Forging forming technology for large-size high-intensity and heat-resistant magnesium alloy thick plate

A forming process and magnesium alloy technology, which are applied in the deformation processing of magnesium alloys and the forging deformation field of Mg-RE alloys to achieve the effect of small composition segregation and fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

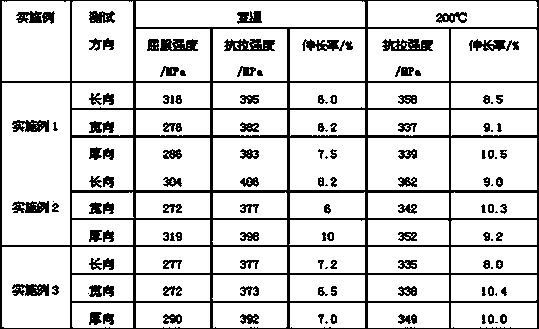

[0015] Example 1 : Mg-8Gd-3Y-0.6Zr (wt.%) alloy ingots with a diameter of Ф200mm and a length of 480 mm are machined by semi-continuous casting in a large furnace, and the ingots are homogenized and annealed. Heat the ingot at 520°C for 4 hours, perform upsetting and drawing forging on the hydraulic press, the reduction speed is 200-400mm / min, the reduction of the upsetting pass is 30-50%, and the reduction of the elongation pass is 5-10% . When the billet temperature is lower than 430°C, it is returned to the furnace for annealing, the annealing temperature is 510°C, and the holding time is 2h. After annealing, the upsetting process is repeated, and the ingot is forged into a billet of near-final size after three times of upsetting and drawing. The billet reserves 10-15% deformation in the height direction and width direction for the low temperature rapid forging process. After the billet was kept at 500 °C for 2 hours, it was quickly forged on an air hammer to forge a t...

Embodiment 2

[0016] Example 2: Firstly, use a large melting furnace to melt the raw materials, and then mechanically process a Mg-9Gd-4Y-0.6Zr (wt.%) (wt.%) alloy billet with a diameter of Ф300mm and a length of 400mm after semi-continuous casting, and uniformly cast the ingot annealing treatment. After 6 hours of heat preservation at 530°C, perform upsetting forging on a hydraulic press, with a reduction speed of 200-400mm / min, a reduction of 30-50% for upsetting passes, and a reduction of 5-10% for elongating passes. When the surface temperature of the billet is lower than 430°C, it is returned to the furnace for annealing, the annealing temperature is 510°C, and the holding time is 2h. Repeat the upsetting and drawing process after annealing, and forge the ingot into a billet after three times of upsetting and drawing. The billet reserves 10-15% deformation in the height and width directions for the low-temperature rapid forging process. After the billet was kept at 480°C for 4 hour...

Embodiment 3

[0017] Example 3: Using a large melting furnace to melt raw materials, semi-continuous casting, machining a Mg-9Gd-2Y-0.6Zr (wt.%) alloy billet with a diameter of Ф300 mm and a length of 500 mm, and homogenizing annealing for the ingot. After 8 hours of heat preservation at 500 ℃, carry out upsetting and drawing forging billet opening on a hydraulic press, with a reduction speed of 200-400mm / min, a reduction of 30-50% for upsetting passes, and a reduction of 5-10% for elongating passes. When the surface temperature of the ingot is lower than 430°C, return to the furnace for annealing, the annealing temperature is 490°C, and the holding time is 4 hours. Repeat the upsetting and drawing process after annealing, and forge the ingot into a billet after three times of upsetting and drawing. The billet reserves 10-15% deformation in the height and width directions for the low-temperature rapid forging process. After the billet was kept at 490°C for 3 hours, it was quickly forged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com