Production process for barrel-making hot dip galvanized steel strip

A production process, hot-dip galvanizing technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve the inability to fully utilize the performance advantages of DQ grade products, high annealing temperature in the galvanizing process, and material utilization Low-level problems, to achieve the effect of improving plate shape and surface quality, reasonable chemical composition design, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

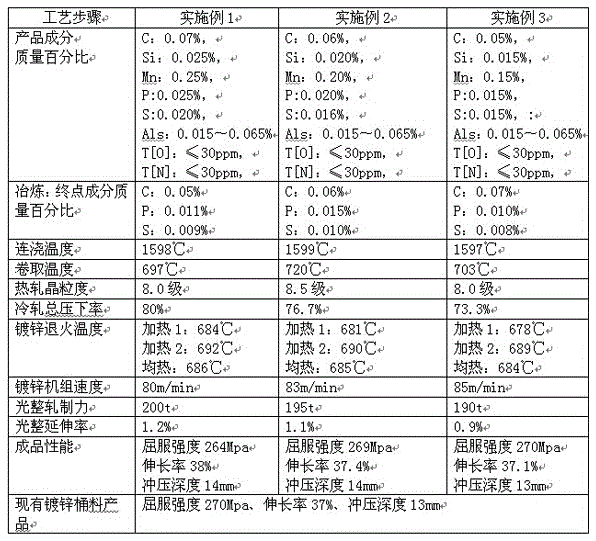

[0024] The present invention will be further described below by example.

[0025] A production process of hot-dip galvanized steel strip for barrel making, the chemical composition percentage of hot-dip galvanized steel strip: C: ≤0.07%, Si: ≤0.025%, Mn: ≤0.25%, P≤0.025%, S≤0.020% , Als: 0.015~0.065%, T[O]: ≤30ppm, T[N]: ≤30ppm, the rest is iron and unavoidable inclusions, the production process of the hot-dip galvanized steel strip includes the following process steps:

[0026] (1) Smelting: Converter smelting end point mass percentage: C: 0.03~0.07%, P≤0.020%, S≤0.015%; continuous pouring temperature: 1594~1604℃;

[0027] (2) Hot rolling: the billet start-rolling temperature is 1080-1130°C, the final rolling temperature is 885-905°C, and the coiling temperature is 685-725°C;

[0028] (3) Cold rolling: the total reduction rate of cold rolling is controlled at 70% to 85%;

[0029] (4) Galvanizing: ① The concentration of degreasing agent in the scrubbing section is 8-10g / L, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com