Chlorinated polyvinyl chloride DN400 tee junction pipe fitting once injection moulding technique and device thereof

A chlorinated polyvinyl chloride, injection molding technology, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of long pre-molding time, difficult to control friction heat, easy to burn, etc., to improve the friction temperature High speed, stable rotation speed, and the effect of reducing frictional heat

Inactive Publication Date: 2010-09-08

YOULI HLDG GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

DN400 tee fittings refer to large-scale tee fittings with a nominal diameter of 400. When the existing technology is used for one-time injection molding of DN400 tee series fittings, the following problems often exist: (1) due to PVC-C (chlorinated polyvinyl chloride) (2) PVC-C (chlorinated polyvinyl chloride) resin has a high chlorine content, and the temperature control range deviation is small , the friction heat generated by the screw during premolding is difficult to control, so the premolding time required for DN400 tee fittings is long, and the material is easily burnt in the barrel; (3) PVC-C (chlorinated polyvinyl chloride) resin Good toughness, high impact strength, large cut, during the process of processing, the rotation speed of the injection molding machine oil motor is unstable during pre-molding

Due to the above reasons, according to the existing technology and process, it is impossible to solve the problem of one-time injection molding of DN400 tee series pipe fittings

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Login to View More

Abstract

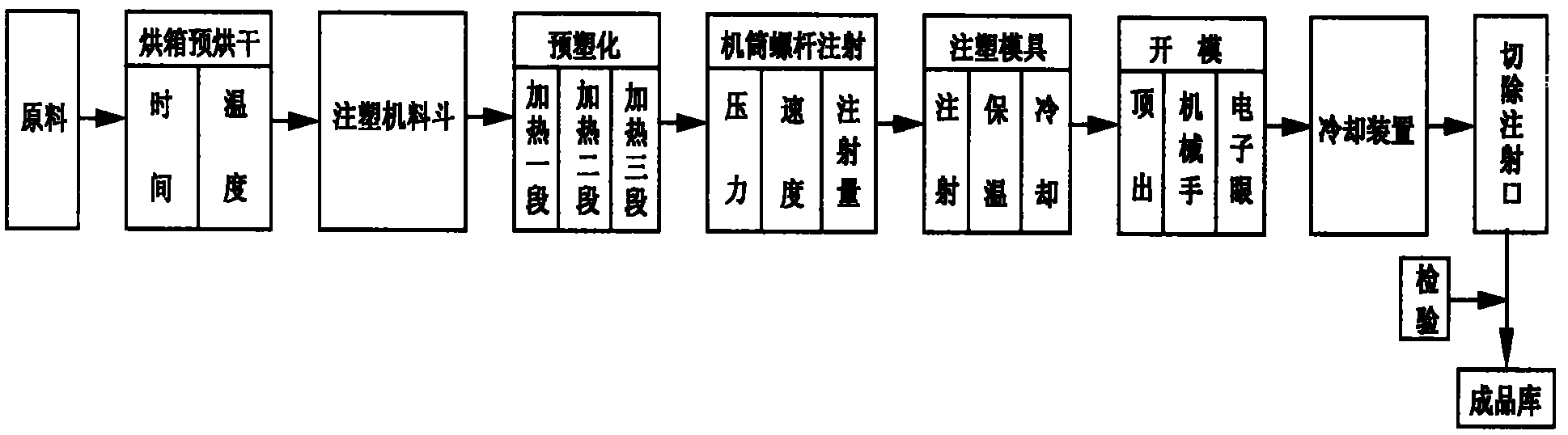

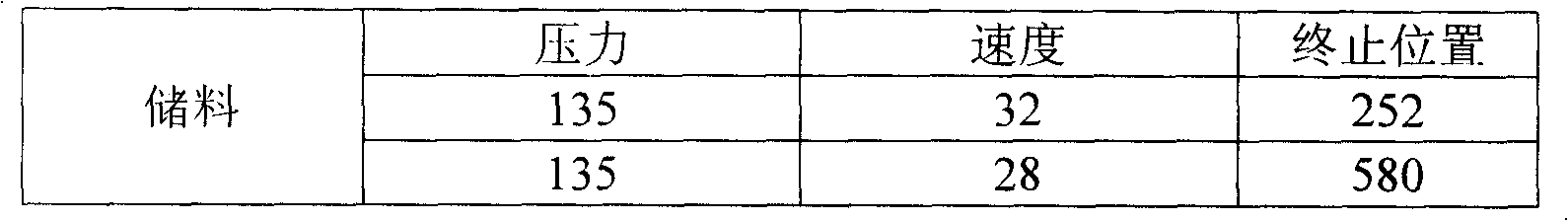

The invention relates to a manufacturing technique of a wood-gum tubular element, in particular to a disposable injection molding technique and device of a CPVC three-way tubular element. The technique comprises technical processes of charge mixture, drying, injection made, pressure maintaining and open modeling, wherein a heating position of a charging barrel of an injection machine is divided into seven segments in the process of injection, the temperature ranges of the segments are respectively 150-155 DEG C, 168-173 DEG C, 162-167 DEG C, 160-165 DEG C, 155-160 DEG C, 150-155 DEG C, and 145-150 DEG C, and the temperature of a mould is controlled between 60 and 70 DEG C. When injecting, the pressure of ejection is divided into three segments which are respectively 58 MPa, 60 MPa and 78 MPa. The pitch of screw of a screw rod of the injection machine used by the method is equal to the diameter of the screw rod, a feeding segment takes up 25 percent of the total length, a compression segment takes up 50 percent of the total length, and a homogenizing segment takes up 25 percent of the total length. The invention achieves the disposable injection molding of a DN400 large-scale three-way tubular element via the improvement of the technique and the device.

Description

technical field The invention relates to a production process of resin pipe fittings, in particular to a one-time injection molding process and equipment for chlorinated polyvinyl chloride tee pipe fittings. Background technique PVC-C (chlorinated polyvinyl chloride) is produced by the chlorination of PVC free radicals. The general chlorine content is 63% to 69%. Different chlorination methods, states and chlorine reactions, the resulting PVC-C has Big difference. Its chlorination reaction process is as follows: start up: Derivation: RH+Cl→R+HCl R+Cl 2 →RCl+Cl Termination: R+Cl→RCl Cl+Cl→Cl 2 R+R→R 2 (RH stands for PVC, → stands for heating) PVC-C is produced according to the chlorination reaction mechanism of PVC free radicals mentioned above, controlling a certain percentage of chlorine content, controlling start-up temperature and other process factors. Its chlorine content is as high as 74%, and its Vicat softening point temperature is 123°C. Conceptu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C45/78B29C45/77B29C45/72B29C45/76B29C45/60B29K27/06B29L23/00

Inventor 胡旭阳赵崇强梅天云

Owner YOULI HLDG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com