Batch production method of fuel cell membrane electrode

A fuel cell membrane, mass production technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low efficiency, unfavorable mass production, damage to membrane electrodes, etc. better sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

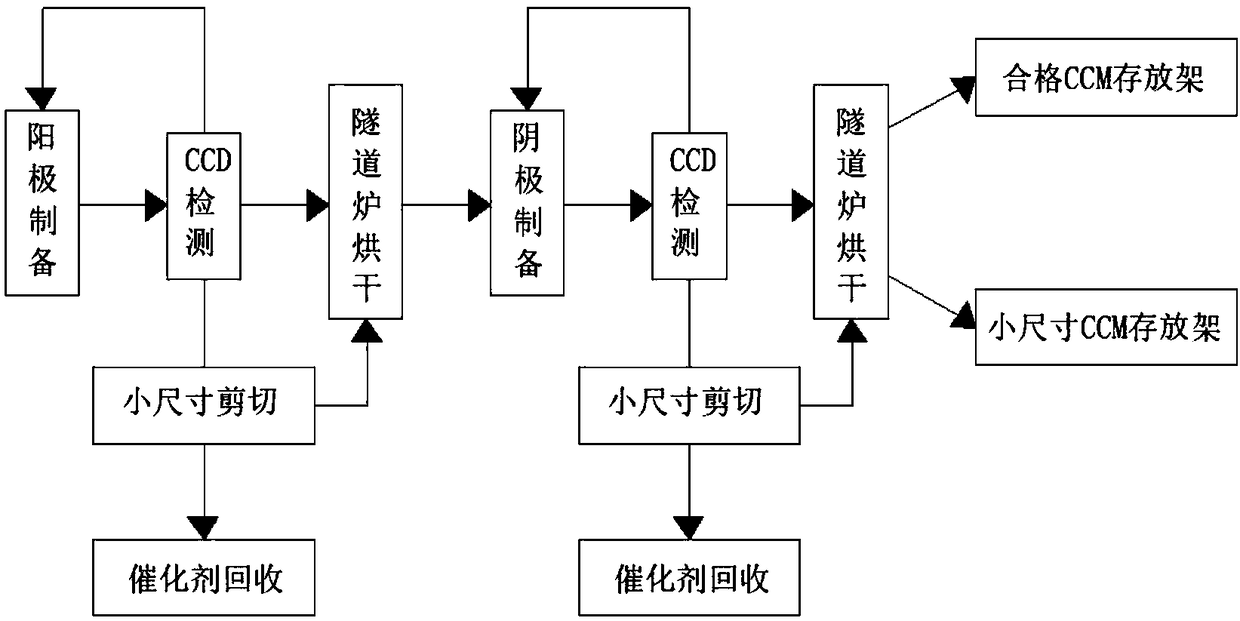

[0074] A method for batch production of fuel cell membrane electrodes, specifically comprising the following steps:

[0075] (1) prepare catalyst slurry A, get catalyst particle and The monomer solution (perfluorosulfonic acid solution) is dispersed in a mixed solvent by ultrasonic waves and high-speed stirring. The mixed solvent includes three components: isopropanol, deionized water and 2-ethoxyethanol. Vacuum defoaming process is adopted The ionomer is filled and adsorbed into the micropores of the catalyst and its carrier particles to obtain a catalyst slurry A; wherein, in terms of mass ratio, the catalyst particles: Monomer solution: isopropanol: deionized water: 2-ethoxyethanol = (8-10): (3-5): (38-45): (36-43): (5-10) prepared.

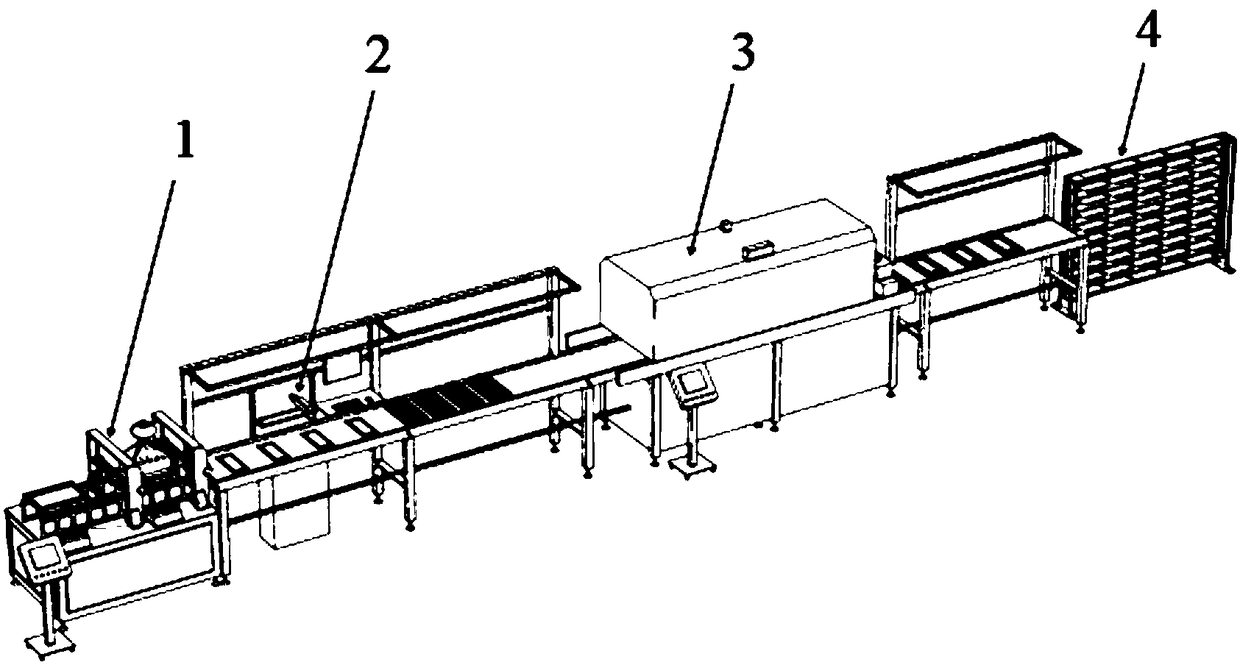

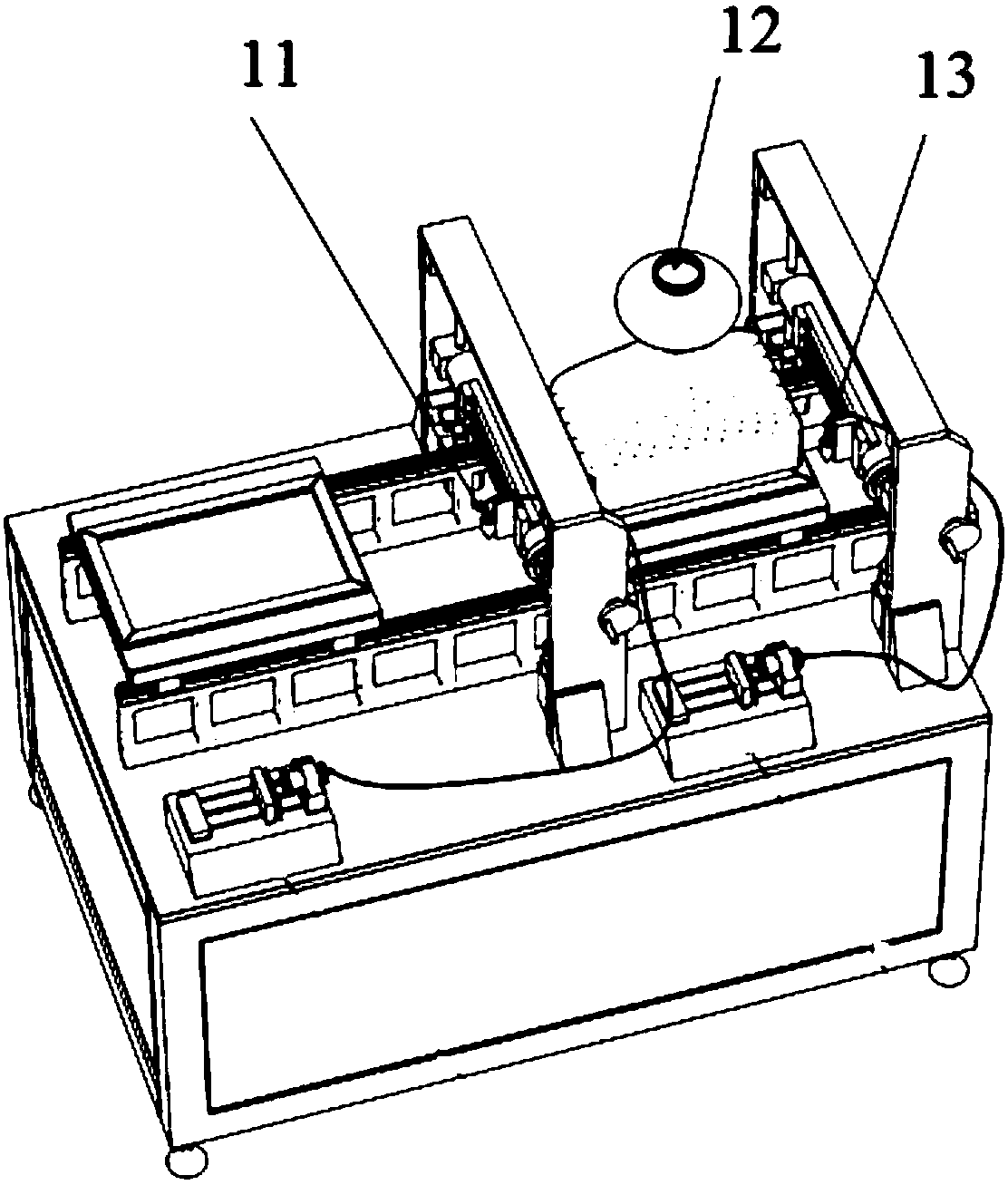

[0076] (2) In the anode / cathode preparation area 1 of the membrane electrode, the catalyst slurry A is coated on the membrane electrode by methods such as spray coating, scrape coating, slit coating or heat transfer printing, and three laye...

Embodiment 1-1

[0090] A method for batch production of fuel cell membrane electrodes, specifically comprising the following steps:

[0091] (1) prepare catalyst slurry A, get catalyst particle and The monomer solution (perfluorosulfonic acid solution) is dispersed in a mixed solvent by ultrasonic waves and high-speed stirring. The mixed solvent includes three components: isopropanol, deionized water and 2-ethoxyethanol. Vacuum defoaming process is adopted The ionomer is filled and adsorbed into the micropores of the catalyst and its carrier particles to obtain a catalyst slurry A; wherein, in terms of mass ratio, the catalyst particles: Monomer solution: isopropanol: deionized water: 2-ethoxyethanol=8:3:38:36:5.

[0092] (2) In the anode / cathode preparation area 1, the catalyst slurry A is coated on the membrane electrode by methods such as spray coating, doctor blade coating, slit coating or hot press transfer printing, and a three-layer anode catalytic layer is prepared;

[0093] (3) T...

Embodiment 1-2

[0100] A method for batch production of fuel cell membrane electrodes, specifically comprising the following steps:

[0101] (1) prepare catalyst slurry A, get catalyst particle and The monomer solution (perfluorosulfonic acid solution) is dispersed in a mixed solvent by ultrasonic waves and high-speed stirring. The mixed solvent includes three components: isopropanol, deionized water and 2-ethoxyethanol. Vacuum defoaming process is adopted The ionomer is filled and adsorbed into the micropores of the catalyst and its carrier particles to obtain a catalyst slurry A; wherein, in terms of mass ratio, the catalyst particles: Monomer solution: isopropanol: deionized water: 2-ethoxyethanol = 10:5:45:43:10.

[0102] (2) In the anode / cathode preparation area 1, the catalyst slurry A is coated on the membrane electrode by methods such as spray coating, doctor blade coating, slit coating or hot press transfer printing, and a three-layer anode catalytic layer is prepared;

[0103] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com