Patents

Literature

30results about How to "No scorching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

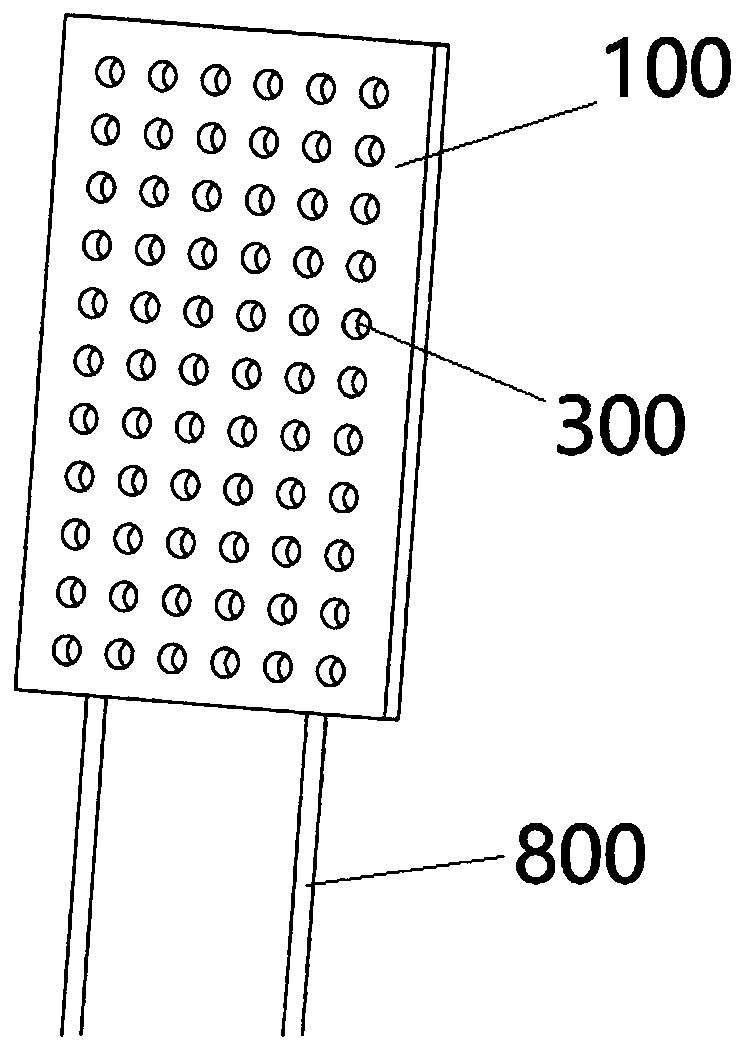

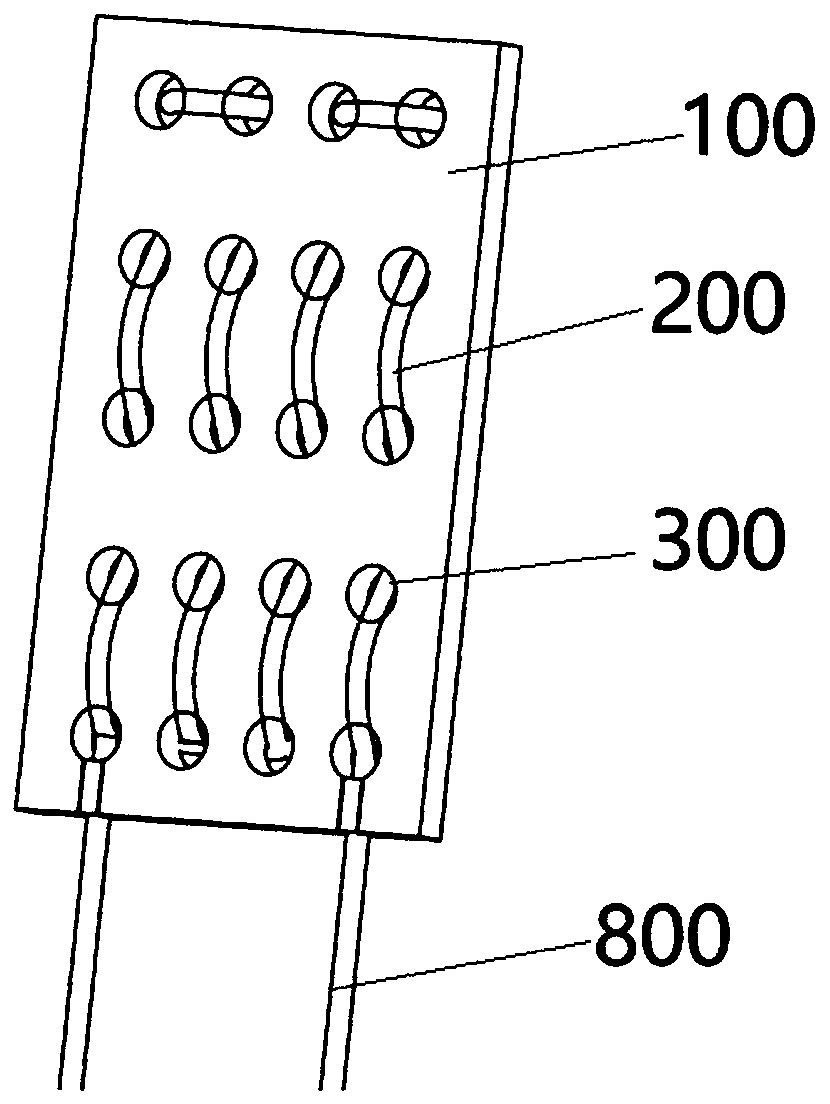

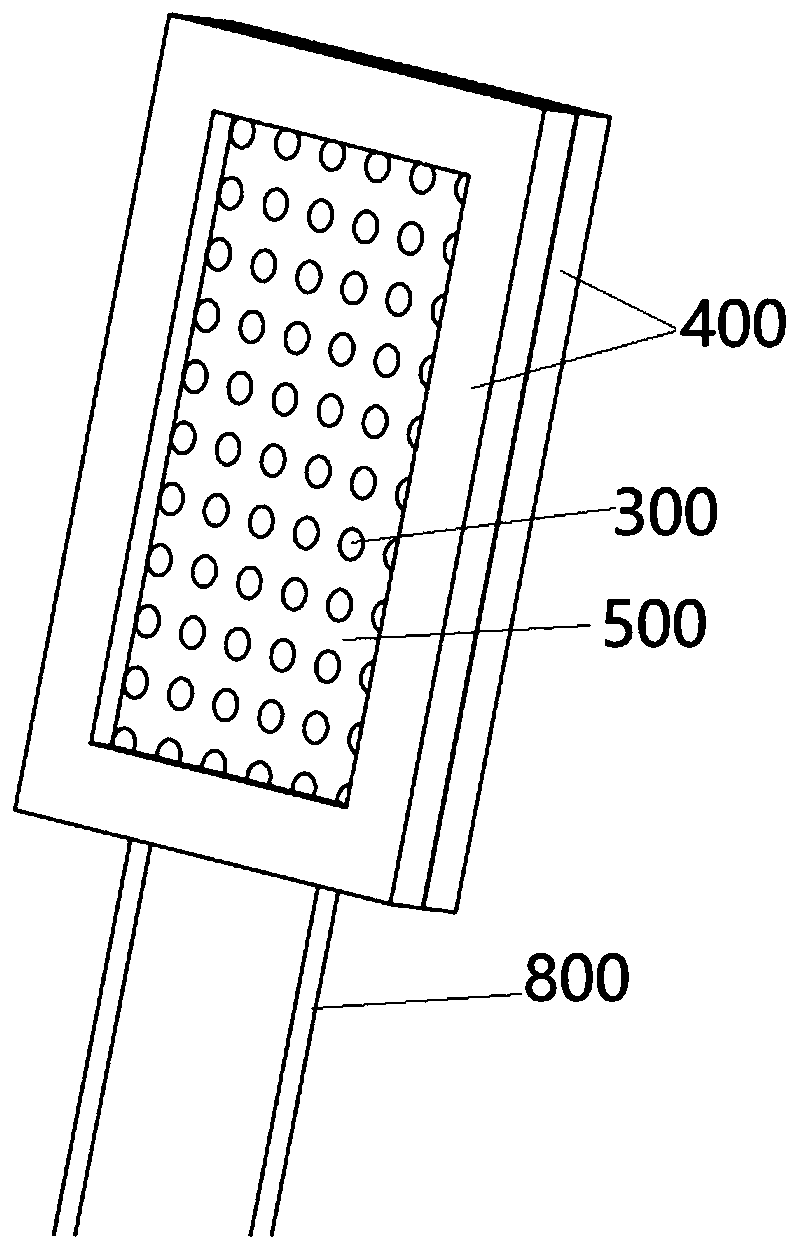

Heating sheet for atomizer, atomizer and electronic cigarette

The invention provides a heating sheet for an atomizer, the atomizer and electronic cigarette. The heating sheet for the atomizer comprises a support component, the support component is provided with a heating component and an extraction electrode, and the heating component and the extraction electrode are connected; and the support component or the heating component is provided with a plurality of through holes. The heating sheet with a mesh-shaped structure is adopted in the heating sheet of the atomizer, heating is more even, the phenomenon of singe of cigarette tar is avoided, tar guiding is smooth, atomizing is full, and the stability is good; condensed fluid flows back to be used through a support inclined surface, infiltrates tar guiding cotton through the through holes of the heating sheet, and enters into an atomizing chamber to be further atomized, the reduction degree of the cigarette tar is high, the amount of smoke is full, better atomizing taste is achieved, and the problem that the atomized condensate cigarette tar is prone to flowing out of an air channel in the prior art is solved.

Owner:SHENZHEN BAUWAY TECH LTD

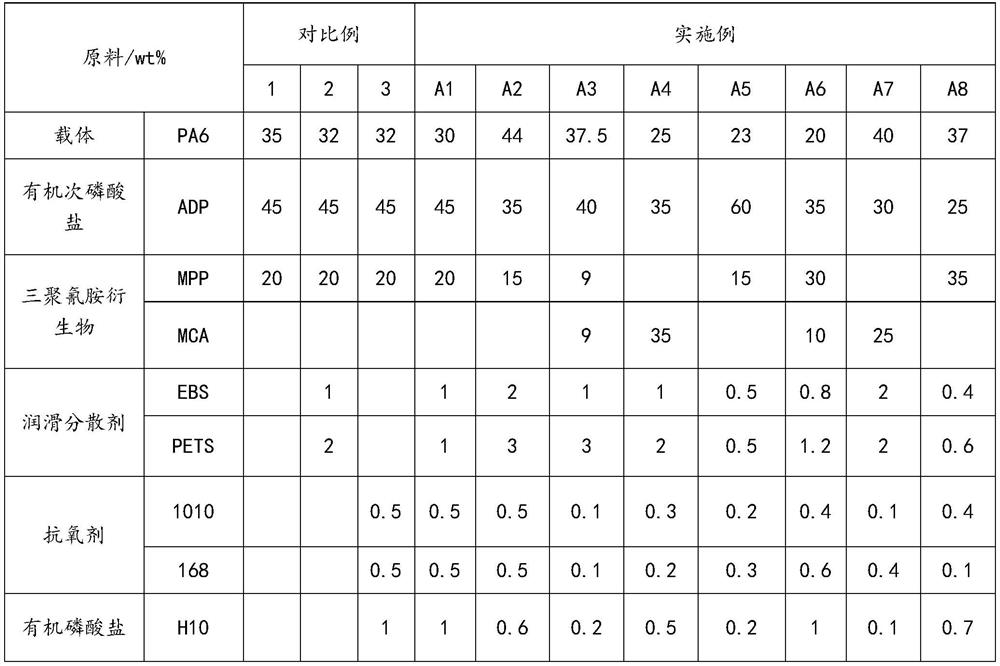

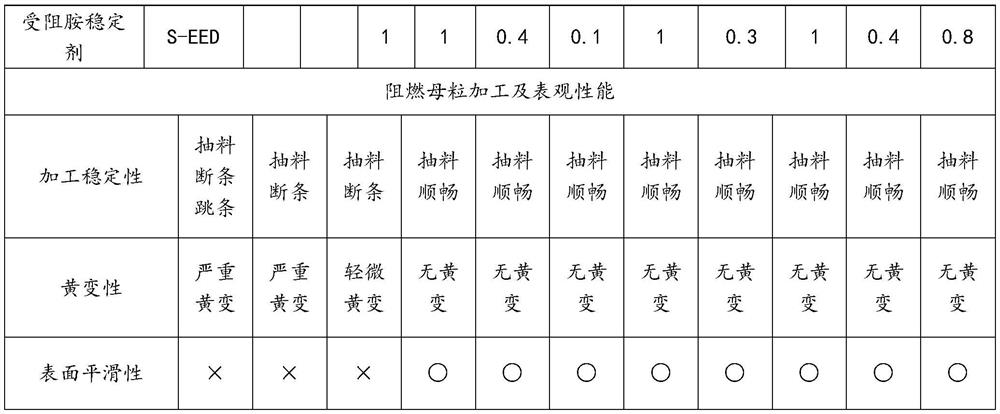

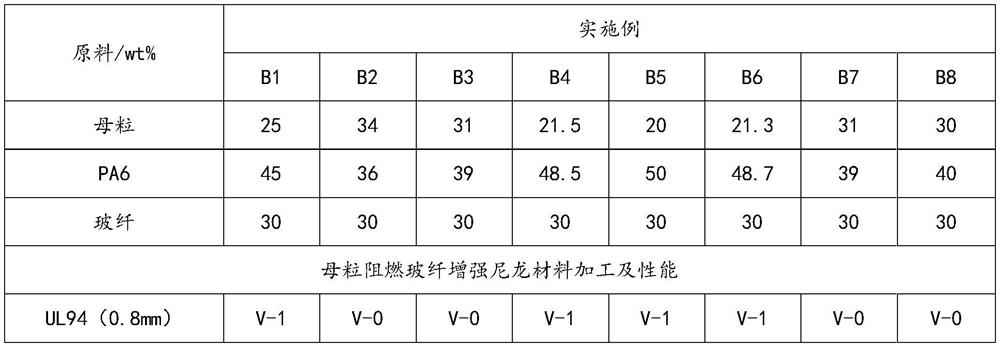

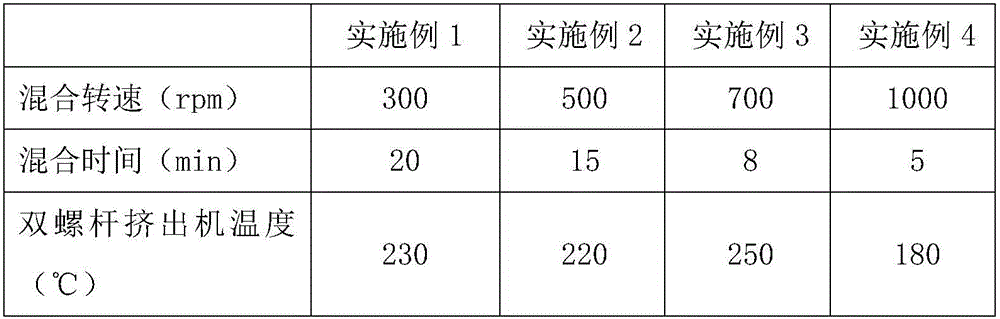

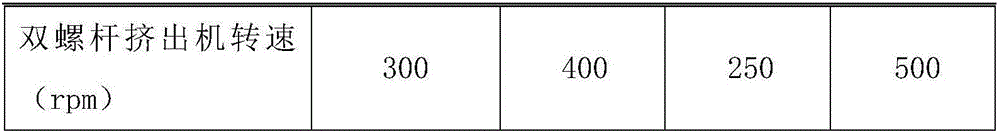

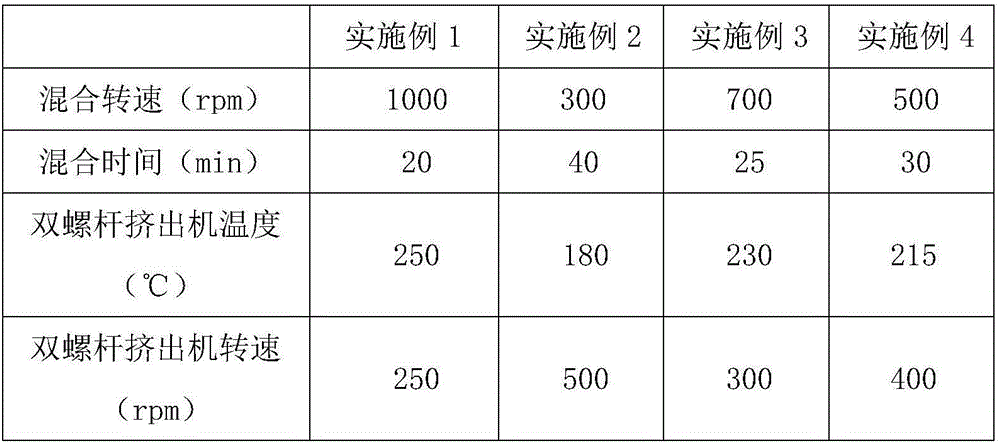

High-dispersity high-concentration nylon-based halogen-free flame-retardant master batch and preparation method thereof

The invention discloses a high-dispersity high-concentration nylon-based halogen-free flame-retardant master batch and a preparation method thereof. The high-dispersity high-concentration nylon-based halogen-free flame-retardant master batch comprises the following components in parts by mass: 20%-45% of a nylon resin carrier and 25%-60% of organic hypophosphite, wherein the mass percentage content of the melamine derivative is 15%-40%, the relative viscosity of the nylon resin carrier is 1.8-3.0, and the effective concentration of the flame-retardant masterbatch is 50%-75%. By screening nylon resin, a lubricating dispersant and an anti-yellowing agent, high filling performance of the nylon carrier is achieved, the organic hypophosphite and melamine derivative compound flame retardant masterbatch is prepared, the effective concentration is 50%-75%, and the flame retardant efficiency is high. The invention also provides a preparation method of the halogen-free flame-retardant master batch.

Owner:ZHEJIANG XUSEN NON HALOGEN SMOKE FLAME RETARDANT CO LTD

Plastic for electronic instrument shell

The invention discloses a plastic for an electronic instrument shell. The plastic is prepared from the following raw materials in parts by weight: 40-60 parts of polyimide, 40-50 parts of butyl rubber, 10-20 parts of polyurethane rubber, 8-16 parts of chlorosulfonated polyethylene, 2-4 parts of cross-linking agent, 45-55 parts of nanometer kieselguhr, 8-12 parts of ricinus communis fiber, 4-8 parts of expanded perlite, 8-16 parts of zeolite powder, 2-4 parts of silane coupling agent, 4-8 parts of carboxymethylcellulose compound, 4-8 parts of plasticizer, 1.5-2.5 parts of 2,6-di-tert-butylphenol and 1.5-2.5 parts of anti-aging agent 4010NA. The plastic is high in hardness and excellent in toughness, has an excellent buffering property under a stressed state, has an excellent waterproof property and can meet the requirement for the electronic instruments.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

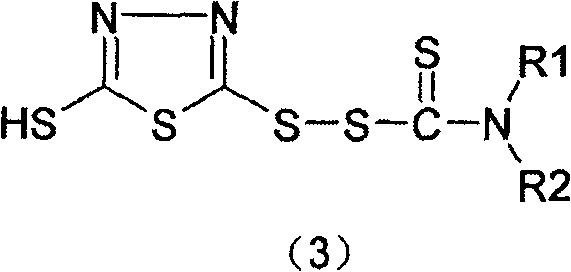

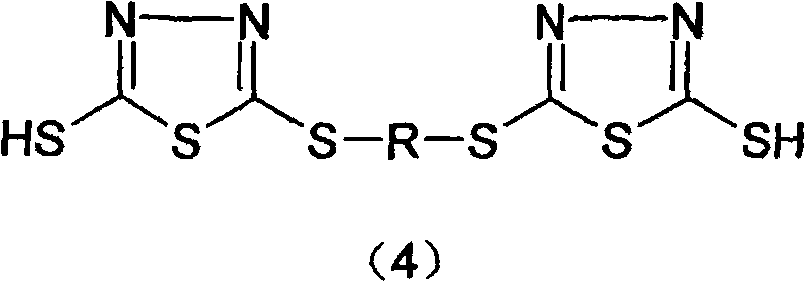

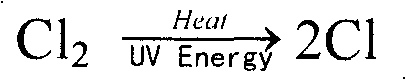

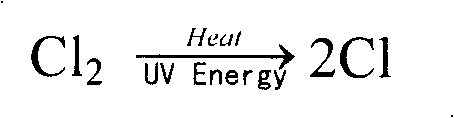

Thiadiazole derivative for vulcanized cross-linking of halogen-containing polymer

InactiveCN102093310AGood mechanical propertiesSolve the problem of high toxicityOrganic chemistryArylPolymer science

The invention discloses a thiadiazole derivative for vulcanized cross-linking of a halogen-containing polymer. The structural formula of the thiadiazole derivative is shown in a formula (1) or (2), wherein R is aryl group or C1-17alkyl group. The thiadiazole derivative for the vulcanized cross-linking of the halogen-containing polymer can be used as a vulcanized agent.

Owner:烟台恒鑫化工科技有限公司

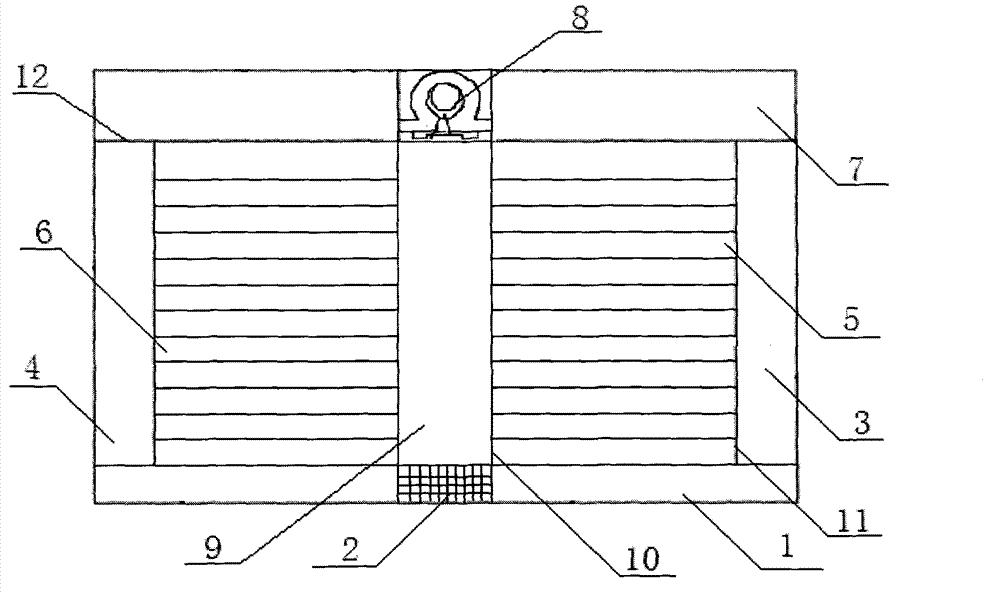

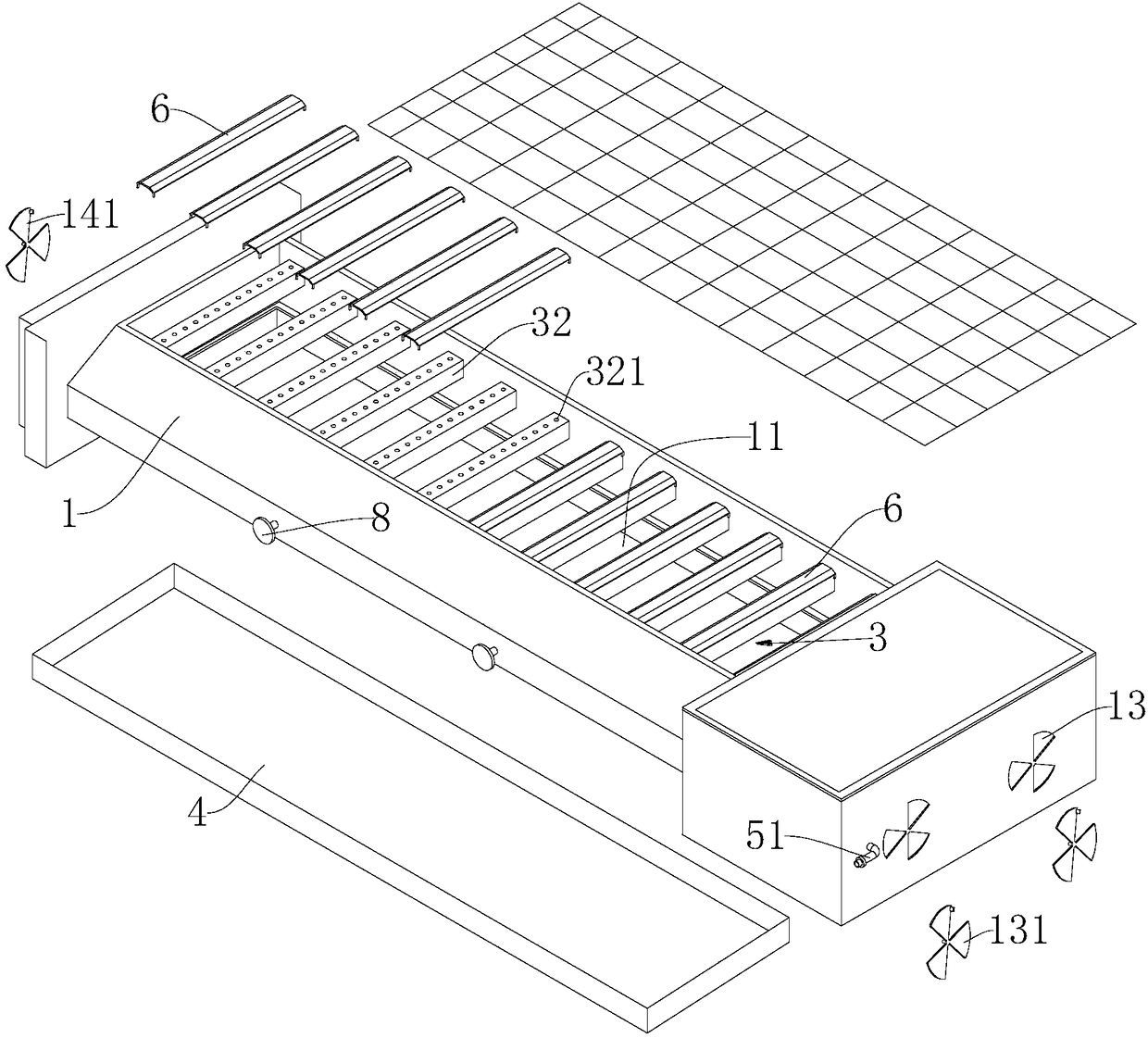

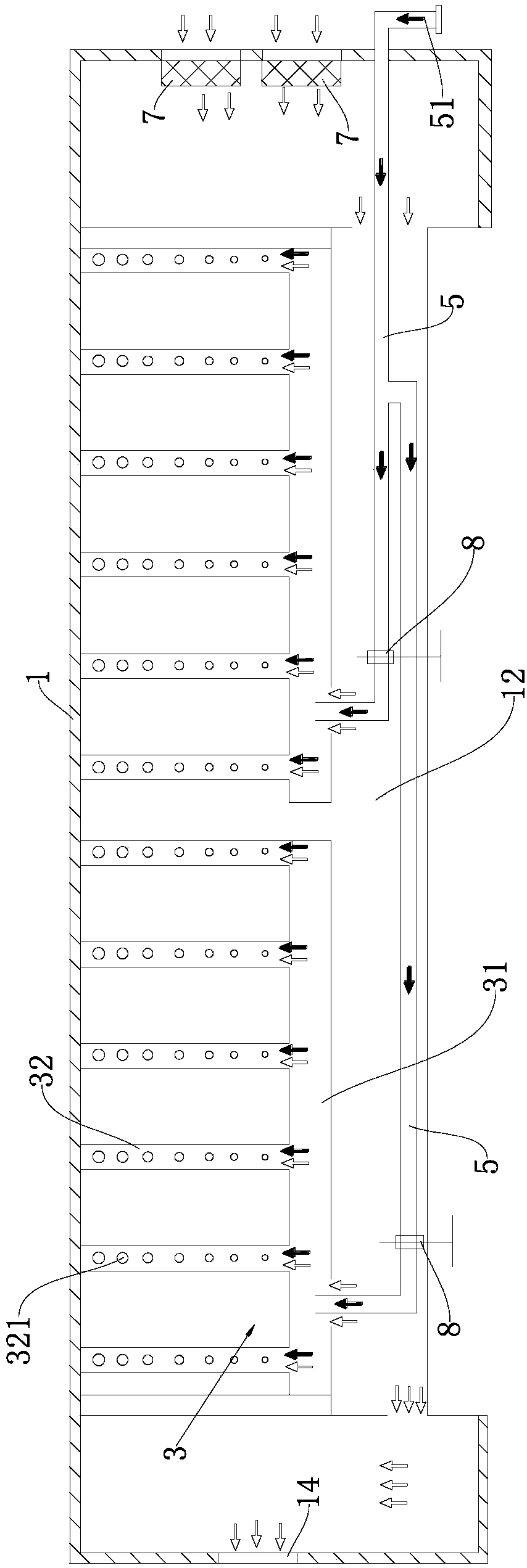

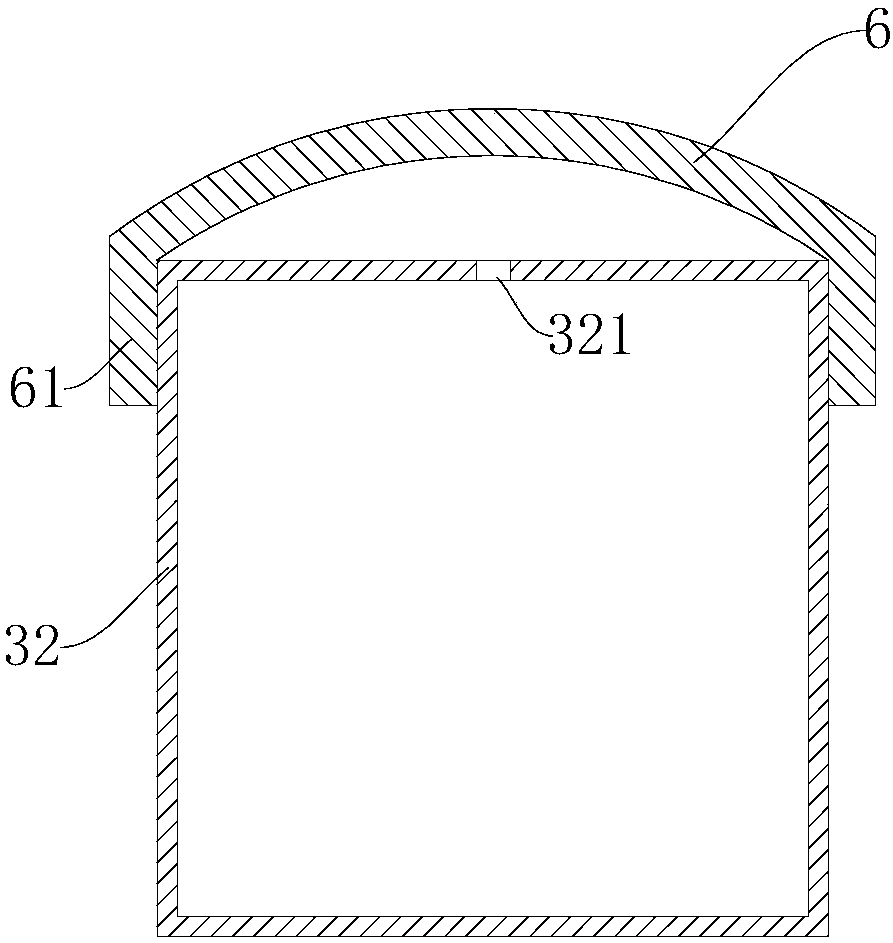

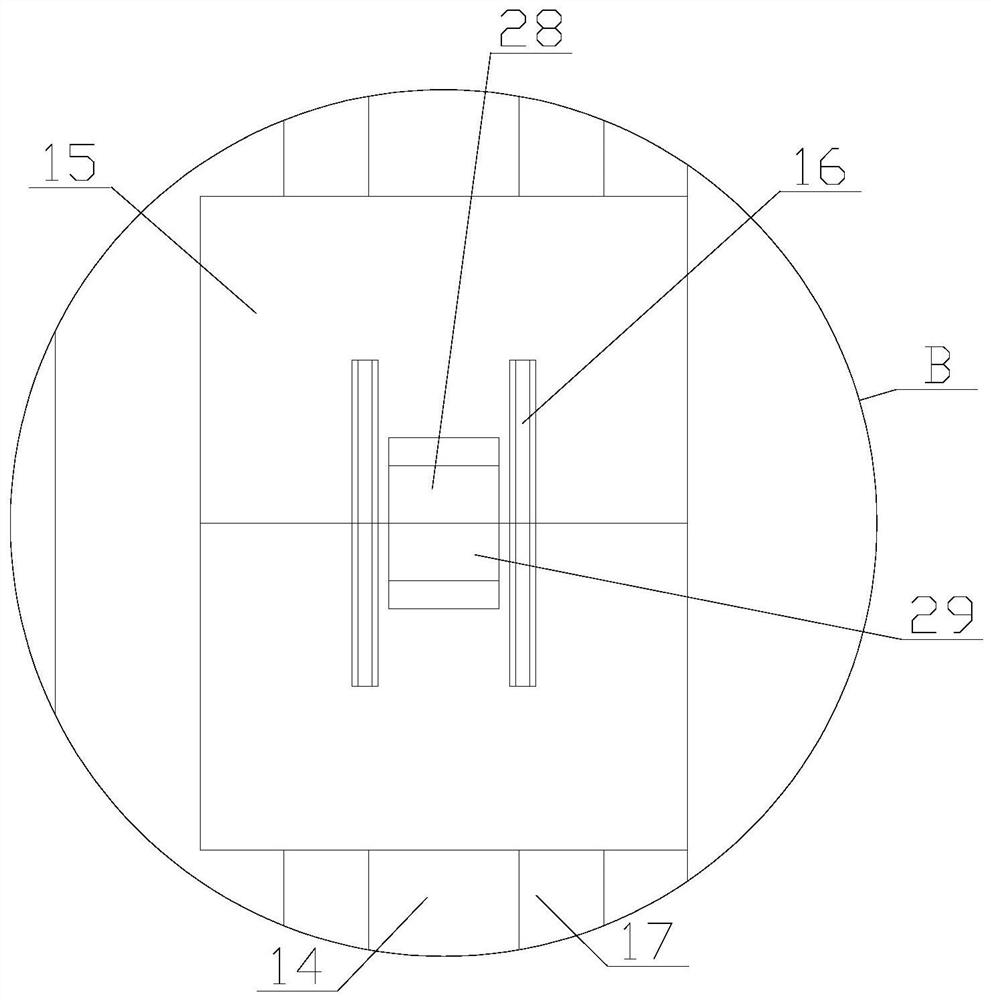

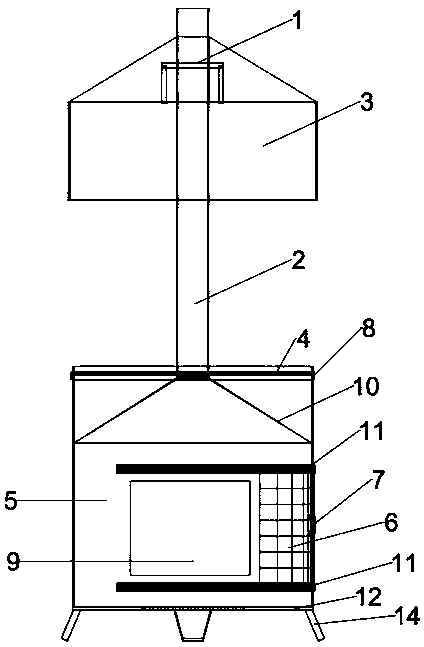

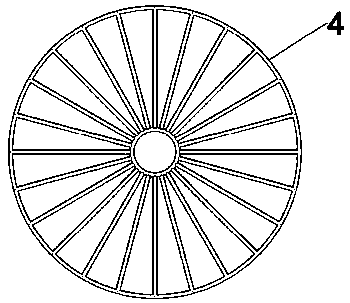

Hot air furnace drying box

InactiveCN103047834ASimple structureKeep dryDrying gas arrangementsDrying machines with local agitationPulp and paper industryCentrifugal fan

The invention relates to a hot air furnace drying box. The hot air furnace drying box comprises a base, a hot air furnace arranged at the center of the base, a central air supply cavity communicated with the hot air furnace, a left ventilating and drying cavity, a right ventilating and drying cavity, a left ventilating tube, a right ventilating tube, top ventilating tubes arranged at the upper ends of the left ventilating tube and the right ventilating tube, and a centrifugal fan arranged at the upper portion of the central air supply cavity, wherein the left ventilating and drying cavity and the right ventilating and drying cavity are arranged at the left end and the right end of the central air supply cavity and communicated with the central air supply cavity through hot air inlets, and the left ventilating tube and the right ventilating tube are respectively arranged the end portions of the left ventilating and drying cavity and the right ventilating and drying cavity. The left ventilating and drying cavity and the right ventilating and drying cavity are respectively communicated with the left ventilating tube and the right ventilating tube through hot air outlets. The hot air furnace drying box is balanced in material drying and good in drying effect.

Owner:赵立地

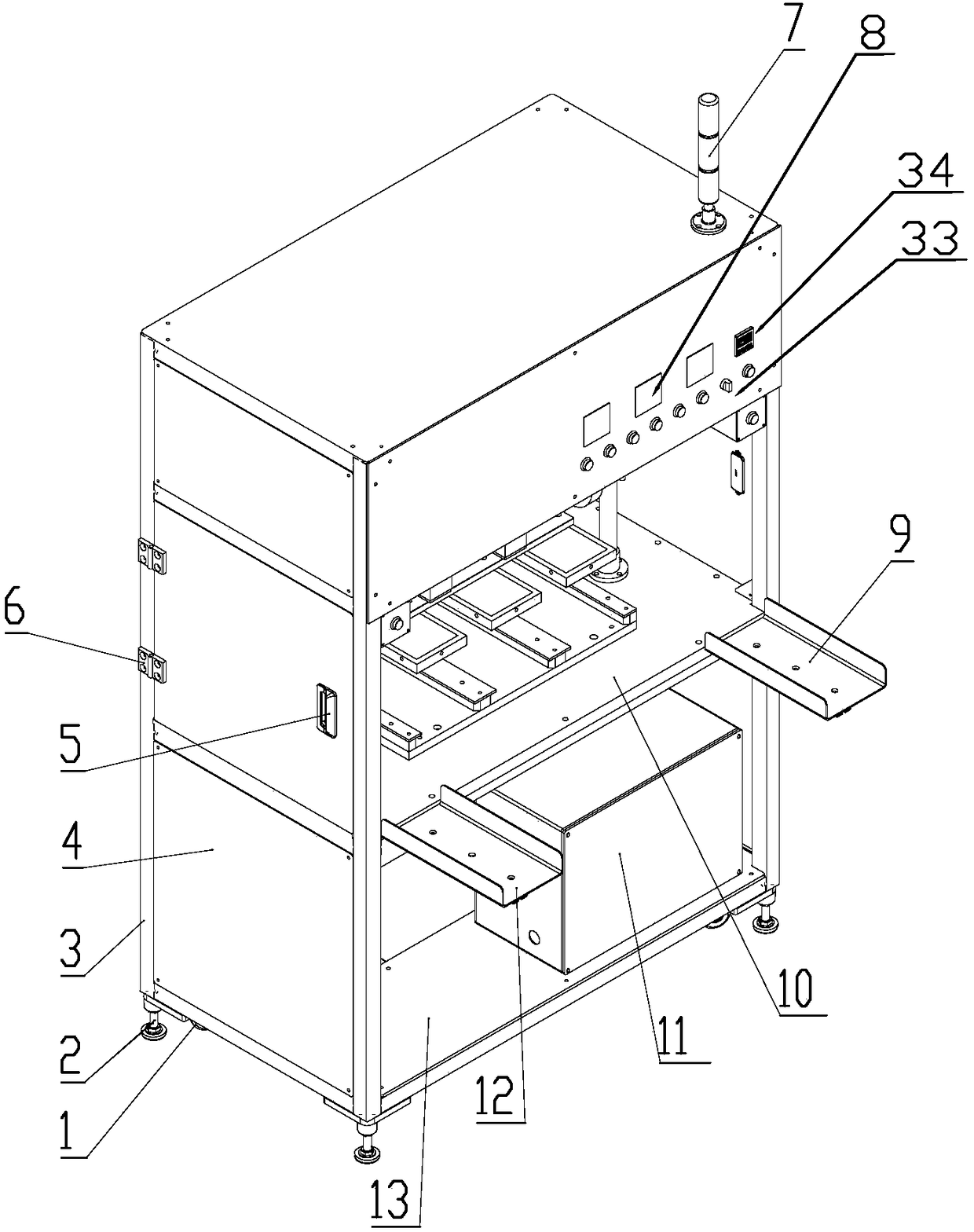

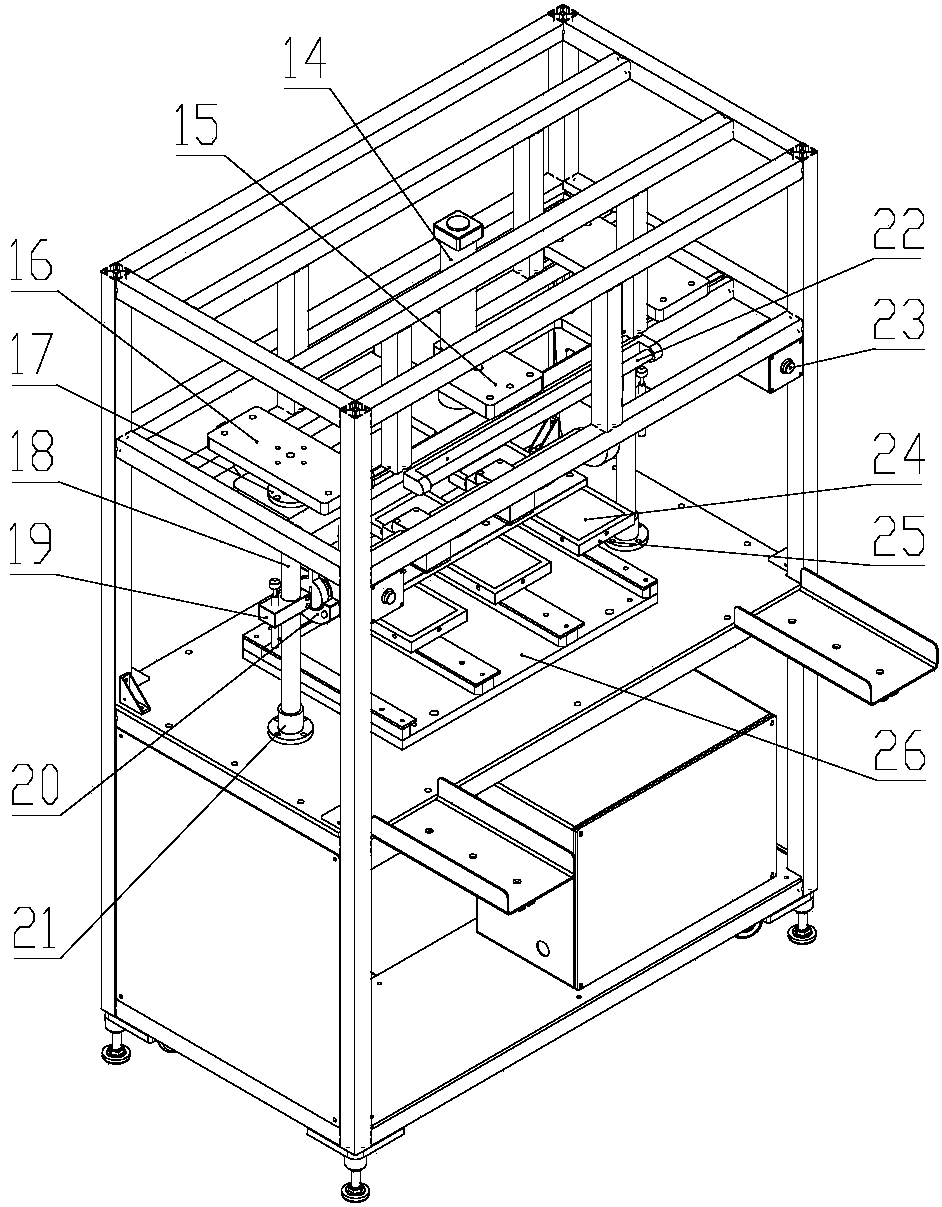

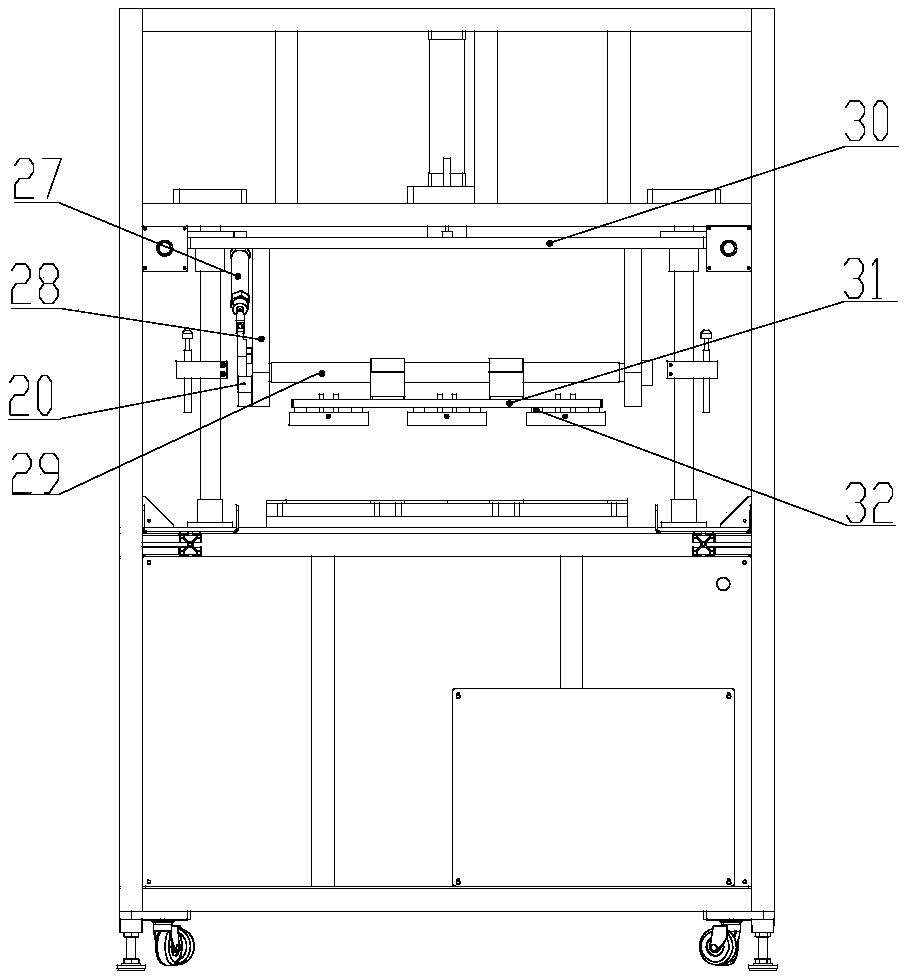

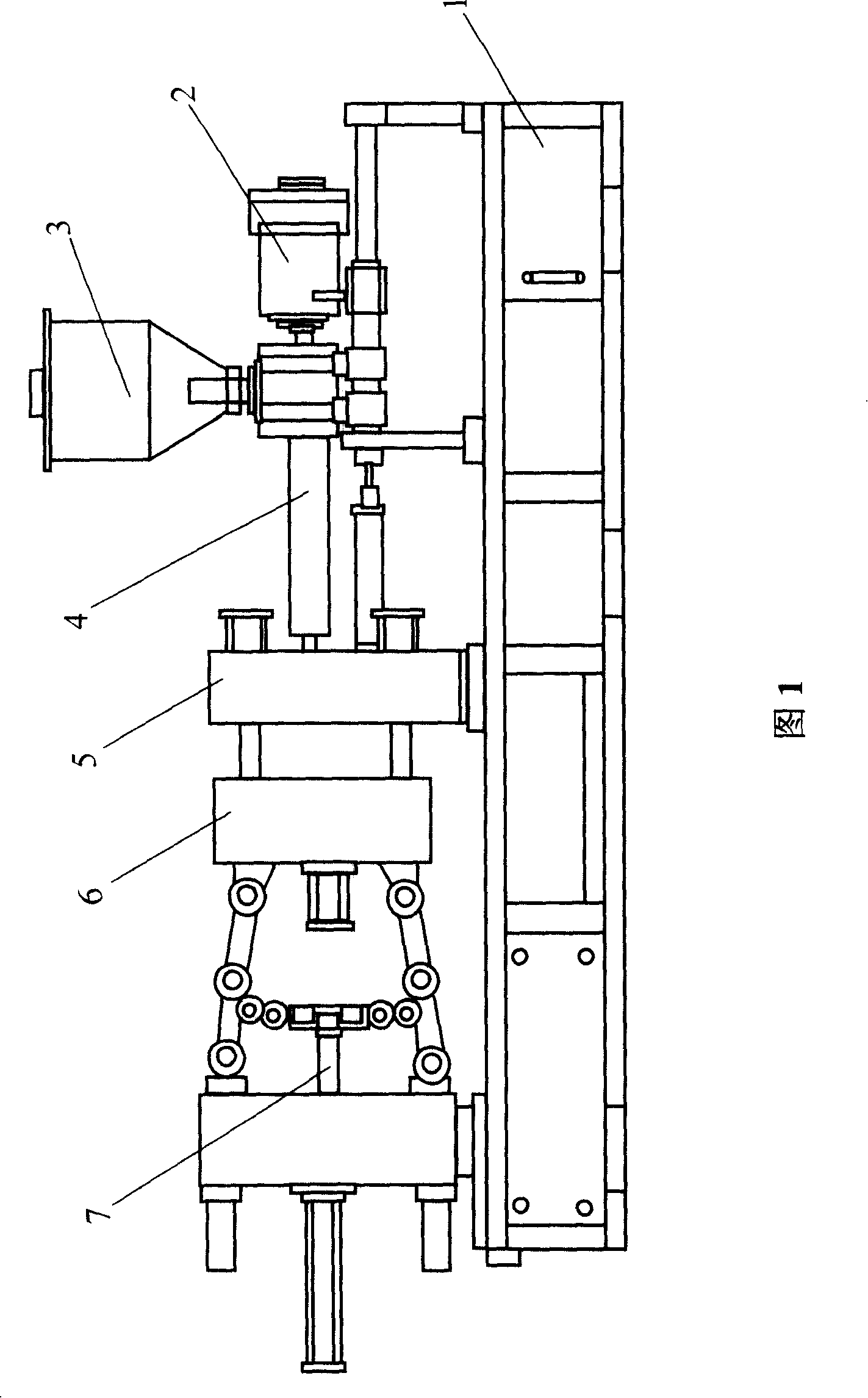

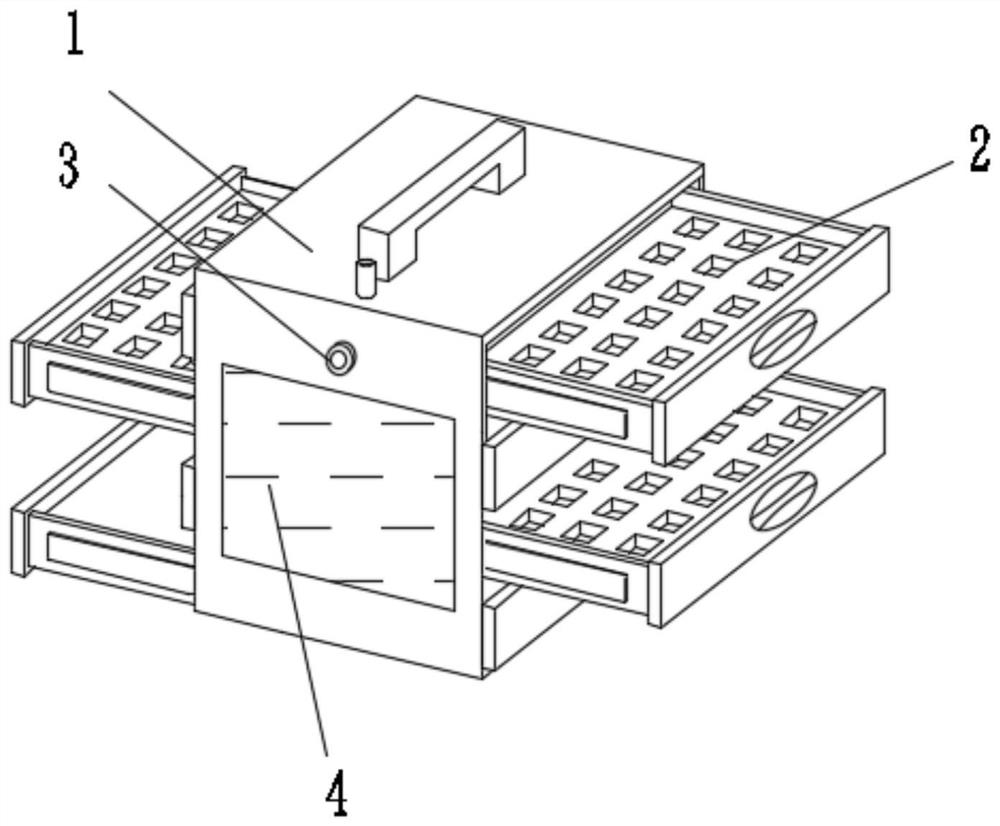

Pearl wool grooving device

PendingCN108262805AEasy to operateAdjust the production speed at willMetal working apparatusEngineeringElectric control

The invention discloses a pearl wool grooving device. The pearl wool grooving device comprises a framework, a lifting mechanism, an overturning mechanism, an upper grooving mold, a lower grooving moldand a control module; a hot cutter is assembled on the upper grooving mold, and is arranged in cutter rows with multiple cutter types; the framework comprises a frame, a base plate and a working platform; a loading tray and a taking tray are arranged in front of the working platform; the base plate is provided with an electric control box; the control module is arranged at the front part of the frame; the lower grooving mold and an inner frame are arranged on the working platform; the lifting mechanism is arranged on the inner frame, and is provided with the overturning mechanism through a lifting connection plate; and the overturning mechanism is provided with the upper grooving mold. The pearl wool grooving device adopts an automatic grooving device for grooving of multiple pearl wools,can once cut various grooves, randomly adjusts the production speed, is stable and flexible in mechanical operation and smooth in trimming without cokes, once finishes automatic feeding and collection, and is high in groove cutting efficiency.

Owner:苏州莱德泰克精密电子设备有限公司

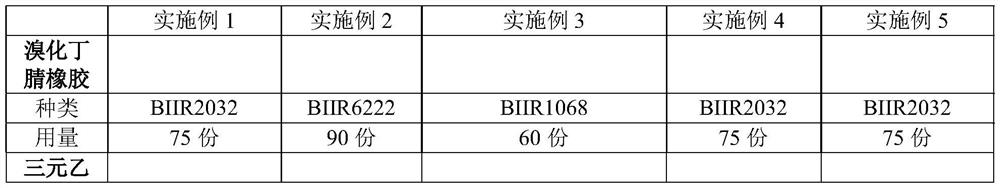

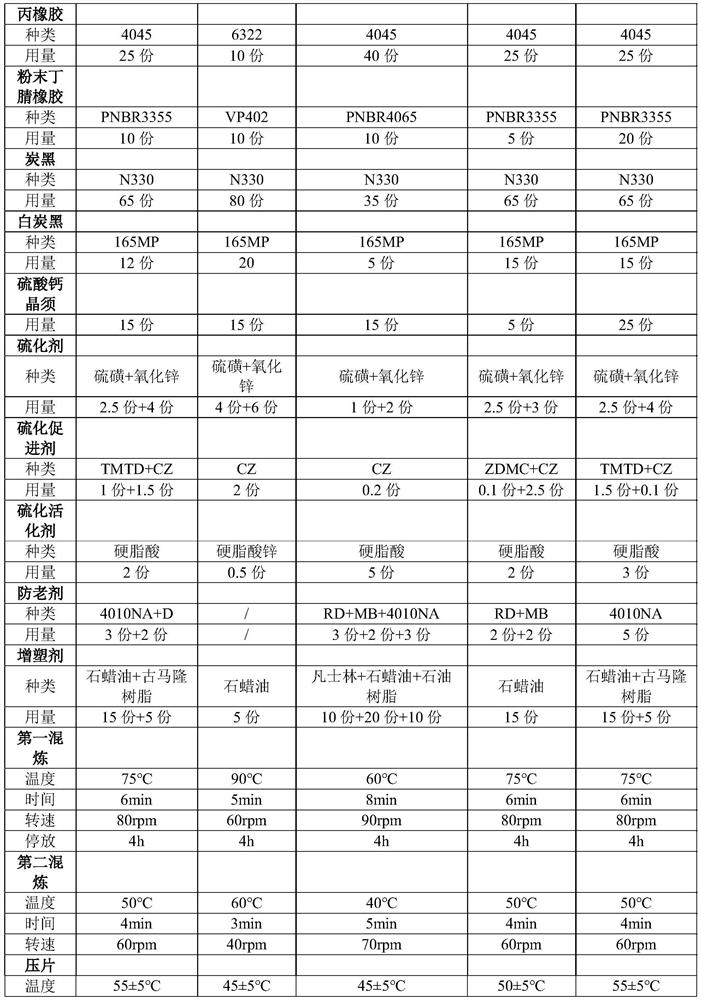

Acid-resistant rubber composition and application thereof, vulcanized rubber and preparation method and application thereof

PendingCN114181470AGood basic mechanical propertiesImprove acid resistanceRubber materialPolymer science

The invention relates to the field of rubber materials, and discloses an acid-resistant rubber composition and application thereof, vulcanized rubber as well as a preparation method and application thereof, the composition contains a rubber matrix, powdered nitrile rubber, a reinforcing agent, calcium sulfate whiskers, a vulcanizing agent, a vulcanization accelerator, a vulcanization activator and a plasticizer, and optionally contains an anti-aging agent, the rubber matrix is a combination of brominated nitrile rubber and ethylene propylene diene monomer, and the reinforcing agent is a combination of carbon black and white carbon black. The vulcanized rubber prepared by applying the rubber composition disclosed by the invention is excellent in acid resistance and good in basic mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

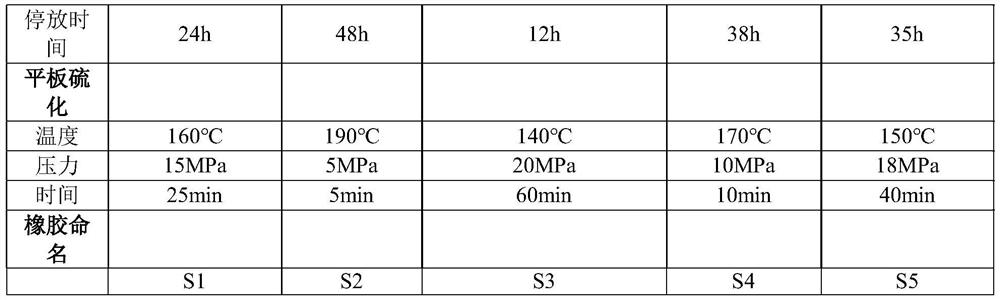

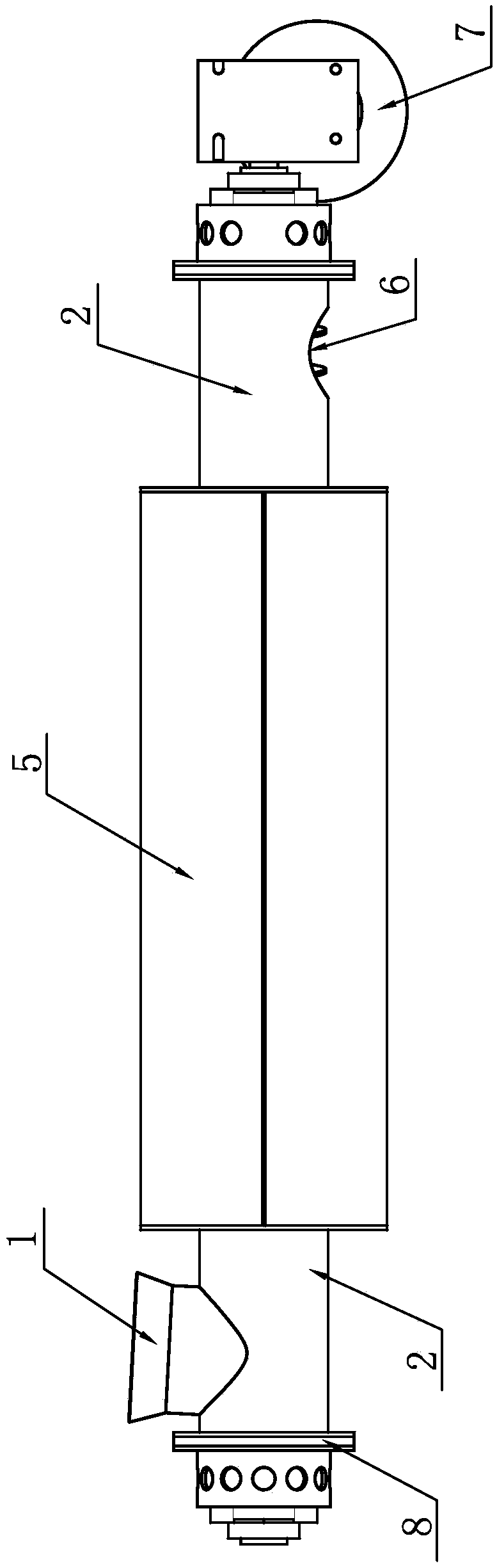

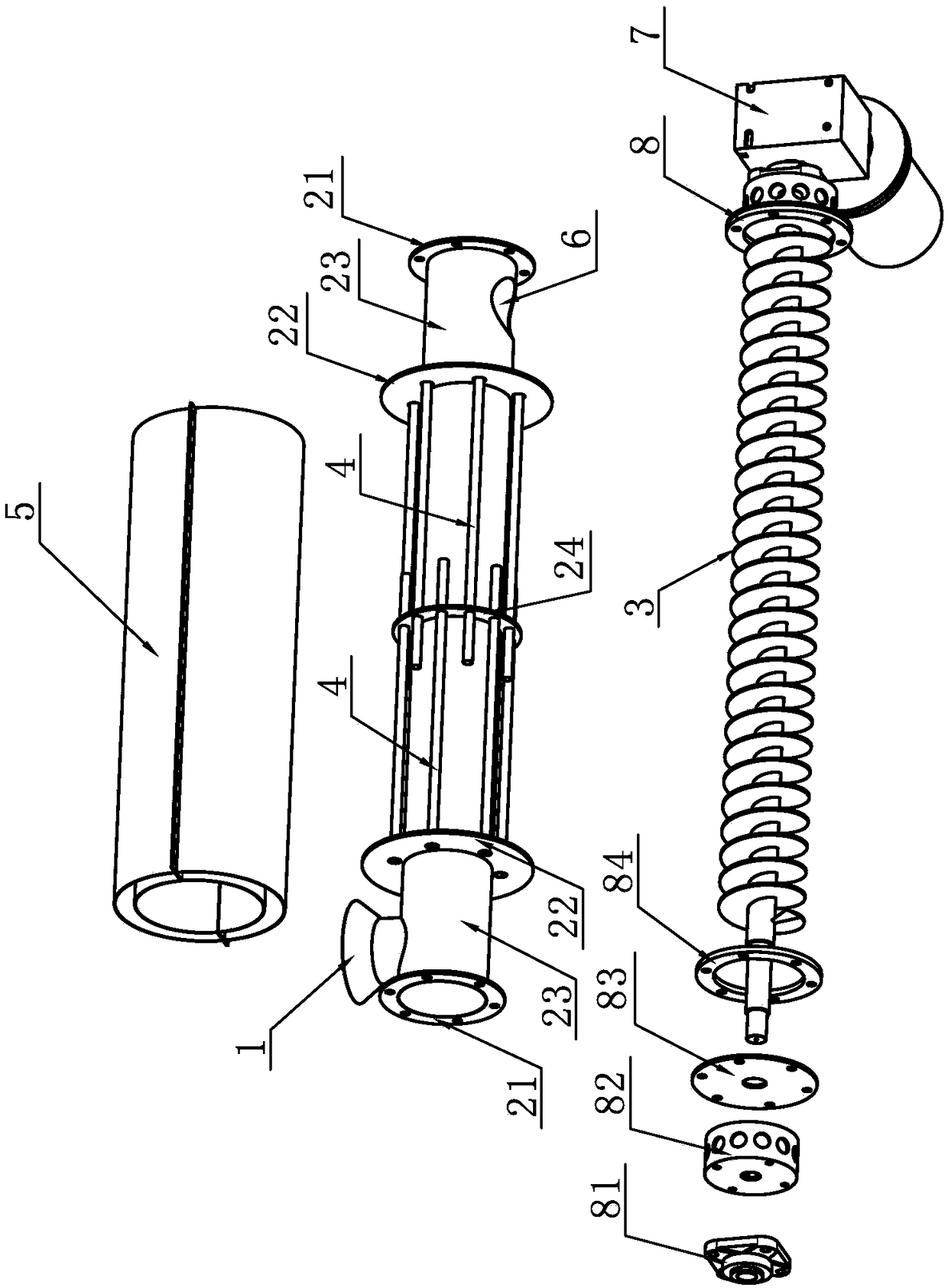

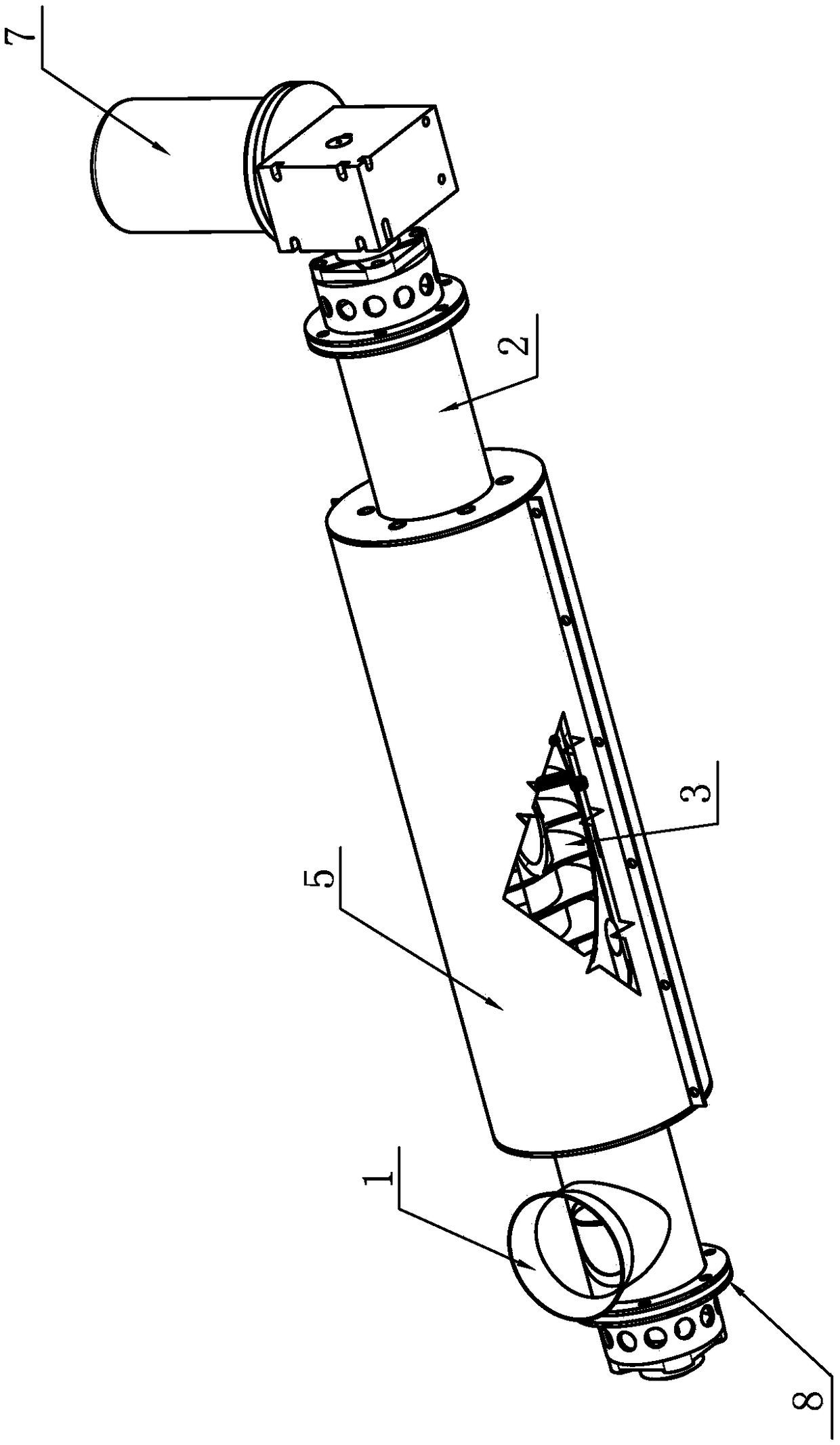

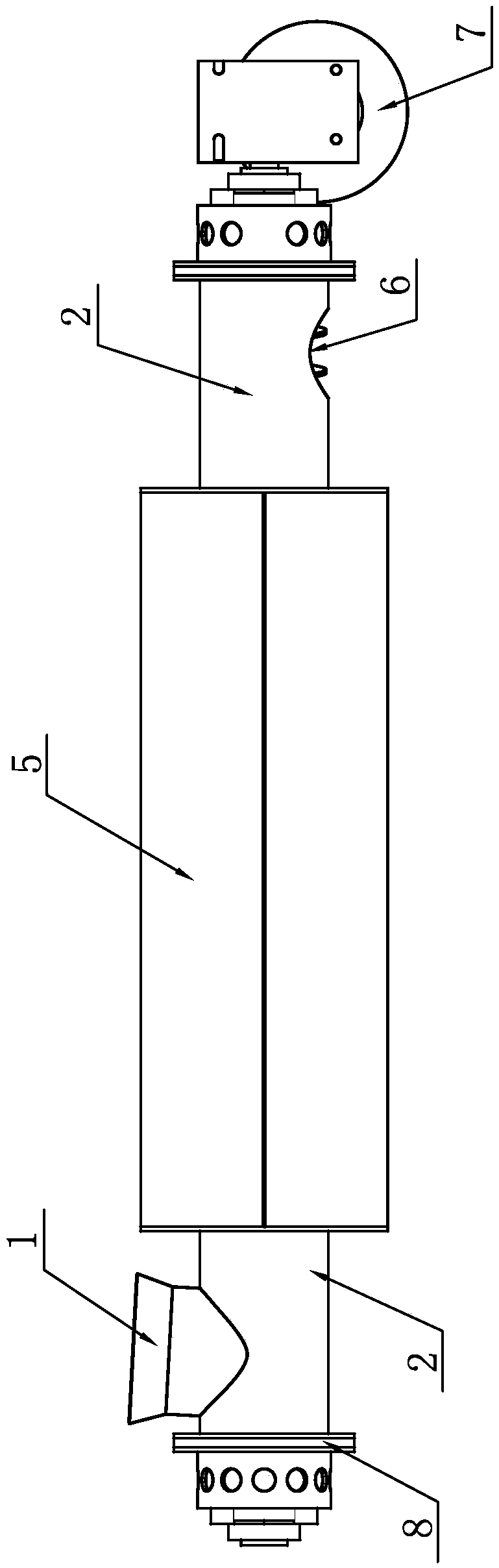

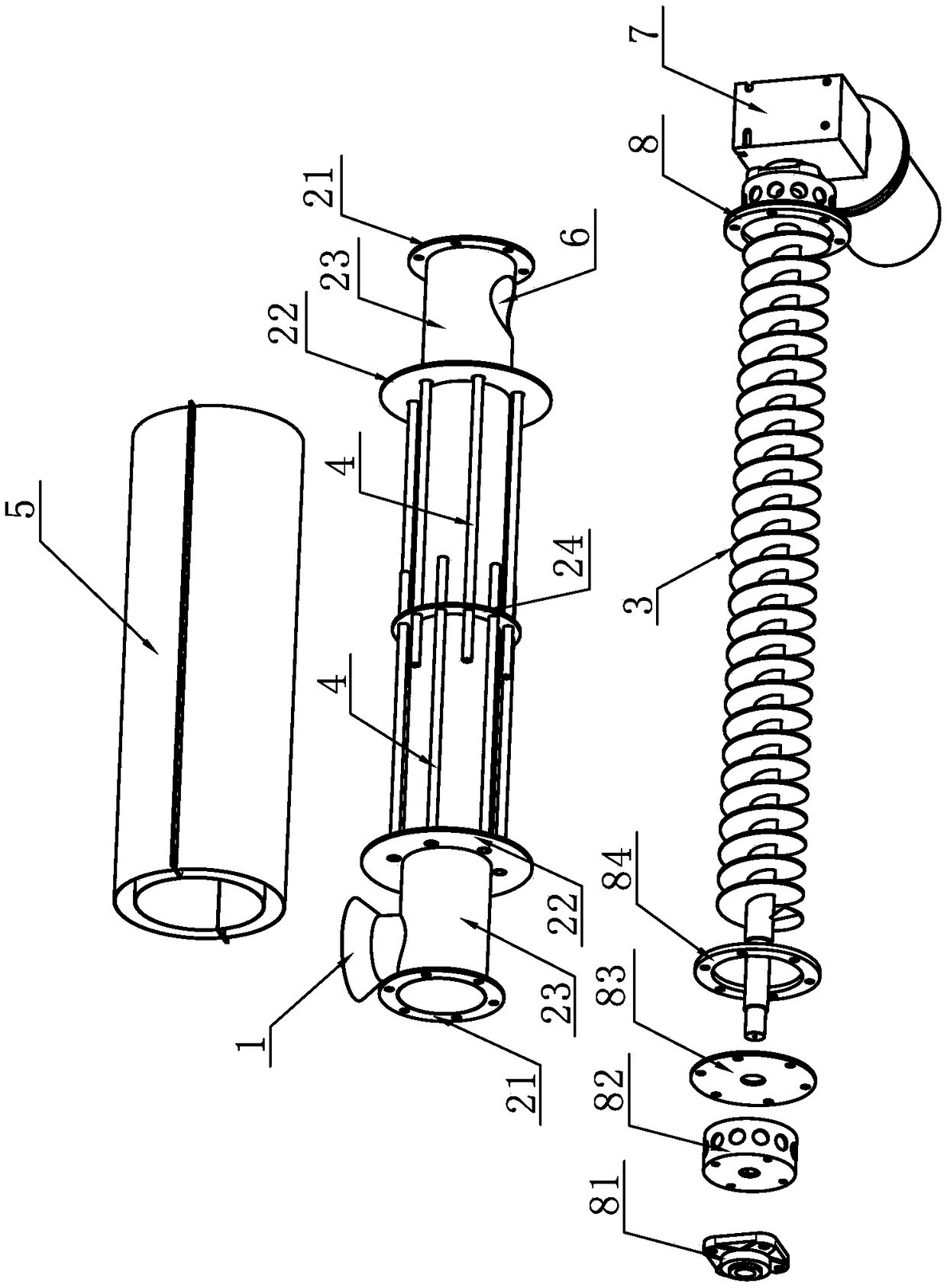

Transfer type heat sterilization drying pipeline part

PendingCN109210916AImprove dehydration efficiencyHeating evenlyDrying solid materialsGarbage dryingProcess engineeringFlange

The invention discloses a transfer type heat sterilization drying pipeline part. The transfer type heat sterilization drying pipeline part comprises a feeding pipe, a conveying pipe, heating parts, aheat insulation and heat preservation pipe and a drying discharging opening, wherein the heating parts are arranged between the heat insulation and heat preservation pipe and the conveying pipe. End face connecting flanges, heat preservation cylinder connecting flanges, a pipe body and a supporting ring are arranged on the conveying pipe, the heat preservation cylinder connecting flanges are arranged on a heating section of the pipe body, the supporting ring is arranged between the two heat preservation cylinder connecting flanges, the heating parts are installed on the heat preservation cylinder connecting flanges and the supporting ring, and the heat insulation and heat preservation pipe is installed between the two heat preservation cylinder connecting flanges. The transfer type heat sterilization drying pipeline part is a temperature field for heating, heat preservation, dehydration, drying and sterilization in a drying sterilization treatment device. A spiral auger is used for transporting materials to enable the materials to subjected to heating glue stir-frying under continuous stirring conditions, the dehydration efficiency is high, heating is uniform, sterilization is thorough, and no scorching and no caking are achieved. The transfer type heat sterilization drying pipeline part is matched with a belt type material transport mechanism for use to heat, dehydrate, dry and sterilize the materials.

Owner:江苏恒通环保科技有限公司

Special material for white polyvinylidene fluoride cast film

The invention discloses a special material for a white polyvinylidene fluoride cast film. The formula comprises the following components in parts by weight: 50-90 parts of polyvinylidene fluoride, 5-20 parts of titanium dioxide and 5-30 parts of polymethyl methacrylate; and the formula can further contain 0.05-1 weight part of antioxidant and / or 3-10 parts of compatibilizer. In the special material disclosed by the invention, the fluidity of polyvinylidene fluoride is improved by use of high-fluidity polymethyl methacrylate, and the casting film formation is facilitated; and meanwhile, the special material is prepared by a two-step method, namely that the polymethyl methacrylate and titanium dioxide masterbatch are prepared first, and then the special material for white polyvinylidene fluoride cast film is prepared, thus the decomposition promoting effect of the titanium dioxide on polyvinylidene fluoride is reduced. The special material disclosed by the invention easily flows in a casting mould while the scorching phenomenon is avoided; and the prepared polyvinylidene fluoride film has the advantages of uniform whiteness, no obvious dark lines, uniform film thickness and no obvious crystal points.

Owner:郑泓

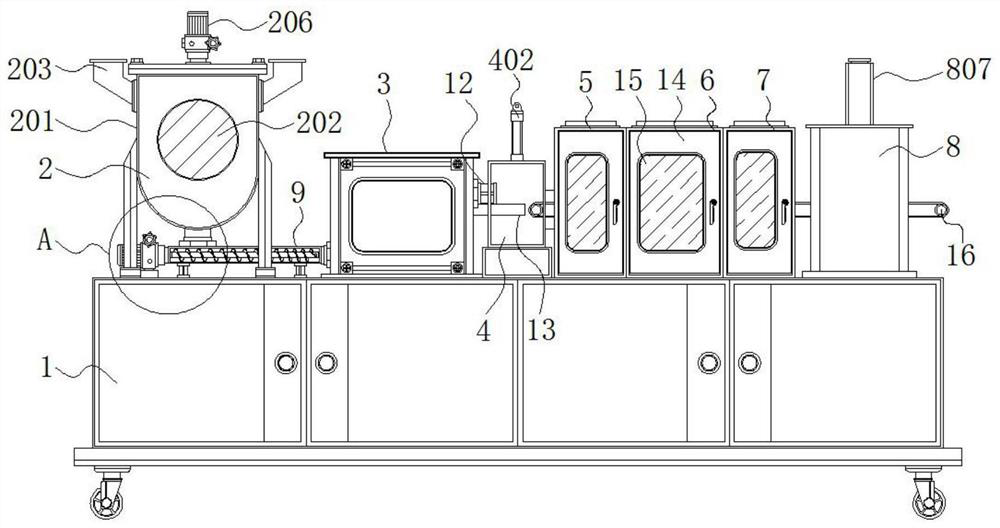

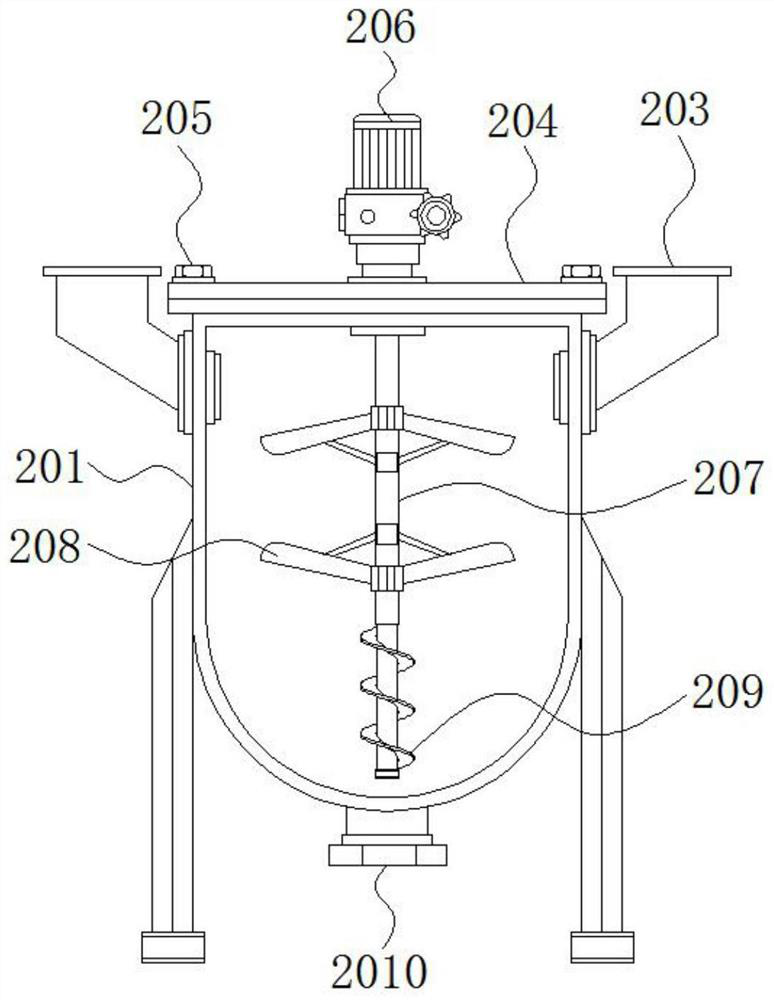

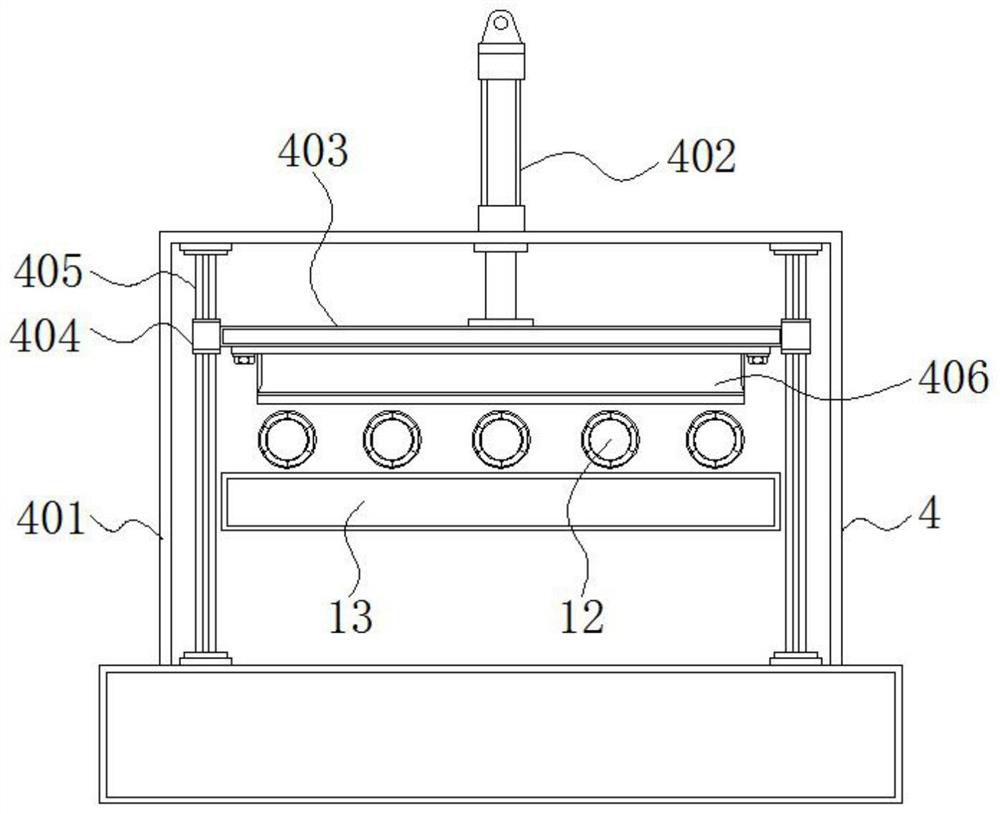

Oat bread formula and production equipment thereof

InactiveCN112385674AEasy to cleanRealize the delivery workDough treatmentMixing/kneading structural elementsProcess engineeringFermentation

The invention discloses an oat bread formula and production equipment thereof, and relates to the technical field of oat bread production. The oat bread production equipment comprises a bearing base,a conveying pipe and a temperature-resistant conveying belt, and a stirring mechanism, a puffing fermentation assembly, a cutting mechanism, a preheating baking box, a heating baking box, a low-heat baking box and an oil coating mechanism are sequentially arranged at the upper end of the bearing base from left to right. Through the preheating baking box, the heating baking box and the low-heat baking box which are distributed in parallel, cut fermentation raw materials are sequentially conveyed into the preheating baking box, the heating baking box and the low-heat baking box through the temperature-resistant conveying belt to complete the baking of bread. Through the arrangement of the preheating baking box, the heating baking box and the low-heat baking box, the quality of baked bread isguaranteed, the situation of bread scorching caused by directly entering high temperature baking is avoided, and the internal situation of the three baking boxes can be checked in real time through arranged heat insulation glass so as to ensure the continuity and effectiveness of baking work.

Owner:南通梦桦食品有限公司

Smoke-free gas barbecue grill

PendingCN108451386AEvenly heatedUniform temperatureDomestic stoves or rangesLighting and heating apparatusHeat conductingEngineering

The invention discloses a smoke-free gas barbecue grill. The smoke-free gas barbecue grill comprises a grill body, a gas division device and a grill grid, wherein an opening of which the upper part and the lower part penetrate through each other is formed in the furnace body; the gas division device is fixed in the opening; the grill grid is movably erected on the opening; the gas division devicecomprises a main pipeline and a plurality of branch pipelines communicated with the main pipeline; one end, away from the main pipeline, of the corresponding branch pipe is sealed and a column of exhaust holes are formed in the upper ends of the branch pipelines; an inner cavity communicated with the main pipeline is formed in the grill body; a gas pipe communicated with the main pipeline is arranged in the inner cavity; a gas inlet which enables the inner cavity to be communicated with the outside is formed in a side wall of the grill body. The smoke-free gas barbecue grill also comprises metal heat conducting pieces corresponding to the branch pipelines; the metal heat conducting pieces are detachably buckled and covered on the upper end surfaces of the branched pipelines; the cross sections of the metal heat conducting pieces are arched; an oil receiving tray is arranged under the opening. When the grill is used, heat is uniform, oil smoke is avoided, and the grill is clean and sanitary, and is convenient to clean.

Owner:GUANGZHOU HAKE KITCHEN EQUIP

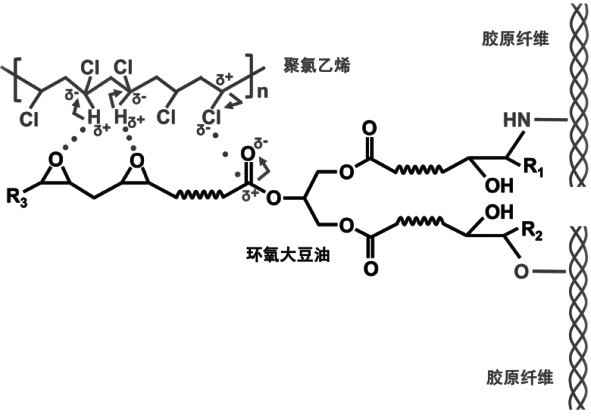

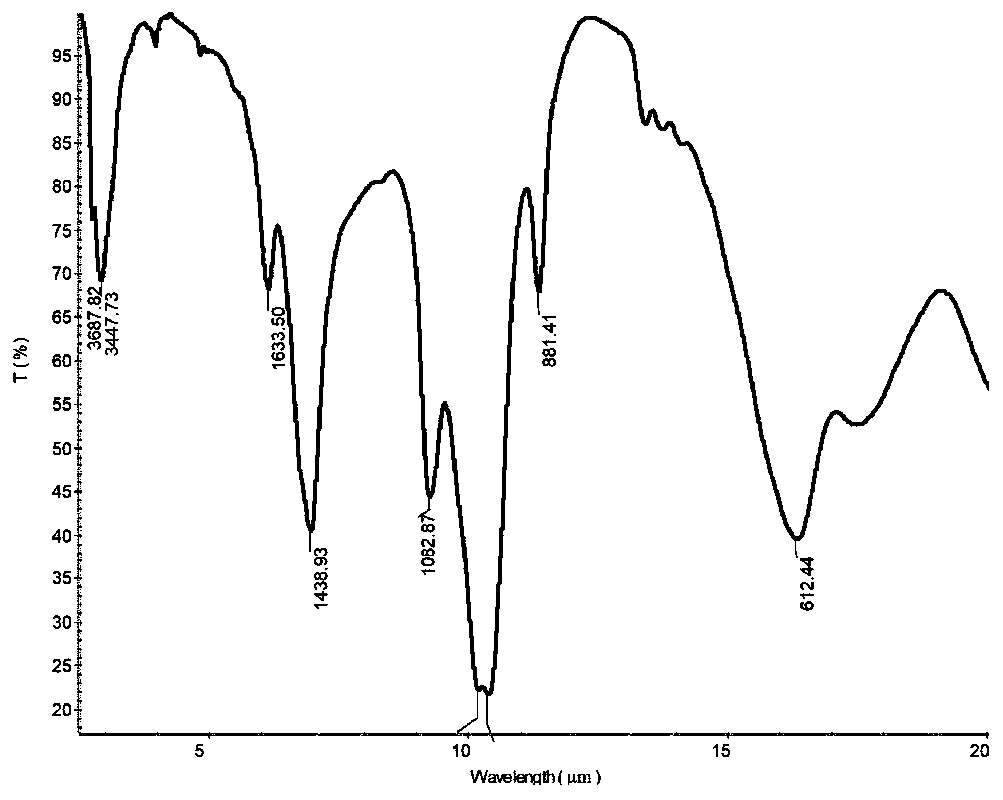

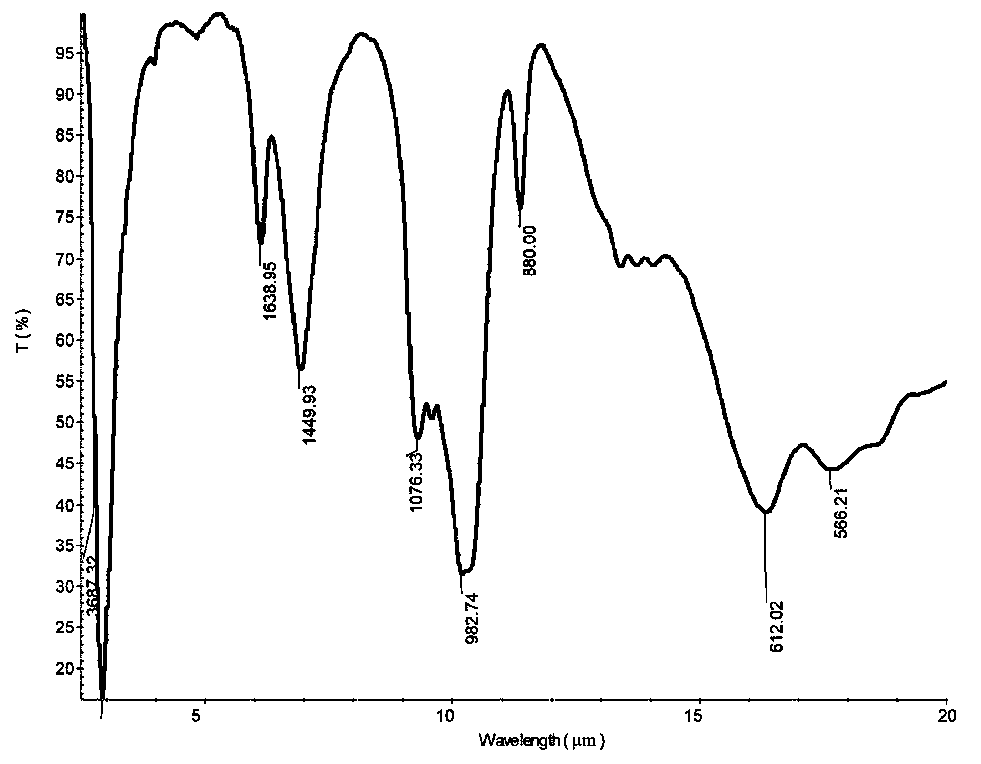

Epoxidized soybean oil modified collagen fiber as well as preparation method and application thereof

ActiveCN114086390AAchieve hydrophobic modificationLower free energyLiquid repellent fibresAnimal fibresFiberPolymer science

The invention relates to the technical field of composite materials, and provides an epoxidized soybean oil modified collagen fiber as well as a preparation method and application thereof. The preparation method comprises the following steps: carrying out ring-opening grafting reaction on pretreated collagen fibers and a solution containing epoxidized soybean oil and a catalyst at 80-140 DEG C for 4-12 hours. The invention further provides a modified composite material which comprises the epoxidized soybean oil modified collagen fiber and a high polymer, and the high polymer is a high polymer material with the forming processing temperature not higher than the dry heat denaturation temperature of the collagen fiber. According to the invention, the collagenous fiber is modified by using the epoxidized soybean oil, so that the surface free energy of the collagenous fiber is reduced, and the surface of the collagenous fiber has hydrophobicity. The prepared epoxidized soybean oil modified collagenous fibers are mixed with a high polymer matrix, so that the surface free energy and surface polarity difference between the collagenous fibers and the high polymer matrix are reduced, and the obtained modified composite material has excellent mechanical properties and heat resistance.

Owner:SICHUAN UNIV

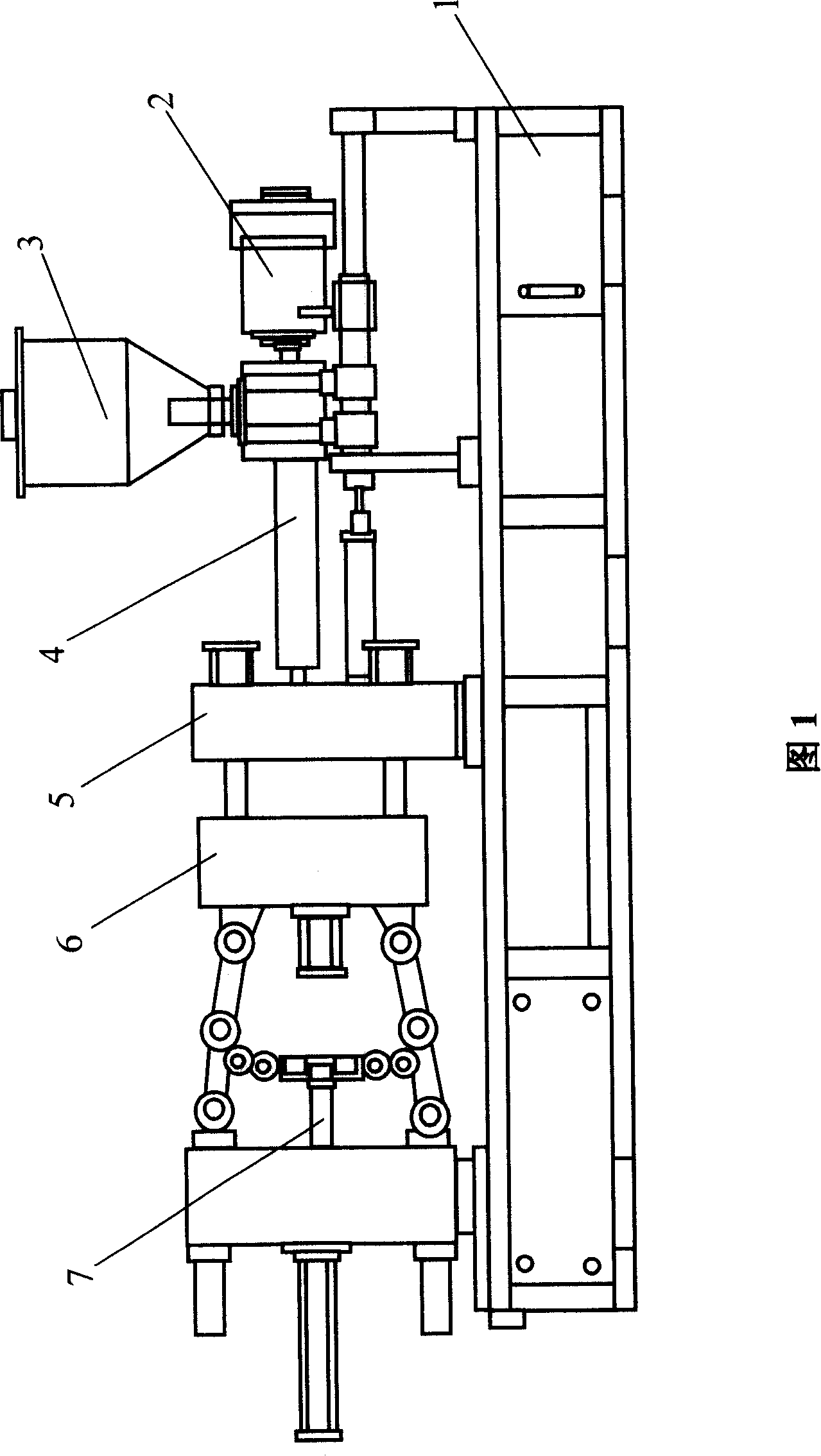

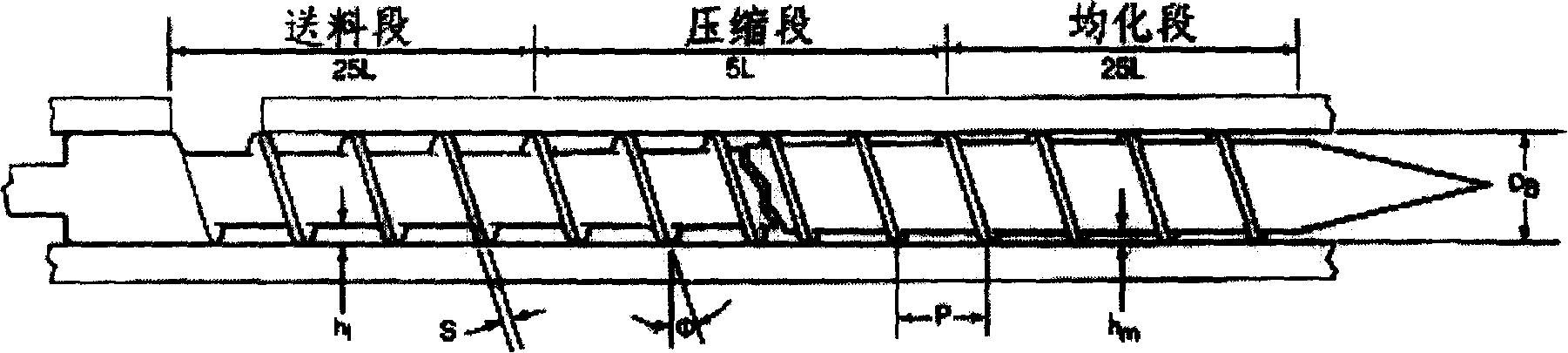

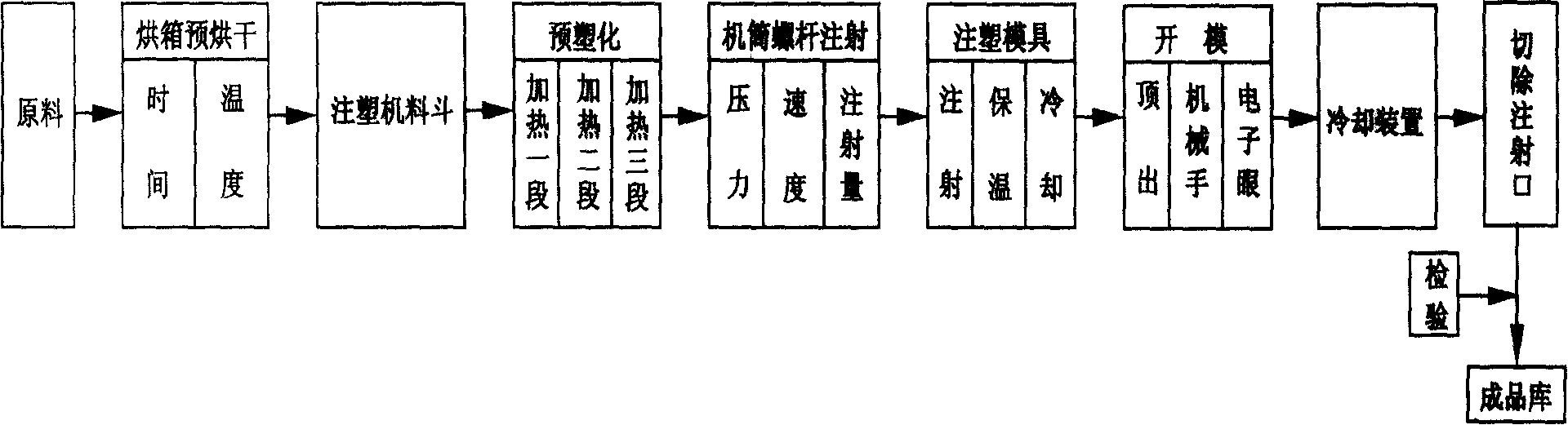

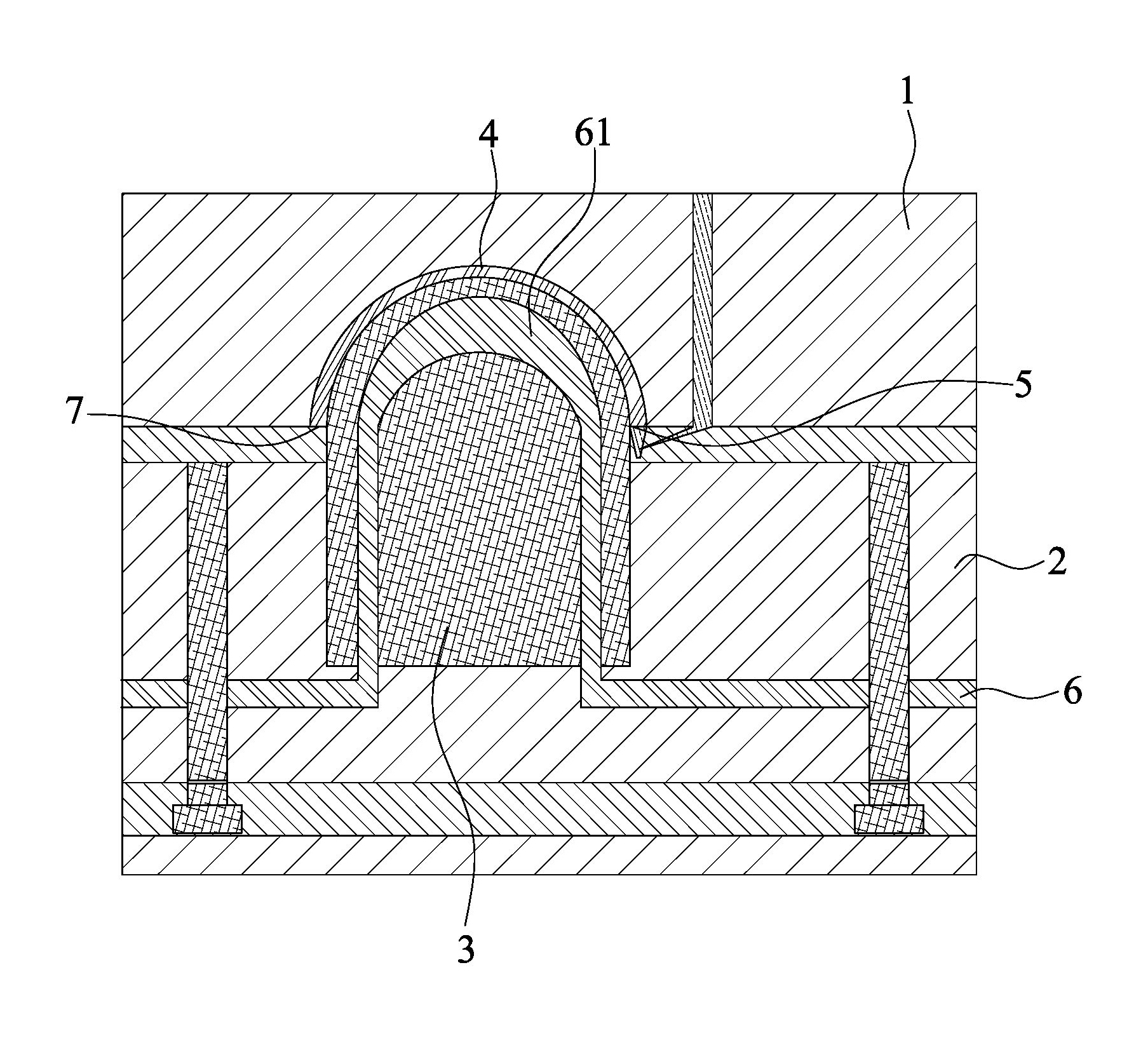

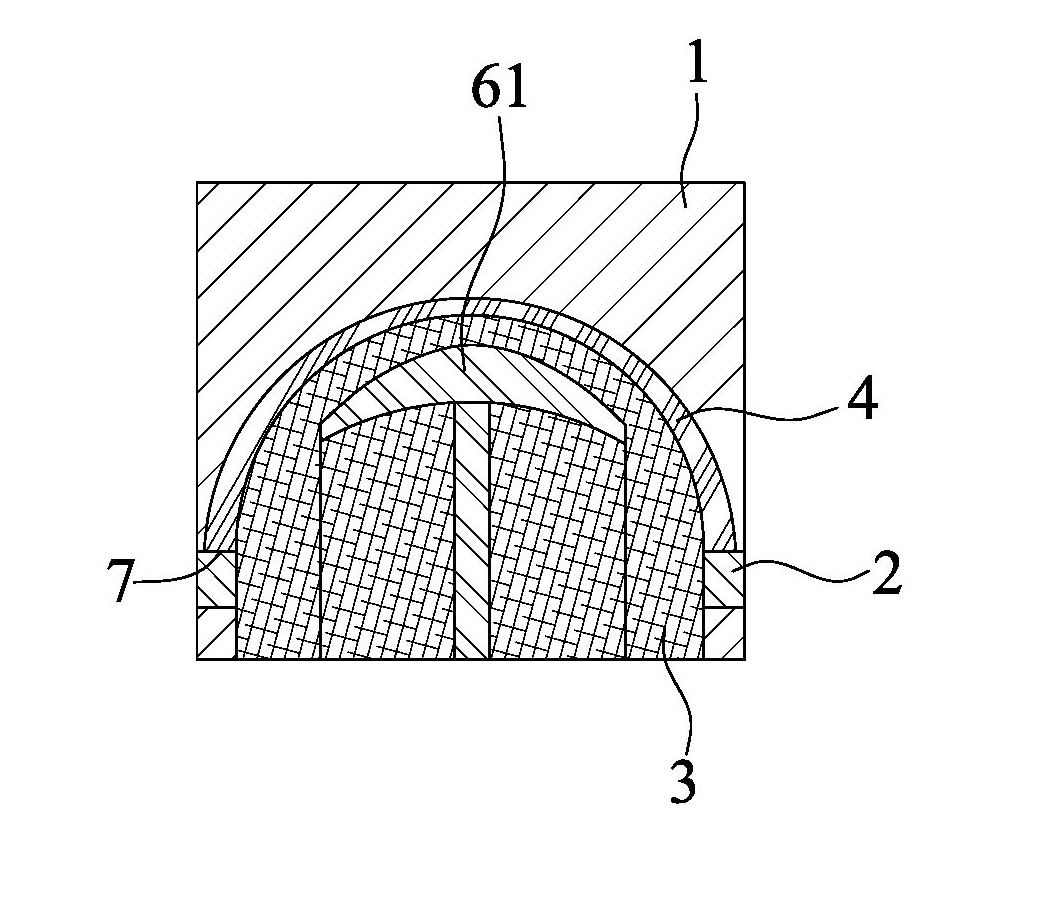

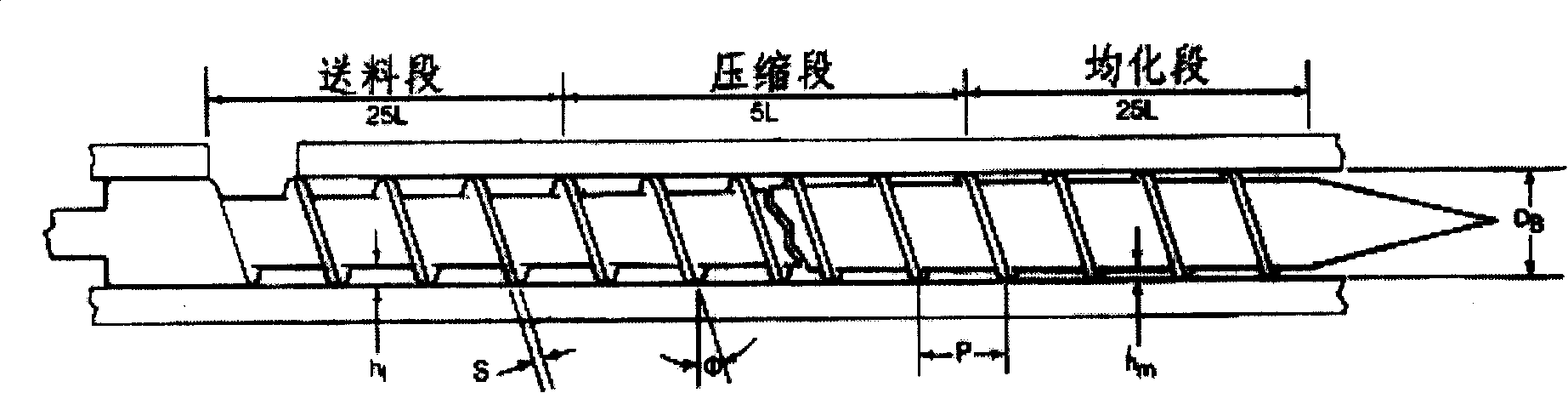

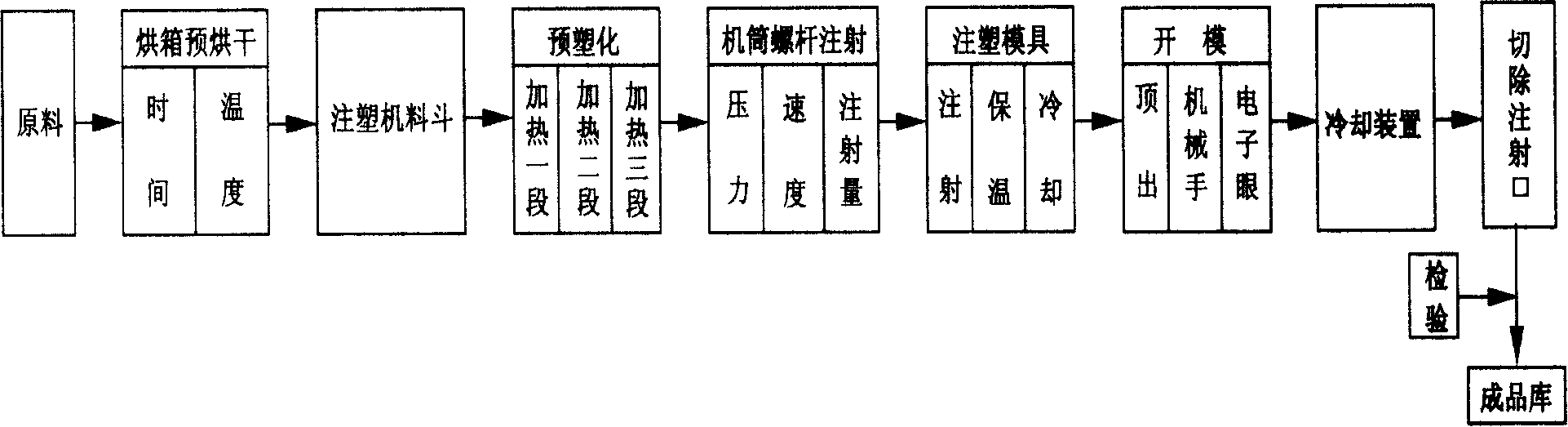

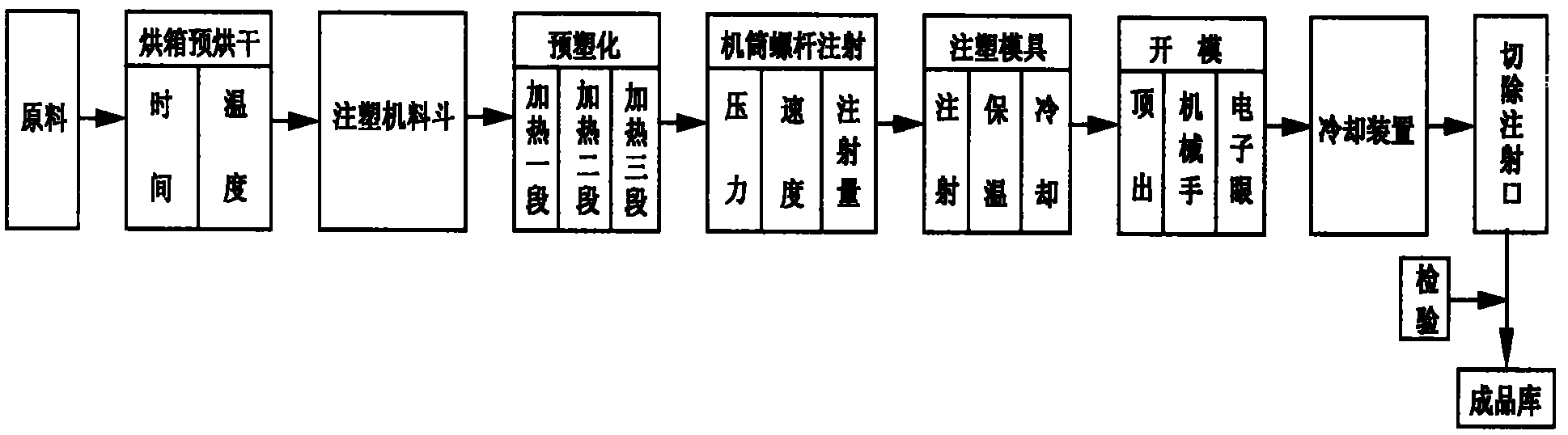

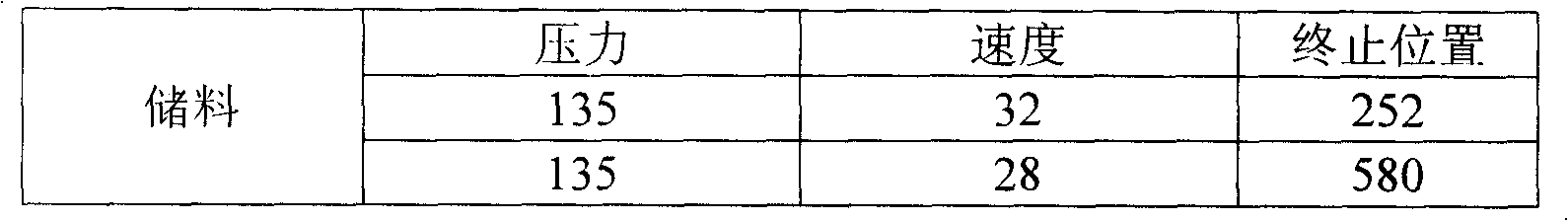

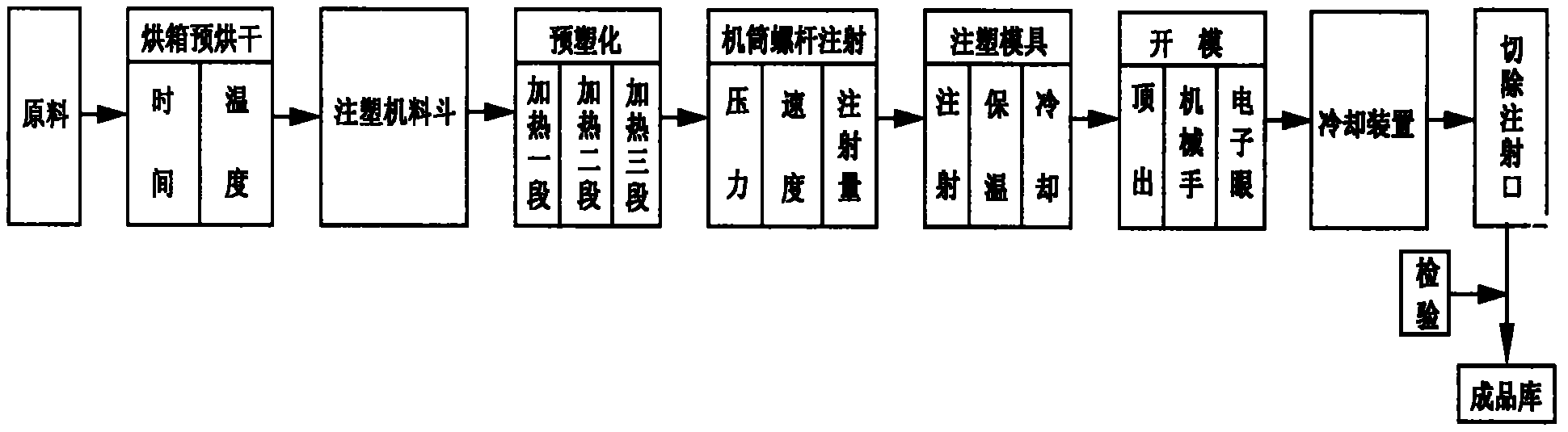

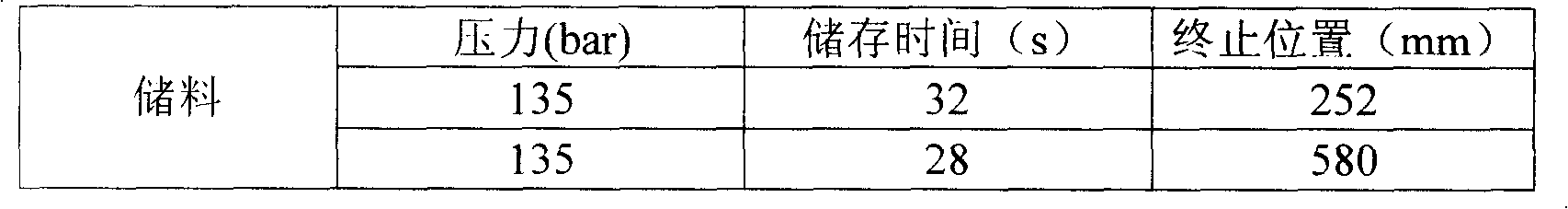

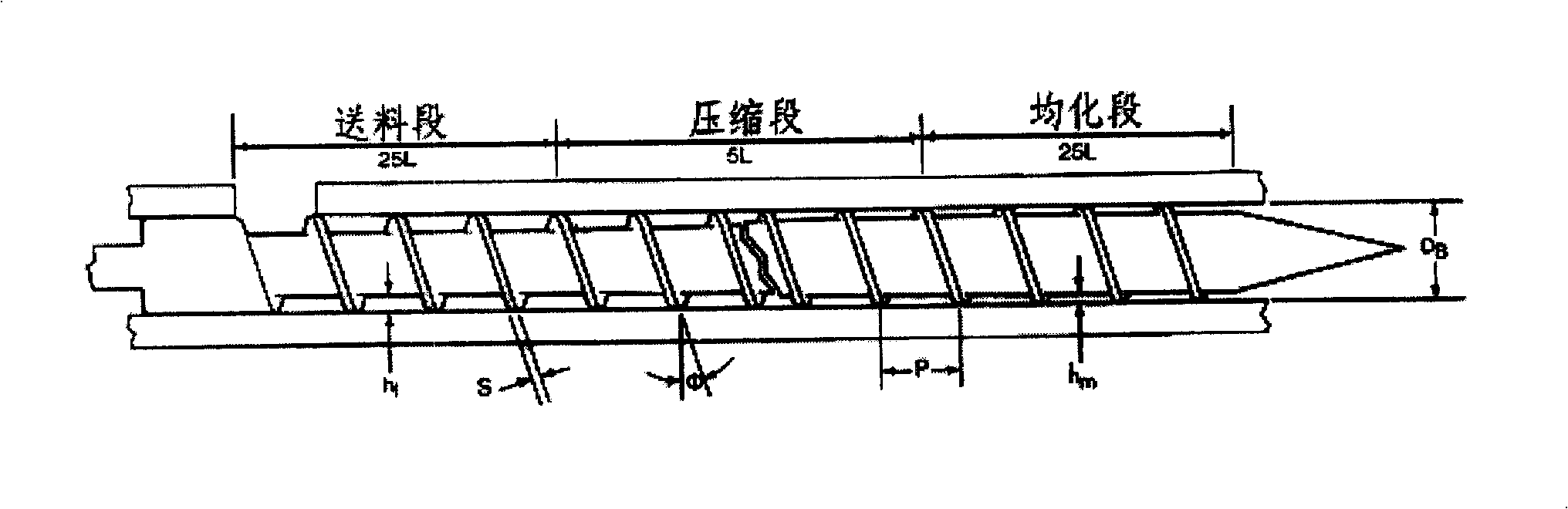

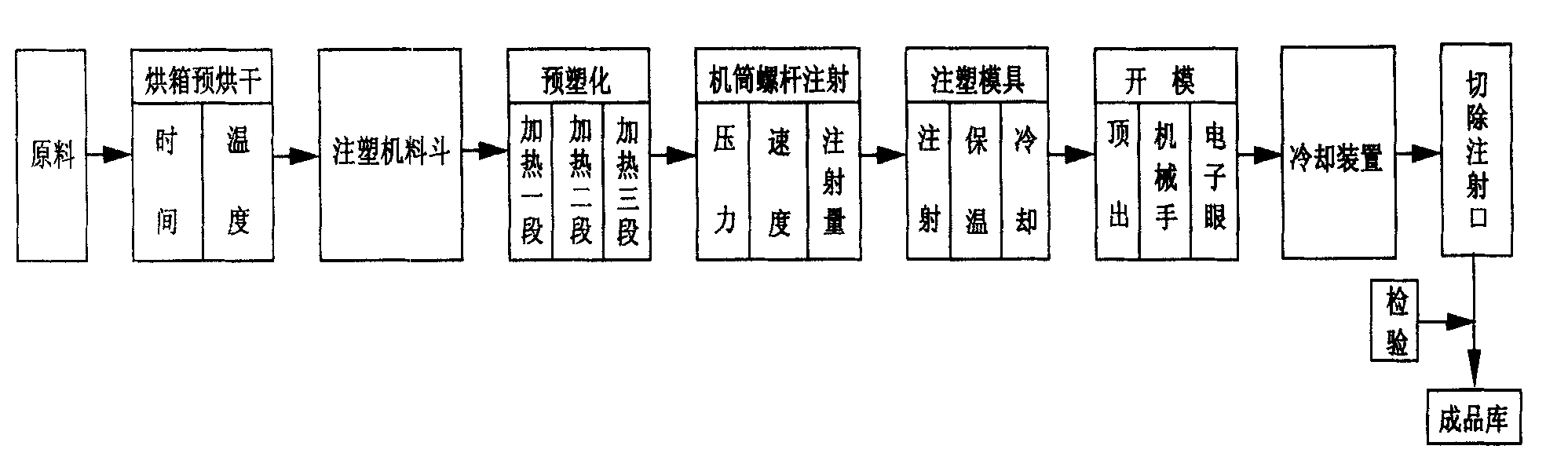

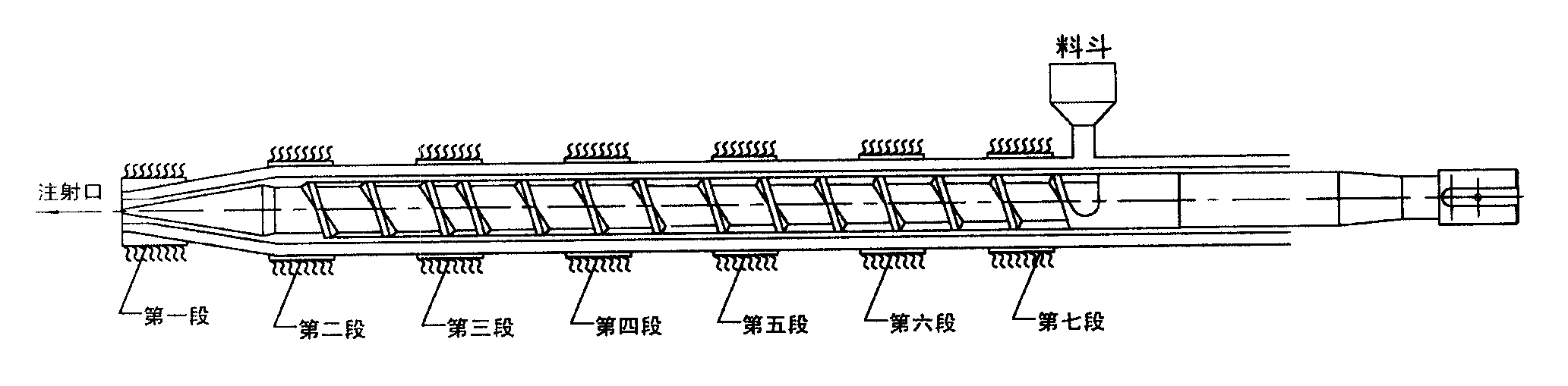

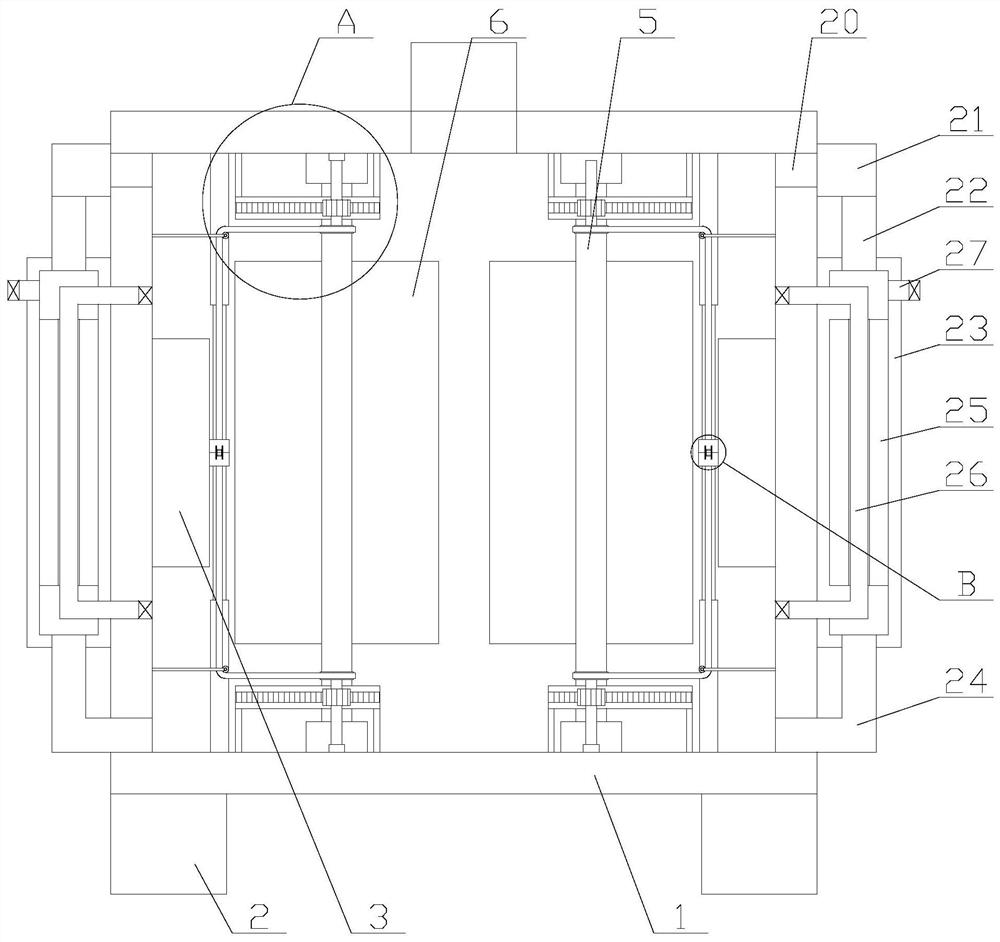

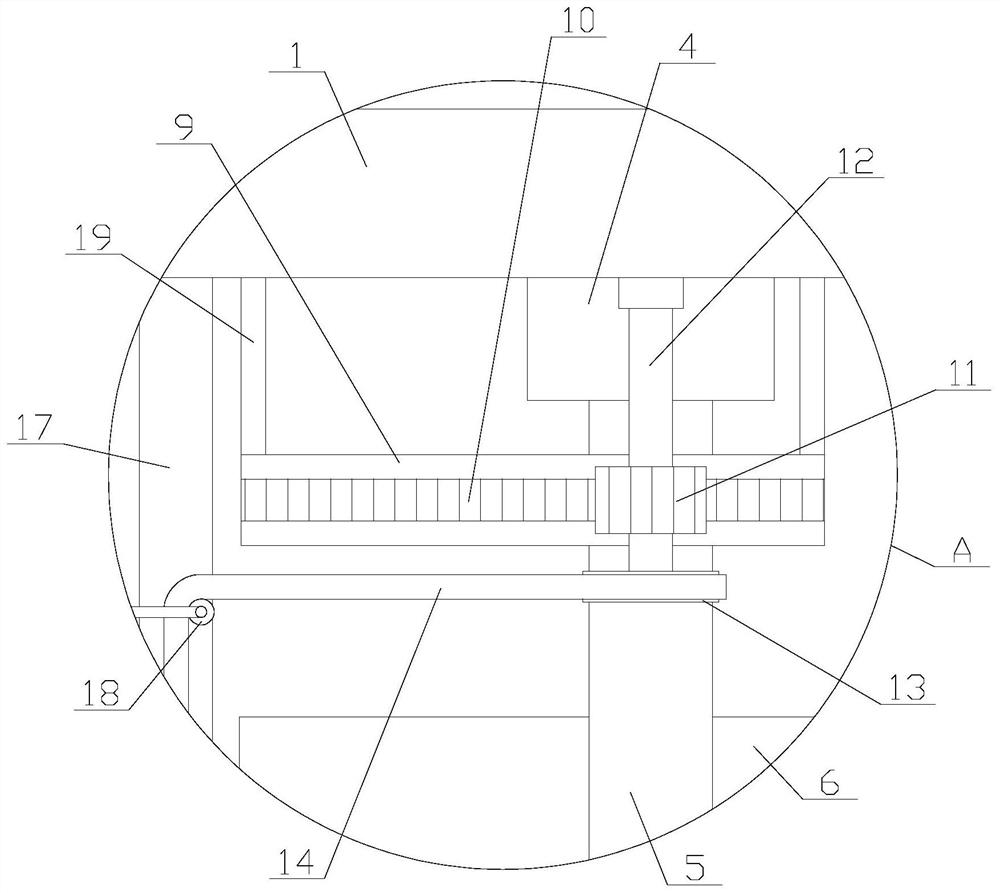

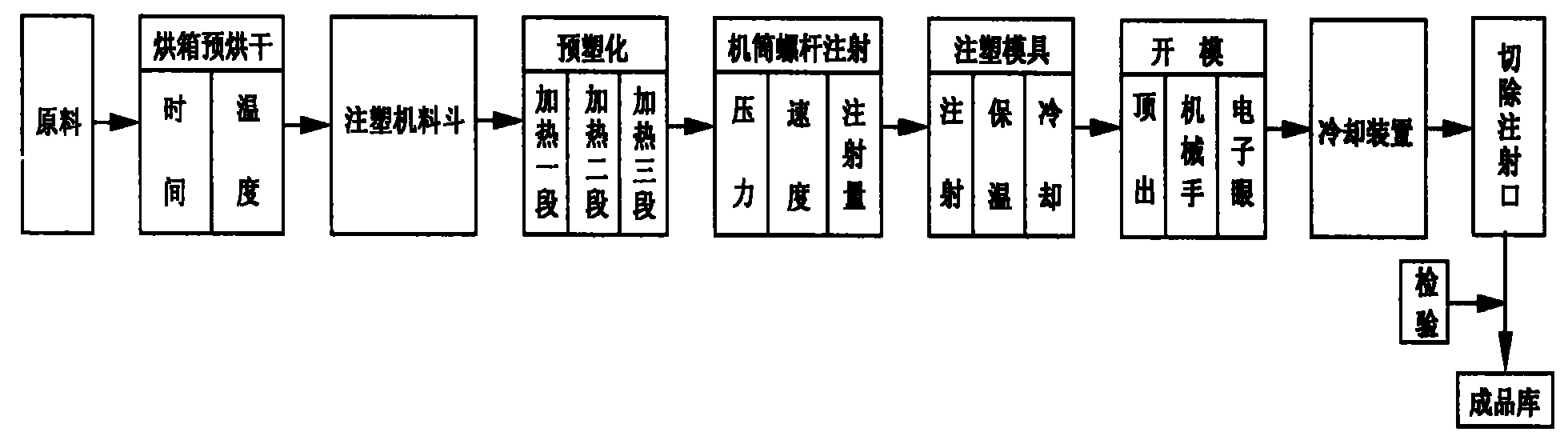

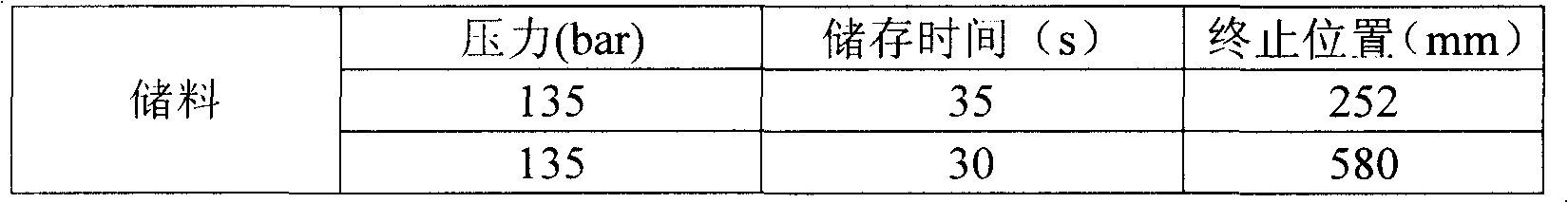

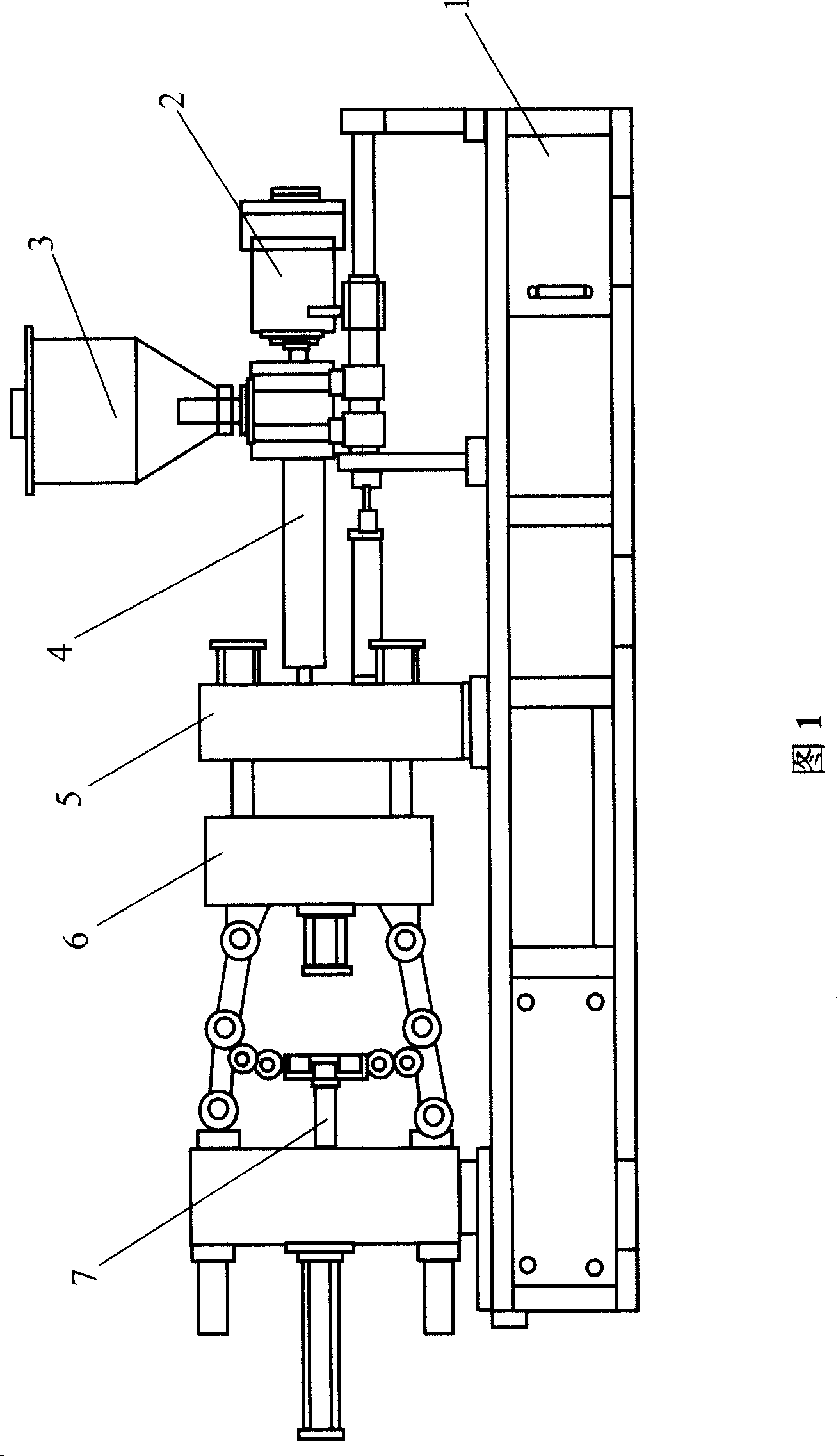

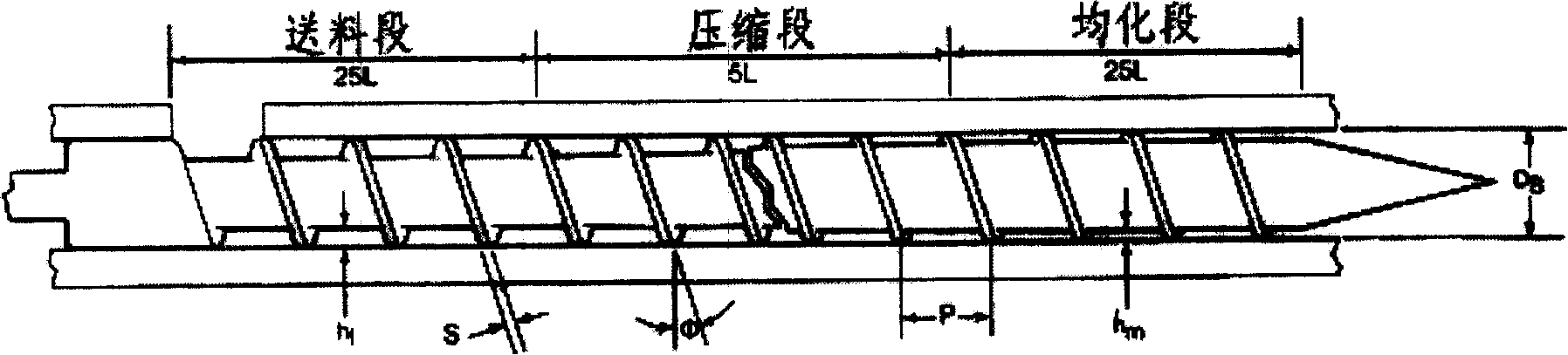

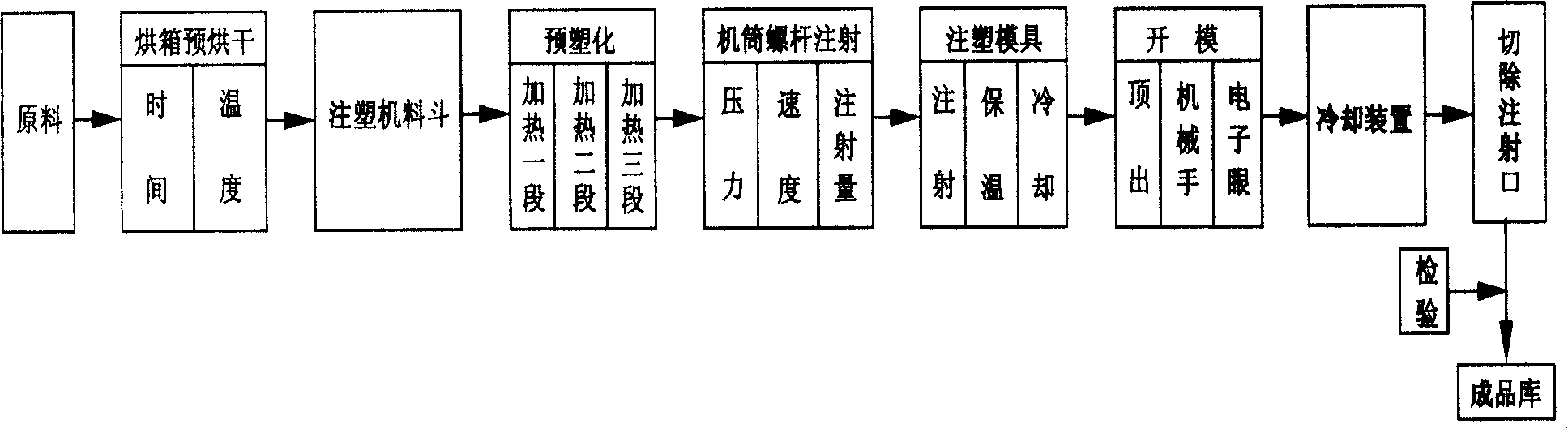

Chlorinated polyvinyl chloride DN400 elbow pipe fitting once injection moulding technique and device thereof

InactiveCN101168286AReduce frictional heatStable speedTubular articlesTemperature controlInjection pressure

The invention relates to a production process of resin pipe fittings, in particular to a one-time injection molding process and equipment for chlorinated polyvinyl chloride elbow pipe fittings. The process includes batching, drying, injection molding, pressure holding, and mold opening process. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the temperature range of each section is 150-155°C and 168-173°C. , 162~167℃, 160~165℃, 155~160℃, 150~155℃, 145~150℃, the mold temperature is controlled between 60~70℃; the injection pressure during injection molding is divided into three sections, respectively 58MPa , 65MPa and 80MPa. The pitch of the injection molding machine screw used in the method is equal to the diameter of the screw, the feeding section accounts for 25% of the total length, the compression section accounts for 50% of the total length, and the homogenization section accounts for 25% of the total length. The invention realizes one-time injection molding of DN400 large elbow pipe fittings through the improvement of process and equipment.

Owner:YOULI HLDG GRP

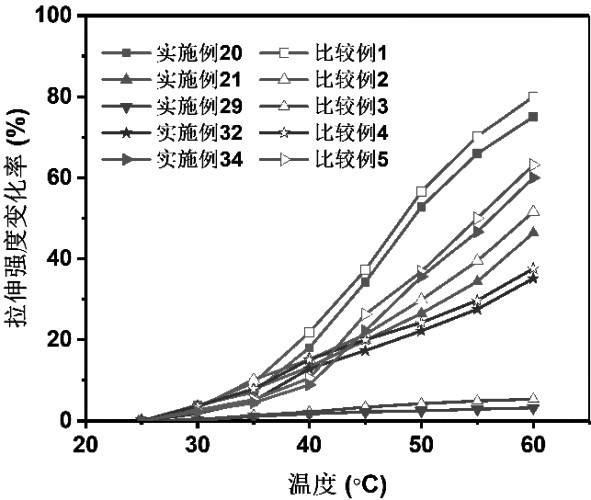

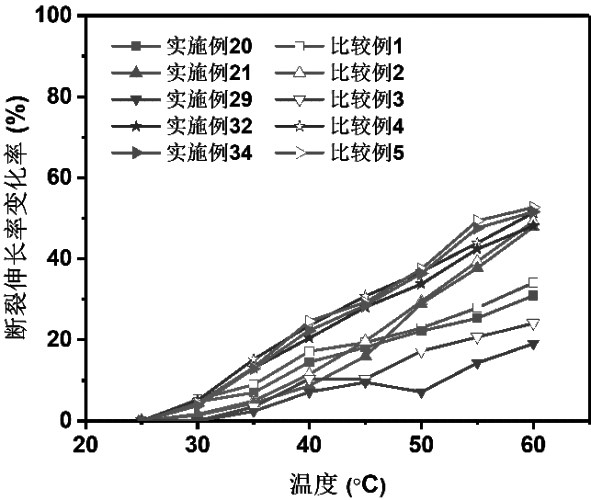

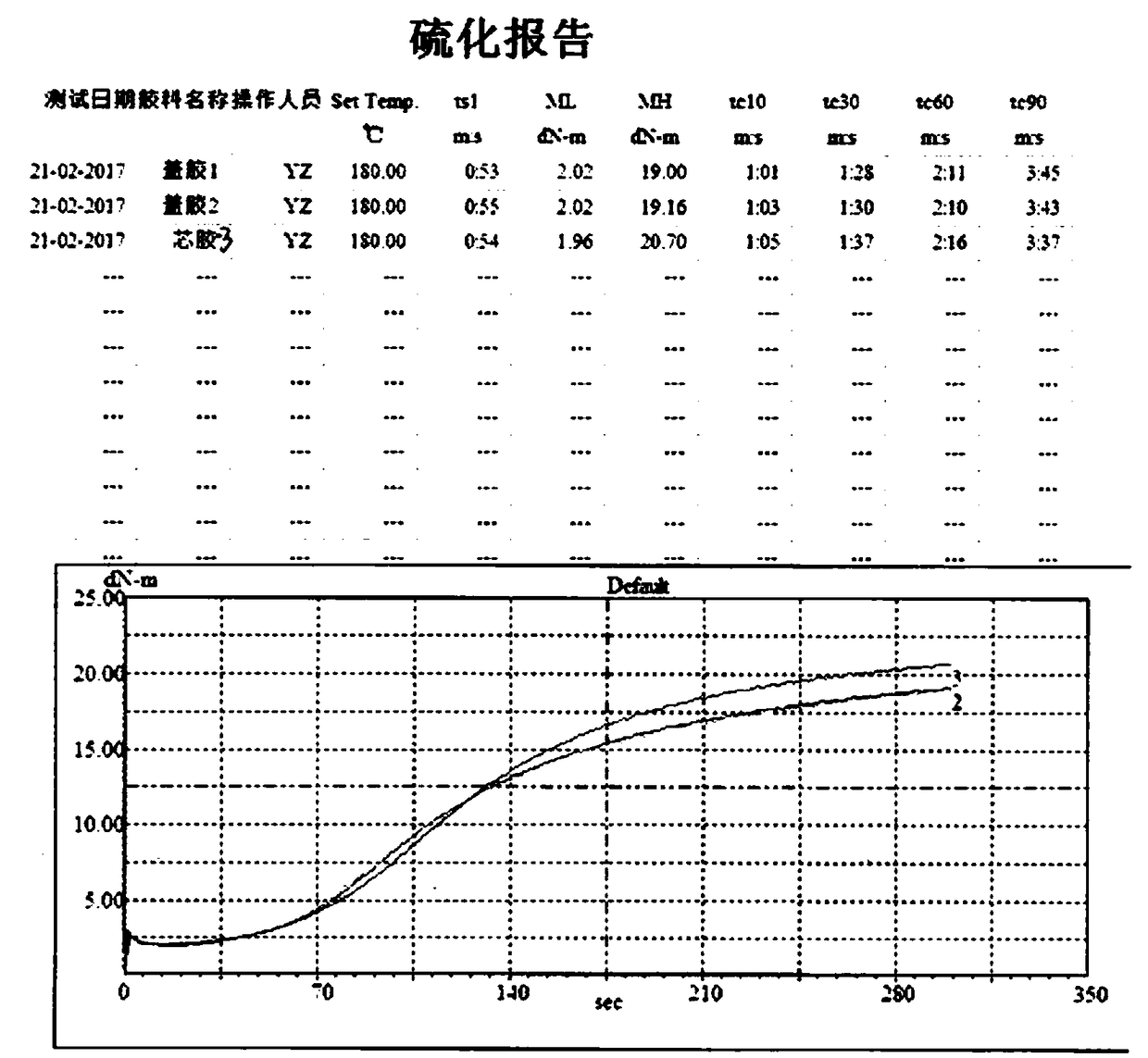

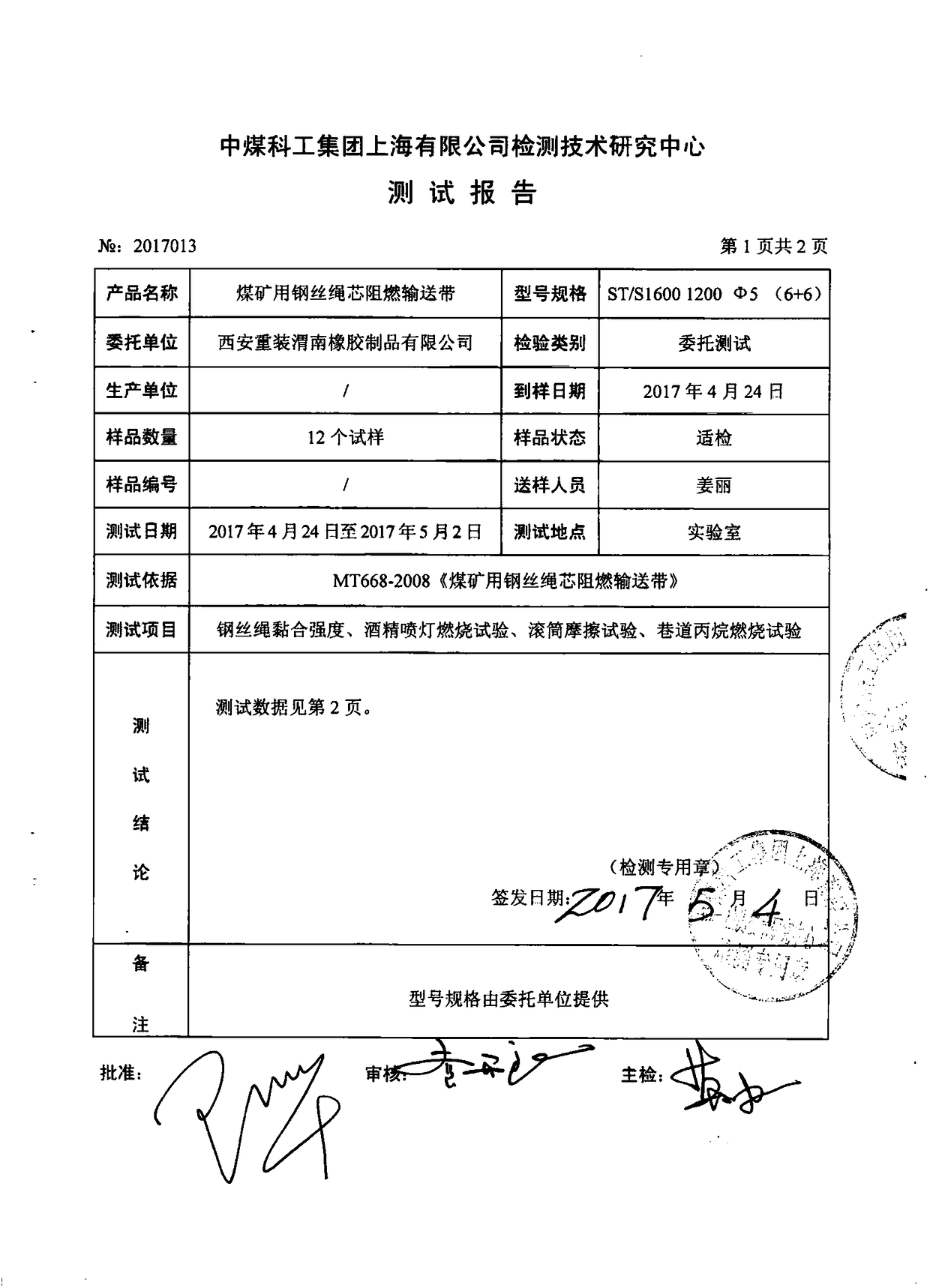

Preparation method of high-performance, low-halogen, environment-friendly and flame-retardant steel wire rope core conveyer belt

The invention discloses a formula of a high-performance, low-halogen, environment-friendly and flame-retardant steel wire rope core conveyer belt. The conveyer belt is prepared from raw materials in parts by weight as follows: 60.0 parts of styrene-butadiene rubber, 20.0 parts of butadiene rubber, 20.0 parts of standard rubber, 6.0 parts of indirect zinc oxide, 0.8 parts of an anti-aging agent RD,1.5 parts of an anti-aging agent 4010NA, 1.5 parts of paraffin, 18.0 parts of 70# chlorinated paraffin, 7.0 parts of antimony trioxide (0 level), 8.0 parts of ammonium polyphosphate, 30.0 parts of aflame retardant WX-01, 12.0 parts of a flame retardant WX-02, 15.0 parts of a flame retardant WX-03, 1.2 parts of an accelerant CZ, 0.6 parts of an accelerant DM, 45.0 parts of carbon black N234 and 3.0 parts of sulfur powder. Cover rubber pressed with the formula has no rubber breakage, rubber rotting or rubber scorching phenomena, discharge cover rubber sheets have flat and smooth surfaces, a good foundation is laid for vulcanization of good finished products in a vulcanization process, manual rubber holding is not required, the labor intensity is greatly reduced, and the worker demand is reduced.

Owner:XIAN ZHONGZHUANG WEINAN RUBBER PROD

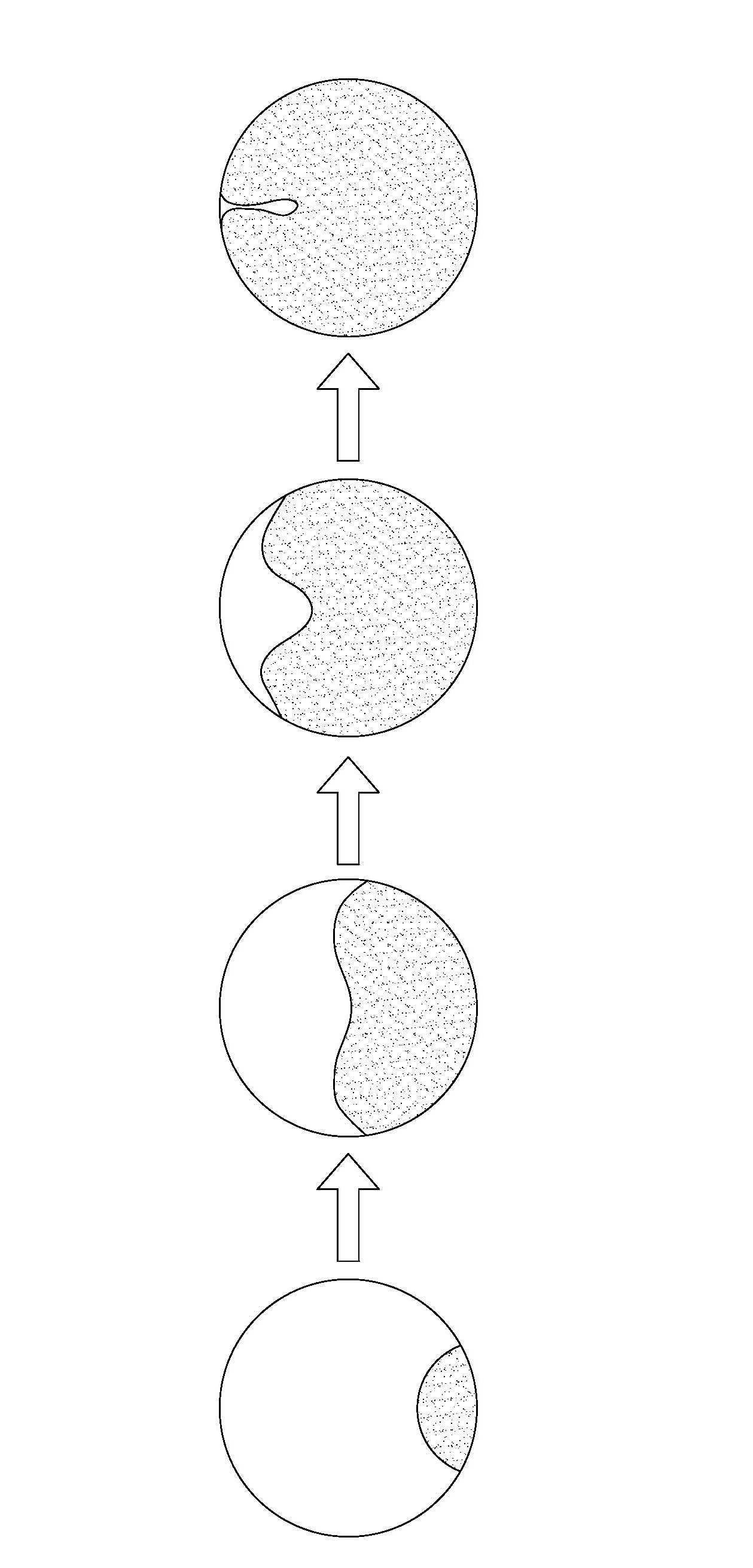

Forming method of trackless lampshade and forming mould

InactiveCN102320103ANo yellowingDoes not form burnt phenomenonHollow articlesRisk strokeFusion welding

The invention discloses a forming method of a trackless lampshade. The method comprises the following steps of: arranging a cavity corresponding to the shape of a cast in a mould; taking the opened edge of the corresponding cast as a parting surface to arrange a charge hole at a certain position of the parting surface; injecting a molten casting material in the cavity of the mould through the charge hole; locally heating the cavity in the injection process, wherein the heating position is a position with highest advance resistance of a forward material; and, when advance resistances are same, the heating position is the longest stroke from the charge hole to the parting surface of the forward material, therefore, the forward materials in all positions are collected on the parting surface; and finally, obtaining the trackless cast. By using the method disclosed by the invention, all the forward materials of the casting material can be finally collected on the parting surface of the mould, therefore, any casting point, fusion welding line or fusion welding point cannot be formed on the cast; and the trackless lampshade can be completely formed. The invention further discloses a forming mould of the trackless lampshade.

Owner:XIAMEN HONTAY INDAL

Chlorinated polyvinyl chloride DN400 tee junction pipe fitting once injection moulding technique and device thereof

InactiveCN101168287AImprove high friction temperatureReduce frictional heatTubular articlesInjection molding processEngineering

The invention relates to a production process of resin pipe fittings, in particular to a one-time injection molding process and equipment for chlorinated polyvinyl chloride tee pipe fittings. The process includes batching, drying, injection molding, pressure holding, and mold opening process. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the temperature range of each section is 150-155°C and 168-173°C. , 162~167℃, 160~165℃, 155~160℃, 150~155℃, 145~150℃, the mold temperature is controlled between 60~70℃; the injection pressure during injection molding is divided into three sections, respectively 58MPa , 60MPa and 78MPa. The pitch of the injection molding machine screw used in the method is equal to the diameter of the screw, the feeding section accounts for 25% of the total length, the compression section accounts for 50% of the total length, and the homogenization section accounts for 25% of the total length. The invention realizes one-time injection molding of DN400 large-scale three-way pipe fittings through the improvement of process and equipment.

Owner:YOULI HLDG GRP

Ultra-low-temperature adhesive for retreading precured tyre and manufacturing process

InactiveCN101781532BEasy to storeEasy to transportNatural rubber adhesivesNon-macromolecular adhesive additivesVulcanizationAdhesive

The invention relates to an ultra-low-temperature adhesive for retreading a precured tyre, which comprises the following raw materials in parts by weight: 100 of natural standard rubber, 1.1 to 1.6 of promoter M, 1.4 to 2 of promoter D, 0.8 to 1.2 of sulfur, 0.7 to 0.9 of promoter TMTD, 20 to 28 of carbon black N754, 10 to 15 of carbon black N 330, 5 of zinc oxide, 2 to 2.5 of stearic acid, 0.7 to 0.9 of anti-aging agent MB, 1 to 1.3 of anti-aging agent 4020, 0.9 to 1.2 of anti-aging agent TNP, 0.7 to 1 of anti-aging agent RD, 0.8 to 1.1 of antioxidant, 1.2 to 1.6 of dispersant and 0.04 to 0.06 of anti-scorching agent; and the invention also discloses a manufacturing process. The invention is an ultra-low-temperature vulcanization process for retreading the tyre and a matching tread adhesive and has good aging resistance, high safety, energy saving, low cost and high qualified rate of a product; and the invention is beneficial to increasing the service life and the retreading frequency of the tyre.

Owner:重庆超科实业发展有限公司

Chlorinated polyvinyl chloride DN400 tee junction pipe fitting once injection moulding technique and device thereof

InactiveCN101168287BReduce shear forceReduce frictional heatTubular articlesChlorinated polyvinyl chloridePipe fitting

The invention relates to a manufacturing technique of a wood-gum tubular element, in particular to a disposable injection molding technique and device of a CPVC three-way tubular element. The technique comprises technical processes of charge mixture, drying, injection made, pressure maintaining and open modeling, wherein a heating position of a charging barrel of an injection machine is divided into seven segments in the process of injection, the temperature ranges of the segments are respectively 150-155 DEG C, 168-173 DEG C, 162-167 DEG C, 160-165 DEG C, 155-160 DEG C, 150-155 DEG C, and 145-150 DEG C, and the temperature of a mould is controlled between 60 and 70 DEG C. When injecting, the pressure of ejection is divided into three segments which are respectively 58 MPa, 60 MPa and 78 MPa. The pitch of screw of a screw rod of the injection machine used by the method is equal to the diameter of the screw rod, a feeding segment takes up 25 percent of the total length, a compression segment takes up 50 percent of the total length, and a homogenizing segment takes up 25 percent of the total length. The invention achieves the disposable injection molding of a DN400 large-scale three-way tubular element via the improvement of the technique and the device.

Owner:YOULI HLDG GRP

Cross-linking semiconductive inner shielding cable material for 35KV crosslinked polyethylene cable and preparation method thereof

ActiveCN103030865BEvenly dispersedReduce dosagePower cables with screens/conductive layersShielded cableCross-link

The invention discloses a cross-linking semiconductive inner shielding cable material for a 35KV crosslinked polyethylene cable. A preparation method of the cross-linking semiconductive inner shielding cable material comprises the following steps of: uniformly mixing additives such as EVA (Ethylene-vinyl Acetate) resin, conductive carbon black, an antioxidant, a dispersant, a plasticizer, fuel oil, a copper resistance agent and the like firstly, then extruding the mixture by an extruder to carry out granulation, and finally, adding a peroxide crosslinking agent through an imbibition method. According to the cross-linking semiconductive inner shielding cable material disclosed by the invention, the copper resistance agent is added, thus avoiding the scorching phenomenon caused by pre-crosslinking due to copper ions produced by a conductor core layer in the cable extruding process; and in addition, the fuel oil is also added in the cross-linking semiconductive inner shielding cable material as a lubricant, so that the carbon black and the various additives can be uniformly dispersed in the EVA, thus reducing the dosage of the plasticizer and lowering the cost.

Owner:CHINA PETROLEUM & CHEM CORP

Chlorinated polyvinyl chloride DN400 loose flange once injection moulding technique and device thereof

InactiveCN101168288BReduce shear forceReduce frictional heatDomestic articlesInjection pressureChlorinated polyvinyl chloride

The invention relates to a productive technology for producing wood-gum flange, in particular to a technology and device for one time injection molding of chlorinated polyvinyl chloride lap joint flanges. The technology comprises industrial processes of burdening, drying, injection molding, pressure maintaining and model opening, wherein in the injection molding process, the heating portion of a charging barrel of an injection machine is divided into seven segments, the temperature ranges of the segments are respectively 150-155 DEG C, 168-173 DEG C, 162-167 DEG C, 160-165 DEG C, 155-160 DEG C, 150-155 DEG C, and 145-150 DEG C, the temperature of a die is controlled between 60 and 70 DEG C, the injection pressure when injection molding is divided into three segments which are respectively56 MPa, 59MPa and 76MPa. The pitch of a screw of the injection machine used in the method is equal to the diameter of the screw, the delivery segment occupies 25 percent of the whole length, the compressing segment occupies 50 percent of the whole length, and the homogenizing segment occupies 25 percent of the whole length. The invention realizes one time injection molding of DN400 large-scale lap joint flanges via improving the technology and the device.

Owner:YOULI HLDG GRP

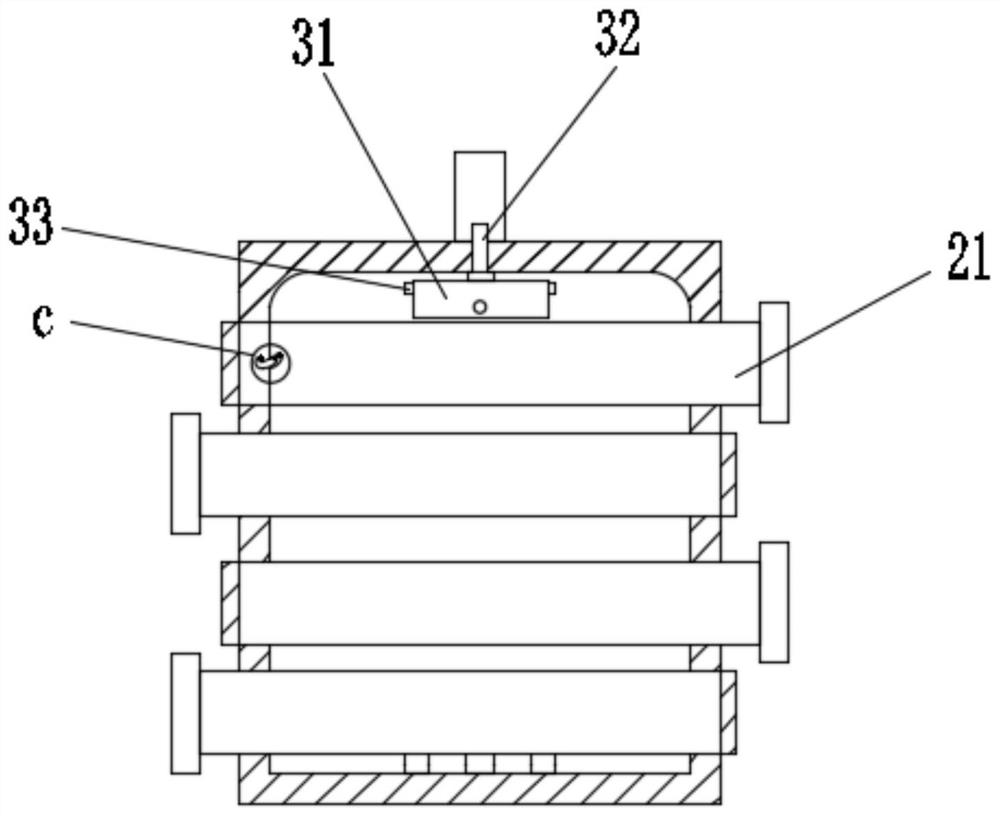

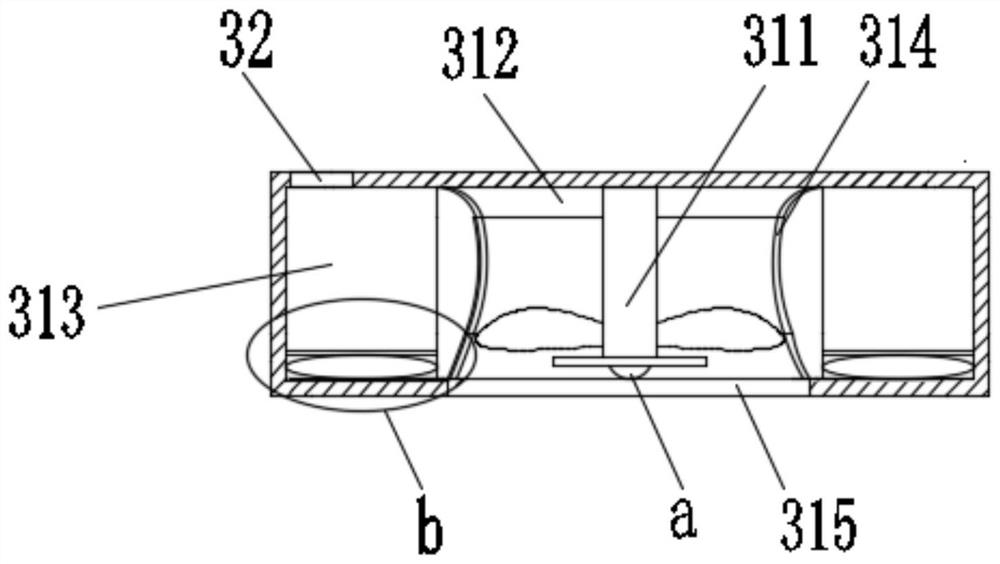

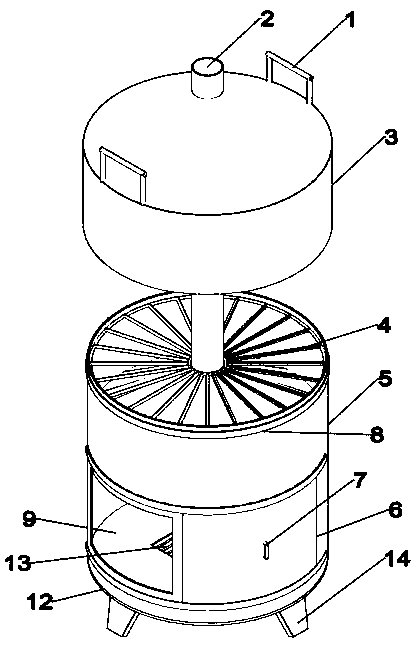

Traditional Chinese medicinal material drying device

ActiveCN112833630AEasy to dryNo scorchingDrying chambers/containersDrying solid materialsProcess engineeringMechanical engineering

The invention discloses a traditional Chinese medicinal material drying device which comprises a box body. An observation window is installed on the side face of the box body, a placing mechanism is arranged in the box body, a clamping device is arranged on the surface of the placing mechanism, and a drying heat dissipation mechanism is installed at the top of the inner wall of the box body. The invention relates to the technical field of traditional Chinese medicinal material drying. According to the traditional Chinese medicinal material drying device, the purpose of drying traditional Chinese medicinal materials is achieved, the placing mechanism and the drying heat dissipation mechanism are additionally arranged in the box body, the traditional Chinese medicinal materials needing to be dried can be effectively and rapidly dried through drying heat dissipation, and the situation that the traditional Chinese medicinal materials are burnt due to the fact that the temperature in the box body is high during drying is avoided. According to the traditional Chinese medicinal material drying device, various traditional Chinese medicinal materials can be dried through the placing mechanism, the problem that the traditional Chinese medicinal materials are burnt during drying through a common traditional Chinese medicinal material drying device is solved, and due to the fact that the number of placing cabinets in the placing mechanism is large, many traditional Chinese medicinal materials can be placed in the placing cabinets to be dried.

Owner:安徽金鑫旭智能装备制造有限公司

Chlorinated polyvinyl chloride DN400 conduction through pipe fitting once injection moulding technique and device thereof

InactiveCN101168285BReduce frictional heatStable speedTubular articlesTemperature controlChlorinated polyvinyl chloride

Owner:YOULI HLDG GRP

High-reliability grain drying equipment

InactiveCN112503883ARealize the function of continuous water absorptionAchieve recyclingDrying gas arrangementsDrying chambers/containersGear wheelHeater Rod

The invention relates to high-reliability grain drying equipment. The high-reliability grain drying equipment comprises a main body, two heating rods and two supporting legs, and further comprises twostirring mechanisms and two circulating mechanisms, each stirring mechanism comprises a motor, a rotating shaft, a first bearing, two cleaning assemblies and a plurality of rotating plates, a transmission unit comprises a half gear, a driving frame, a connecting rack and two driving racks, each circulating mechanism comprises a control assembly, a sucking pump, an air inlet pipe, an air outlet pipe, a fixing box, a sponge block, a connecting pipe, a heating pipe and an exhaust pipe, and each control assembly comprises a control switch and an abutting plate. The high-reliability grain drying equipment has the advantages that through the stirring mechanisms, the stirring function on the interior of the main body is achieved, grains around the heating rods are in a flowing state, so that thephenomenon that the grains are burnt can be avoided, and therefore the drying quality is improved; and through the circulating mechanisms, the circulating flowing function on hot air in the main bodyis achieved, all the grains in the main body can be fully heated, and therefore the drying effect is improved.

Owner:深圳市迅成科技有限公司

Chlorinated polyvinyl chloride DN400 elbow pipe fitting once injection moulding technique and device thereof

InactiveCN101168286BReduce shear forceReduce frictional heatTubular articlesTemperature controlChlorinated polyvinyl chloride

The invention relates to a manufacturing technique of a wood-gum tubular element, in particular to a disposable injection molding technique and device of a CPVC bent tubular element. The technique comprises technical processes of charge mixture, drying, injection molding, pressure maintaining and open modeling, wherein a heating position of a charging barrel of an injection machine is divided into seven segments in the process of injection, the temperature ranges of the segments are respectively 150-155 DEG C, 168-173 DEG C, 162-167 DEG C, 160-165 DEG C, 155-160DEG C, 150-155 DEG C, and 145-150DEG C, and the temperature of a mould is controlled between 60 and 70 DEG C. When injecting, pressures of ejection is divided into three segments which are respectively 58 MPa, 65 MPa and 80 MPa. The pitch of screw of a screw rod of the injection machine used by the method is equal to the diameter of the screw rod, a feeding segment takes up 25 percent of the total length, a compression segment takes up 50 percent of the total length, and a homogenizing segment takes up 25 percent of the total length. The invention achieves the disposable injection molding of a DN400 large-scale bent tubularelement via the improvement of the technique and the device.

Owner:YOULI HLDG GRP

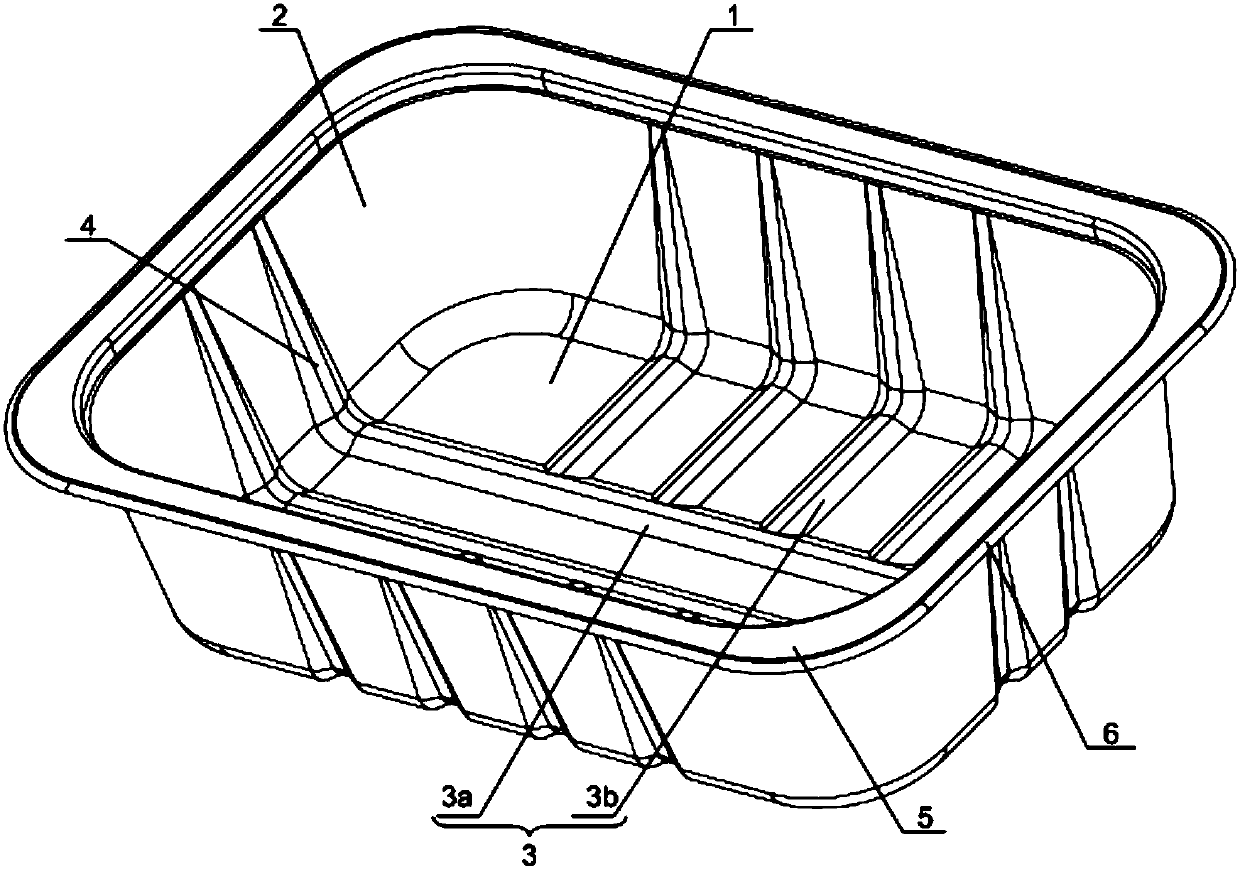

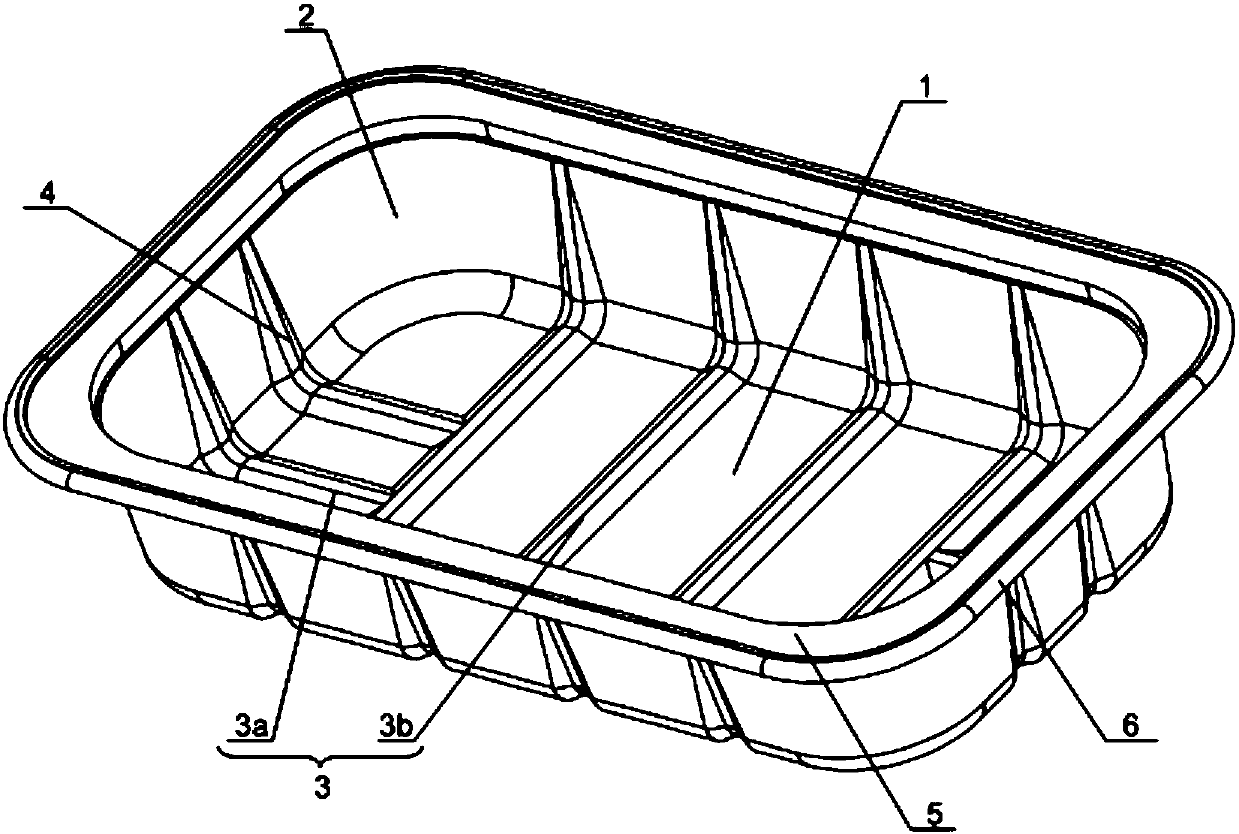

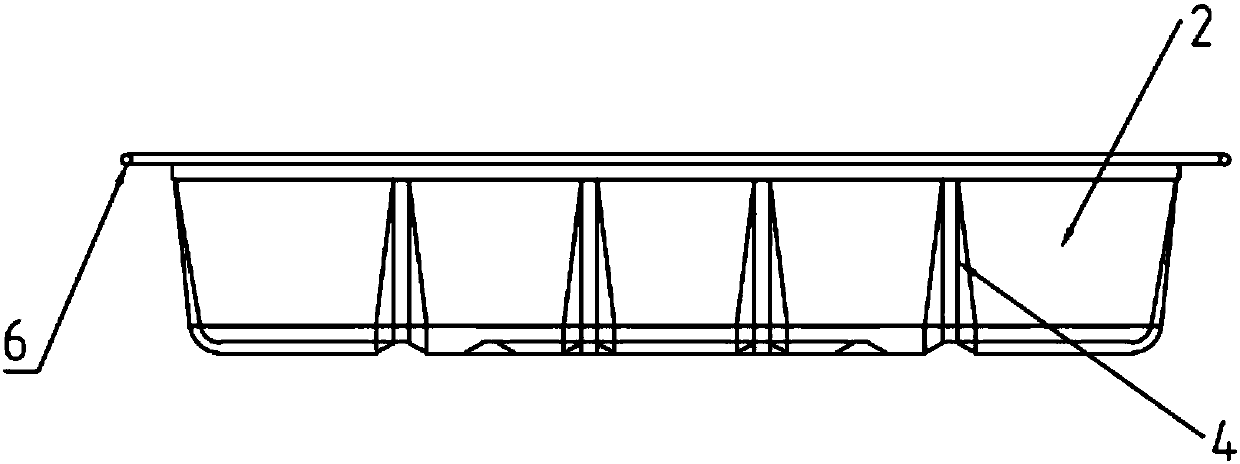

Aluminum foil container structure for food modified atmosphere packaging

PendingCN107618718AExtended shelf lifeUniform shelf lifeTray containersMetallurgyModified atmosphere

The invention discloses an aluminum foil container structure for food modified atmosphere packaging. The aluminum foil container structure comprises an aluminum foil box, the aluminum foil box is composed of an aluminum foil base plate and an aluminum foil circumferential side plate, one end of the aluminum foil circumferential side plate is provided with a smooth opening, the aluminum foil circumferential side plate is arranged in an inclined manner relative to the aluminum foil base plate, and the area of an opening plane of the aluminum foil circumferential side plate is larger than the area of the aluminum foil base plate; the aluminum foil base plate is provided with first reinforcing ribs inwards protruding towards the interior of the aluminum foil box, the aluminum foil circumferential side plate is provided with second reinforcing ribs inwards protruding towards the interior of the aluminum foil box, and the first reinforcing ribs and the second reinforcing ribs are communicated into a whole. The reinforcing ribs are connected into a whole, the rigidity of the box is improved, and meanwhile, the material thickness can be reduced; during air exchanger, air in most space isolated by the reinforcing ribs and located at the bottom of the container can be pumped out, the oxygen remaining rate is reduced to the maximum degree, and the food refreshing time is greatly prolonged. During food baking, heating is more even, and foods tightly attached to the box bottom cannot be burned in baking. In addition, an aluminum foil material can be repeatedly used and can be melted into an aluminum pig at the high temperature, and therefore environment protecting is achieved.

Owner:NINGBO TIMES ALUMINUM FOIL MFG

Kitchen waste separation and solid matter drying and sterilization device

PendingCN108981369AReduce passAvoid failureDrying solid materialsGarbage dryingEngineeringSolid matter

A kitchen waste separation and solid matter drying and sterilization device comprises a feeding pipe, a conveying pipe, a spiral conveyor, a heating part, a heat insulation and heat preservation pipe,a drying discharging outlet, a spiral conveyor driving device and end cover seats. The feeding pipe is arranged at the feeding end of the conveying pipe. The drying discharging outlet is formed in the discharging end of the conveying pipe. The spiral conveyor is arranged in the conveying pipe. The two ends of the spiral conveyor are fixed to the end cover seats correspondingly. The spiral conveyor driving device is directly connected with the spiral conveyor. The heating part is arranged between the heat insulation and heat preservation pipe and the conveying pipe. The spiral conveyor drivingdevice drives the spiral conveyor to rotate. According to the kitchen waste separation and solid matter drying and sterilization device, solid matter containing water can be heated, stir-fried, sterilized and dried, the dehydration efficiency is high, heating is uniform, sterilization is thorough, the situation that the solid matter is stir-fried to brown and caked is avoided, the end cover seatsfor supporting the spiral conveyor have the heat insulation and heat dissipation functions, working is stable, and the service life is long.

Owner:江苏恒通环保科技有限公司

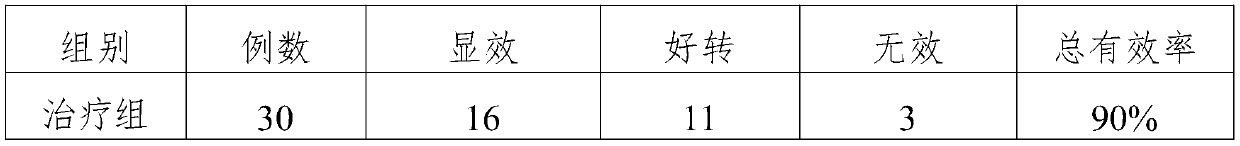

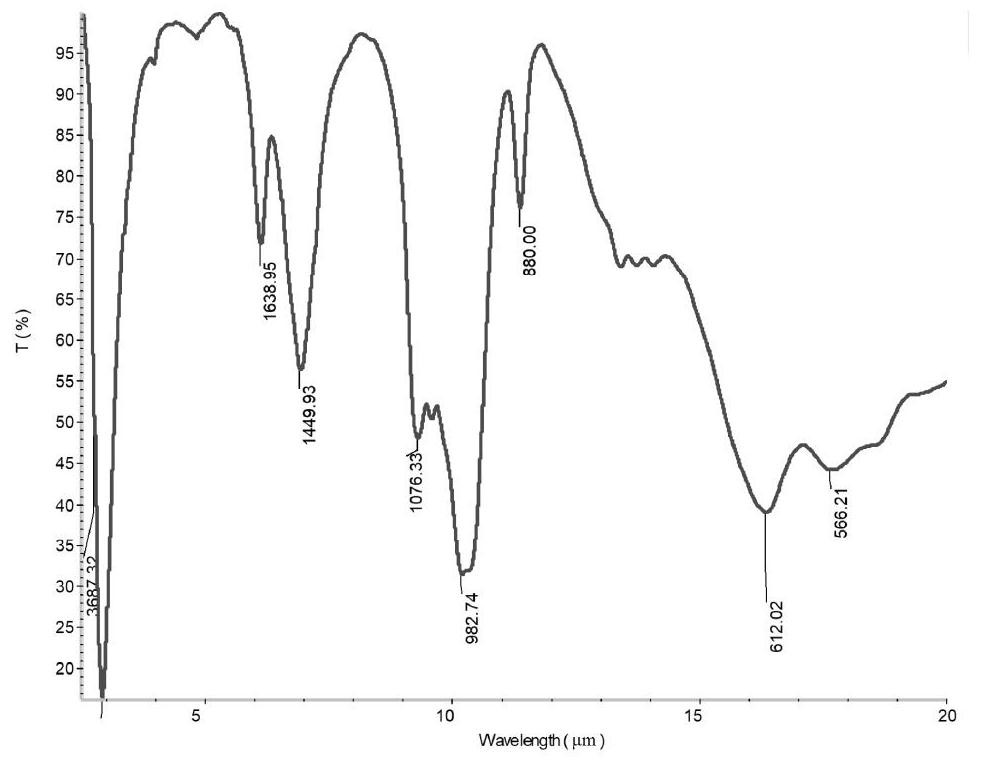

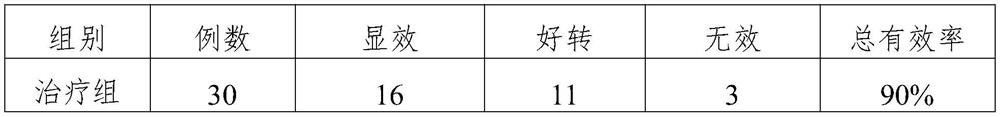

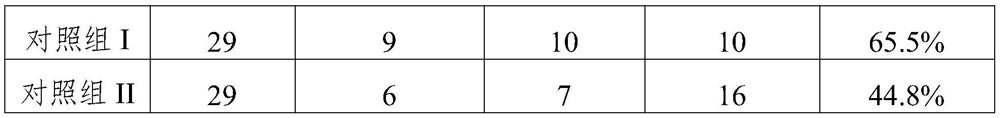

Application of modified jade powder in health care and treatment patches

ActiveCN111348934AAdjust immune functionPromote percutaneous absorptionMedical devicesAntinoxious agentsSmoke EmissionBiomedical engineering

The embodiment of the invention discloses application of modified jade powder in health care and treatment patches, and belongs to the technical field of patches. The invention discloses a health careand treatment patch which has an action mechanism similar to that of moxibustion and can generate or exceed the moxibustion effect and a preparation method of the health care and treatment patch. According to the health care and treatment patch provided by the invention, a traditional moxibustion therapy mode is thoroughly changed, and compared with common moxibustion, the health care and treatment patch has the advantages that the effect is mild, and the scorching phenomenon of moxibustion is avoided; no smoke pollution exists, and wide acceptance is easy; the action time is long, and the action effect is improved; the operation is simple and convenient, and the help of other people is not needed.

Owner:汉方中医药研发(大连)有限公司 +1

Application of modified jade powder in health care and therapeutic patches

ActiveCN111348934BAdjust immune functionPromote percutaneous absorptionMedical devicesAntinoxious agentsEfficacySmoke Emission

The embodiment of the invention discloses the application of a modified jade powder in a health care and treatment patch, and belongs to the technical field of the patch. The invention discloses a health care and treatment patch which has a similar action mechanism to moxibustion and can produce or exceed the efficacy of moxibustion and a preparation method thereof. The health care and treatment patch provided by the invention completely changes the traditional moxibustion treatment mode, has a milder effect than ordinary moxibustion, does not produce the burning phenomenon of moxibustion; has no smoke pollution, and is easy to be widely accepted; It is beneficial to improve the effect; it is easy to operate and does not need help from others.

Owner:汉方中医药研发(大连)有限公司 +1

Chlorinated polyvinyl chloride DN400 loose flange once injection moulding technique and device thereof

InactiveCN101168288AReduce frictional heatStable speedDomestic articlesTemperature controlInjection pressure

The invention relates to a production process of a resin flange, in particular to a one-time injection molding process and equipment for a chlorinated polyvinyl chloride loop flange. The process includes batching, drying, injection molding, pressure holding, and mold opening process. During the injection molding process, the heating part of the barrel of the injection molding machine is divided into seven sections, and the temperature range of each section is 150-155°C and 168-173°C. , 162~167℃, 160~165℃, 155~160℃, 150~155℃, 145~150℃, the mold temperature is controlled between 60~70℃; the injection pressure during injection molding is divided into three sections, respectively 56MPa , 59MPa and 76MPa. The pitch of the injection molding machine screw used in the method is equal to the diameter of the screw, the feeding section accounts for 25% of the total length, the compression section accounts for 50% of the total length, and the homogenization section accounts for 25% of the total length. The invention realizes the one-time injection molding of the DN400 large loose sleeve flange through the improvement of the process and equipment.

Owner:YOULI HLDG GRP

Smokeless high-efficiency energy-saving baking oven

InactiveCN110353523APut an end to directAvoid food contactRoasters/grillsCooking & bakingCombustion chamber

A smokeless high-efficiency energy-saving baking oven comprises an oven body and heat transfer plates, and is characterized in that the oven body is provided with an inner cavity, the inner part of the oven body is fixedly connected with the heat transfer plates, the heat transfer plates divide the inner cavity of the oven body into two parts, a baking chamber is arranged above the heat transfer plates, and a combustion chamber is arranged below the heat transfer plates; the top end of the heat transfer plate is fixedly connected with a smoke exhaust pipe; the smoke exhaust pipe is communicated with the combustion chamber of the oven body; the smoke exhaust pipe is provided with an annular baking net which is connected in a penetrating and sliding manner, and the annular baking net is positioned above the heat transfer plate; the smoke exhaust pipe is provided with a furnace cover which is connected in a penetrating and sliding manner; compared with the prior art, the smokeless high-efficiency energy-saving baking oven separates the smoke generated by fuel combustion from food by adopting a conical heat transfer plate with good heat transfer performance, and avoids the direct contact of the smoke and the food; and the food is baked by heating the air, so that the food can be heated all around and uniformly heated, the phenomenon of scorching cannot occur, and a specially-assigned person does not need to turn over the food.

Owner:广州溪岭环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com