Alkali battery

An alkaline battery, alkaline technology, applied in the direction of alkaline battery electrodes, dry batteries, secondary batteries, etc., can solve the problem of cycle life, not put into practical use and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

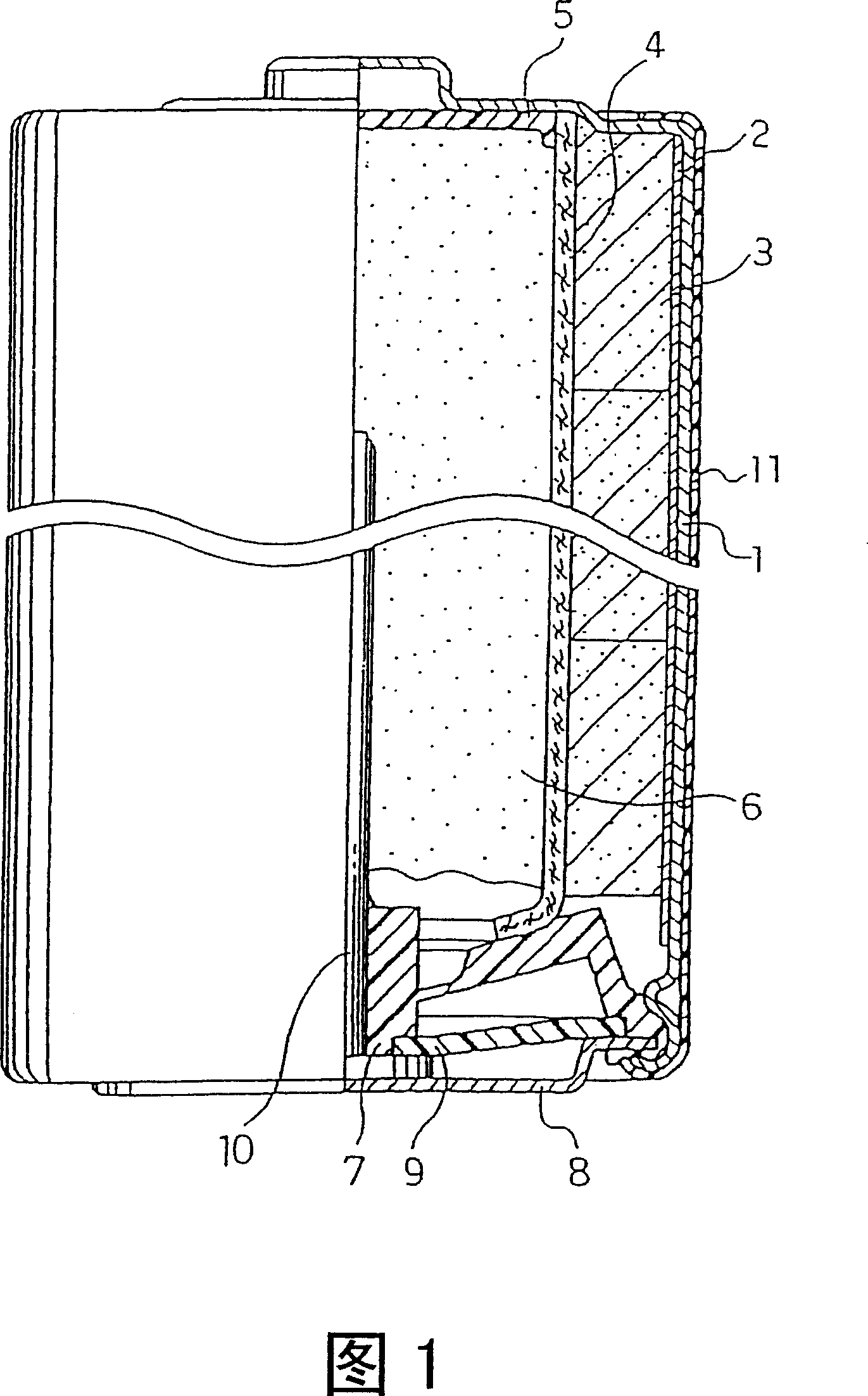

Image

Examples

Embodiment 1

[0054] Preparation of source material nickel hydroxide

[0055] Pure water and a small amount of hydrazine (reducing agent) were poured into a reaction vessel equipped with a stirring blade, followed by operating the stirring blade. While bubbling with nitrogen gas, use a pump to disperse nickel (II) sulfate aqueous solution, manganese (II) sulfate aqueous solution, sodium hydroxide aqueous solution, and ammonia water with predetermined concentrations into the water being stirred in the container so that the solution in the container Has a constant pH of 12.5 and a constant temperature of 50°C. During this operation, the solution in the vessel was kept sufficiently stirred, so that spherical nickel hydroxide, which is a solid solution including manganese dissolved therein and containing β-type structure crystals, was precipitated and grown.

[0056] Subsequently, the obtained solid solution nickel hydroxide was heated in an aqueous sodium hydroxide solution different from the...

Embodiment 2

[0117] In order to reveal the optimum content of expanded graphite included in the positive electrode material mixture, the following evaluation was performed using expanded graphite f.

[0118] Positive electrode material mixture powders X1, X2, X3, X4, X5 and X6 are obtained in the following manner: mix electrolytic manganese dioxide and nickel oxyhydroxide P in a weight ratio of 50:50, and add 5 wt% of nickel oxyhydroxide P to it The amount of zinc oxide is further added, and graphite f is further mixed therein, so that the content of graphite f in the total amount of nickel oxyhydroxide P, electrolytic manganese dioxide, and graphite f is 0.5wt%, 1wt%, 3wt%, 5wt%, respectively %, 8wt% and 15wt%.

[0119] AA-sized nickel-manganese batteries X1 to X6 were produced in the same manner as in Example 1, except that the above-mentioned positive electrode material mixture powders X1 to X6 were used respectively, and the and .

[0120] For each characteristic, the results obtaine...

Embodiment 3

[0124] In order to obtain findings regarding the attachment of cobalt oxide to the surface of the nickel oxyhydroxide particles, the following evaluations were performed.

[0125] Preparation of nickel hydroxide supported on cobalt hydroxide

[0126] With the same nickel hydroxide (composition: Ni hydroxide) with the source material nickel hydroxide prepared in embodiment 1 0.95 mn 0.05 (OH) 2 ) was introduced into the cobalt sulfate aqueous solution in the reaction vessel, an aqueous sodium hydroxide solution was gradually added thereto, and stirring was continuously performed in the vessel while controlling the solution in the vessel so as to have a constant temperature of 35° C. and a constant pH of 10. As a result, cobalt hydroxide was precipitated on the surface of the source material nickel hydroxide particles. The amount of cobalt hydroxide precipitated on the surface of the nickel hydroxide particles was adjusted to 2% by weight relative to the amount of the source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com