Patents

Literature

53results about How to "Guaranteed final performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

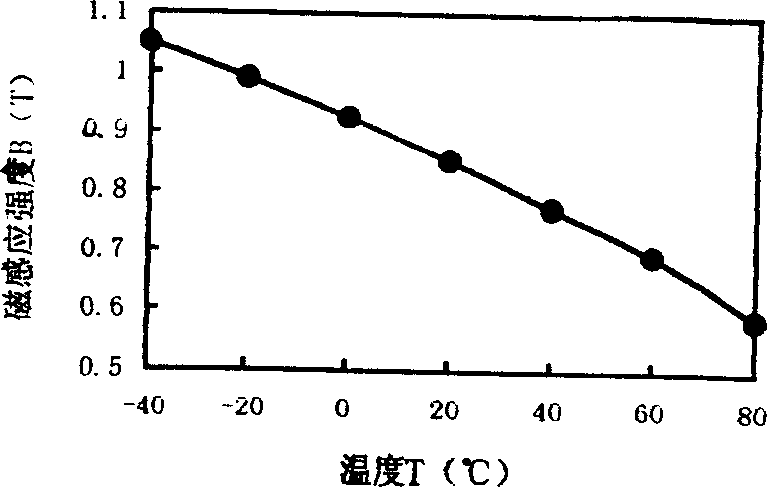

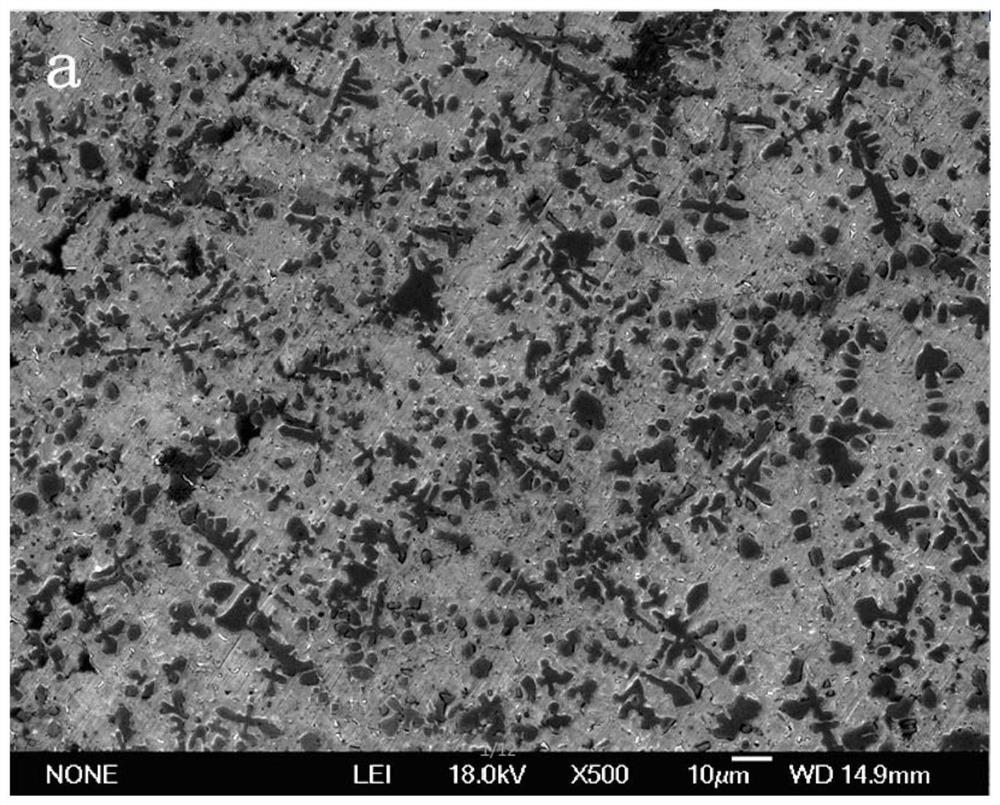

Resource-saving Q345 low-alloy series steel plate and production method thereof

InactiveCN103045939AImprove performanceGuaranteed final performanceHeat treatment process controlAlloyPearlite

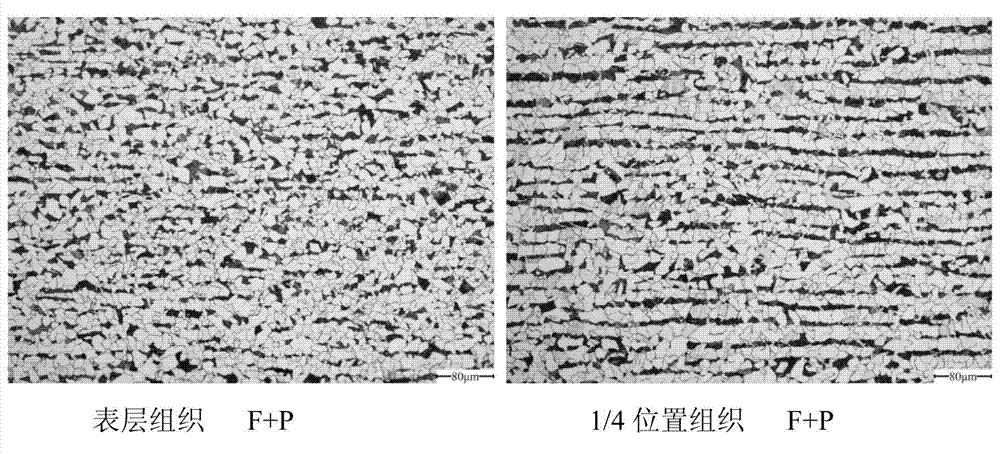

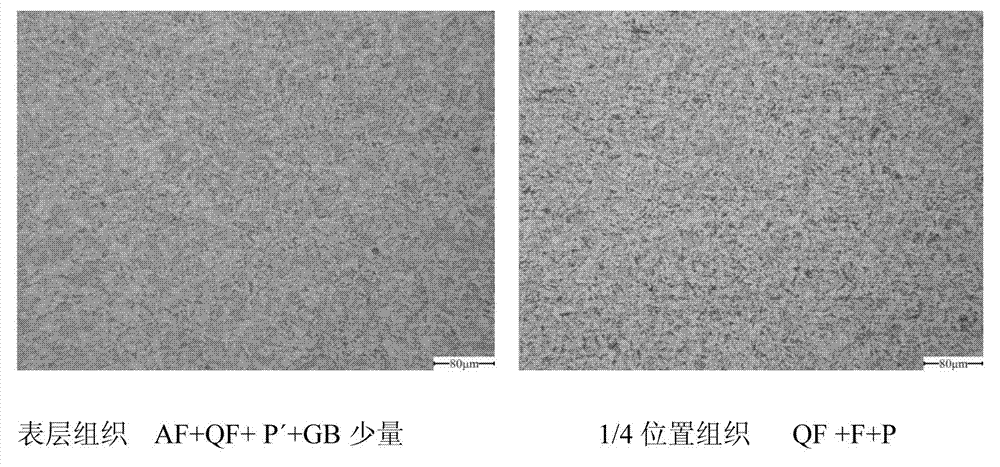

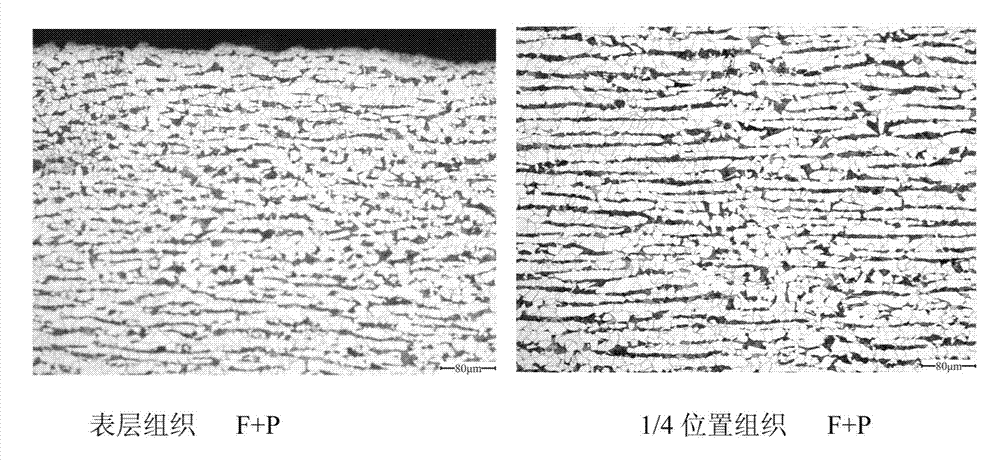

The invention discloses a resource-saving Q345 low-alloy series steel plate and a production method thereof. The steel plate comprises the following chemical components in percent by weight: 0.15 to 0.18 percent of C, 0.15 to 0.50 percent of Si, 1.10 to 1.25 percent of Mn, not more than 0.030 percent of P, not more than 0.035 percent of S, 0 to 0.045 percent of Alt, not more than 0.44 percent of carbon equivalent, and the balance of Fe and inevitable impurities. The production process of the steel plate comprises 150 t converter, LF external refining, slab continuous casting, slab heating, steckel mill controlled rolling, controlled cooling, thermal straightening, cooling, shearing and mark warehousing. The resource-saving Q345 low-alloy series steel plate, produced by the production method, has the yield strength of 360 to 420 MPa, the tensile strength of 500 to 550 MPa, and the elongation of 24 to 32%, and acicular ferrite with the thickness of 3 to 6 mm, polygonal ferrite, degenerate perlite and a small amount of granular bainite are arranged on the surface layer of the steel plate.

Owner:ANYANG IRON & STEEL

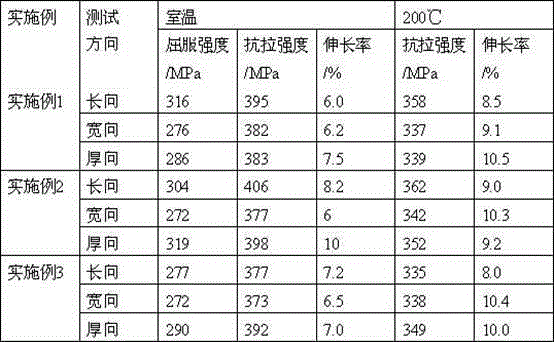

Forging forming technology for large-size high-intensity and heat-resistant magnesium alloy thick plate

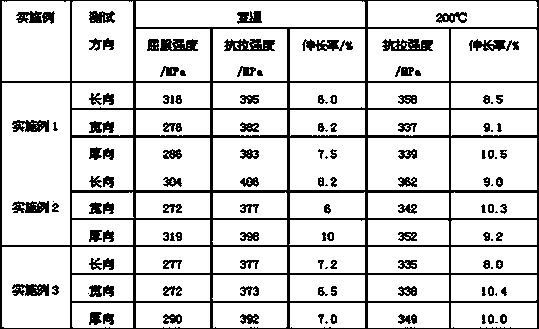

The invention discloses a forging forming technology for a large-size high-intensity and heat-resistant magnesium alloy thick plate and provides a forging forming technology for a magnesium alloy thick plate which is thicker than or as thick as 150mm. The forging forming technology comprises the steps of large-furnace smelting, semi-continuous casting, homogenizing annealing, variable-temperature multi-directional forging, fast forging and after-forming thermal treatment, wherein the variable-temperature multi-directional forging is executed on an oil press; before forging, the temperature of an ingot blank is preserved at 500-530 DEG C for 4-6 hours; the pressing speed is 200-400mm / min, the upsetting gate pressing amount is 30-50 percent, and the swaging gate pressing amount is 5-10 percent; the fast forging is executed on an air hammer; before fast forging, the temperature of the ingot blank is preserved at 480-500 DEG C for 2-4 hours. According to the forging forming technology, the high-temperature plasticity of a magnesium alloy is fully achieved, and the usability is obviously improved; at the temperature of 200 DEG C, the tensile strength of the thick plate in the length direction, the width direction and the height direction is higher than or equal to 330MPa, and the elongation rate is larger than or equal to 8 percent.

Owner:CENT SOUTH UNIV

High-strength high-heat-conductivity 6-series aluminum alloy strip and preparation method thereof

The invention discloses a high-strength high-heat-conductivity 6-series aluminum alloy strip and a preparation method thereof. The high-strength high-heat-conductivity 6-series aluminum alloy strip comprises, by mass, 0.20-0.55% of Si, 0.03-0.08% of Fe, 0.01-0.10% of Cu, 0.01-0.02% of Mn, 0.40-0.80% of Mg, 0.01-0.10%fo Cr, 0.01-0.02% of Zn, 0.01-0.03% of Ti, and the balance Al and inevitable impurities, wherein aluminum ingots, aluminum intermediate alloy ingots, magnesium ingots and manganese additives serve as raw materials, and the high-strength high-heat-conductivity 6-series aluminum alloy strip is prepared through the steps of melting, casting, soaking, hot rolling, cold rolling, solid treatment, stretch straightening, ageing treatment and the like. By controlling alloy chemical components and optimizing technological parameters, the prepared 6-series aluminum alloy strip has the advantages of high surface quality, smooth strip shape, high strength, good in formability and high heat conduction performance, and the overseas technical monopoly in this aspect is broken.

Owner:中铝东南材料院(福建)科技有限公司 +1

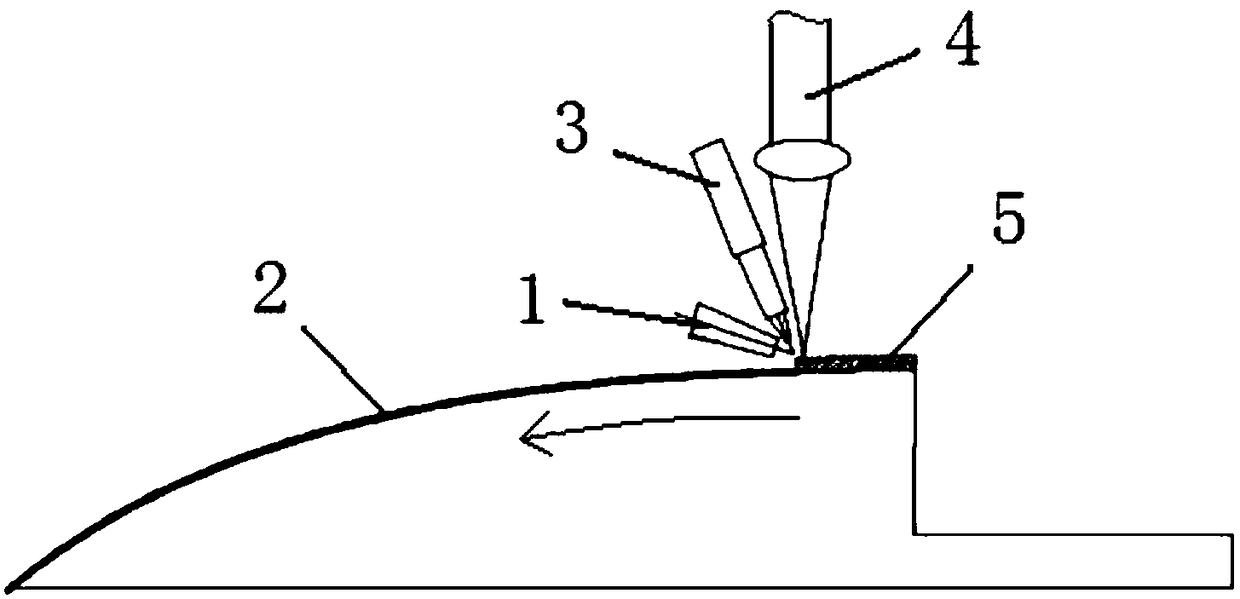

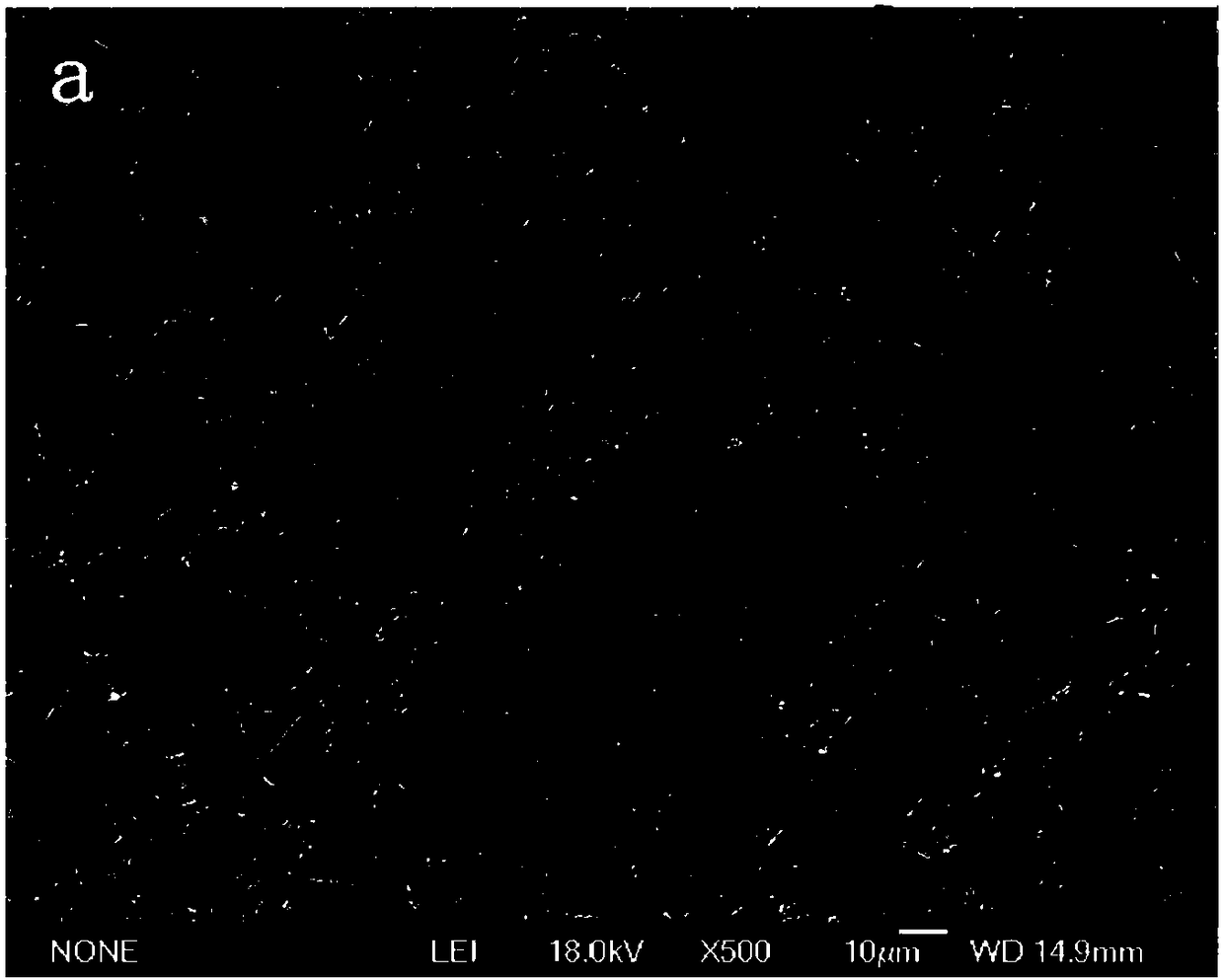

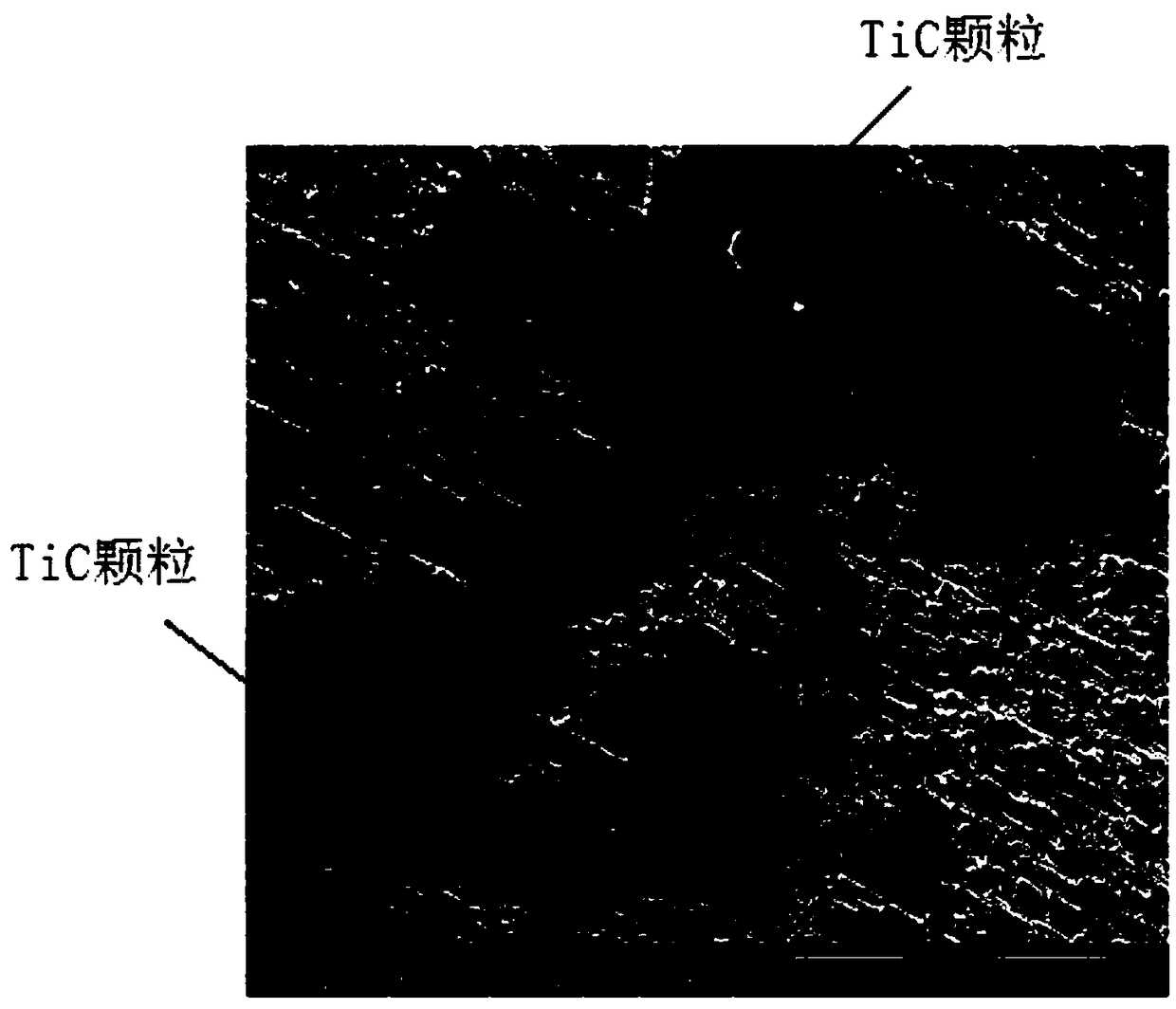

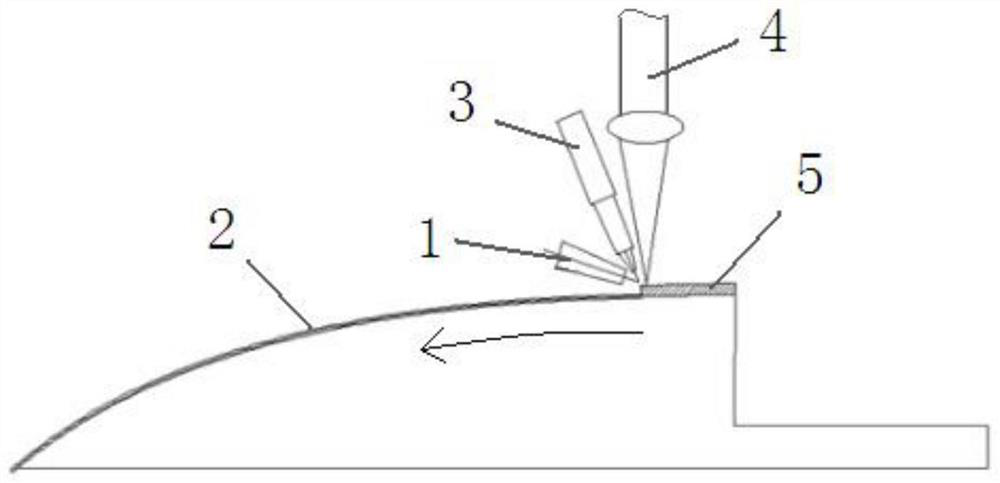

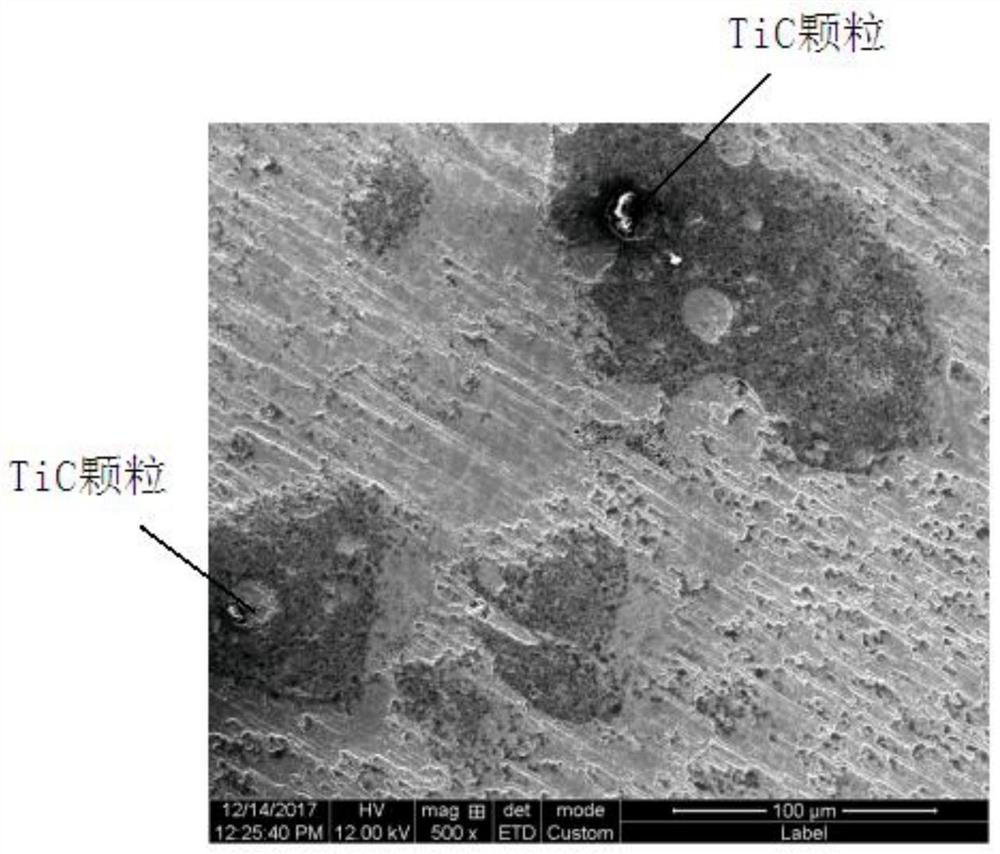

Cutting edge treatment method

ActiveCN108453345AImprove performanceReduce manufacturing costArc welding apparatusMetallic material coating processesManufacturing technologyEngineering

The invention belongs to the technical field of cutter manufacturing, and particularly relates to a cutting edge treatment method. In order to solve the problem that when imported high-quality steel is adopted to manufacture a cutter so as to improve the cutting edge performance of the cutter at present, the manufacturing cost of the cutter is high, the invention discloses the cutting edge treatment method. The cutting edge treatment method specifically comprises the following steps that S1, manufacturing preparation of a cutter is carried out, and the cutting edge part is cleaned; S2, a welding and laser cladding combined mode is adopted for machining a cutting edge strengthened layer; and S3, the cutting edge strengthened layer is coped, and final cutting edges are obtained. When the cutting edge treatment method is adopted for cutting edge treatment, not only can the performance of the cutting edges be greatly improved, the use effect of the cutter is guaranteed, but also the requirements for cutter body materials can be reduced, and the cost of the cutter is reduced.

Owner:YANGJIANG DONGHUA LASER INTELLIGENT TECH CO LTD +1

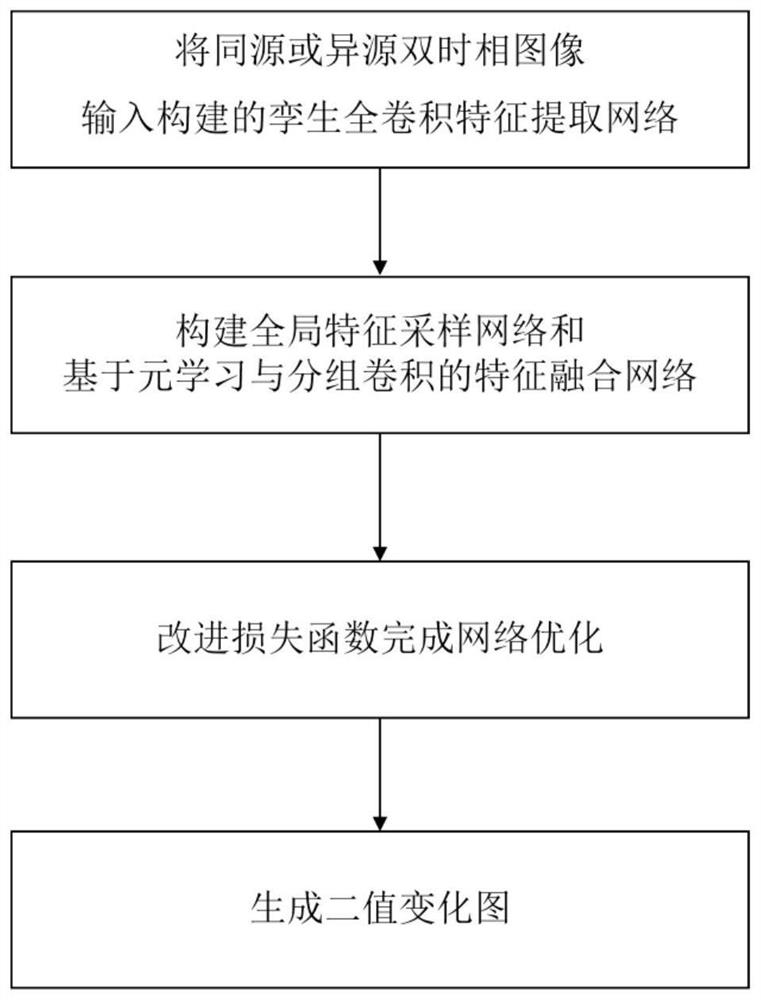

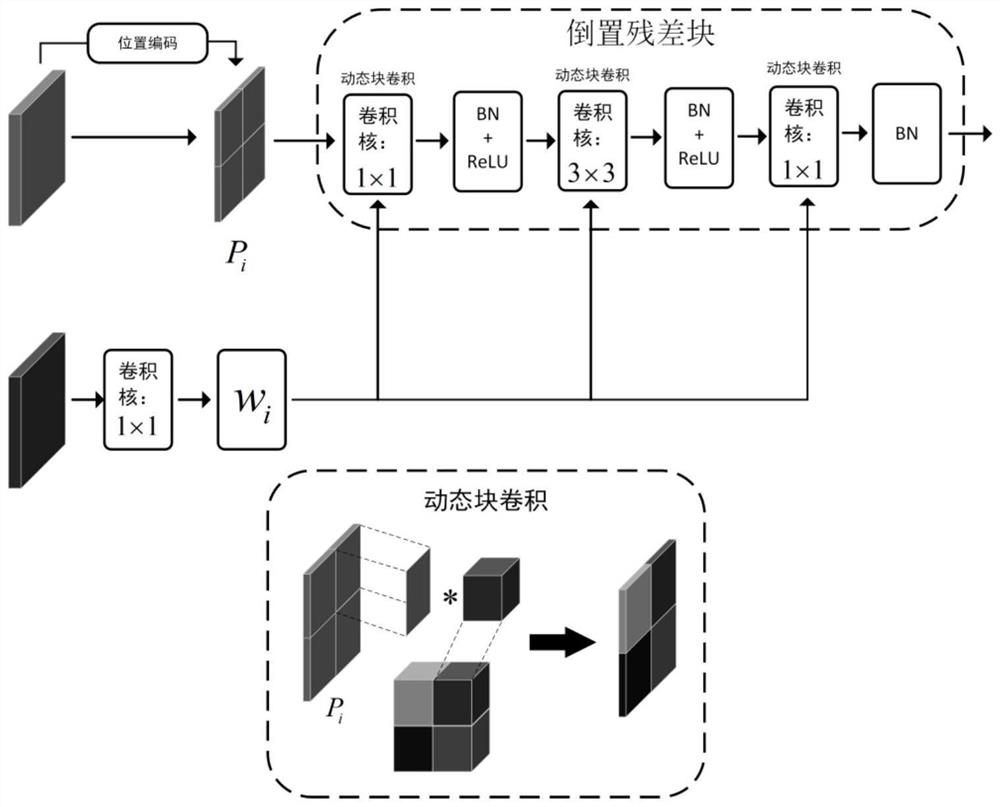

Unsupervised change detection method and system for homologous or heterologous remote sensing image

PendingCN113901900AFully excavate and preserve deep featuresMining and Preserving Deep FeaturesCharacter and pattern recognitionNeural architecturesDifference-map algorithmThresholding

The invention discloses an unsupervised change detection method and system for a homologous or heterologous remote sensing image; the method comprises the steps: inputting a homologous or heterologous dual-time-phase image into a twin full-convolution feature extraction network, and obtaining feature difference images of different scales; constructing a feature fusion network which corresponds to each scale and is based on meta learning and grouping convolution, and fusing the feature difference graphs of different scales to obtain a difference graph; using an improved objective function to complete optimization of the twin full convolution feature extraction network and the feature fusion network based on meta learning and packet convolution, and using an Adam optimization method to iteratively update weight values of the twin full convolution feature extraction network and the feature fusion network; in the training process, continuously increasing the numerical value difference between the variable pixels and the invariable pixels in the difference image, and completing binarization operation on the trained difference image through a threshold value to obtain a binary change image with the same size as the original image. According to the method, a change detection result of a pair of homologous or heterologous dual-temporal remote sensing images can be efficiently and accurately obtained in an unsupervised mode.

Owner:XIDIAN UNIV

Hygroscopic catalyst and preparation method thereof

The invention discloses a hygroscopic catalyst and a preparation method thereof. The hygroscopic catalyst comprises an oxidant, an incendiary agent, chloride and carbonate; 10 to 20 mass percent of liquid rubber is taken as an adhesive; toluene diisocynate is added to serve as a curing agent; and the content of the curing agent is 1 / 15 to 1 / 13 of the using amount of the adhesive. The method comprises the following steps of: putting the chloride, the incendiary agent, the carbonate and the adhesive into a kneading machine, mixing uniformly, adding the oxidant at intervals, mixing uniformly, adding the curing agent for mixing, vacuum-pouring or extruding and squeezing mixed materials into a shell, and performing high-temperature curing in a drying oven to obtain a finished product. Various ingredients of the hygroscopic catalyst produced by adopting a pouring production process are difficult to damp and deteriorate due to the crosslinking coating effect of the liquid rubber adhesive, so the performance of the product is guaranteed. Moreover, the catalyst has high bonding strength, and cannot break due to the vibration. By the method, a production process is simplified, production period is shortened, the mechanical sensitivity of the catalyst is reduced, and the safety of the catalyst is improved.

Owner:SHAANXI ZHONGTIAN ROCKET TECH CO LTD

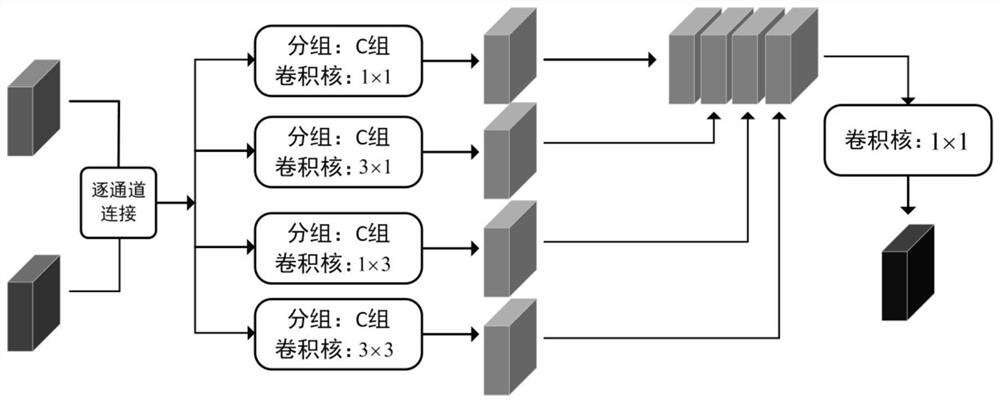

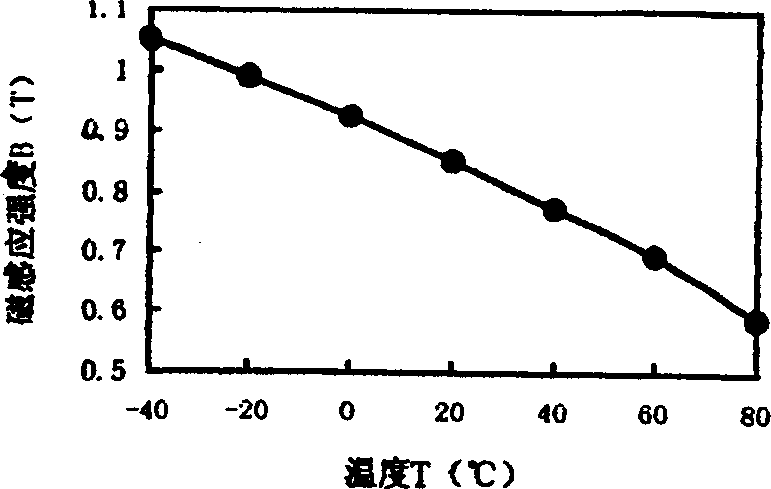

High magnetic induction wide temperature interval linear magnetic temperature compensating alloy and production process thereof

The invention relates to a highly magnetic induction, linear magnet-temperature compensation alloy with broad temperature regioand its production process. The alloy components in percent are as follows: Ni 31.5-32.5%, Mn<=0.4%, Si<=0.3%, C 0.10-1.50%, surplus Fe. The production process is: first adopting vacuum induction melting then casting to make electrode bar, then electroslag remelting it to cast ingot, heating to 1100-1150 DEG C, hot forging hot-rolled sheet blank, heating to 1050 DEG C-1100 DEG C, hot-rolling to sheet, 1050 DEG C-1100 DEG C heat treatment, acid cleaning, cold rolling and obtaining band of finished product thickness, after processing element, using after final ageing treatment 1-2 hours in vacuum heat treatment furnace under 400 DEG C-500 DEG C. The inventive alloy has a wider usage temperature range, temperature point for testing is more than before, and B-t linearity is well, so the inventive alloy surpass the existing FeNi magnet compensation alloy in usage temperature range and magnet compensation ability.

Owner:CHONGQING MATERIALS RES INST

Synthesis-gas carbon-based catalyst preparation method by reforming methane and carbon dioxide

ActiveCN104984769ALarge specific surface areaHigh catalytic activityCarbon compoundsHydrogen productionAtmosphereMethane

The invention relates to a synthesis-gas carbon-based catalyst preparation method by reforming methane and carbon dioxide. The method comprises the following steps that 1 coal with the grain size ranging from 60-80 meshes is liquefied directly, the residue is mixed with a composite modifying agent according to a mass ratio of 1:1-3, and the mixture is grinded uniformly; the composite modifying agent comprises, by weight, 90-98% of alkali and 2-20% of nitrate; 2 the obtained mixture grinded uniformly is heated in inert atmosphere to conduct carbonizing treatment; 3 the mixture in which carbonizing treatment is conducted is cooled and washed to be neutral; 4 the mixture washed to be neutral is dried, and the carbon-based catalyst is obtained. According to the synthesis-gas carbon-based catalyst preparation method by reforming the methane and the carbon dioxide, the residue CLR of shenhua coal being liquefied directly is used as raw material, the carbon-based catalyst is obtained through the carbonizing treatment on the residue, the main by-product produced in the direct coal liquefaction process is utilized effectively, the preparation method is simple, and the prepared catalyst is large in specific surface area; the catalyst has a good catalytic activity on the reforming reaction of the methane and the carbon dioxide.

Owner:陕西荷螓能源科技有限公司

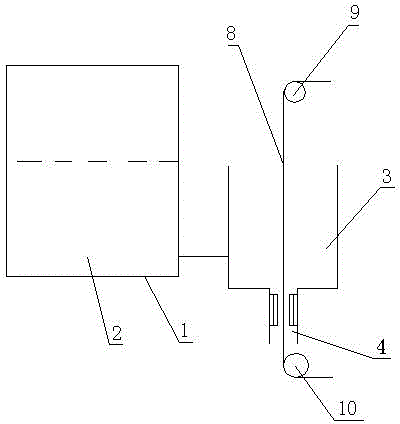

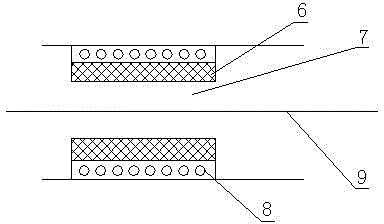

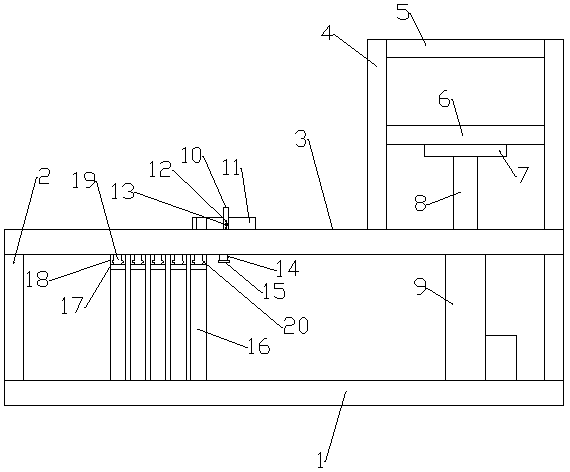

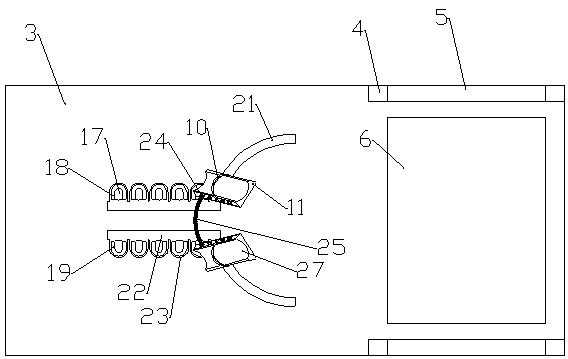

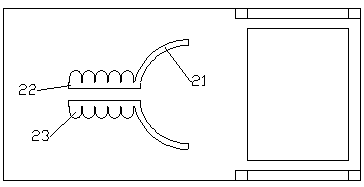

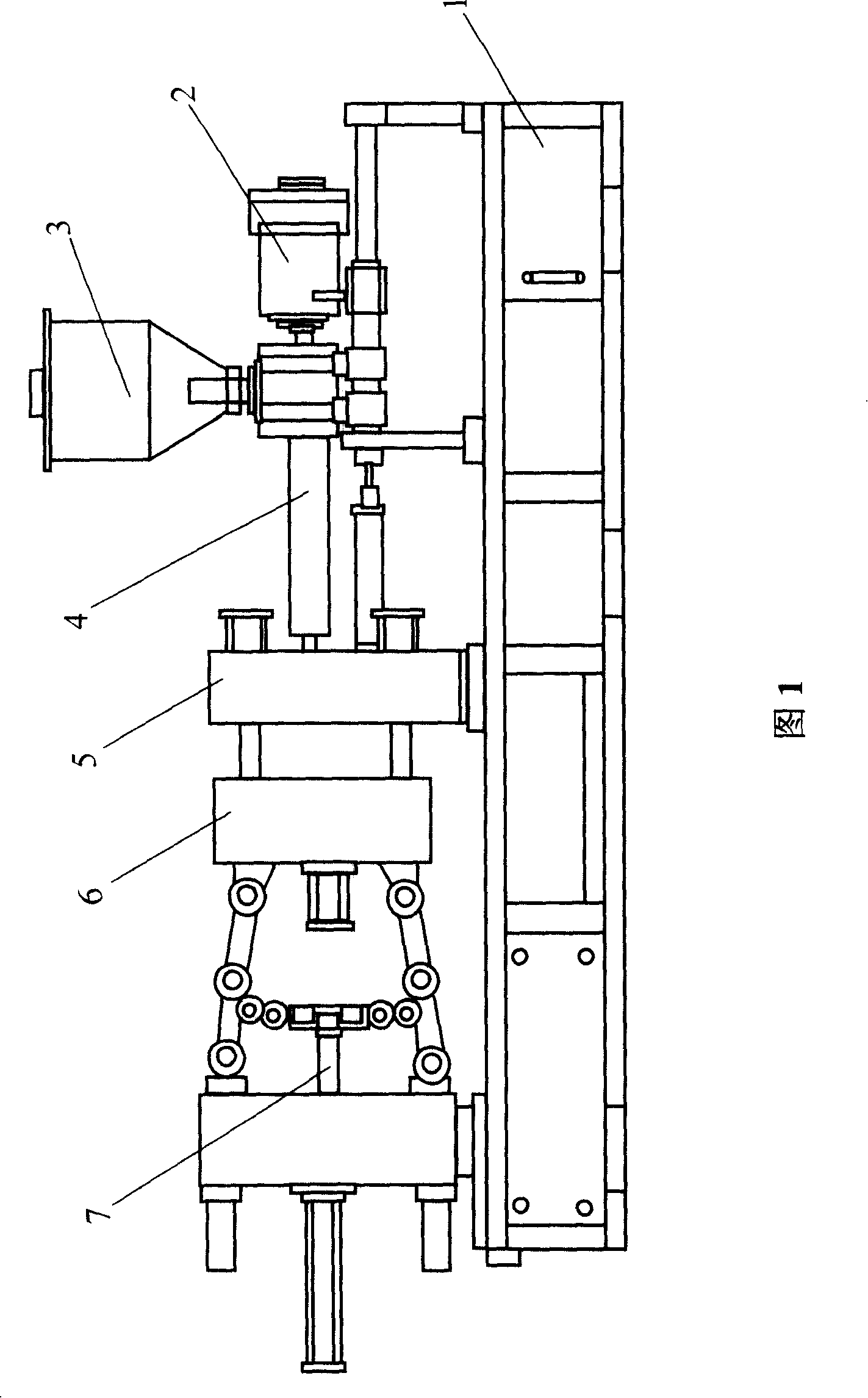

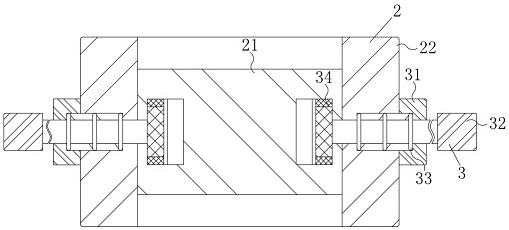

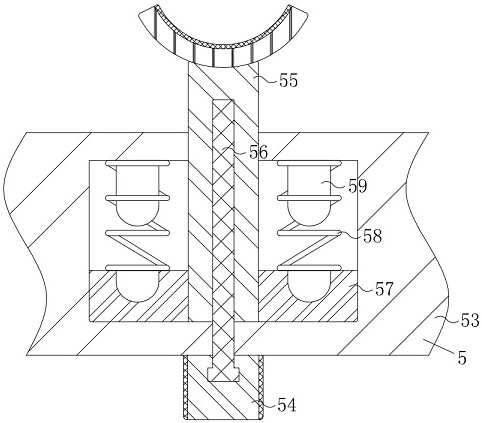

Railway through ground wire as well as preparation device and preparation method thereof

ActiveCN104700940AImprove bindingGuaranteed final performanceInsulated cablesCable/conductor manufactureMaterials scienceCopper alloy

The invention relates to a railway through ground wire. The ground wire comprises a cable core and a copper alloy protective sleeve which covers the outer layer of the cable core and is 0.9-10mm thick. The invention additionally provides a preparation device of a railway through ground wire and a corresponding preparation method, the copper alloy protective sleeve is formed by pouring a copper alloy solution to an outer layer of the cable core to crystallize and condense, the thickness of the copper alloy protective sleeve can be realized by changing the pipe diameter of a lower guide channel of a crystallizer, and the copper alloy molten solution in the lower guide channel can be controlled to grow from inside to outside the surface of the cable core by a heating induction coil and circulating cooling water channel, so as to obtain the railway through ground wire which has reliable connection on a separating place between the protective sleeve and the cable core and uniform metallographic structures of the protective sleeve.

Owner:江阴和宏精工科技有限公司

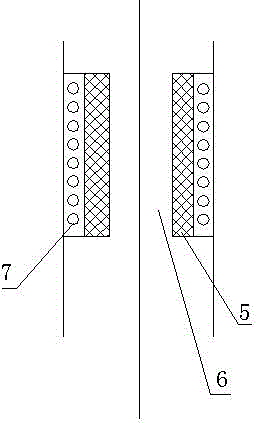

Production process for barrel-making hot dip galvanized steel strip

InactiveCN105648321AReduce manufacturing costIncrease production costHot-dipping/immersion processesReduction rateChemical composition

The invention relates to a production process for a barrel-making hot dip galvanized steel strip, and belongs to the technical field of galvanized steel strips in the metallurgical industry. According to the technical scheme, the barrel-making hot dip galvanized steel strip consists of the following chemical components in percentage by mass: less than or equal to 0.07% of C, less than or equal to 0.025% of Si, less than or equal to 0.25% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.015-0.065% of Als, less than or equal to 30 ppm of T[O], less than or equal to 30 ppm of T[N], the balance iron and inevitable impurities. The production process comprises the following process steps: controlling the mass percentage of the components at a converter smelting end-point as follows: 0.03-0.07% of C, less than or equal to 0.020% of P, and less than or equal to 0.015% of S; (2) controlling a finish rolling temperature of hot rolling to be 885-905 DEG C, and controlling a coiling temperature to be 685-725 DEG C; (3) controlling a cold-rolling total reduction rate to be 70%-85%; and (4) controlling a plate temperature in a continuous annealing furnace to be 670-700 DEG C. The production process has the beneficial effects of reducing the production cost, improving the product performances and meeting using requirements.

Owner:TANGSHAN GUOFENG IRON & STEEL

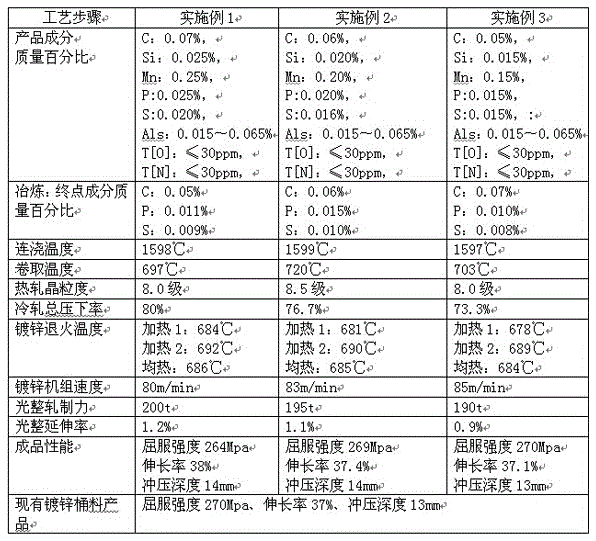

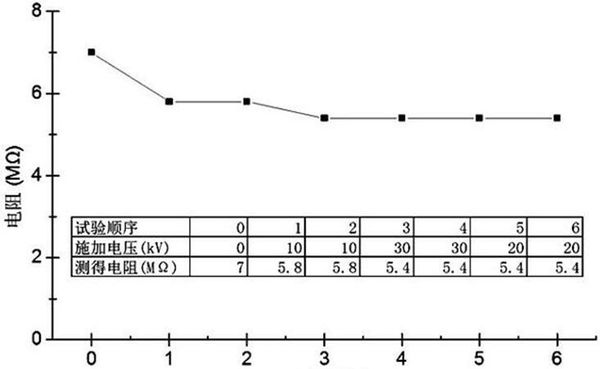

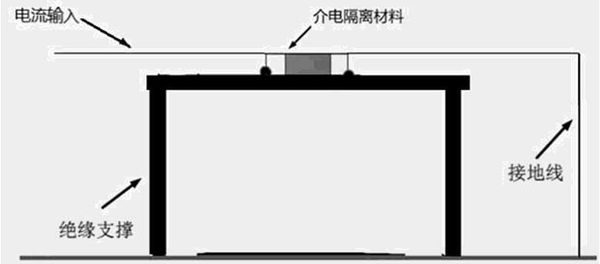

Dielectric isolation material taking thermosetting resin as matrix and preparation method of material

PendingCN112778707AGood mechanical propertiesGood electrical insulationResin matrixMechanical properties of carbon nanotubes

The invention discloses a dielectric isolation material taking thermosetting resin as a matrix and a preparation method of the dielectric isolation material, and belongs to the technical field of electrical insulation composite materials. According to the invention, the dielectric isolation material is prepared by dispersing a static dissipative agent in the thermosetting resin matrix, dipping continuous fibers in a glue solution and carrying out defoaming, low-temperature pre-curing, high-temperature curing and other processes. The resistivity of the dielectric isolation material can reach 104-1010 omega.cm, and the dielectric isolation material has the mechanical properties of high tensile strength and high tensile modulus and can be applied to the field of high-temperature curing. And after 6 times of electric shock with a voltage of more than 10 kV, the performance of the material is kept unchanged. The material and preparation method thereof have the advantages of simple and feasible industrial implementation, low production cost and short curing time, has the obvious effects of static electricity conduction and strong current blocking when being used for lightning isolation and protection, and is easy to popularize and apply in general industries as a lightning protection material.

Owner:YIBIN SANJIANG MACHINERY

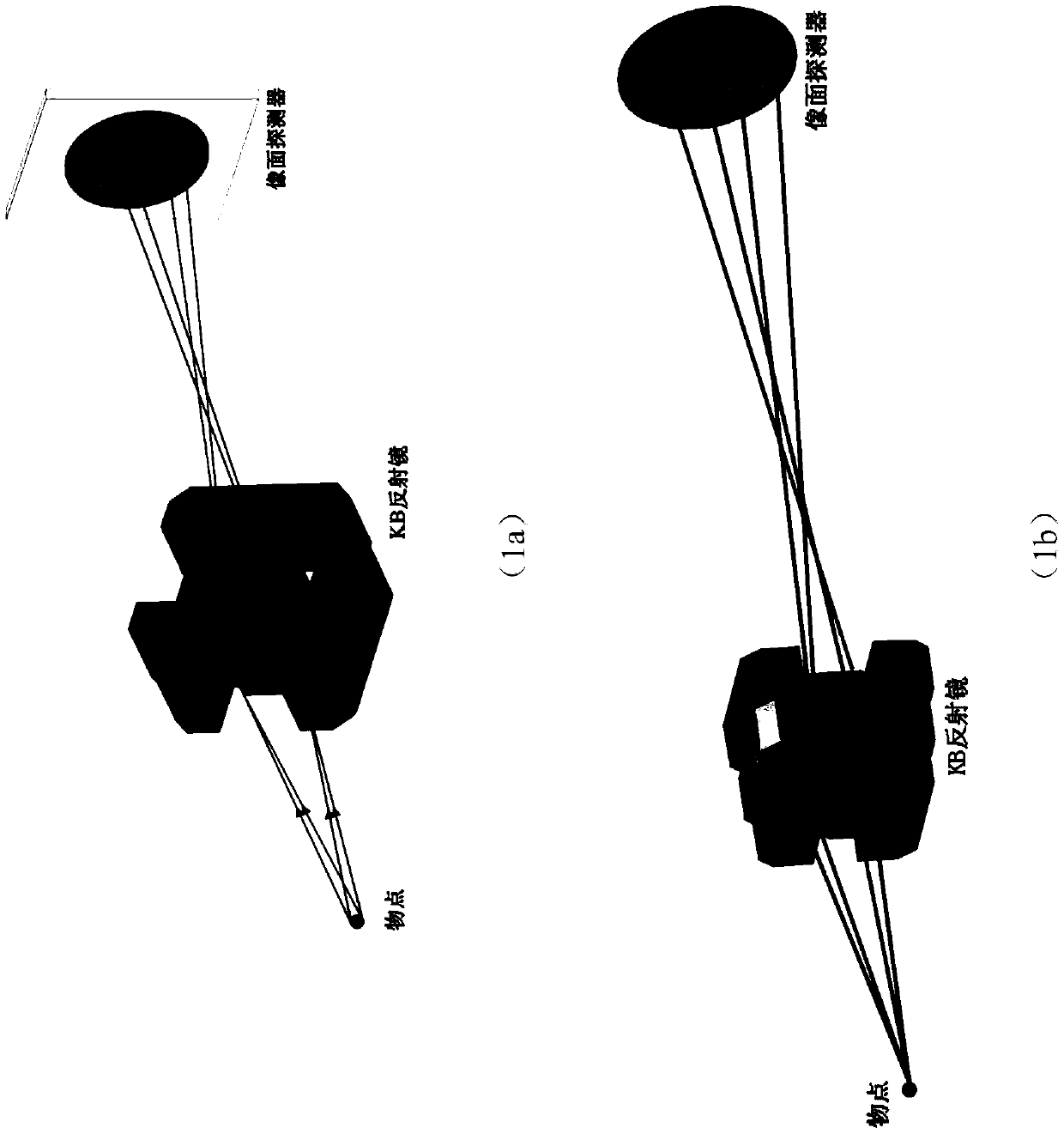

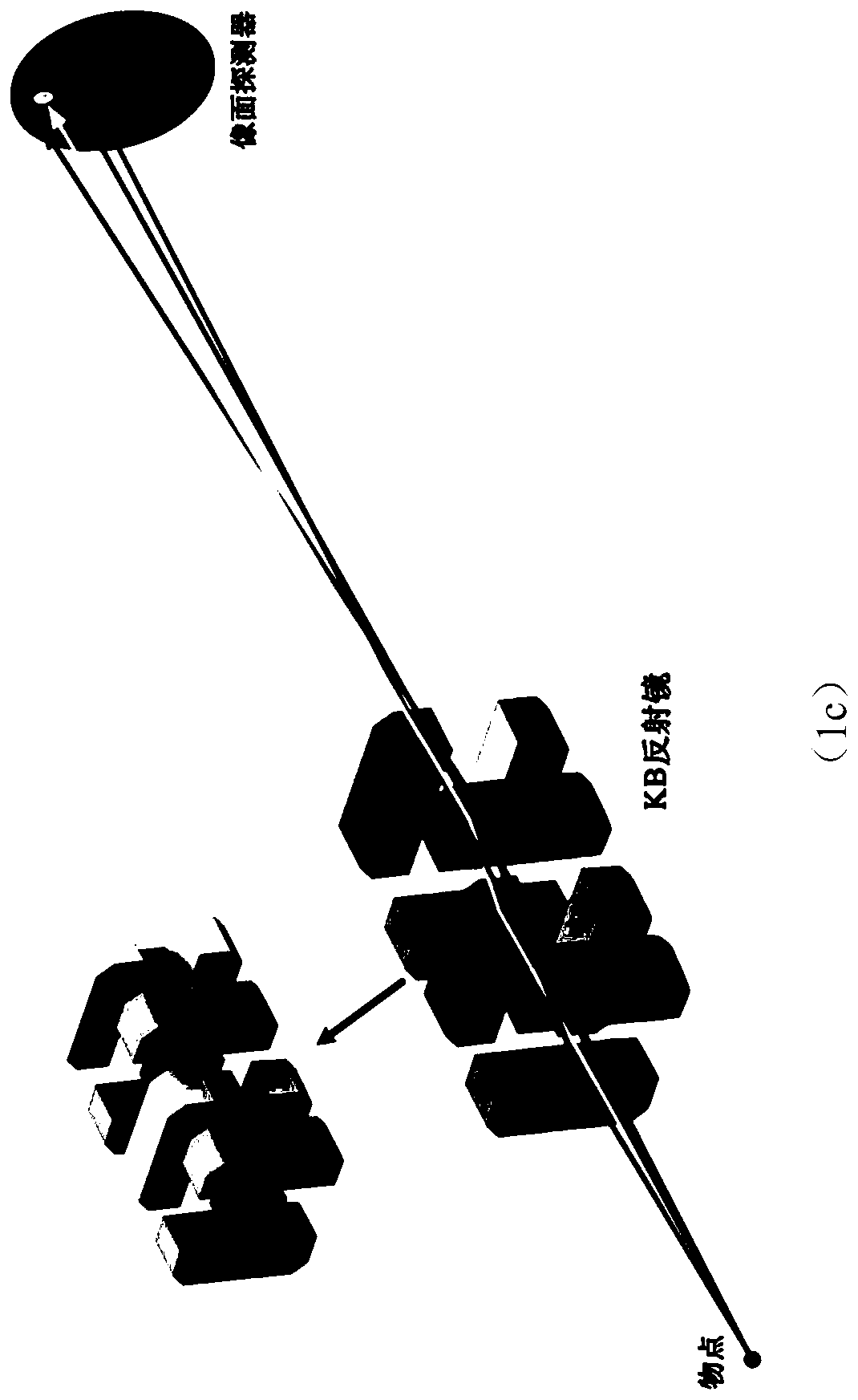

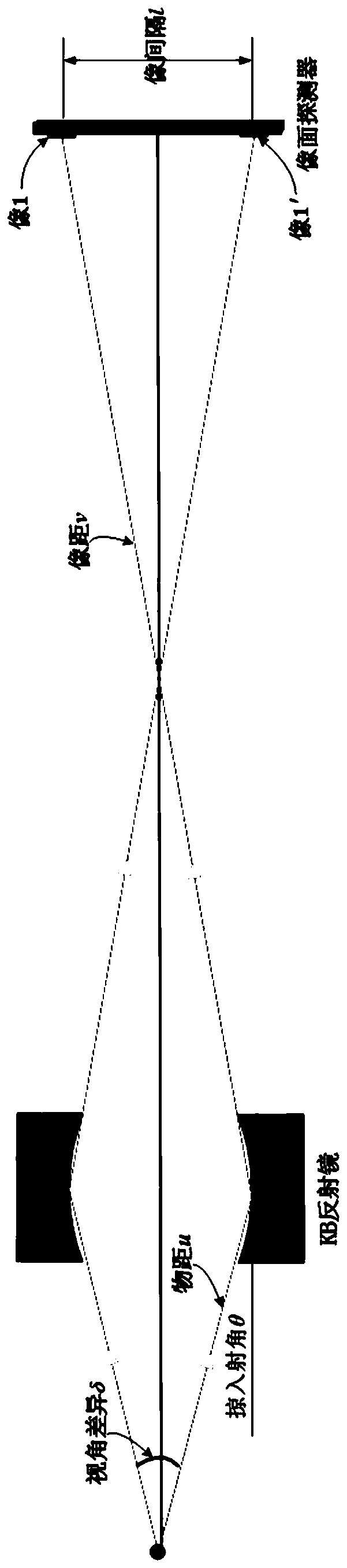

Multichannel KB microscope structure with quasi-coaxial observation function

ActiveCN111562716AHigh measurement accuracyImprove coaxialityNuclear energy generationStereoscopic photographyOptical axisEngineering

The invention relates to a multichannel KB microscope structure with a quasi-coaxial observation function. The structure comprises a plurality of reflecting mirror sets which are sequentially arrangedin the optical axis direction, wherein each reflecting mirror set is composed of a first reflecting mirror arranged in the meridian direction and a second reflecting mirror arranged in the sagittal direction, so that a plurality of independent imaging channels are formed. Compared with the prior art, the structure of the invention has the advantages of high coaxiality, reduction of observation visual angle difference, independent imaging, consideration of different X-ray energy requirements and the like. According to the invention, X-ray reflection is realized in a large energy span especially for the research of ICF (Inertial Constraint Fusion), so that the observation precision of ICF physical experiments can be effectively improved, and the difficulties of fusion ignition related research at home and abroad are solved.

Owner:科晶瑞思(苏州)科技有限公司

Railway through earth line as well as preparation device and preparation method thereof

ActiveCN104700941AEasy to replaceEasy to installInsulated cablesCable/conductor manufactureCrystal structureTube diameter

The invention relates to a railway through earth line. The railway through earth line comprise a cable core and a copper alloy protective sleeve coating the outer layer of the cable core, wherein the thickness of the copper alloy protective sleeve is 0.9mm-10mm. The invention further provides a preparation device and a preparation method for the railway through earth line, wherein the copper alloy protective sleeve is formed by pouring a copper alloy solution to the outer layer of the cable core for being crystallized and condensed; the thickness of the copper alloy protective sleeve can be realized by changing the tube diameter of a crystallization channel of a crystallizer; the copper alloy solution in a channel is guided to directionally grow from the inside to the outside on the surface of the cable core under the control through a heating induction coil and a circulating cooling water path to obtain the railway through earth line which is reliable in combining the protective sleeve with the cable core boundary and uniform in protective sleeve crystal structure.

Owner:江阴和宏精工科技有限公司

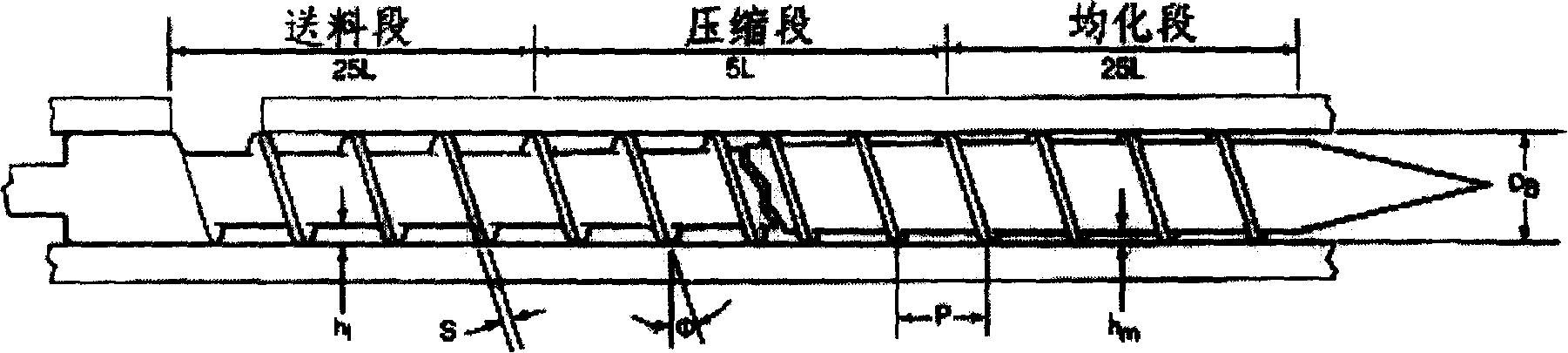

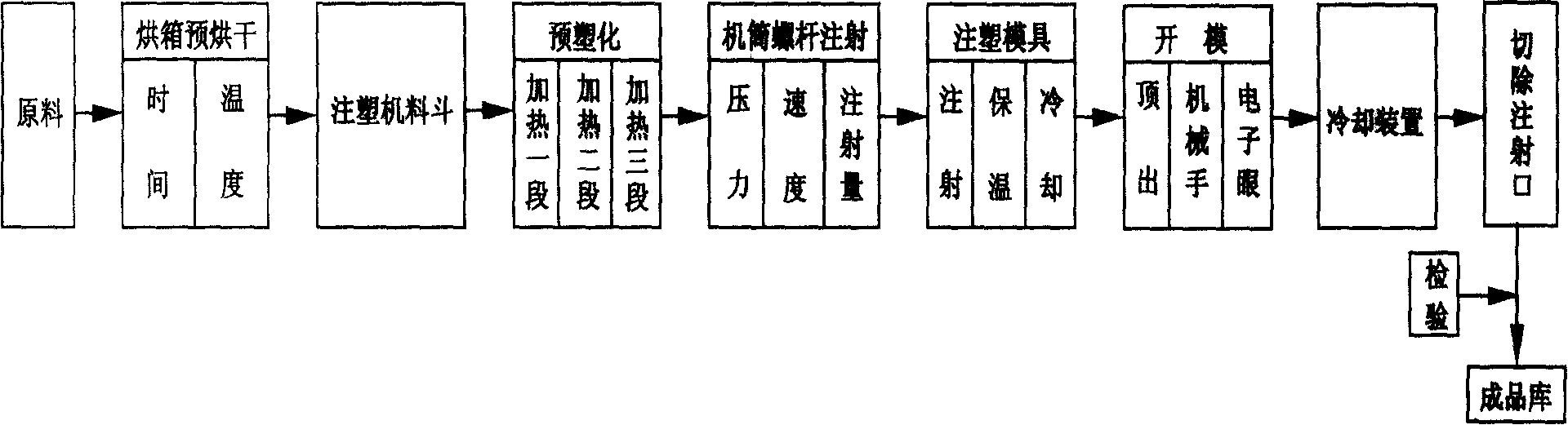

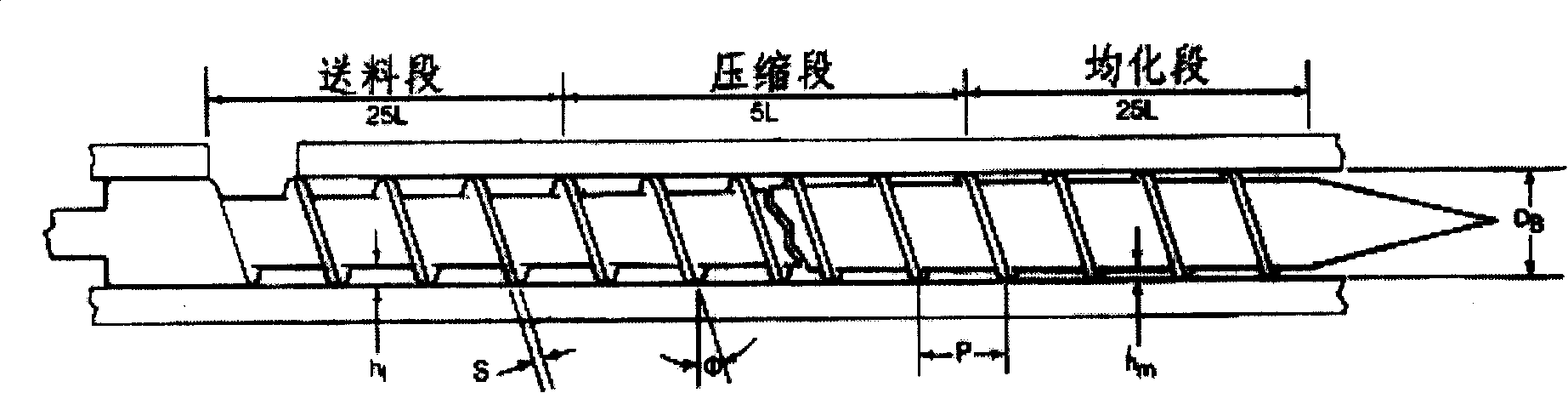

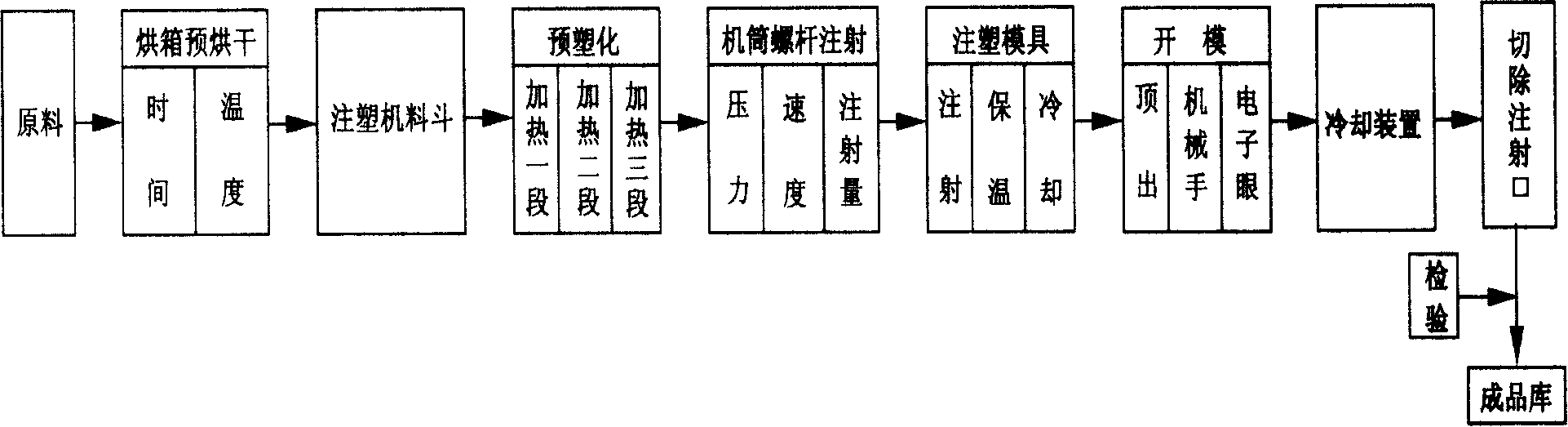

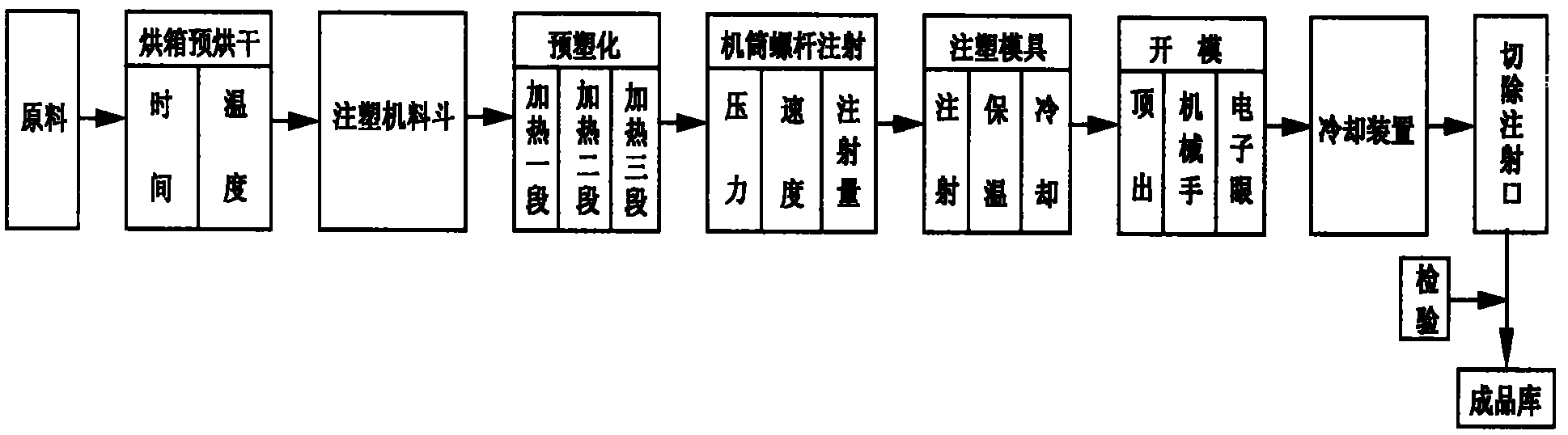

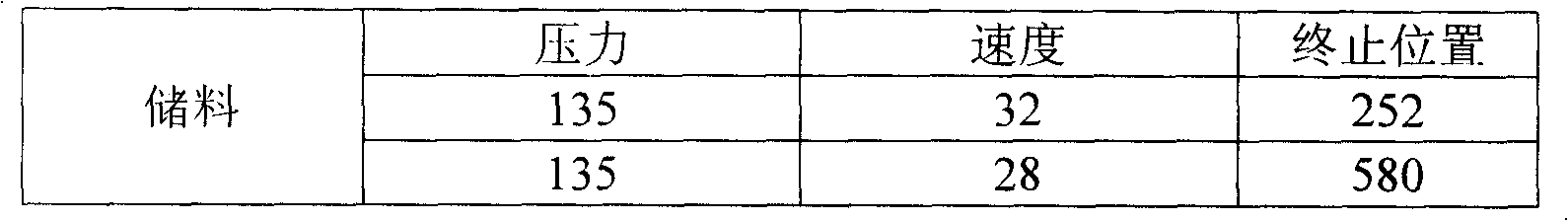

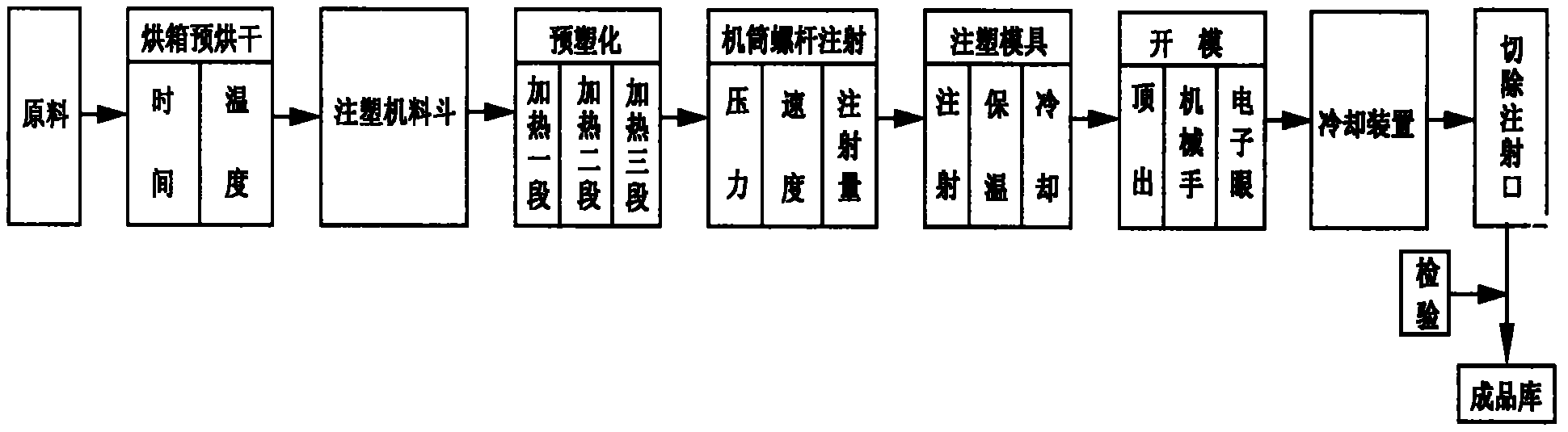

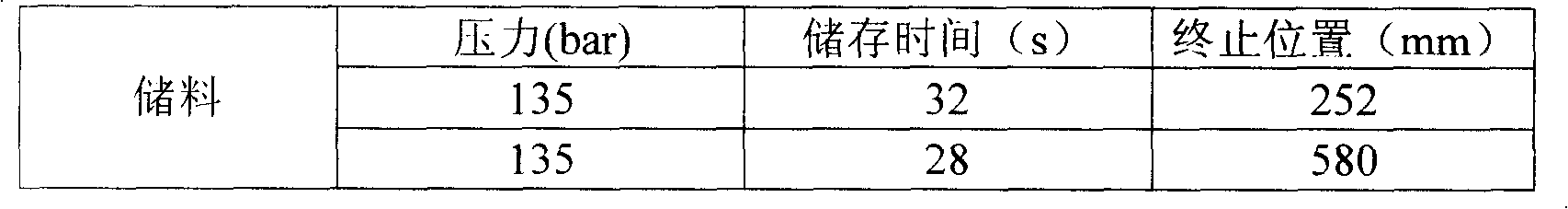

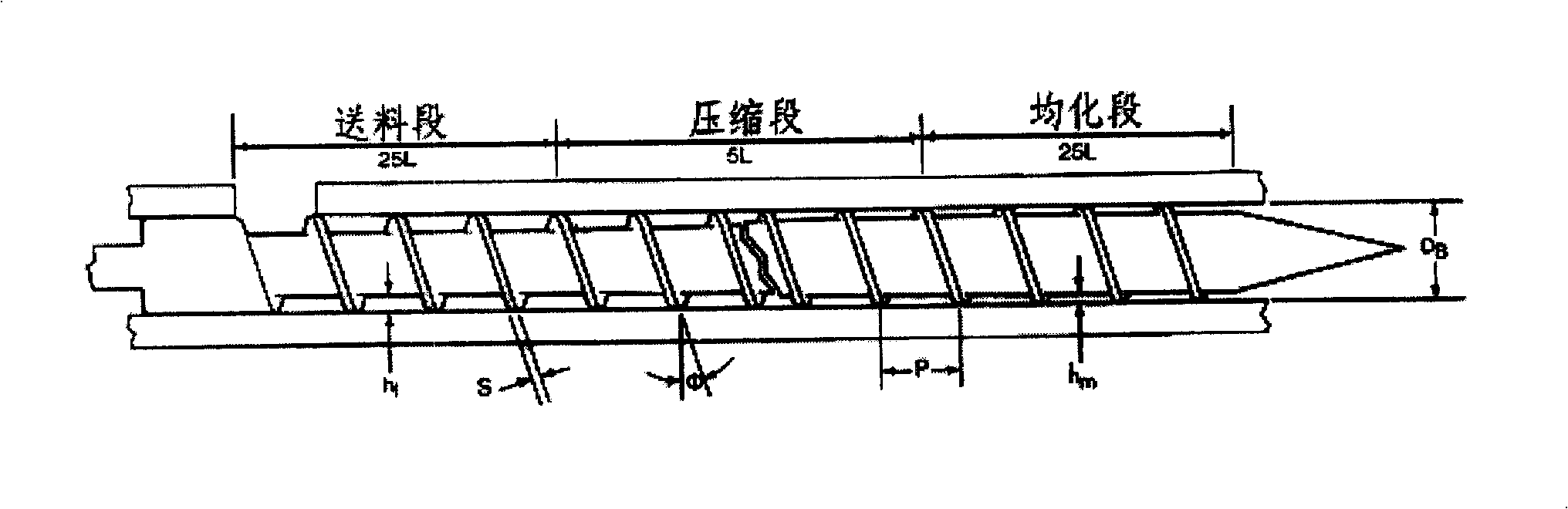

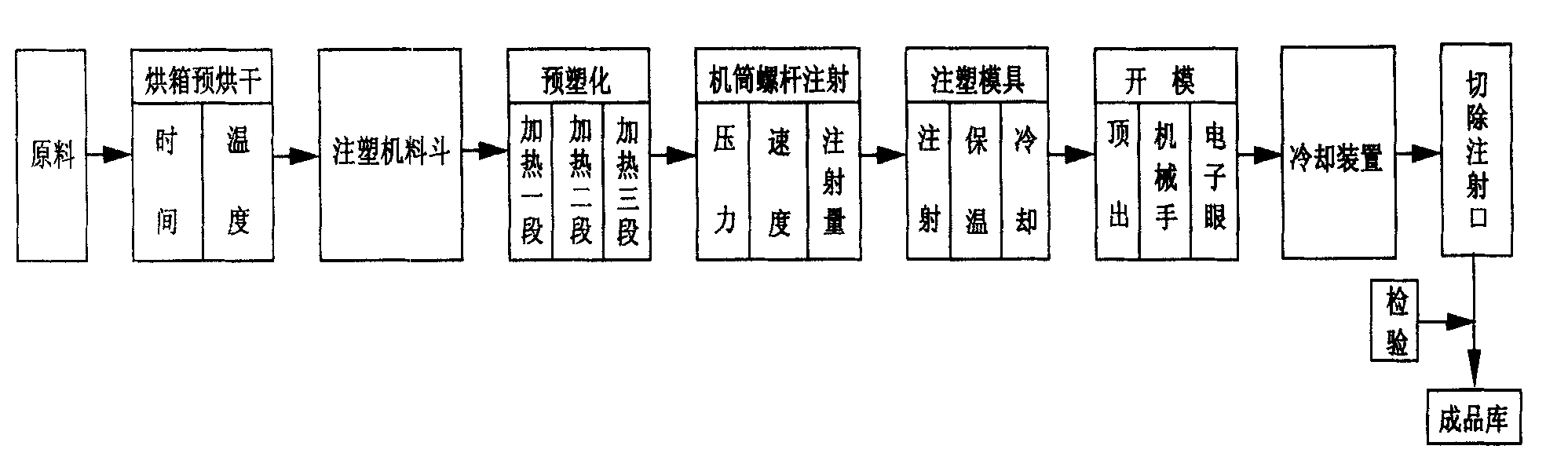

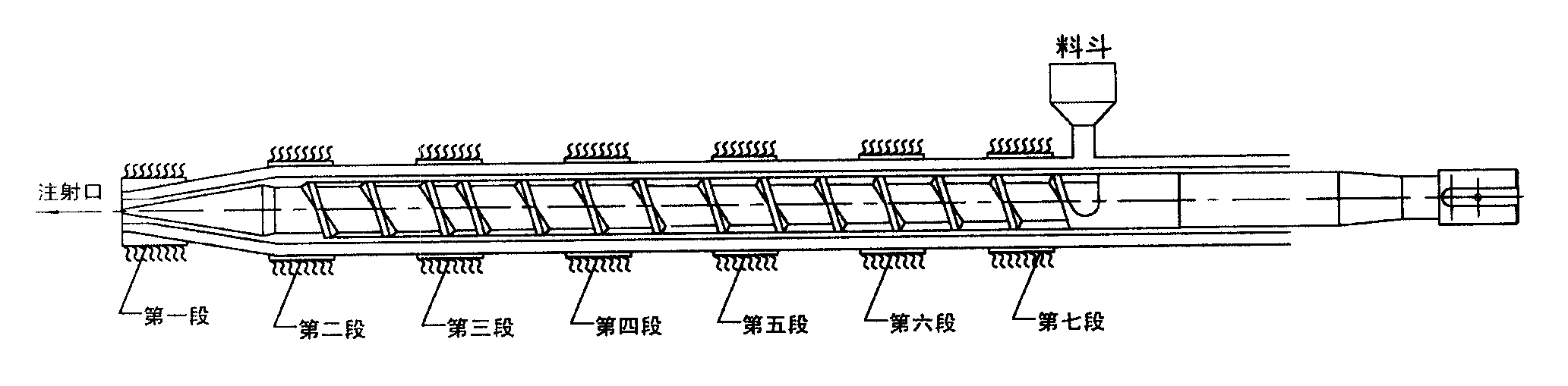

Chlorinated polyvinyl chloride DN400 elbow pipe fitting once injection moulding technique and device thereof

InactiveCN101168286AReduce frictional heatStable speedTubular articlesTemperature controlInjection pressure

The invention relates to a production process of resin pipe fittings, in particular to a one-time injection molding process and equipment for chlorinated polyvinyl chloride elbow pipe fittings. The process includes batching, drying, injection molding, pressure holding, and mold opening process. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the temperature range of each section is 150-155°C and 168-173°C. , 162~167℃, 160~165℃, 155~160℃, 150~155℃, 145~150℃, the mold temperature is controlled between 60~70℃; the injection pressure during injection molding is divided into three sections, respectively 58MPa , 65MPa and 80MPa. The pitch of the injection molding machine screw used in the method is equal to the diameter of the screw, the feeding section accounts for 25% of the total length, the compression section accounts for 50% of the total length, and the homogenization section accounts for 25% of the total length. The invention realizes one-time injection molding of DN400 large elbow pipe fittings through the improvement of process and equipment.

Owner:YOULI HLDG GRP

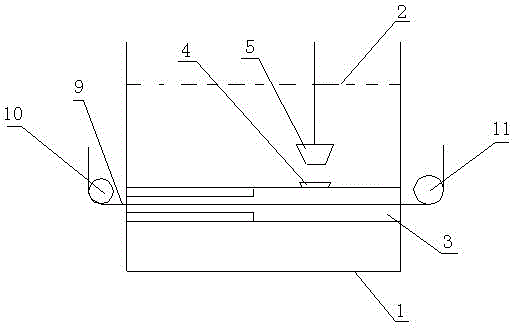

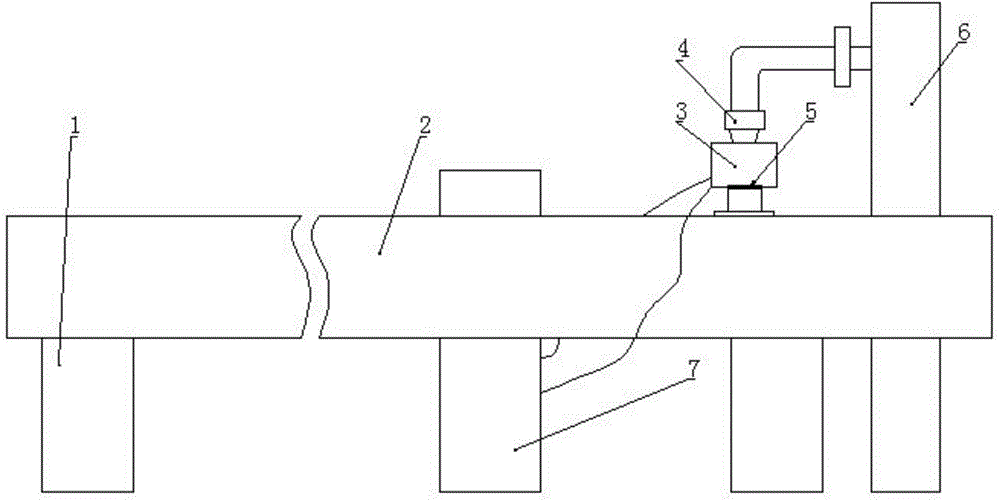

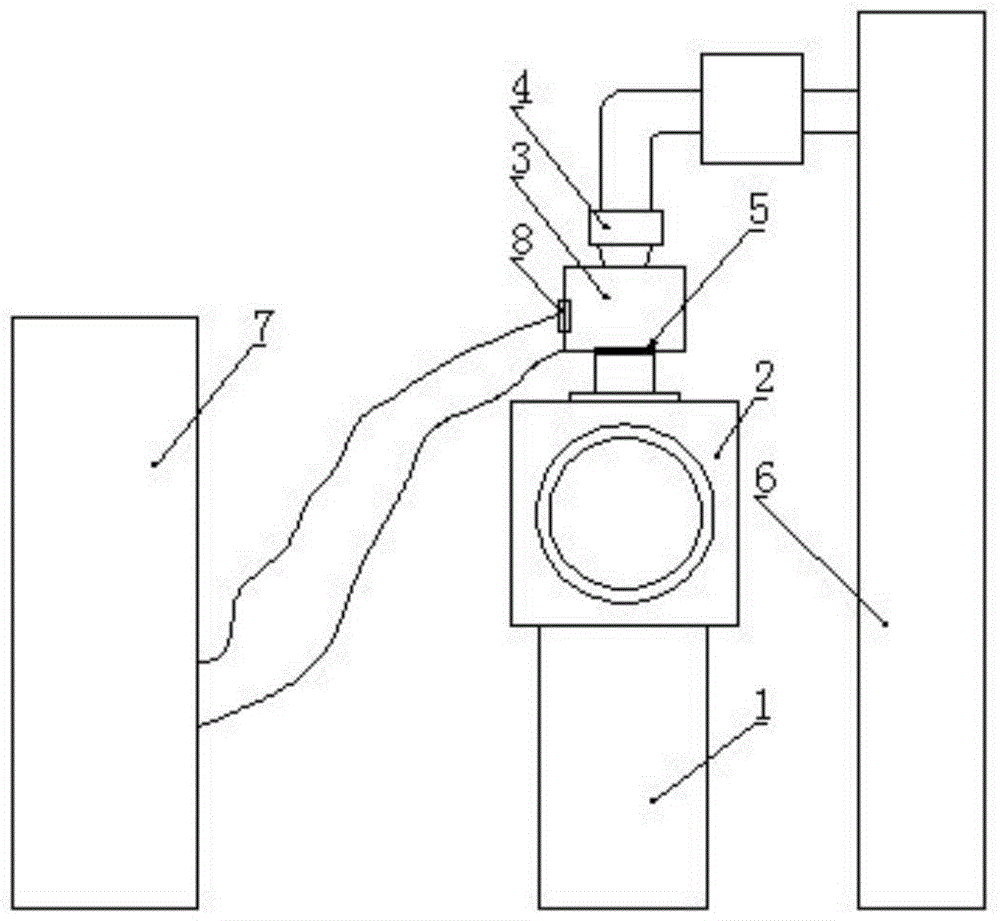

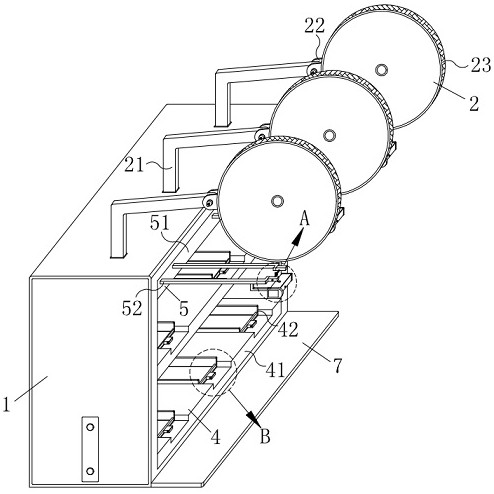

Feed control device for PE fuel gas pipe production

The invention relates to a feed control device for PE fuel gas pipe production. The feed control device comprises an injection molding machine and a suction machine; a feed port of the suction machine communicates with an injection molding particle charging barrel, and a discharge port of the suction machine is fixedly arranged above a feed bin of the injection molding machine; a material storage bin is arranged on the suction machine; the bottom of the material storage bin is provided with a baffle plate; a weight sensor is mounted on the baffle plate and is connected with a PLC control cabinet through a wire; the PLC control cabinet is connected with a driving component of the baffle plate through a wire to realize opening and closing of the baffle plate. Through reasonable assembling, the material storage bin is arranged on the suction machine, weight information can be immediately transmitted to the PLC control cabinet by additionally arranging the baffle plate and a weight acquiring device, the PLC control cabinet is used for driving the opening and closing of the baffle plate through comparison and computation to finish blanking; standardized and unified feeding amount can be uniformly represented each time just by enabling the material on the baffle plate to achieve a preset release amount, and the final effect of injection molding is guaranteed.

Owner:天津满华管材有限公司

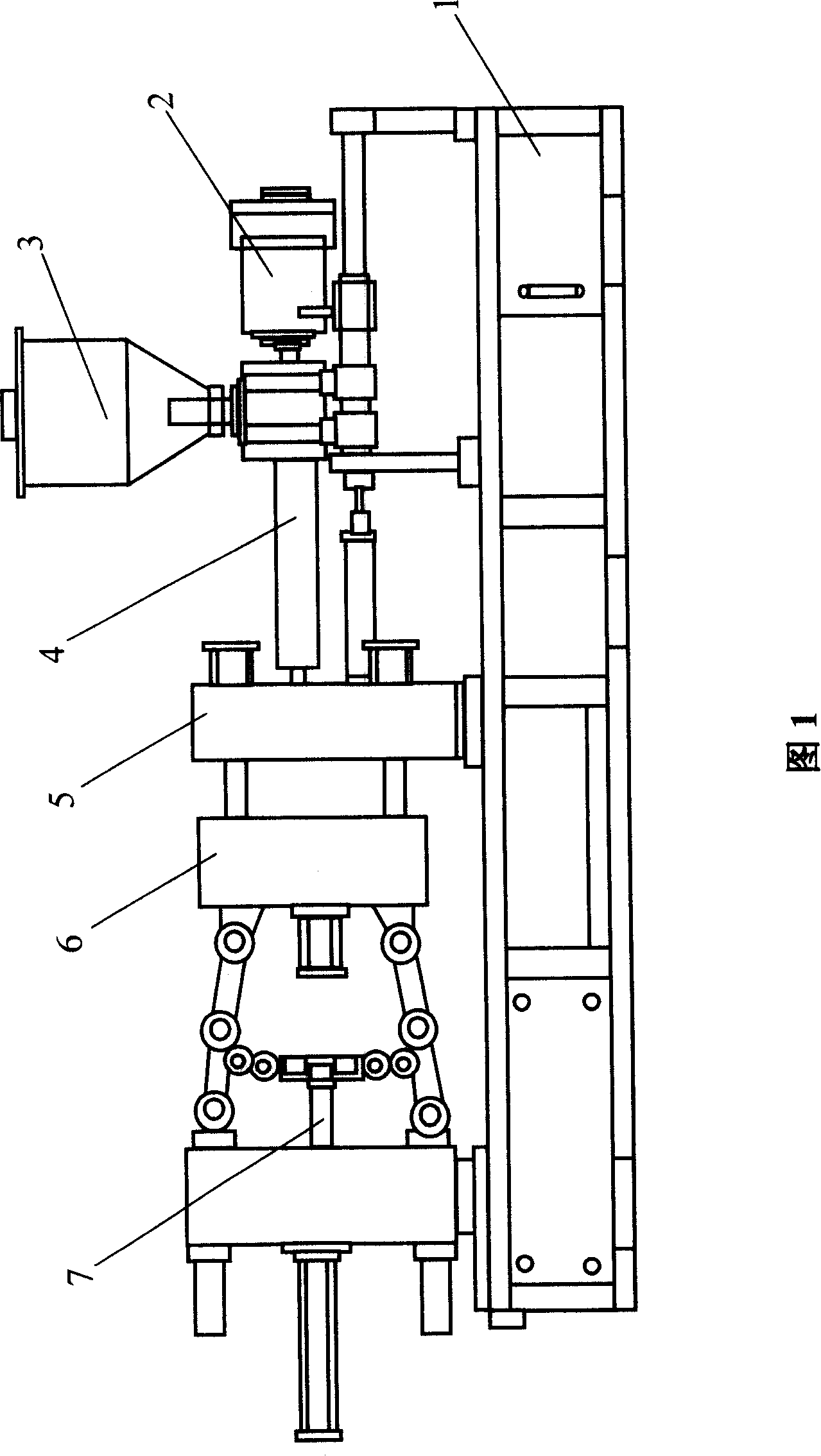

Lower limb rehabilitation training apparatus and use method thereof

ActiveCN110833678ASimple structureEasy to operateResilient force resistorsEngineeringPhysical therapy

The invention relates to a lower limb rehabilitation training apparatus and a use method thereof. A spring fixed sleeve is fixedly arranged on a base below a bottom connecting plate, a vertical springis arranged in the spring fixed sleeve in a sleeving manner, the bottom of the vertical spring is fixedly connected with the internal of the bottom of the spring fixed sleeve, the top of the verticalspring is fixedly connected with the bottom of the bottom connecting plate, a horizontal spring mounting ring is fixedly arranged at the inner side of a foot fixer, and a horizontal spring is arranged on the horizontal spring mounting ring. Even though the patient does have walking capacity, the patient still can enter the sitting posture training state as early as possible, thereby implementingthe lower limb training in stages and gradients; and meanwhile, the training apparatus is in favor of the integral combined training of the legs and the pelvis of the patient, the comprehensive lowerlimb combined training of the sitting posture position is realized by adopting a combined training way of the sitting posture leg-bending opening-closing training and the sitting posture leg-unbendingstep-reaching training, and the combined effect of the lower limb training is greatly improved.

Owner:河南省健琪医疗器械有限公司

Chlorinated polyvinyl chloride DN400 tee junction pipe fitting once injection moulding technique and device thereof

InactiveCN101168287AImprove high friction temperatureReduce frictional heatTubular articlesInjection molding processEngineering

The invention relates to a production process of resin pipe fittings, in particular to a one-time injection molding process and equipment for chlorinated polyvinyl chloride tee pipe fittings. The process includes batching, drying, injection molding, pressure holding, and mold opening process. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the temperature range of each section is 150-155°C and 168-173°C. , 162~167℃, 160~165℃, 155~160℃, 150~155℃, 145~150℃, the mold temperature is controlled between 60~70℃; the injection pressure during injection molding is divided into three sections, respectively 58MPa , 60MPa and 78MPa. The pitch of the injection molding machine screw used in the method is equal to the diameter of the screw, the feeding section accounts for 25% of the total length, the compression section accounts for 50% of the total length, and the homogenization section accounts for 25% of the total length. The invention realizes one-time injection molding of DN400 large-scale three-way pipe fittings through the improvement of process and equipment.

Owner:YOULI HLDG GRP

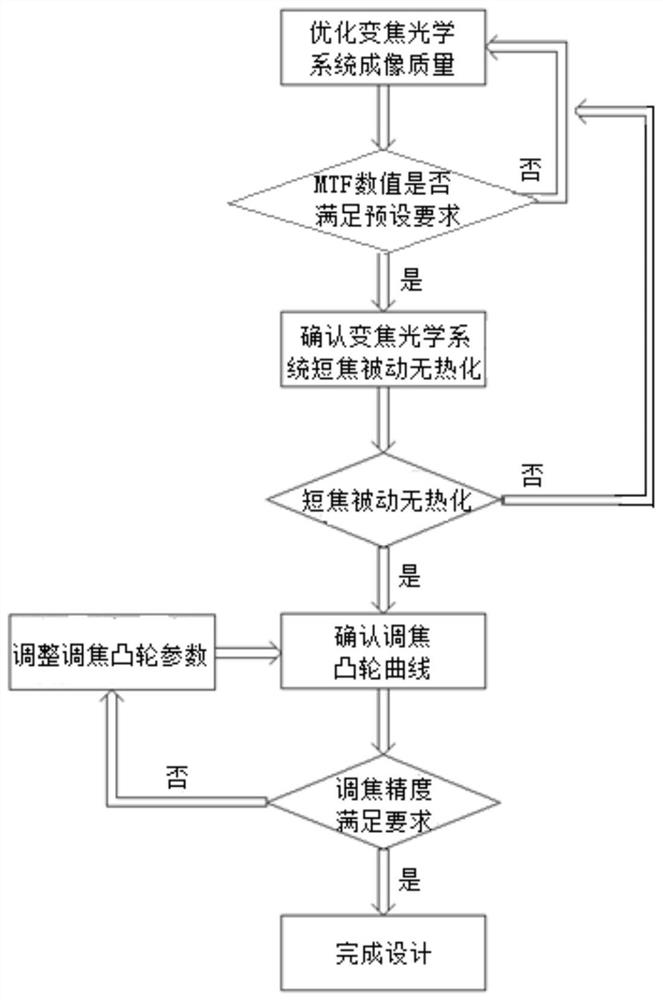

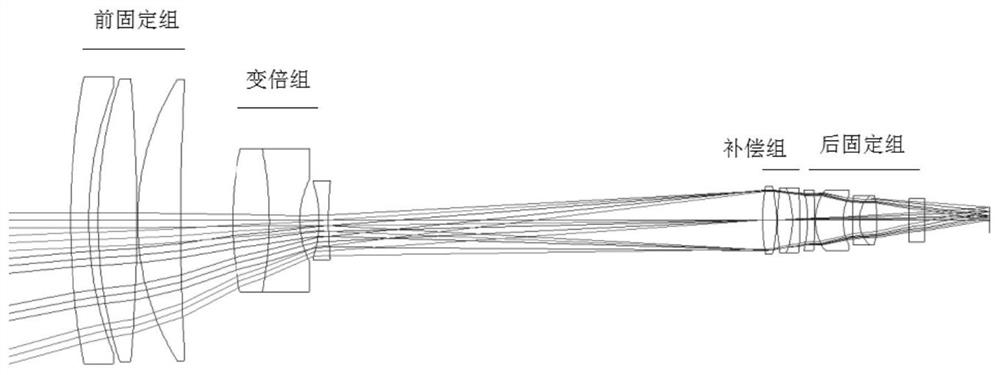

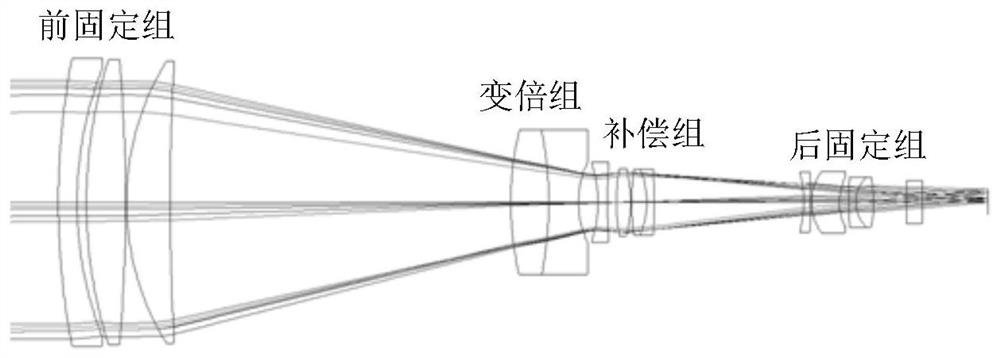

Method for improving focusing precision of zoom optical system

ActiveCN111650746AReduce focusThe amount of focus is reducedOptical elementsOphthalmologyImaging quality

The invention belongs to an optimal design method of a zoom optical system. In order to solve the technical problems that the focusing stroke of a focusing group is too large, the focusing is slow andthe focusing precision is insufficient due to the fact that the focusing amount is not considered at the same time in the existing method for improving the focusing precision, the invention providesa method for improving the focusing precision of a zoom optical system, which comprises the following steps of: S1, optimizing the imaging quality of the zoom optical system; s2, carrying out passivesemi-athermalization design of the zoom optical system; s3, designing a focusing cam curve of the zoom optical system; and S4, adjusting and confirming the focusing precision. Starting from the sourceof an optical system, a passive semi-athermalization design method adopted by a zoom optical system is provided, namely, short focus is in passive athermalization design, and a linear design method is adopted by a focusing cam curve. The focusing amount of the focusing group is greatly reduced, and quick focusing of a zoom system is facilitated; and the focusing precision of the system is greatlyimproved, and the defects of a traditional focusing curve are overcome.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

A kind of blade treatment method

ActiveCN108453345BImprove performanceReduce manufacturing costArc welding apparatusMetallic material coating processesIndustrial engineeringWelding

The invention belongs to the technical field of cutter manufacturing, and particularly relates to a cutting edge treatment method. In order to solve the problem that when imported high-quality steel is adopted to manufacture a cutter so as to improve the cutting edge performance of the cutter at present, the manufacturing cost of the cutter is high, the invention discloses the cutting edge treatment method. The cutting edge treatment method specifically comprises the following steps that S1, manufacturing preparation of a cutter is carried out, and the cutting edge part is cleaned; S2, a welding and laser cladding combined mode is adopted for machining a cutting edge strengthened layer; and S3, the cutting edge strengthened layer is coped, and final cutting edges are obtained. When the cutting edge treatment method is adopted for cutting edge treatment, not only can the performance of the cutting edges be greatly improved, the use effect of the cutter is guaranteed, but also the requirements for cutter body materials can be reduced, and the cost of the cutter is reduced.

Owner:YANGJIANG DONGHUA LASER INTELLIGENT TECH CO LTD +1

Chlorinated polyvinyl chloride DN400 tee junction pipe fitting once injection moulding technique and device thereof

InactiveCN101168287BReduce shear forceReduce frictional heatTubular articlesChlorinated polyvinyl chloridePipe fitting

The invention relates to a manufacturing technique of a wood-gum tubular element, in particular to a disposable injection molding technique and device of a CPVC three-way tubular element. The technique comprises technical processes of charge mixture, drying, injection made, pressure maintaining and open modeling, wherein a heating position of a charging barrel of an injection machine is divided into seven segments in the process of injection, the temperature ranges of the segments are respectively 150-155 DEG C, 168-173 DEG C, 162-167 DEG C, 160-165 DEG C, 155-160 DEG C, 150-155 DEG C, and 145-150 DEG C, and the temperature of a mould is controlled between 60 and 70 DEG C. When injecting, the pressure of ejection is divided into three segments which are respectively 58 MPa, 60 MPa and 78 MPa. The pitch of screw of a screw rod of the injection machine used by the method is equal to the diameter of the screw rod, a feeding segment takes up 25 percent of the total length, a compression segment takes up 50 percent of the total length, and a homogenizing segment takes up 25 percent of the total length. The invention achieves the disposable injection molding of a DN400 large-scale three-way tubular element via the improvement of the technique and the device.

Owner:YOULI HLDG GRP

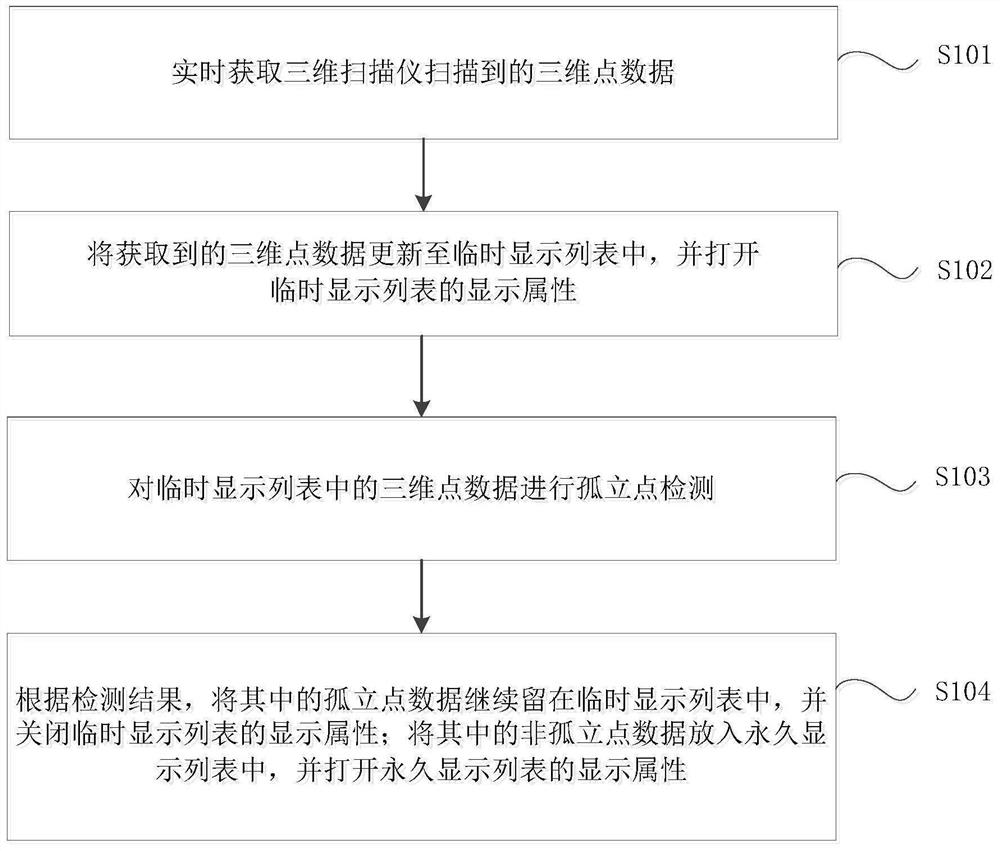

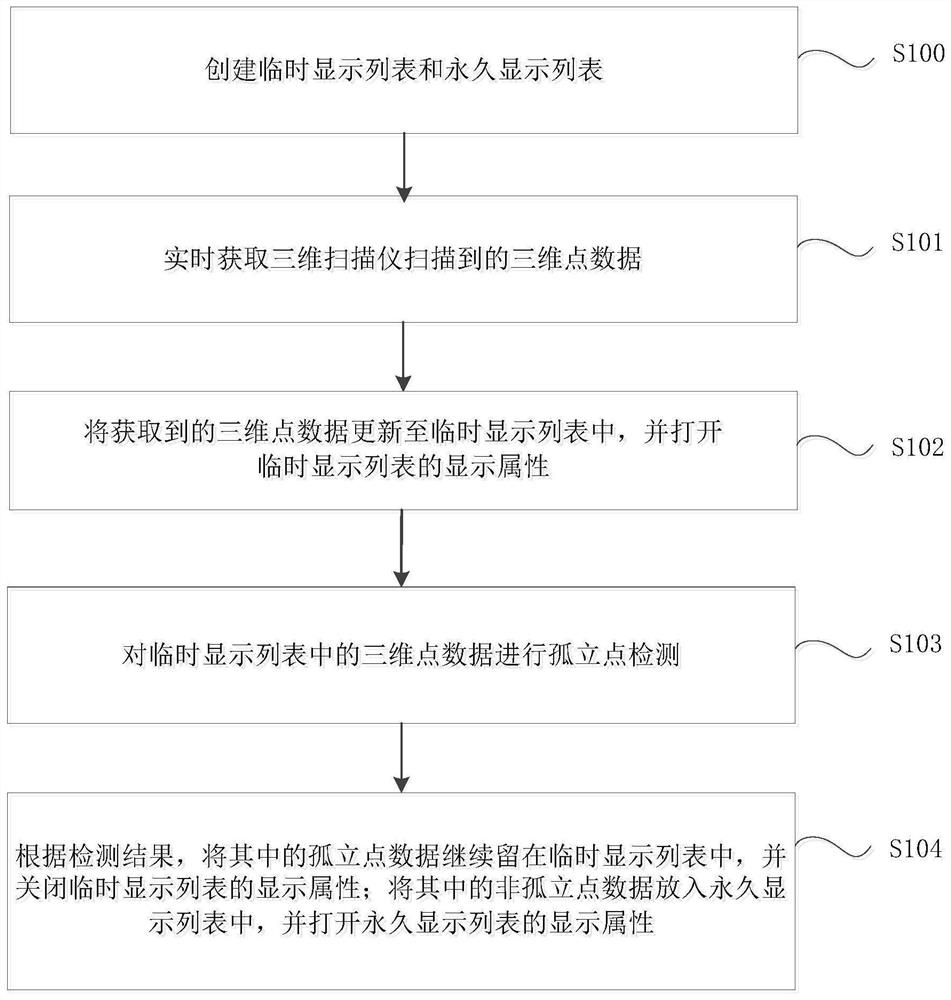

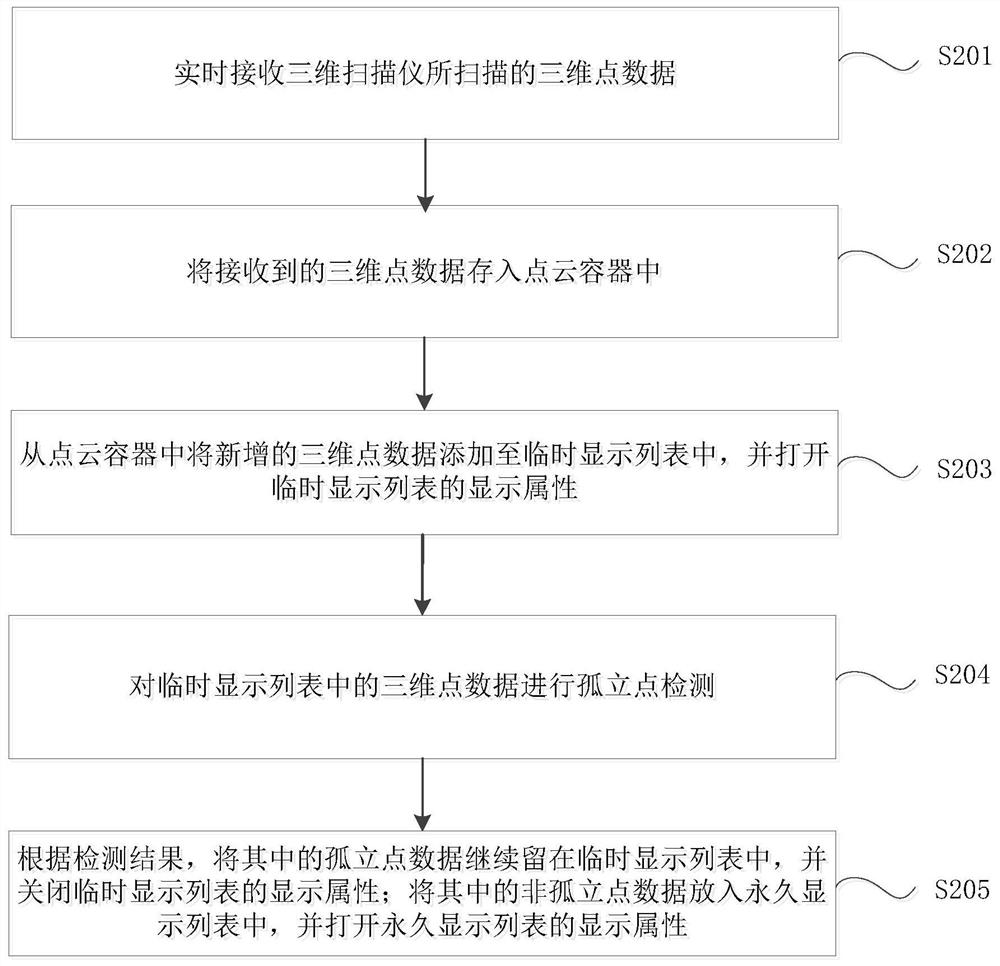

Real-time isolated point removing method and device for three-dimensional scanner

PendingCN111932465AGood real-time point cloud look and feelStrong real-timeImage enhancementImage analysisComputer hardwarePoint cloud

The invention relates to a real-time isolated point removing method, device and system for a three-dimensional scanner, computer equipment and a computer readable storage medium, and the method comprises the steps: obtaining three-dimensional point data scanned by the three-dimensional scanner in real time; updating the obtained three-dimensional point data to a temporary display list, and openingthe display attribute of the temporary display list; carrying out isolated point detection on the three-dimensional point data in the temporary display list; according to the detection result, continuously leaving the isolated point data in the temporary display list, and closing the display attribute of the temporary display list; and putting the non-isolated point data into a permanent displaylist, and opening the display attribute of the permanent display list. According to the invention, real-time isolated point removal can be realized, visual drop feeling of people is avoided, and excellent real-time point cloud impression is brought to scanners while the final effect is ensured.

Owner:SCANTECH (HANGZHOU) CO LTD

Forging forming process of a large-size high-strength heat-resistant magnesium alloy thick plate

The invention discloses a forging forming technology for a large-size high-intensity and heat-resistant magnesium alloy thick plate and provides a forging forming technology for a magnesium alloy thick plate which is thicker than or as thick as 150mm. The forging forming technology comprises the steps of large-furnace smelting, semi-continuous casting, homogenizing annealing, variable-temperature multi-directional forging, fast forging and after-forming thermal treatment, wherein the variable-temperature multi-directional forging is executed on an oil press; before forging, the temperature of an ingot blank is preserved at 500-530 DEG C for 4-6 hours; the pressing speed is 200-400mm / min, the upsetting gate pressing amount is 30-50 percent, and the swaging gate pressing amount is 5-10 percent; the fast forging is executed on an air hammer; before fast forging, the temperature of the ingot blank is preserved at 480-500 DEG C for 2-4 hours. According to the forging forming technology, the high-temperature plasticity of a magnesium alloy is fully achieved, and the usability is obviously improved; at the temperature of 200 DEG C, the tensile strength of the thick plate in the length direction, the width direction and the height direction is higher than or equal to 330MPa, and the elongation rate is larger than or equal to 8 percent.

Owner:CENT SOUTH UNIV

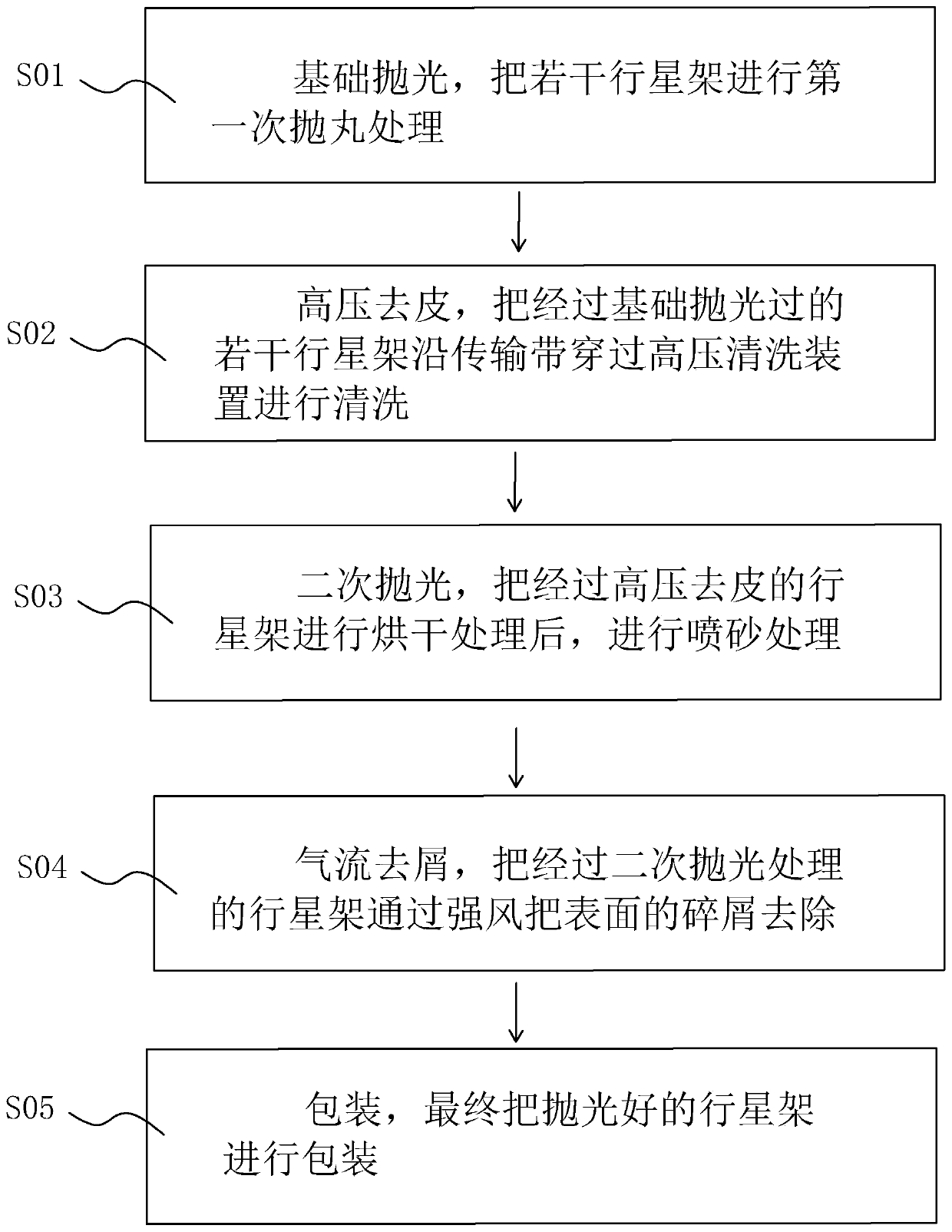

Forging process of planet carrier

ActiveCN110757343AEasy to handleGuaranteed final performanceCleaning using gasesCleaning using liquidsAbrasive blastingSkin treatments

The invention discloses a forging process of a planet carrier, and relates to the processing technology field of the planet carrier. The forging process of the planet carrier aims at solving the technical problems that randomness in processing of a shot blasting machine is large, and unthorough oxide skin treatment of the planet carrier is easily caused. The main point of the technical scheme includes that the basic shot blasting machine is used for polishing, the surface of the planet carrier is washed through high pressure water, oxide skin adhered to the surface of the planet carrier is removed, then secondary sand blasting is performed for fine treatment, and finally high pressure airflow is used for removing chippings; and the treatment effect for the oxide skin is improved.

Owner:山东昌东锻造有限公司

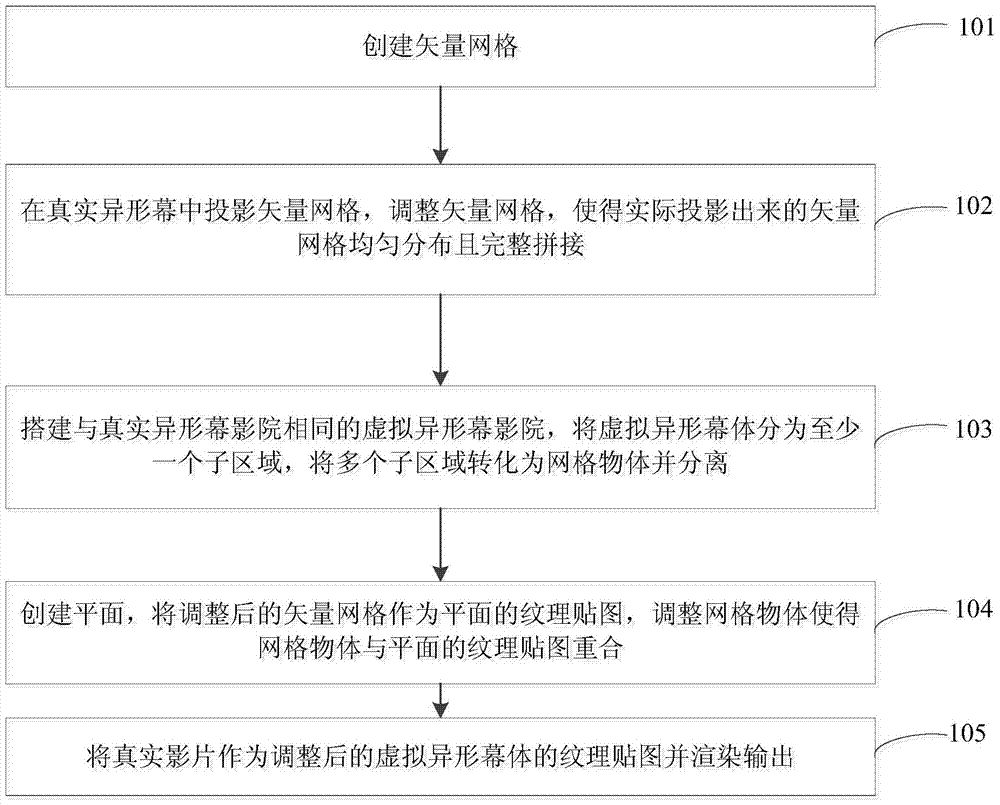

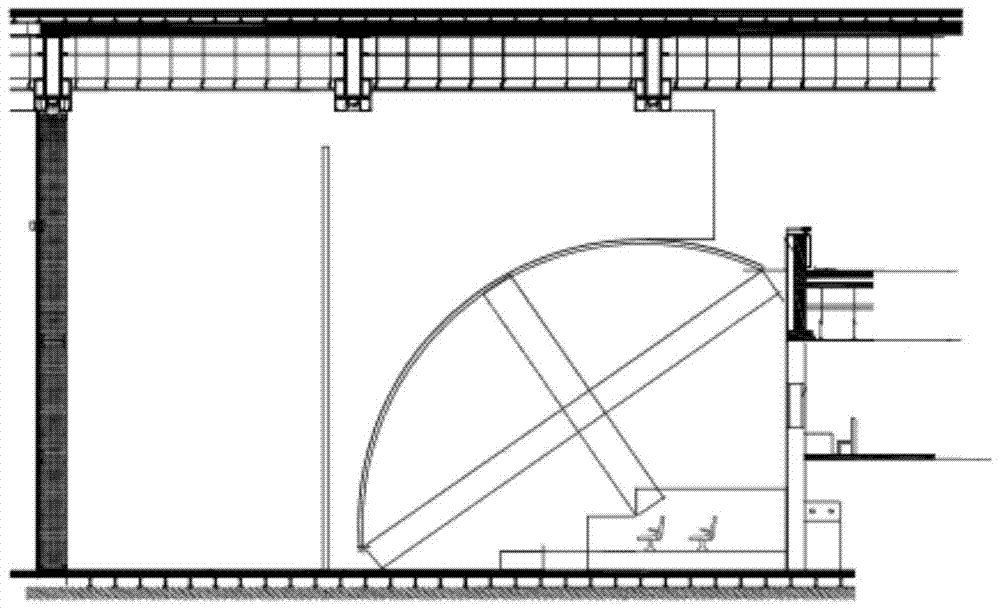

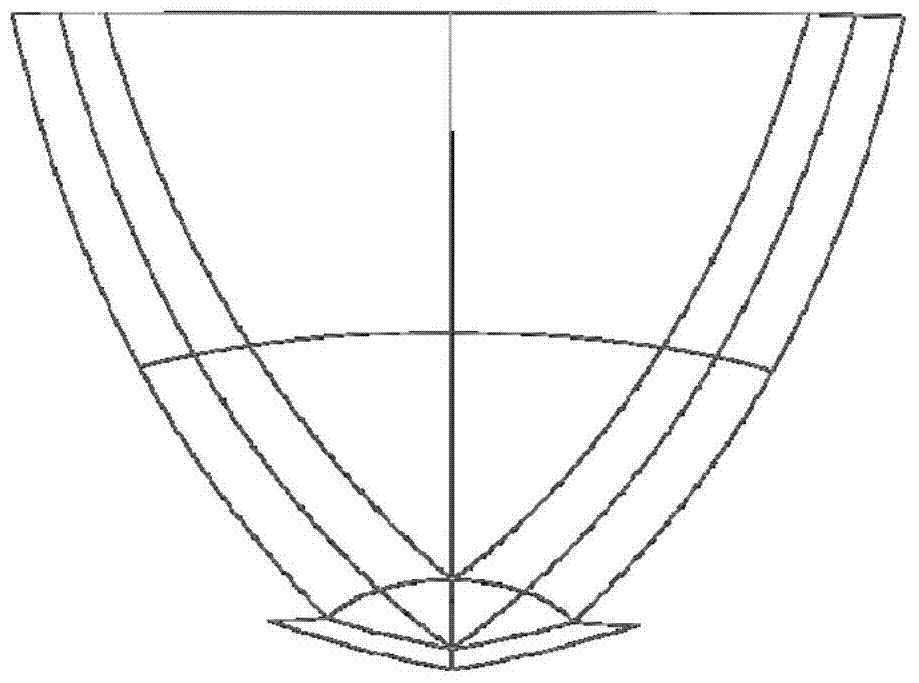

A kind of production method of special-shaped screen film

ActiveCN105469448BConducive to screeningEasy to use3D-image rendering3D modellingVirtual screenMesh grid

The invention relates to a production method of a special-shaped screen film, comprising: according to the number of projection channels, using a path tool to describe the shape of a real special-shaped screen by channel, forming a vector grid: projecting the vector grid on the real special-shaped screen, according to the projection Adjust the vector grid according to the positional relationship between the vector grid and the real special-shaped screen; set up the three-dimensional virtual screen body of the real special-shaped screen, carry out texture mapping to the three-dimensional virtual screen body with a standard grid, and divide it into at least one Subregions, convert each said subregion into a mesh and separate: create a plane, use the adjusted vector network as the texture map of the plane, adjust the mesh so that the mesh coincides with the texture map of the plane ; Use the real film as the texture map of the adjusted 3D virtual curtain body and render the output. Compared with the prior art, the present invention has the advantages of being simple, fast, and highly adaptable, and is not subject to too many limitations of the construction conditions of the theater itself, and the configuration conditions of software and hardware.

Owner:SHANGHAI HUABO INFORMATION SERVICE

Winding anti-deviation assembly capable of being used for yarns with different thicknesses

The invention relates to the field of textile equipment, in particular to a winding anti-deviation assembly capable of being used for yarns with different thicknesses. The winding anti-deviation assembly comprises a storage frame, the storage frame is fixedly connected with a placement mechanism and a bottom plate, the placement mechanism is provided with an adjusting mechanism, the storage frame is internally provided with the placement mechanism and a limiting mechanism, and the limiting mechanism is provided with a stretching mechanism; through the placement mechanism, the yarns of different specifications can be conveniently arranged before being wound, and the yarns of different thicknesses can be wound in cooperation with the limiting mechanism; the limiting mechanism is arranged in the storage frame, under the cooperation of the placement mechanism, a yarn can be conveniently limited through the limiting mechanism, deviation of the yarn in the winding process is avoided, and meanwhile the winding anti-deviation assembly capable of being used for the yarns with different thicknesses is suitable for winding of the yarn with different thicknesses; the stretching mechanism is arranged on the limiting mechanism, the tension in the winding process is controlled through the stretching mechanism, yarn deviation in the winding process is further avoided, and the final winding effect is guaranteed.

Owner:XIANGSHUI BAOJI TEXTILE

High magnetic induction wide temperature interval linear magnetic temperature compensating alloy and production process thereof

ActiveCN1262681CGuaranteed ingredientsGuaranteed final performanceElectro-slag remeltingHeat treated

The invention relates to a highly magnetic induction, linear magnet-temperature compensation alloy with broad temperature regioand its production process. The alloy components in percent are as follows: Ni 31.5-32.5%, Mn<=0.4%, Si<=0.3%, C 0.10-1.50%, surplus Fe. The production process is: first adopting vacuum induction melting then casting to make electrode bar, then electroslag remelting it to cast ingot, heating to 1100-1150 DEG C, hot forging hot-rolled sheet blank, heating to 1050 DEG C-1100 DEG C, hot-rolling to sheet, 1050 DEG C-1100 DEG C heat treatment, acid cleaning, cold rolling and obtaining band of finished product thickness, after processing element, using after final ageing treatment 1-2 hours in vacuum heat treatment furnace under 400 DEG C-500 DEG C. The inventive alloy has a wider usage temperature range, temperature point for testing is more than before, and B-t linearity is well, so the inventive alloy surpass the existing FeNi magnet compensation alloy in usage temperature range and magnet compensation ability.

Owner:CHONGQING MATERIALS RES INST

Chlorinated polyvinyl chloride DN400 loose flange once injection moulding technique and device thereof

InactiveCN101168288BReduce shear forceReduce frictional heatDomestic articlesInjection pressureChlorinated polyvinyl chloride

The invention relates to a productive technology for producing wood-gum flange, in particular to a technology and device for one time injection molding of chlorinated polyvinyl chloride lap joint flanges. The technology comprises industrial processes of burdening, drying, injection molding, pressure maintaining and model opening, wherein in the injection molding process, the heating portion of a charging barrel of an injection machine is divided into seven segments, the temperature ranges of the segments are respectively 150-155 DEG C, 168-173 DEG C, 162-167 DEG C, 160-165 DEG C, 155-160 DEG C, 150-155 DEG C, and 145-150 DEG C, the temperature of a die is controlled between 60 and 70 DEG C, the injection pressure when injection molding is divided into three segments which are respectively56 MPa, 59MPa and 76MPa. The pitch of a screw of the injection machine used in the method is equal to the diameter of the screw, the delivery segment occupies 25 percent of the whole length, the compressing segment occupies 50 percent of the whole length, and the homogenizing segment occupies 25 percent of the whole length. The invention realizes one time injection molding of DN400 large-scale lap joint flanges via improving the technology and the device.

Owner:YOULI HLDG GRP

Hygroscopic catalyst and preparation method thereof

ActiveCN102161605BIncrease elasticityHigh elongationExplosive working-up apparatusAdhesiveMixed materials

The invention discloses a hygroscopic catalyst and a preparation method thereof. The hygroscopic catalyst comprises an oxidant, an incendiary agent, chloride and carbonate; 10 to 20 mass percent of liquid rubber is taken as an adhesive; toluene diisocynate is added to serve as a curing agent; and the content of the curing agent is 1 / 15 to 1 / 13 of the using amount of the adhesive. The method comprises the following steps of: putting the chloride, the incendiary agent, the carbonate and the adhesive into a kneading machine, mixing uniformly, adding the oxidant at intervals, mixing uniformly, adding the curing agent for mixing, vacuum-pouring or extruding and squeezing mixed materials into a shell, and performing high-temperature curing in a drying oven to obtain a finished product. Various ingredients of the hygroscopic catalyst produced by adopting a pouring production process are difficult to damp and deteriorate due to the crosslinking coating effect of the liquid rubber adhesive, sothe performance of the product is guaranteed. Moreover, the catalyst has high bonding strength, and cannot break due to the vibration. By the method, a production process is simplified, production period is shortened, the mechanical sensitivity of the catalyst is reduced, and the safety of the catalyst is improved.

Owner:SHAANXI ZHONGTIAN ROCKET TECH CO LTD

Chlorinated polyvinyl chloride DN400 conduction through pipe fitting once injection moulding technique and device thereof

InactiveCN101168285BReduce frictional heatStable speedTubular articlesTemperature controlChlorinated polyvinyl chloride

Owner:YOULI HLDG GRP

A kind of method of methane carbon dioxide reforming to produce synthesis gas carbon-based catalyst

ActiveCN104984769BLarge specific surface areaHigh catalytic activityCarbon compoundsHydrogen productionCarbonizationAtmosphere

A method for producing a carbon-based catalyst for synthesis gas by reforming methane and carbon dioxide, comprising the following steps: step 1, taking the coal direct liquefaction residue with a particle size of 60-80 mesh and a composite modifier according to the mass ratio of 1: (1-3) Mix and grind evenly; the composite modifier includes 90% to 98% alkali and 2% to 10% nitrate in terms of mass fraction; step 2, heat up the obtained uniformly ground mixture under an inert atmosphere for carbonization treatment; step 3 1. Cooling the carbonized mixture and washing it to neutrality; step 4, drying the mixture washed to neutrality to obtain a carbon-based catalyst. The present invention uses Shenhua coal direct liquefaction residue CLR as a raw material to obtain a carbon-based catalyst through carbonization treatment, effectively utilizes the main by-products during direct coal liquefaction, has a simple preparation method, and the prepared catalyst has a large specific surface area and is effective for methane carbon dioxide reforming reaction better catalytic activity.

Owner:陕西荷螓能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com