Patents

Literature

144results about How to "Reduce focus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

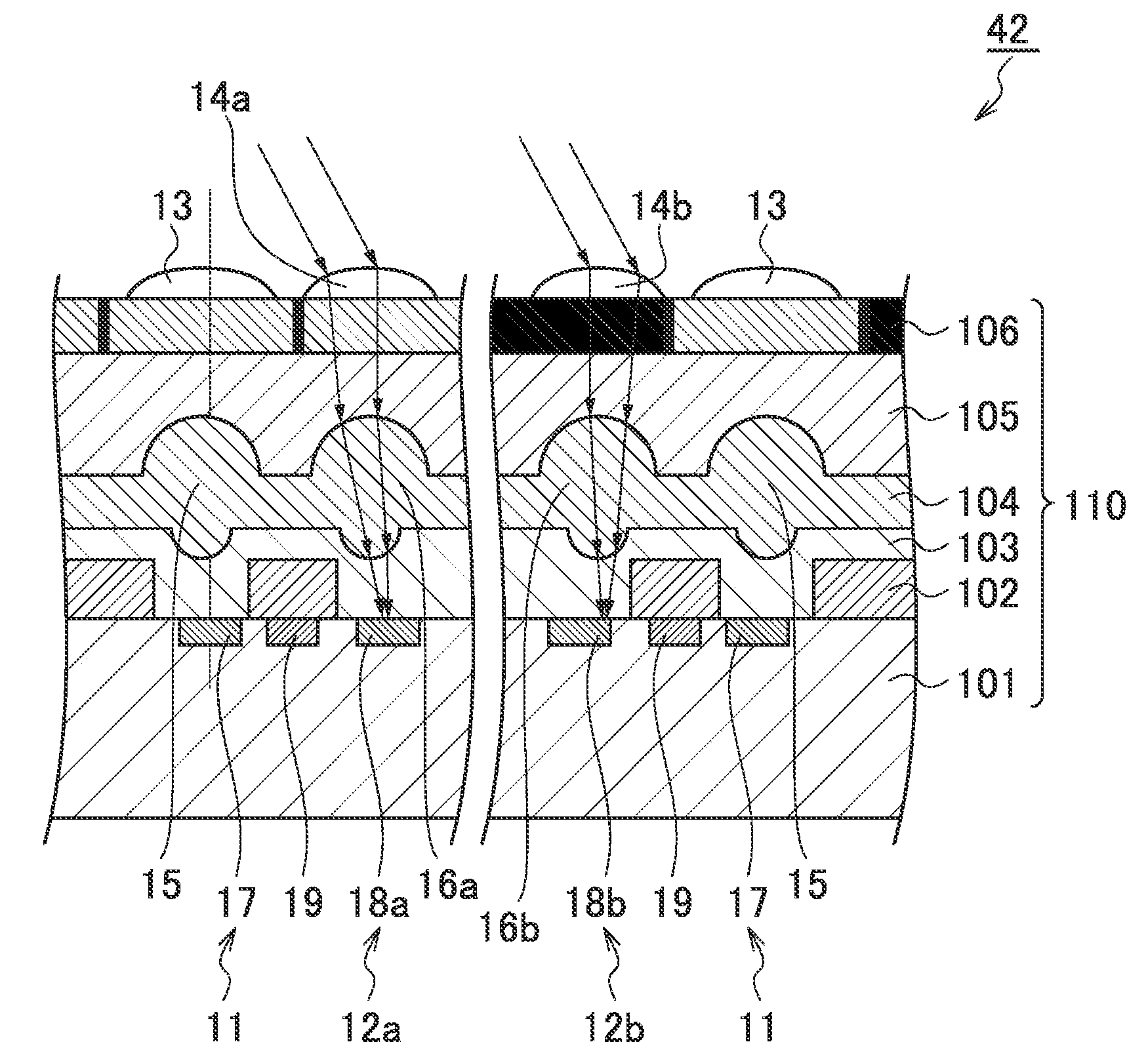

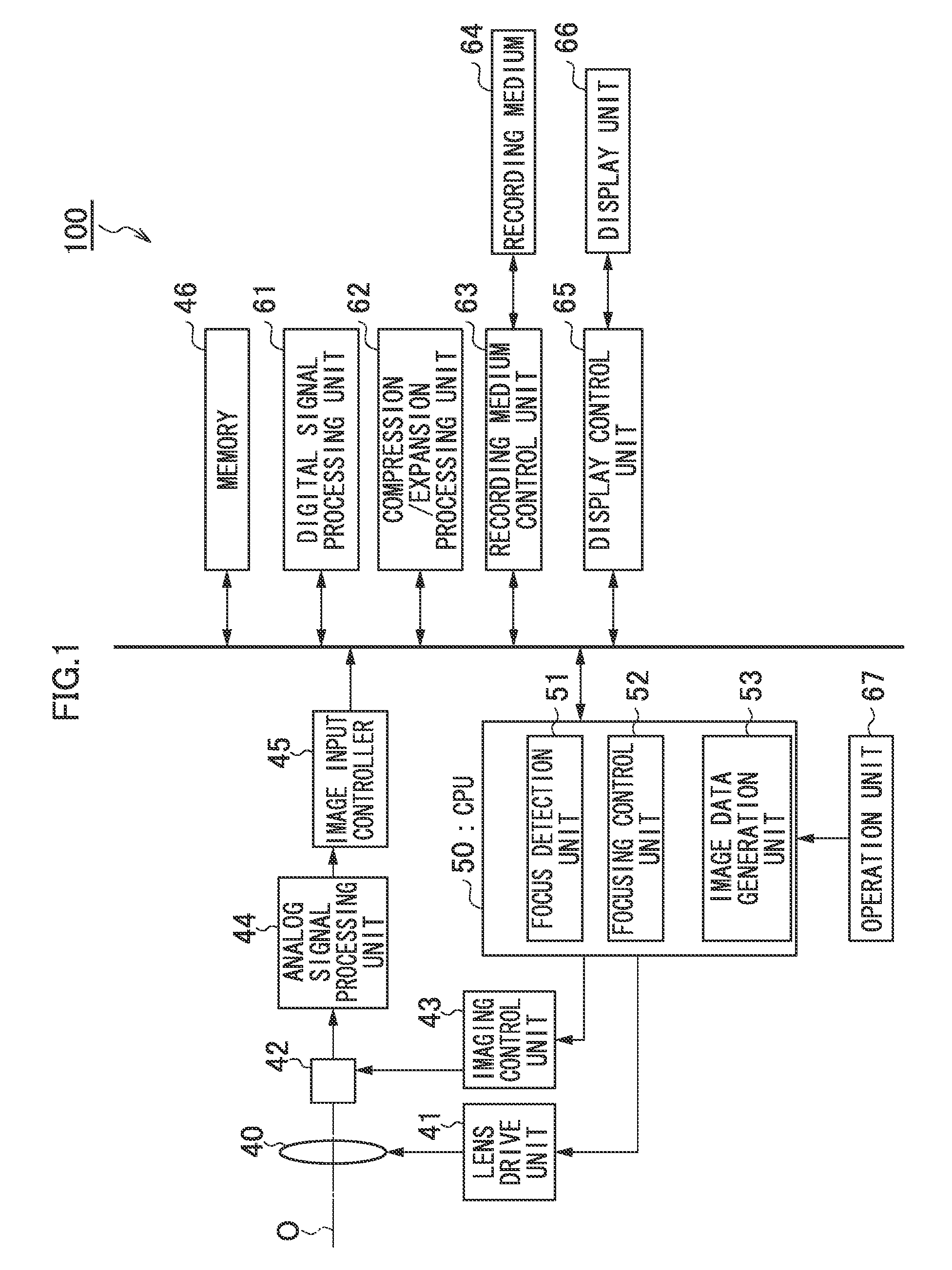

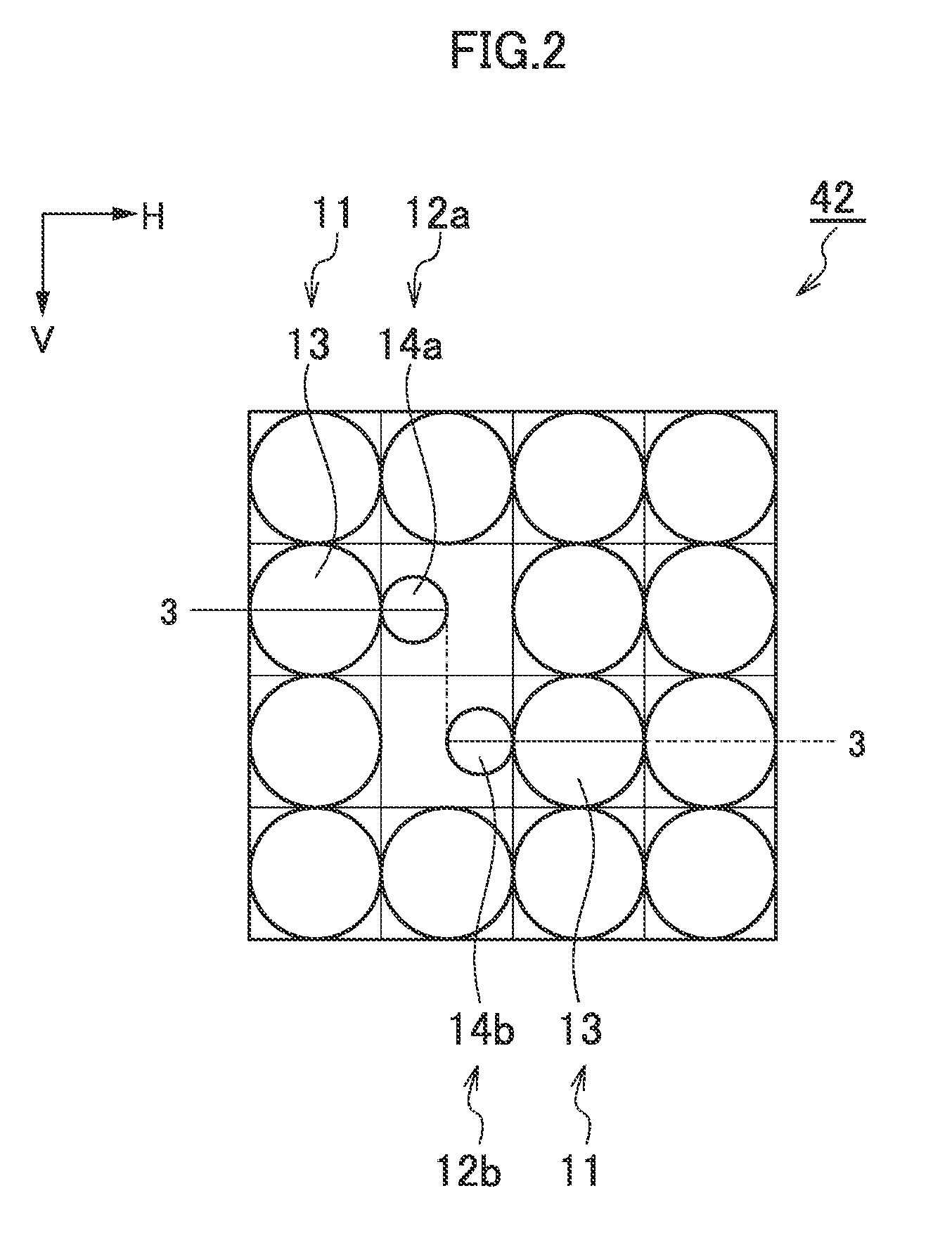

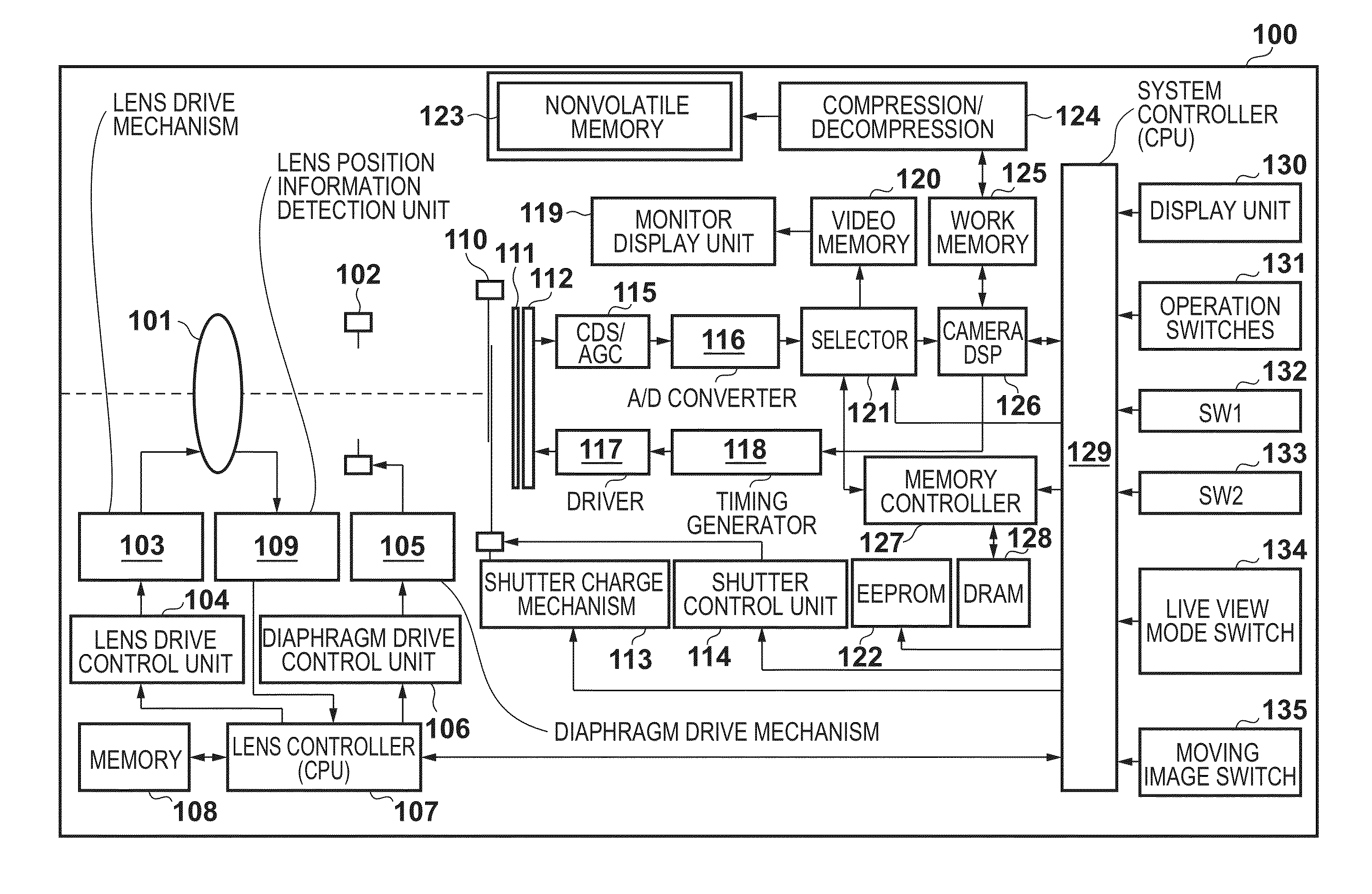

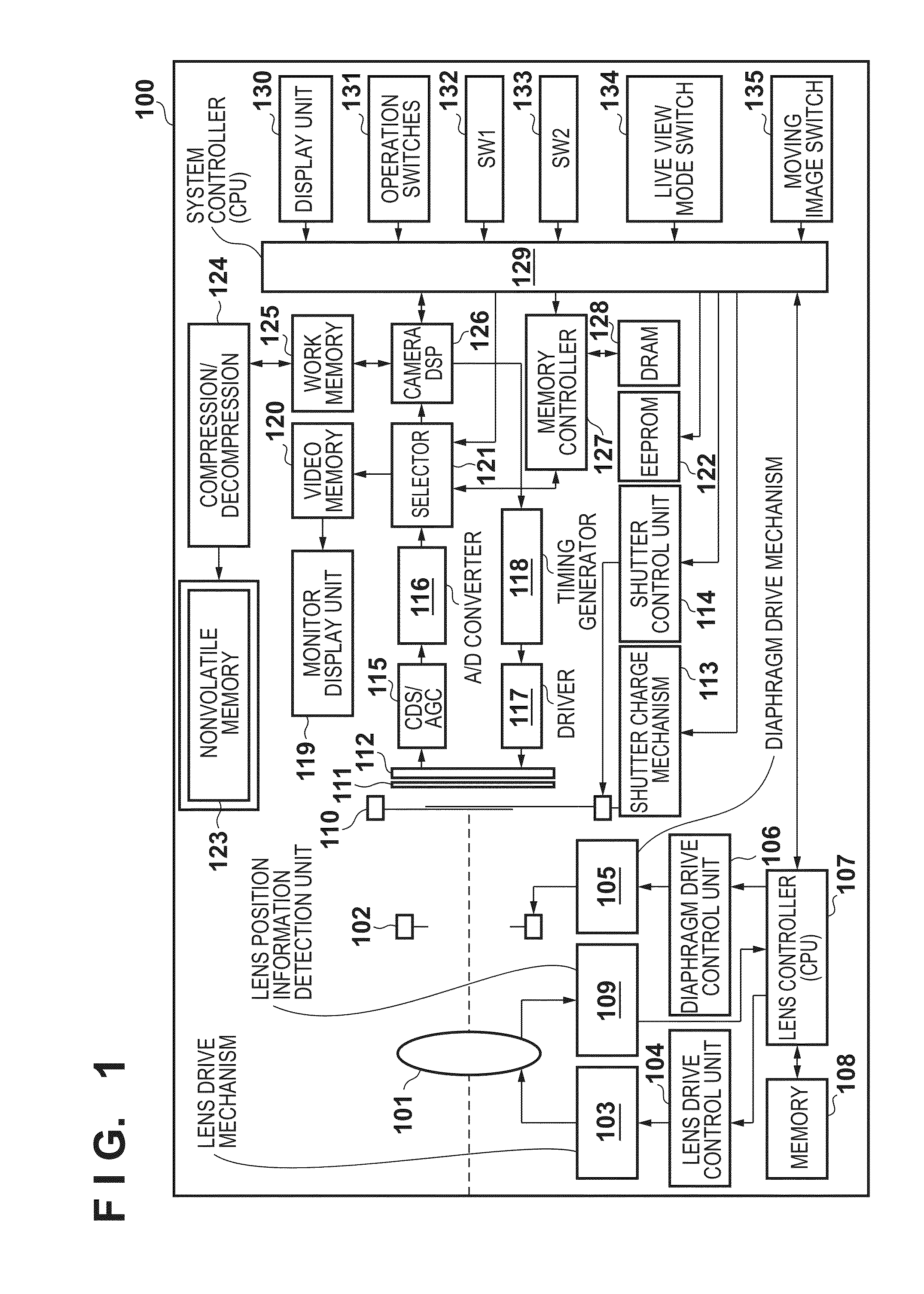

Imaging device and electronic camera

InactiveUS20110076001A1Reduce the amount of lightLow costTelevision system detailsSolid-state devicesPhase differenceOptical axis

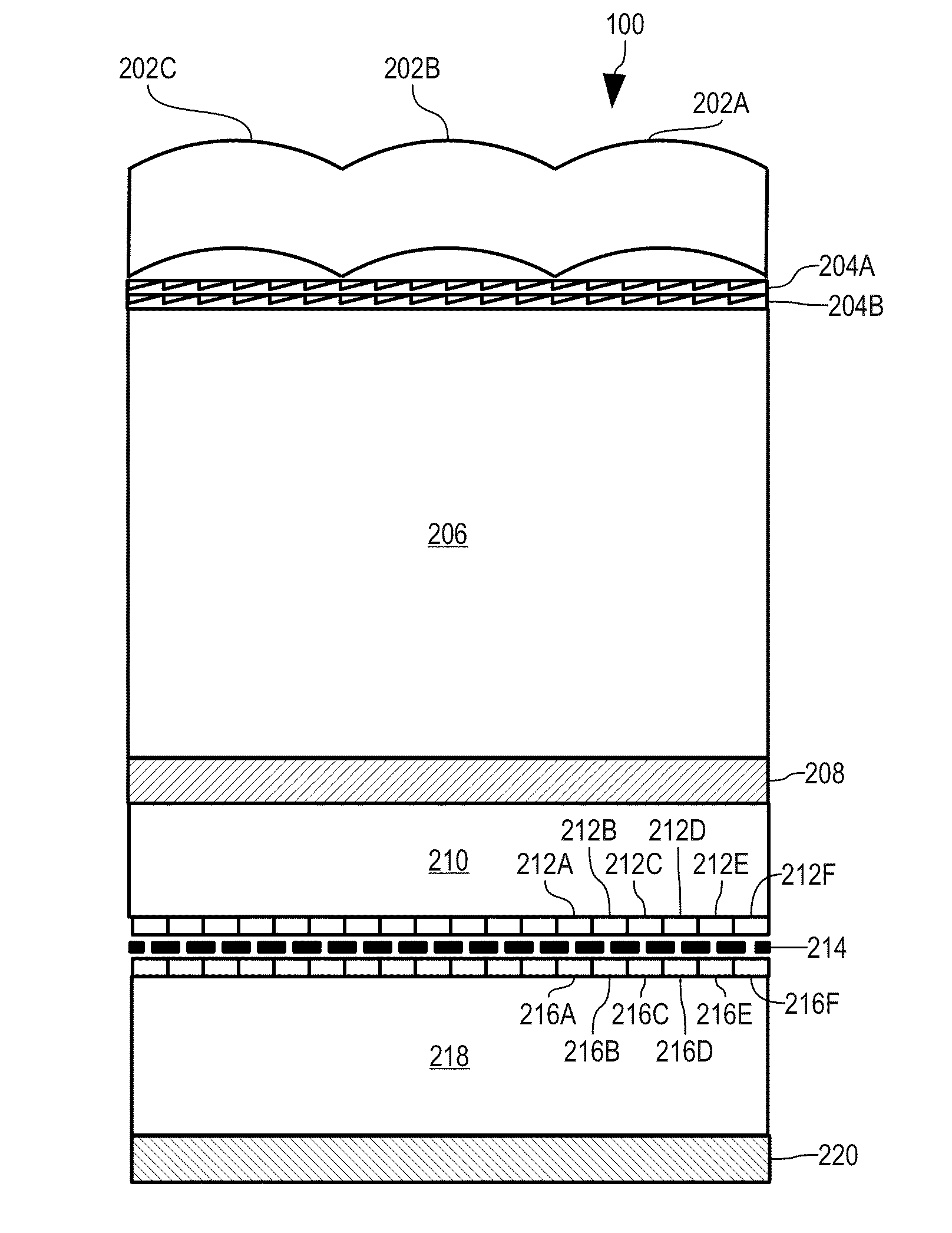

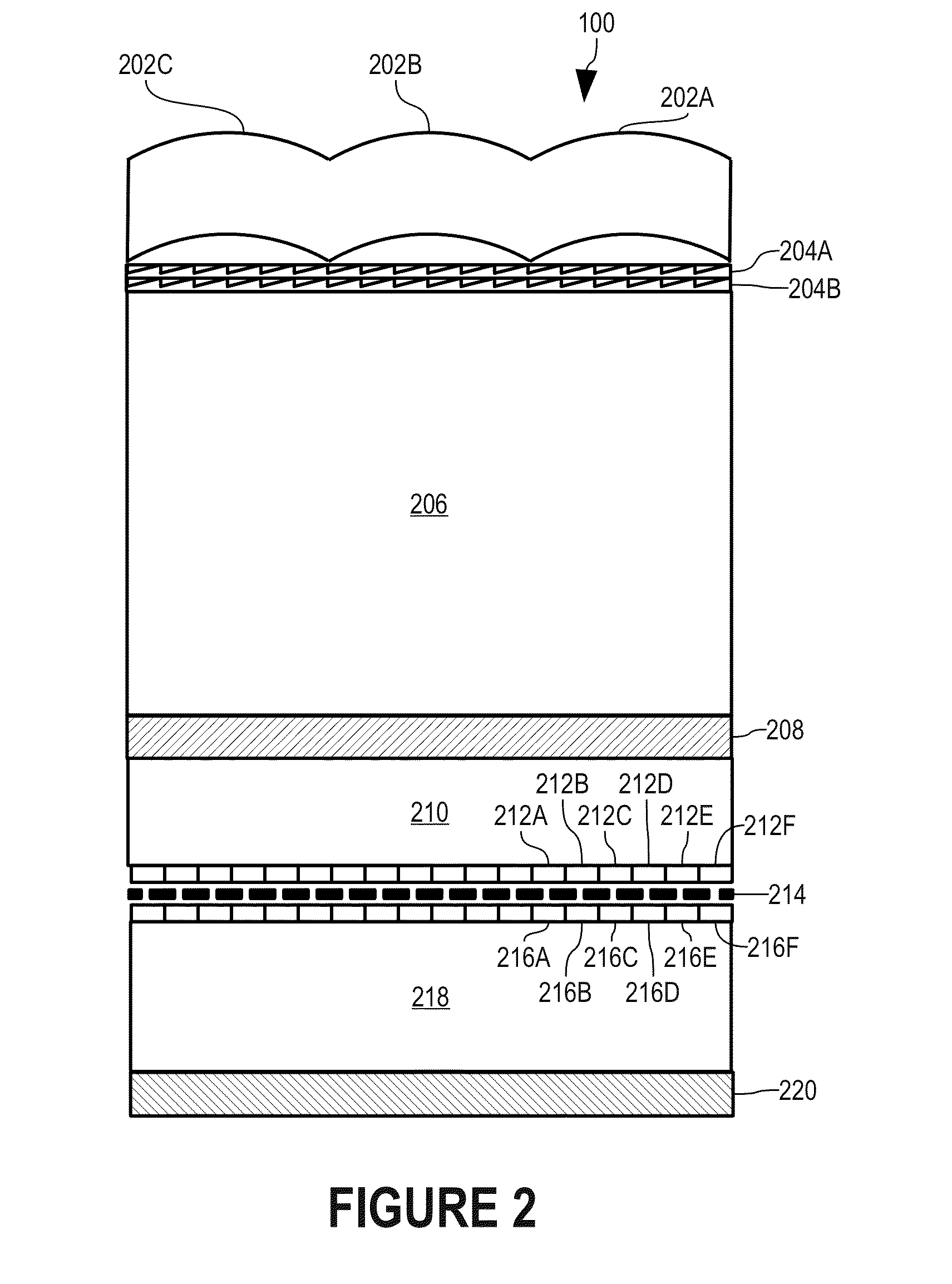

An imaging device includes an arrayed imaging element group configured to receive light passing through a photographic lens, wherein the imaging element group includes a plurality of photographic elements used for photographic image data generation and a plurality of phase difference detection elements used for phase difference detection for focus detection of the photographic lens, each of the photographic elements and each of the phase difference detection elements include: an on-chip microlens configured to collect light passing through the photographic lens; a photoelectric conversion element configured to receive the light passing through the on-chip microlens; and an internal microlens disposed between the on-chip microlens and the photoelectric conversion element, the photographic element is configured such that an optical axis of the on-chip microlens matches an optical axis of the internal microlens, and the phase difference detection element is configured such that the optical axis of the on-chip microlens is shifted from the optical axis of the internal microlens.

Owner:FUJIFILM CORP

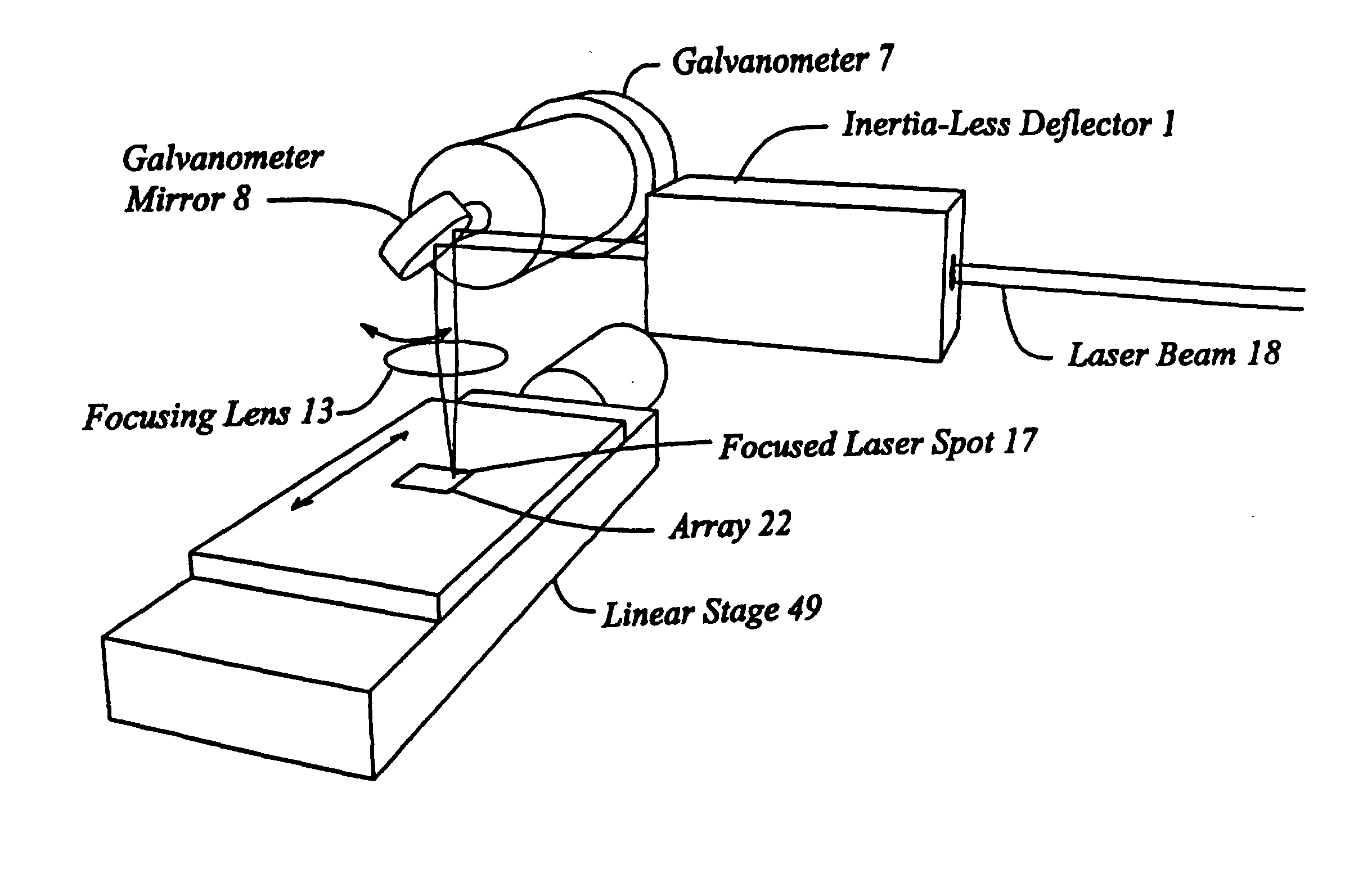

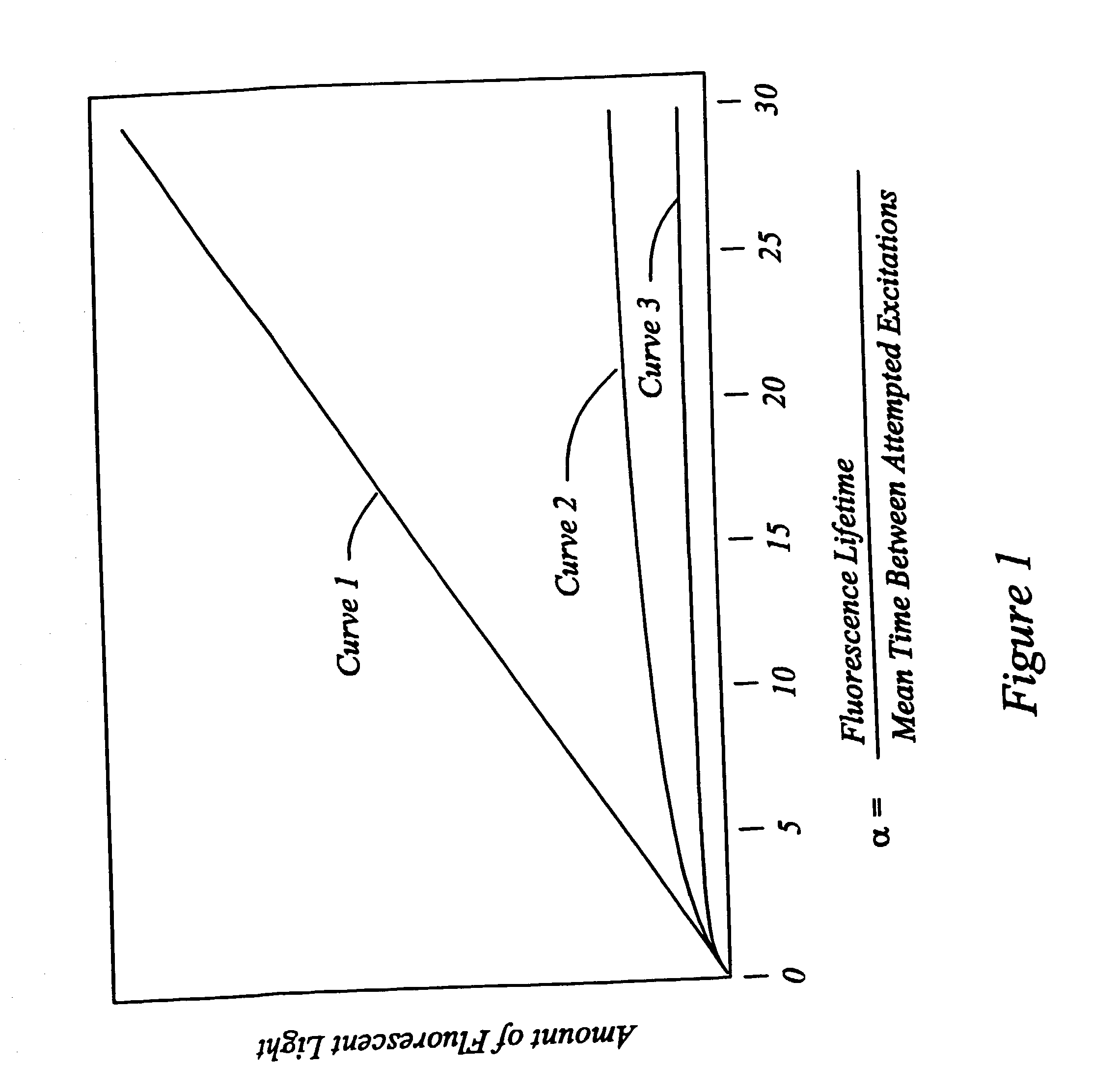

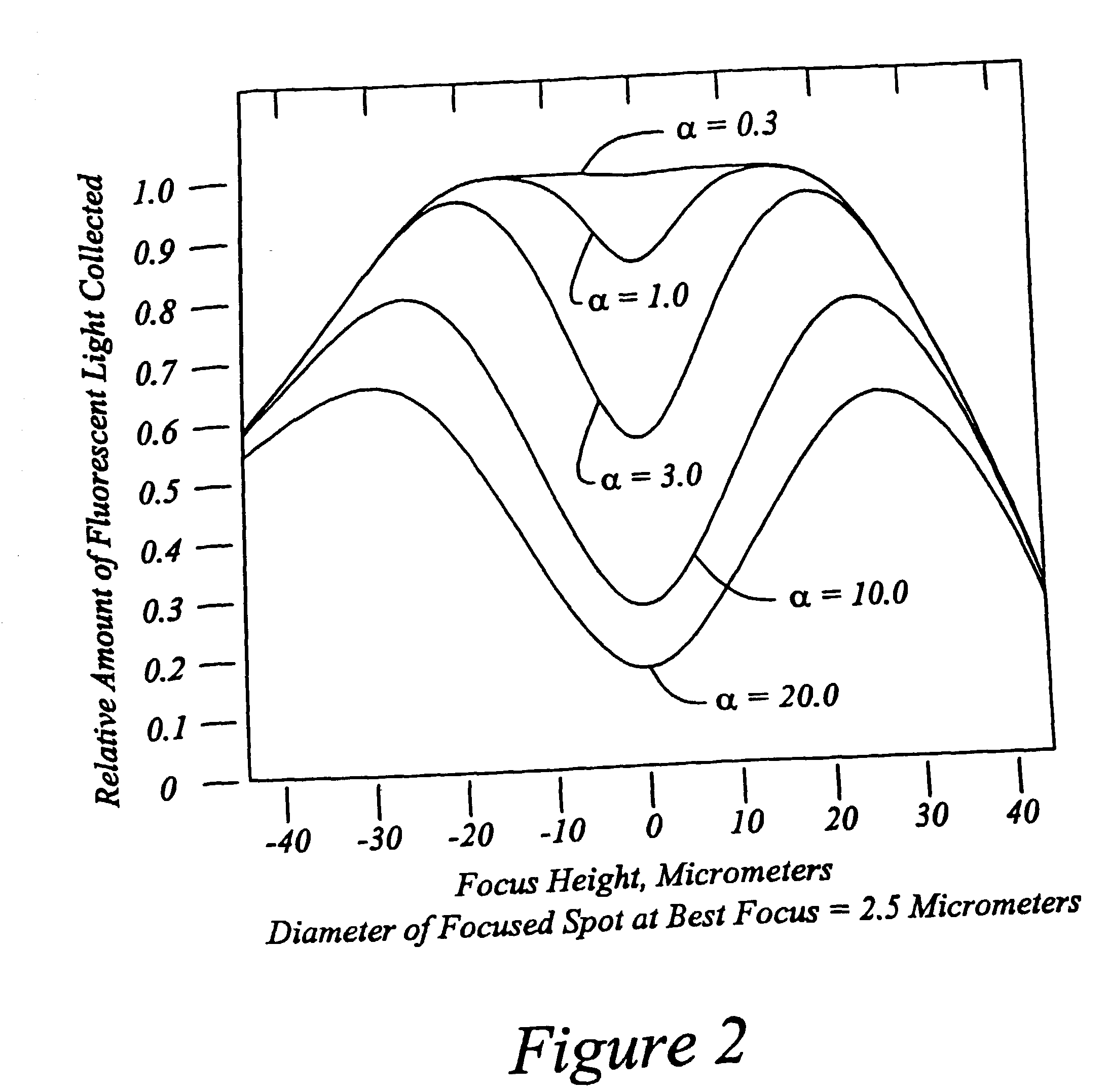

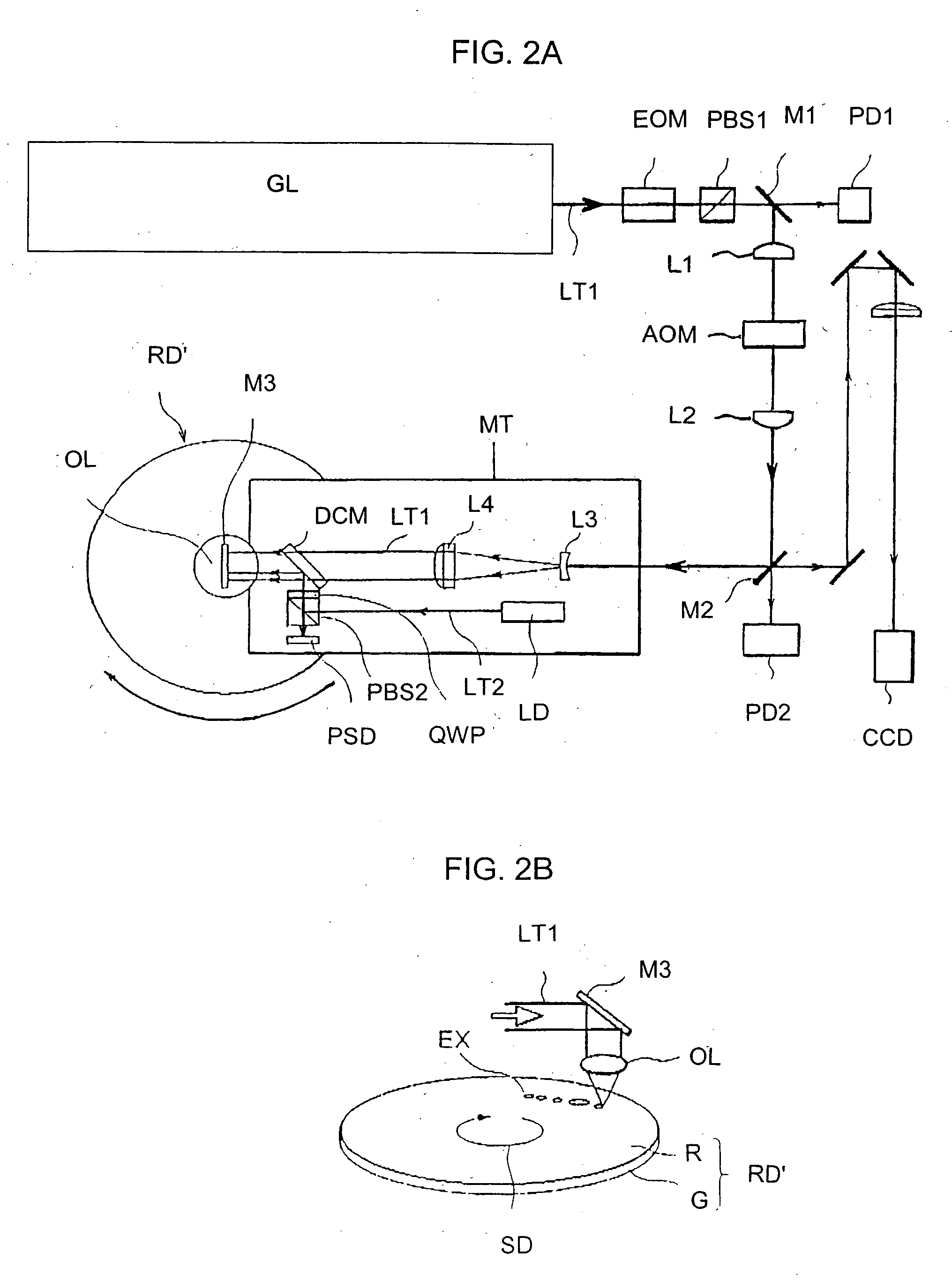

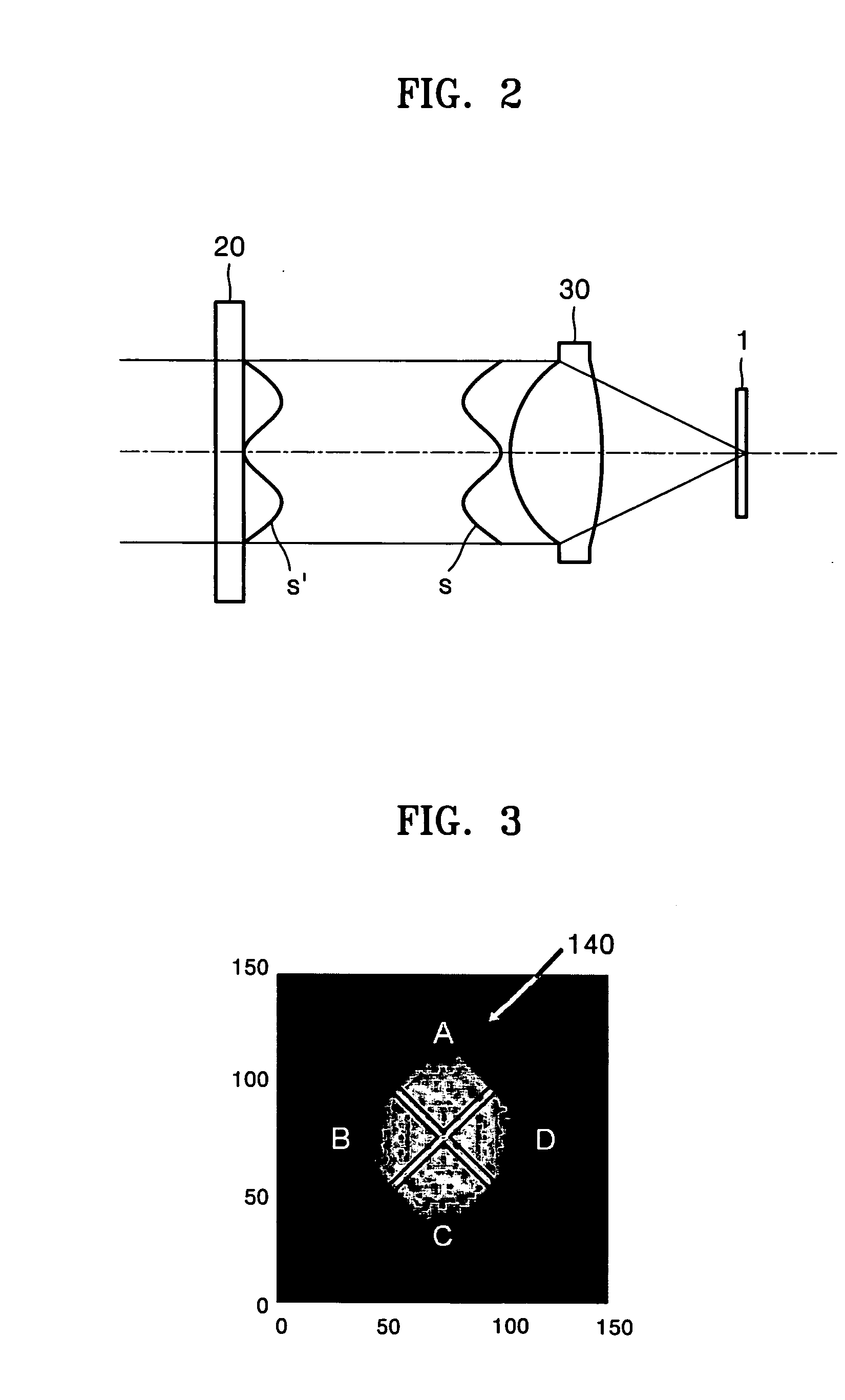

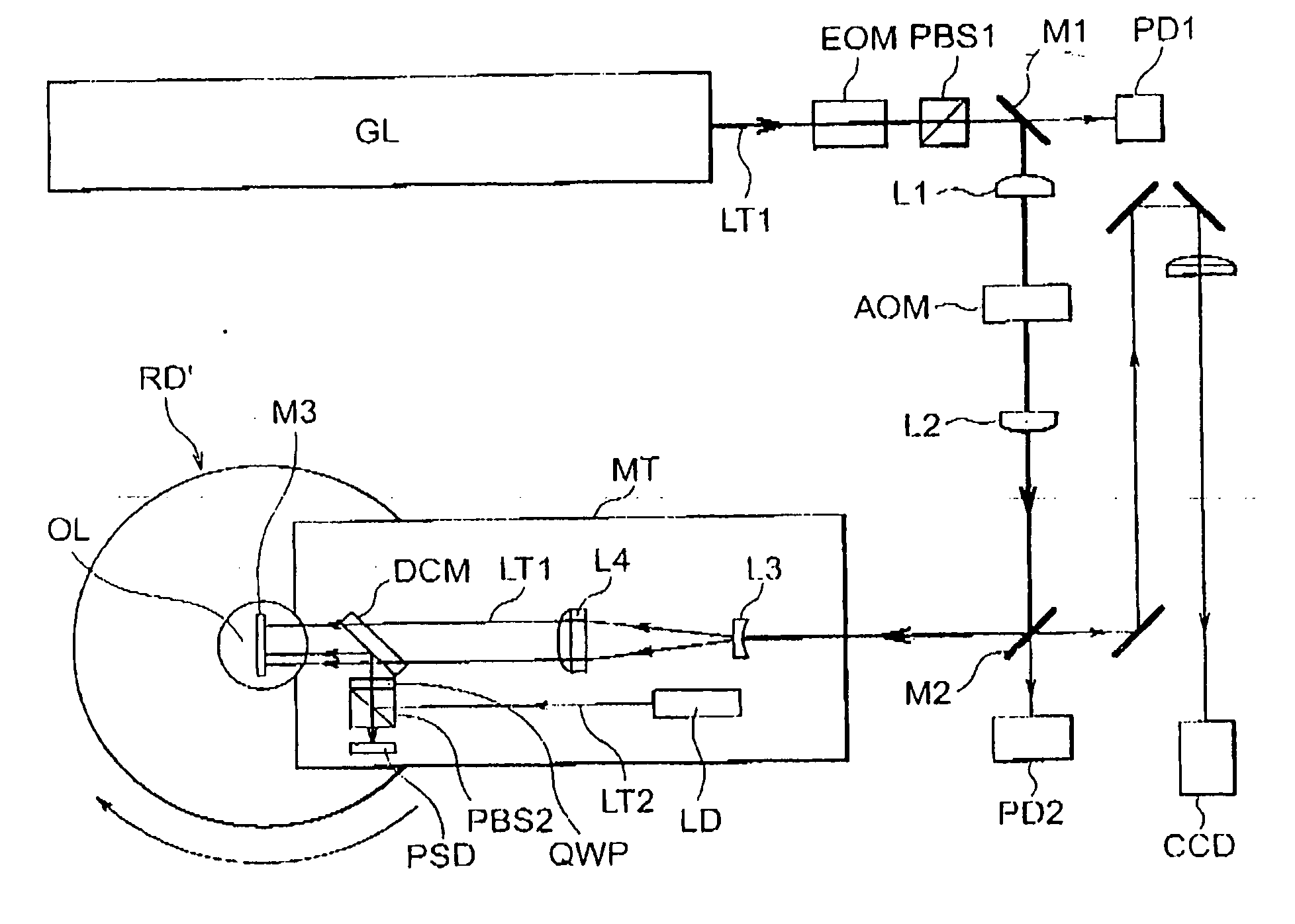

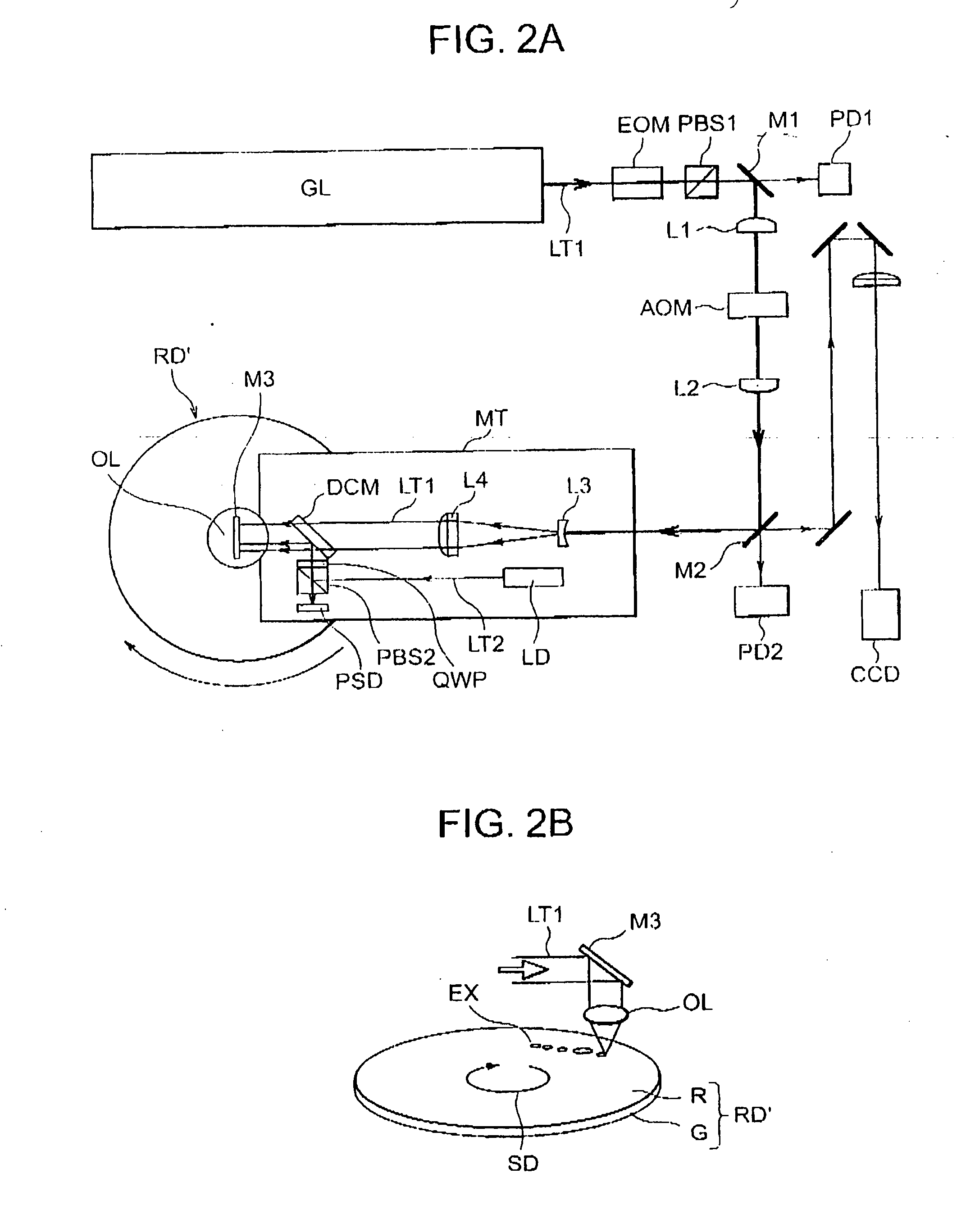

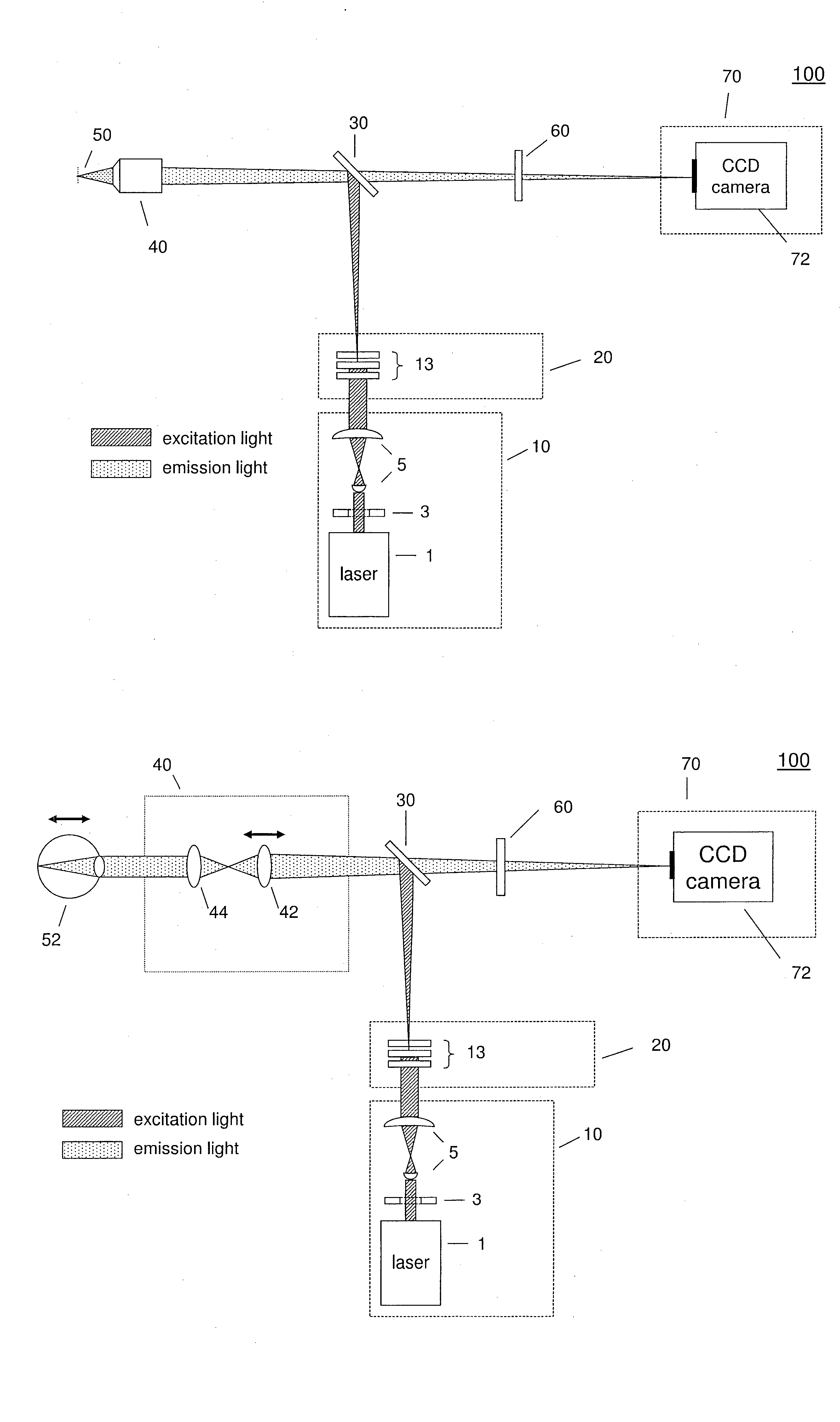

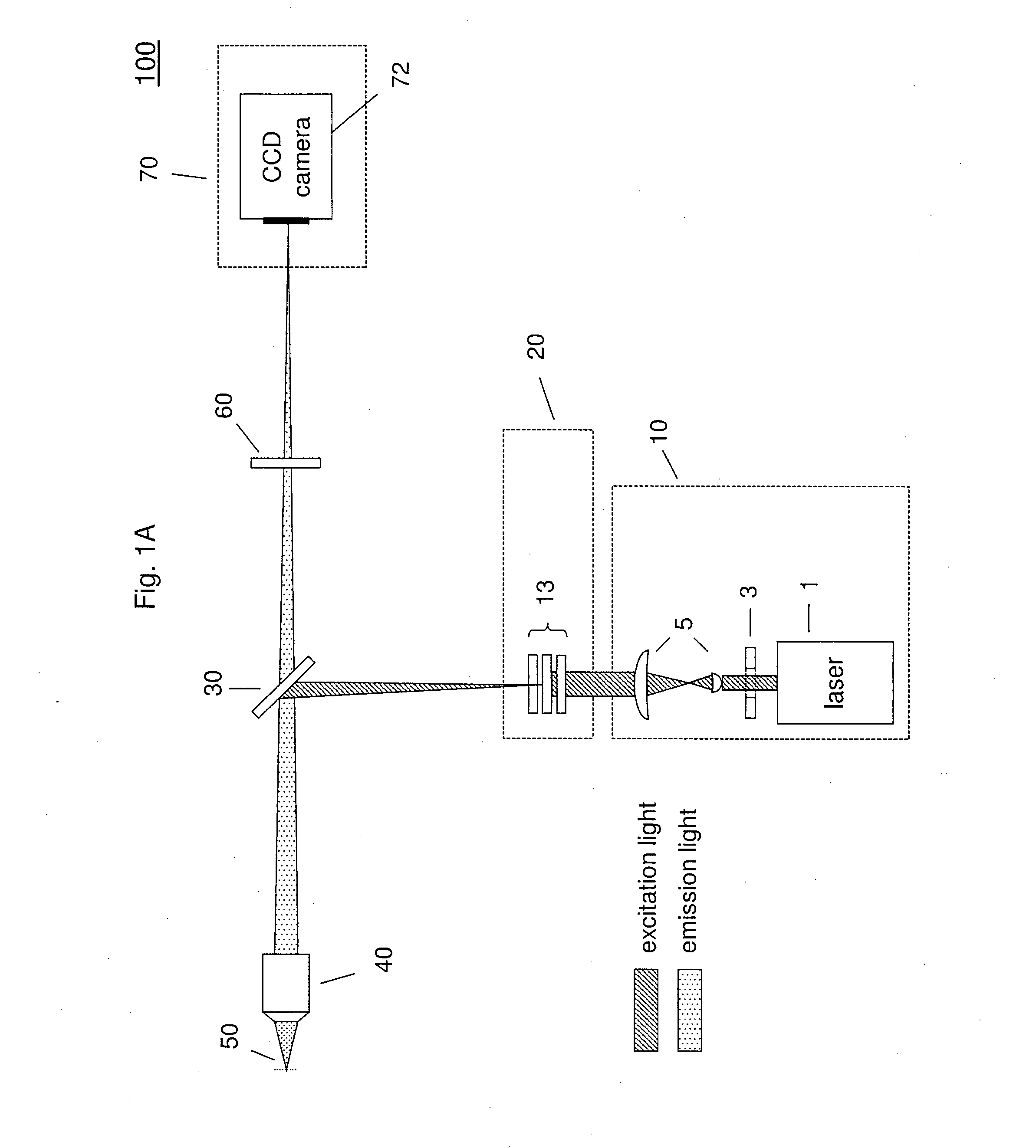

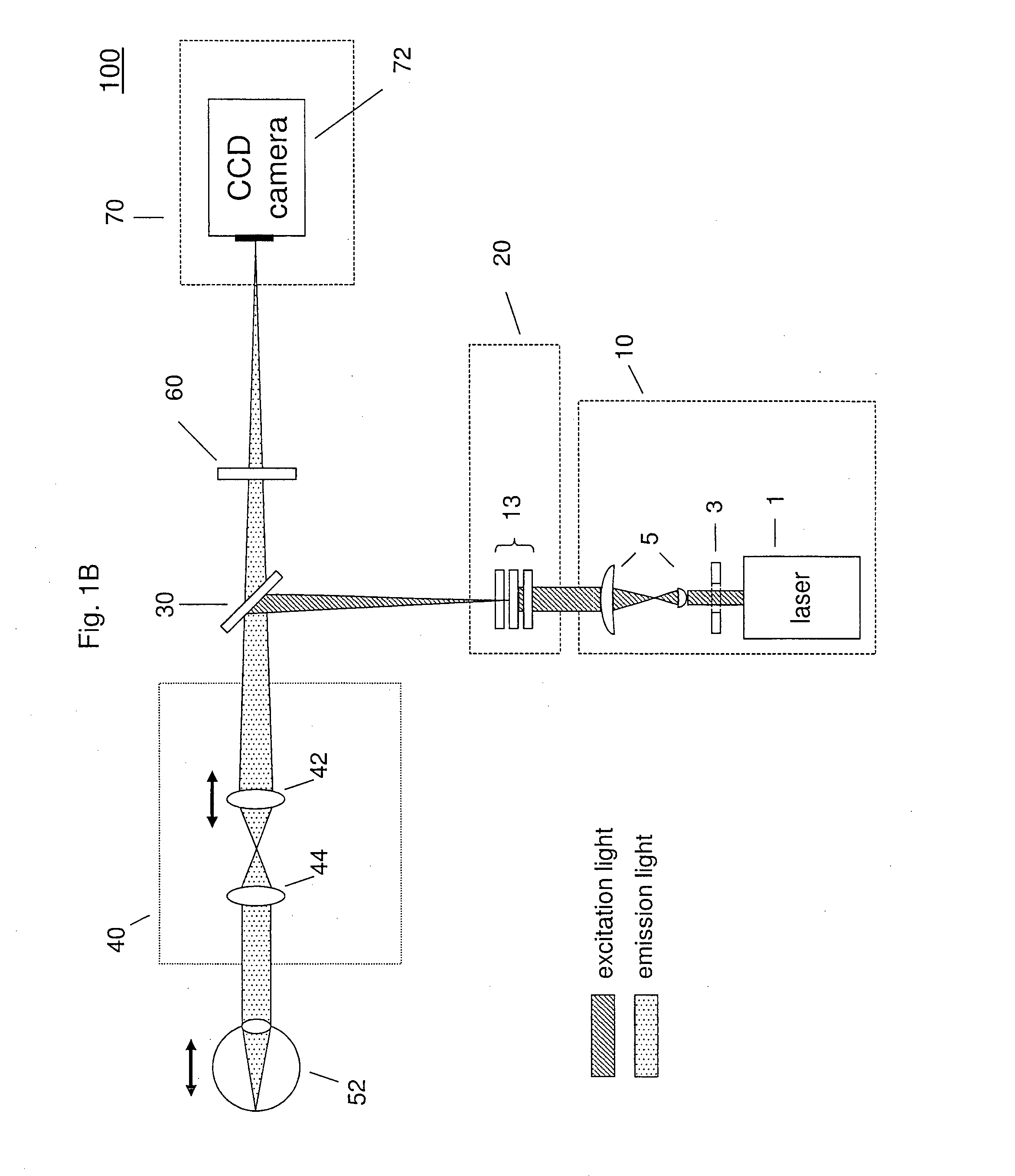

Scanning microscopy, fluorescence detection, and laser beam positioning

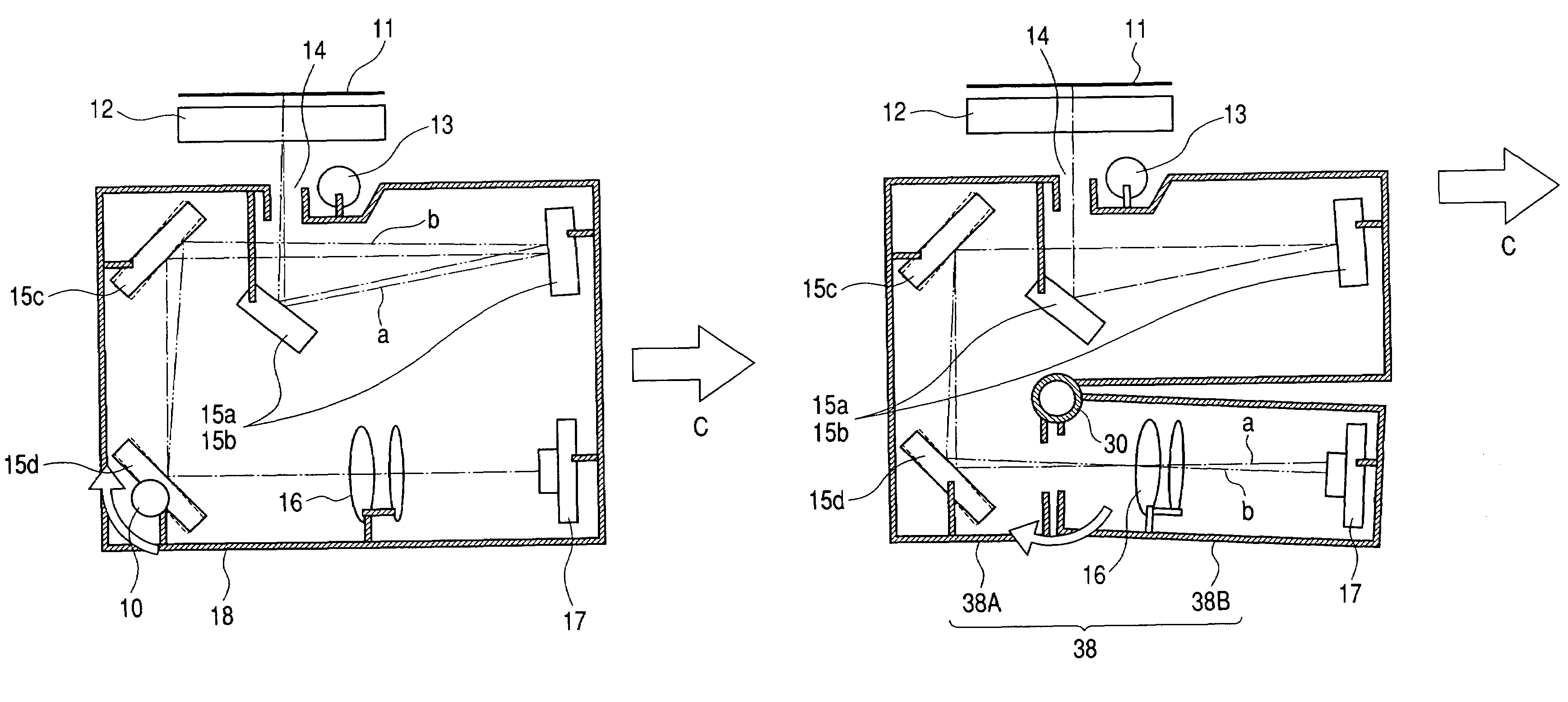

InactiveUS20030156323A1Diameter of to varyEnsure high efficiency and accuracyMirrorsMaterial analysis by optical meansWide areaGrating

High speed, wide area microscopic scanning or laser positioning is accomplished with an inertia-less deflector (for example an acousto-optic or electro-optic deflector) combined with a high speed wide area microscopic scanning mechanism or laser positioner mechanism that has inertia, the motion of the inertia-less deflector specially controlled to enable a focused spot to stabilize, for example to stop and dwell or be quickly aimed. It leads to improved data acquisition from extremely small objects and higher speed operation. In the case of fluorescence reading of micro-array elements, dwelling of fluorophore-exciting radiation in a spot that is relatively large enables obtaining the most fluorescent photons per array element, per unit time, a winning criterion for reducing fluorophore saturation effects. The same inertia-less deflector performs stop and dwell scanning, edge detection and raster scans. Automated mechanism for changing laser spot size enables selection of spot size optimal for the action being performed.

Owner:OVERBECK JAMES W

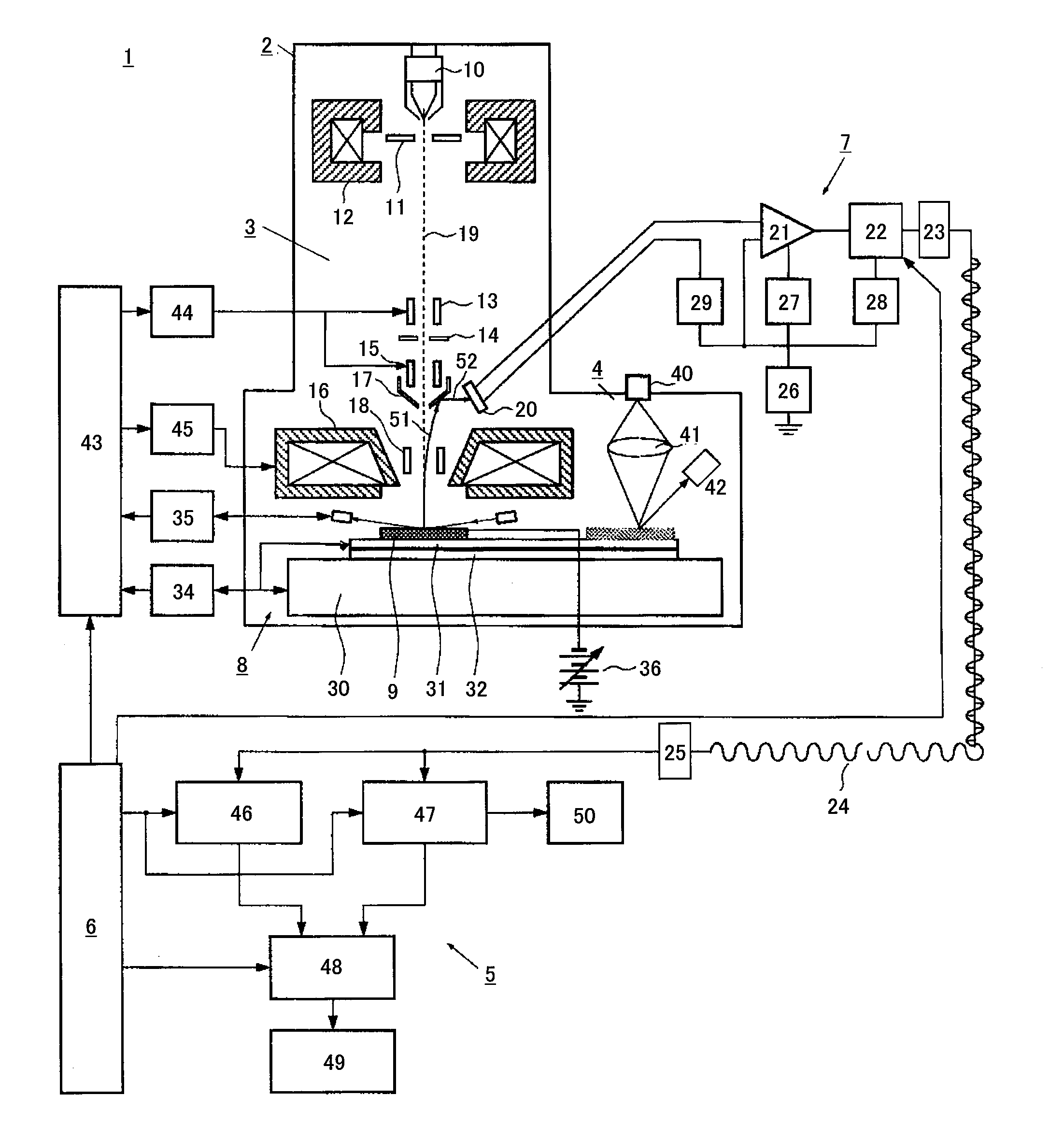

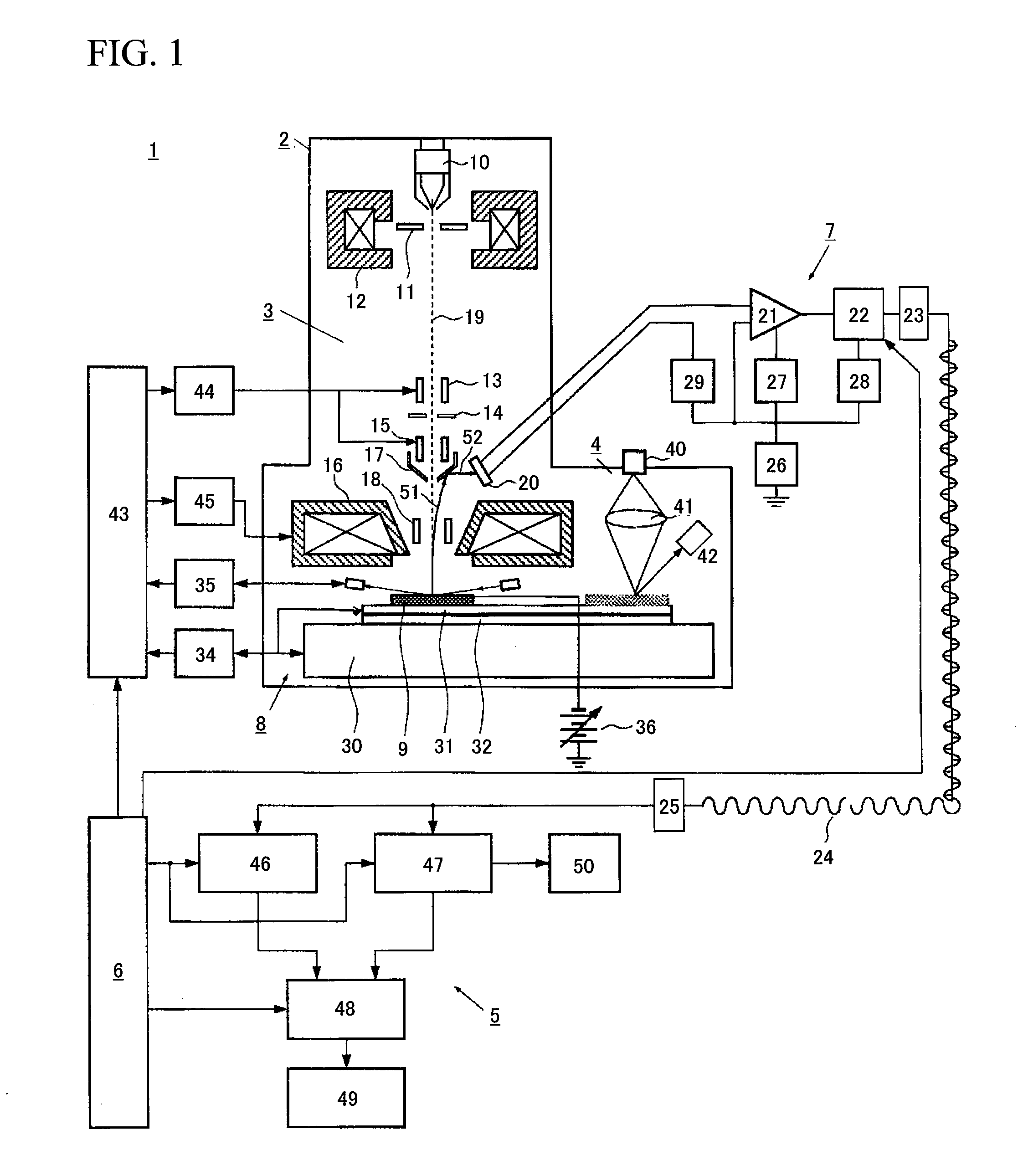

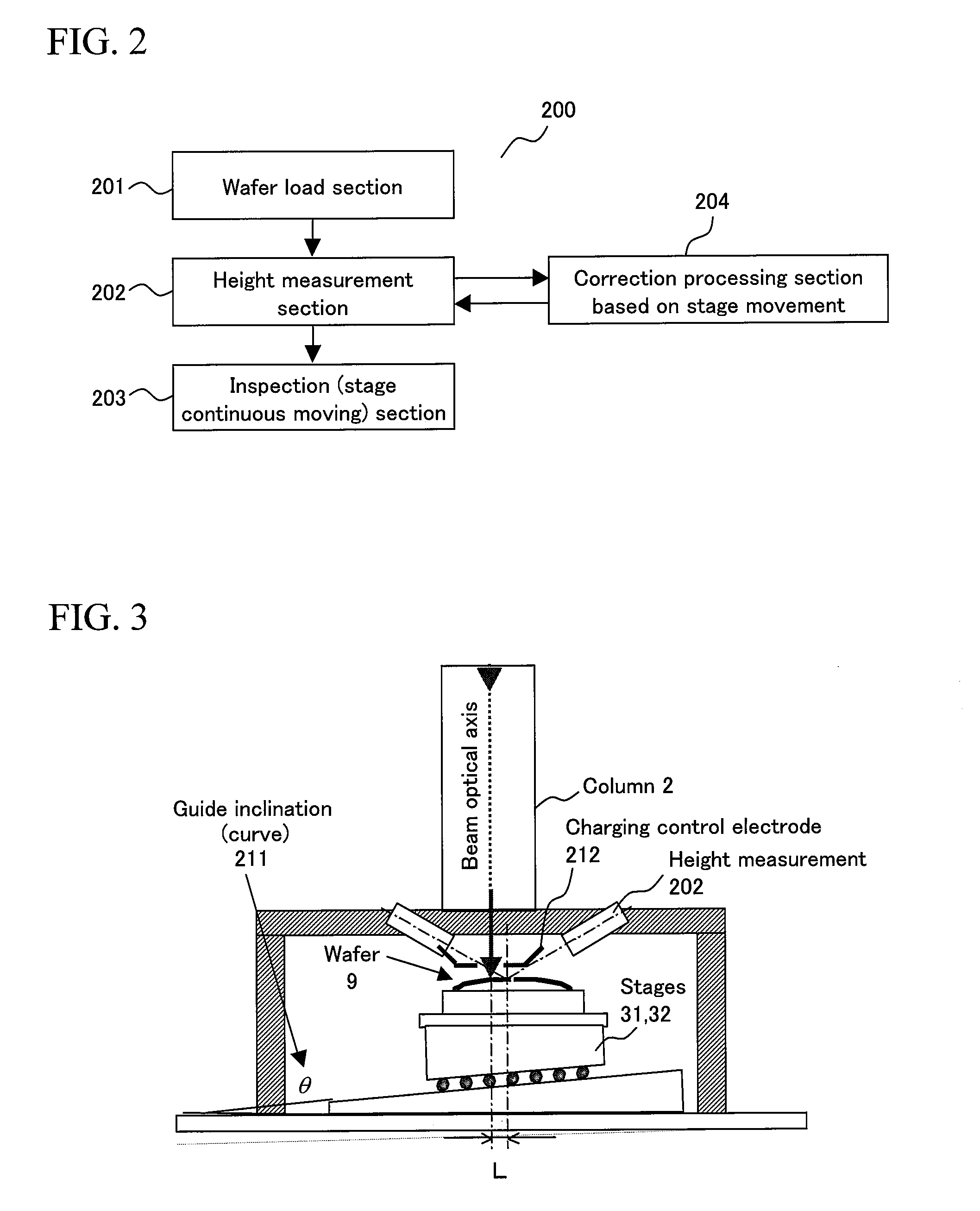

Apparatus for inspecting a substrate, a method of inspecting a substrate, a scanning electron microscope, and a method of producing an image using a scanning electron microscope

InactiveUS20090309022A1Excellent substrate inspectionSensitive defect detecting capabilityStability-of-path spectrometersMaterial analysis using wave/particle radiationScanning tunneling microscopeScanning electron microscope

An object of the present invention provides an inspection apparatus and an inspection method which use an electron beam image to accurately detect a defect that is difficult to detect in an optical image, the apparatus and method also enabling prevention of a possible decrease in focus accuracy of an inspection image which affect the defect detection. To accomplish the object, the present invention includes a height measurement section which measures height of the electron beam irradiation position on the substrate after the substrate is loaded onto a movable stage, a height correction processing section which corrects the measured height, and a control section which adjusts a focus of the electron beam according to the height corrected by the height correction processing section, wherein a stage position set when the height measurement section measures the height differs from a stage position set when the substrate is irradiated with the electron beam, and the height correction processing section corrects a possible deviation in height resulting from movement from the stage position for the height measurement to the stage position for the electron beam irradiation.

Owner:HITACHI HIGH-TECH CORP

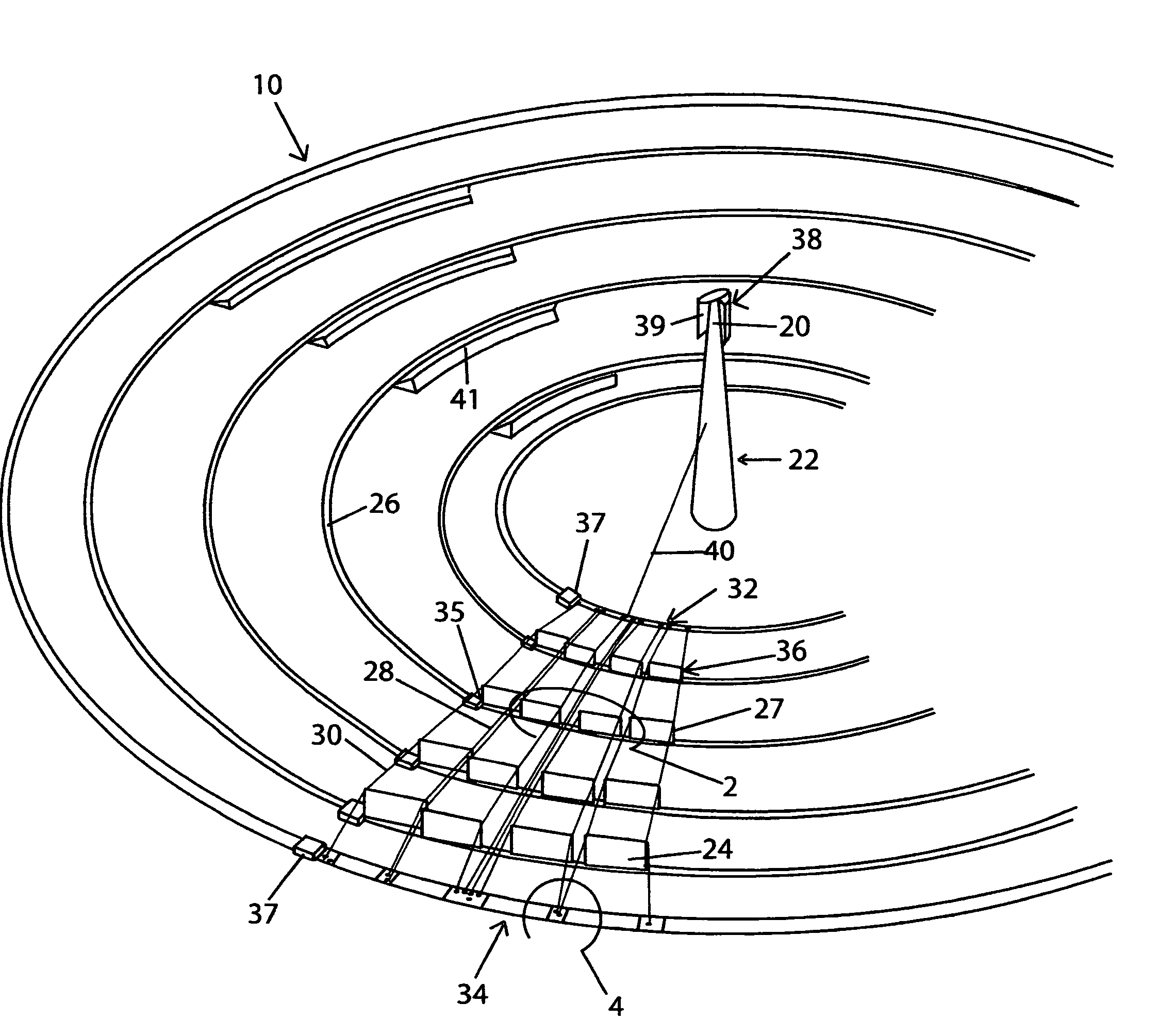

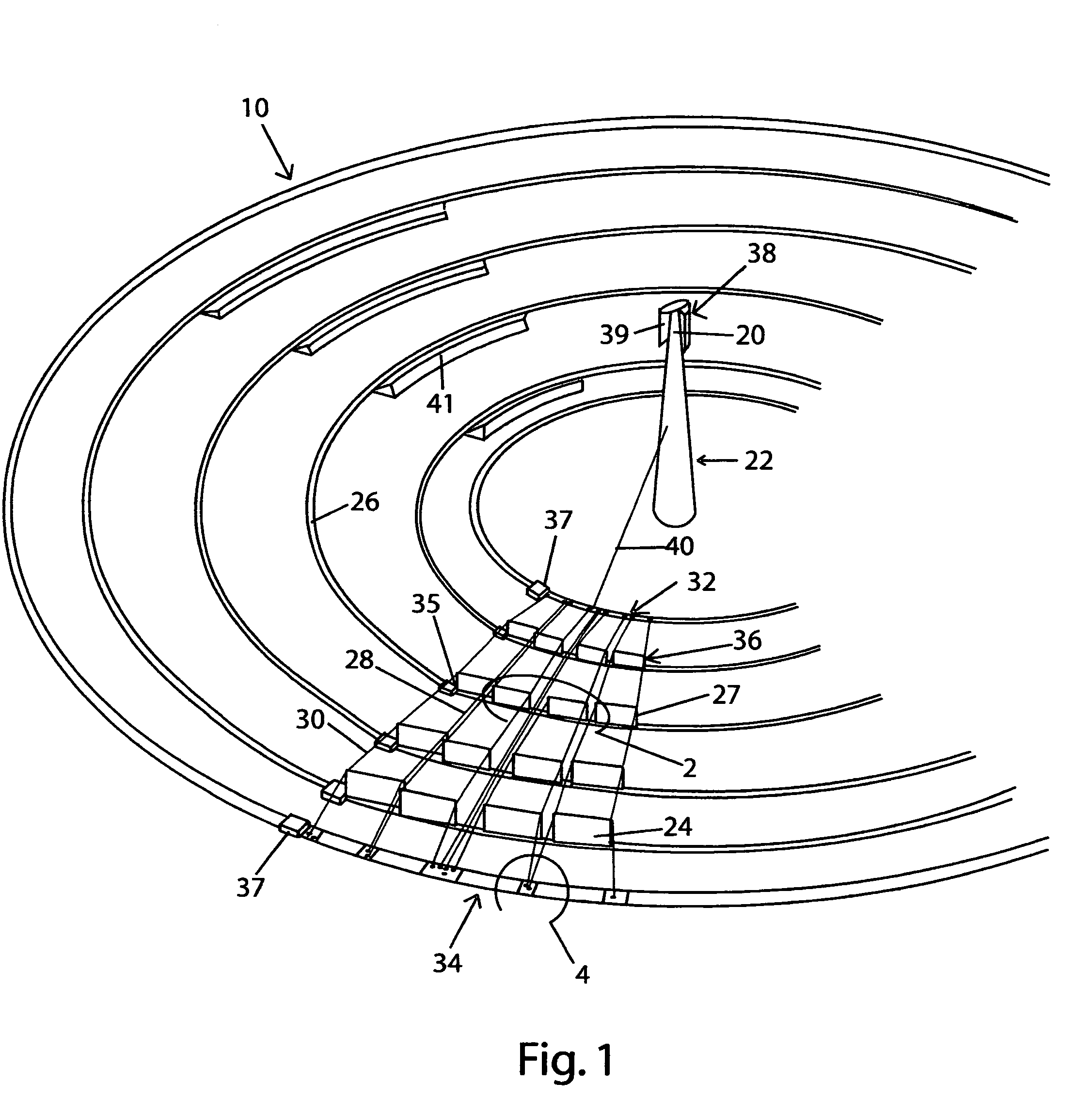

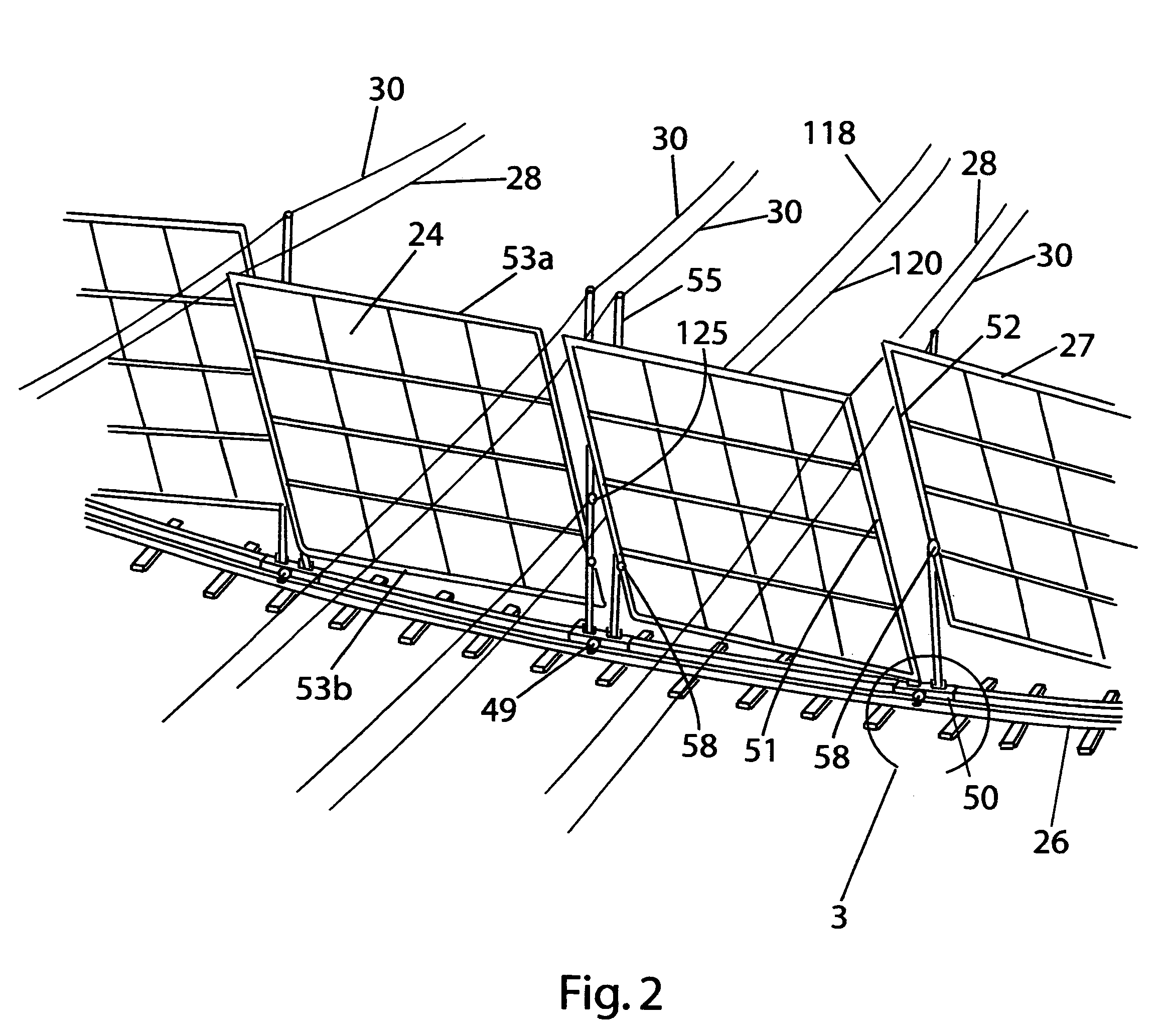

Solar energy concentrator for power plants

ActiveUS7380549B1Low costReduce the amount requiredSolar heating energySolar heat collector controllersElectricityPower station

A solar concentrator includes a mirror 24 having a frame 27 connected with a lever 55, a train 36 supporting the frame 27 and the lever 55, a first control cable 28 connected with the frame 27, and a second control cable 30 connected with the lever 55. A first locomotive 35 moves the train along a curvilinear path to keep the mirror 24 opposite the sun. The first control cable 28 controls pitch of the mirror 24 and the second control cable 30 controls yaw of the mirror 24. When a concentrator includes a plurality of mirrors 24 they are preferably controlled collectively by pulling all of the first control cables 28 with one motor to control pitch and by pulling all of the second control cables 30 with one motor to control yaw. Sunlight focused on the receiver 20 preferably boils water to form steam that is transmitted to a turbine connected to a generator for producing electricity.

Owner:RATLIFF GEORGE D

Lithographic apparatus, substrate holder and method of manufacturing

ActiveUS7110085B2Easy transferEasy to copySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLight beamEngineering

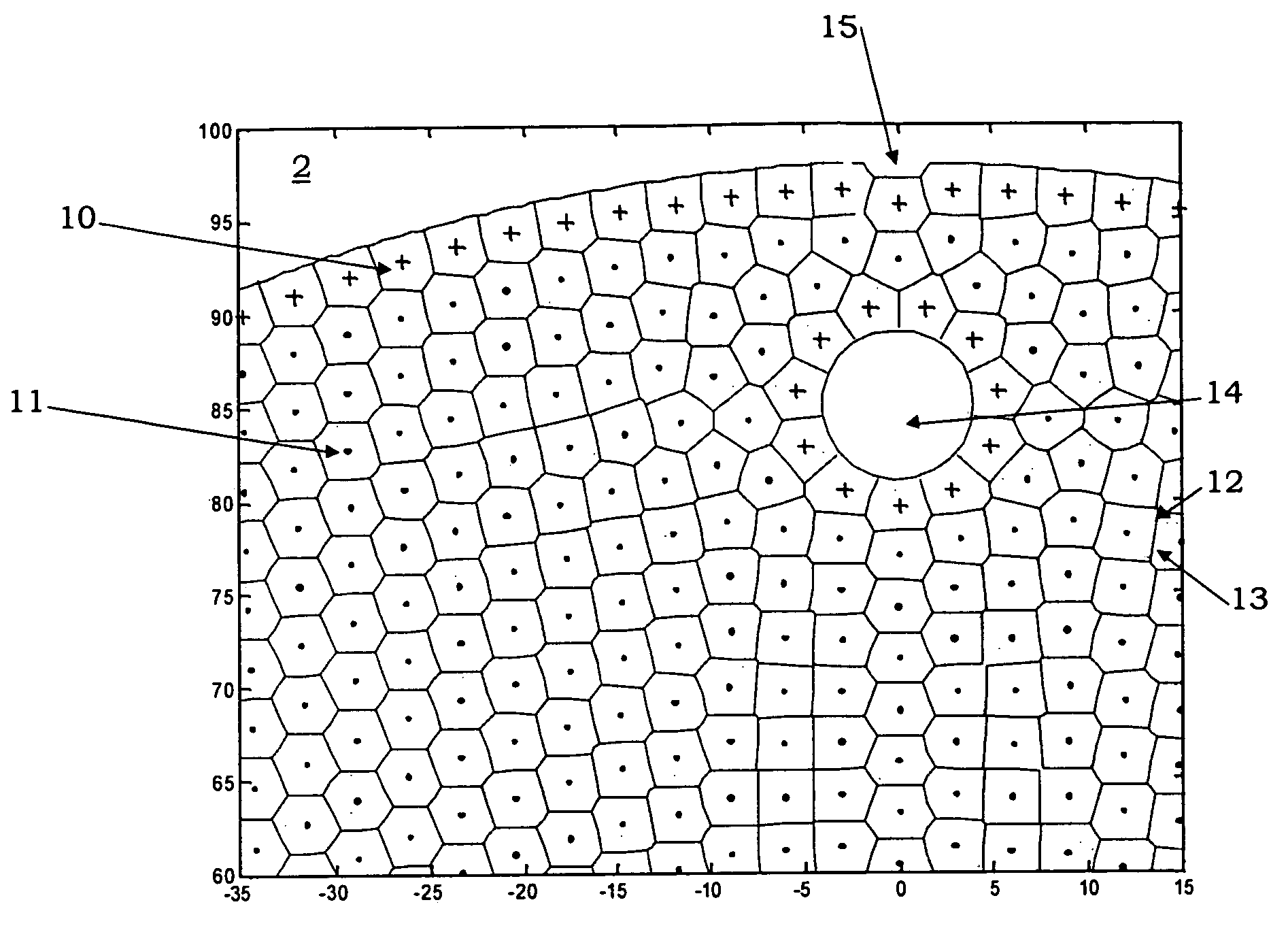

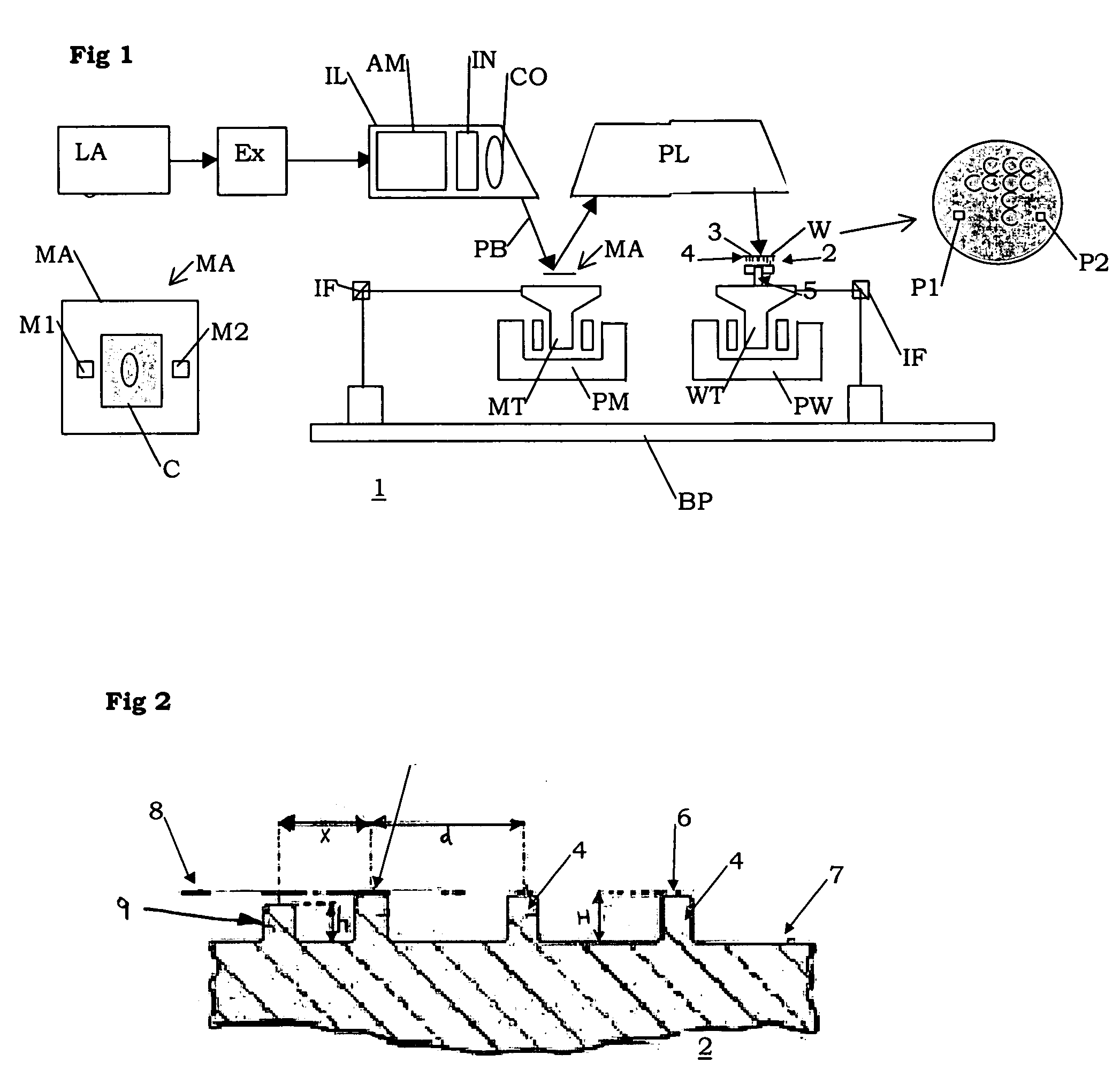

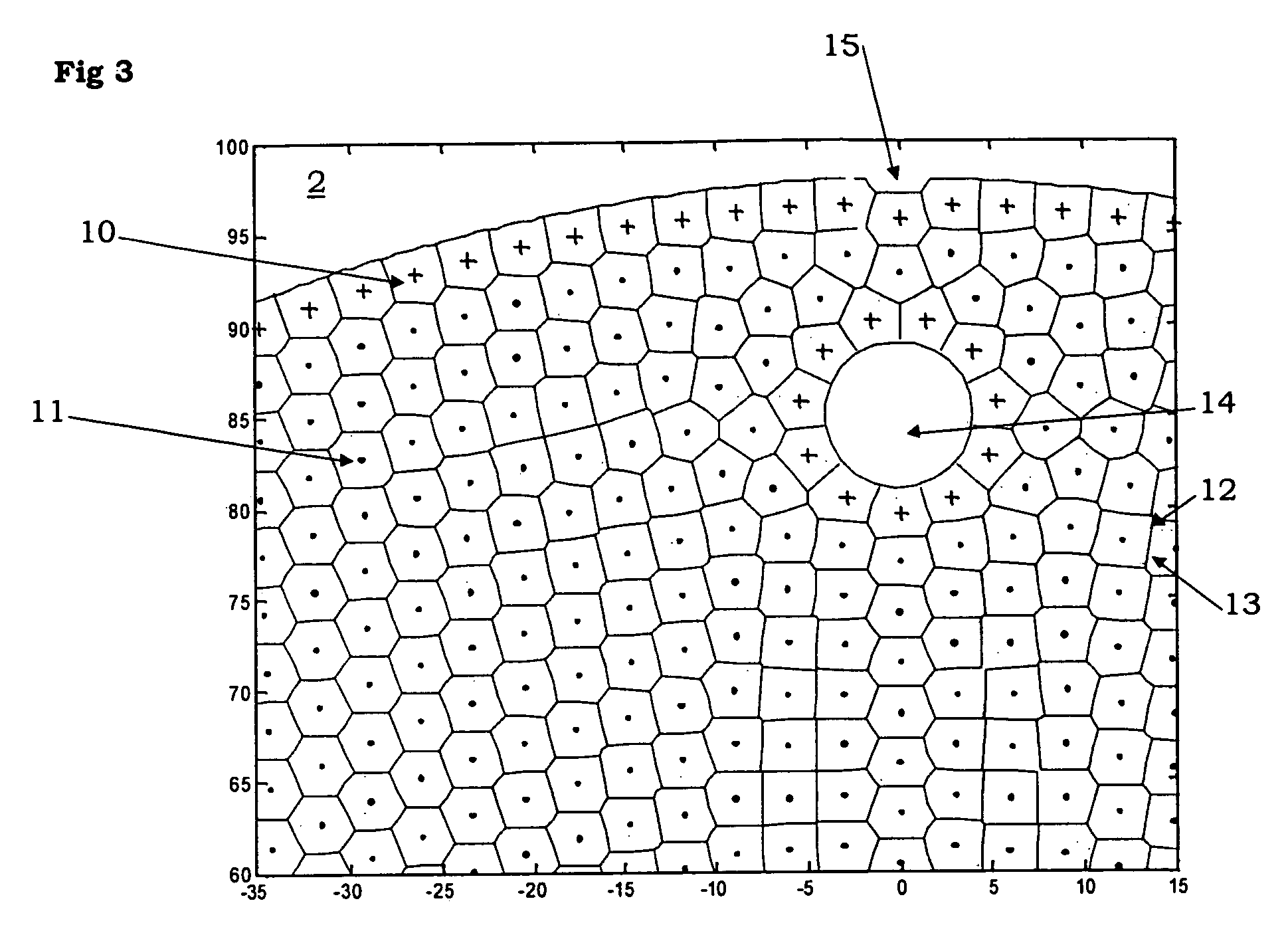

A lithographic projection apparatus including a radiation system for providing a projection beam of radiation; a support structure for supporting a patterning device, the patterning device serving to pattern the projection beam according to a desired pattern; a substrate holder having a plurality of protrusions, the extremities thereof defining a substantially flat plane of support for supporting a substantially flat substrate, the substrate holder provided with the ability to provide a pressing force for pressing the substrate against the extremities of the protrusions, the protrusions in an edge zone of the substrate holder arranged to provide a substantially flat overhanging of the substrate in relation to the pressing force of the pressing means; and a projection system for projecting the patterned beam onto a target portion of the substrate. The lithographic projection apparatus is characterized in that the protrusions in an off-edge zone of the substrate holder are distributed so as to provide a substantial equal supporting area for each protrusion of the plurality of protrusions, the supporting areas being defined by a Voronoi diagram distribution associated to the protrusions. The lithographic apparatus offers a substrate holder with a reduced overlay and focus error.

Owner:ASML NETHERLANDS BV

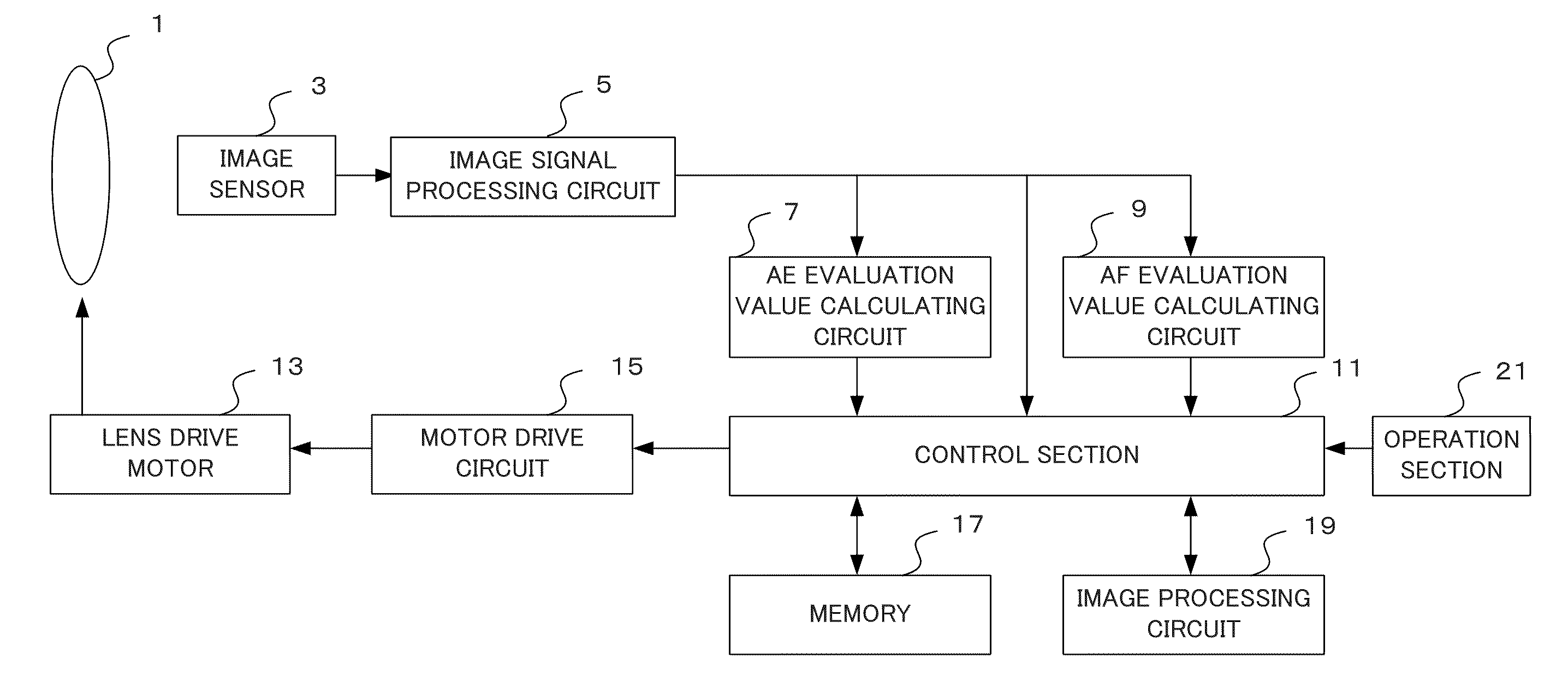

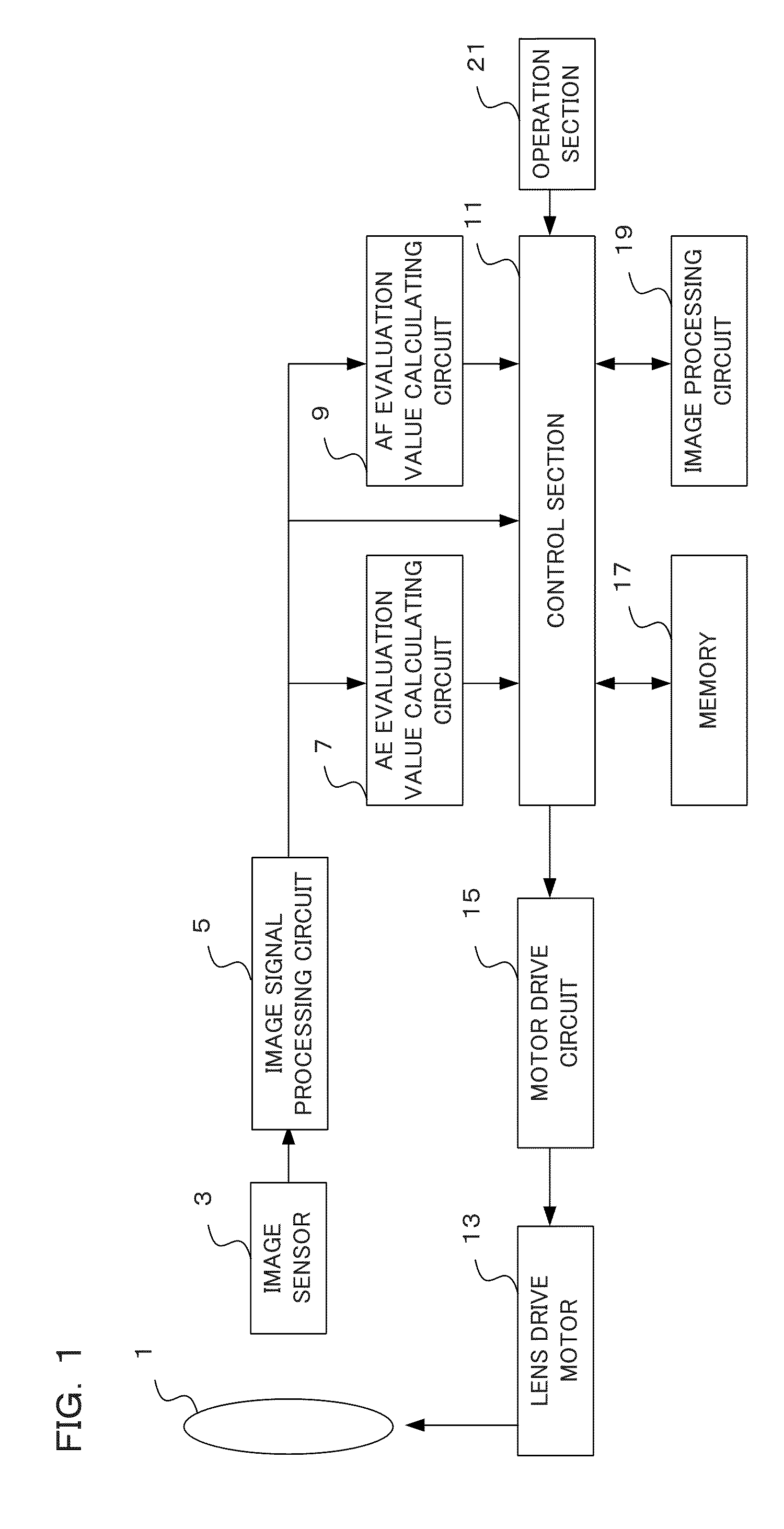

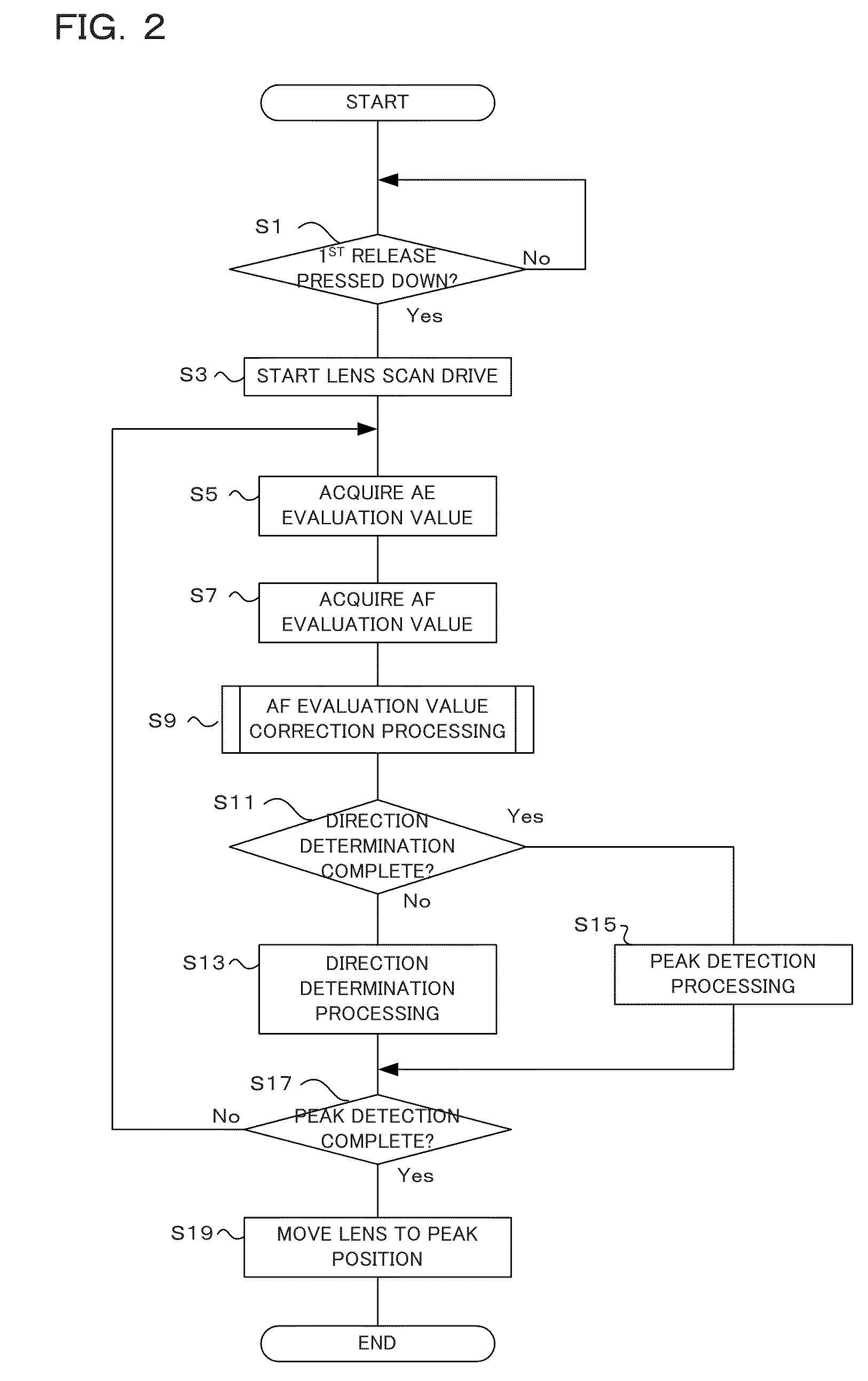

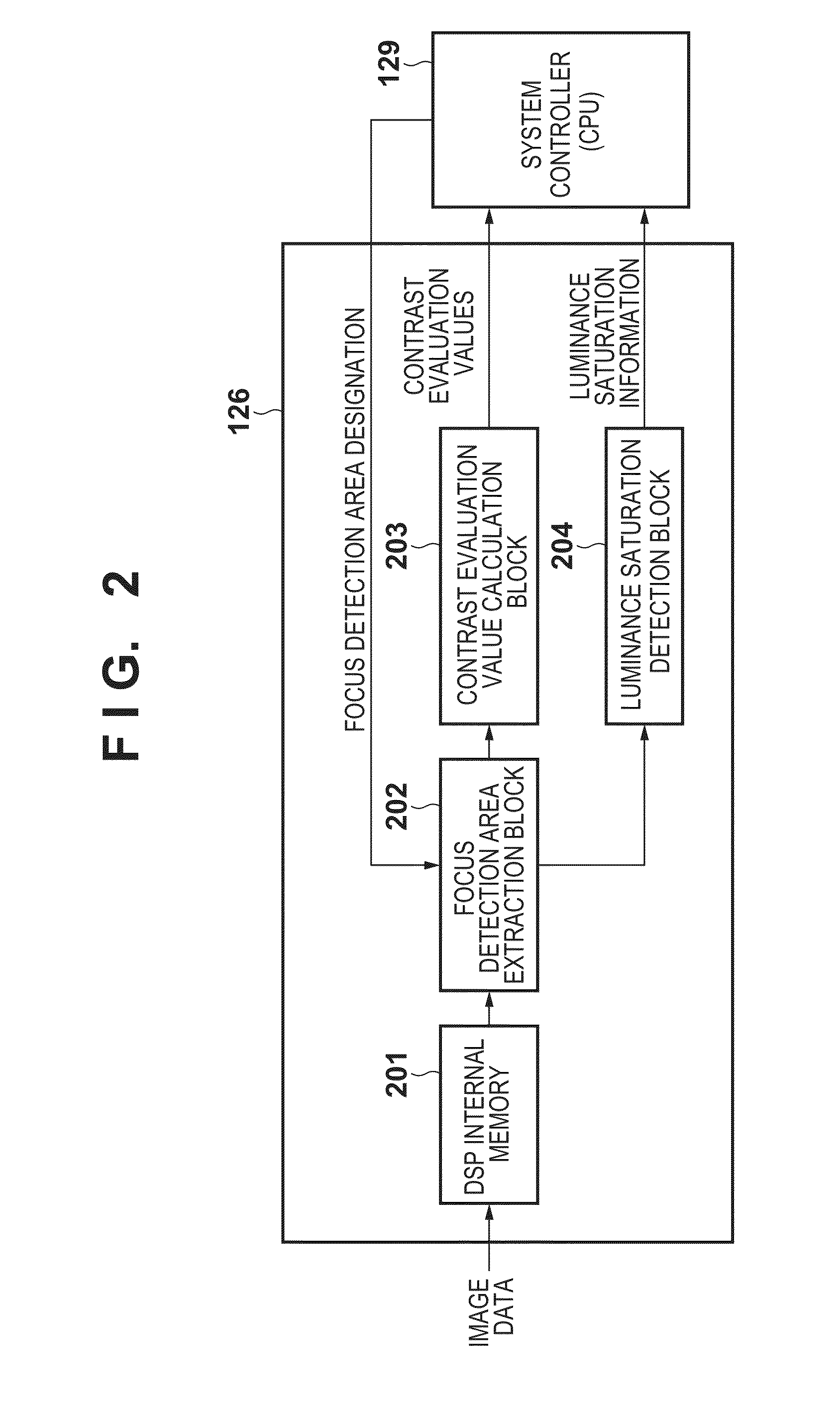

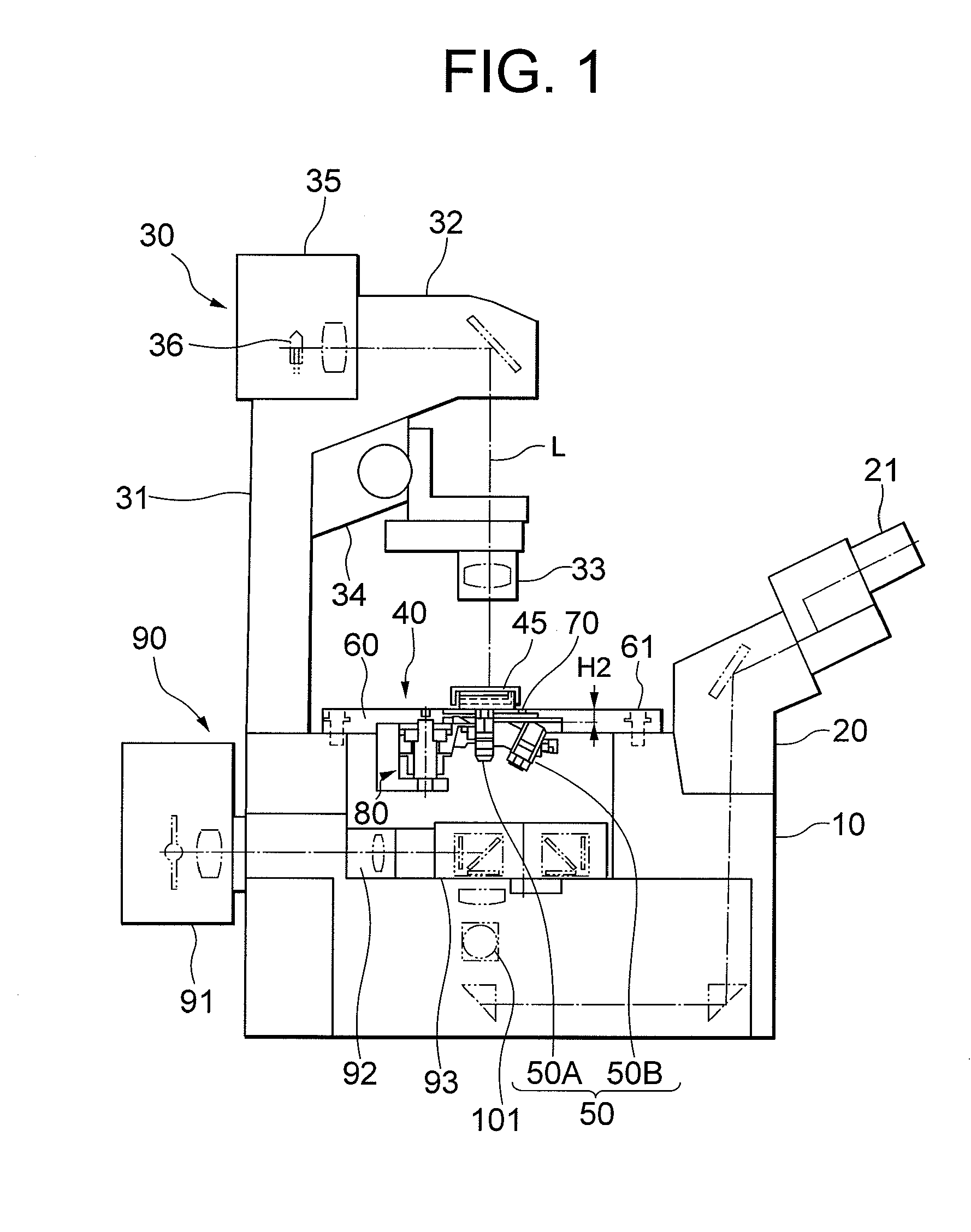

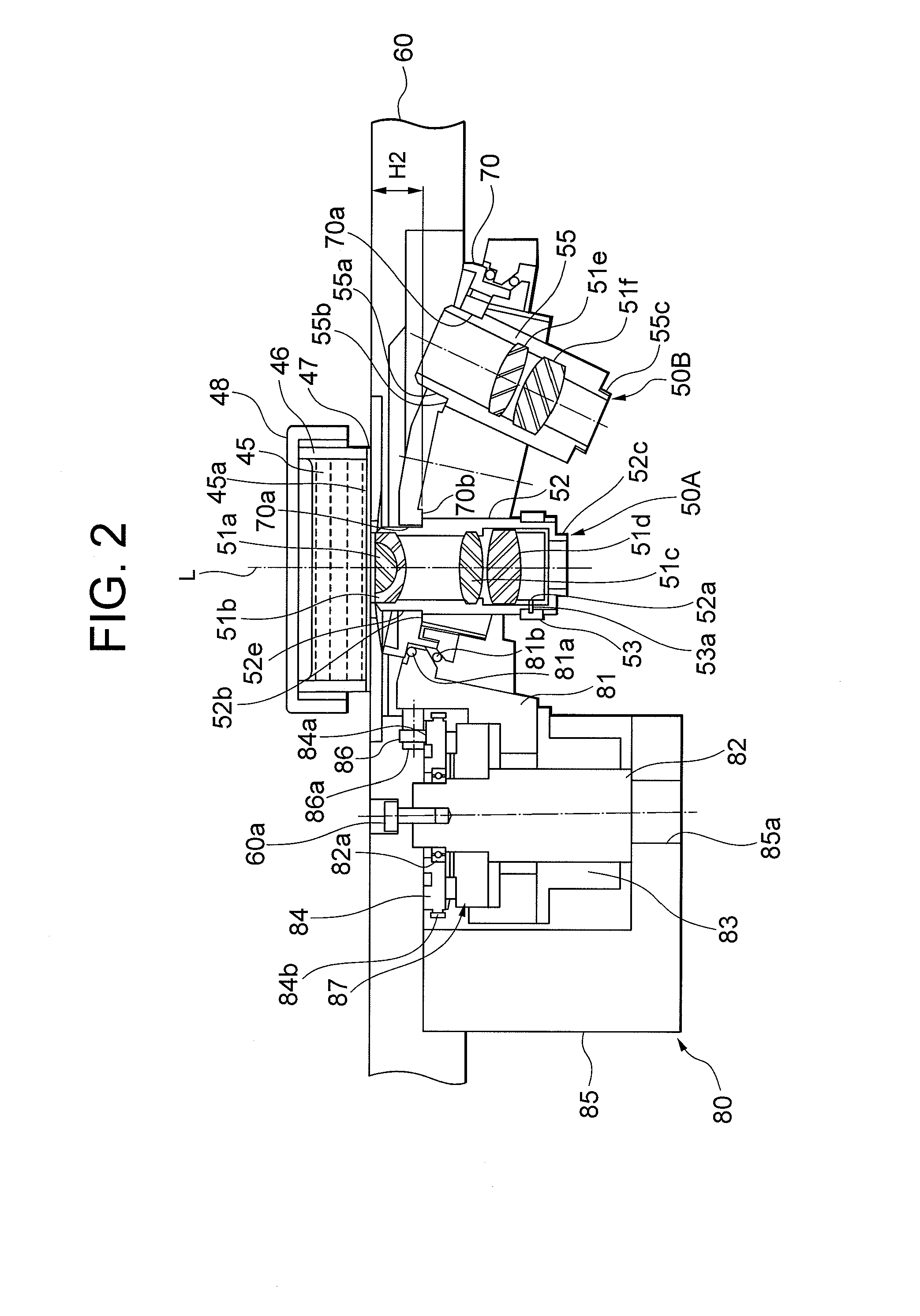

Imaging device and automatic focus adjustment method

ActiveUS20110205403A1Reducing false focusIncrease speedTelevision system detailsProjector focusing arrangementBrightness perceptionContrast ratio

Owner:OLYMPUS CORP

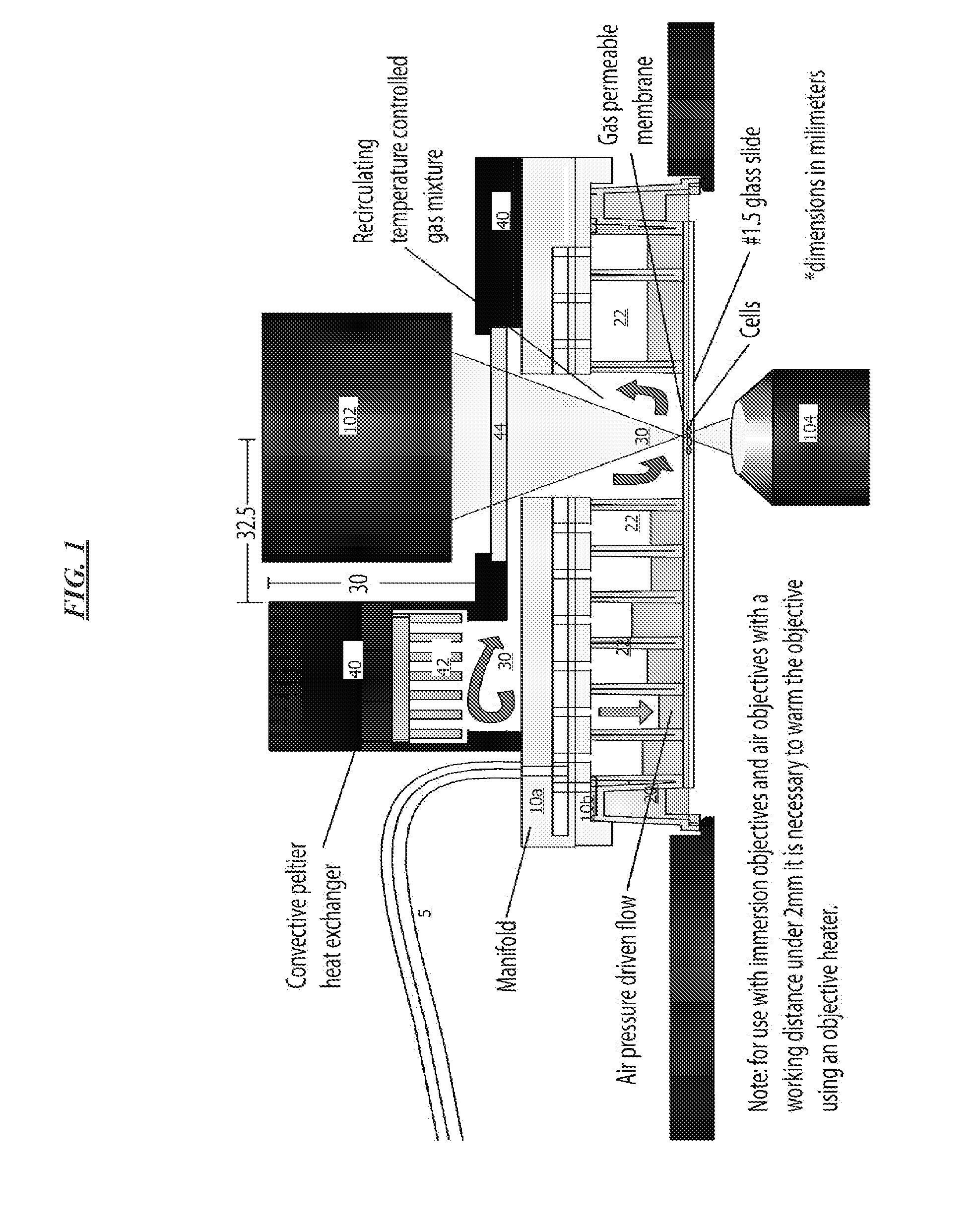

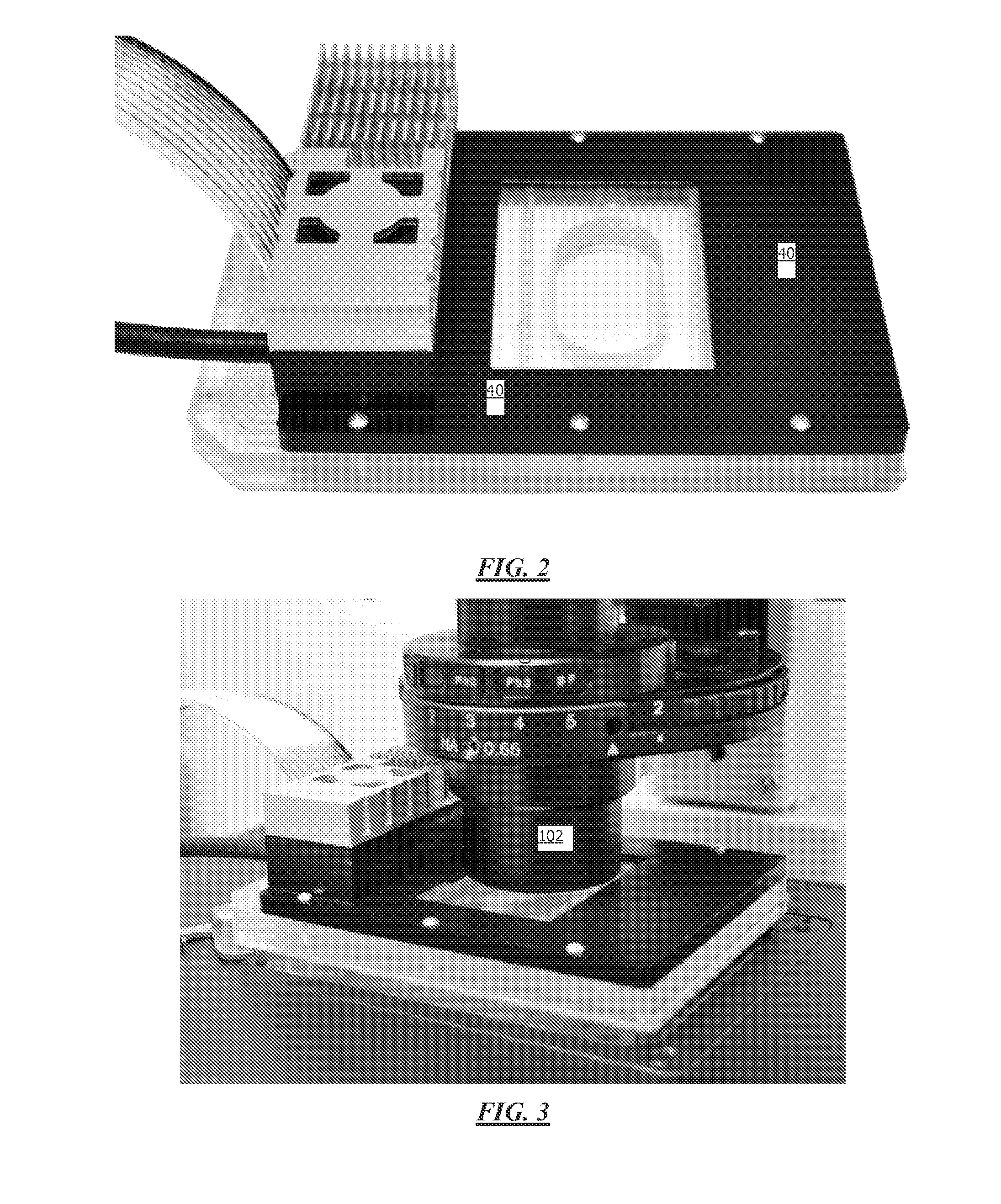

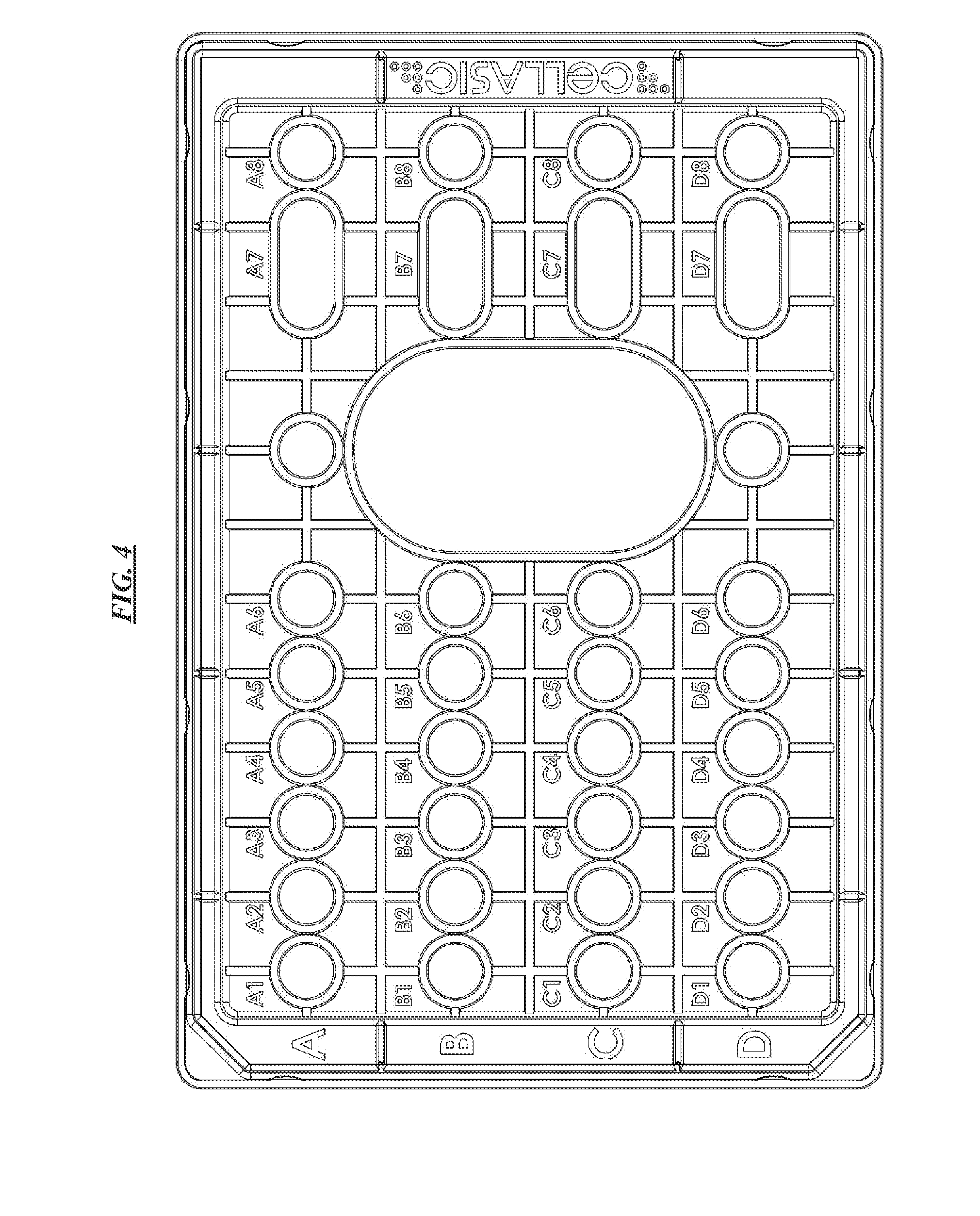

Micro-Incubation Systems For Microfluidic Cell Culture And Methods

ActiveUS20140287489A1Good adhesionEasy to removeBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringCultured Cell Line

A micro-incubator manifold for improved microfluidic configurations and systems and methods of manufacture and operation for a manifold and automated microfluidic systems.

Owner:MILLIPORE CORP

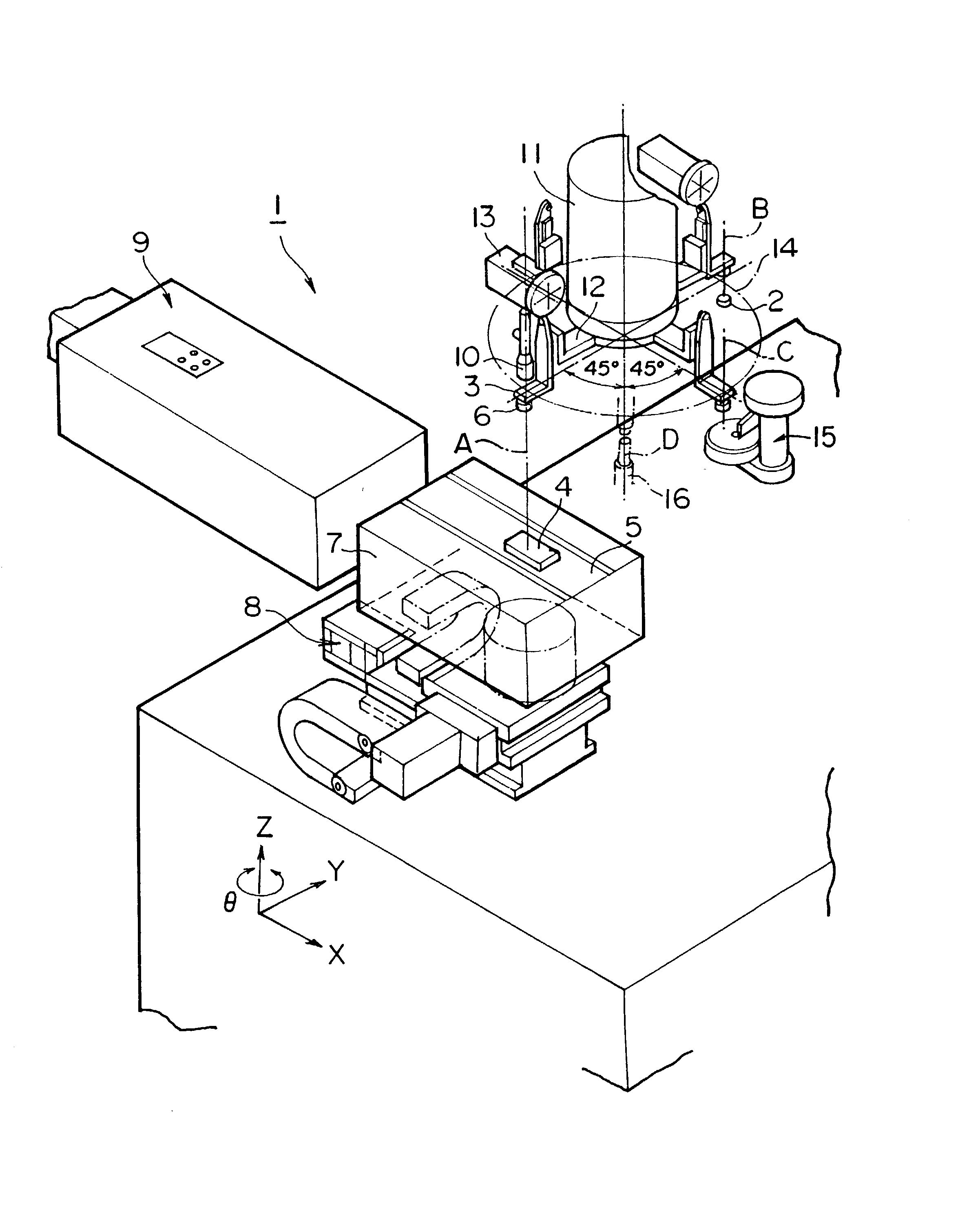

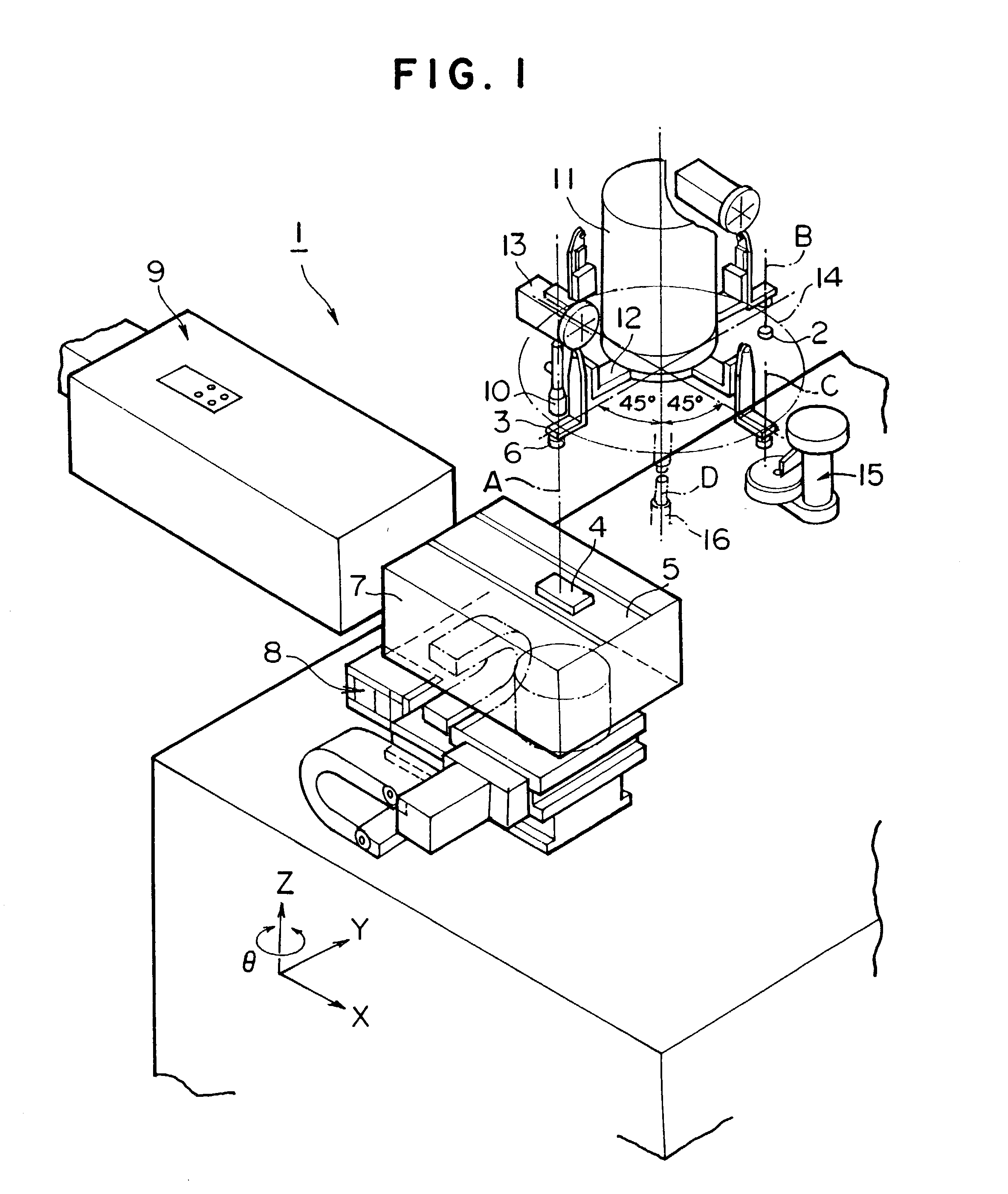

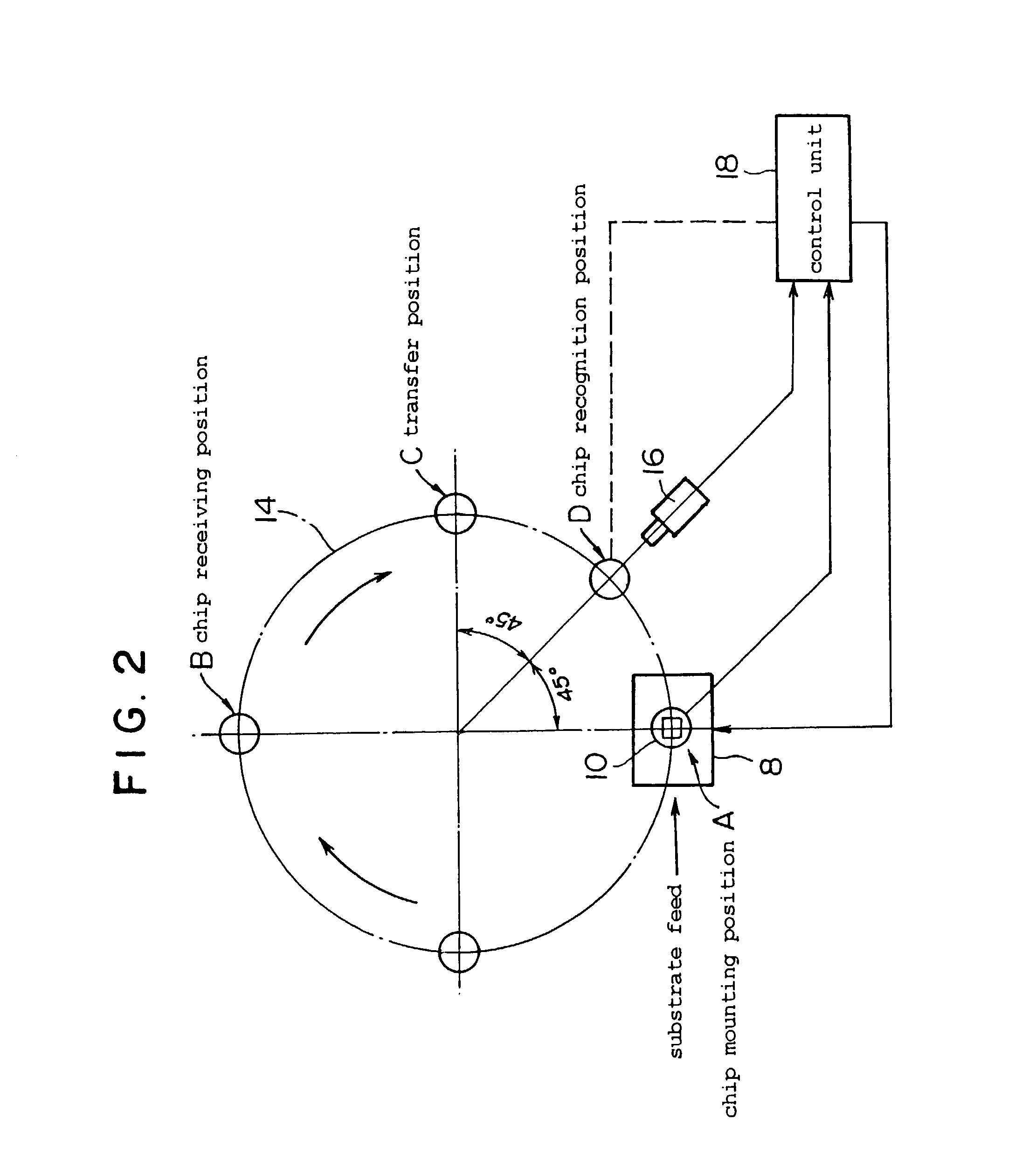

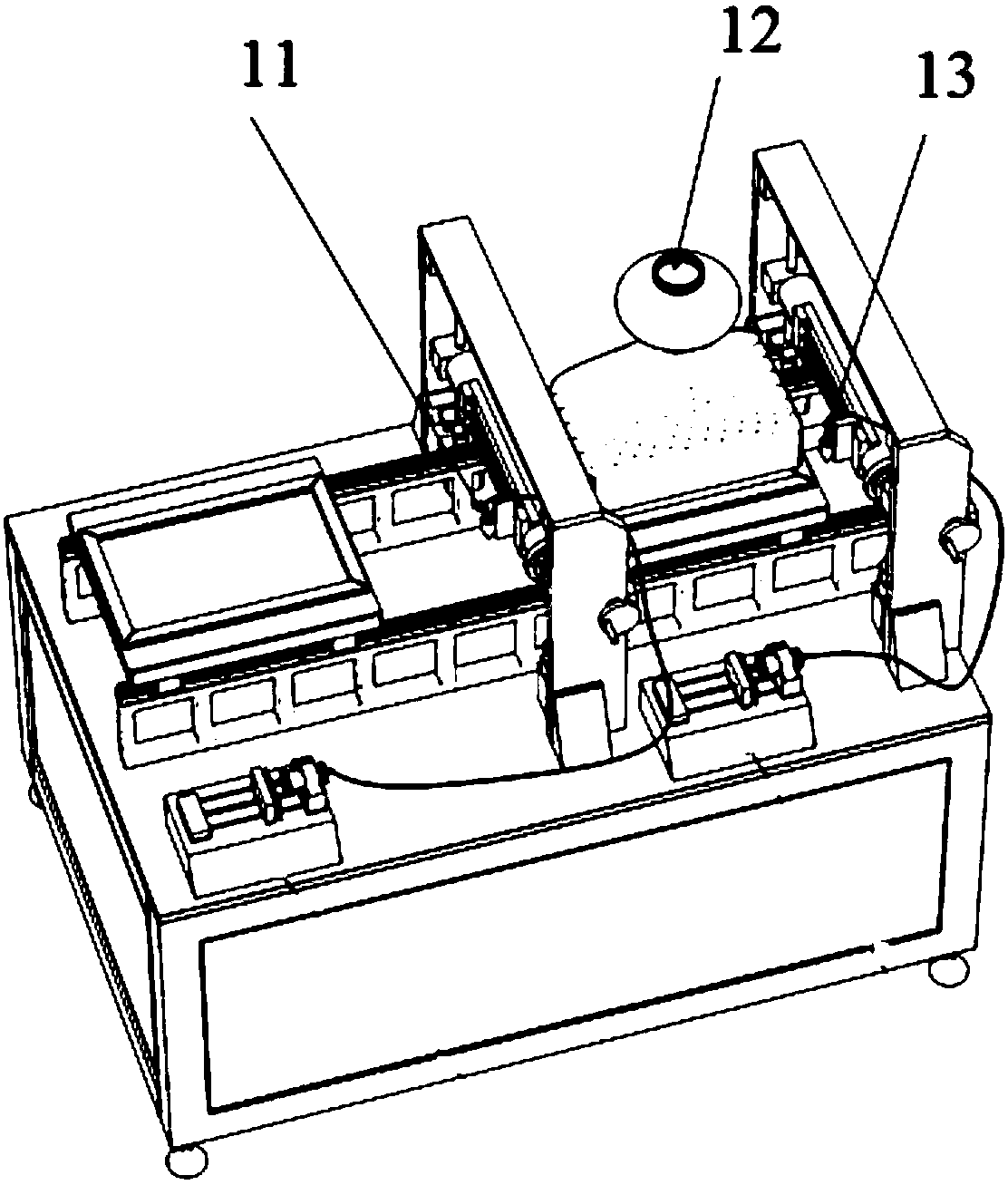

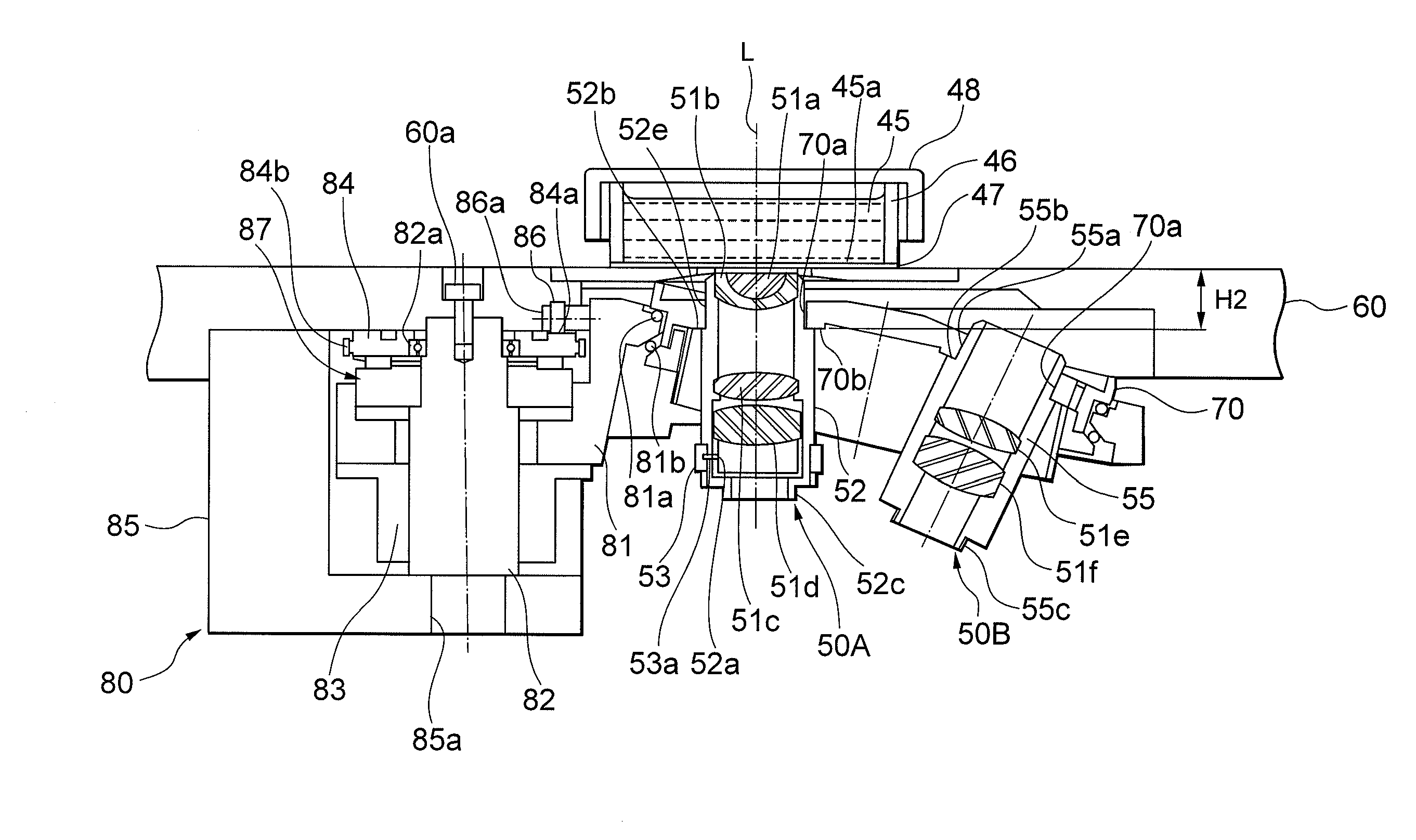

Chip-mounting device and method of alignment thereof

InactiveUS20030046812A1Increase speedShorten the timePrinted circuit assemblingAutomatic control devicesEngineeringIdentification device

A mounting device (1) including a plurality of heads (3), each holding a chip (2), arranged on a circle, is used to realize accurate and high-speed mounting. A mounting device comprises a plurality of heads (3) with calibration marks, first recognition means (10) fixed in a chip mounting position (A), and second recognition means (16) fixed in another position. Prior to mounting operation, the first recognition mechanism and the second recognition mechanism recognize and store the positions of the calibration marks of the heads (3) In mounting operation, the first recognition means (10) recognizes the positions of a substrate (4) and the calibration marks of the heads (3), whereas the second recognition means (16) recognizes the positions of chips (2) attracted on the heads (3). The heads are moved vertically to adjust plane to be recognized. The chip (2) and the substrate (4) are aligned according to the position information obtained by the recognition mechanisms, and the chips are mounted.

Owner:TORAY ENG CO LTD

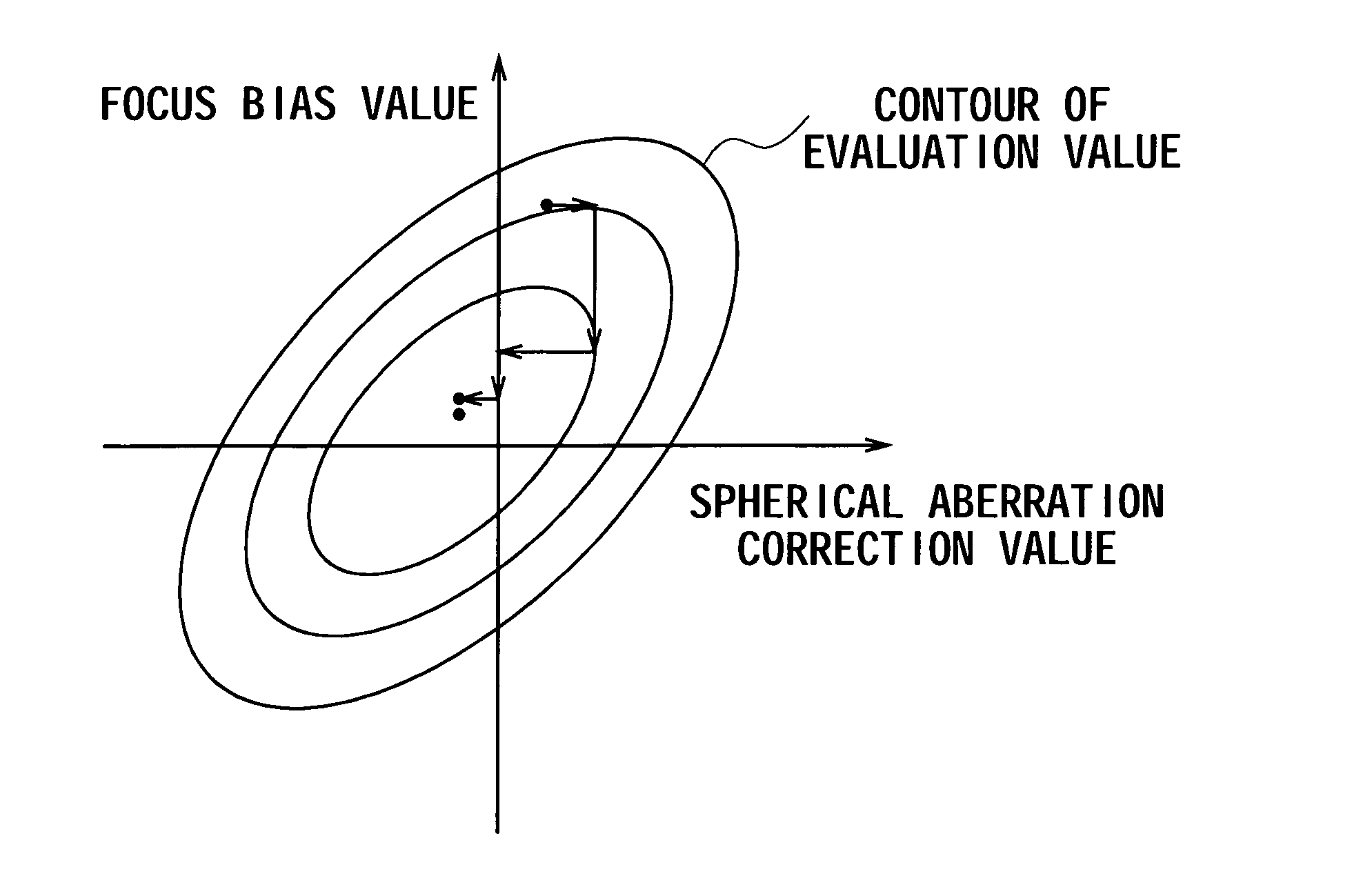

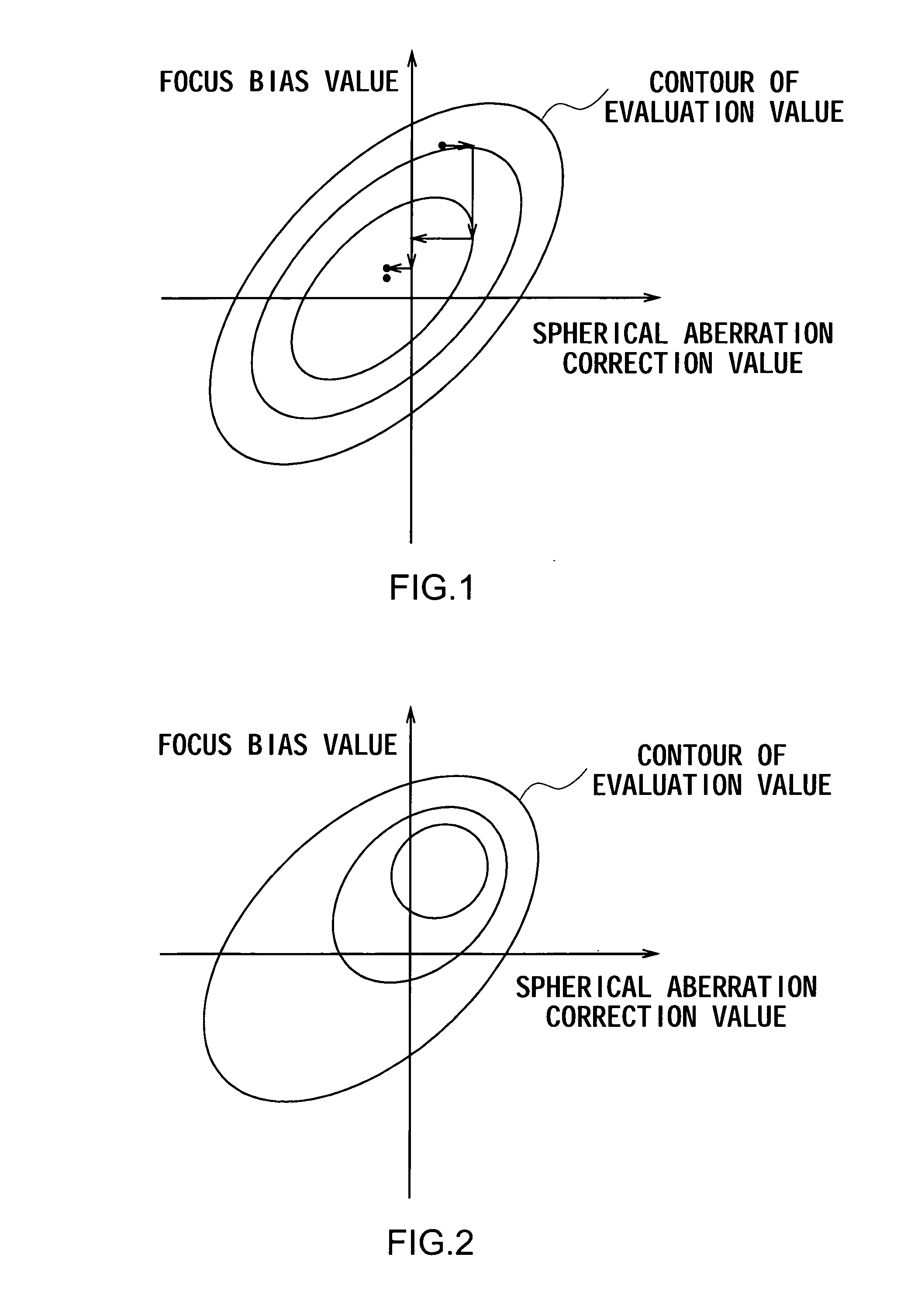

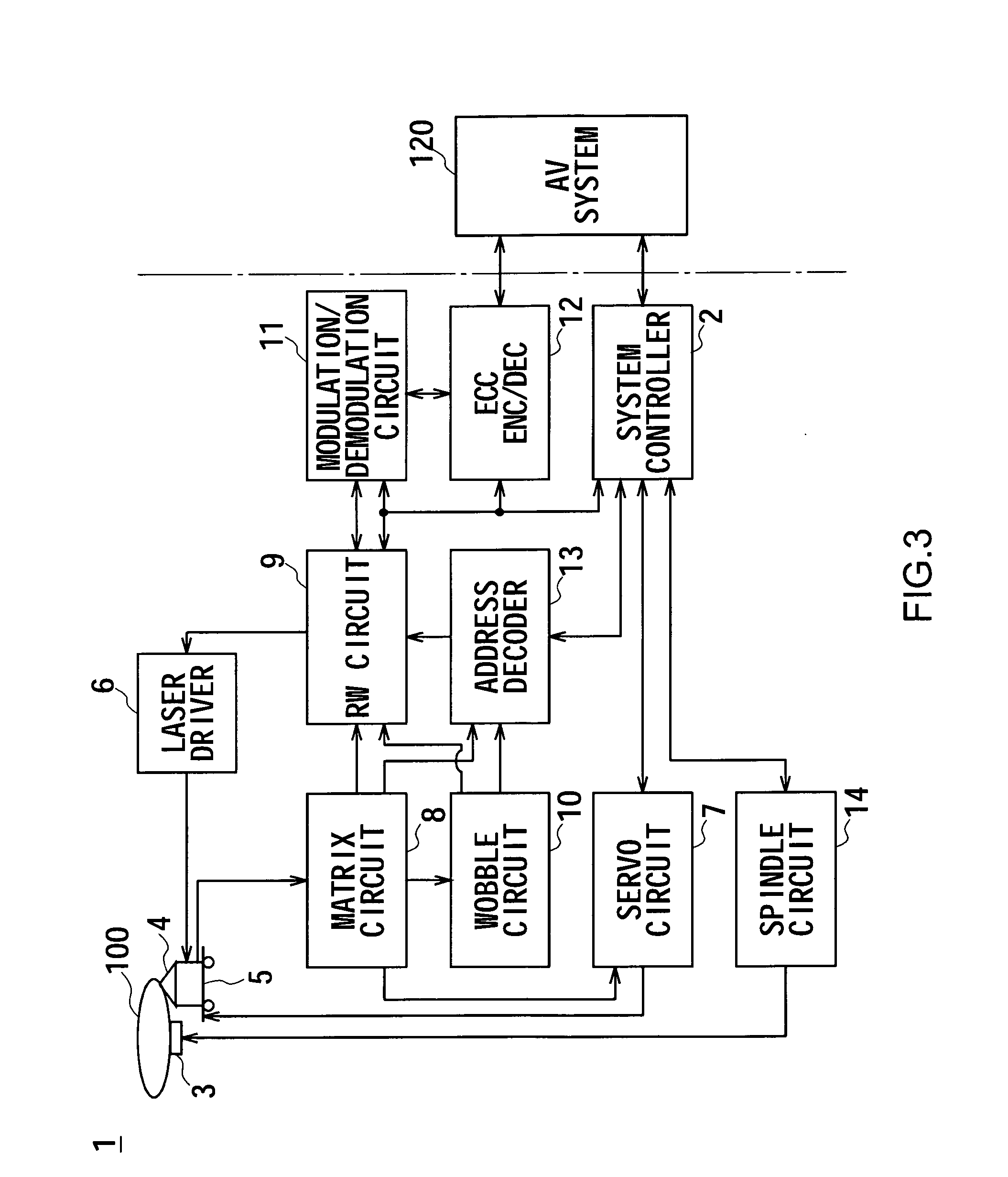

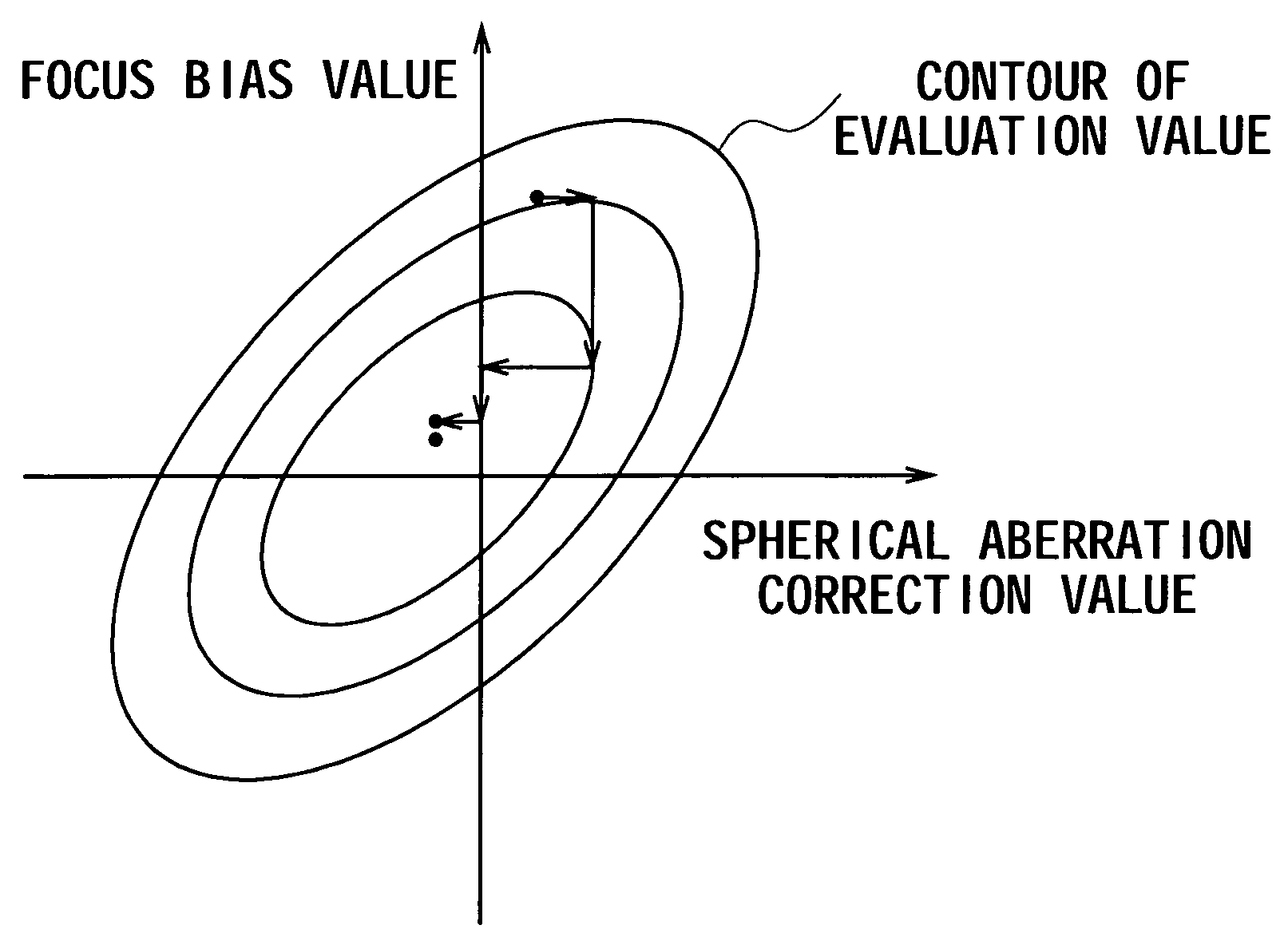

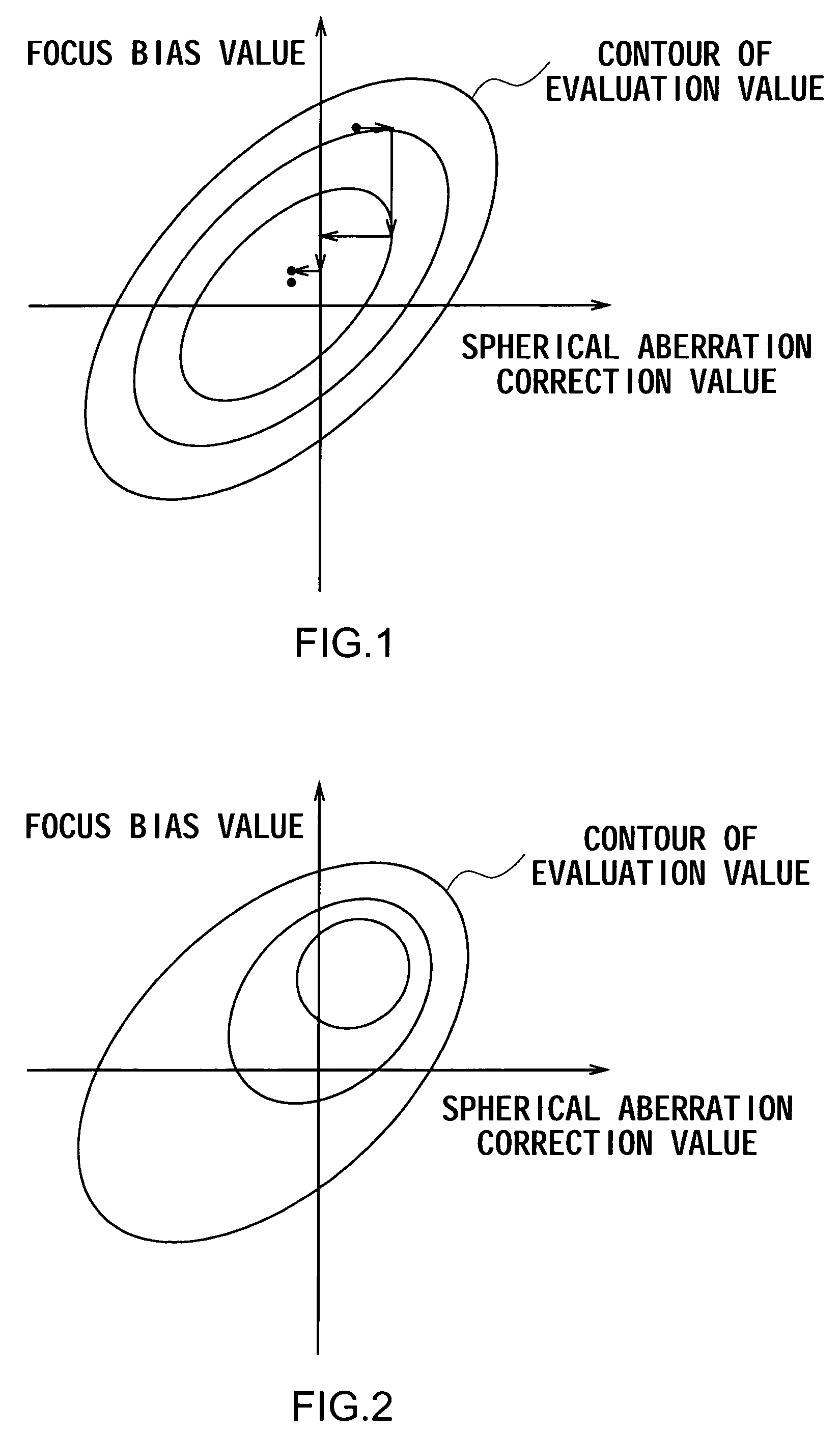

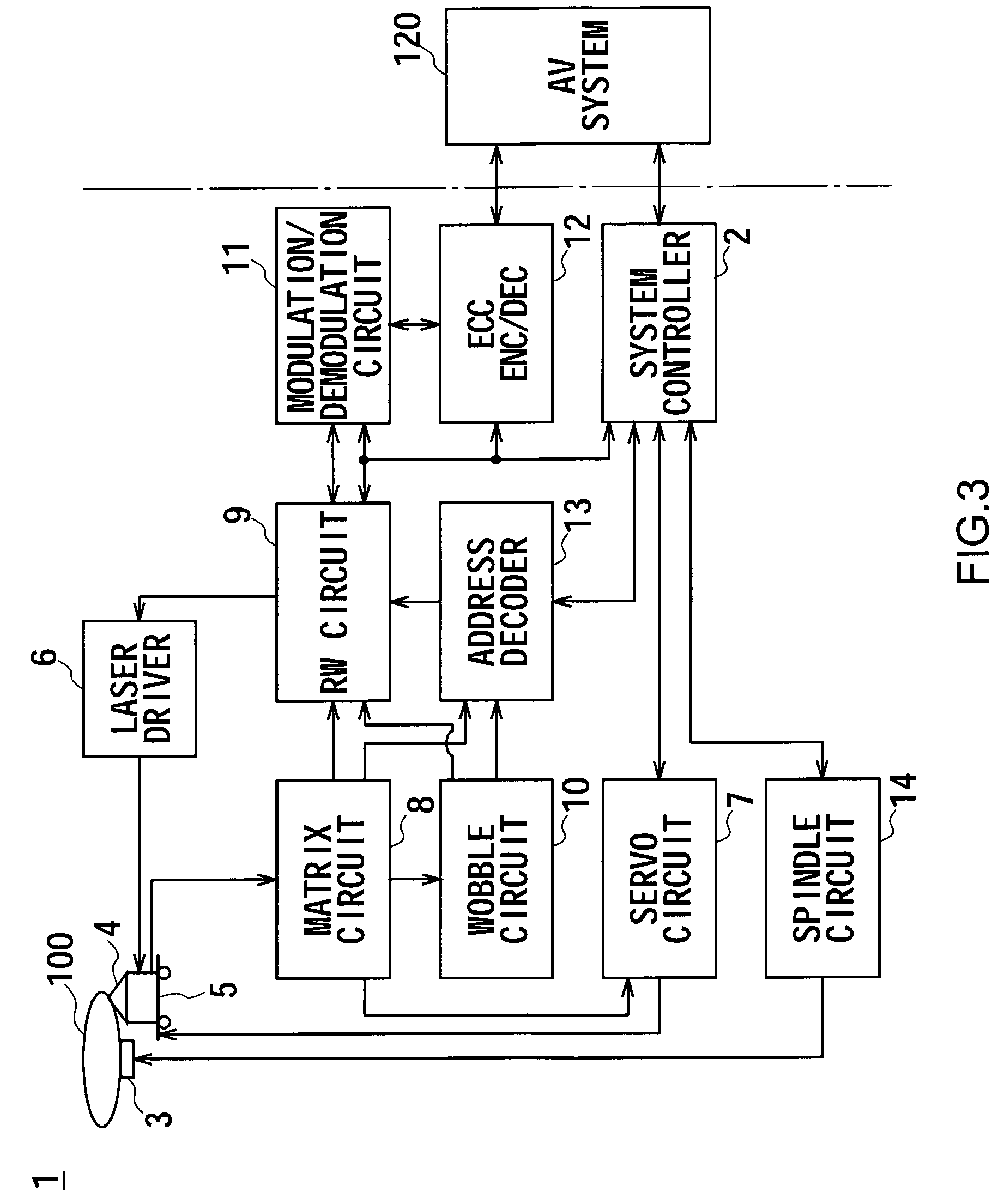

Optical pickup control apparatus, optical pickup control method, and optical disc apparatus

InactiveUS20060164949A1Reduce aberrationReduce focusCombination recordingDisposition/mounting of recording headsOptical pickupMeasurement point

The present invention has been made to adequately and quickly adjust the spherical aberration and focus bias in an optical pickup. In the present invention, evaluation values are measured on a plurality of respective measurement points each determined by a combination of a spherical aberration correction value and focus bias value and a two-variable function having the spherical aberration correction value and focus bias value as variables is approximated to the evaluation values. Based on the two-variable function obtained by the approximation, the optimal value of the spherical aberration correction value and focus bias value on which the evaluation value becomes optimal is calculated. As a result, it is possible to adequately and quickly adjust the spherical aberration and focus bias in an optical pickup.

Owner:SONY CORP

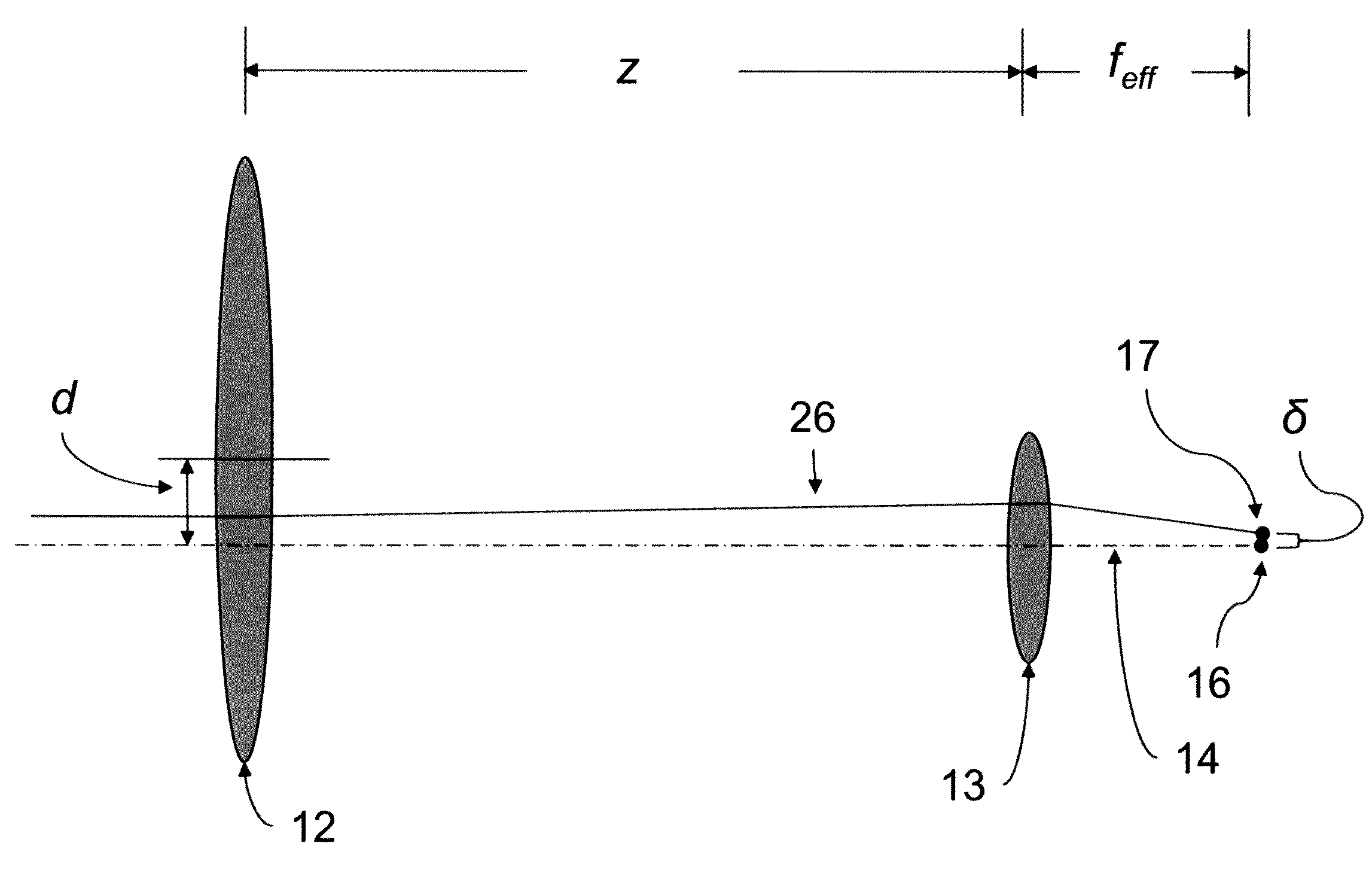

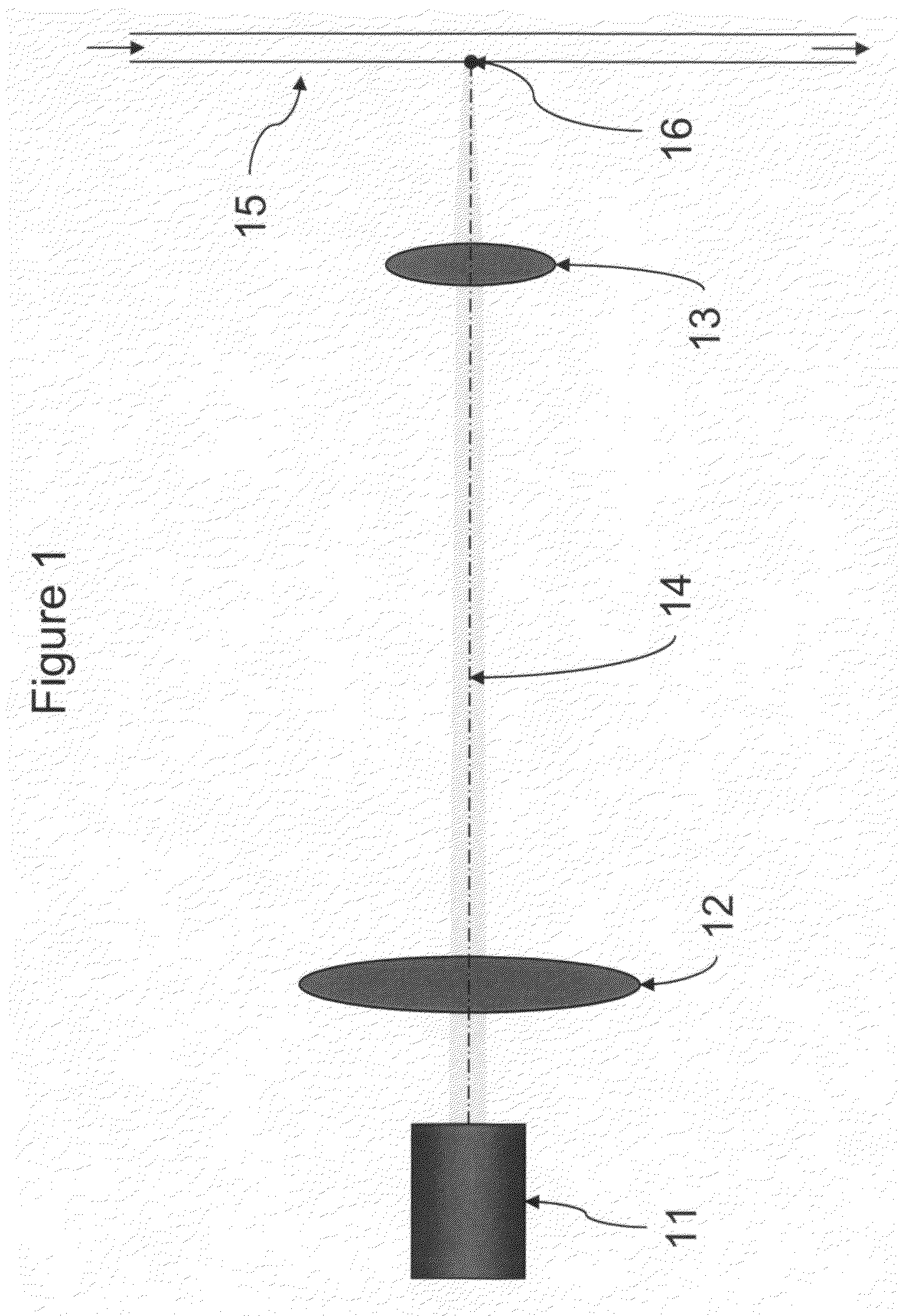

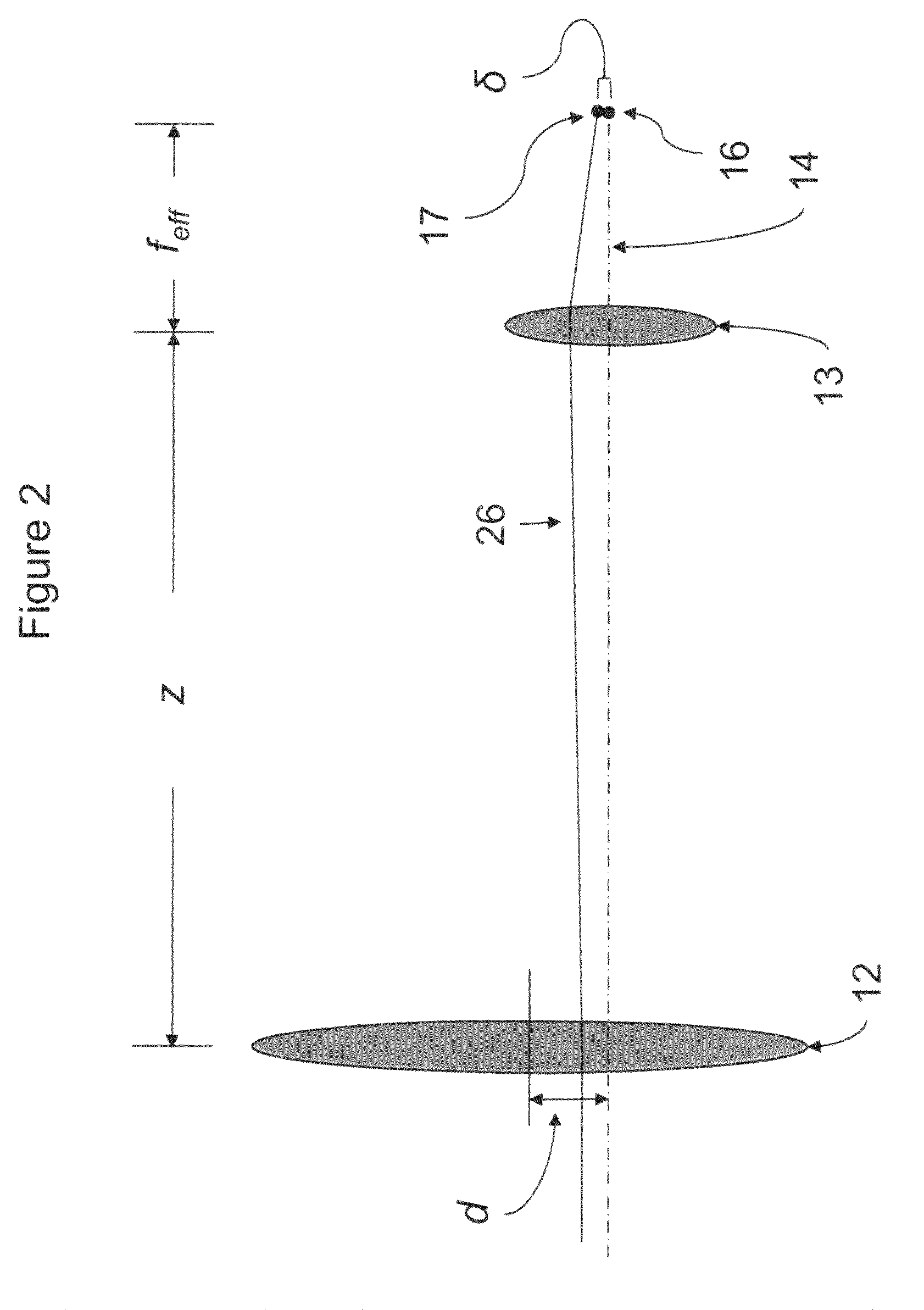

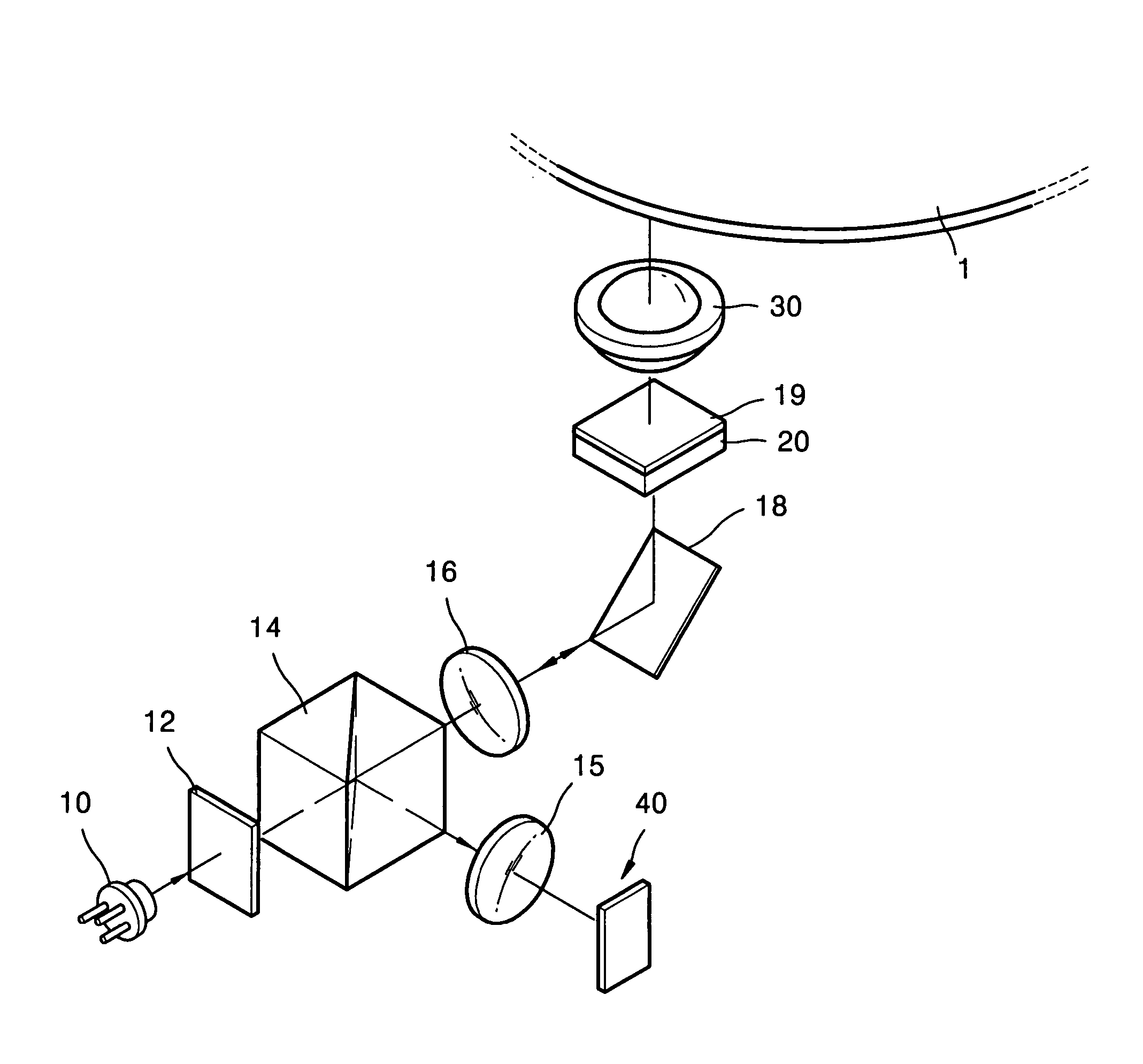

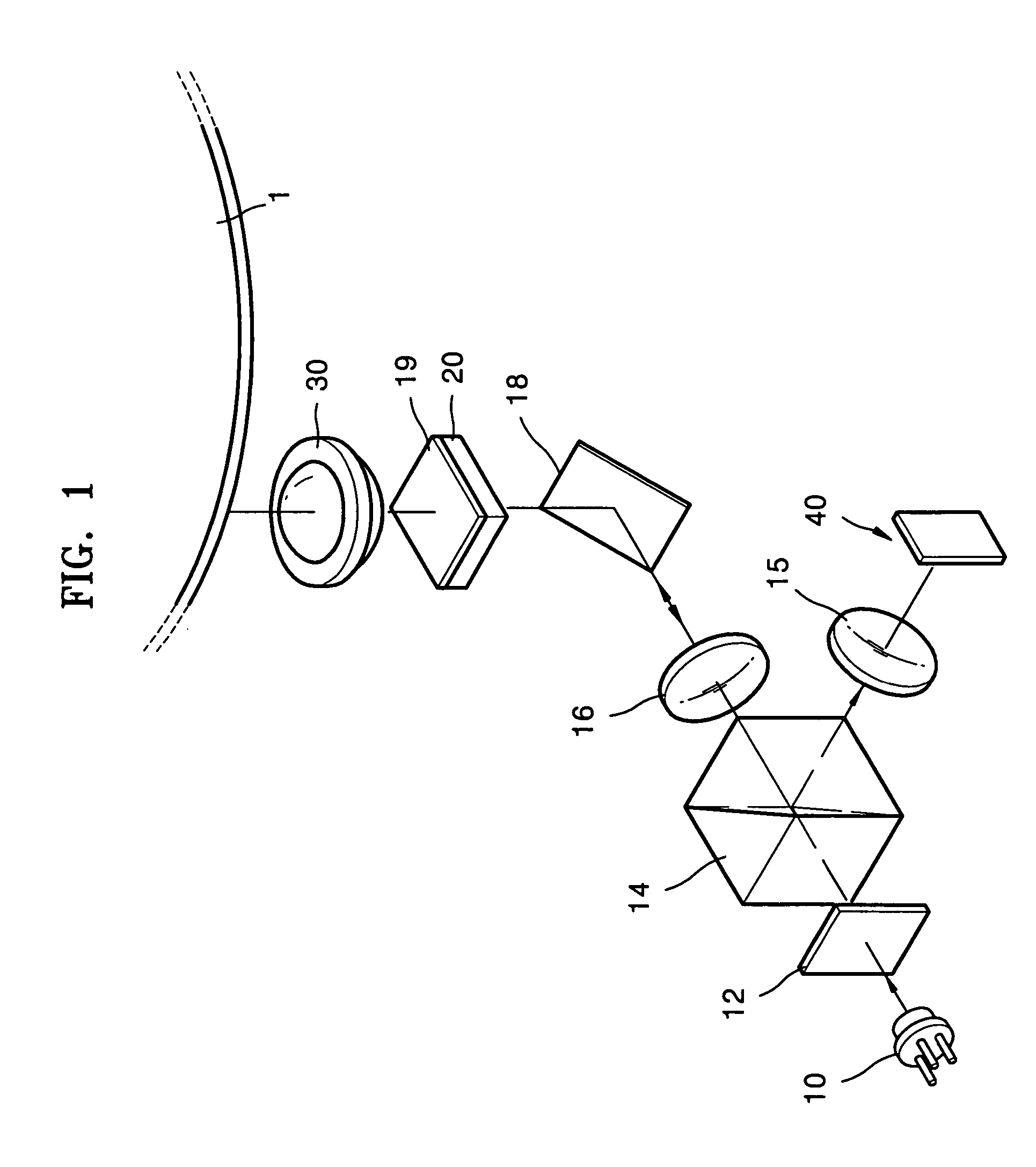

Beam-adjusting optics

ActiveUS7787197B2Precise positioningReduce sensitivityMaterial analysis by optical meansMountingsBeam sourceLight beam

The present invention provides an optical analyzer having illumination optics that include a light source, such as a laser or other source, adapted to emit a collimated, or approximately collimated, light beam, a focusing lens that focuses the beam onto a focus spot within a detection region, and beam-adjusting optics positioned in the light path between the light beam source and the focusing lens, which allow for precise positioning of the focus spot within the detection region. The beam-adjusting optics of the present invention comprise at least one movable focusing lens, mounted in a positioning device that allows repositioning of the lens in a plane perpendicular to the light path.

Owner:BECTON DICKINSON & CO

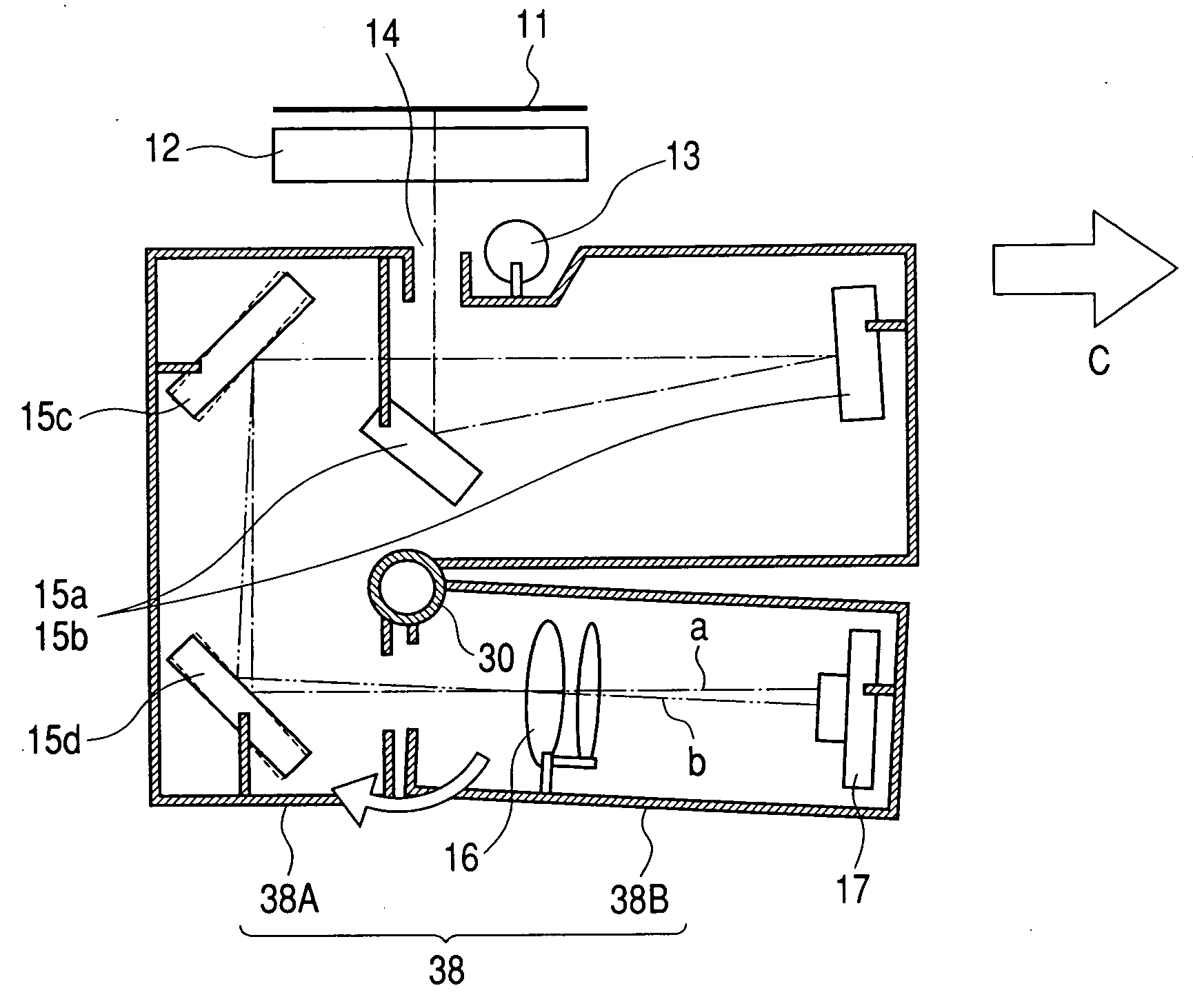

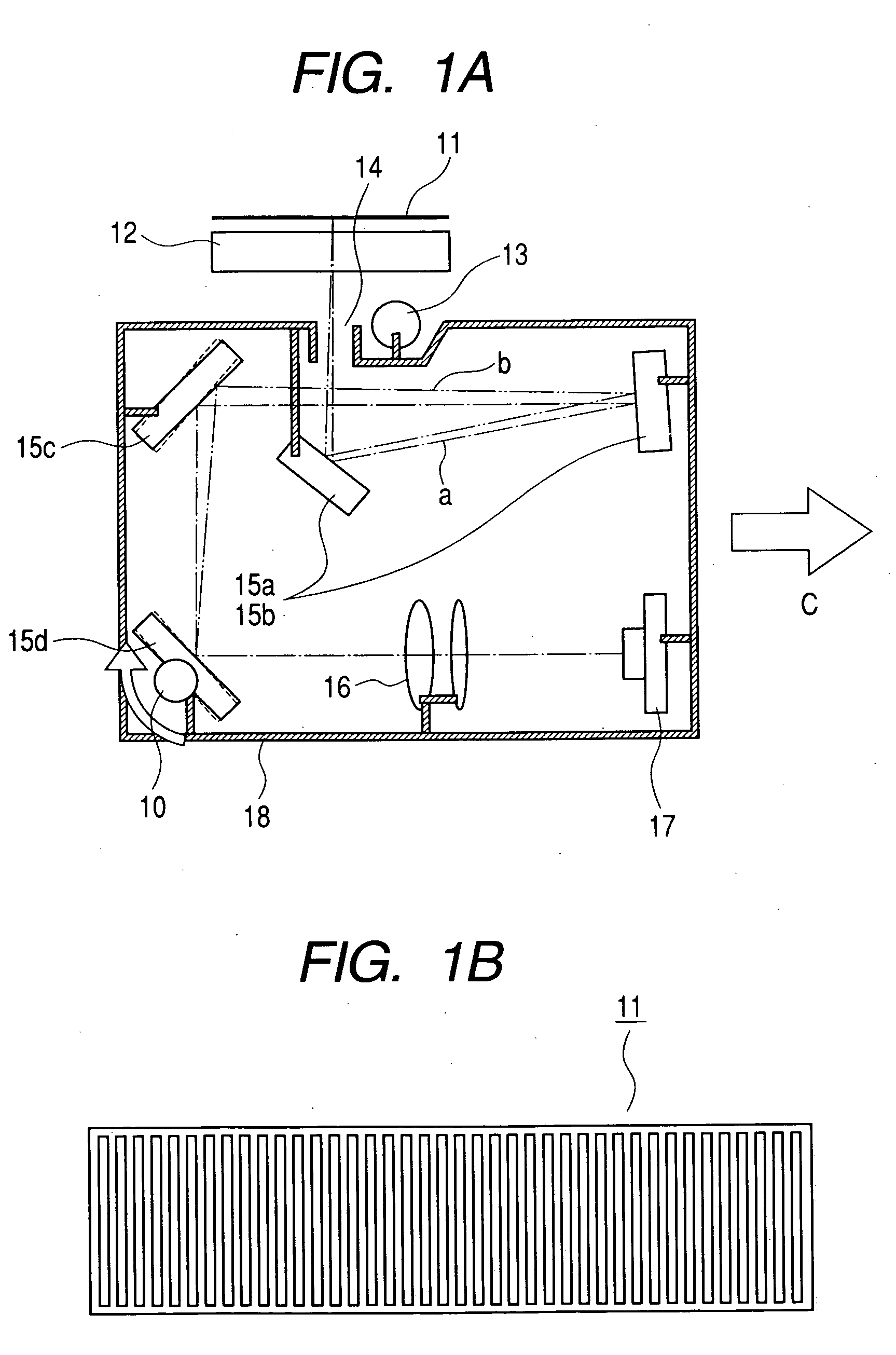

Adjusting method of image reading apparatus and image reading apparatus

InactiveUS20050063025A1High quality image informationSmall sizePhotographic printingPictoral communicationOptical axisLight beam

Disclosed is a method of adjusting an image reading apparatus which reads image information of an original by moving relative to the original a carriage retaining a light source, a slit portion, a plurality of mirrors, an imaging device including an optical element with an optical surface rotationally asymmetrical with respect to the optical axis, and a reading device, the method including placing an adjustment chart allowing resolving power evaluation in the sub scanning direction on an original table glass, illuminating the adjustment chart by the light source, and adjusting, by using an image of the adjustment chart thus illuminated, the relative positional relationship in the sub scanning direction among the slit portion, the imaging device, and the reading device by a positioning adjustment device such that imaging of the light beam passing through a slit center of the slit portion is effected on the surface of the reading device. By performing information through adjustment using the adjustment chart, there are provided an adjusting method of image reading apparatus and an image reading apparatus which provide high quality image.

Owner:CANON KK

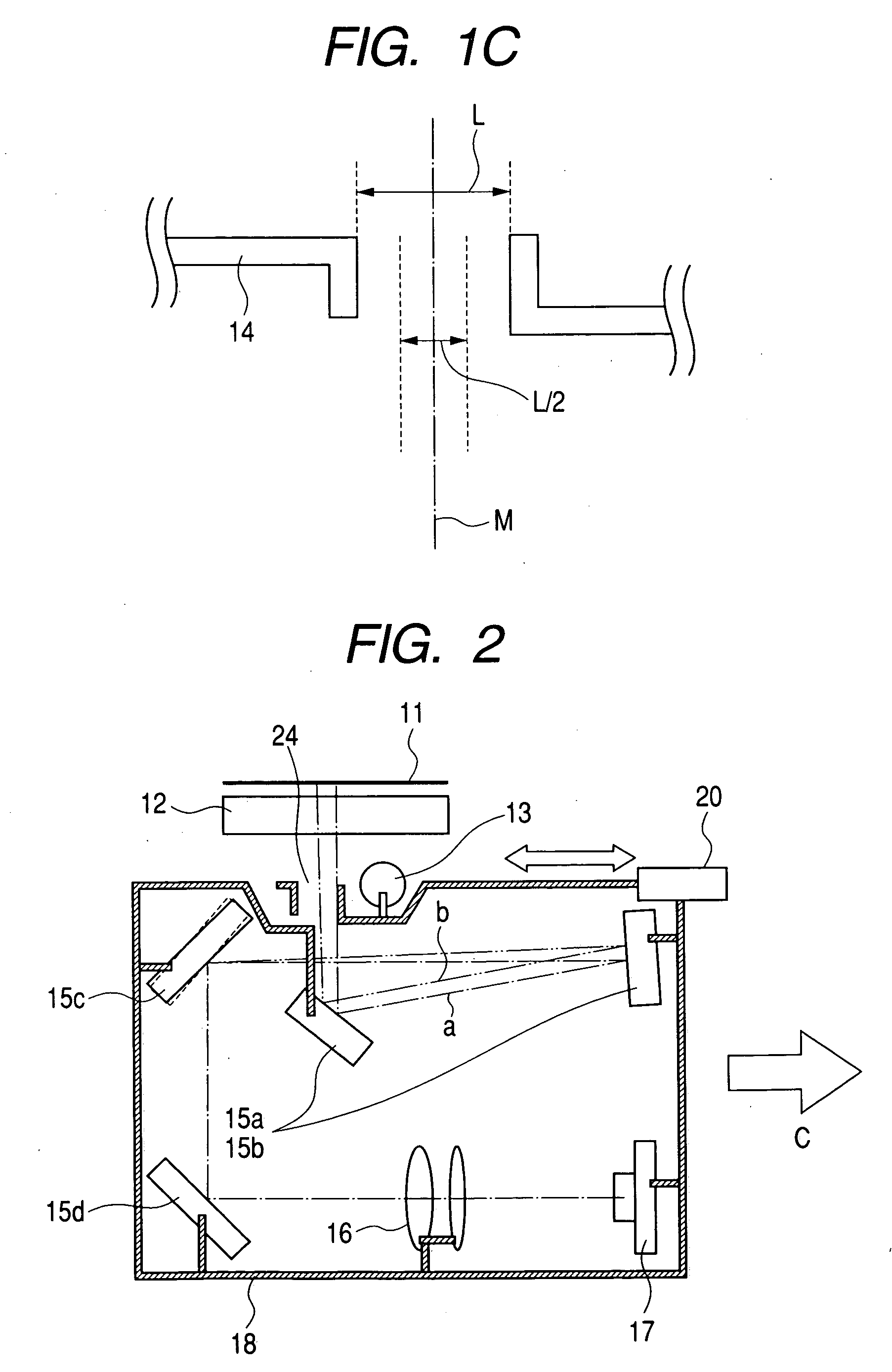

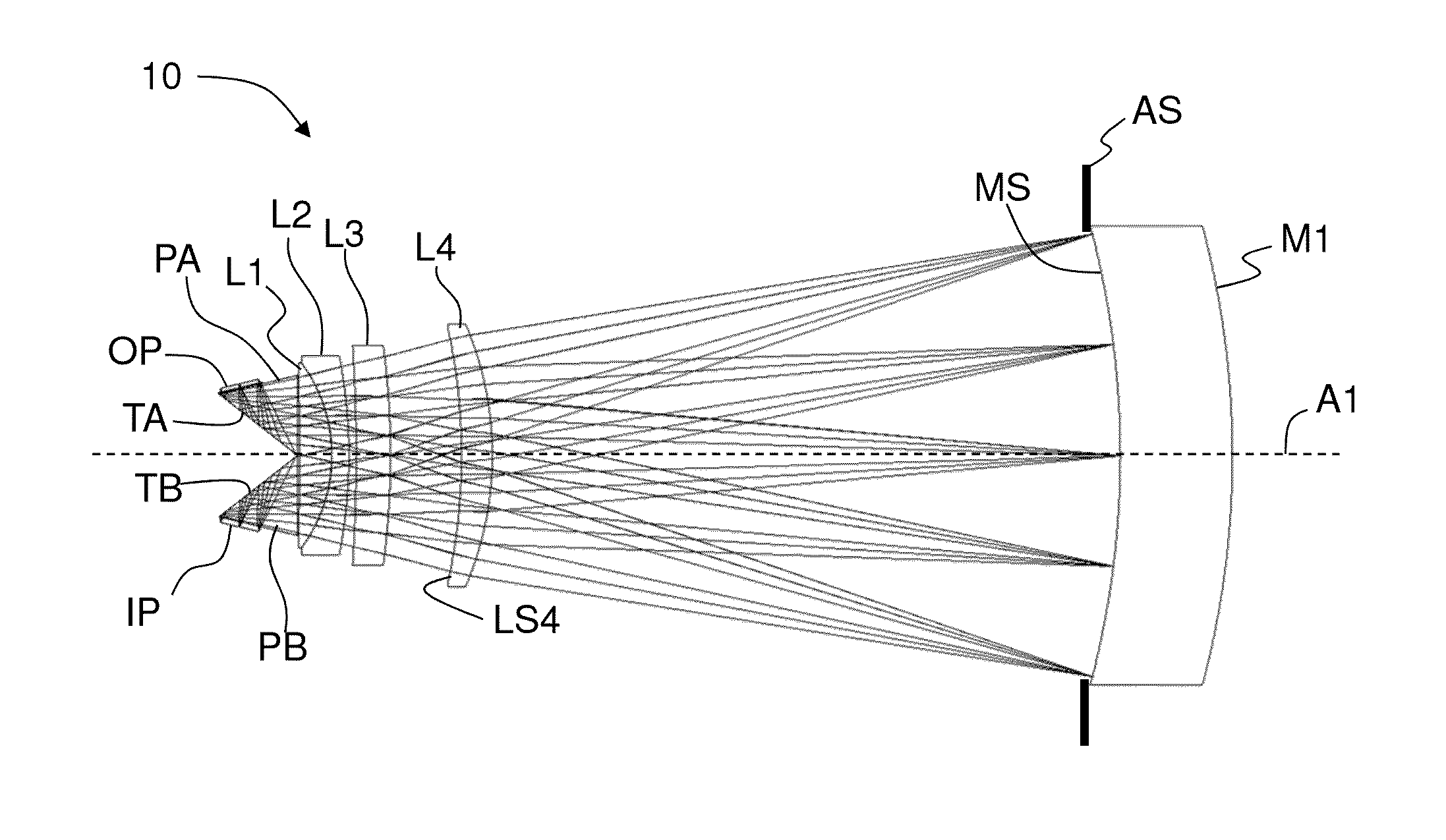

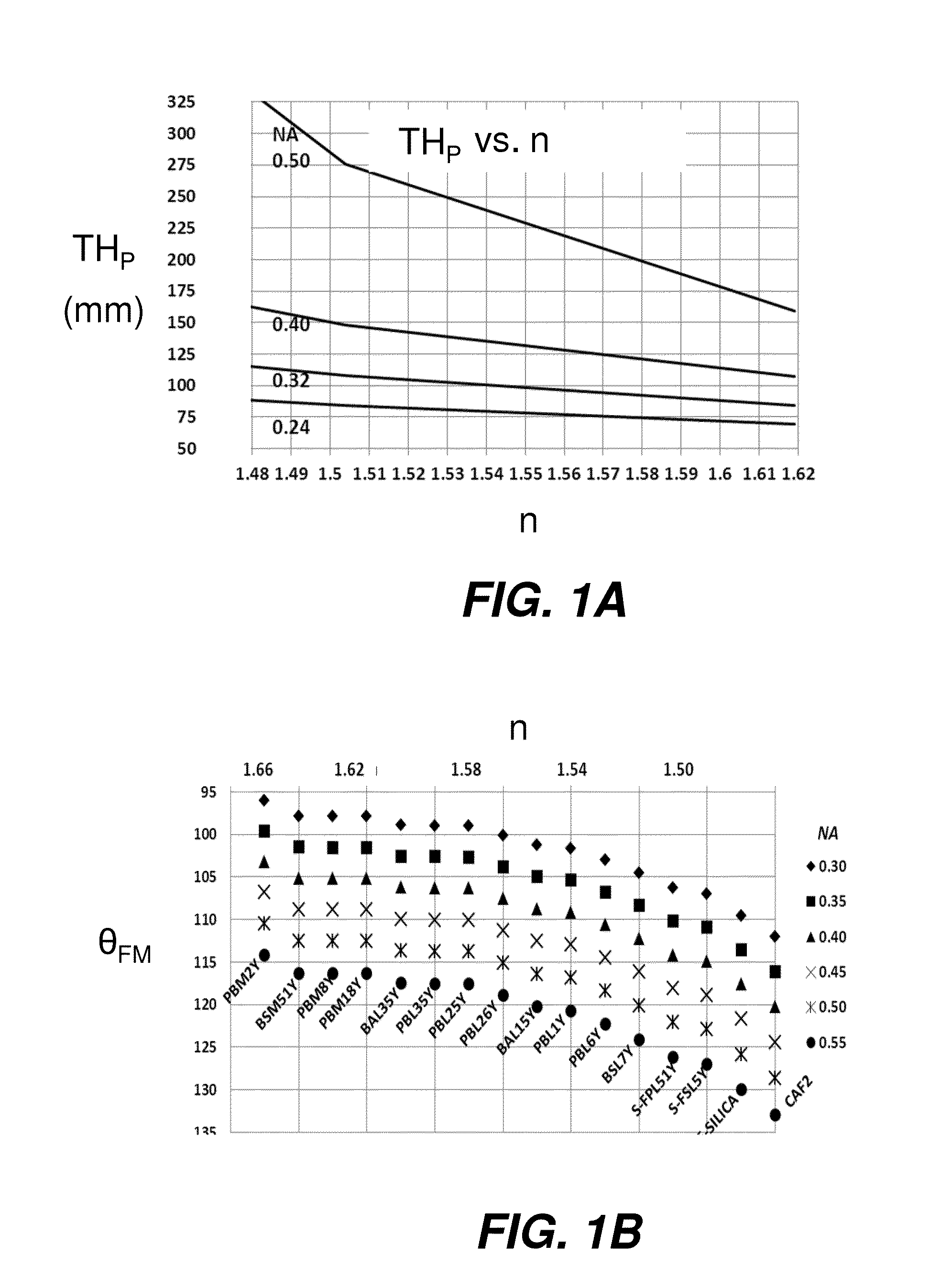

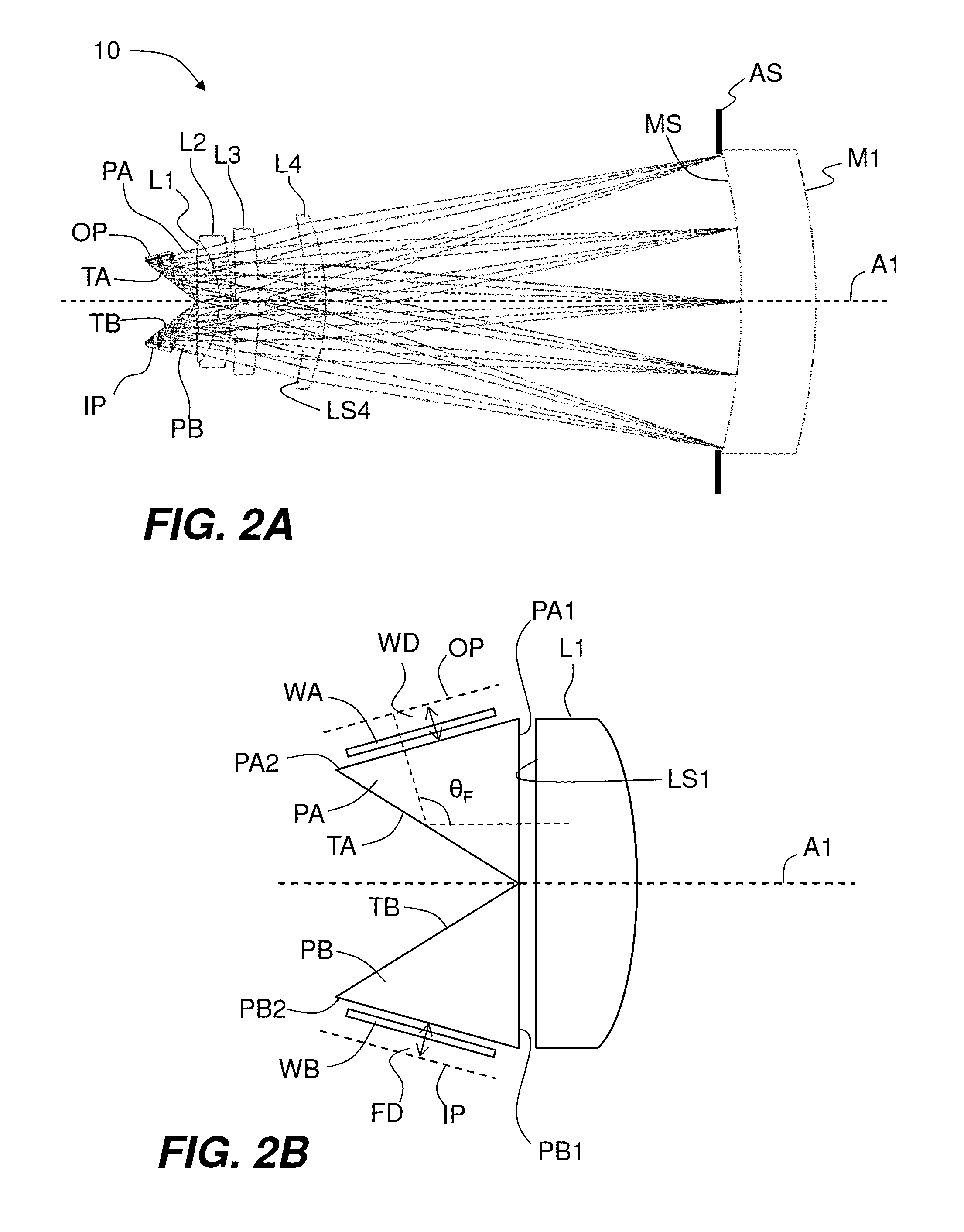

Unit magnification large-format catadioptric lens for microlithography

A unit magnification Wynn-Dyson lens for microlithography has an image field sized to accommodate between four and six die of dimensions 26 mm×36 mm. The lens has a positive lens group that consists of either three or four refractive lens elements, with one of the lens elements being most mirror-wise and having a prism-wise concave aspheric surface. Protective windows respectively reside between object and image planes and the corresponding prism faces. The lens is corrected for at least the i-line LED wavelength spectrum or similar LED-generated wavelengths.

Owner:VEECO INSTR

Action control device, action control method, imaging device, and program

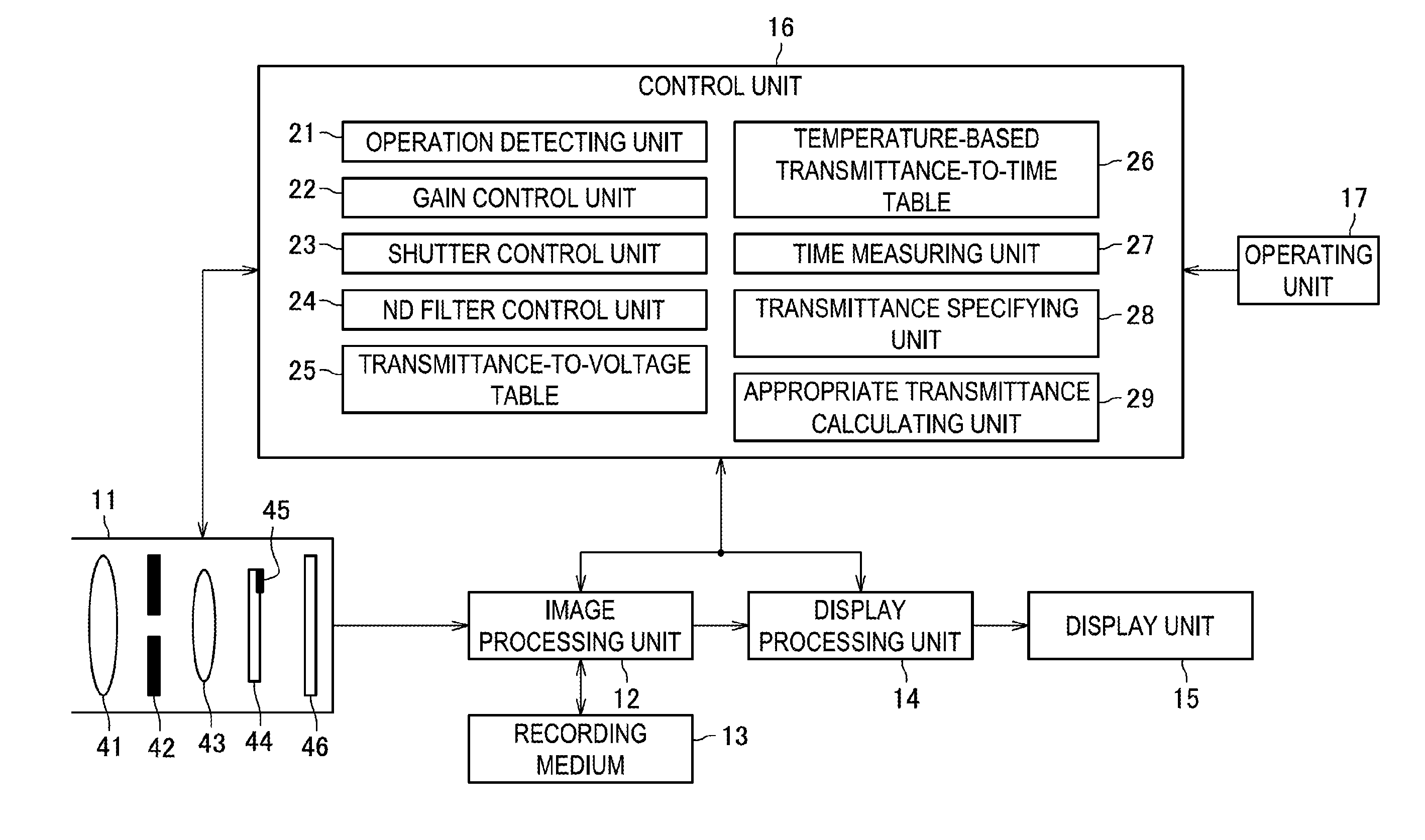

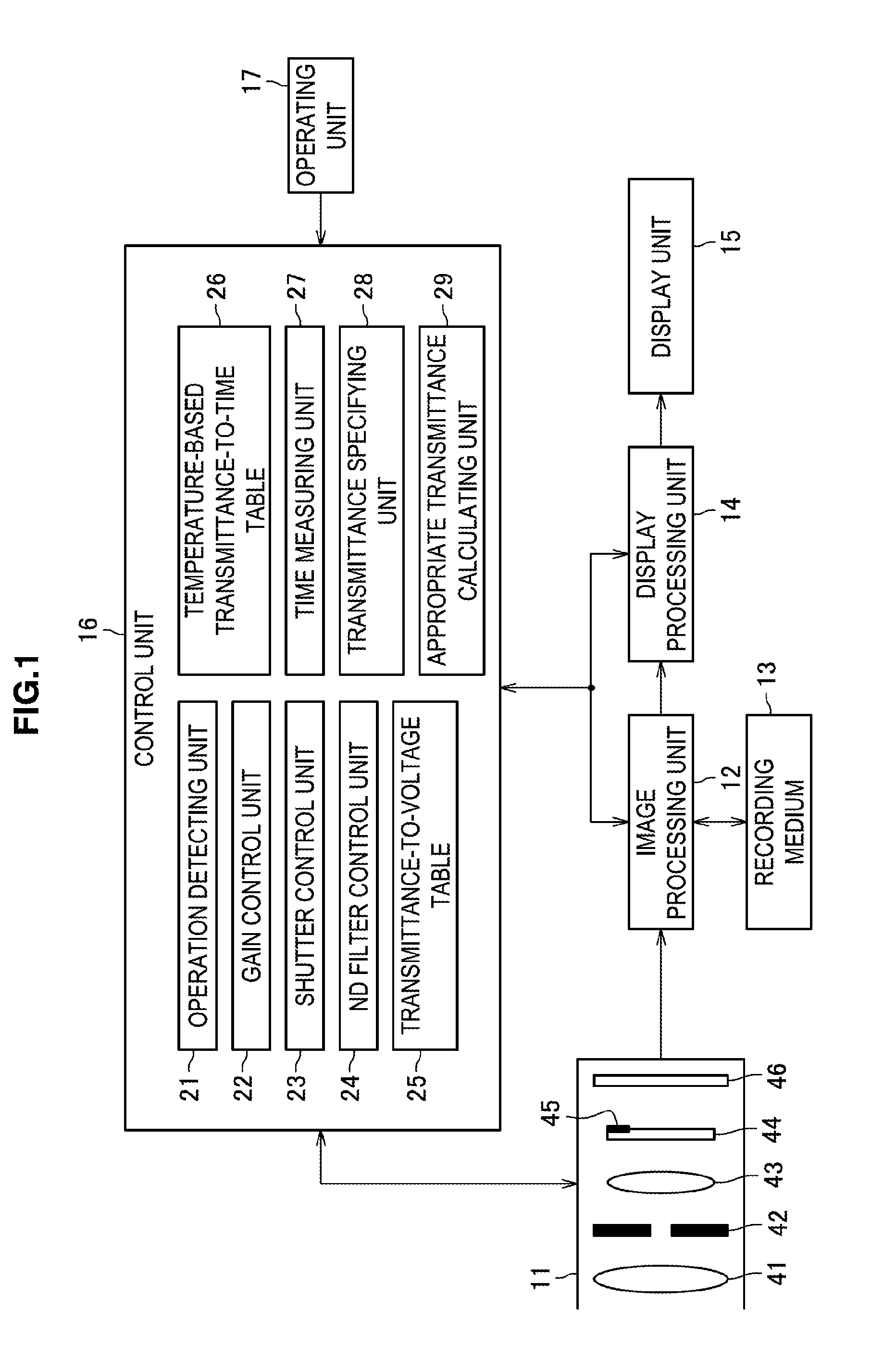

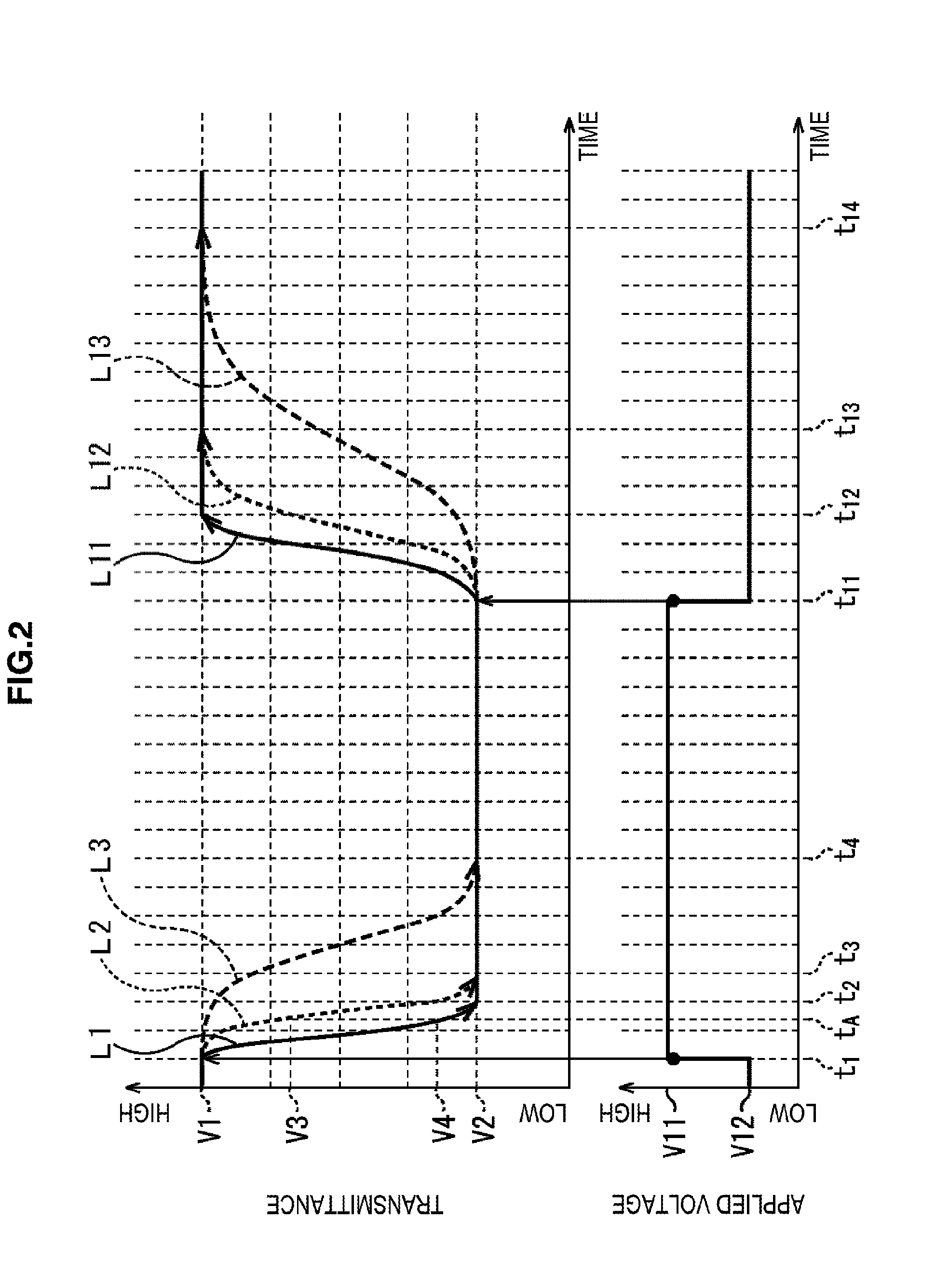

ActiveUS20140247386A1Reduce focus lagReduce focusTelevision system detailsStatic indicating devicesTransmittanceAction control

According to the first aspect of the present technology, there is provided an action control device, including a transmittance specifying unit configured to specify a transmittance of a variable-transmittance neutral density (ND) filter having a transmittance that varies according to an applied voltage, and an applied voltage control unit configured to control a voltage to be applied to the variable-transmittance ND filter such that the transmittance specified by the transmittance specifying unit is obtained. The applied voltage control unit controls the voltage to be applied to the variable-transmittance ND filter such that the transmittance of the variable-transmittance ND filter specified by the transmittance specifying unit is maintained at a timing at which an imaging preparation instruction or an imaging instruction is given.

Owner:SONY CORP

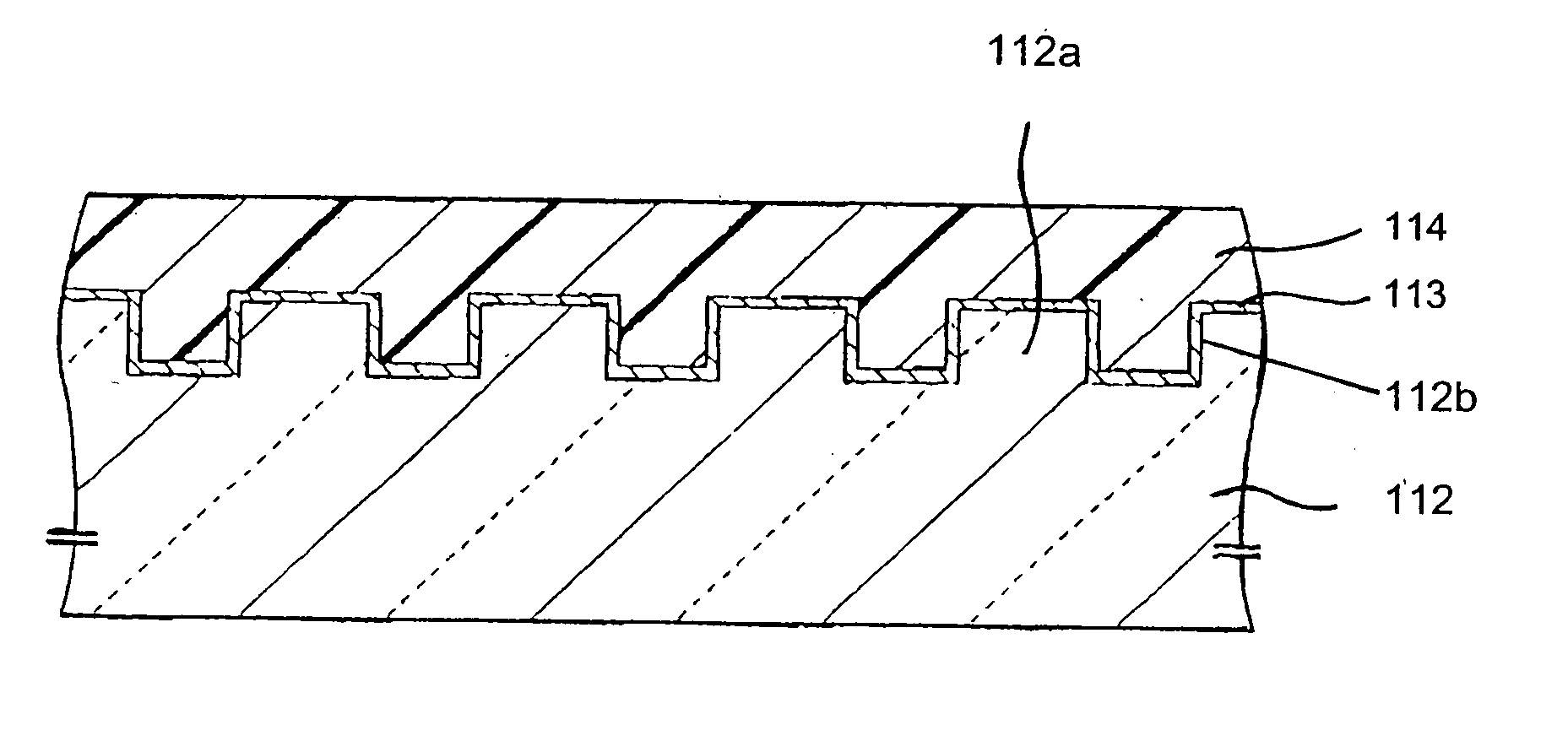

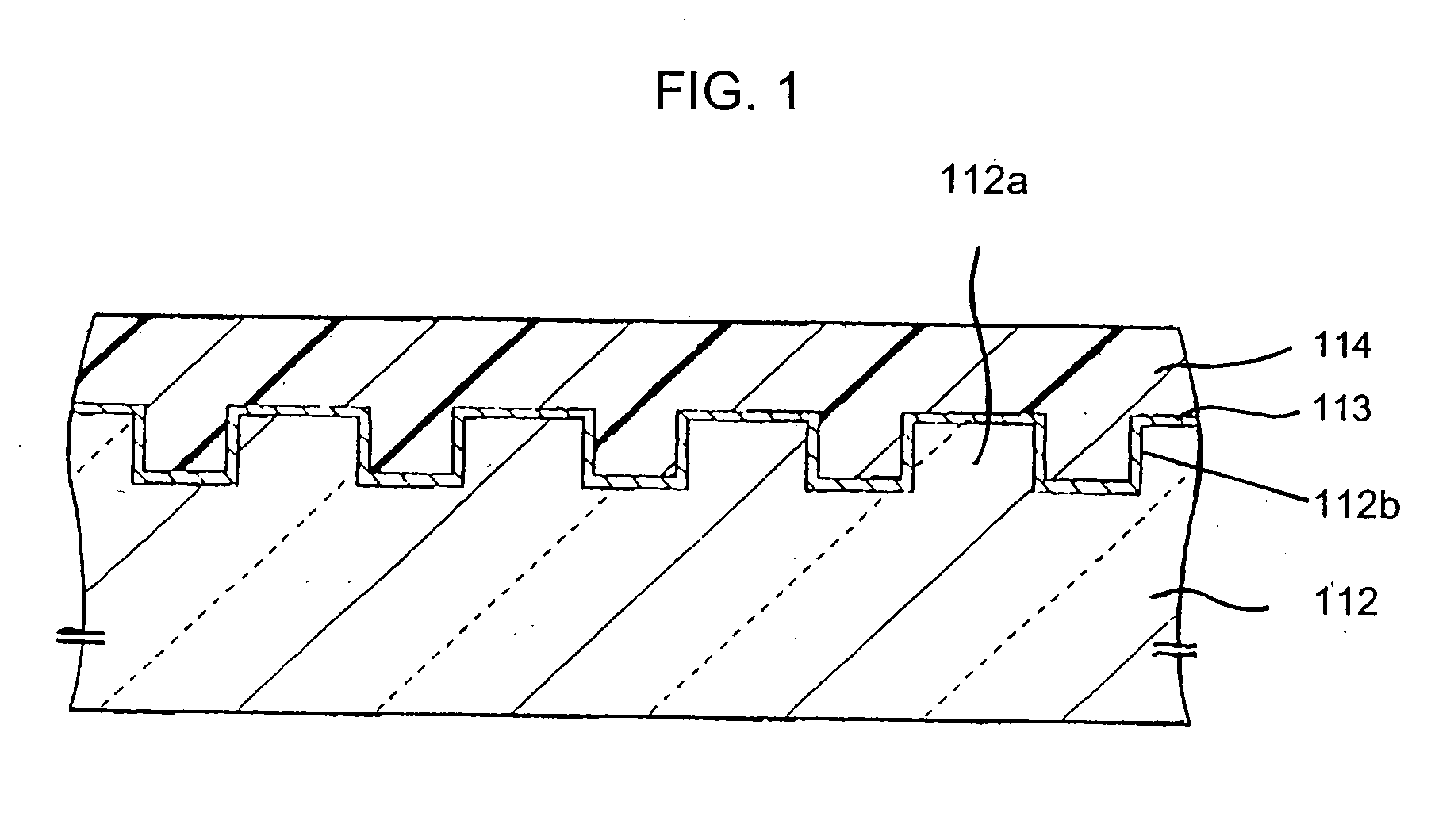

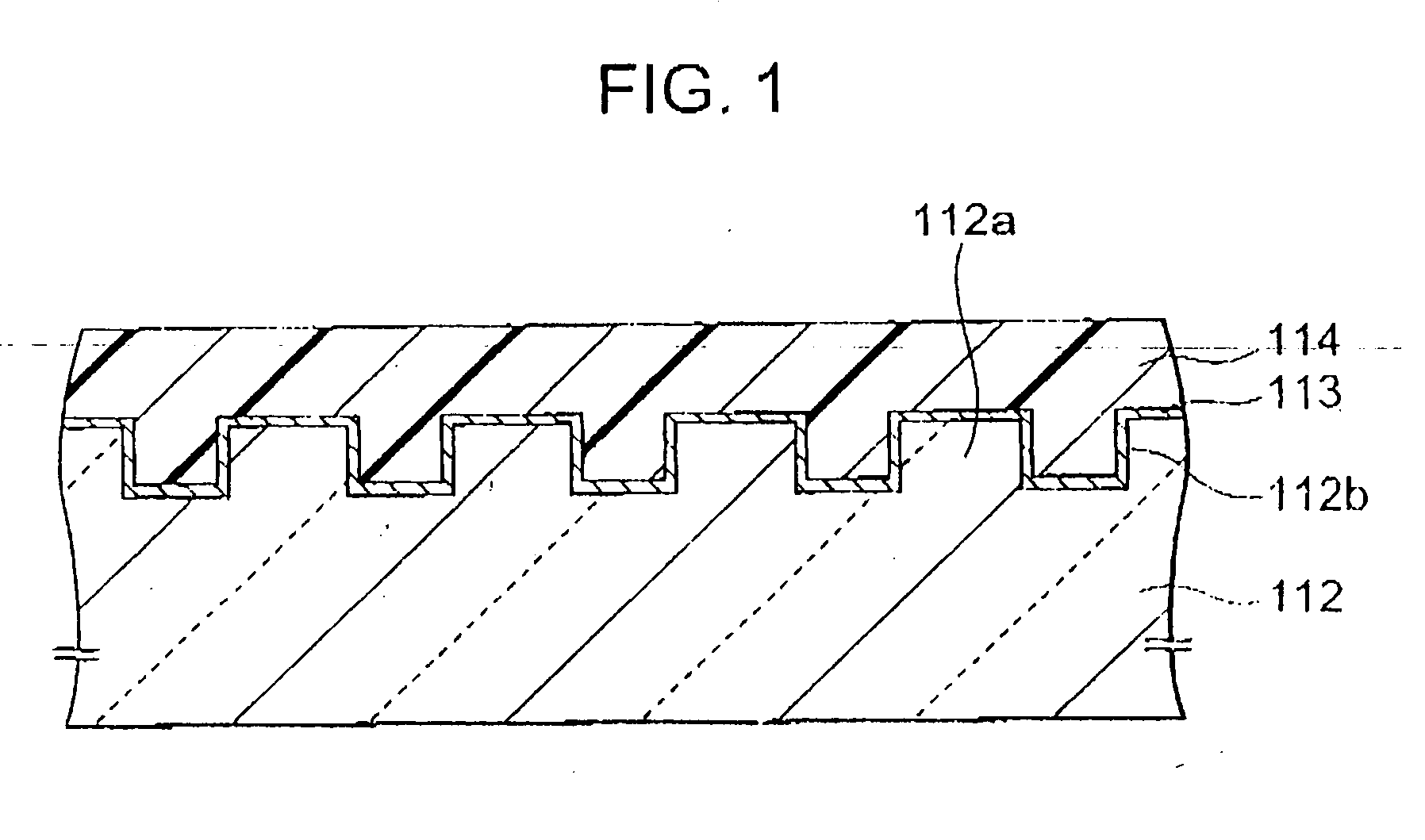

Stamper for producing optical recording medium, optical recording medium, and methods of producing the same

InactiveUS20050219992A1Reduce low frequency noiseReduce focusRecord carriersElectron beam carrier recordingResistUltraviolet

Owner:SONY CORP

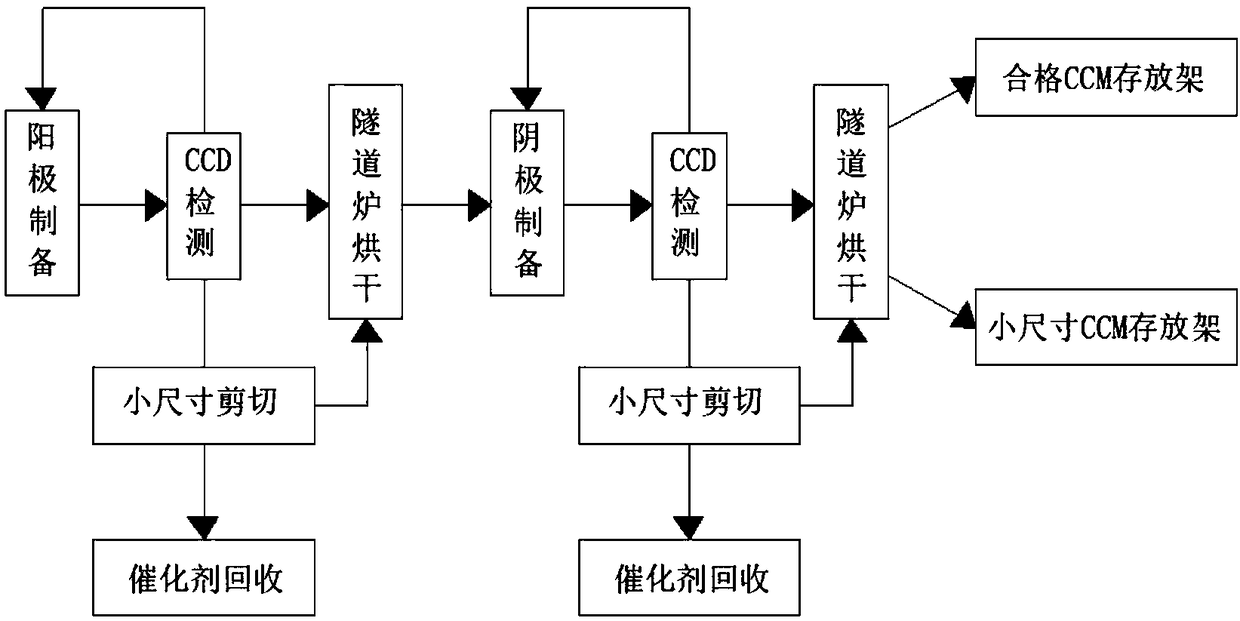

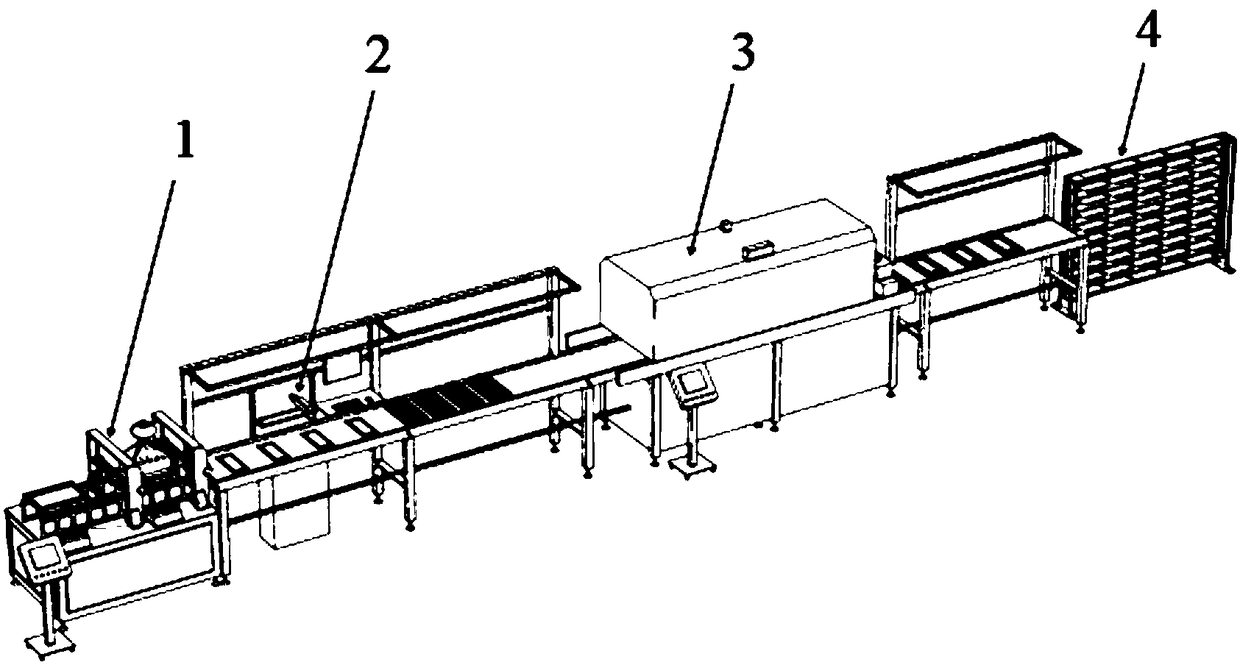

Batch production method of fuel cell membrane electrode

ActiveCN108365231AReduce focusUniform thicknessCell electrodesOptically investigating flaws/contaminationFuel cellsHeating furnace

The invention relates to a batch production method of a fuel cell membrane electrode. The batch production method comprises the following steps of (1) preparing a positive electrode catalyst layer membrane electrode in a membrane electrode positive electrode preparation region; (2) transferring the prepared membrane electrode into a CCD detection region, putting on a transparent glass plate tidily, and performing membrane electrode catalyst layer surface appearance detection; (3) transferring the prepared qualified membrane electrode into a drying region, and performing dust-free drying on thecatalyst layer by a tunnel heating furnace; and (4) transferring the membrane electrode into a negative electrode preparation region, and repeatedly executing the steps of (1)-(3) to prepare the fuelcell membrane electrode CCM with relatively high consistency. Compared with the prior art, the batch production method is simple in process and efficient and reliable; screening is performed in the initial stage of membrane electrode assembly (MEA) manufacturing, so that the manufacturing process of the CCM is optimized, the percent of pass of the CCM product is improved, and batch production canbe performed favorably; and in addition, the produced products are higher in consistency, the production cost of the fuel cell is lowered effectively, and the batch production method is suitable fora high-current-discharge fuel cell vehicle-mounted electric pile.

Owner:河南豫氢动力有限公司

Optical pickup capable of reducing focus offset and optical recording and/or reproducing apparatus employing the same

InactiveUS20050036432A1Reduce focus offsetReduce focusOptical beam sourcesOptical detectorsOptical pickupPhase difference

An optical pickup to reduce a focus offset by alleviating the effect of at least a part of a region of a beam whose intensity is high due to residual aberration on a signal detected by a photodetector even when the aberration remains in a beam received by the photodetector due to a phase difference introduced by a correcting element to compensate for spherical aberration.

Owner:SAMSUNG ELECTRONICS CO LTD

Live bacterial preparation of bacillus coagulans for the treatment of ulcerative colitis, method for producing the same and use thereof

The present invention discloses a method for preparation of live Bacillus coagulans and the use of the bacteria in treatment of ulcerative colitis. The live bacteria are effective in the treatment of experimental ulcerative colitis in rats. They are also used in the clinical treatment of patients suffering from ulcerative colitis and the efficacy and safety are evaluated. The present invention also discloses the formulation and production method of the live bacterial preparation of Bacillus coagulans, the count of live bacterial in the preparation, and dosage form of the preparation. The present invention shows that the live bacterial preparation is effective and safe for treatment of ulcerative colitis, and the stability of said preparation is good and could be stored at room temperature. Patients can take the preparation for a long term without adverse effect. The present invention provides a new means for the treatment of ulcerative colitis and a new use of live bacterial preparation of Bacillus coagulans in treating ulcerative colitis.

Owner:QINGDAO EASTSEA PHARMA +1

Optical pickup control apparatus, optical pickup control method, and optical disc apparatus

InactiveUS7344077B2Reduce aberrationReduce focusCombination recordingDisposition/mounting of recording headsOptical pickupMeasurement point

Owner:SONY CORP

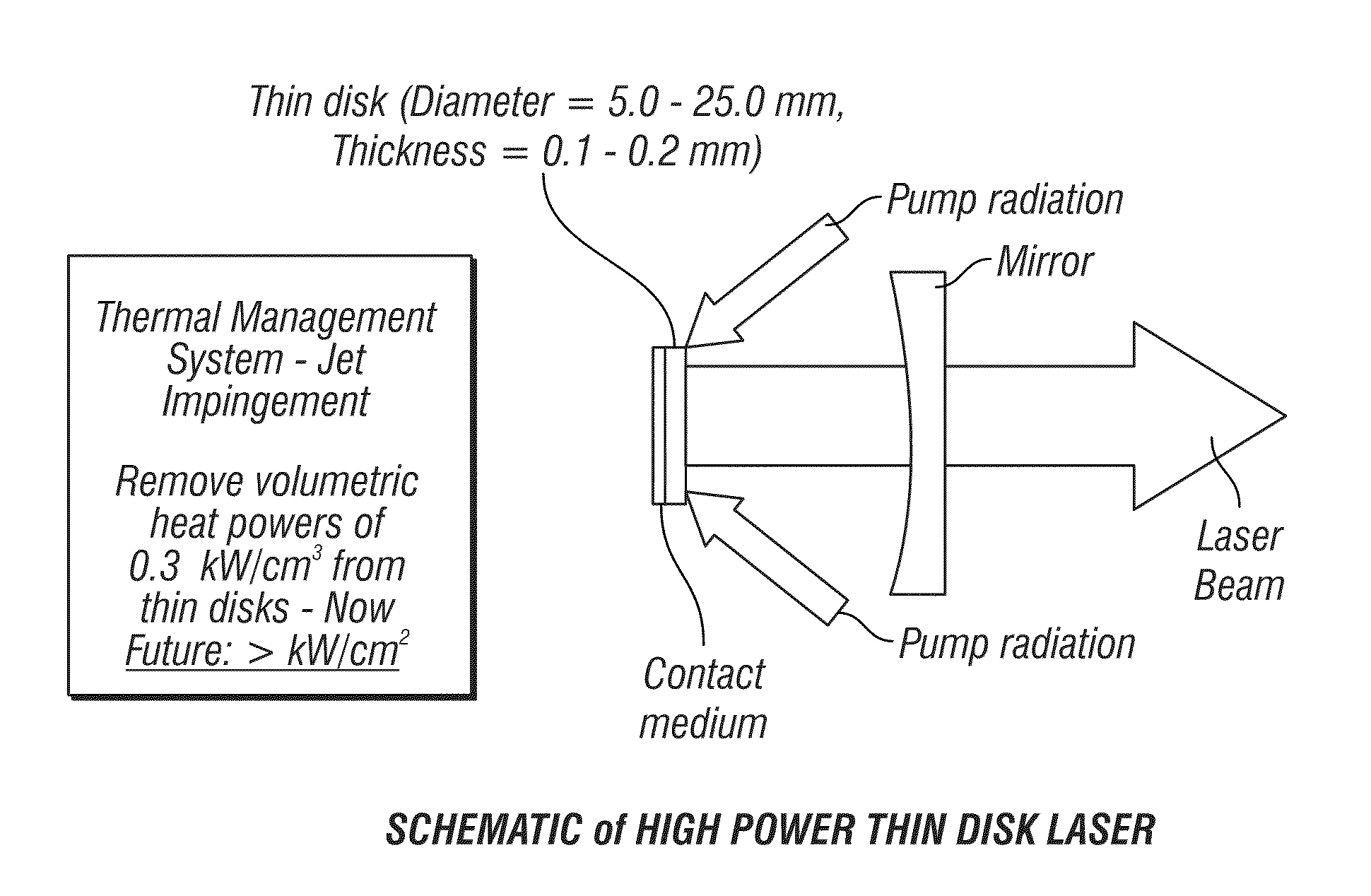

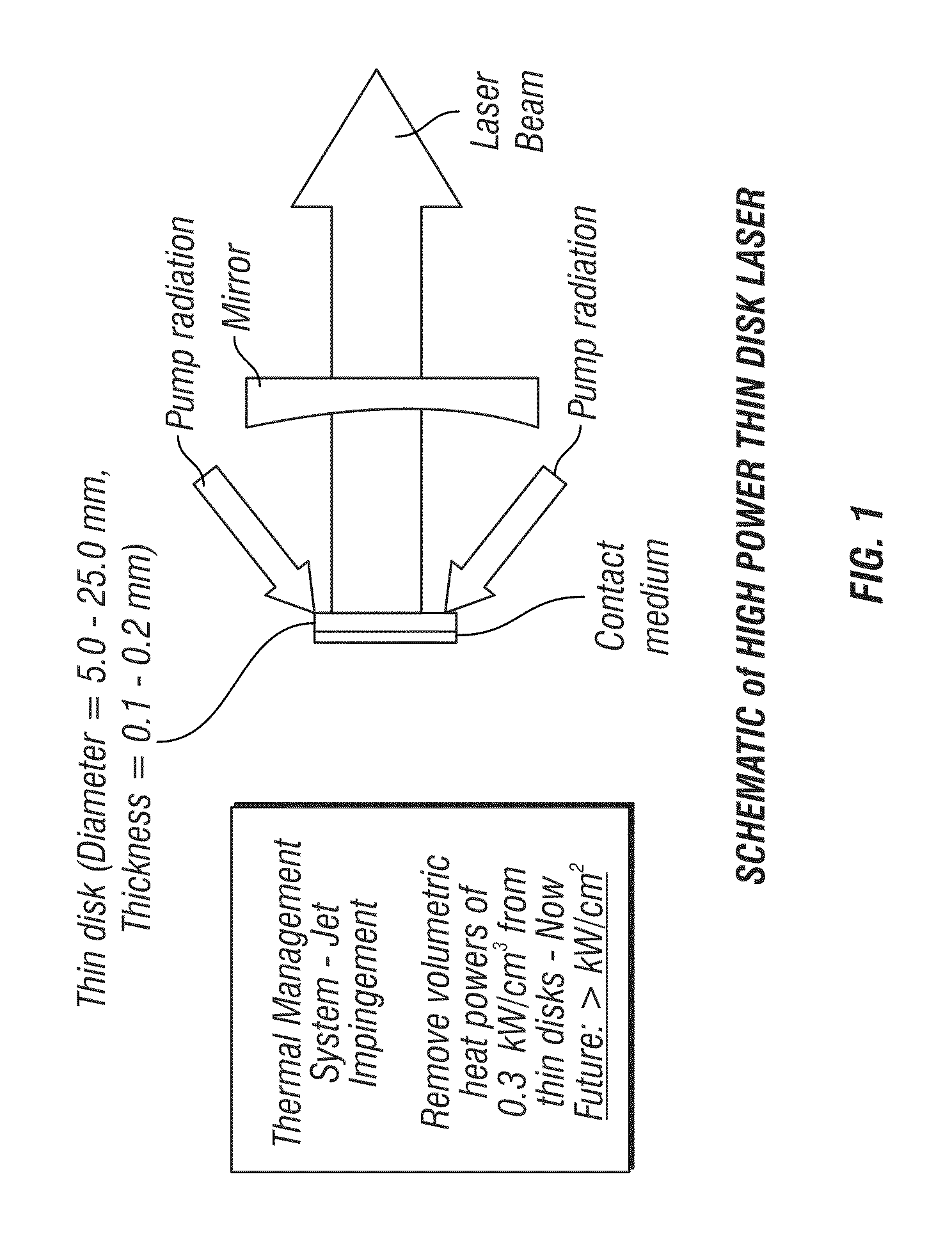

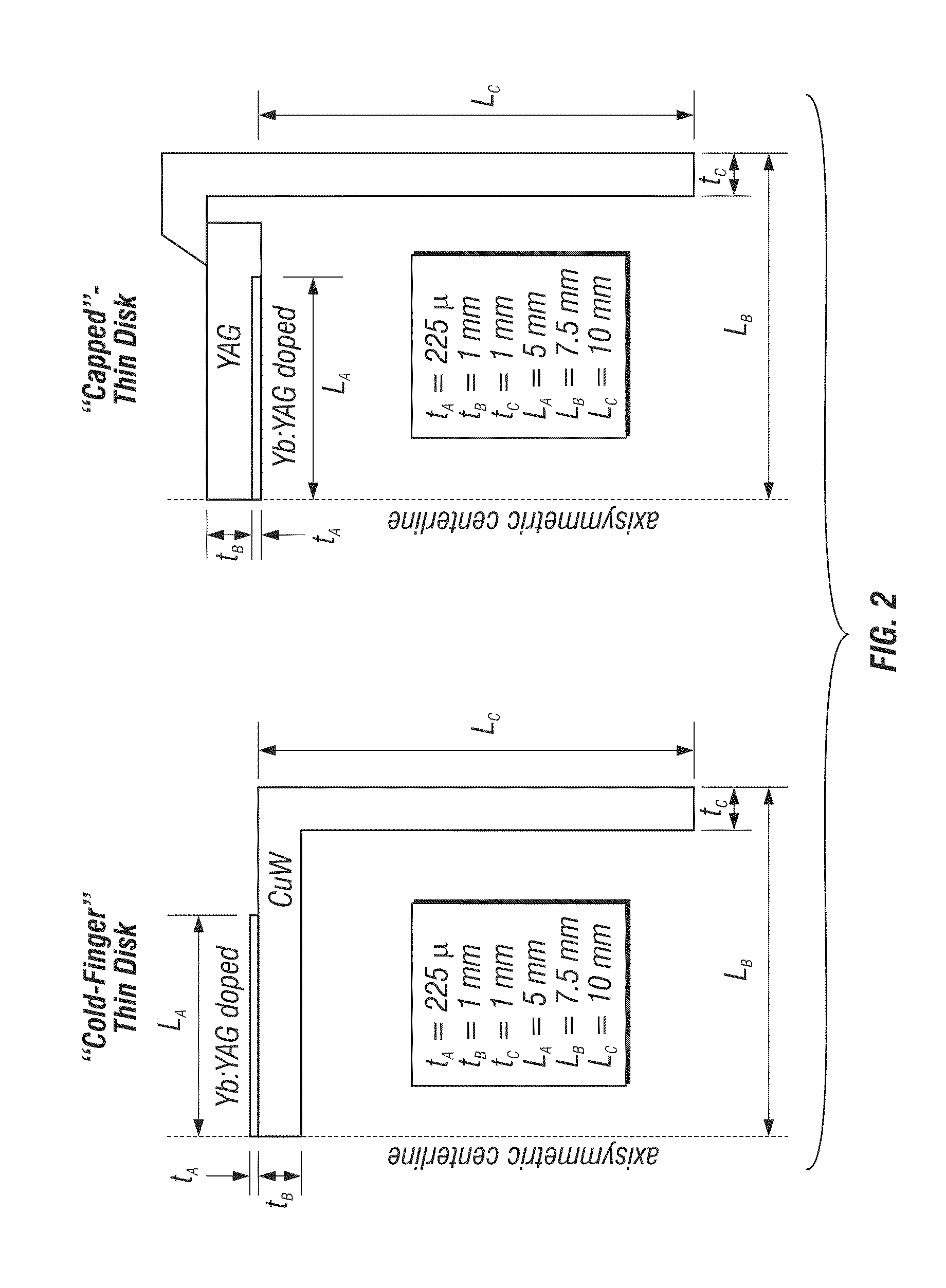

Thin disk laser operations with unique thermal management

ActiveUS8213471B2Effective thermal conductivityImprove performanceActive medium shape and constructionLaser cooling arrangementsThermal expansionCeramic

Owner:INTEGRAL LASER SOLUTIONS +1

Image capturing apparatus and control method thereof

ActiveUS20130300895A1Suppresses reduction in focus detectionReduce focusTelevision system detailsColor television detailsExposure controlControl area

An image capturing apparatus comprises: a sensor that photoelectrically converts incidence light and outputs an image signal; a focus control unit that performs focus control based on a contrast of the image signal corresponding to each of a plurality of focus control areas set within an image capturing area; a counting unit that detects and counts, from among the plurality of focus control areas, high luminance focus control areas indicating a luminance of at least a predetermined luminance; and an exposure control unit that performs exposure control, in a case where the counted number is a first number, so as to reduce an exposure amount of the sensor to less than when the counted number is a second number that is smaller than the first number, the exposure control being performed before the focus control by the focus control unit.

Owner:CANON KK

Stamper for producing optical recording medium, optical recording medium, and methods of producing the same

InactiveUS20050167868A1Reduce low frequency noiseImproving crosstalk characteristicRecord carriersVacuum evaporation coatingResistUltraviolet

A stamper suppressed in surface roughness, uneven thickness, and deviation of circularity in inner circumference, a method of producing the same, an optical recording medium produced by molding using the stamper, and a method of producing the same, wherein a base member having a mirror polished main surface and comprising silicon or glass is formed with a resist film; the resist film is exposed by a focused electron beam, an ultraviolet ray laser, etc. and developed so as to form a resist film of a pattern corresponding to relief shapes; the mirror surface of the base member is processed to relief shapes (projecting regions and recessed regions) by dry etching etc. using the obtained resist film as a mask so as to obtain a stamper; the obtained stamper is used for injection molding to form a medium substrate; and an optical recording multilayer film and a protective layer are formed to thereby produce an optical recording medium.

Owner:SONY CORP

Resolution For Autostereoscopic Video Displays

ActiveUS20150015685A1Well focusFocusColor television detailsSteroscopic systemsAutostereogramImage resolution

A single pixel of a video display can display respective individual pixels of multiple views. In other words, a video display can include more views for an autostereoscopic image than the physical pixels of the video display would ordinarily support. The physical pixel is time-multiplexed in that the physical pixel displays a pixel of one view for a given time interval and a view multiplexer deflects the light from the physical pixel by a predetermined angle to make the pixel appear in a location corresponding to the pixel of the view. In another time interval, the physical pixel displays a pixel of a different view and the view multiplexer deflects light from the physical pixel by a different predetermined angle to make the pixel appear in a location corresponding to the pixel of the different view.

Owner:SOLIDDD

Adjusting method of image reading apparatus and image reading apparatus

InactiveUS7505184B2High image informationReduce focusPhotographic printingPictoral communicationFlat glassCamera lens

An image reading apparatus in which an original is illuminated with visible light and with infrared light, and in which a lens assembly forms an image of the original on the surface of a reading device such as a CCD. The lens assembly is housed in a lens barrel. A focus correcting device such as a flat glass or resin plate is movably mounted to the lens barrel, so as to correct defocus of the original on the surface of the reading device due to differences in wavelength between the visible light and the infrared light. The lens assembly includes a resin lens which is disposed on a side of the lens assembly nearest to the reading device, and which is mounted in close proximity to the focus correcting device.

Owner:CANON KK

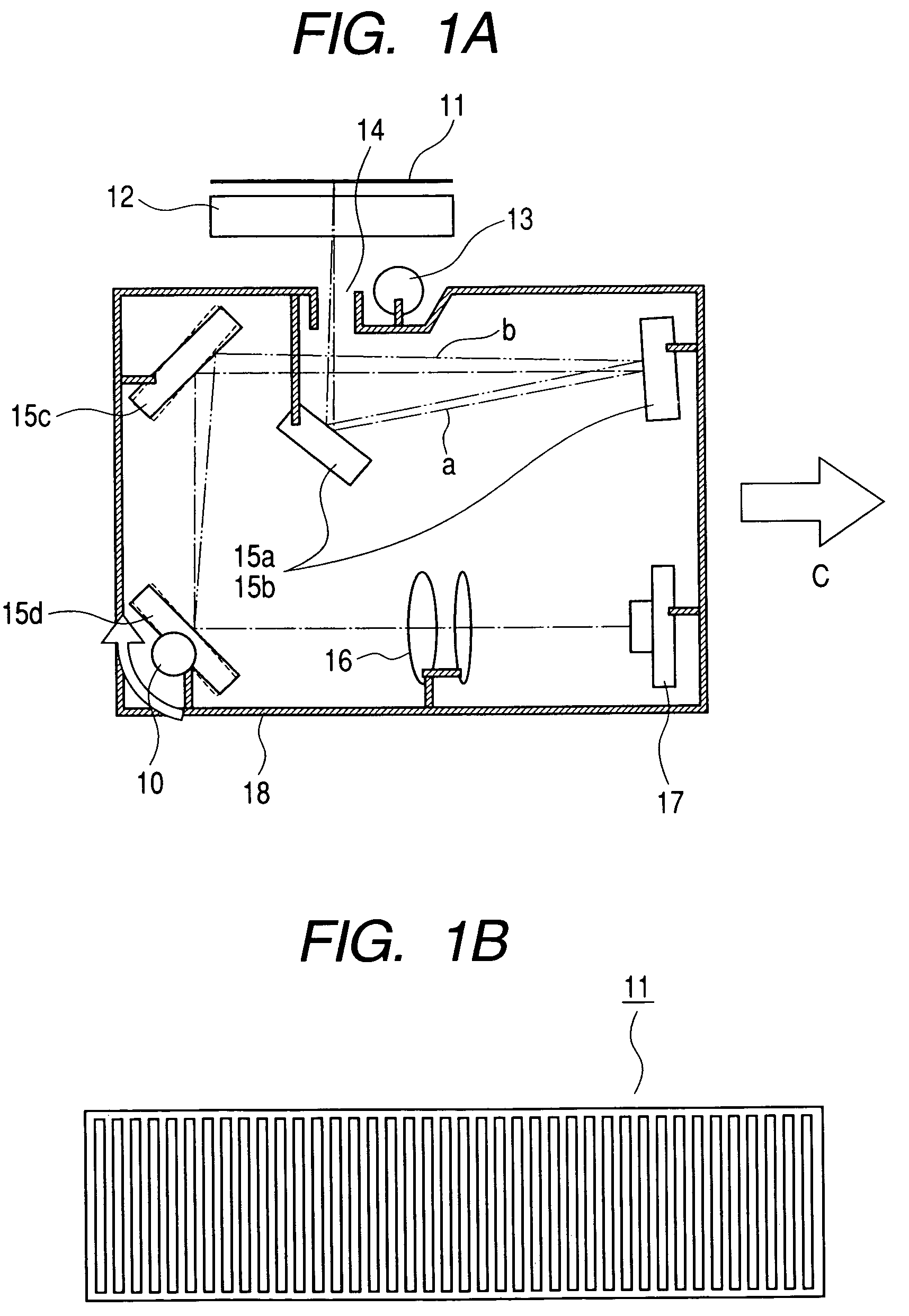

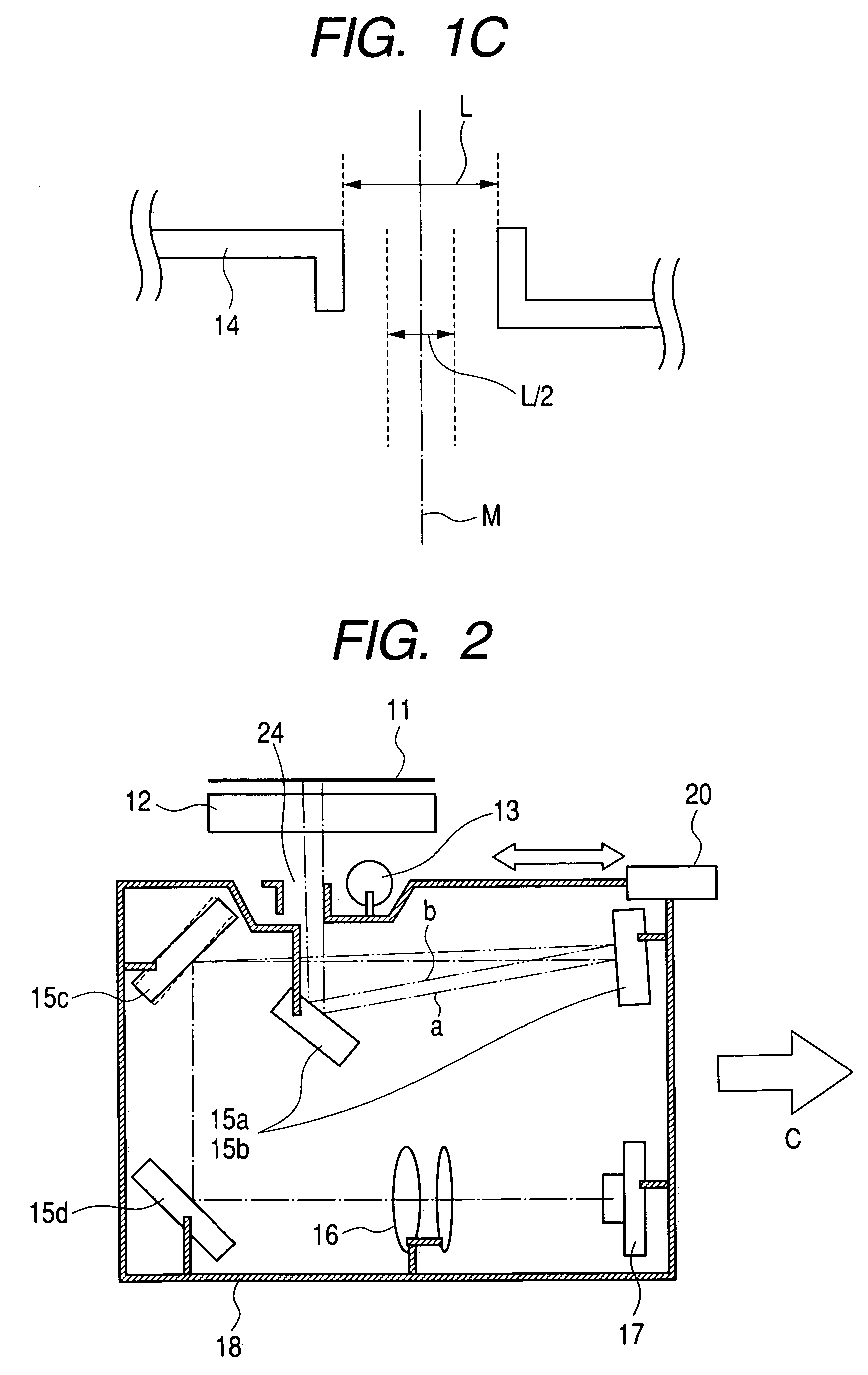

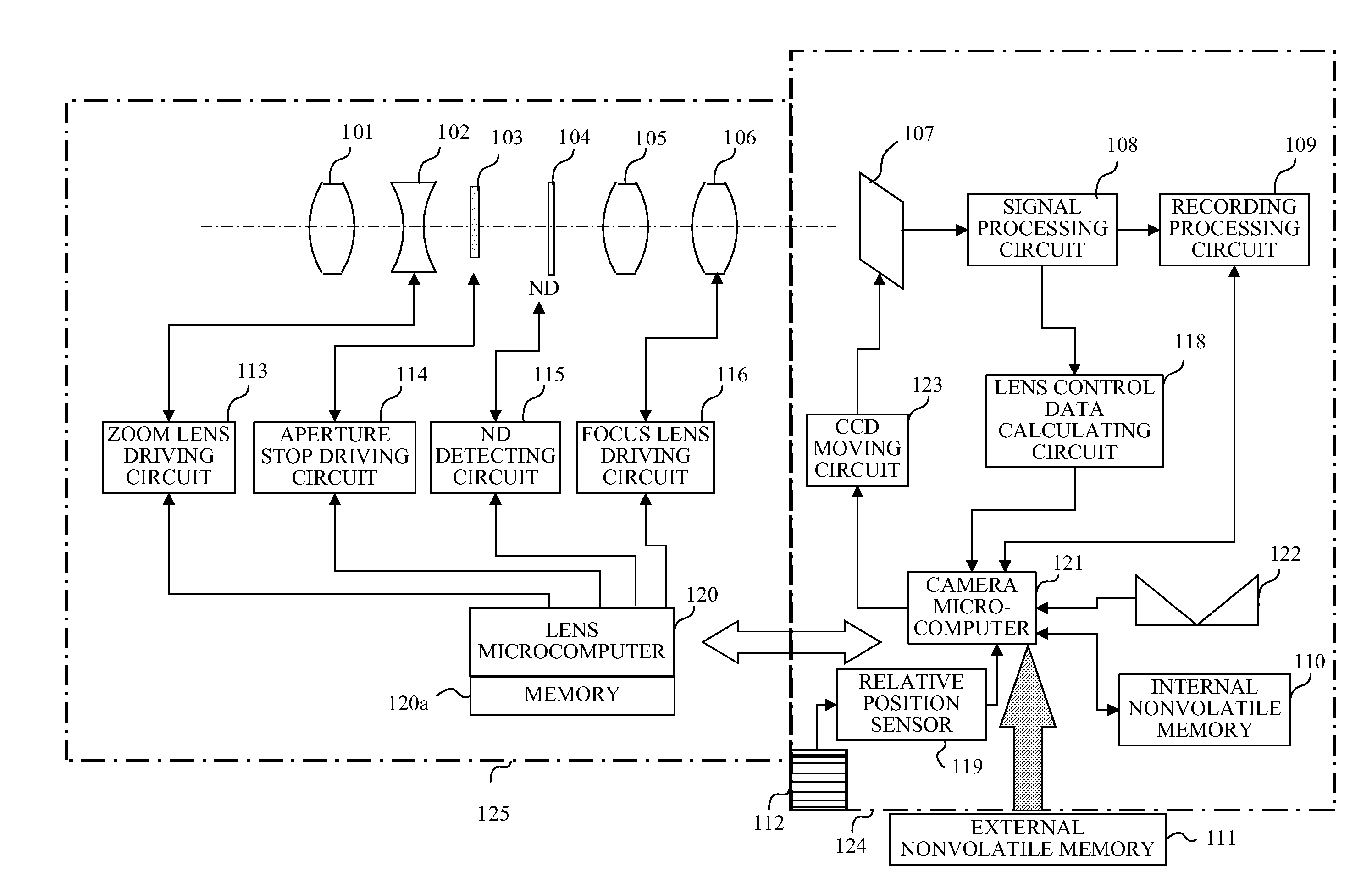

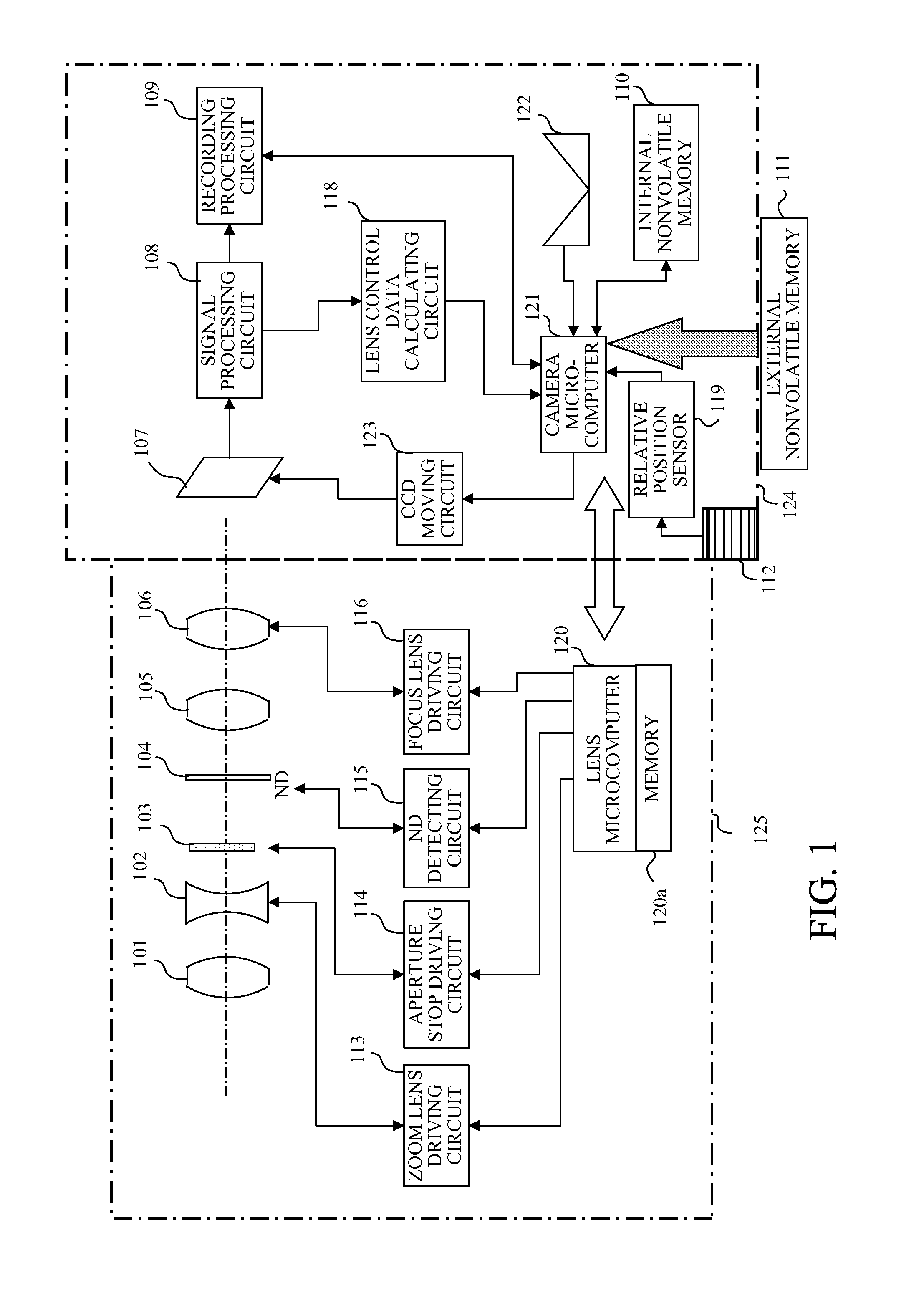

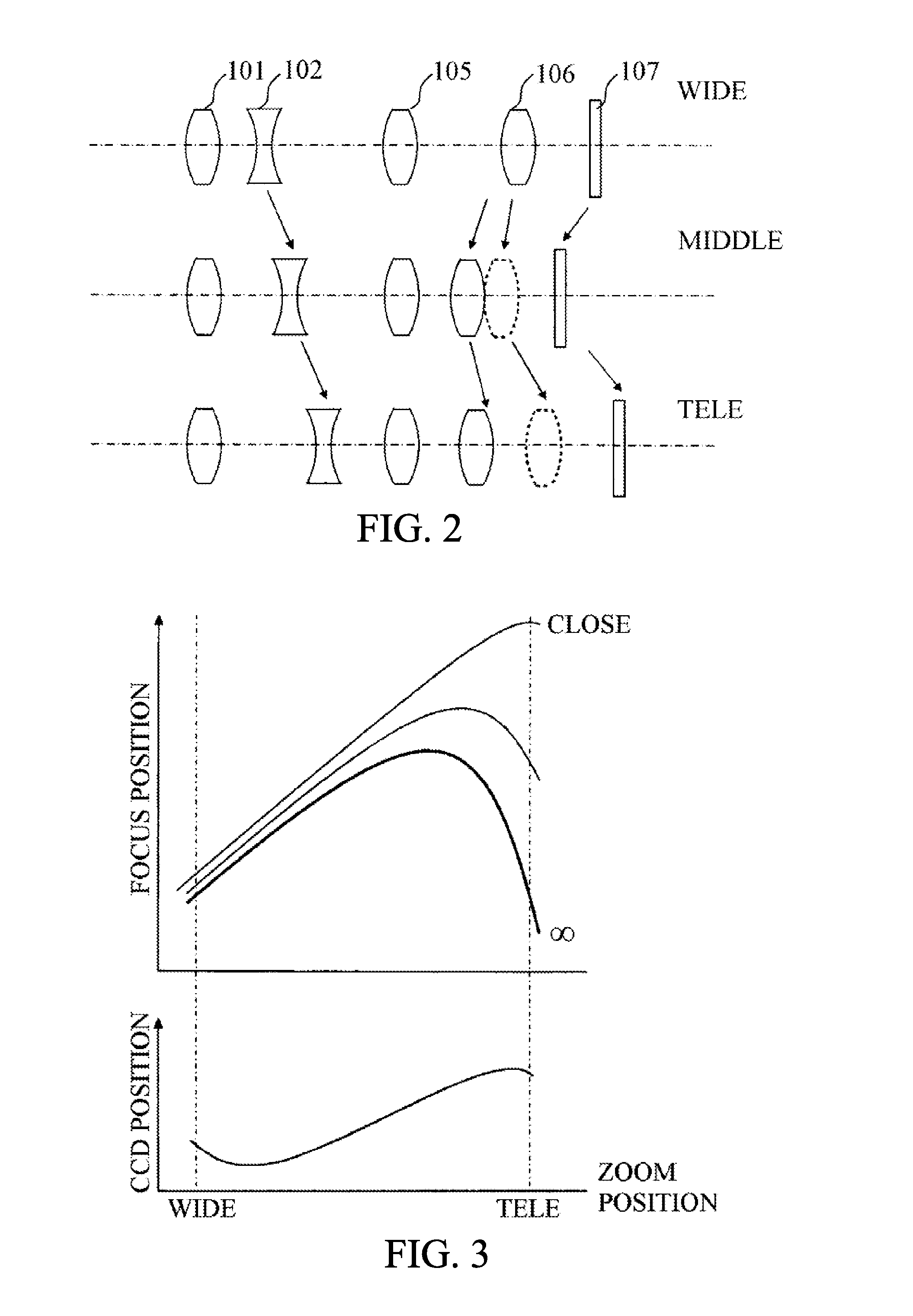

Image pickup system, camera and interchangeable lens

InactiveUS20120044409A1Reduce variationReduce focusTelevision system detailsProjector focusing arrangementCamera lensImage sensor

The image pickup system includes a camera and an interchangeable lens having an image-taking optical system. The camera includes an image sensor to photoelectrically convert an object image formed by the image-taking optical system and to be moved in an optical axis direction, and a camera controller configured to control movement of the image sensor such that focus variation caused due to variation of magnification of the interchangeable lens is reduced. The camera controller is configured to acquire image sensor moving data corresponding to the interchangeable lens attached to the camera, and controls the movement of the image sensor by using the image sensor moving data.

Owner:CANON KK

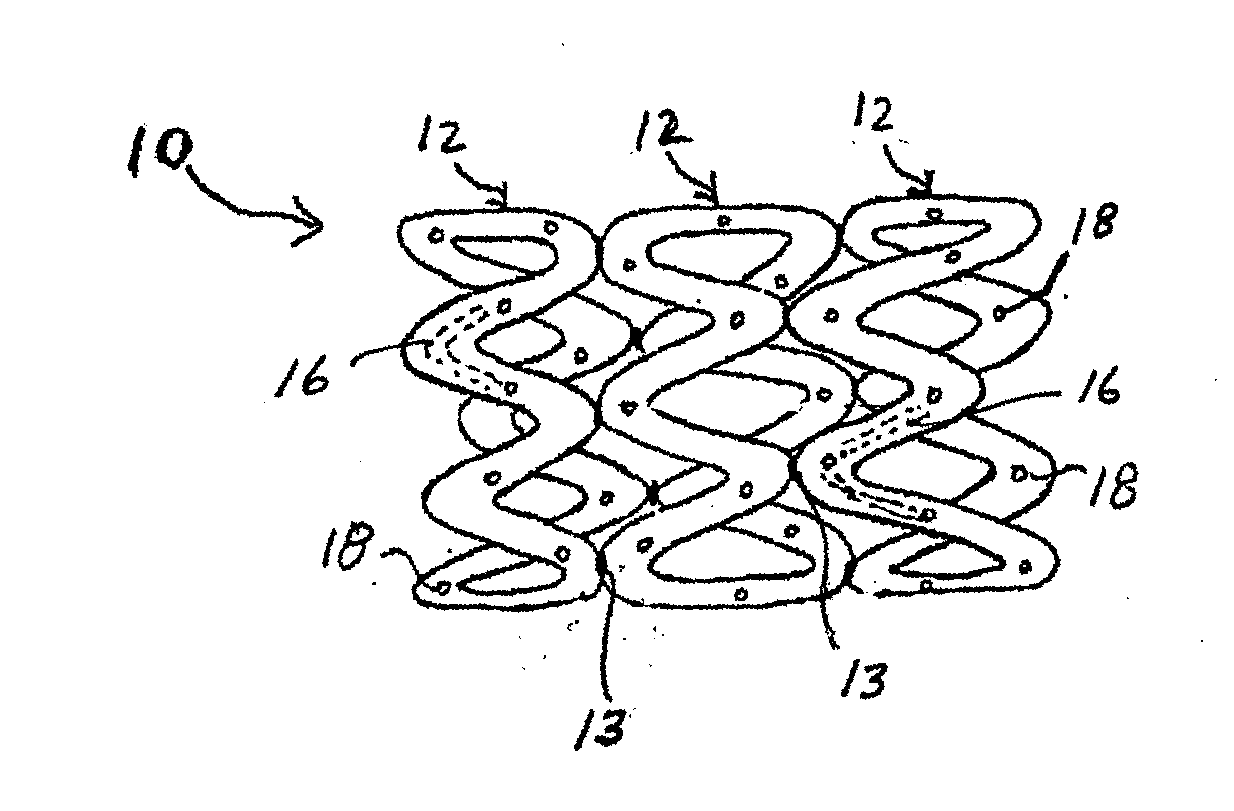

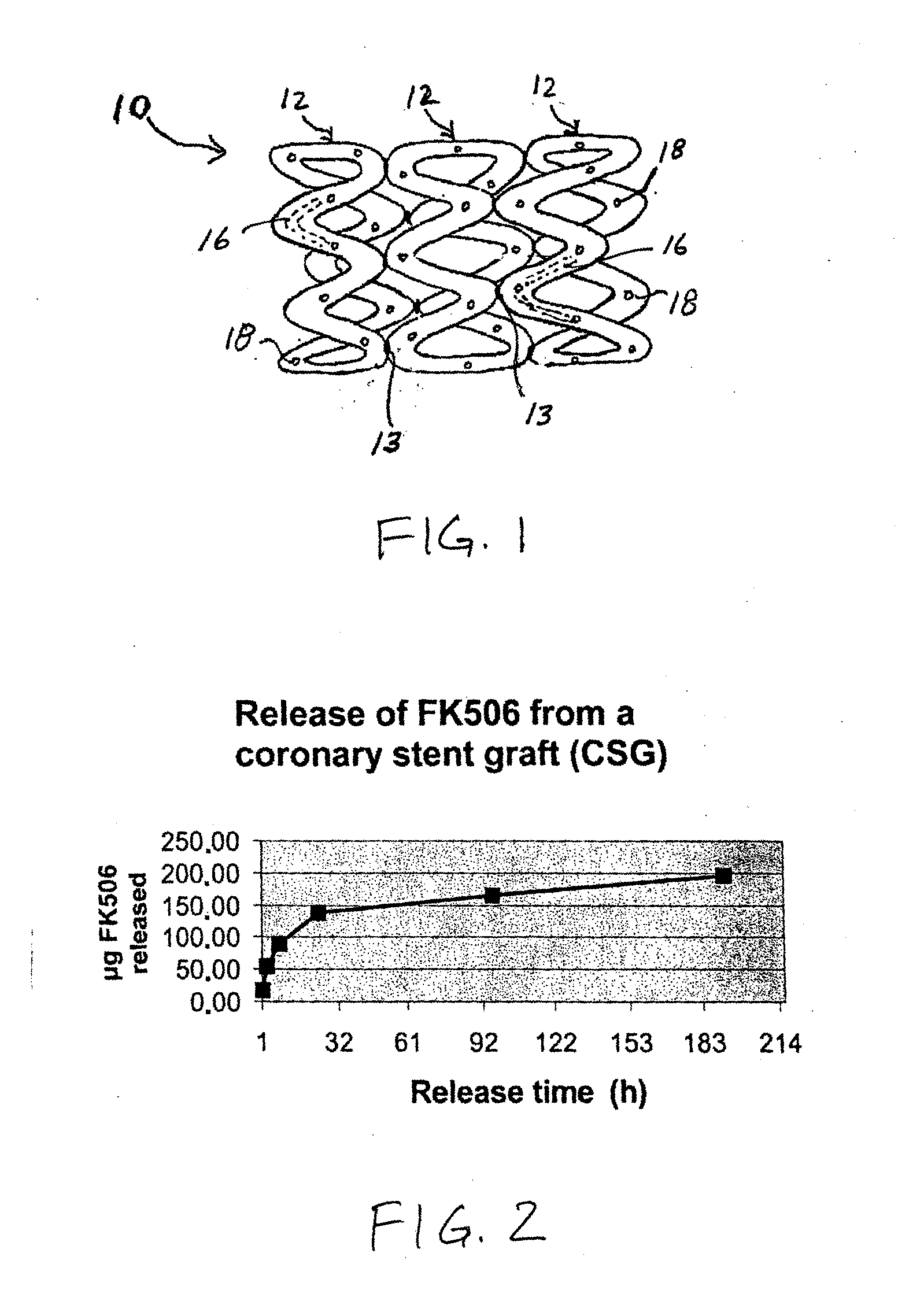

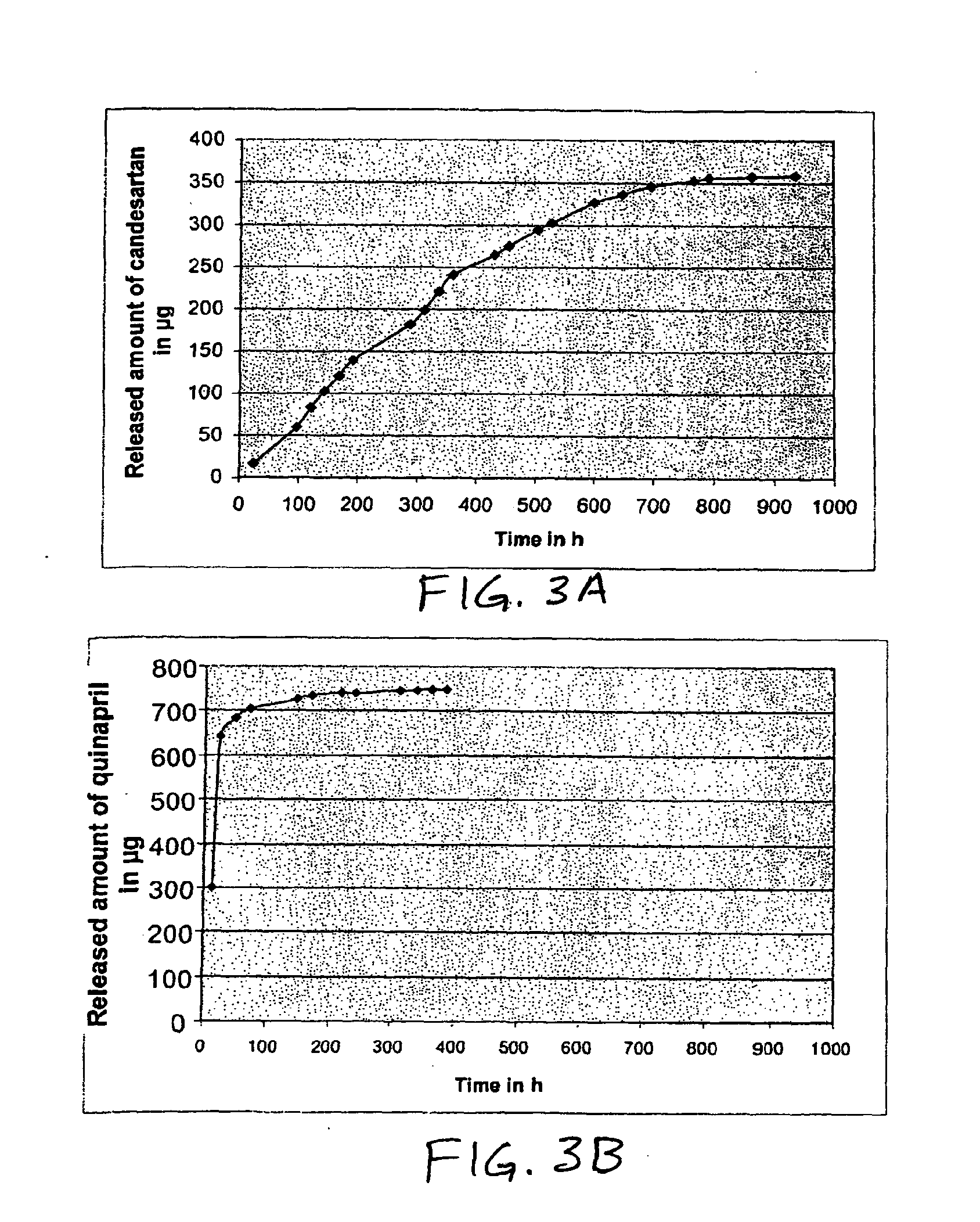

Medical implants containing fk506 (tacrolimus) methods of making and methods of use thereof

Implants and methods of making same are provided for treatment or prophylaxis of coronary or peripheral vascular constrictions or vascular occlusions, and particularly, stenoses or restenoses, that comprise FK506 in chemically covalently bound, non-covalently bound or physically immobilized form.

Owner:ASTELLAS PHARMA INC +1

Structured illumination ophthalmoscope

ActiveUS20150297076A1Reduce focusInfluence of disturbance can be reducedOthalmoscopesControl mannerOphthalmoscopes

A method for non-invasive observations of a fundus using an ophthalmoscope is provided. The method includes illuminating a retinal region of an eye by projecting an illumination pattern of illumination light onto the retinal region, at least one of detecting a portion of fluorescent light emitted from the retinal region and detecting a portion of illumination light reflected from the retinal region, thereby capturing a series of images of the retinal region at a plurality of different relative positions of the retinal region with respect to the illumination pattern projected onto the retinal region, wherein between the capturing of at least two images of the series the relative position of the retinal region with respect to the illumination pattern projected onto the retinal region is shifted in a non-controlled manner, and processing the captured images to extract a sub-resolution image of the retinal region.

Objective lens, nosepiece and inverted microscope equipped therewith

ActiveUS20100091363A1Reduce focus shiftReduce focusMicroscopesMountingsImaging lensInverted microscope

An objective lens to be fitted into a fitting hole of a nosepiece of a microscope includes an imaging lens that is composed of a plurality of lens groups, and a lens barrel that holds the imaging lens. The lens barrel is formed with a fitting portion that is fitted to the fitting hole of the nosepiece and provided at an outer circumference of a tip portion side away by a given distance from the tip portion where a first lens group in the imaging lens is held, and a mount surface that comes into contact with a contact surface of the fitting hole of the nosepiece upon fitting at the fitting portion. The nosepiece is equipped with the objective lens. The inverted microscope is equipped with the nosepiece fitting the objective lens.

Owner:NIKON CORP

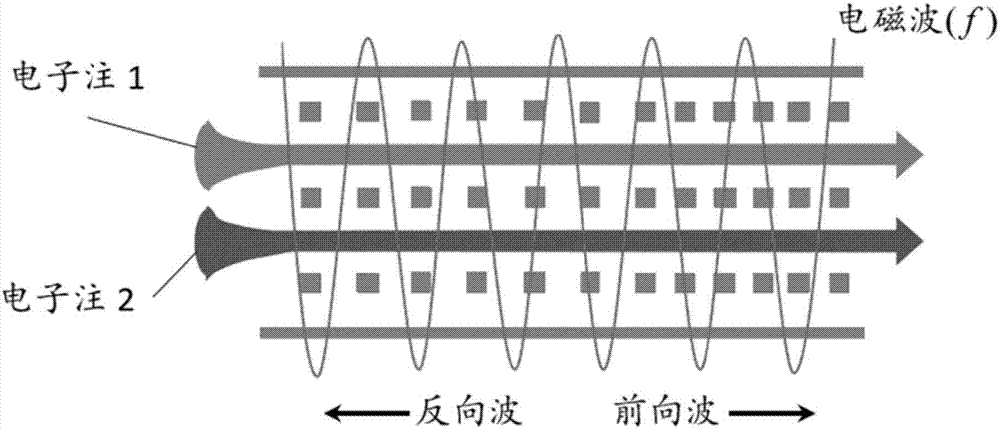

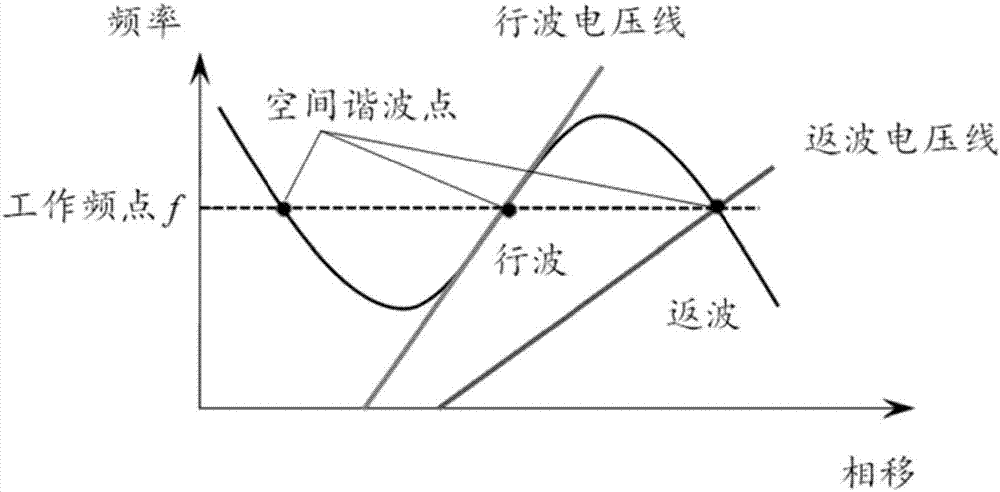

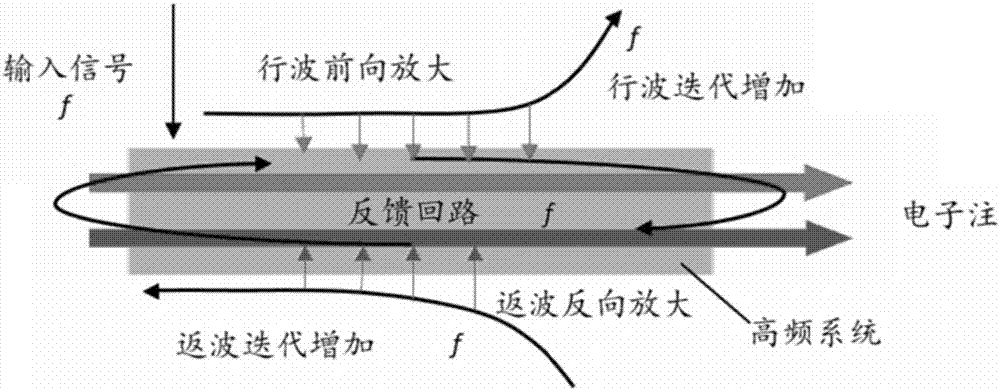

Dual-electron injection terahertz folded travelling-backward wave amplifier

ActiveCN107968031AHigh energyEasy to zoom inTravelling-wave tubesTransit-tube circuit elementsAudio power amplifierElectron injection

The invention discloses a dual-electron injection terahertz folded travelling-backward wave amplifier, and is applied to the technical field of vacuum electron. A mutual effect of two beams of round electron injection with different speeds and the same-frequency electromagnetic wave is employed, working voltages of the two beams of electron injection are respectively synchronized with a forward space harmonic and a reverse space harmonic, an electromagnetic wave signal of which a travelling wave is amplified is propagated forwards, then acts on an oscillation loop of a backward wave and is used as an input signal of the backward wave so as to form a folding loop, an amplified travelling wave signal in a feedback loop acts in the travelling wave to promote amplification of the travelling wave, thus, the electromagnetic wave in a slow wave circuit can participate in amplification of the travelling wave and is simultaneously participate in amplification of the backward wave to form a nature feedback passage, and the energy of the device can be continuously increased unit the beam-wave interaction power is saturated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

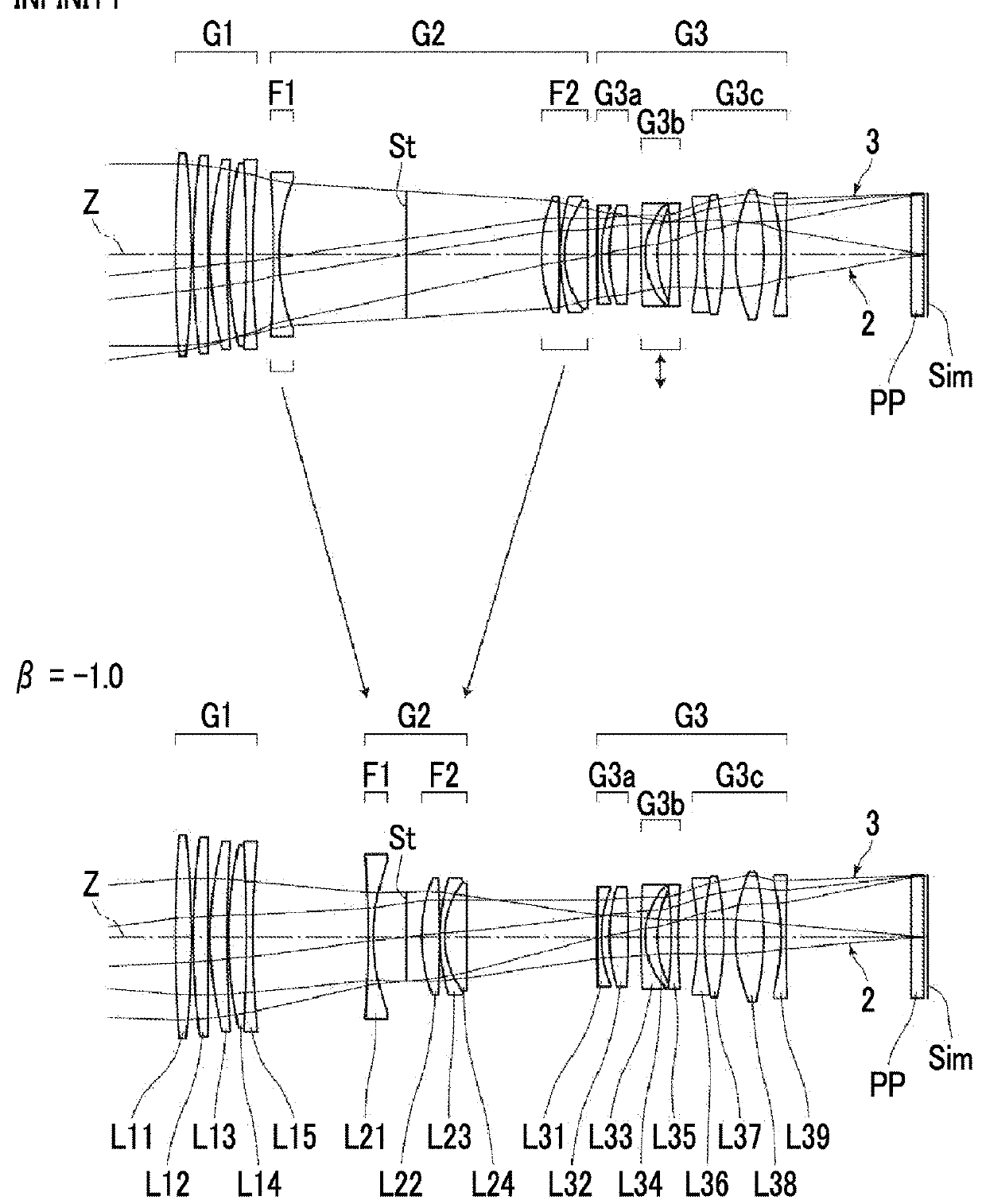

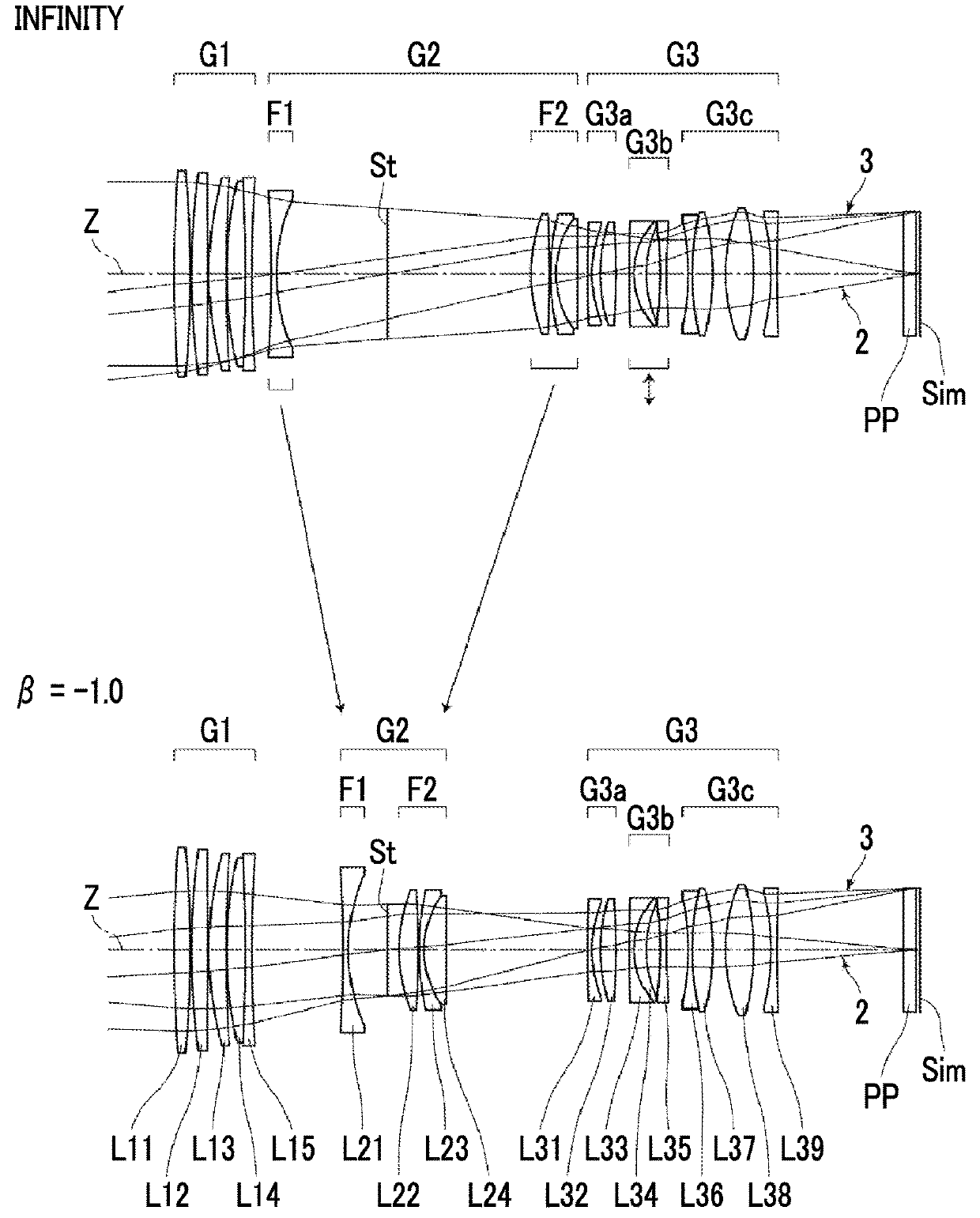

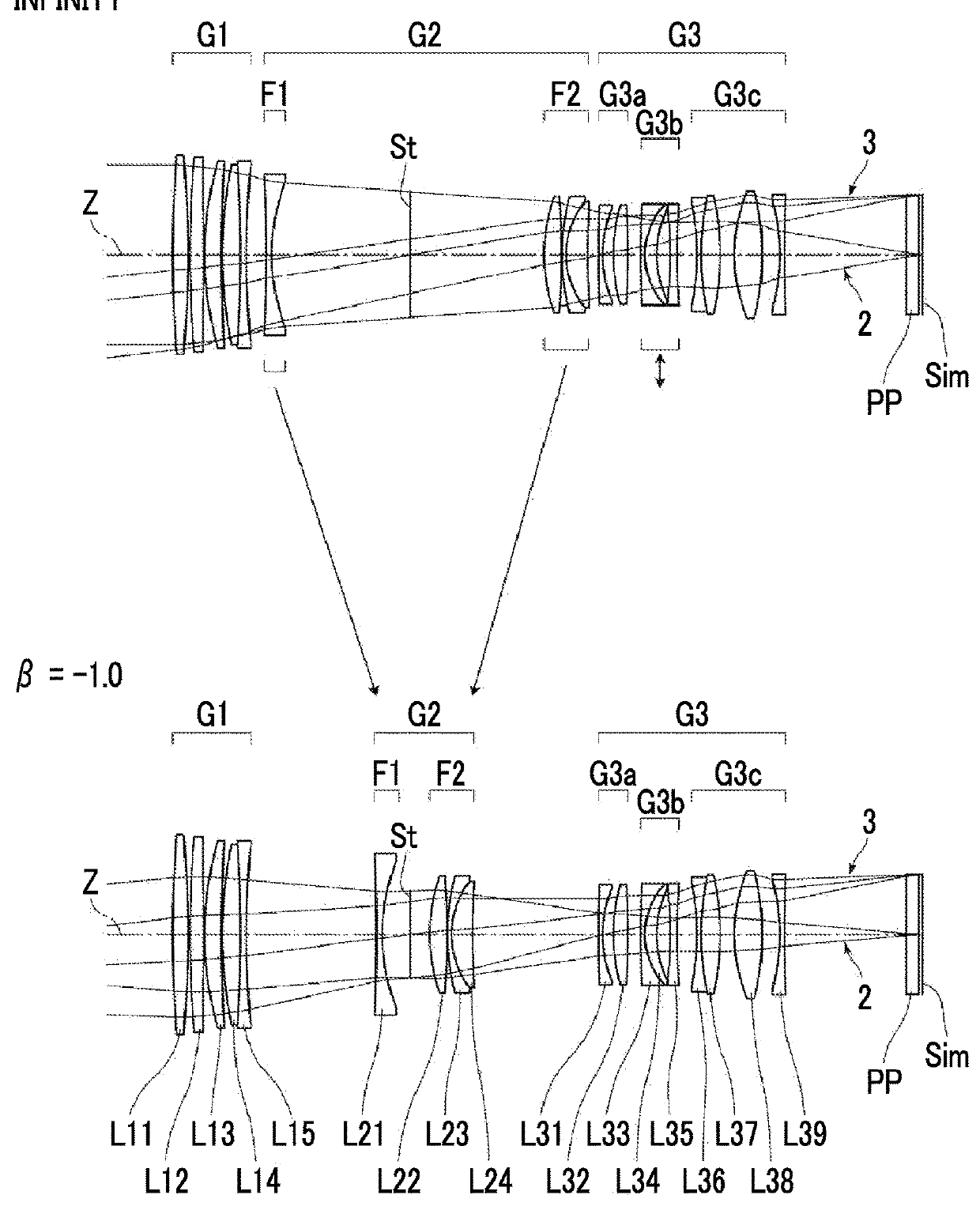

Imaging lens and imaging apparatus

The imaging lens consists of, in order from the object side, a first lens group having a positive refractive power, a second lens group, and a third lens group. In the second lens group, a first focus lens group having a negative refractive power is disposed to be closest to the object side, and a second focus lens group having a positive refractive power is disposed to be closest to the image side. During focusing, only the first and second focus lens groups move by changing the mutual spacing therebetween. The first lens group has two positive lenses and one negative lens. The first focus lens group consists of two or less lenses including a negative lens. Predetermined conditional expressions are satisfied.

Owner:FUJIFILM CORP

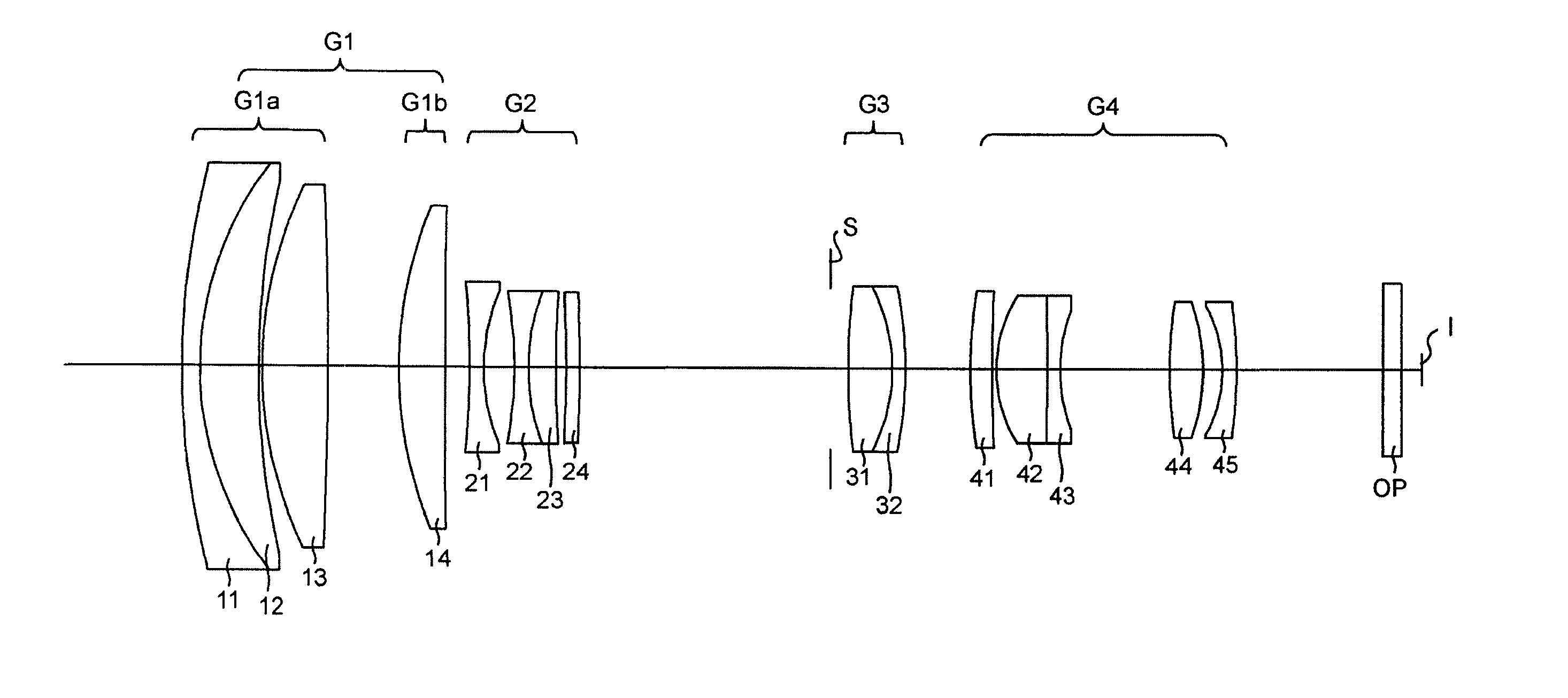

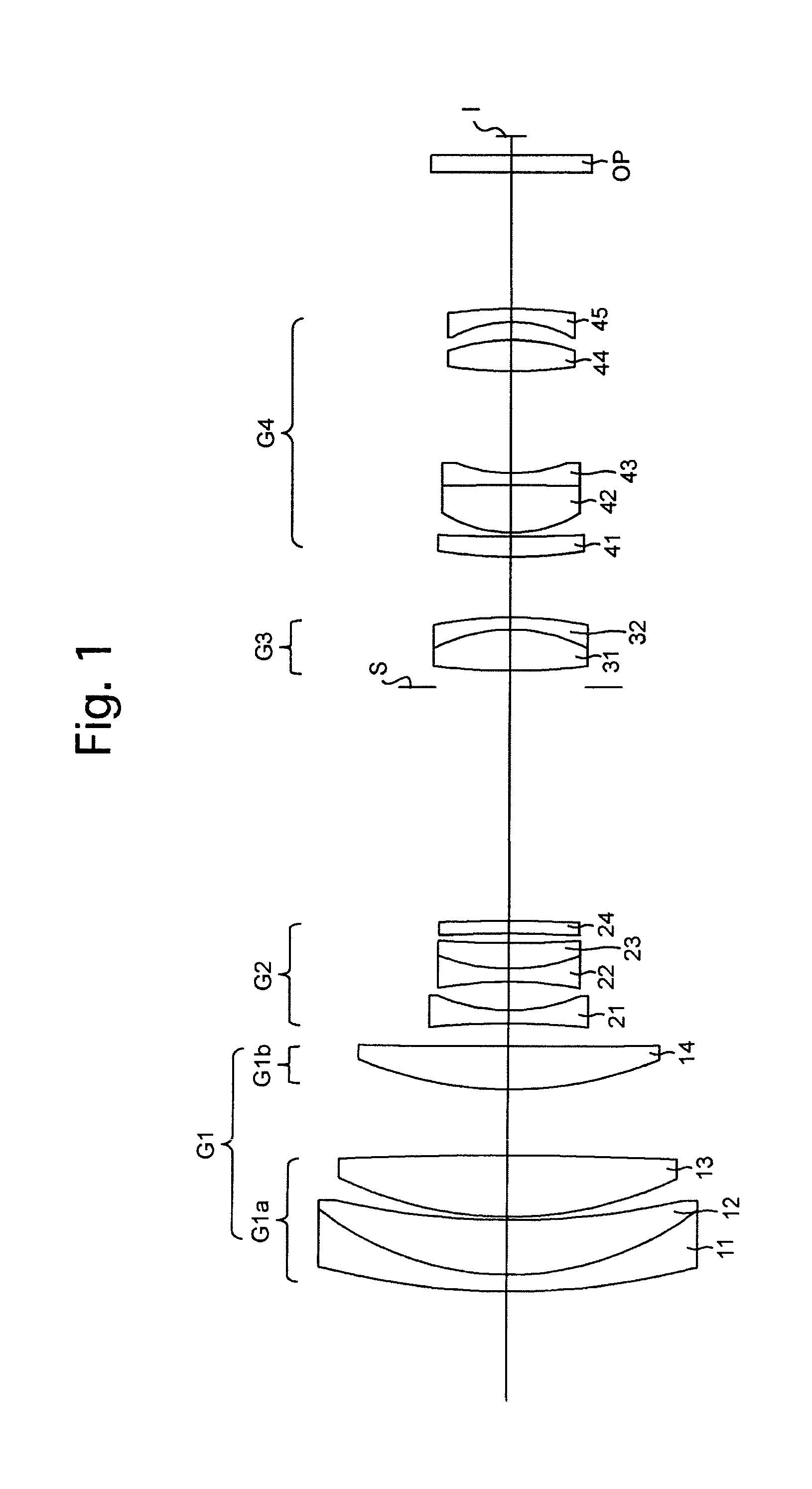

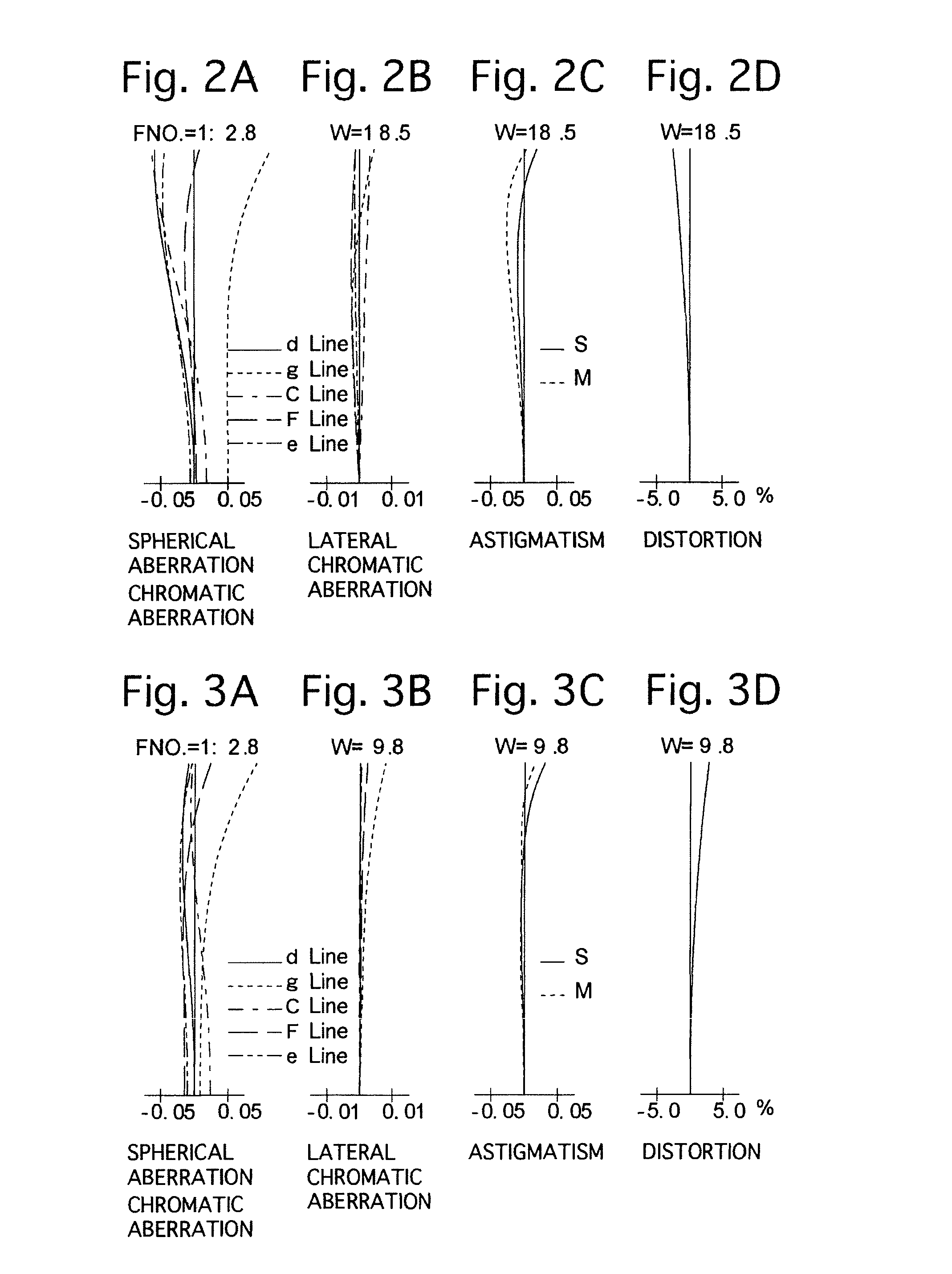

Zoom lens system

ActiveUS20140118840A1Rapid and silent focusing operationShort minimum photographing distanceProjector focusing arrangementCamera focusing arrangementZoom lensPhysics

A zoom lens system includes a plurality of lens groups, a lens group of which is moved to perform zooming, wherein a specified lens group of the lens groups is a focusing lens group; a normal photography mode in which focusing is carried out from infinity to a predetermined photographing distance by moving the focusing lens group of the specified lens group; and a shifting mode which shifts from the normal photography mode to a macro photography mode by moving a lens element of the specified lens group other than the focusing lens group when focusing on an object at a photographing distance that is shorter than the predetermined photographing distance. When the zoom lens system is in the macro photography mode, focusing is carried out from the predetermined photographing distance to a minimum photographing distance by moving the focusing lens group.

Owner:RICOH IMAGING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com