Flake microcapsule

A technology of microcapsules and flakes, applied in the field of flake microcapsules, can solve the problems of color fading, product instability, pollen allergies, etc., and achieve the effect of good safety performance, good properties, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

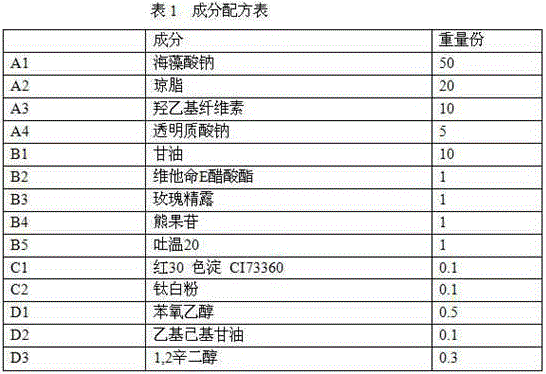

[0014] A sheet-shaped microcapsule of pink rose whitening effect, the composition is as shown in Table 1 below:

[0015]

[0016] The flaky microcapsules of the above-mentioned pink rose whitening effect are prepared by the following method:

[0017] 1) Prepare sodium alginate with purified water to a solution with a mass concentration of 2%, agar with purified water to prepare a solution with a mass concentration of 1%, and hydroxyethyl cellulose with purified water to prepare a solution with a mass concentration of 1%. The solution, the sodium hyaluronate is mixed with purified water into a solution with a mass concentration of 1%;

[0018] 2) After heating the solution prepared in step 1) to 60°C, mix the four solutions and keep them warm for later use;

[0019] 3) Mix the B raw materials in the above table 1 evenly;

[0020] 4) Grind and mix raw material C in the above table 1, and mix it into the mixed raw material B in step 3), and stir evenly;

[0021] 5) Mix D ra...

Embodiment 2

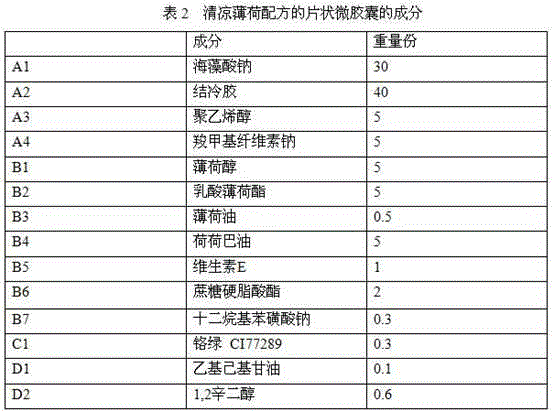

[0025] A kind of flaky microcapsule containing cool and refreshing peppermint formula, described composition is as shown in table 2 below:

[0026]

[0027] Above-mentioned sheet microcapsule adopts following method to prepare:

[0028] 1) Prepare a sodium alginate solution with a mass concentration of 2%, a gellan gum solution with a mass concentration of 1%, a polyvinyl alcohol solution with a mass concentration of 0.5%, and a sodium hydroxymethylcellulose solution with a mass concentration of 1%;

[0029] 2) Heat the solution prepared in step 1) to 60°C, mix and keep warm for later use;

[0030] 3) Evenly mix raw materials B in Table 2 and heat to 60°C;

[0031] 4) Grind and mix raw material C, and mix it into the mixed raw material B in step 3), and stir evenly;

[0032] 5) Mix D raw materials and add them to the mixed materials in step 4) to obtain mixed raw materials;

[0033] 6) Heat the mixed raw materials in step 5) to 60°C, add to the mixed solution in step 2),...

Embodiment 3

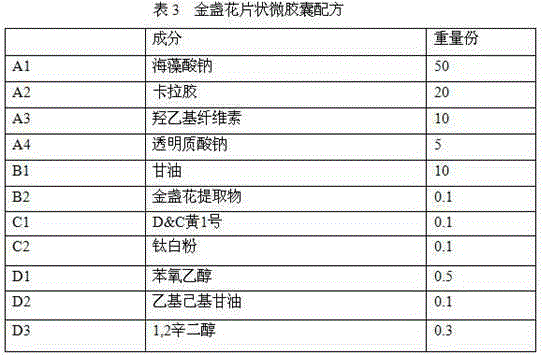

[0036] A kind of calendula flake microcapsule, composition formula is as shown in table 3 below:

[0037]

[0038] Above-mentioned calendula flake microcapsules are prepared by the following method:

[0039] 1) Prepare sodium alginate with purified water to a solution with a mass concentration of 2%, carrageenan with purified water to prepare a solution with a mass concentration of 1%, and hydroxyethyl cellulose with purified water to prepare a solution with a mass concentration of 1 % solution, the sodium hyaluronate is mixed with purified water into a solution with a mass concentration of 1%;

[0040] 2) After heating the solution prepared in step 1) to 60°C, mix the four solutions and keep them warm for later use;

[0041] 3) Mix the B raw materials in the above table 1 evenly;

[0042] 4) Grind and mix raw material C in the above table 1, and mix it into the mixed raw material B in step 3), and stir evenly;

[0043] 5) Mix D raw materials and add them to the mixed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com