a conventional Zn / Al / Zn cladding material, thickness of a connecting part needs to be less than double an existing high-lead solder (about 100 μm) in order to make heat resistance in the connecting part at least equivalent to a level of the existing solder. Moreover, thickness of an Al layer needs to make as thick as possible in order to fully exhibit stress relaxation performance of the Al layer.Provided is a semiconductor device including a semiconductor element, a frame, and a connecting part which connects the semiconductor element and the frame to each other, in which an interface between the connecting part and the semiconductor element and an interface between the connecting part and the frame respectively have the area of Al oxide film which is more than 0% and less than 5% of entire area of the respective interfaces.

Owner:HITACHI LTD

Adhesive agent and adhesive sheet produced using same

ActiveCN105102569AExcellent stress relaxationExcellent peelabilityNon-macromolecular adhesive additivesFilm/foil adhesivesIsocyanateChemistry

The present invention addresses the problem of providing an adhesive agent which enables the production of an adhesive sheet that has excellent removability, is rarely raised from an adherend such as a glass or a plastic material or is rarely detached from the material after being exposed to a high-temperature environment or a high-temperature / high-humidity environment, has a good stress relaxation property, and rarely undergoes the occurrence of indentation on an adhesive agent layer formed therein. An adhesive agent comprising: an acrylic polymer (A) which does not have a hydroxyl group and has a carboxyl group; an acrylic polymer (B) which does not have a carboxyl group and has a hydroxyl group; at least one compound selected from an epoxy compound, a metal chelate compound and an aziridine compound; and a polyisocyanate compound.

Owner:TOYO INK SC HOLD CO LTD +1

Cross-linked foamed pressure sensitive adhesive and method for preparing the same

InactiveUS7612121B2Good solvent resistancePromote recoveryNon-macromolecular adhesive additivesOther chemical processesCross-linkPolymer science

A cross-linked foamed pressure sensitive adhesive having excellent stress relaxing property, restoration property and solvent resistance brought forth by uniform and sufficient cross-linking and foaming irrespective of transmissibility of ultraviolet rays and electron beams to components, and free from drawbacks inherent to low molecular weight acrylic copolymers. A cross-linked foamed pressure sensitive adhesive having restoration property, prepared by heating a heat cross-linkable and heat foamable composition containing a tacky polymer having a molecular weight of at least 100,000, a heat cross-linking agent and a heat foaming agent to cause cross-linking and foaming.

Owner:3M INNOVATIVE PROPERTIES CO

Binder composition for semiconductor device and binder sheet for semiconductor device

InactiveCN1821337AExcellent electrical reliabilityGood adhesionFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesEpoxyDynamic viscoelasticity

The present invention provides one kind of adhesive composition with excellent performances, especially high adhesion capacity and excellent heat tolerance, for semiconductor device and adhered sheet for semiconductor device. The adhesive composition for semiconductor device contains epoxy resin, phenolic resin, and ethylene copolymer containing ethylene and unsaturated carboxylic acid with functional group capable of reacting with the epoxy resin or its derivative. The adhesive composition has its dynamic viscoelasticity before curing measured to have lowest molten viscosity of 400-50,000 Pa.s.

Owner:TOMOEGAWA PAPER CO LTD

Adhesive composition and adhesive sheet and adhesive optical component using the composition

InactiveUS6929855B2Improve adhesionSuppresses and peelingPolyureas/polyurethane adhesivesSynthetic resin layered productsMethacrylatePolymer science

An optical component in combination with an adhesive composition, wherein the adhesive composition comprises (A) a copolymer of a (meth)acrylic ester having a molecular weight of 500,000 to 200,000 and (E) a crosslinking agent comprising an adduct of a polyisocyanate comprising (a) isocyanate difunctional adducts of a diisocyanate with a diol and (b) adducts of a diisocyanate with a polyhydric alcohol, having an isocyanate functionality of three or greater, in a weight ratio of the amounts of (a) to (b) of 95:5 to 10:90. An adhesive sheet and an adhesive optical component comprising a layer of the adhesive composition. The adhesive composition exhibits excellent adhesion with adherents, and stress relaxation and follows changes in the dimensions of substrates.

Owner:LINTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com