Holder made of synthetic resin and angle contact ball bearing

A synthetic resin and cage technology, applied in the direction of rolling contact bearings, ball bearings, bearings, etc., can solve the problems of poor fluidity of lubricants, large shearing force, easy heat generation of lubricants, etc., to reduce bearing torque, shear low force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

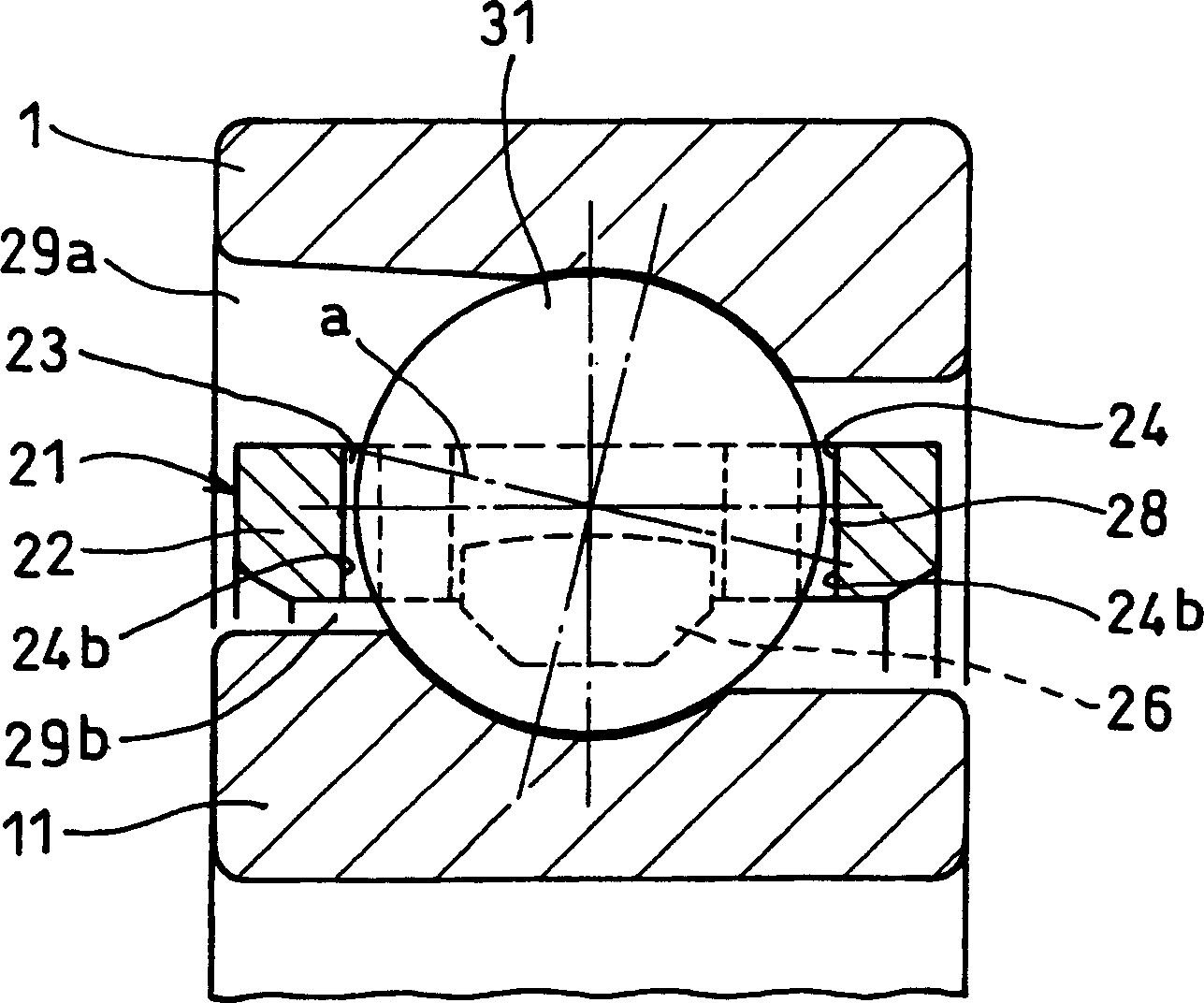

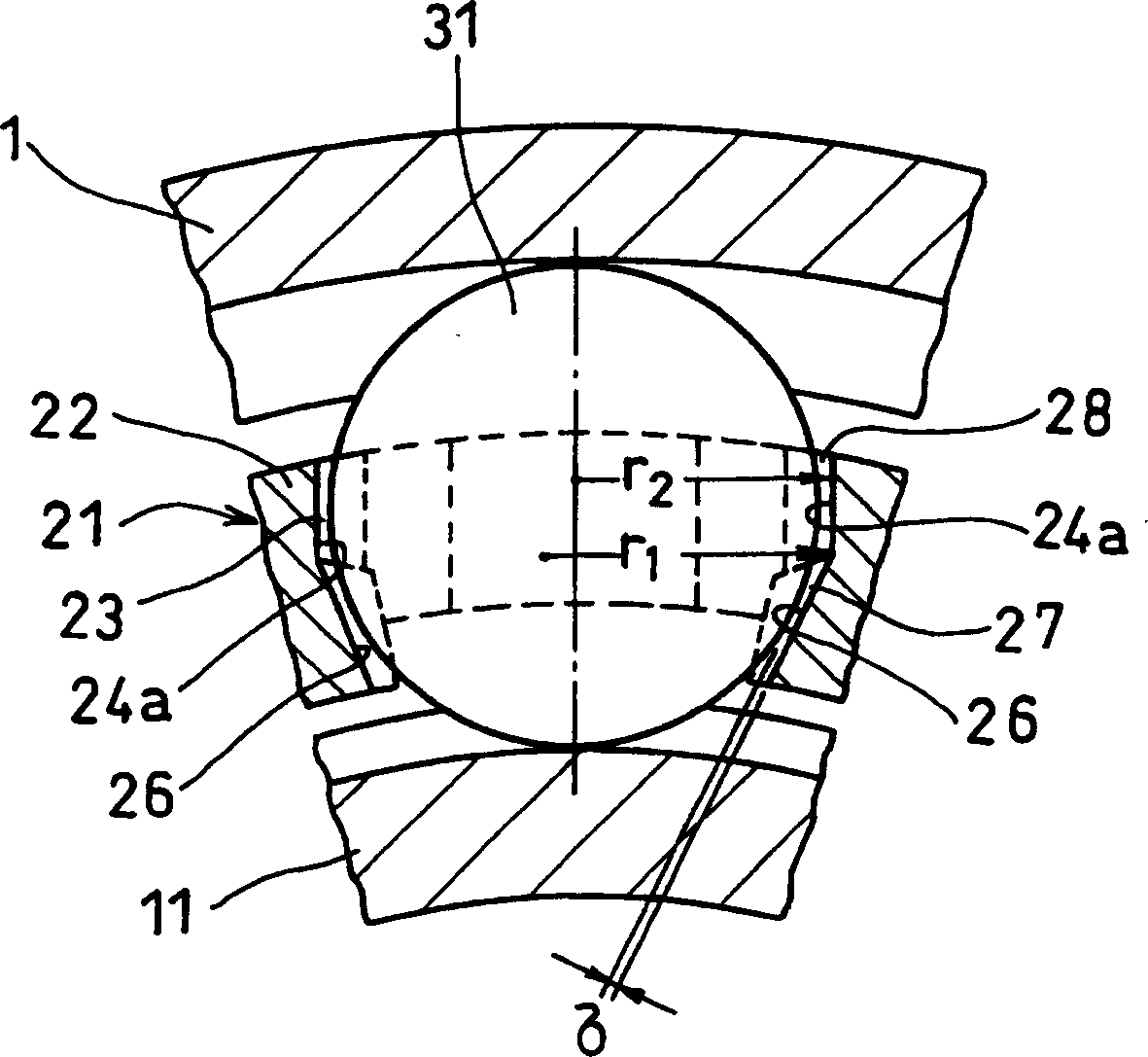

[0046] Below, according to Figure 1 to Figure 14 Embodiments of the present invention will be described. Figure 1 to Figure 6 A first embodiment of the angular contact ball bearing of the present invention is shown. As shown in the figure, the angular contact ball bearing is composed of an outer ring 1 , an inner ring 11 disposed inside the outer ring 1 , a cage 21 inserted between the two rings 1 and 11 , and balls 31 held by the cage 21 .

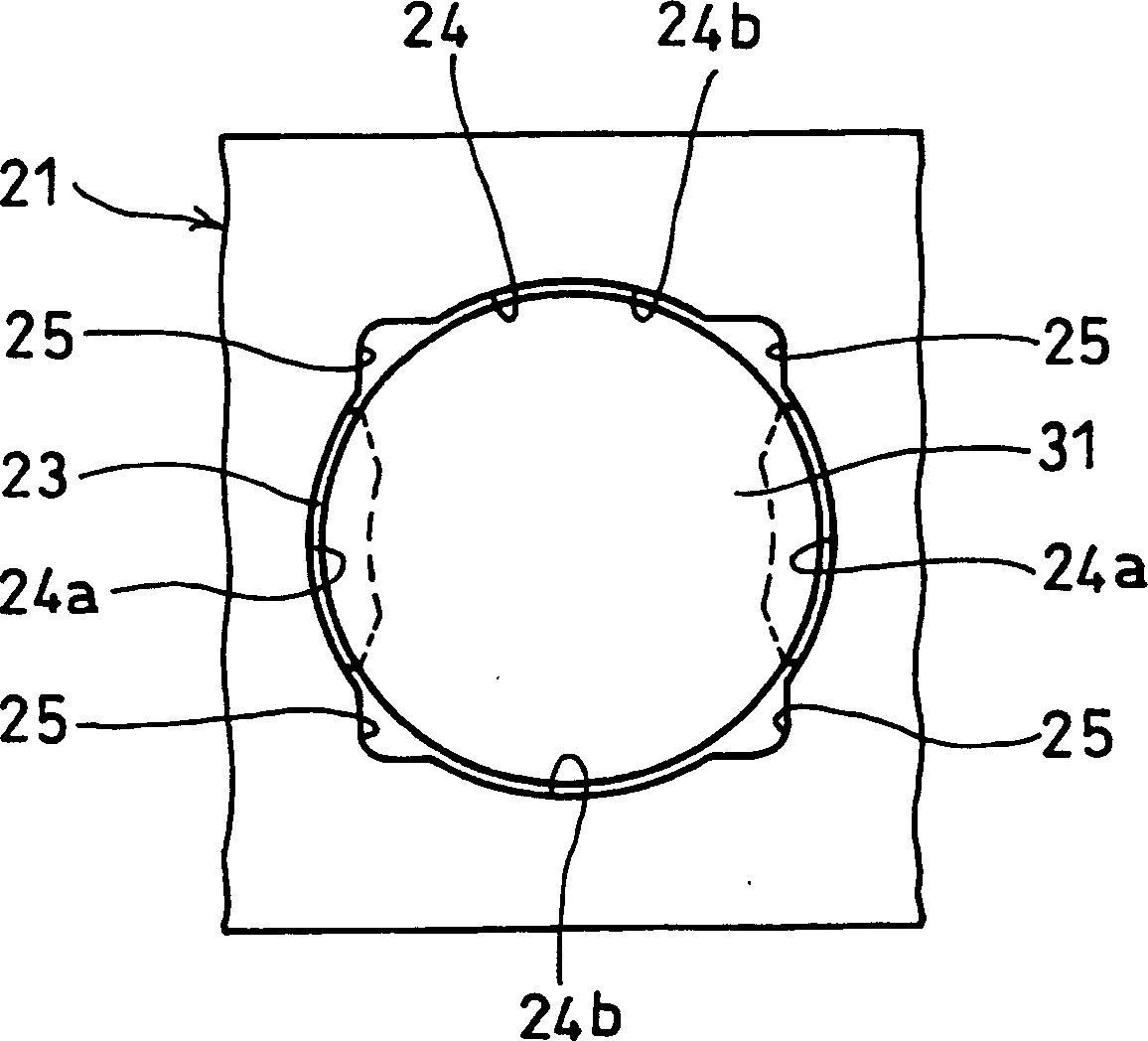

[0047] The holder 21 is composed of a molded product of synthetic resin. Polyamide (PA), polyether ketone ether (PEEK) and polyether sulfane (PES) added with fillers such as glass fiber or carbon fiber are used as synthetic resins.

[0048] The retainer 21 has a configuration in which a plurality of pockets 23 for accommodating the balls 31 are formed at equal intervals in the circumferential direction on the annular body 22 .

[0049] The pocket 23 is made cylindrical. On the cylindrical inner surface 24 of the recess 23, as imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com