Patents

Literature

554results about How to "Promote softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

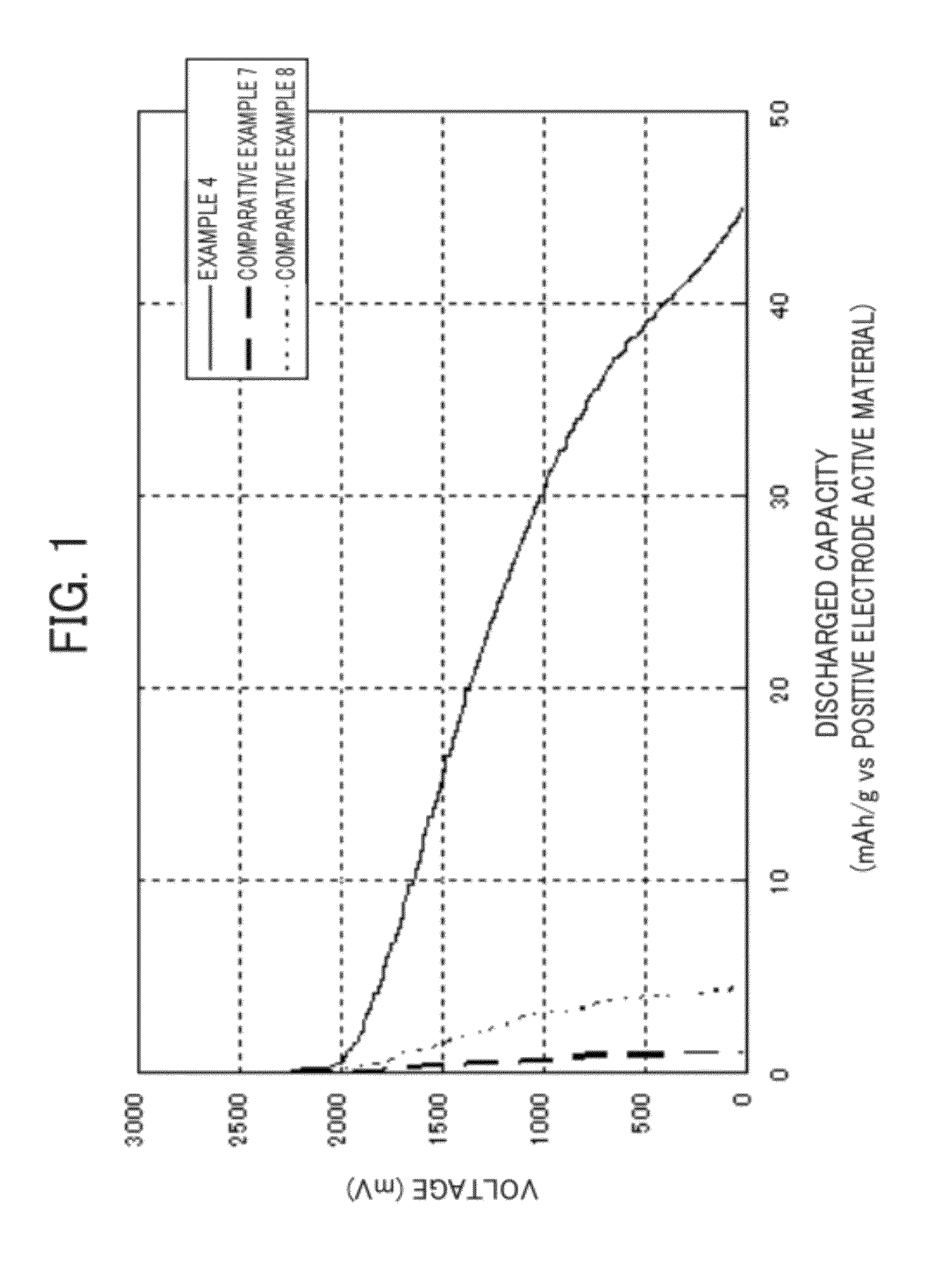

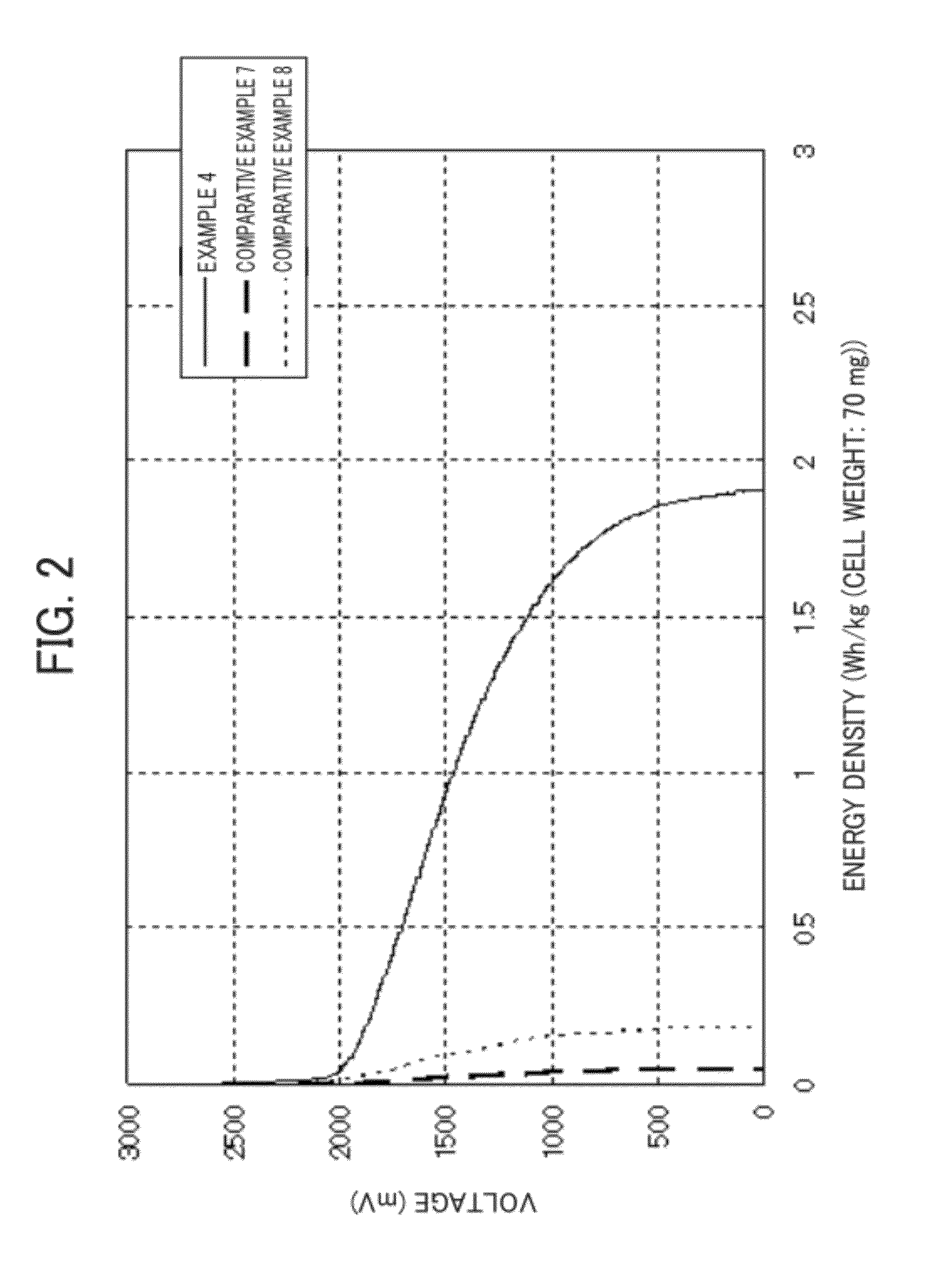

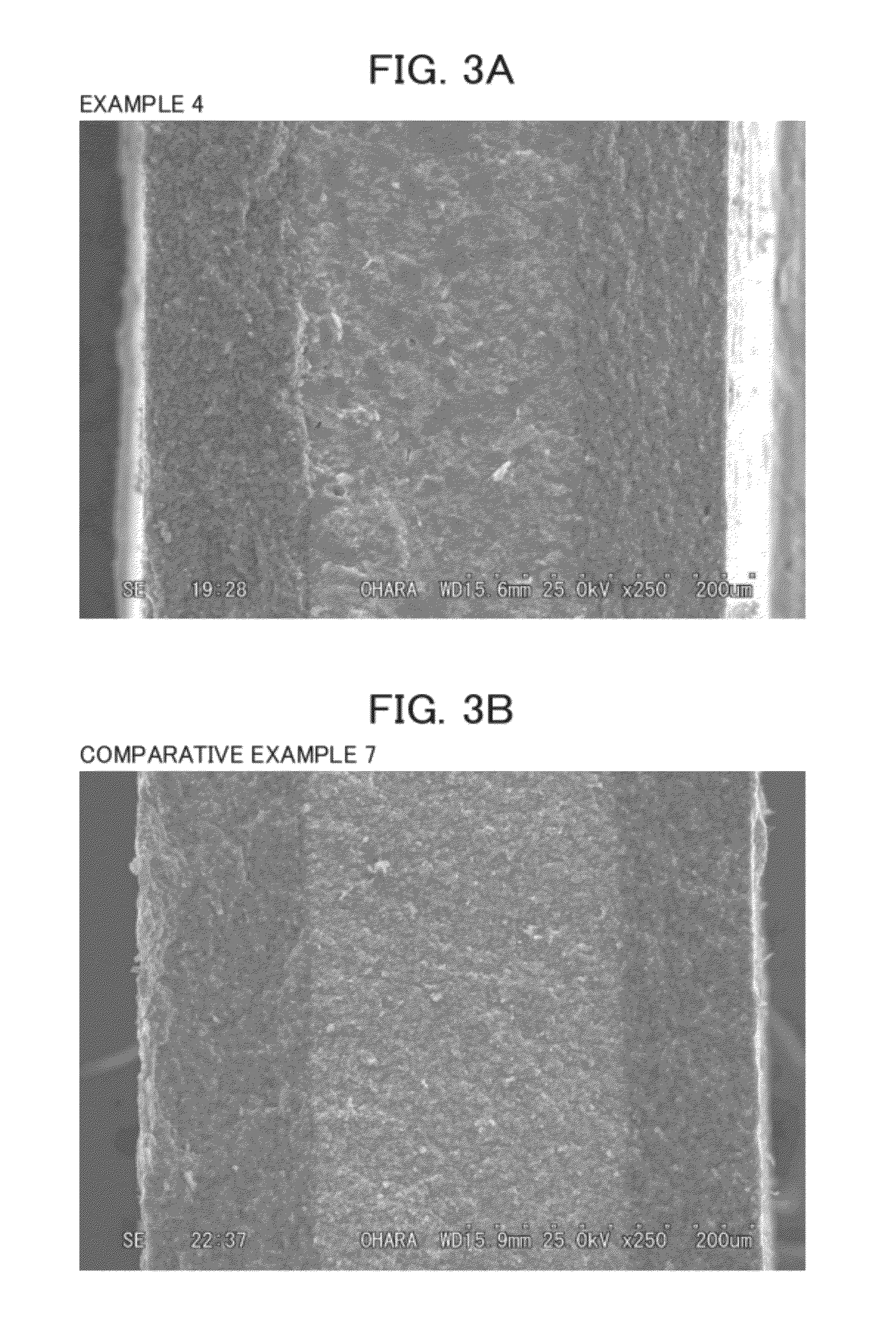

All-solid secondary battery

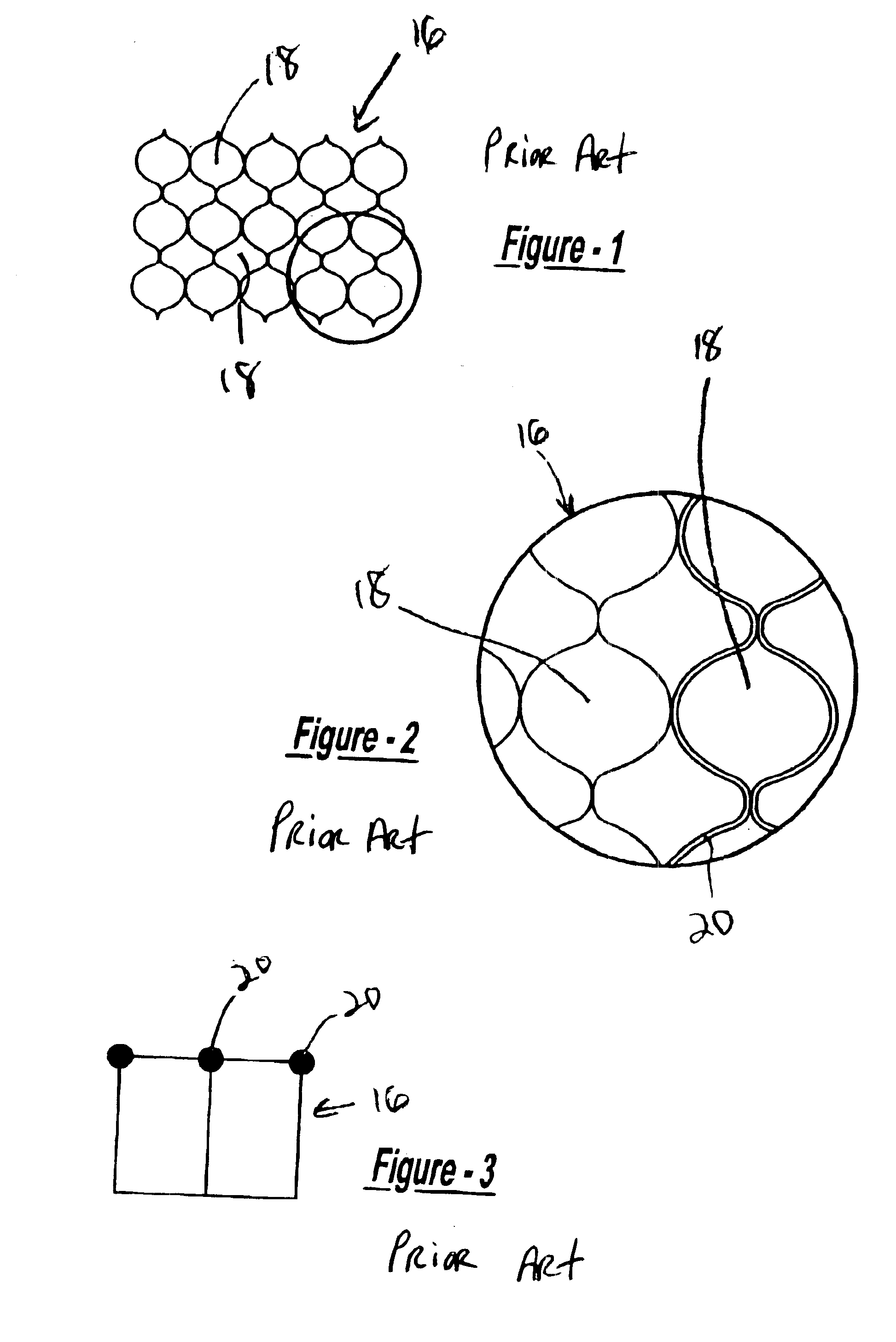

ActiveUS20120237834A1Increase battery capacityFacilitates electron conductionSolid electrolytesFinal product manufactureElectrolyteMaterials science

In the all-solid secondary battery of the present invention, a positive electrode layer and a negative electrode layer are disposed on both sides of a solid electrolyte layer, a first inorganic solid electrolyte and a second inorganic solid electrolyte are included into at least one of the positive electrode layer, the negative electrode layer, and the solid electrolyte layer, the content of transition metal in the first inorganic solid electrolyte is less than 15% by mass on oxide basis, and the content of transition metal in the second inorganic solid electrolyte is 15% by mass or more on oxide basis.

Owner:OHARA

Fabric treatment composition

InactiveUS20030199416A1Promote softeningReduce stainsCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceActive agent

A heat activated fabric treatment composition comprises from 3 to 75 wt % of one or more fabric treatment active ingredients, from 10 to 50 wt % of water, from 5 to 40 wt % of an oil and optionally from 2 to 30 wt % of a nonionic surfactant. The composition is provided in a dispensing device which, in use, is attached to the internal panel of a tumble dryer.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

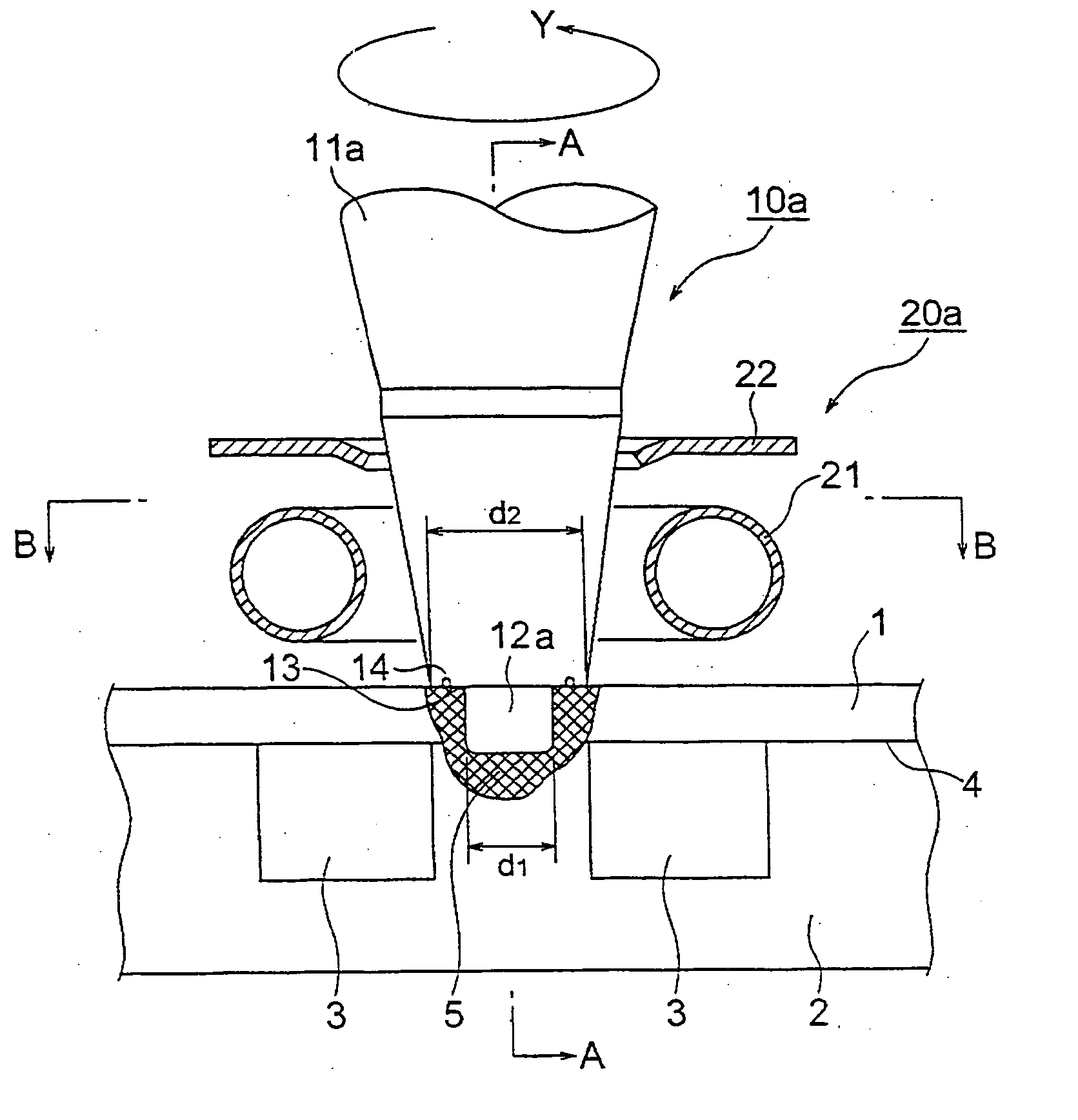

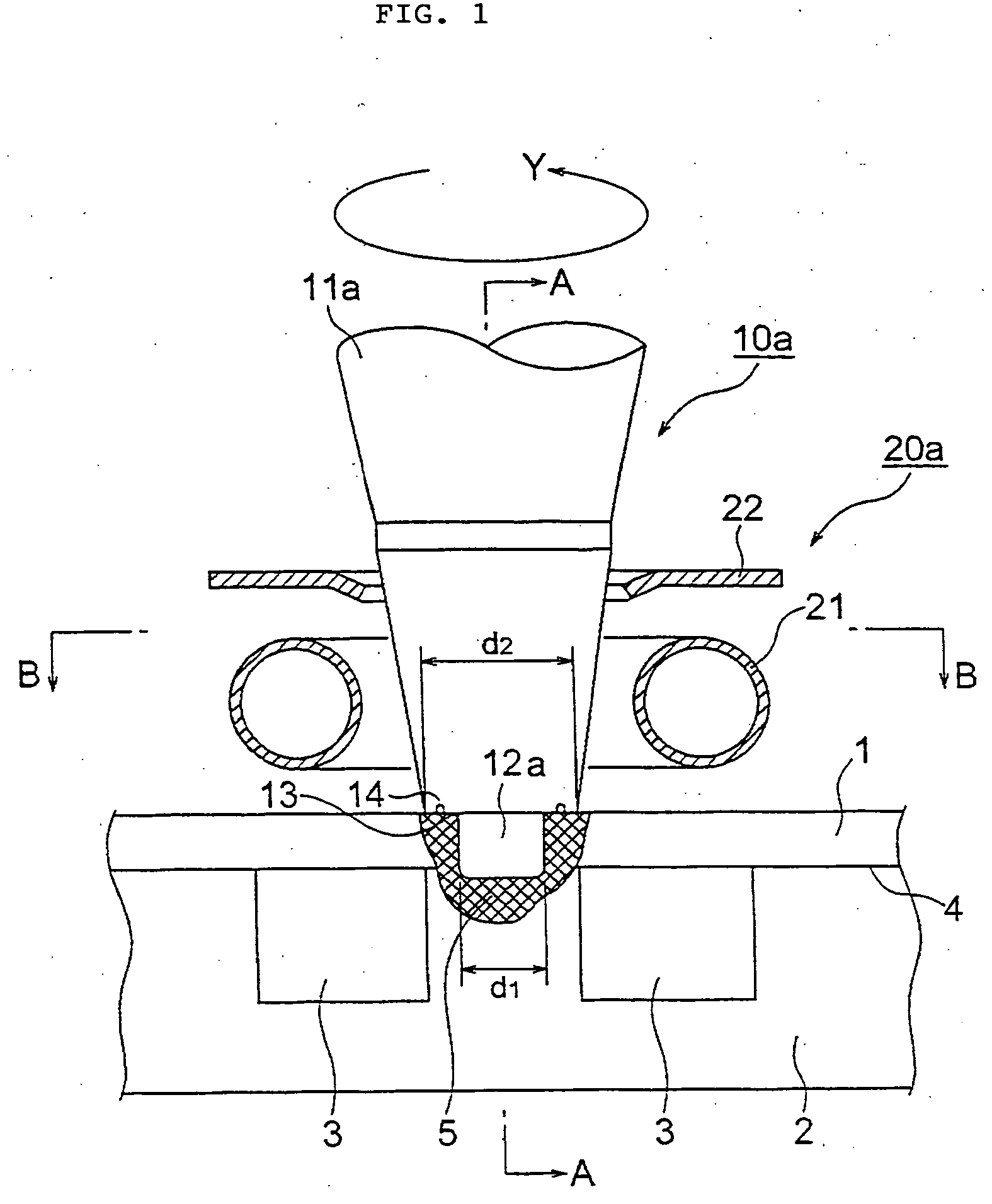

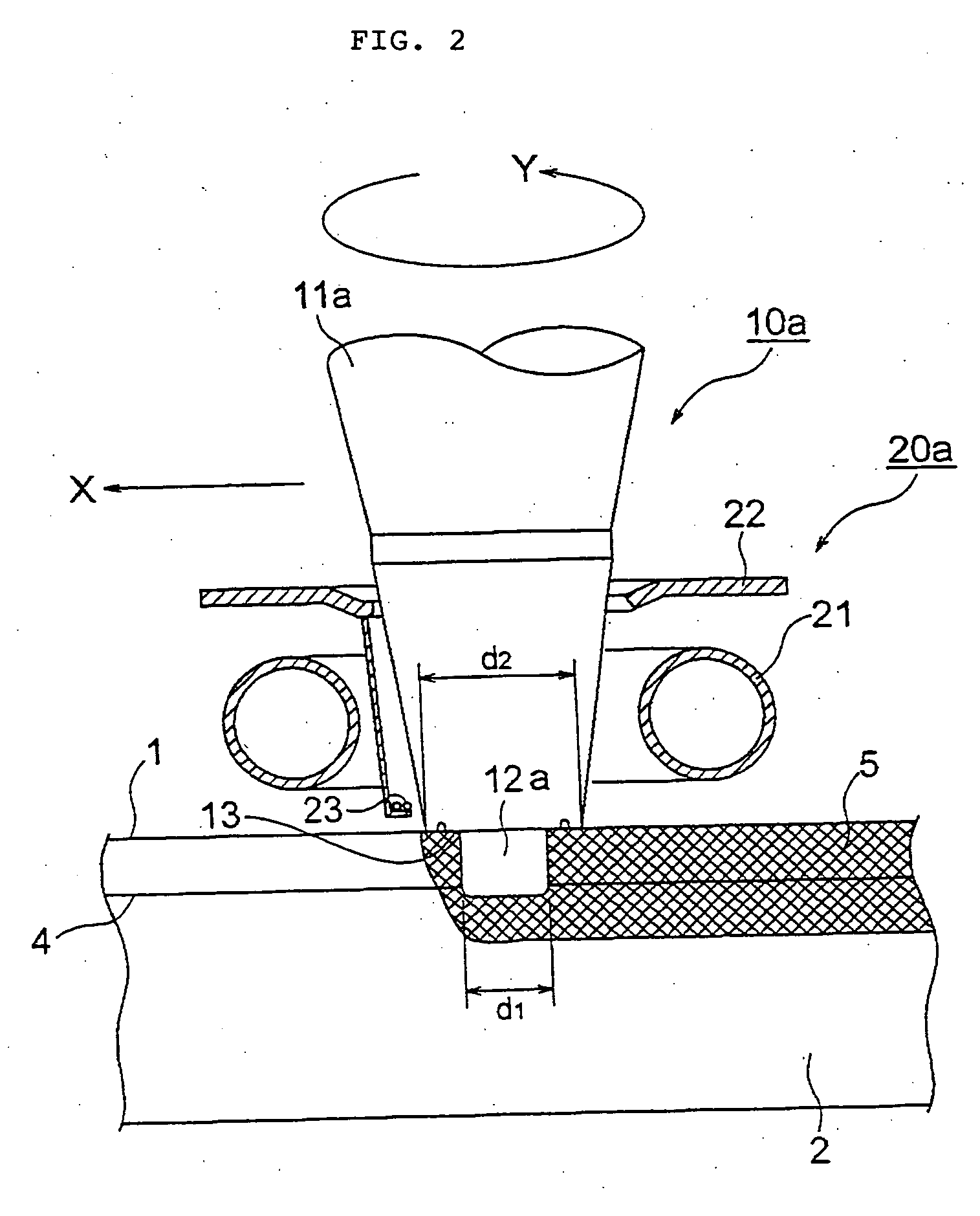

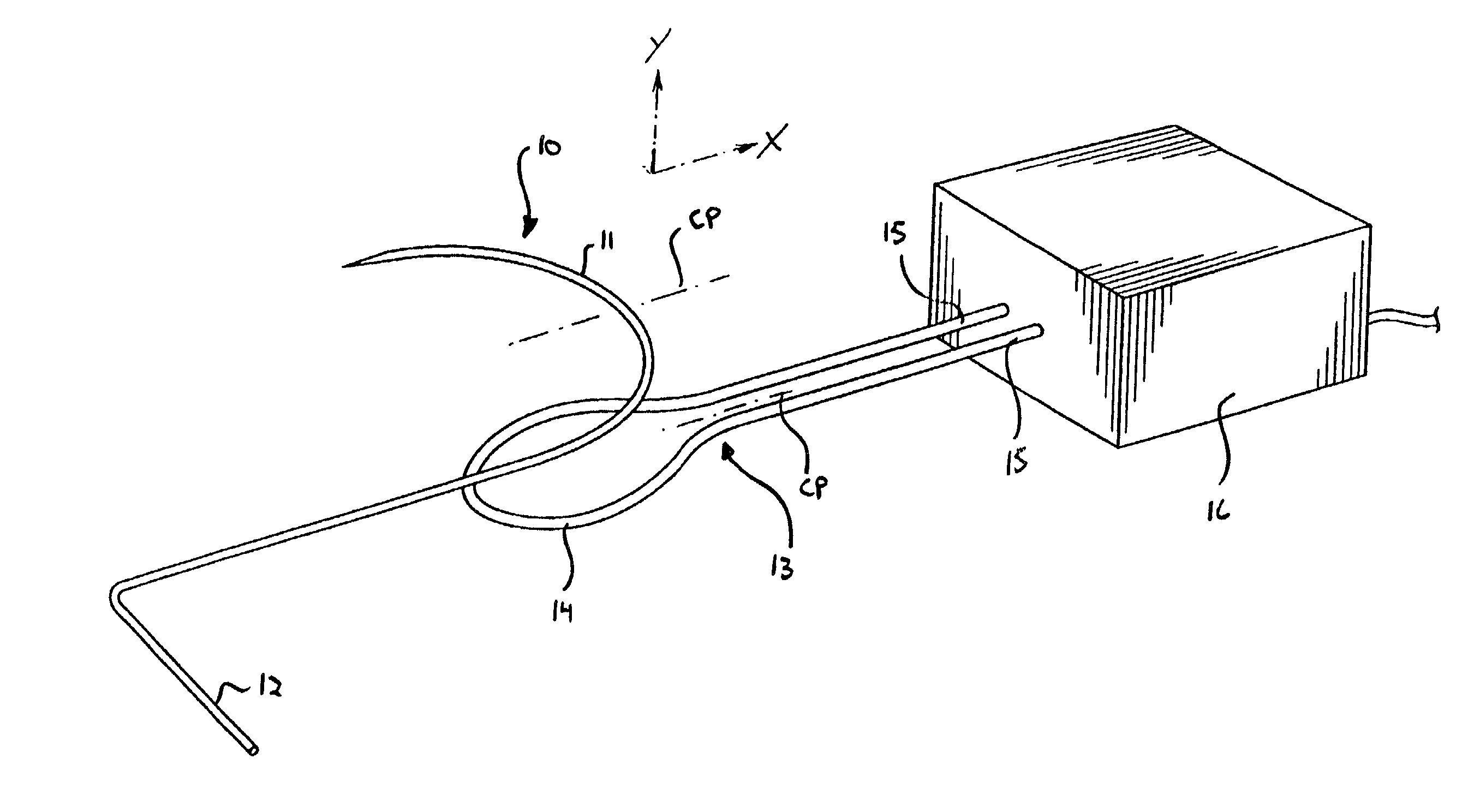

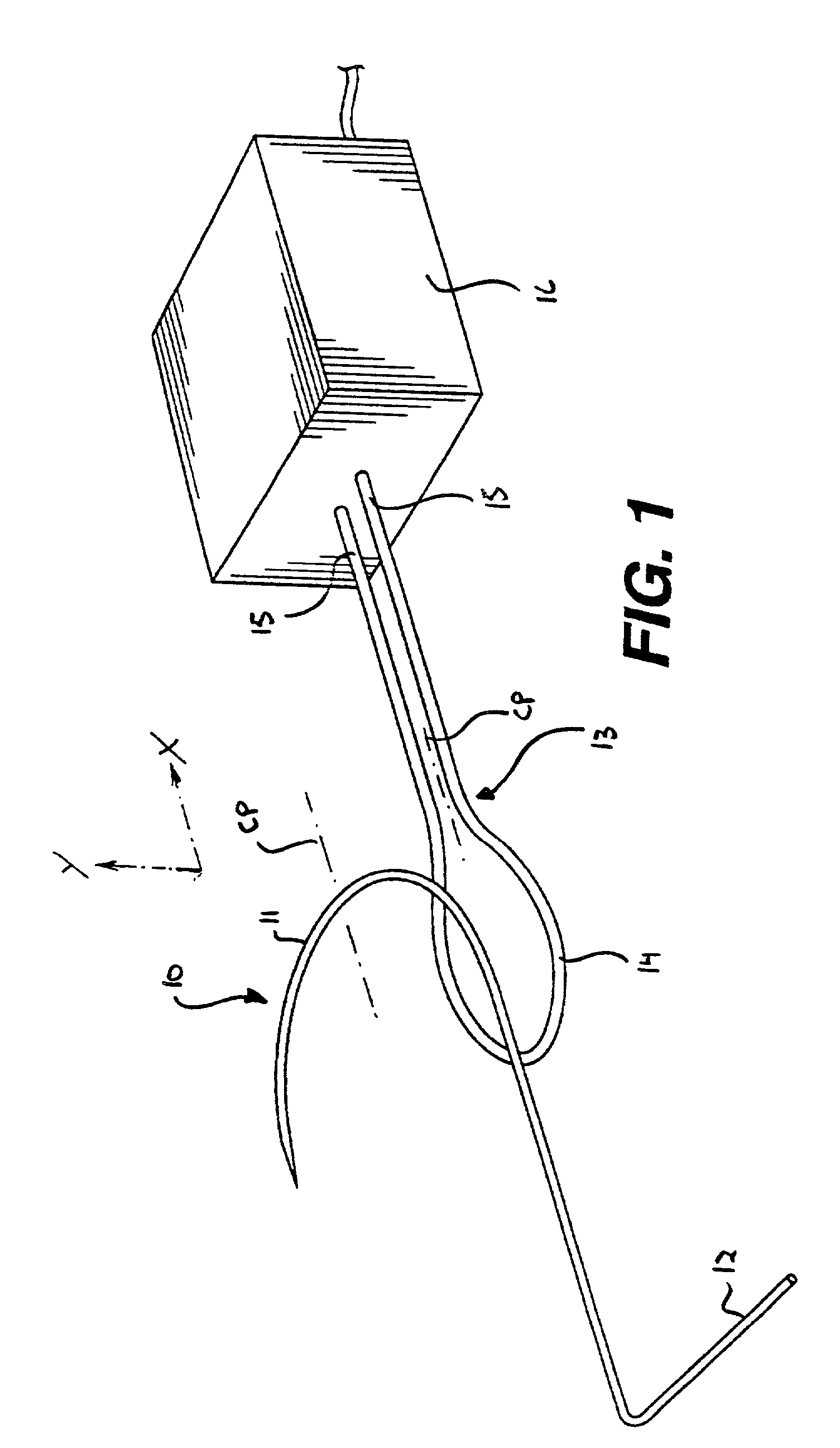

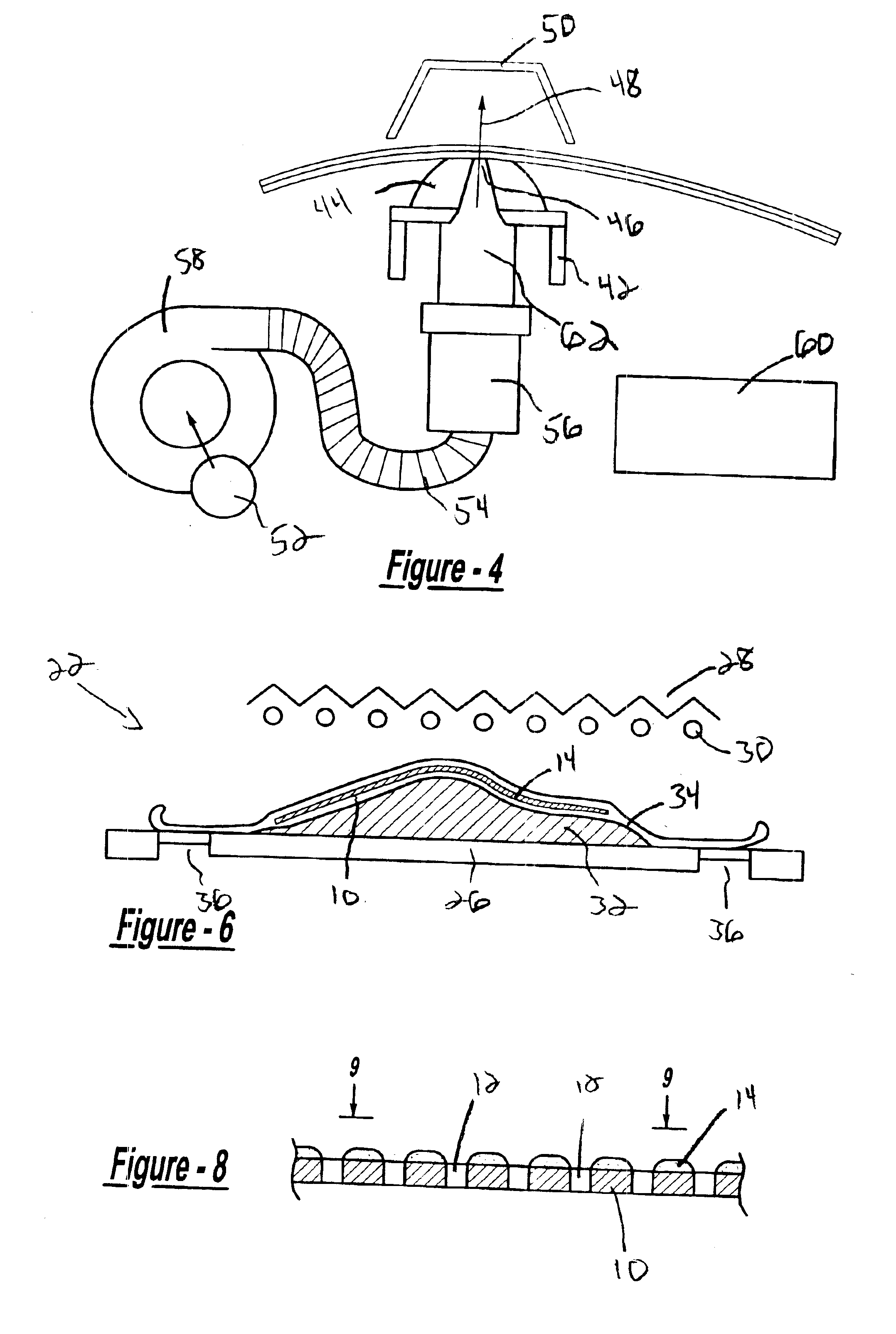

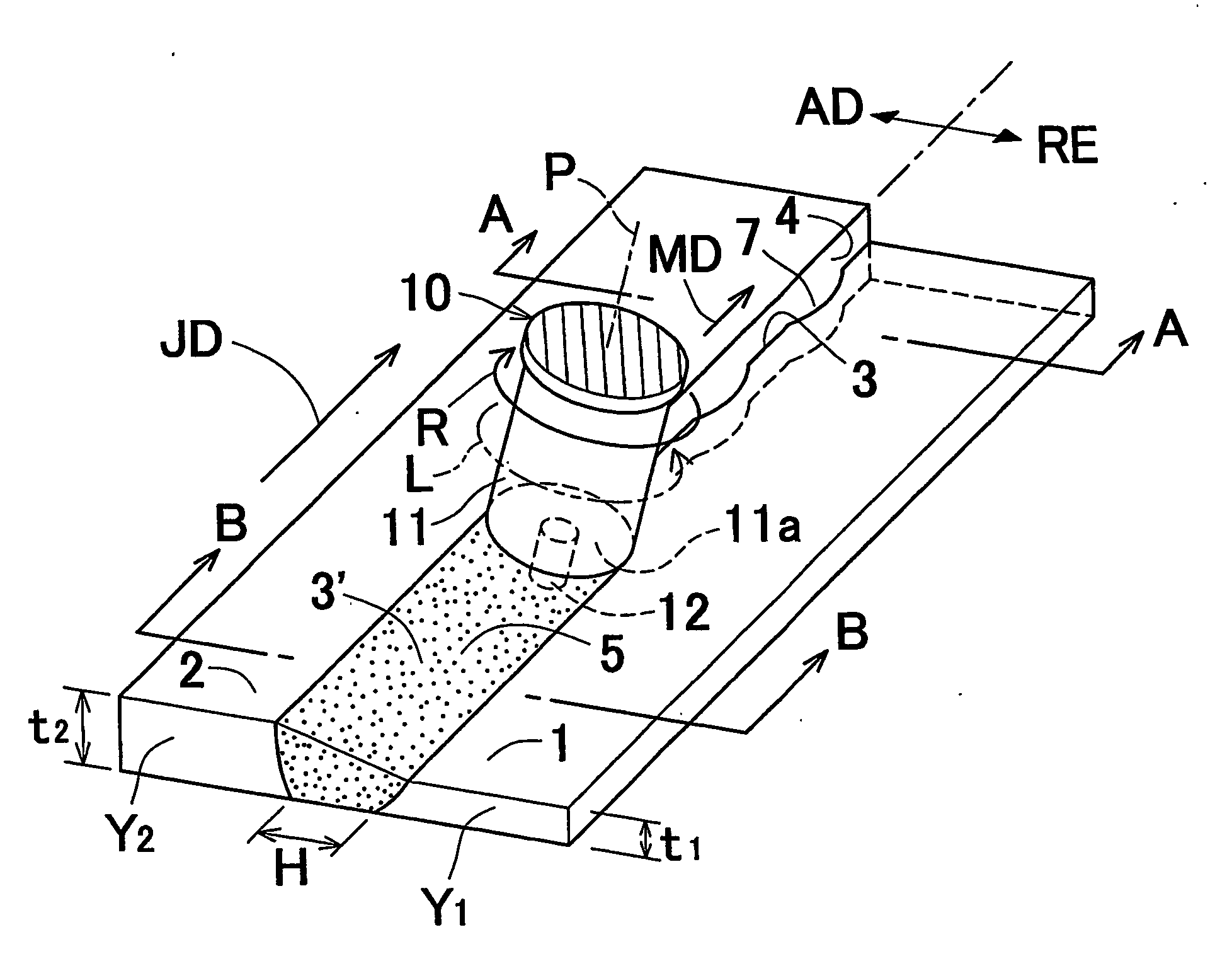

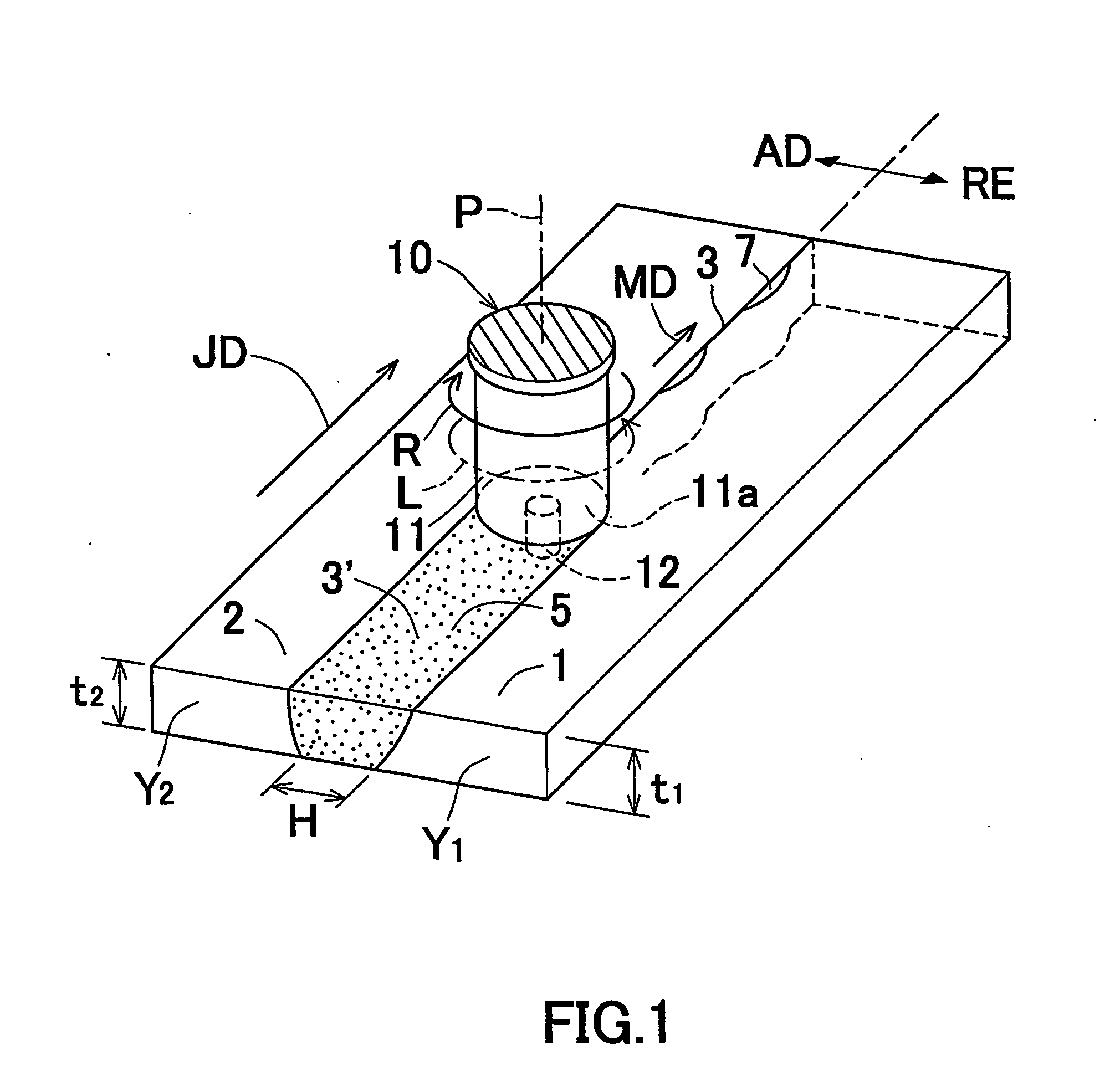

Friction stir welding method and apparatus

InactiveUS20060065698A1Promote softeningEfficient executionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Friction stir welding (FSW) method and apparatus are provided by which power needed for the FSW is reduced and a compact FSW tool can be used. In the FSW method comprising the steps of lapping metal members one on another and inserting a rotating probe of a FSW tool into a contact portion of the metal members making contact with the probe so that the contact portion is softened by frictional heat and stirred by the probe and the metal members are welded together, a portion of the metal members surrounding the probe is heated by a heating means.

Owner:MITSUBISHI HEAVY IND LTD

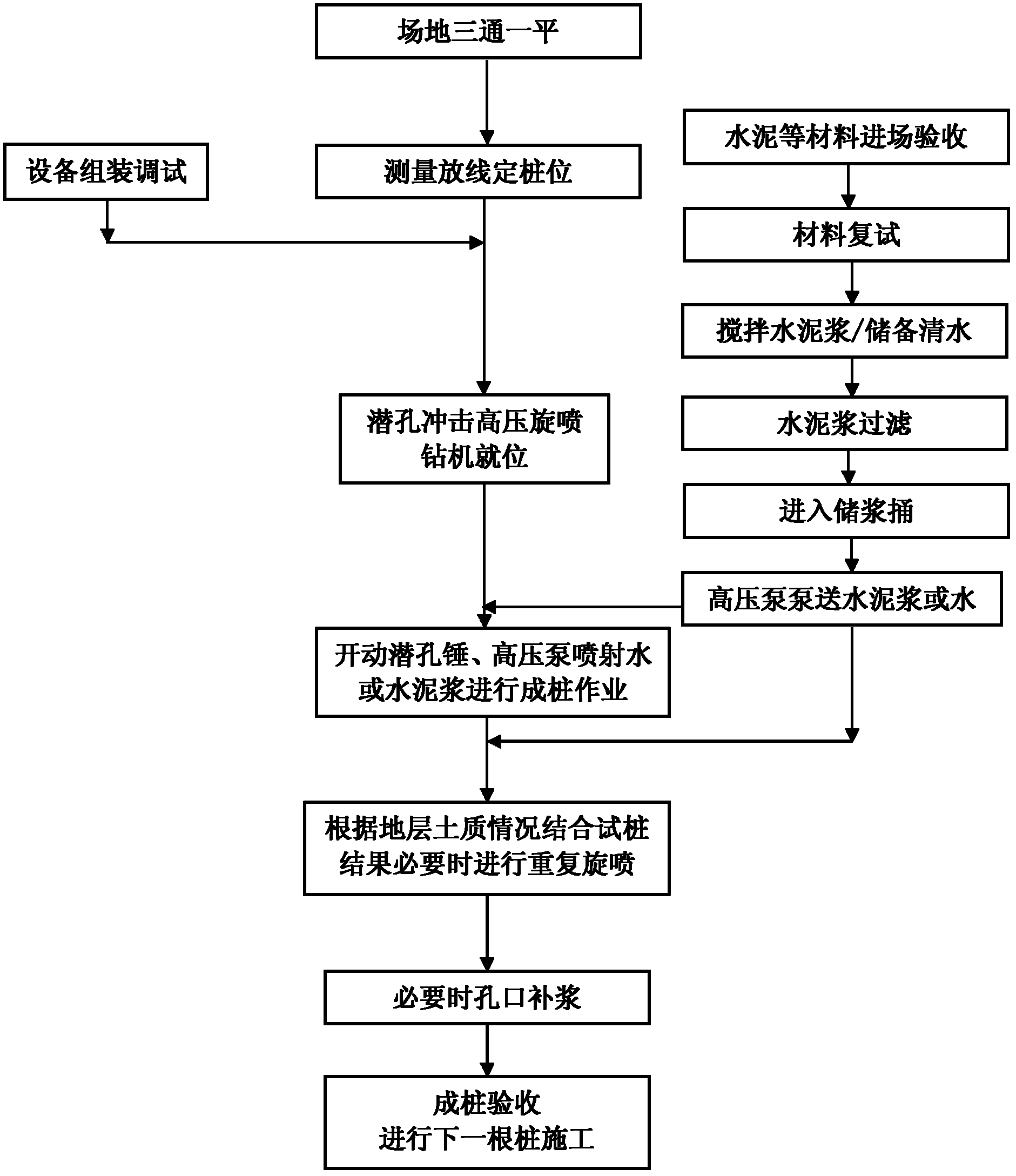

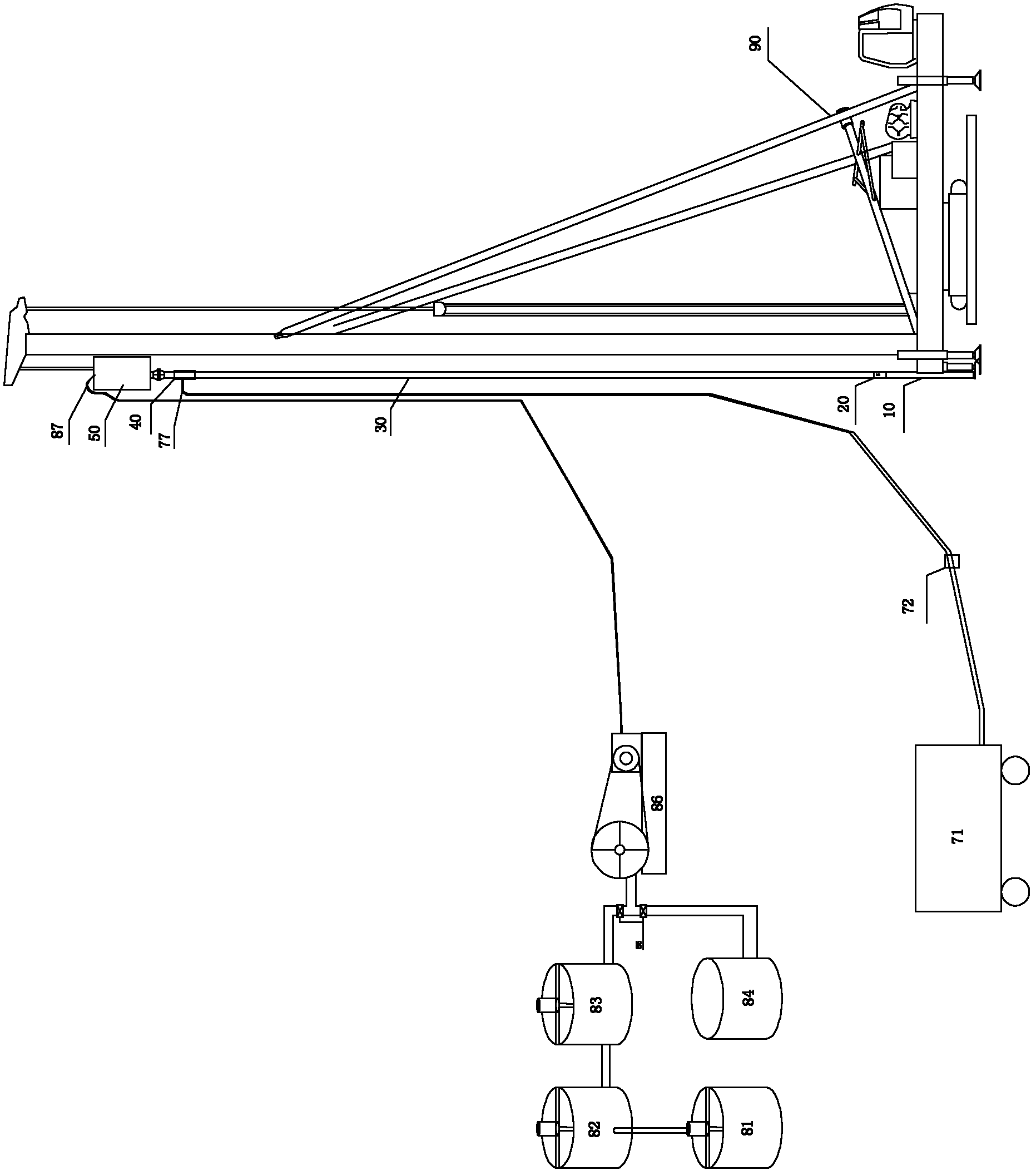

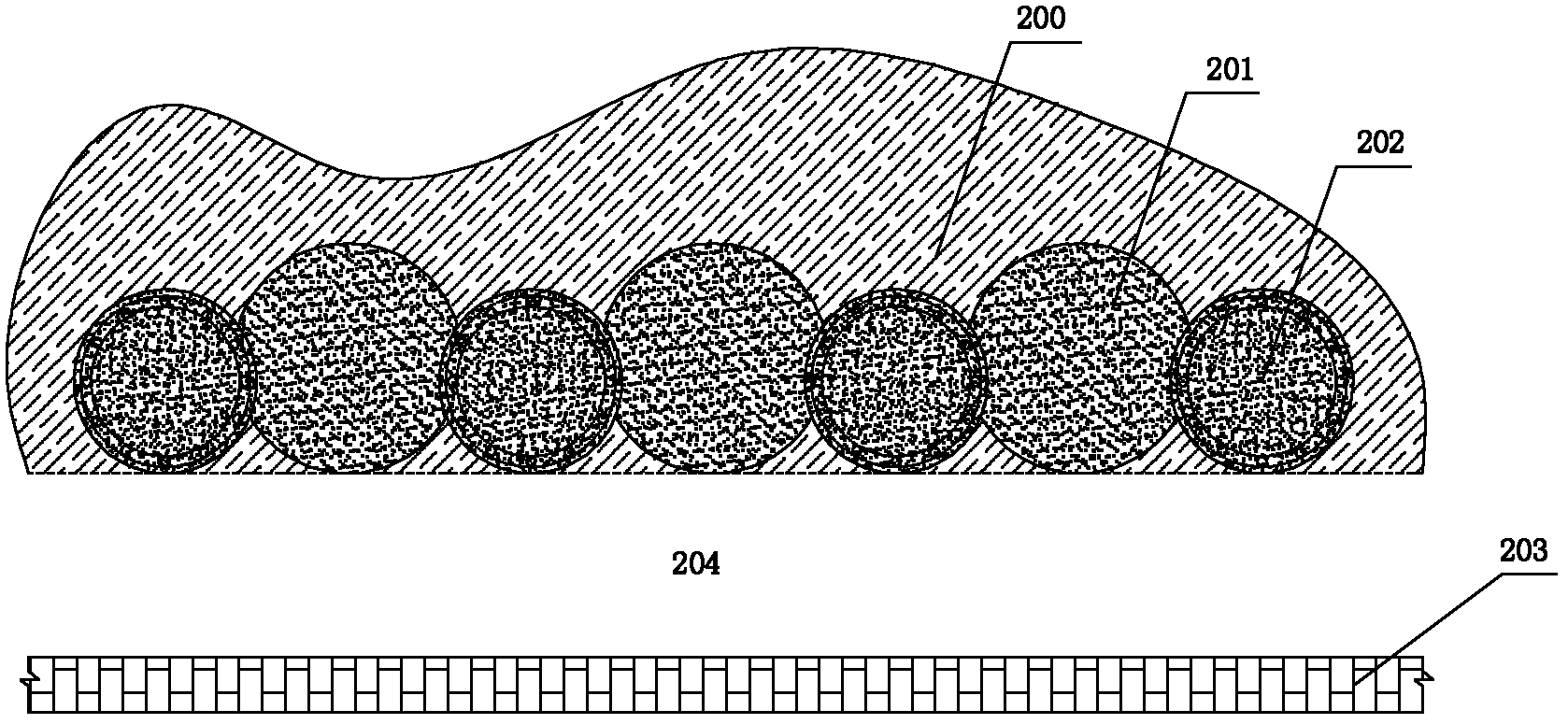

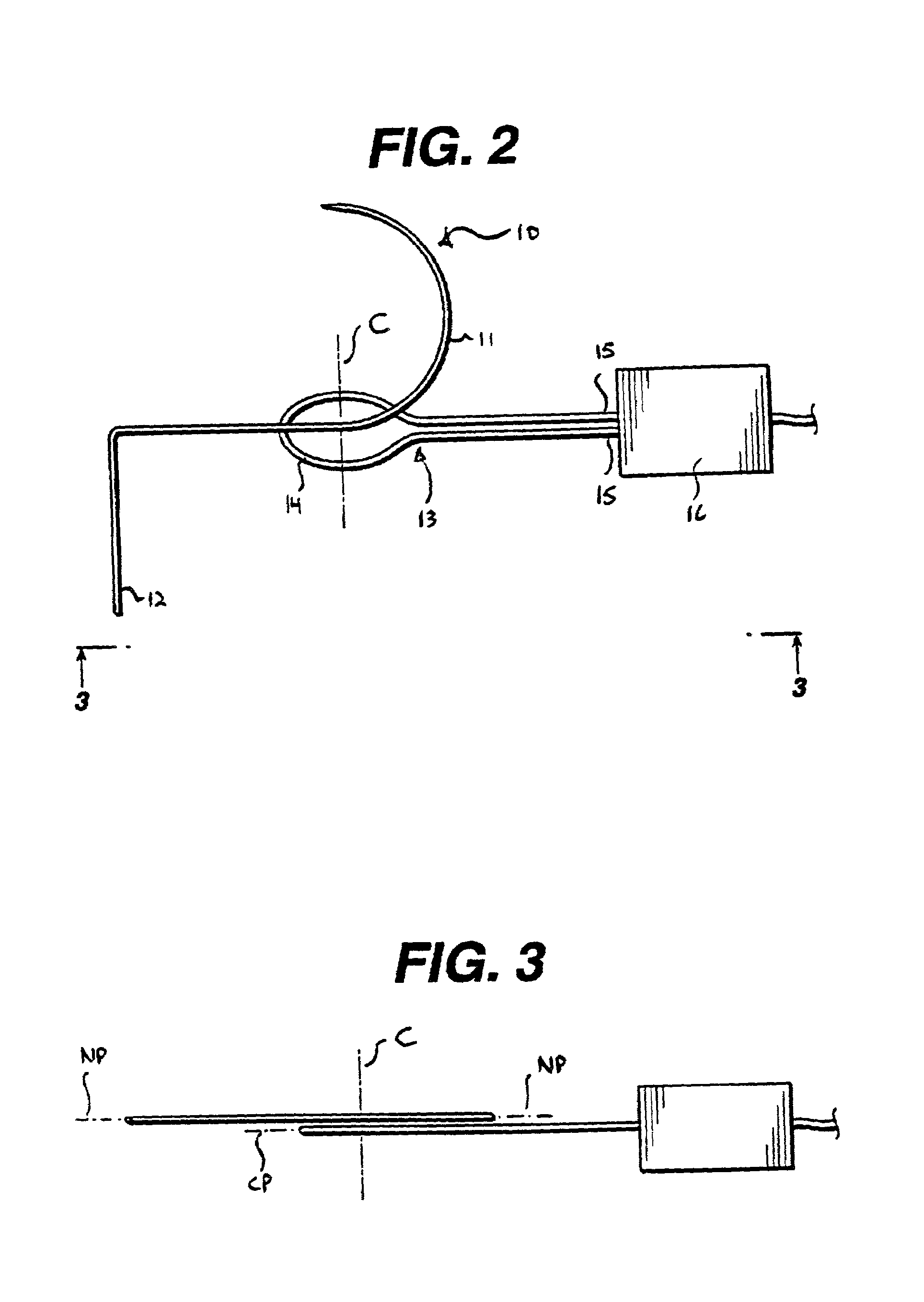

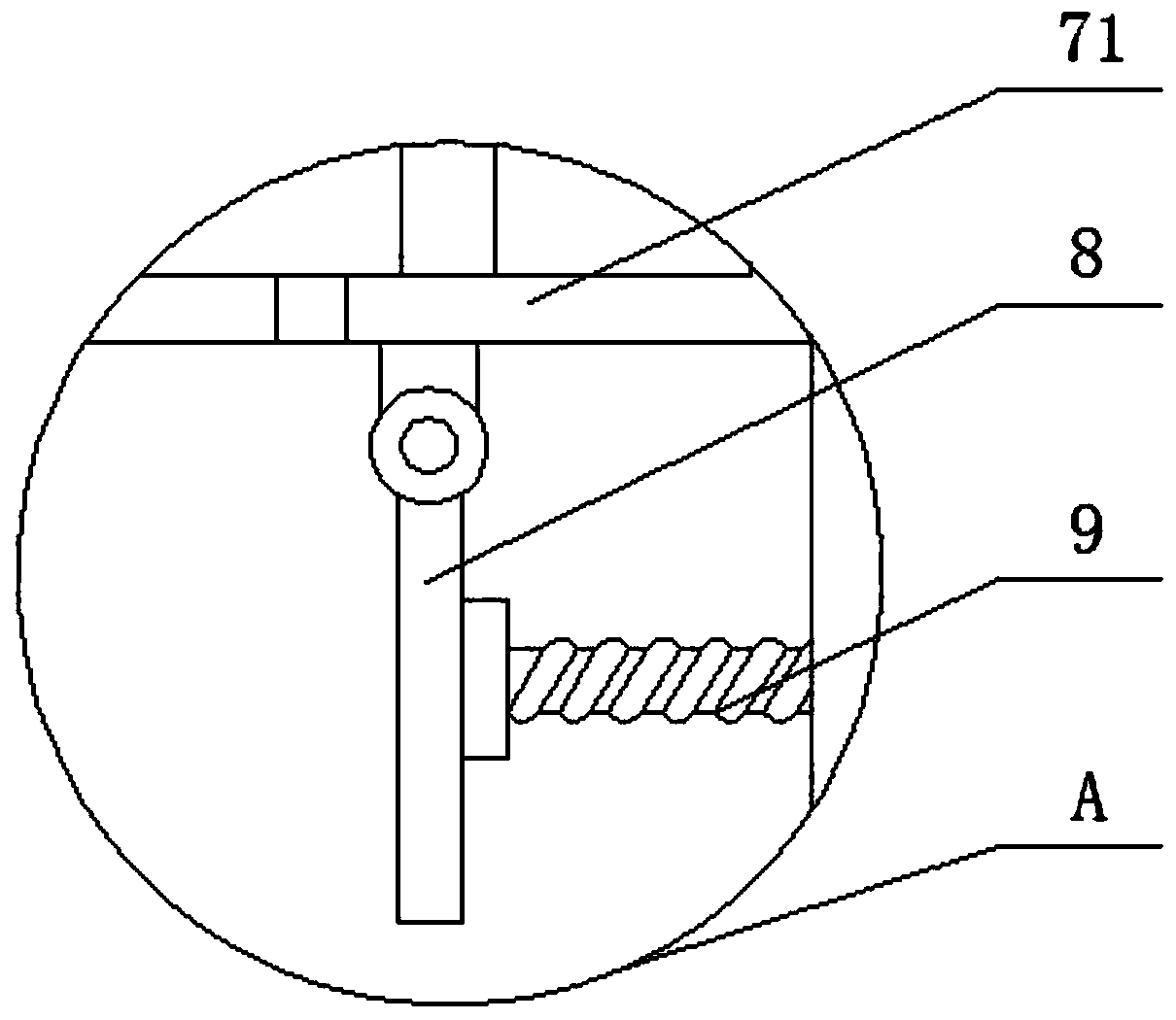

Construction process and equipment for downhole impacting high-pressure jet grouting pile

ActiveCN102322058ASimple mechanical structureStrong stratum adaptabilityDrill bitsDrilling rodsDamage effectsWater jet

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

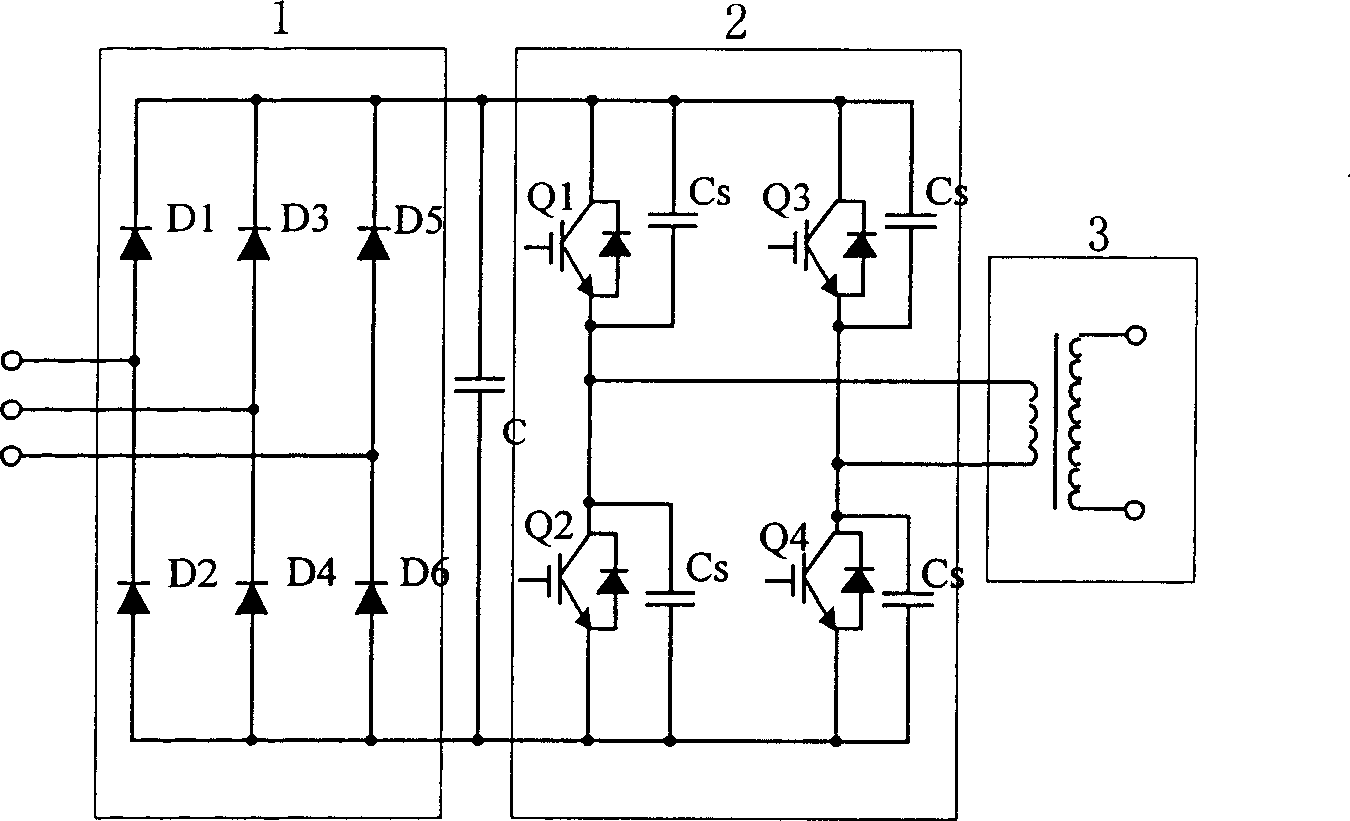

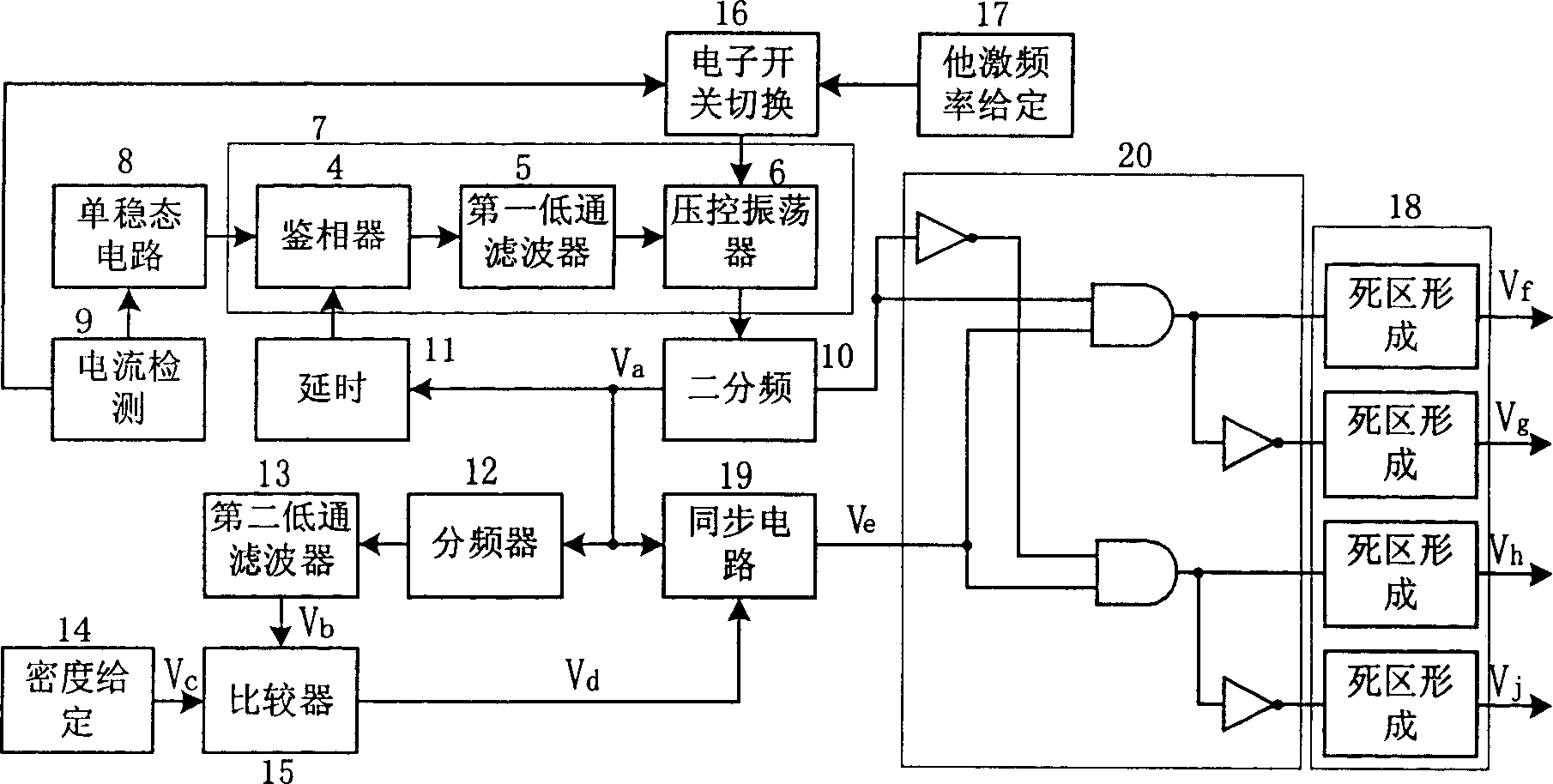

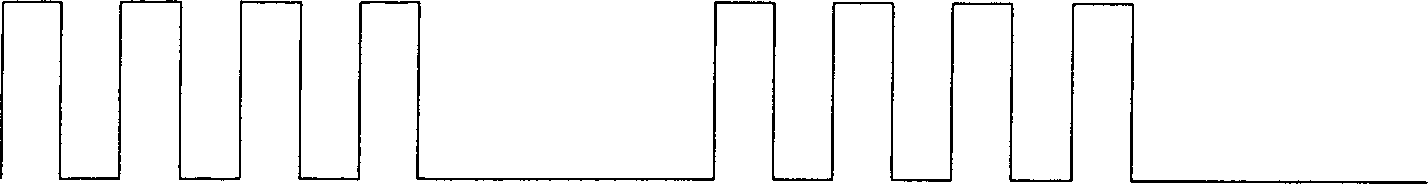

Atmospheric pressure glow discharge control method and its circuit based on pulse density modulation

Present invention discloses pulse number modulation based atmospheric pressure glow discharge control method and circuit. Control method adopts pulse density modulation to generate alternate presented square wave pulsing signal to control inversion circuit switch tube on / off in glow discharge main circuit, each working period containing fixed quantitative square wave pulse, through keeping working period unchanged and changing working period square wave pulse number to control inversion circuit feeding energy time to load, realizing atmospheric pressure glow discharge load fixed frequently constant voltage control. The present invention can realize frequency follow-up control and linear power regulation to atmospheric pressure glow discharge type nonlinear variational capacitive loading.

Owner:ZHEJIANG UNIV

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

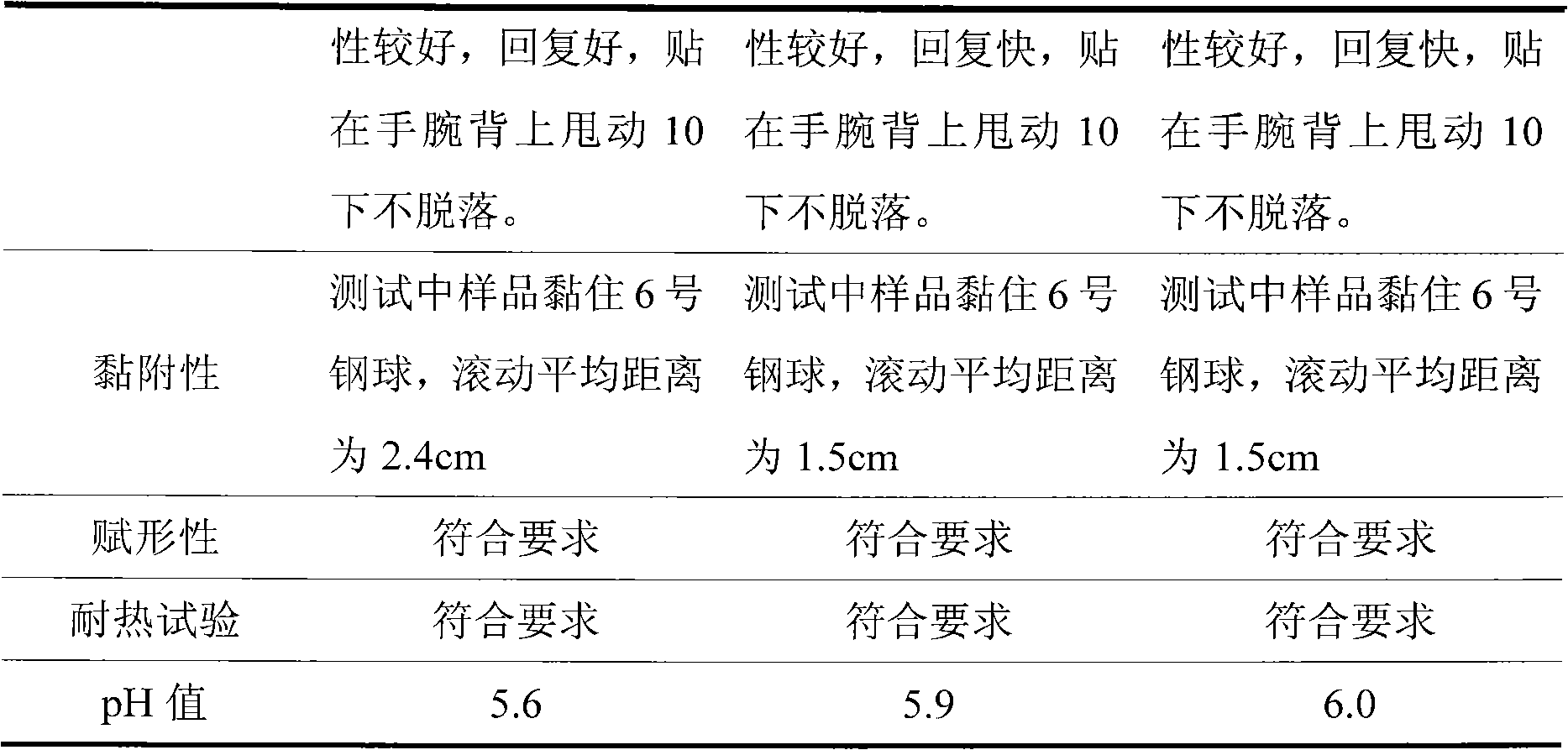

Traumatic injury analgesic cataplasm preparation and preparation method thereof

InactiveCN101780169AGood compatibilityLarge drug loading capacity in matrixAnthropod material medical ingredientsHydroxy compound active ingredientsWater solubleMonkshoods

The invention relates to a traumatic injury analgesic cataplasm and a preparation method thereof, the traumatic injury analgesic cataplasm is produced by formula raw materials of traumatic injury analgesic paste according to the process of the cataplasm and comprises a hydrophilic gel matrix, a non-woven fabric back-up material and a traumatic injury analgesic paste drug, and the traumatic injury analgesic paste drug consists of ground beetle, crude kusnezoff monkshood, nux vomica (stir-fried), rhubarb, rosewood heart wood, shinyleaf pricklyash root, baical skullcap root, amur corktree bark, giant knotweed rhizome, borneol, camphor, menthol, peppermint oil and methyl salicylate. The soluble matrix of the cataplasm has good compatibility with water-soluble and fat-soluble drugs, and the drug loading of the matrix is great, thereby being very applicable to medication features of multiple components and large dose of traditional Chinese medicine; compared with an adhesive plaster agent, the cataplasm is easier to soften the horny layer of skin, is conductive to transdermal absorption of the drug and has better air permeability, adhesion to the skin and moisture retention, thereby having the advantages of comfortable use, small irritation to the skin, repeated tearing and pasting, no pollution of clothes, no residue, no pain when tearing after the use and the like.

Owner:GUANGZHOU BAIYUNSHAN PHARM CO LTD

Process for producing fuel cell film electrode

A processing technology for a fuel battery film electrode characterizes in using chromaticity printing to process multiplayer catalyst to make its inner layer composition to form density gradient along thickness direction, applying superconductive ethyne to process transient layer and applying supersonic wave welding to weld film electrode components increasing usability of noble metal, combination strength of film electrode system, preventing films from damage and distortion and increasing its power density to 0.45-0.5w / cm2.

Owner:江苏隆源双登电源有限公司

Preparation method of actinidia arguta freeze-dried fruit powder

ActiveCN103431331ANo pollution in the processNo pesticide residueFood shapingFood preparationActinidiaFreeze-drying

The actinidia arguta is a specific precious wild resource. The meat of the actinidia arguta is jade green; the actinidia arguta tastes fine, juicy, fragrant and delicious; the sweetness and the sourness are proper; the nutrition is very rich; the actinidia arguta is a fruit well received by customers and is known as the king of fruits. Wild actinidia arguta resources are readily available in Changbai Mountains, but products of the actinidia arguta are few and cannot meet the consumption demands in different seasons, so that the demands of the customers for wild actinidia arguta products are suppressed. The invention discloses a preparation technology for Changbai-mountain pure natural wild actinidia arguta fruit powder. According to the technology, the freeze-dried fruit powder is prepared by selecting fresh and intact actinidia arguta, washing, smashing, pulping and concentrating the actinidia arguta, adding maltodextrin and performing vacuum freeze-drying on mixed fruit paste. The actinidia arguta freeze-dried fruit powder is high in nutrient value and is convenient food suitable for various groups of people.

Owner:通化百泉参业集团有限公司

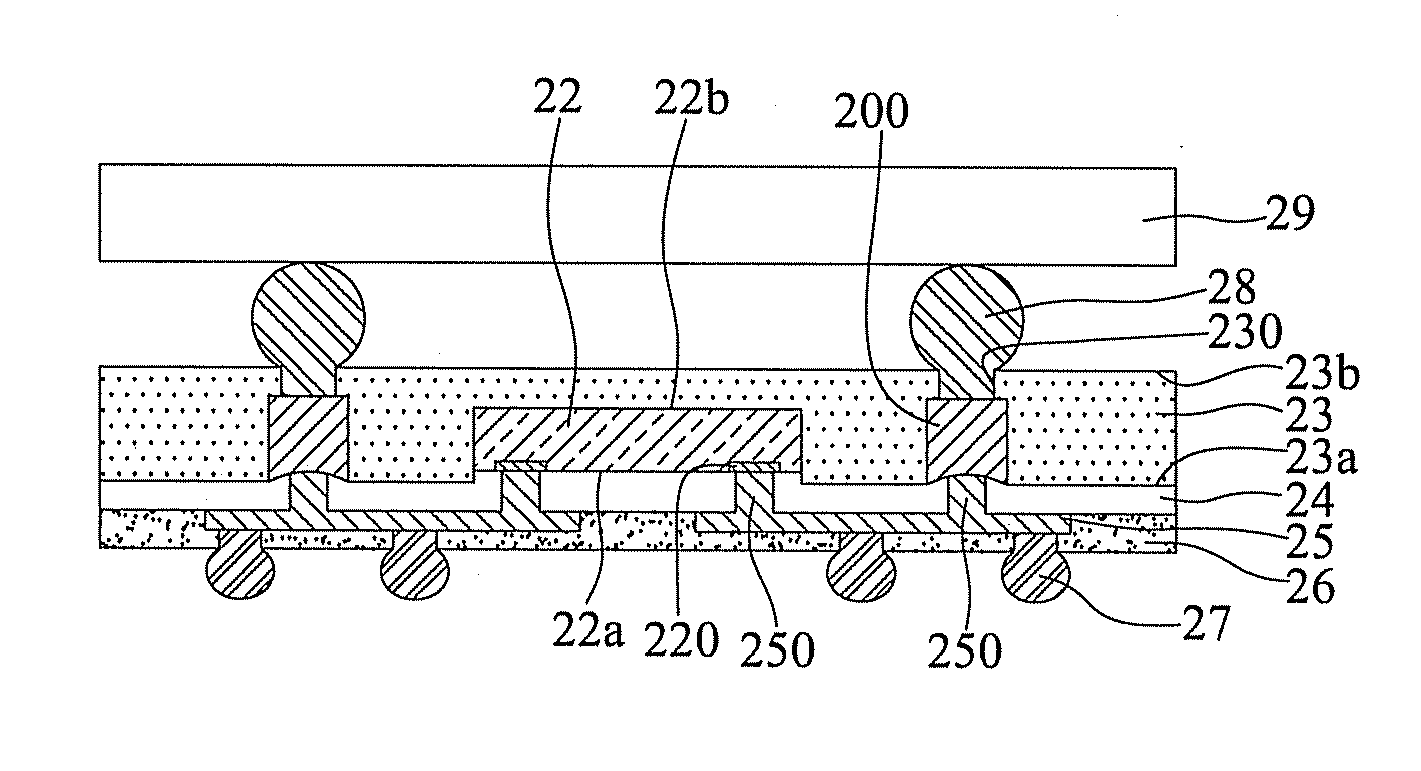

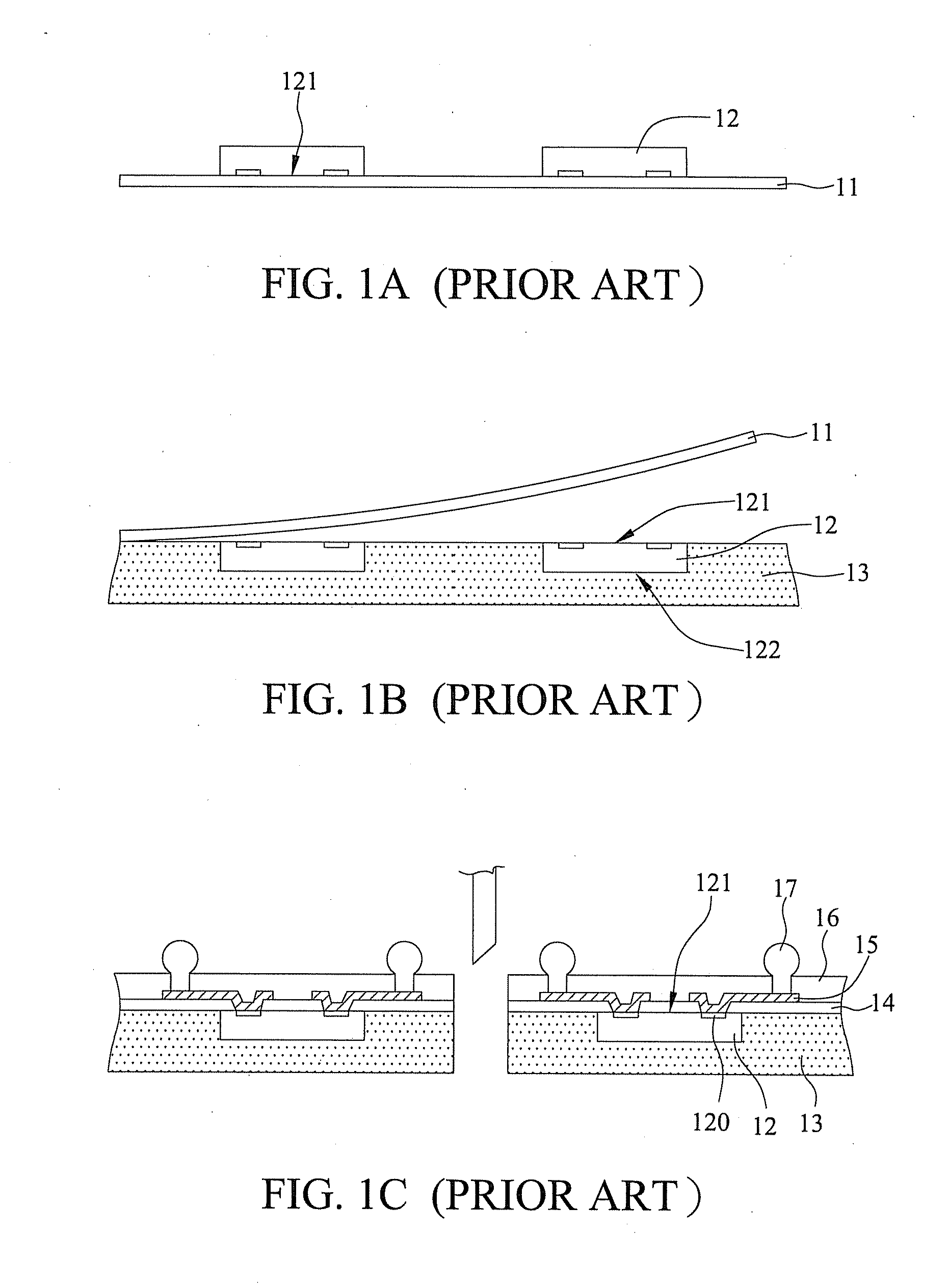

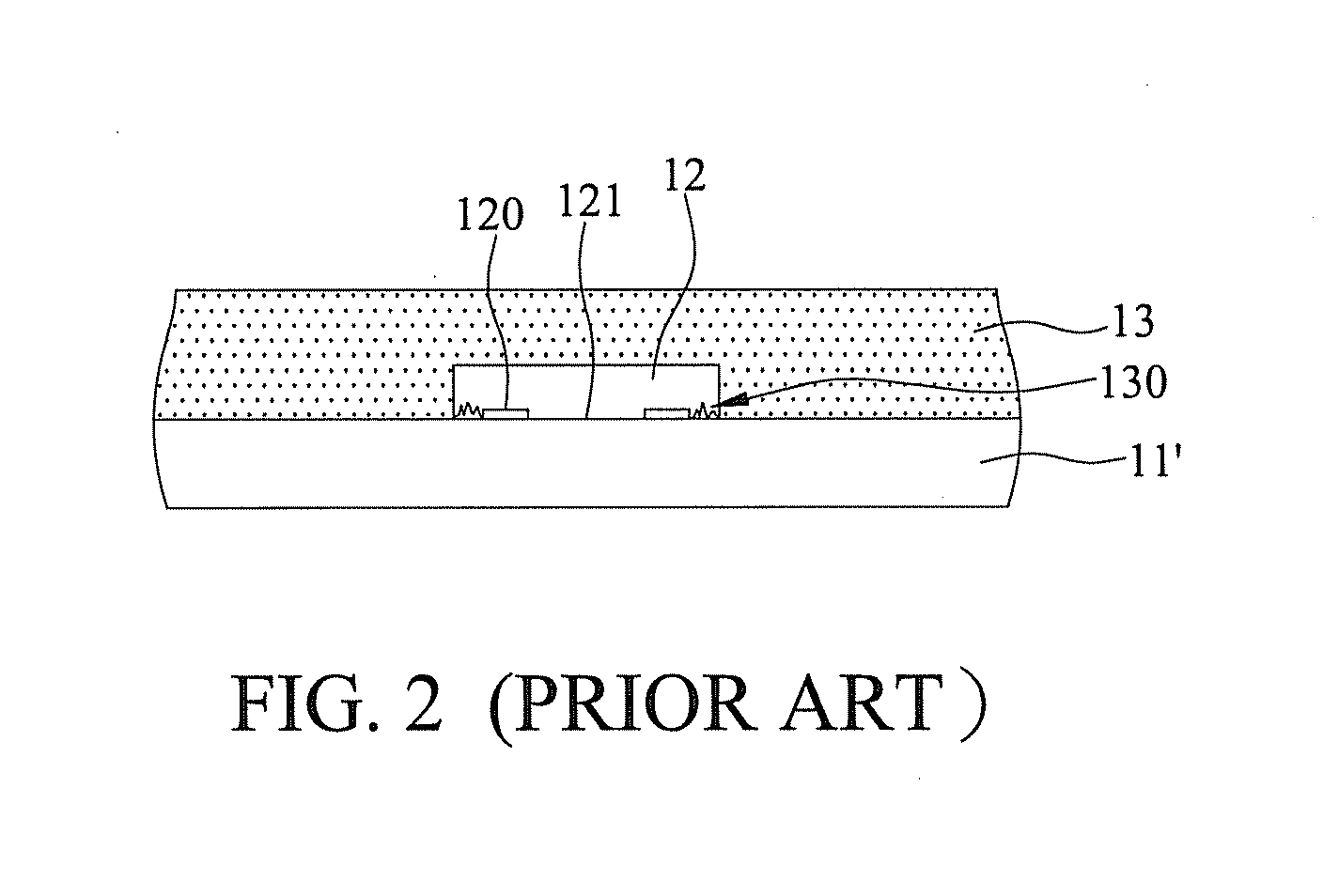

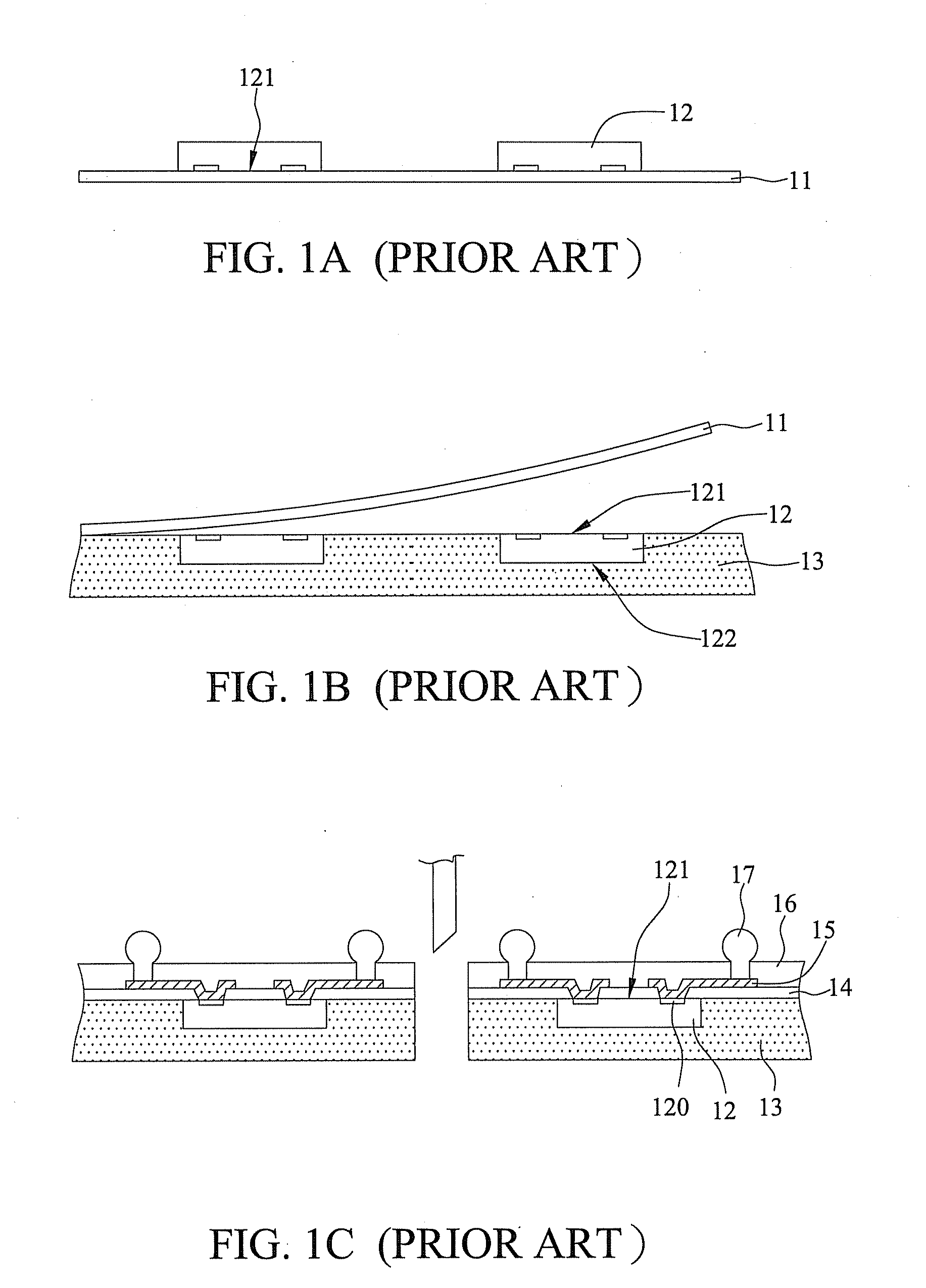

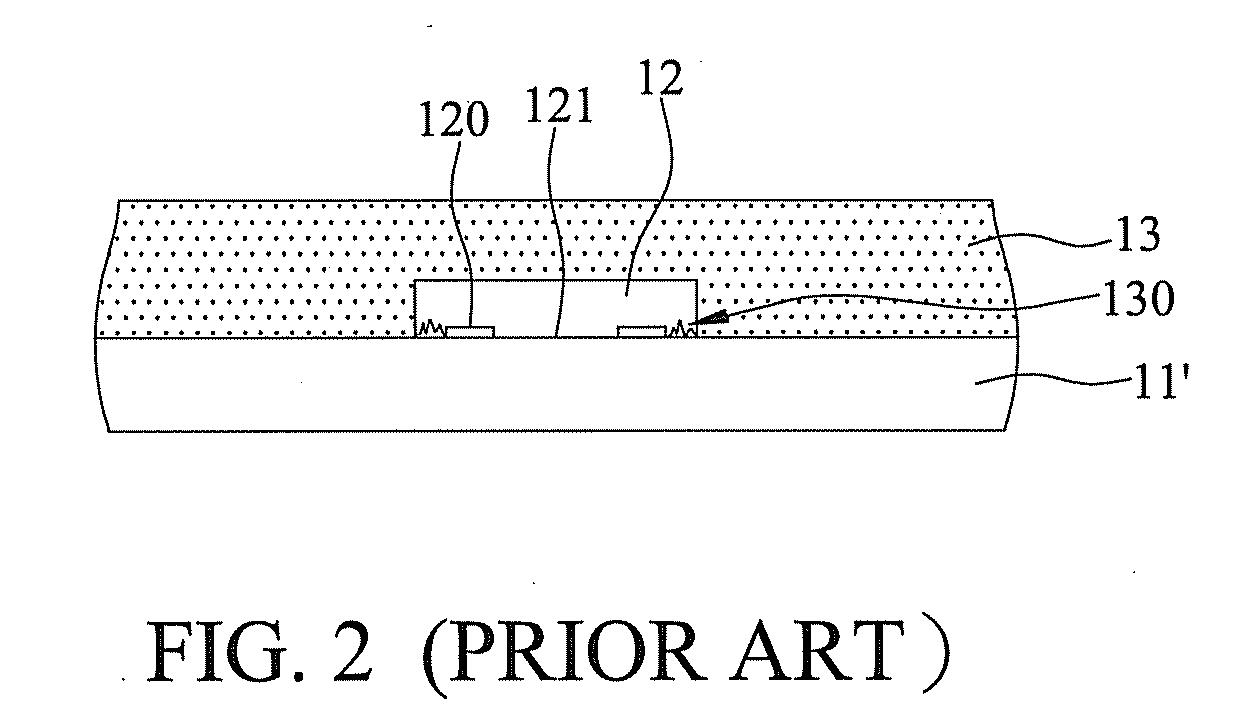

Chip scale package and method of fabricating the same

InactiveUS20120061825A1Stable supportSimplify the manufacturing processSemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

A chip scale package and a method of fabricating the chip scale package. The chip scale package includes a encapsulant having a first surface and a second surface opposing the first surface; a conductive pillar formed in the encapsulant and exposed from the first surface and the second surface; a chip embedded in the encapsulant while exposed from the first surface; a dielectric layer formed on the first surface, the conductive pillar and the chip; a circuit layer formed on the dielectric layer; a plurality of conductive blind vias formed in the dielectric layer electrically connecting the circuit layer, electrode pads and the conductive pillar; and a solder mask layer formed on the dielectric layer and the circuit layer, thereby using conductive pillars to externally connect with other electronic devices as required to form a stacked structure.

Owner:SILICONWARE PRECISION IND CO LTD

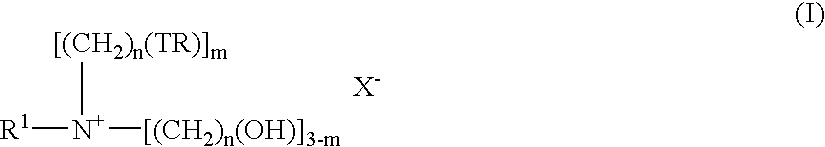

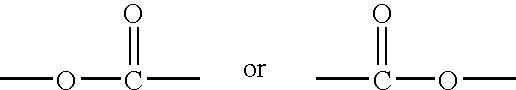

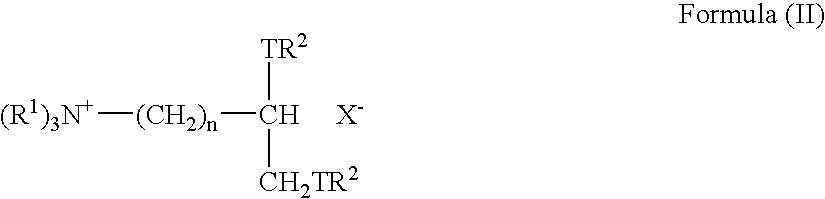

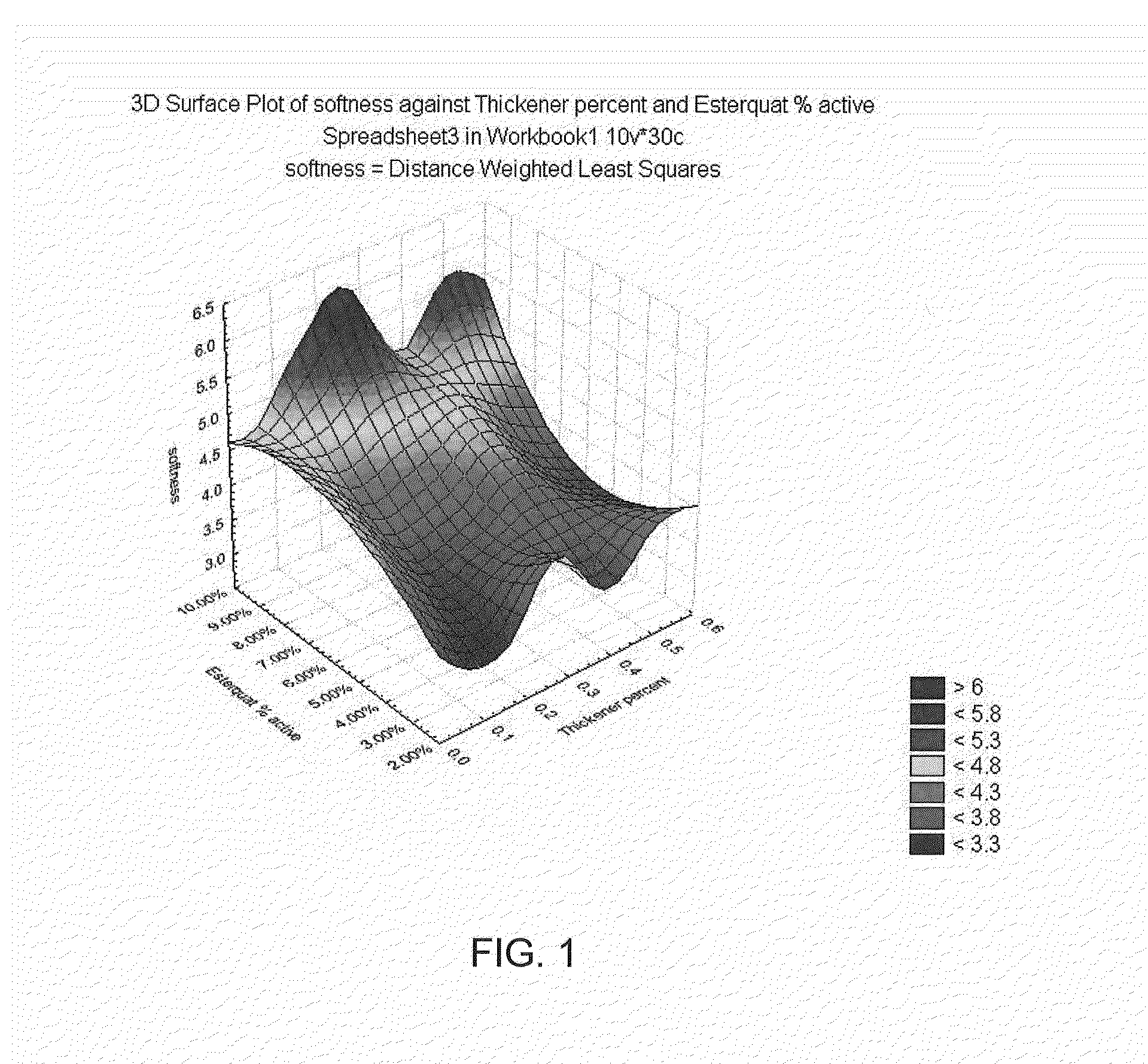

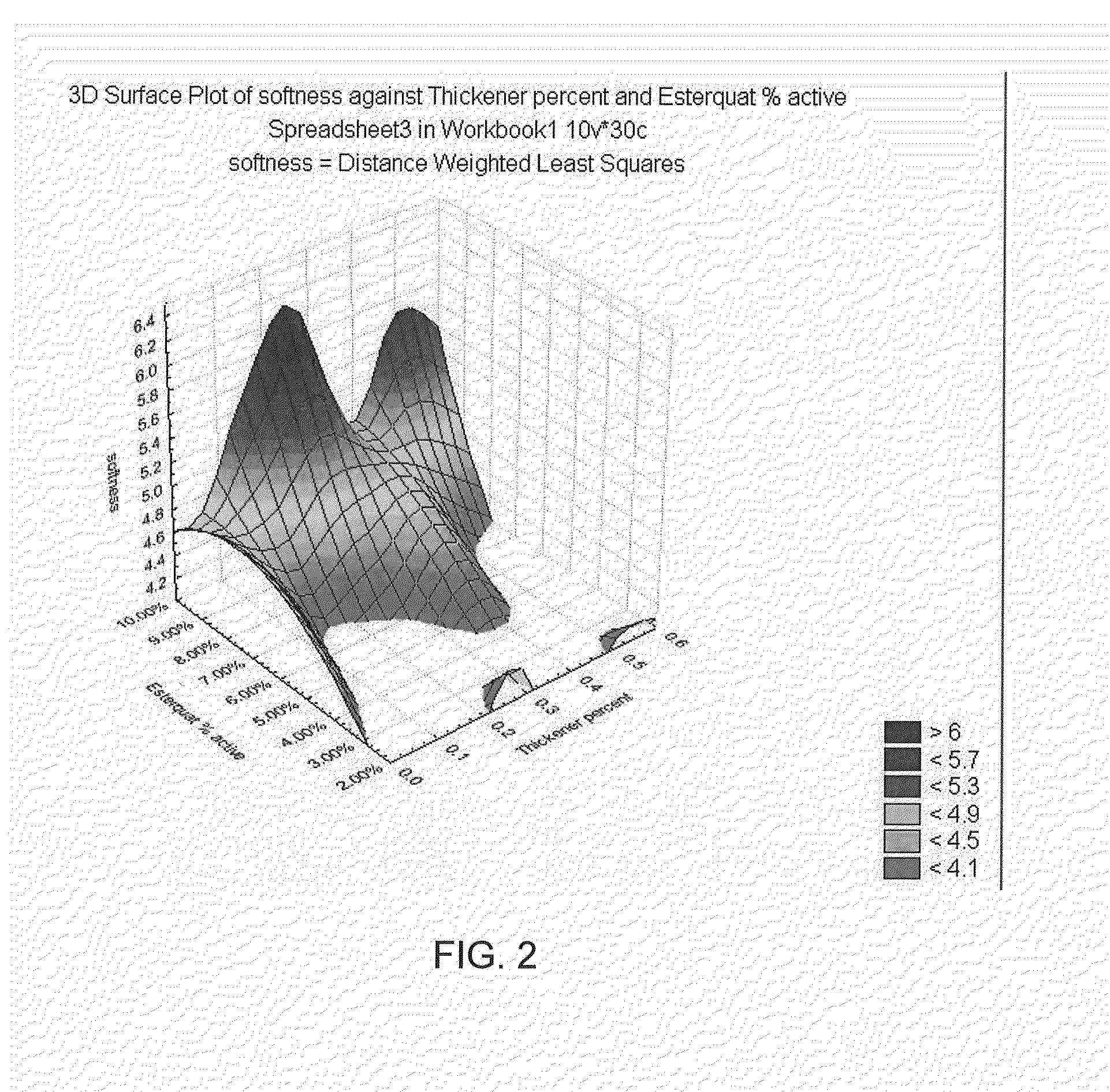

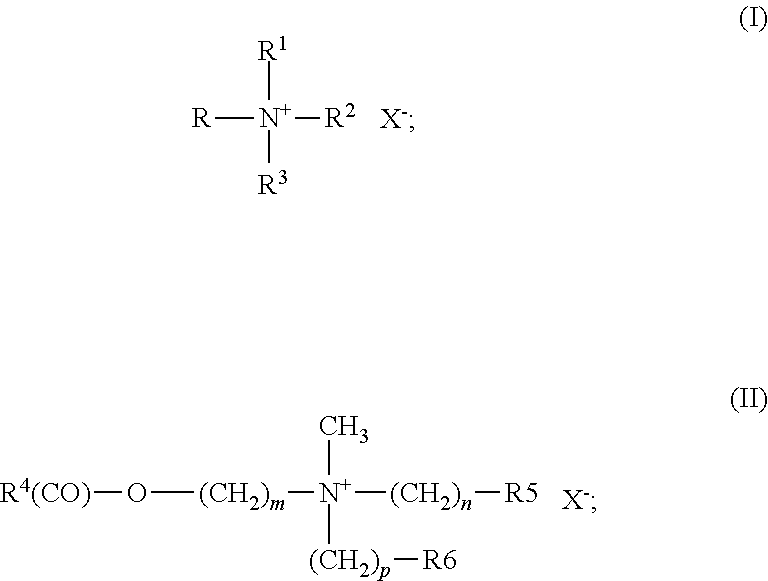

Method of increasing the performance of cationic fabric softeners

ActiveUS20140315779A1Low costLess expensiveCationic surface-active compoundsFibre treatmentChlorideSURFACTANT BLEND

The present invention is method of boosting the performance of a cost-reduced liquid fabric softener comprising a quaternary surfactant fabric softener by adding a quaternary (meth)acrylic polymer that functions dually as a fabric softening active and a rheology modifier. In particular, poly[{2-(methacryloyloxy)ethyl}trimethylammonium chloride], poly[{2-(acryloyloxy)ethyl}trimethylammonium chloride], poly[{3-(methacryloyloxy)propyl}trimethylammonium chloride], and poly[{3-(acryloyloxy)propyl}trimethylammonium chloride] provide synergistic fabric softening with quaternary surfactants to provide superior fabric softening scores from cost-optimized compositions.

Owner:HENKEL KGAA

Conformable multi-layer sheet materials

InactiveUS6869496B1Easy to operatePromote softeningStampsLamination ancillary operationsPolyesterPhysical property

A multi-layer sheet material comprises a film, and adhesive layer and an optional release liner. The film is a polyester blend comprising first and second polyesters that are substantially amorphous and possess certain physical properties including softening temperature, E-modulus, elongation and residual stress.

Owner:3M INNOVATIVE PROPERTIES CO

Method of selectively annealing a needle

InactiveUS7001472B2Facilitate selective hardeningPromote softeningSurgical needlesFurnace typesPower flowImproved method

An improved method of selectively annealing a needle and the needle prepared by the improved method is disclosed. A curved needle is positioned adjacent a flat electromagnetic induction coil. The curved body of the needle is positioned in a plane parallel with the coil plane of the flat induction coil. A current is delivered through the coil to selectively heat and consequently selectively anneal a portion of the needle. The improved method enables the selective annealing of curved needles, and is especially useful for the manufacture of surgical needles.

Owner:ETHICON INC

Planting method for red-fleshed pitaya

InactiveCN106941898APromote thrivingPlay a role in heat preservationAlkali orthophosphate fertiliserExcrement fertilisersFruit treePollination

The invention provides a planting method for red-fleshed pitaya, belonging to the technical field of cultivation of fruit trees. The planting method comprises the following concrete steps: (1) orchard building; (2) field planting; (3) field management: a step of carrying out watering once every 2 to 3 days in 2 to 3 months after planting of a pitaya seedling so as to maintain moist of soil, carrying out watering once every 7 to 13 days after three months, topdressing a fertilizer for 6 to 8 times in the first year after planting of the pitaya seedling, wherein the applying amount of a fertilizer is 1 to 1.5 kg per plant every time, topdressing the fertilizer for 3 to 4 times every year after flowering and fruiting of pitaya, wherein the applying amount of the fertilizer is 9 to 11 kg per plant every time, and controlling diseases and pests in the growth period of the pitaya; (4) pruning; (5) artificial pollination; (6) thinning of flowers and fruits; (7) bagging; and (8) harvesting. The planting method for the red-fleshed pitaya provided by the invention designs a planting scheme by aiming at the growth characteristics of the red-fleshed pitaya, promotes healthy and vigorous growth of the red-fleshed pitaya, and improves the yield of the red-fleshed pitaya.

Owner:陆川县一品养殖专业合作社

Device and method for supercritical carbon dioxide high-pressure jet flow plug removal seepage enhancement

The invention belongs to the technical field of oil-gas well yield increase equipment and relates to a device and method for supercritical carbon dioxide high-pressure jet flow plug removal seepage enhancement. An oil pipe is sleeved with a casing pipe, a packer is arranged between the casing pipe and the oil pipe, and an exploder is arranged in the oil pipe and connected with the oil pipe; a piston is arranged below the exploder and the portion between the piston and the exploder is filled with propellant; a cylinder sleeve is arranged at the lower end of the piston and the piston moves downwards in the cylinder sleeve; a flow guide connector is arranged on the lower portion of the cylinder sleeve; a nozzle is arranged on the flow guide connector and a rupture disk or an elastic body is arranged on the outlet portion of the nozzle; after the propellant is ignited by the exploder, energy is generated, so that the piston is pushed to compress supercritical carbon dioxide, short-time supercritical carbon dioxide jet flow waves generated through breakage of the rupture disk or popup of the elastic body enable rock to crack initially, and cracks are expanded through the pressure of short-time supercritical carbon dioxide jet flow with the low viscosity of the supercritical carbon dioxide. According to the device and method for supercritical carbon dioxide high-pressure jet flow plug removal seepage enhancement, the structure is simple, operation is convenient, raw materials are easy to obtain, cost is low, the energy use rate is high, and the device and method are environmentally friendly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

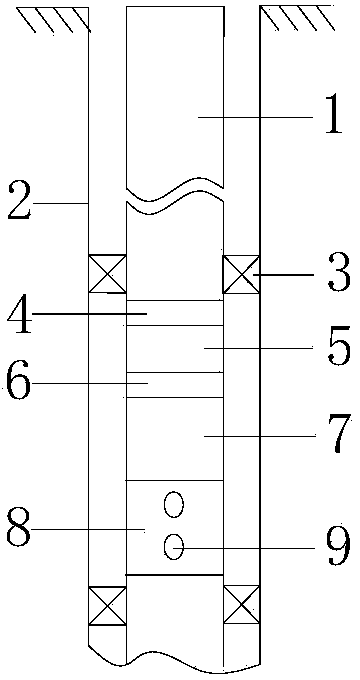

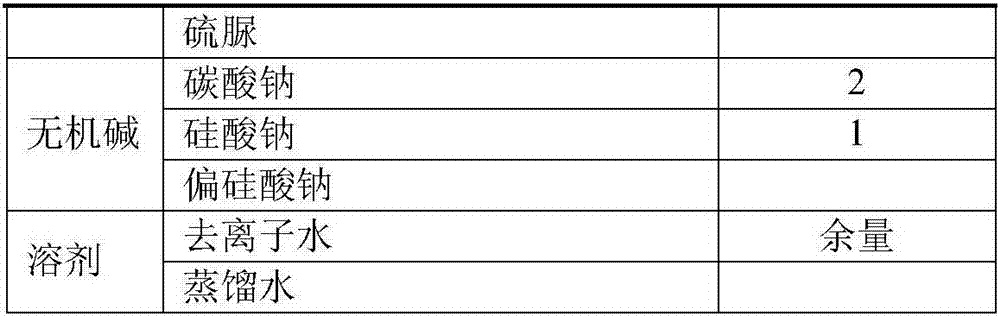

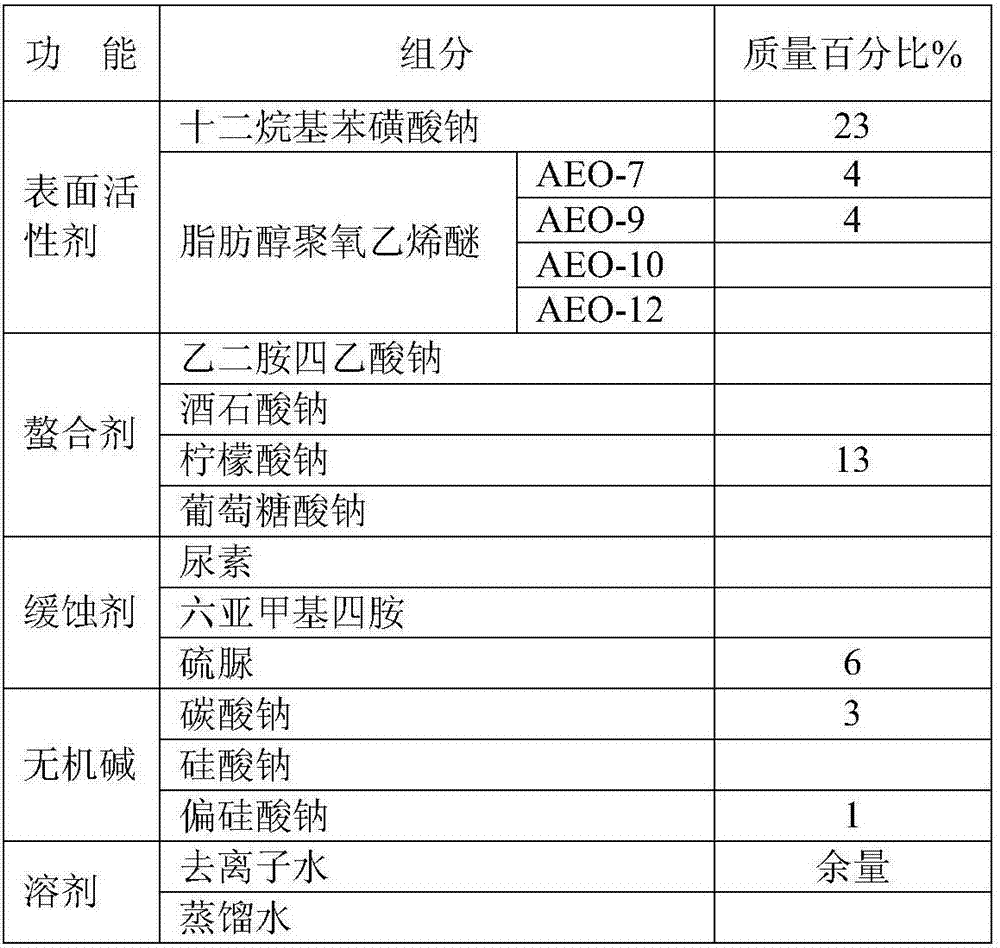

Airplane skin external surface cleaning compound

InactiveCN107254367AImprove wettabilityImprove solubilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsJet aeroplaneSurface cleaning

The invention relates to an airplane skin external surface cleaning compound. The airplane skin external surface cleaning compound comprises a surfactant, a chelating agent, a corrosion inhibitor, inorganic base and a solvent. The airplane skin external surface cleaning compound comprises the following components by mass percentage: 18-34% of the surfactant, 8-13% of the complexing agent, 5-9% of the corrosion inhibitor, 3-8% of the inorganic base, and the balance of the solvent. The cleaning compound employs a complex formulation technology, the components ratio is reasonable, a pollutant deposited on the airplane skin external surface is thoroughly cleaned, effect is good, efficiency is high, the cost of the cleaning compound is low, no corrosion is generation on a body of the airplane, no pollution is generated on human body and environment, the cleaning waste liquid can be directly discharged, and the cleaning compound has the advantages of safety and environmental friendliness.

Owner:AIR FORCE UNIV PLA

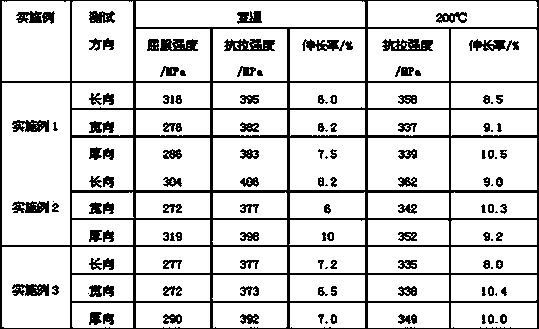

Forging forming technology for large-size high-intensity and heat-resistant magnesium alloy thick plate

The invention discloses a forging forming technology for a large-size high-intensity and heat-resistant magnesium alloy thick plate and provides a forging forming technology for a magnesium alloy thick plate which is thicker than or as thick as 150mm. The forging forming technology comprises the steps of large-furnace smelting, semi-continuous casting, homogenizing annealing, variable-temperature multi-directional forging, fast forging and after-forming thermal treatment, wherein the variable-temperature multi-directional forging is executed on an oil press; before forging, the temperature of an ingot blank is preserved at 500-530 DEG C for 4-6 hours; the pressing speed is 200-400mm / min, the upsetting gate pressing amount is 30-50 percent, and the swaging gate pressing amount is 5-10 percent; the fast forging is executed on an air hammer; before fast forging, the temperature of the ingot blank is preserved at 480-500 DEG C for 2-4 hours. According to the forging forming technology, the high-temperature plasticity of a magnesium alloy is fully achieved, and the usability is obviously improved; at the temperature of 200 DEG C, the tensile strength of the thick plate in the length direction, the width direction and the height direction is higher than or equal to 330MPa, and the elongation rate is larger than or equal to 8 percent.

Owner:CENT SOUTH UNIV

Medicine for treating gynecopathy inflammation and its preparation method

A Chinese medicine for treating gynecologic inflammation is proportionally prepared from 10 Chinese-medicinal materials including Chinese angelica root, sphatholobus stem, zanthoxylum nitidum, persimmon leaf, etc. Its preparing process is also disclosed.

Owner:葵花药业集团(贵州)宏奇有限公司

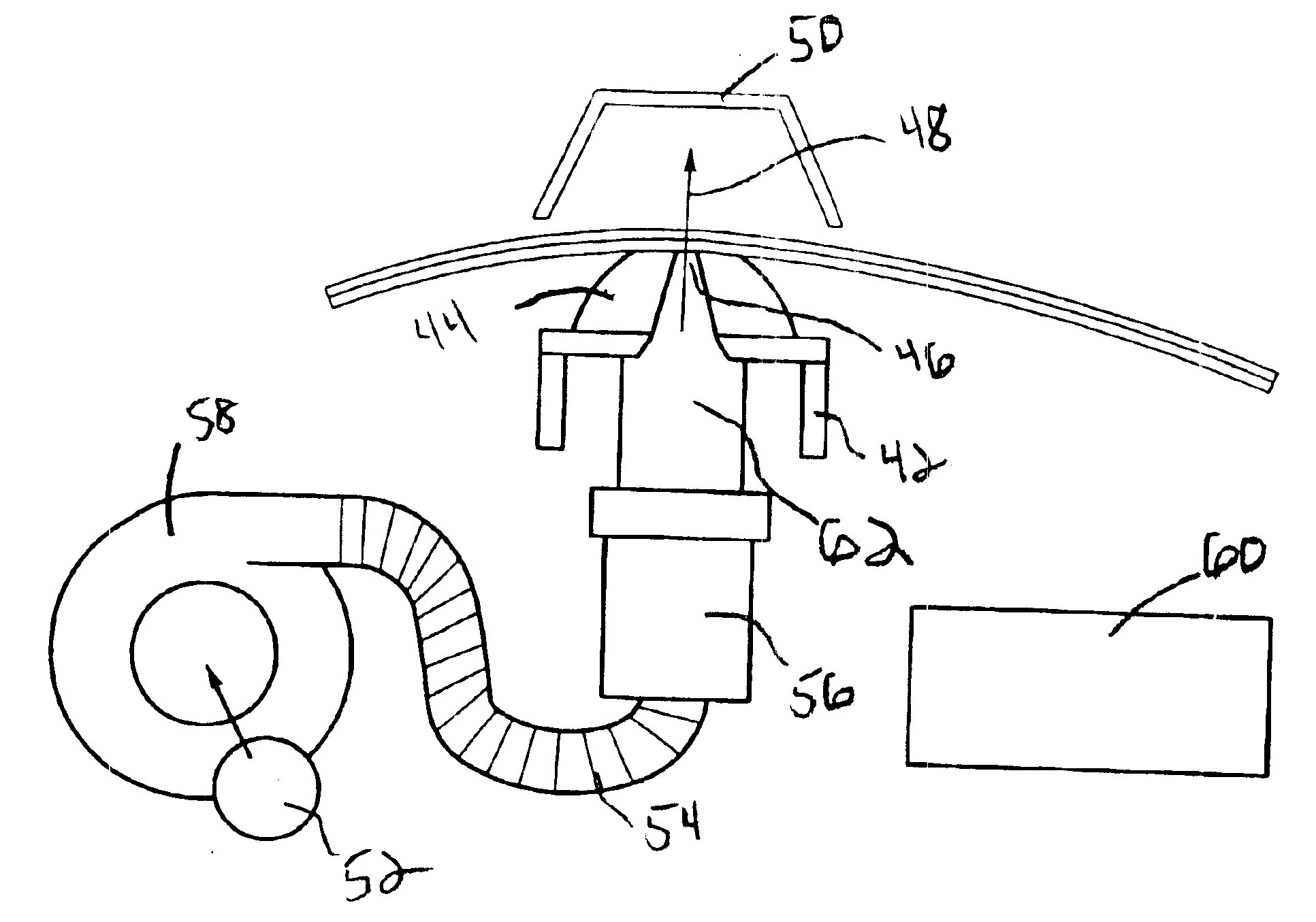

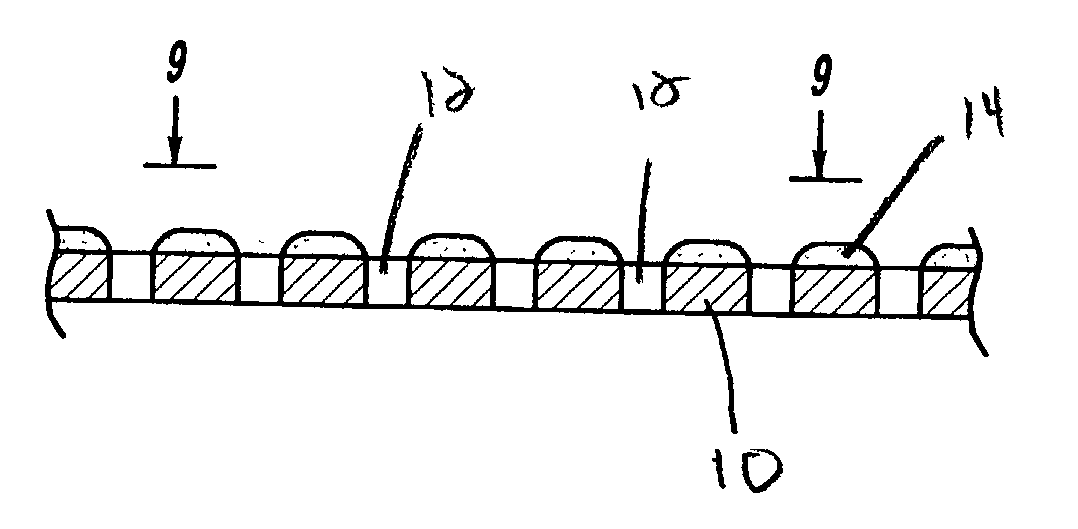

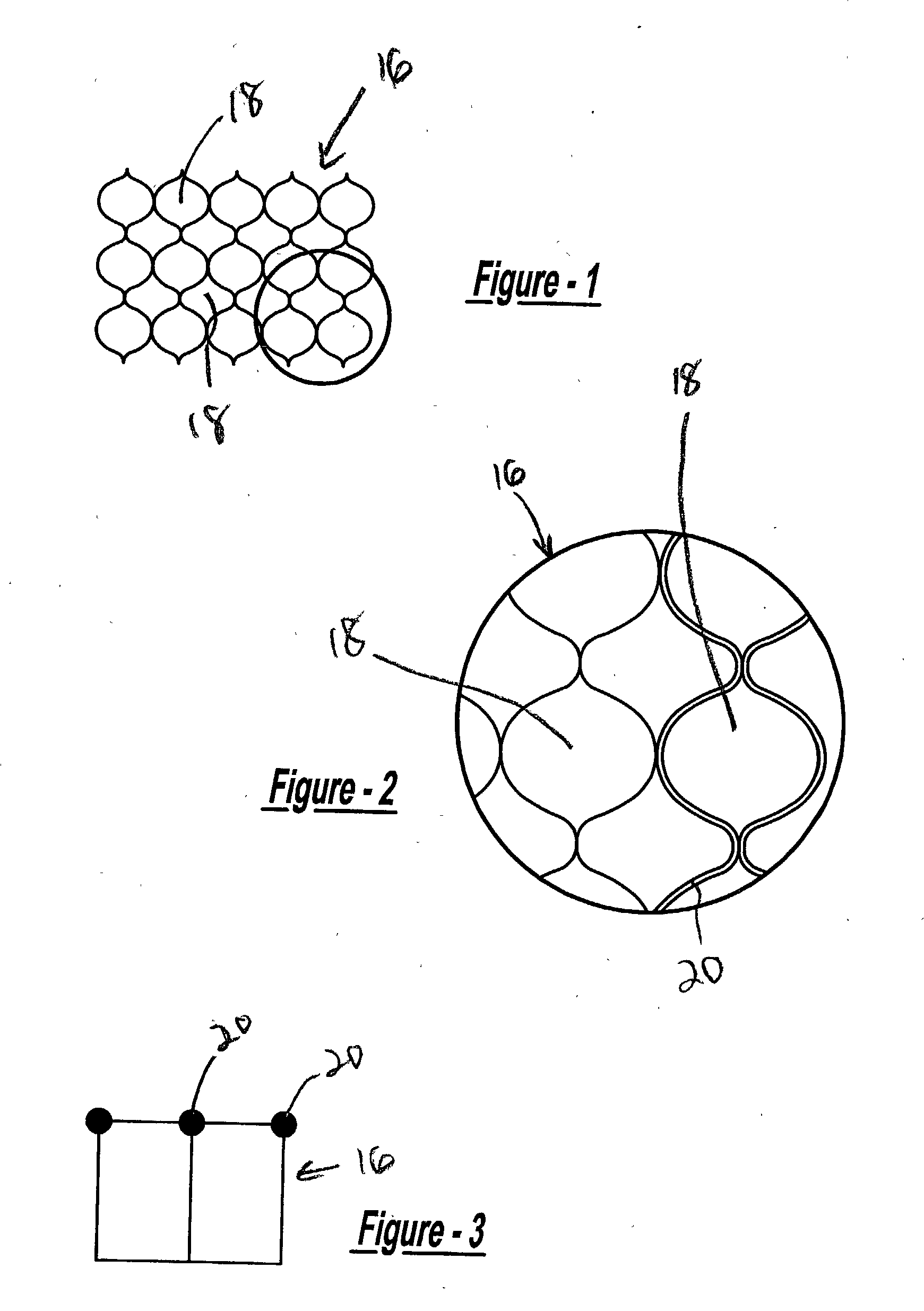

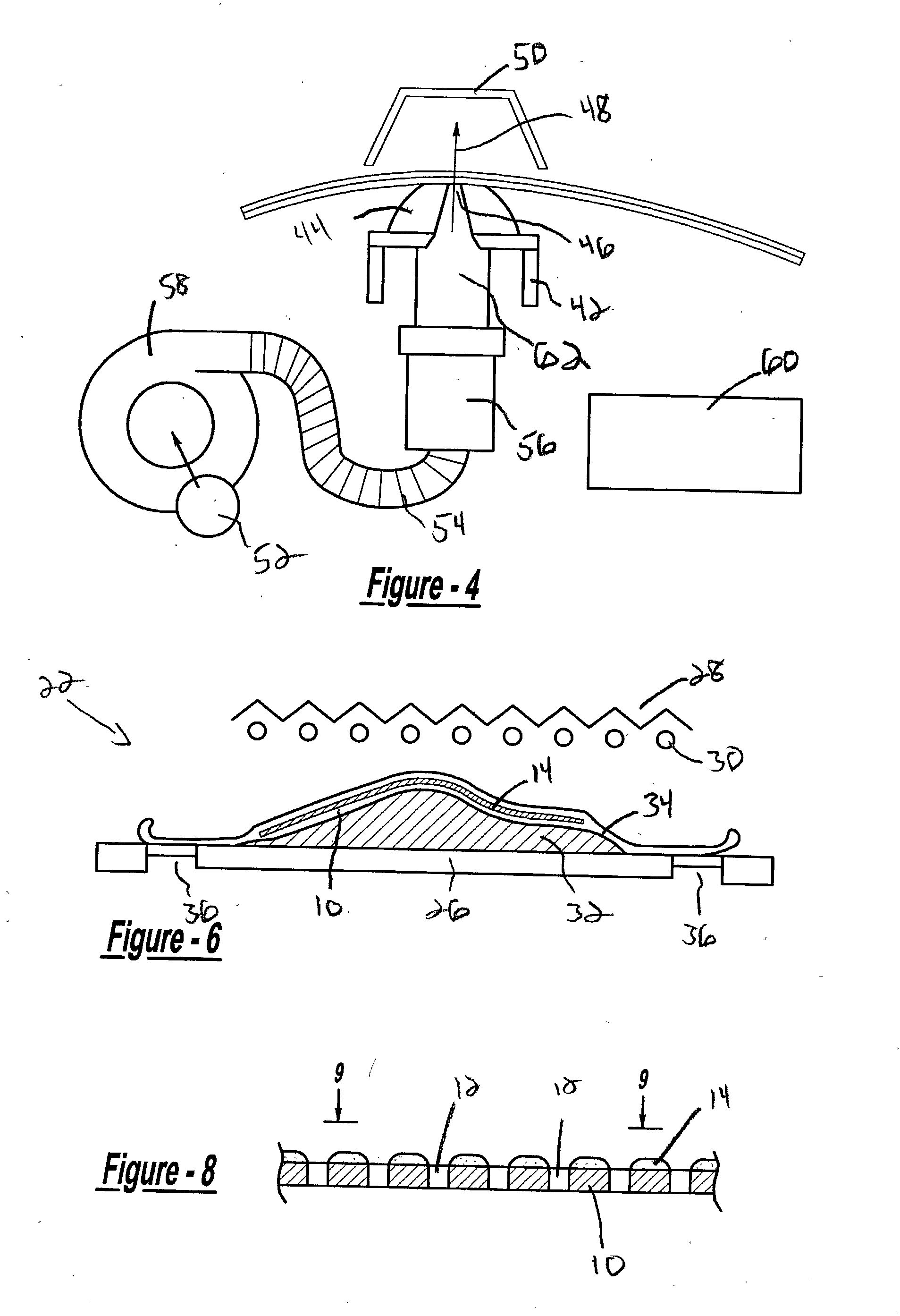

Method and apparatus for applying a film adhesive to a perforated panel

InactiveUS6736181B2Promote softeningStable temperatureLamination ancillary operationsLaminationAdhesiveEngineering

A method and apparatus for preparing a perforated panel for reticulation to a film adhesive. The method includes supporting the perforated panel. The method also includes adhering the film adhesive to the perforated panel without initiating a cure of the film adhesive. The method applies a vacuum to the film adhesive. Next the method will move the perforated panel at a predetermined speed through a reticulation unit. Next the method will soften the film adhesive and finally remove the film adhesive from the perforations by an airflow. The method is generally used for creating acoustic sheet panels for use in many industries.

Owner:GKN WESTLAND AEROSPACE +1

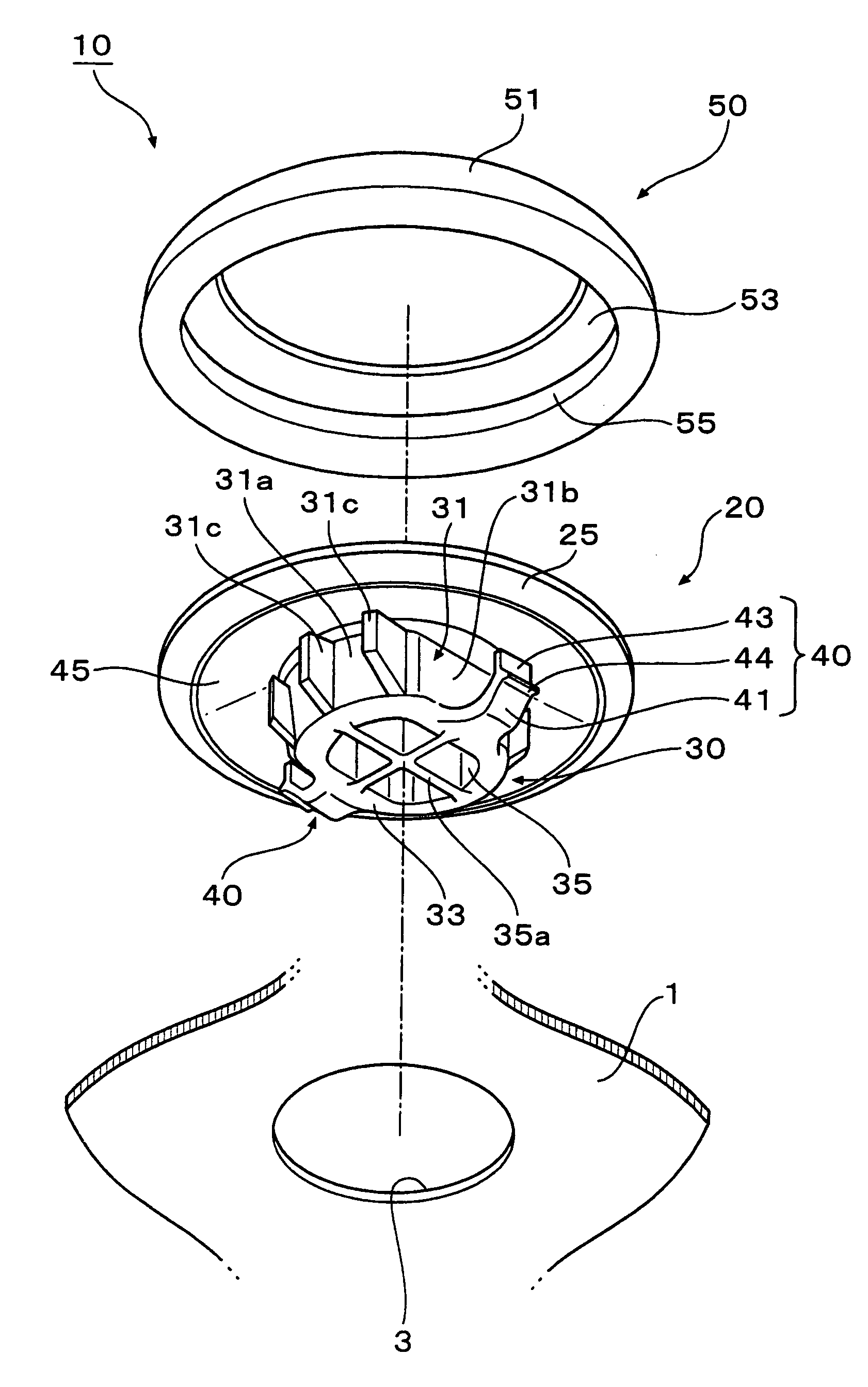

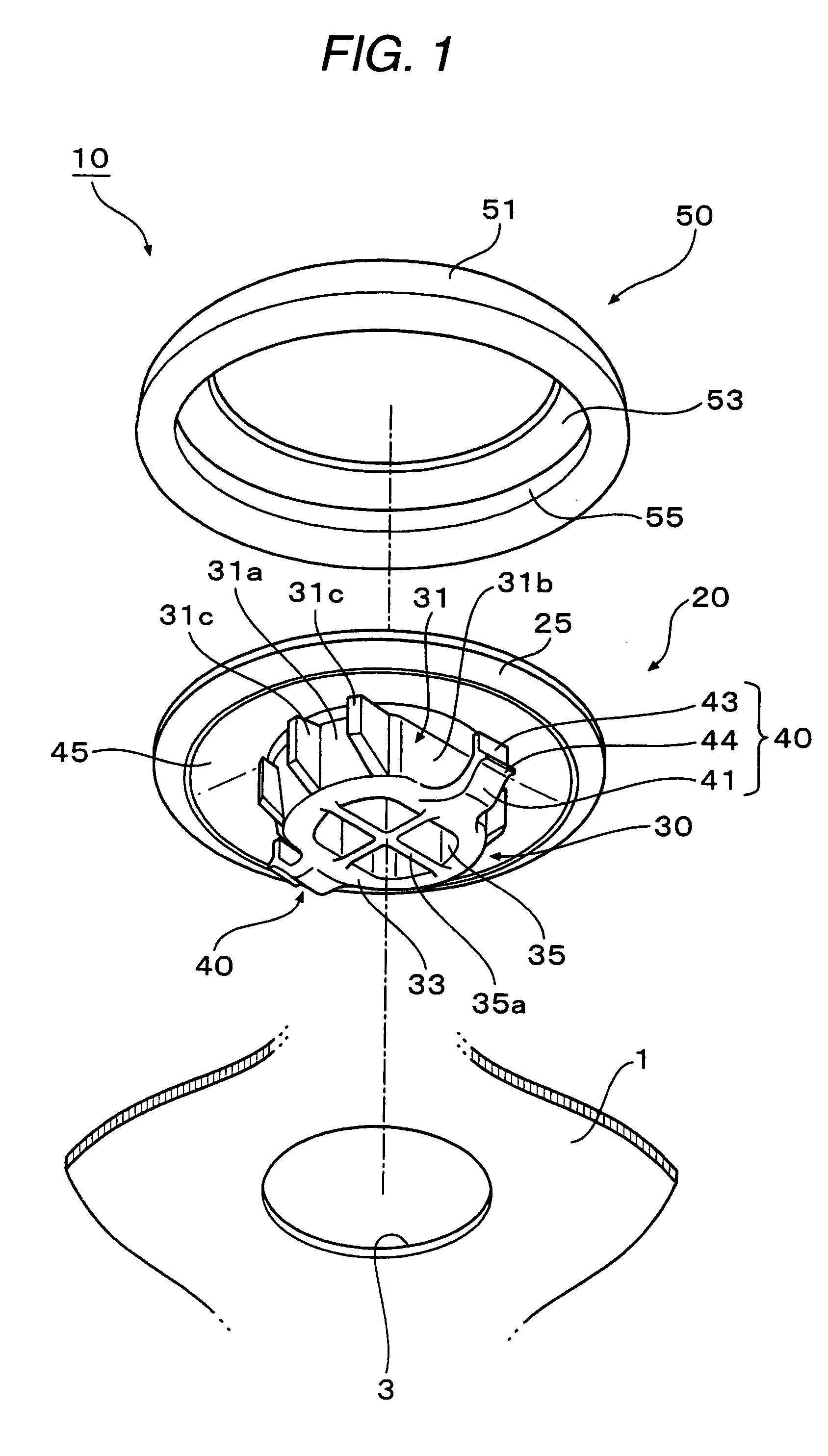

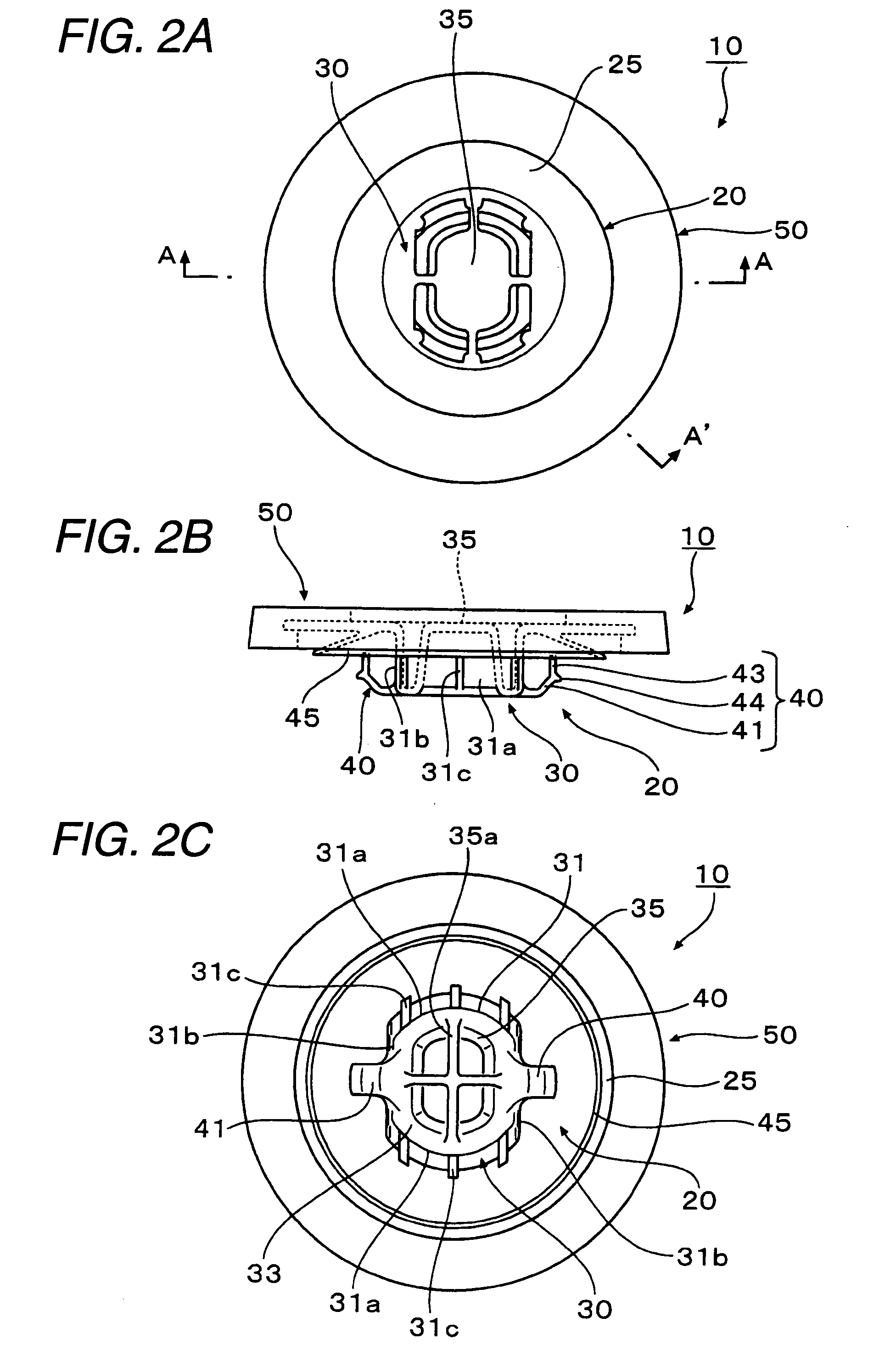

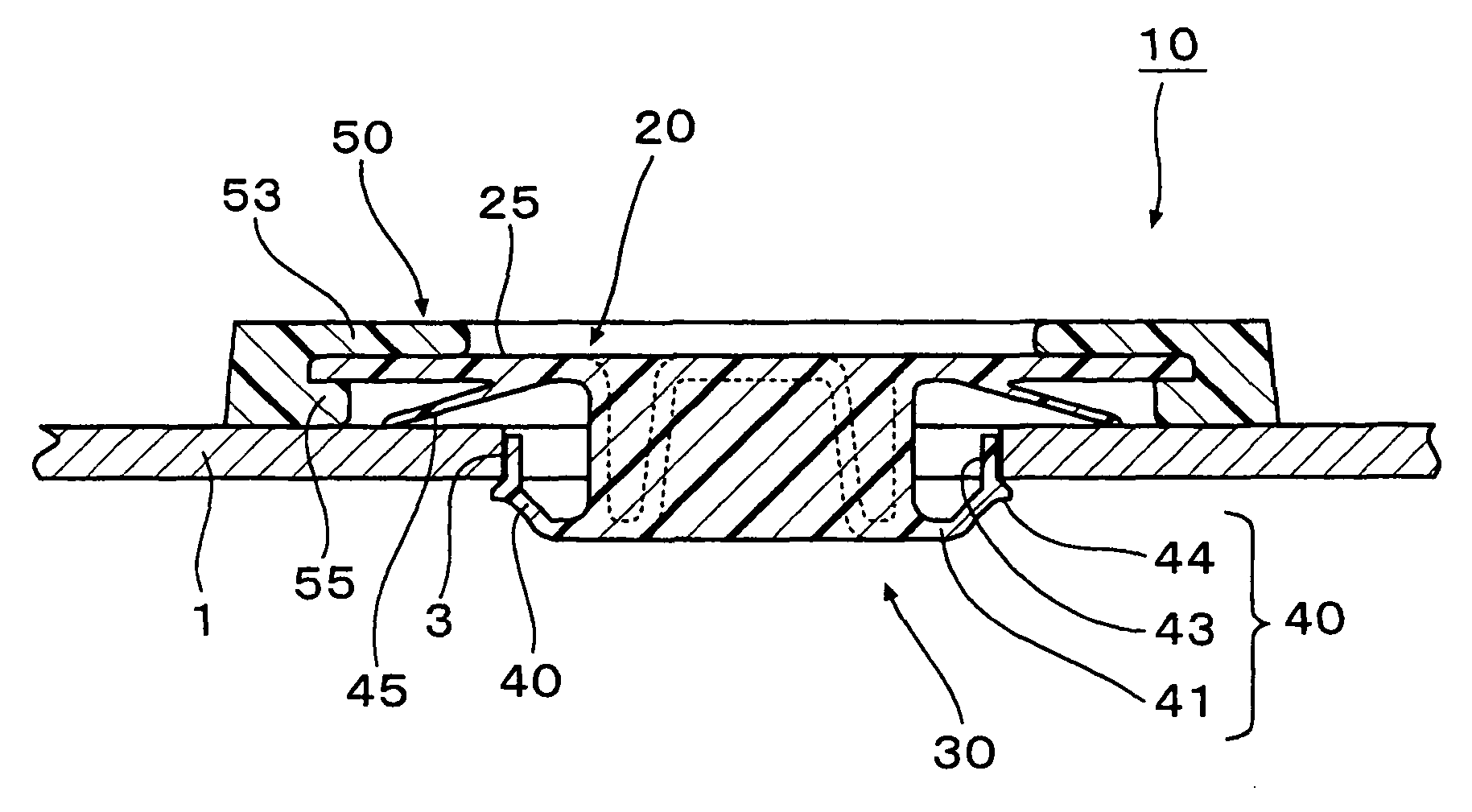

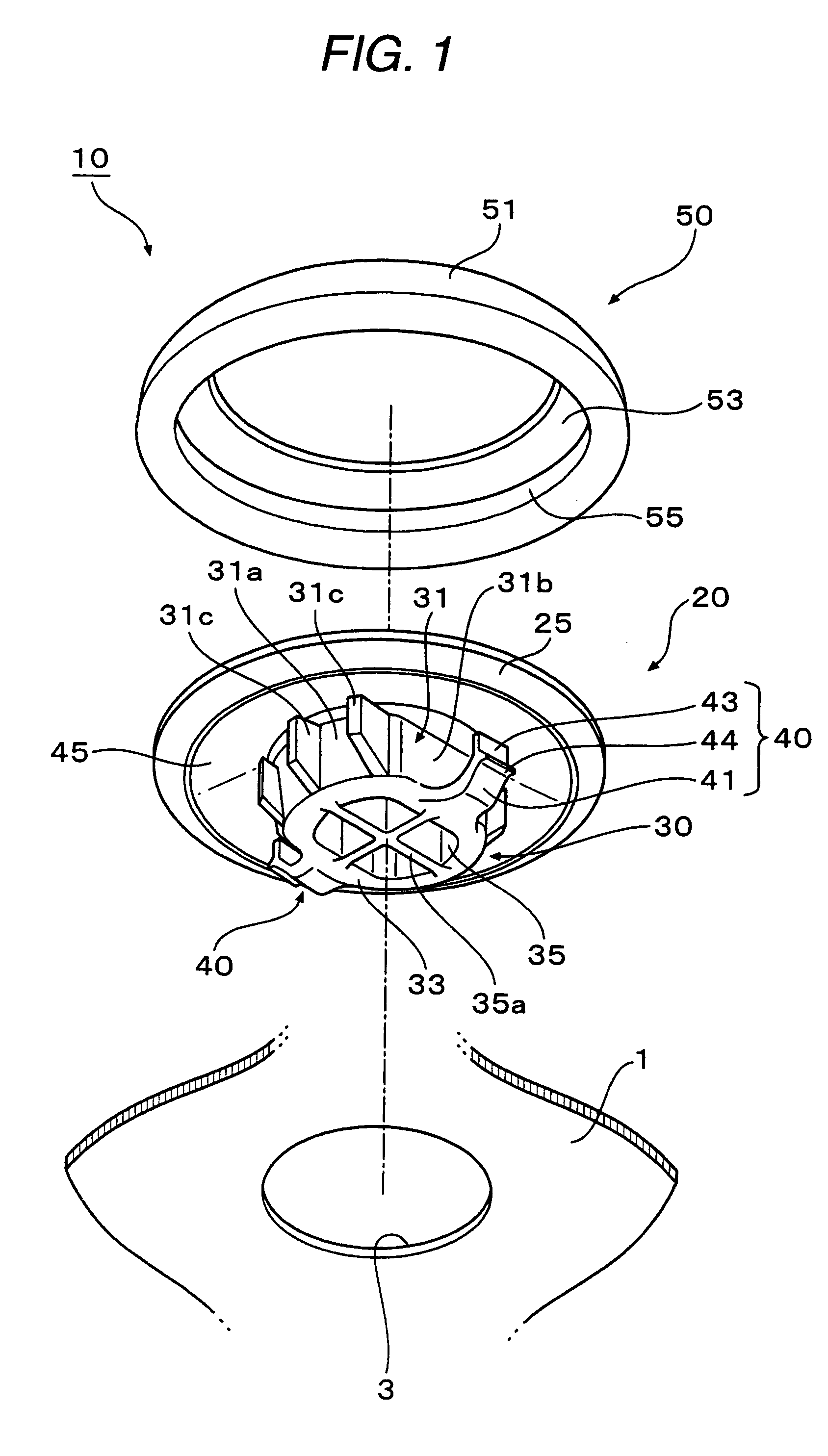

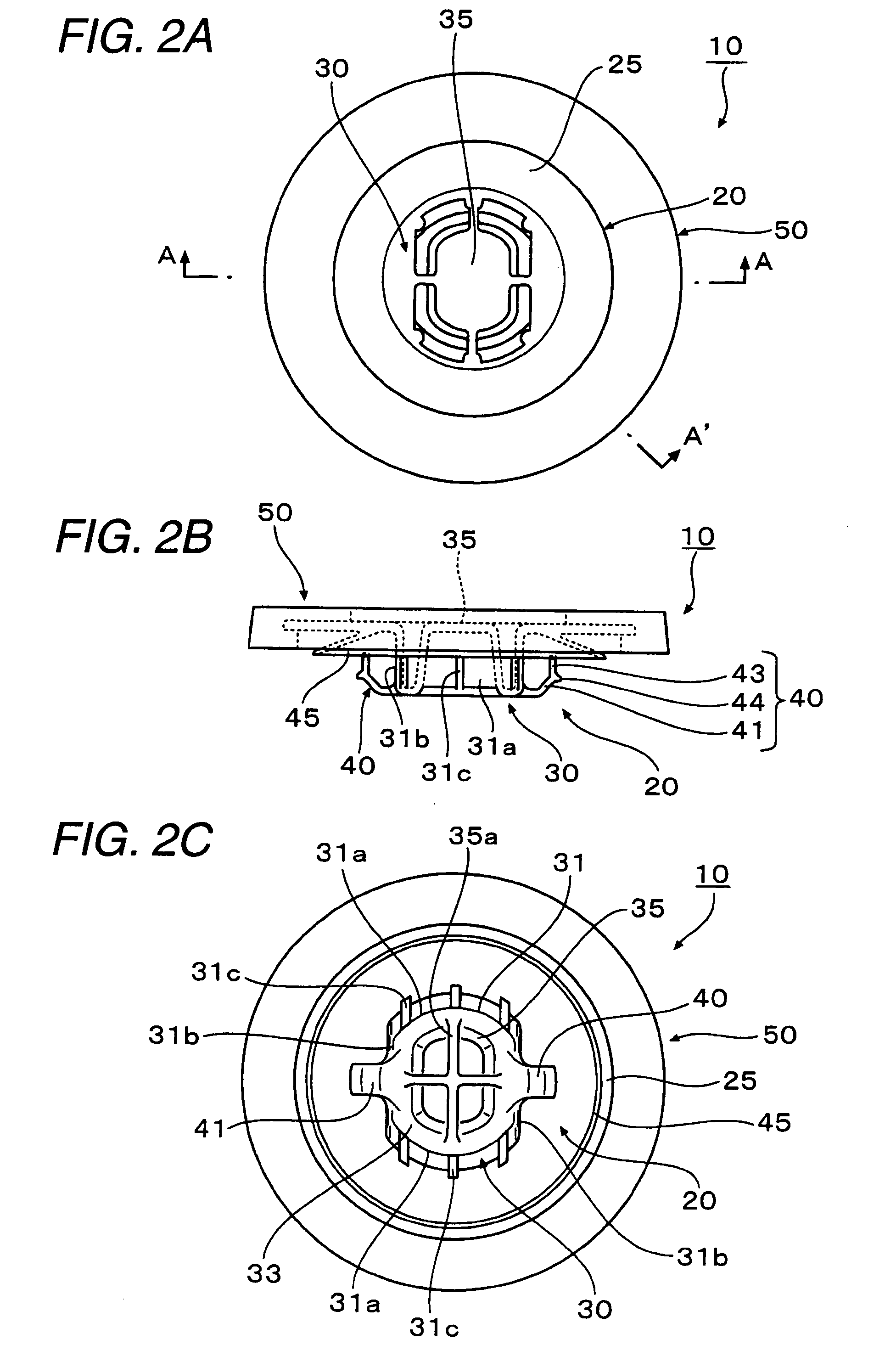

Hole plug

InactiveUS20080142517A1Improve the immunityEasy to insertCapsClosure using stoppersFlangeEngineering

A hole plug comprising: a main body part including a cover flange portion for covering an opening, an insertion portion extended from a central portion of a back surface of the cover flange portion to be inserted into the opening, and an engaging portion formed on an outer periphery of the insertion portion to be engaged with a back side peripheral edge of the opening; a thermo-softening resin member mounted on a peripheral edge of the cover flange portion and allowed to flow into a clearance between the cover flange portion and an opening peripheral edge of the plate-shaped member, thereby fixing them together; and an elastic flange portion extended in a skirt-like manner from the back surface of the cover flange portion toward the peripheral edge of the opening and elastically contactable with the peripheral edge of the opening of the plate-shaped member.

Owner:PIOLAX CO LTD

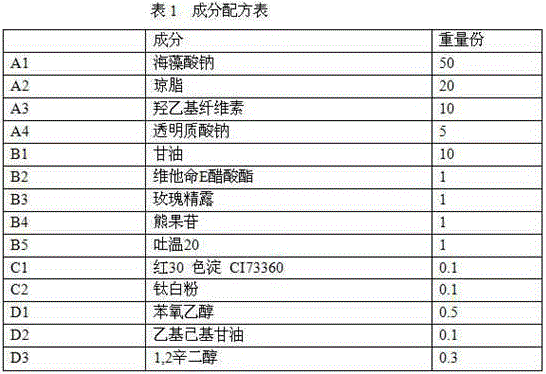

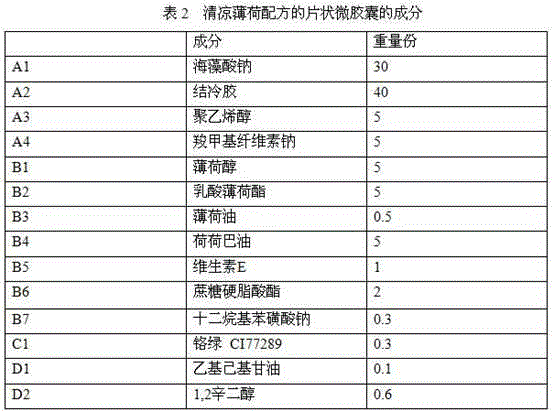

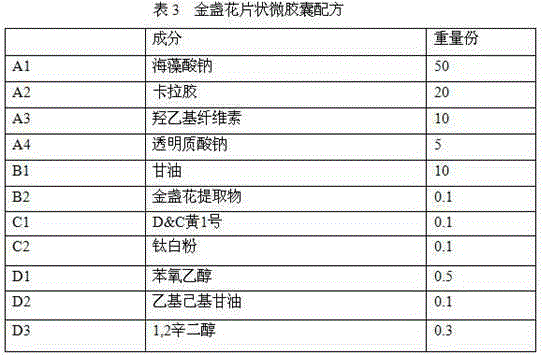

Flake microcapsule

ActiveCN105395373AReduce surface tensionGood natureCosmetic preparationsToilet preparationsPolymer sciencePreservative

The invention discloses a flake microcapsule, which belongs to the technical field of microcapsules, and comprises components with parts by weight: alginate or alginate 30-50 parts, hot melt gel 20-40 parts, water-soluble film-forming materials 5-10 parts and preservatives 0.1-1 part. The flake microcapsule enables surface tension of raw materials after being compounded to be lower than salt solutions such as calcium chloride and the like through a collaborative compatibility effect between various components of the raw materials, and gel extends on the surface of salt water to be unfolded and form a film, thereby forming a flake microcapsule. The flake microcapsule has steady property, is easy to smear, and has excellent quality.

Owner:CHONGQING PELLETS TECHN & TRADE

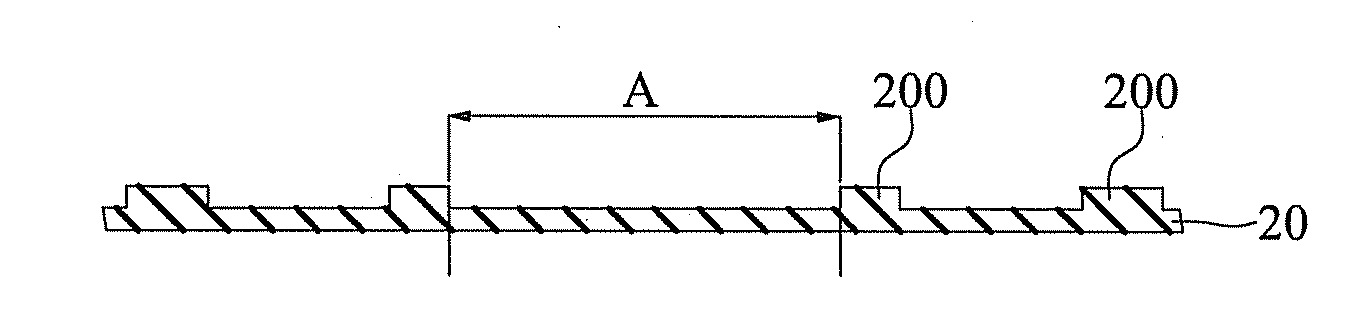

Package with embedded chip and method of fabricating the same

InactiveUS20120086117A1Easily softenAvoid problemSemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

A package embedded with a chip and a method of fabricating the package of embedded chip. The package of embedded chip includes a dielectric layer having a first surface and a second surface opposing the first surface; a plurality of conductive pillars formed in the dielectric layer and exposed from the second surface of the dielectric layer; a chip embedded in the dielectric layer; a circuit layer formed on the first surface of the dielectric layer; a plurality of conductive blind vias formed in the dielectric layer, allowing the circuit layer to be electrically connected via the conductive blind vias to the chip and each of the conductive pillars; and a first solder mask layer formed on the first surface of the dielectric layer and the circuit layer, thereby using conductive pillars to externally connect with other electronic devices as required to form a stacked structure. Therefore, the manufacturing process can be effectively simplified.

Owner:SILICONWARE PRECISION IND CO LTD

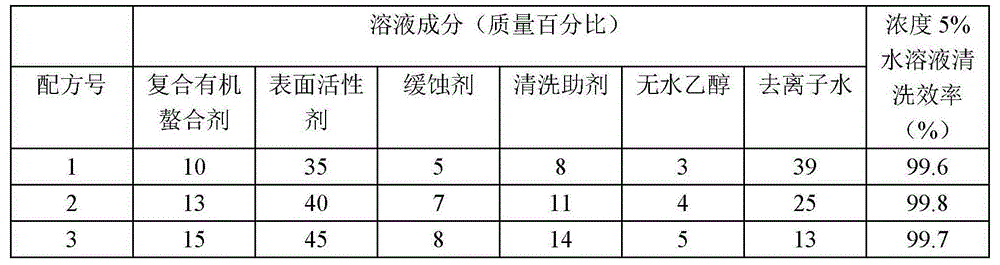

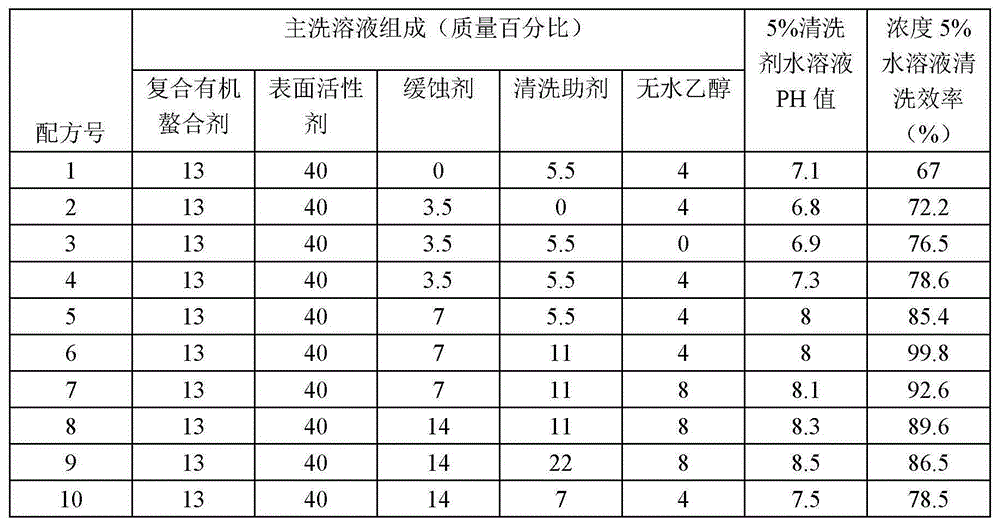

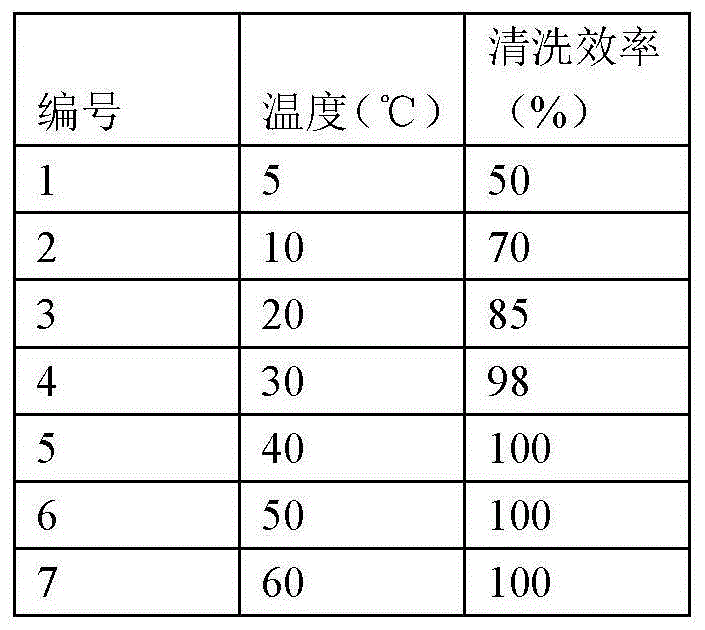

Environment-friendly efficient train cleaning agent and preparation method thereof

The invention provides an environment-friendly efficient train cleaning agent. The cleaning agent is formed by, by weight, 10% to 15% of compound organic chelating agents, 35% to 45% of surface active agents, 5% to 8% of corrosion inhibitors, 8% to 14% of cleaning auxiliaries, 3% to 5% of anhydrous ethanol, and the balance deionized water, wherein the corrosion inhibitors are formed by, by mass fraction, 13-17 parts of urotropine, 28-32 parts of sodium metasilicate pentahydrate and 53-57 parts of benzotriazole. The invention further provides a preparation method of the cleaning agent. The surface of a train body is not damaged by the environment-friendly efficient train cleaning agent, meanwhile, cleaning efficiency is high, the dilution ratio is high, the cleaning agent can be diluted by 20-30 folds through tap water when used normally, and using cost is reduced.

Owner:麻城天安化工股份有限公司

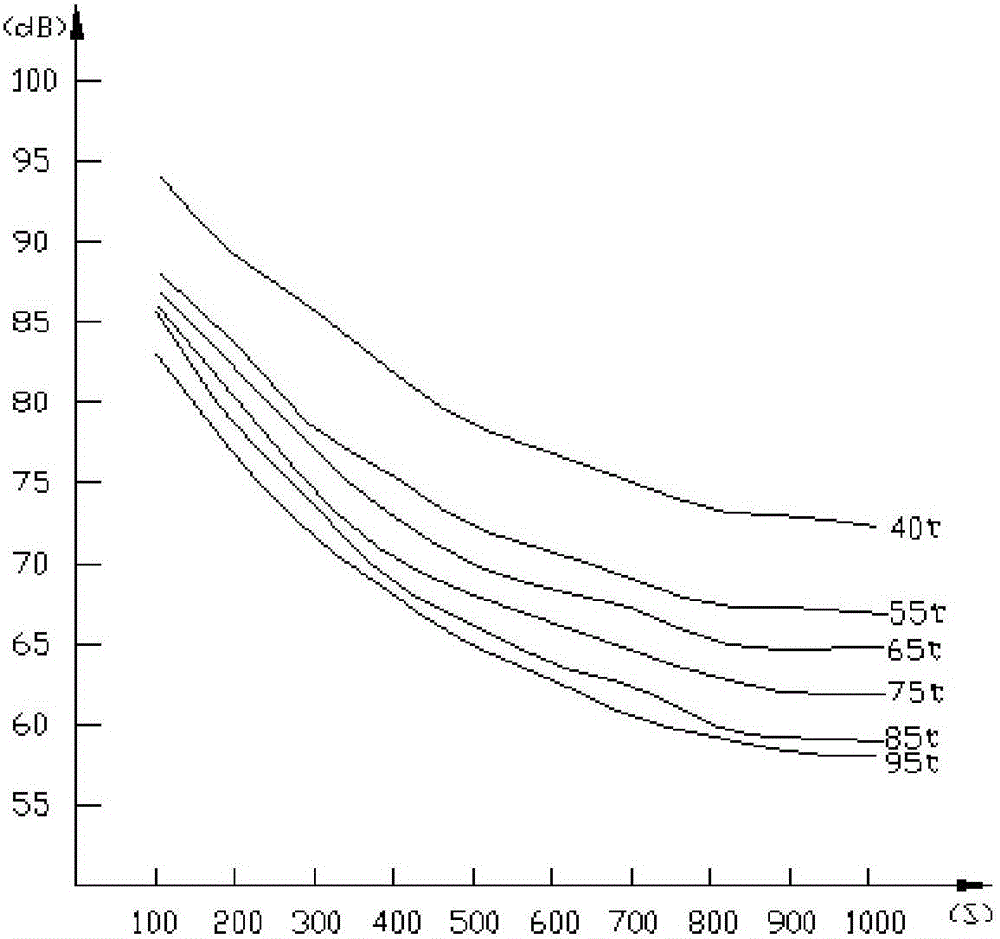

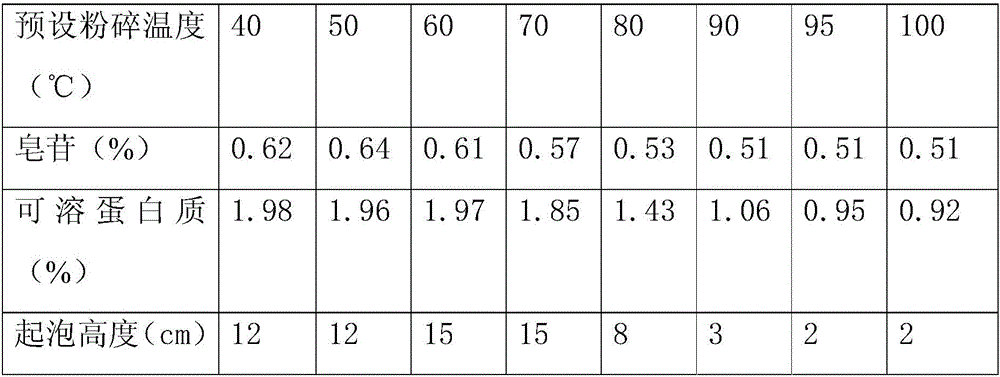

Low-noise milk-preparation method of soybean milk machine

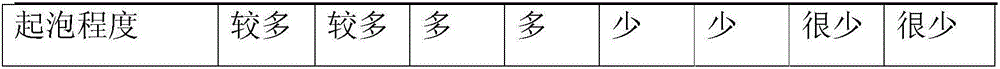

InactiveCN105935247AReduce hardnessBad experienceBeverage vesselsDough shaping and cutting apparatusLow noiseElectricity

The invention relates to a low-noise milk-preparation method of soybean milk machine. A motor, a crushing cutter, a heating device and a cup body are provided. The control unit is electrically connected with the motor, and the heating device. The method at least comprises following phases: (1) a crushing stage: the motor drives the crushing cutter to rotate and crush water and material to milk and goes to the next phase; (2) a boiling phase: the heating device is used for heating milk till it is boiled. When the crushing phase begins, the temperature of liquid is larger than or equal to the pre-set crushing temperature. The pre-set crushing temperature is larger than or equal to 85 DEG C. Before the crushing phase, a heating pre-treatment phase is included. The heating pre-treatment phase lasts for 400 to 800 seconds. Therefore, noise can be effectively decreased and false boiling is avoided and reduced effectively.

Owner:JOYOUNG CO LTD

Hole plug

A hole plug comprising: a main body part including a cover flange portion for covering an opening, an insertion portion extended from a central portion of a back surface of the cover flange portion to be inserted into the opening, and an engaging portion formed on an outer periphery of the insertion portion to be engaged with a back side peripheral edge of the opening; a thermo-softening resin member mounted on a peripheral edge of the cover flange portion and allowed to flow into a clearance between the cover flange portion and an opening peripheral edge of the plate-shaped member, thereby fixing them together; and an elastic flange portion extended in a skirt-like manner from the back surface of the cover flange portion toward the peripheral edge of the opening and elastically contactable with the peripheral edge of the opening of the plate-shaped member.

Owner:PIOLAX CO LTD

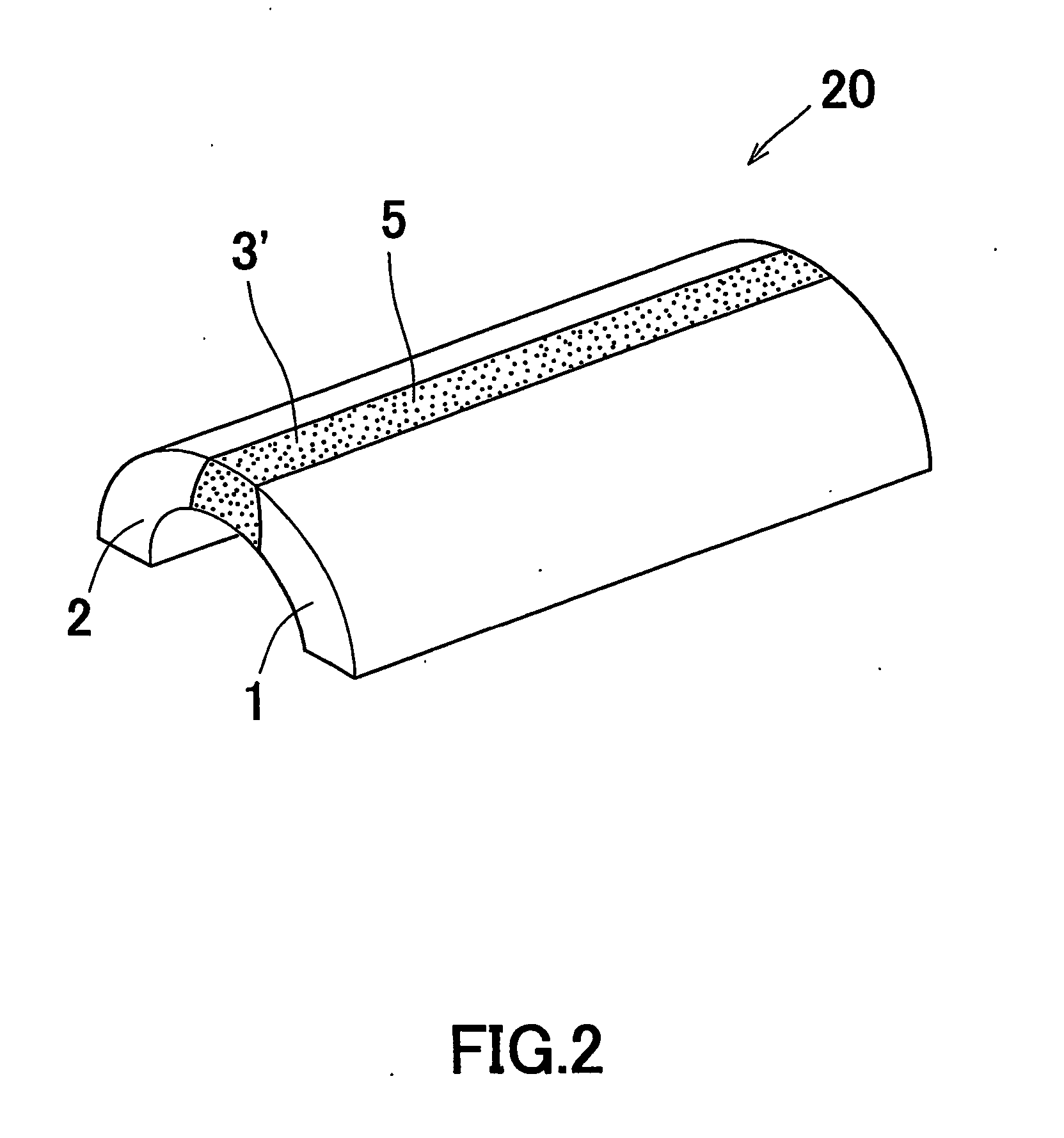

Manufacturing method of butt joint, butt joint, manufacturing method of bent member, and friction stir joining method

InactiveUS20060151576A1Deformation resistancePromote softeningWorkpiece edge portionsNon-electric welding apparatusButt jointEngineering

Two joining members different in high temperature deformation resistance are disposed in an abutted manner. The rotational direction of a probe of a joining member is set to coincide with a rotational direction rotating from the joining member having lower high temperature deformation resistance toward the joining member having higher high temperature deformation resistance. Then, the rotating probe is inserted into the abutting portion of the joining members. The probe is advanced along the abutting portion with the probe inserted in the abutting portion to perform friction stir joining. As a result, a butt joint having high joining strength can be obtained.

Owner:HONDA MOTOR CO LTD +1

Highly water-soluble agave inulin, agave inulin-containing product, agave inulin-origin product, by-product and method for producing the same

InactiveUS20090311370A1Cheap and stable and mass supplyShorten heating timeOrganic active ingredientsAlcoholic beverage preparationAridHigh concentration

Inulin, which is contained at a high concentration in agave plants growing in arid areas, has been utilized hitherto exclusively in producing alcoholic drinks as tequila. It is intended to produce highly water-soluble inulin having a high added value from these plants. It is also intended to produce an agave syrup, tequila, an alcoholic drink or highly water-soluble inulin from the squeezed residue. Agave plant bulbs (several tens kg) having been employed in producing tequila called pina are cut into small pieces and enzymes therein are inactivated and the texture is softened either at room temperature or under heating. Next, the pieces are squeezed to give a liquid extract which is then refined by using an adsorbent resin. The refined product is employed either as such as a concentrate or after drying to give a powder.

Owner:AGAVE

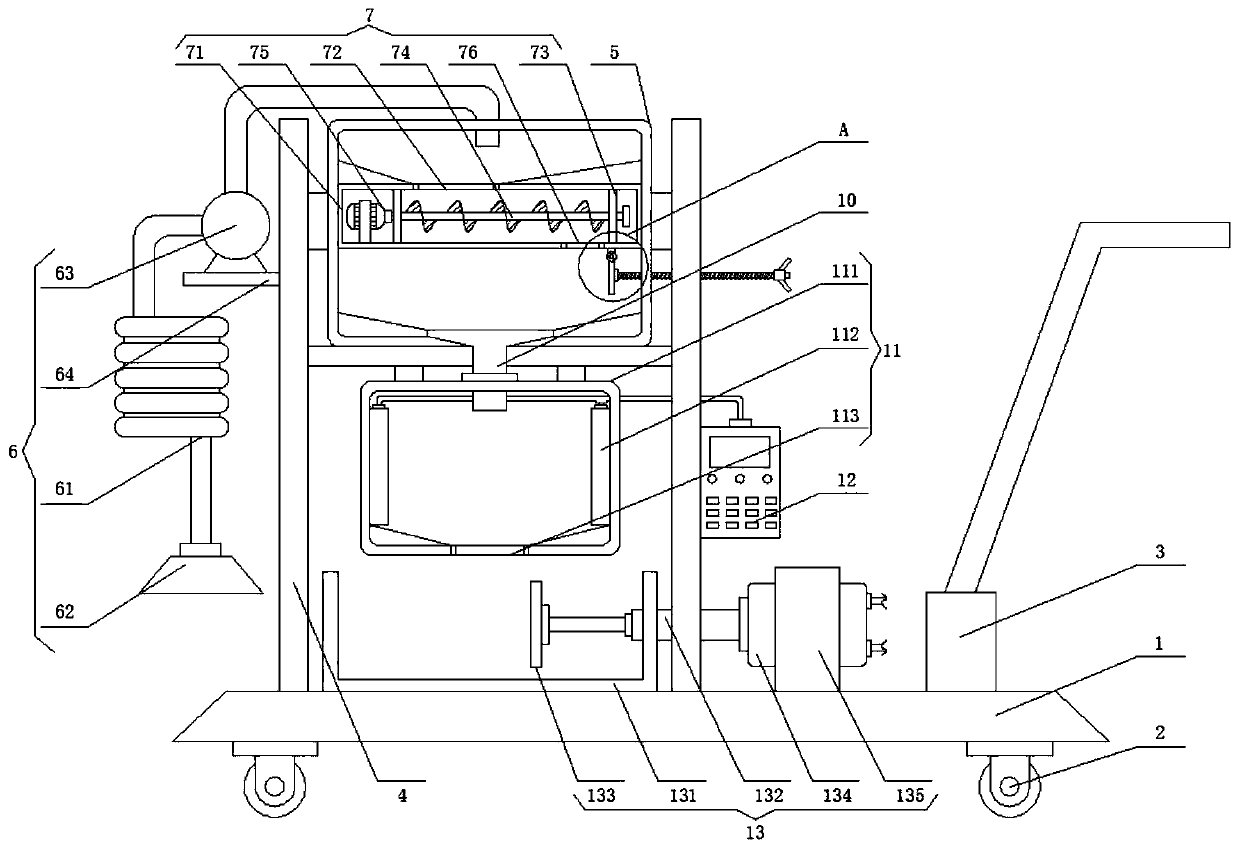

Waste recycling device and method for plastic product production

PendingCN110076935APromote softeningStickyPlastic recyclingMechanical material recoveryRecovery methodWaste recycling

The invention belongs to the technical field of plastic products, and particularly relates to a waste recycling device for plastic product production. The waste recycling device comprises a base, wheels are fixedly installed at the bottom of the base, a push rod is fixedly installed on one side of the top of the base, and a supporting frame is fixedly connected to the top of the base. A treatmentbox is fixedly arranged inside the supporting frame, an absorbing mechanism is arranged at the top of the treatment box, and a crushing mechanism is arranged in the treatment box. A movable plate is fixedly arranged at the bottom of the crushing mechanism, and an adjusting rod is fixedly connected to one side of the movable plate. According to the waste recycling device and method for plastic product production, a softening mechanism is arranged so that wastes can be conveniently softened in the waste recycling process, the wastes can have certain viscidity and can be tightly combined when extruded, the problem that gaps are generated between the wastes is avoided, and the compactness of the wastes is improved.

Owner:荆州市今缘塑料股份有限公司

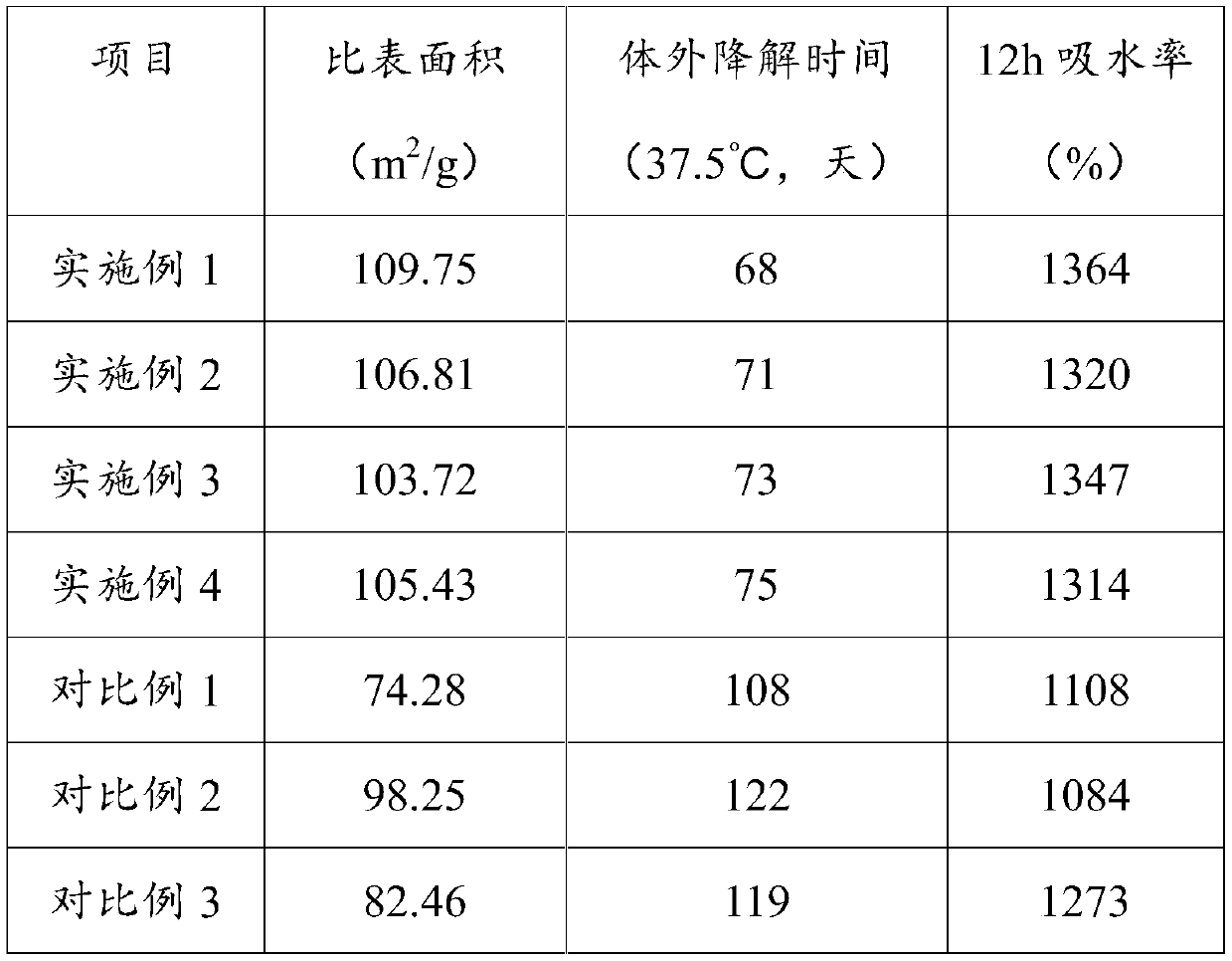

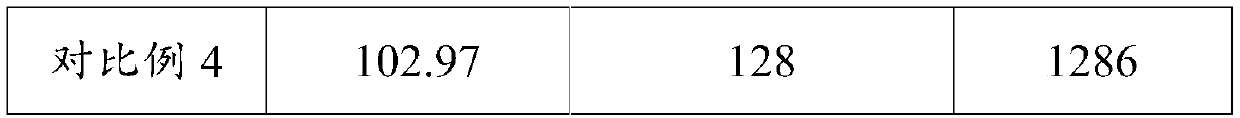

Hemostasis material for clinical internal medicine to stop bleeding and preparation method thereof

InactiveCN109646710AHuge specific surface areaGood biocompatibilitySurgical adhesivesBandagesElectrospinningBiocompatibility Testing

The invention discloses a hemostasis material for the clinical internal medicine to stop bleeding and a preparation method thereof. The hemostasis material is prepared by using a modified chitosan fiber loaded medical glue to be subjected to a low temperature rapid cooling-radiation ray irradiation cross-linking-freezing drying process. The modified chitosan fiber is obtained by softening, grafting, antibacterial process and electrospinning of natural chitosan, and has a good specific surface area, adsorption and an antibacterial property; the medical glue is prepared by mixing a cyanoacrylatecompound and polylactic acid. The hemostasis material has excellent biocompatibility, being non-toxic and non-irritating, is suitable for various complicated bloody wounds in the clinical internal medicine treatment process, is convenient to use, has good biodegradability and absorbability, can significantly promote wound tissue healing and coagulation, and is suitable for large-scale popularization and application in surgical or internal medicine surgery hemostasis process.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Method and apparatus for applying a film adhesive to a perforated panel

InactiveUS20040060652A1Promote softeningStable temperatureLamination ancillary operationsLaminationAdhesiveEngineering

A method and apparatus for preparing a perforated panel for reticulation to a film adhesive. The method includes supporting the perforated panel. The method also includes adhering the film adhesive to the perforated panel without initiating a cure of the film adhesive. The method applies a vacuum to the film adhesive. Next the method will move the perforated panel at a predetermined speed through a reticulation unit. Next the method will soften the film adhesive and finally remove the film adhesive from the perforations by an airflow. The method is generally used for creating acoustic sheet panels for use in many industries.

Owner:GKN WESTLAND AEROSPACE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com