Special material for white polyvinylidene fluoride cast film

The technology of polyvinylidene fluoride and special material is applied in the field of special material for white polyvinylidene fluoride casting film, which can solve the problems of uneven whiteness of polyvinylidene fluoride white film, difficulty in melting and plasticizing, scorching of raw materials, etc. No obvious crystal point, easy flow, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below with implementation examples, but the present invention is not limited to the following examples and implementation methods.

[0043] When the melt index of polyvinylidene fluoride is between 3 and 30 (g / 10min, 5kg, 230°C), the raw material can be melt-processed.

[0044] When the melt index of polymethylmethacrylate is between 10 and 30 (g / 10min, 5kg, 230°C), the fluidity of the formulation can be improved.

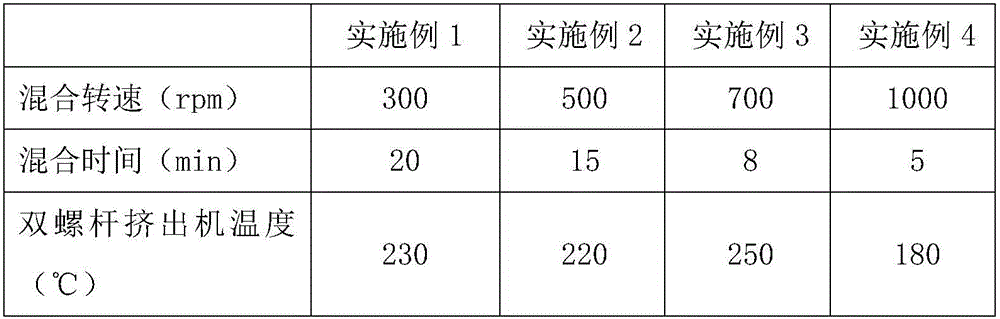

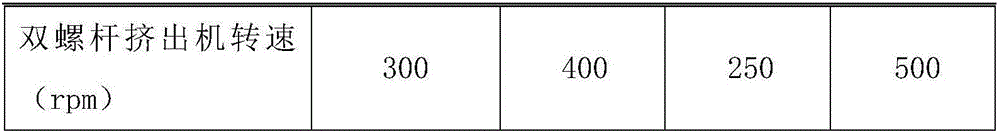

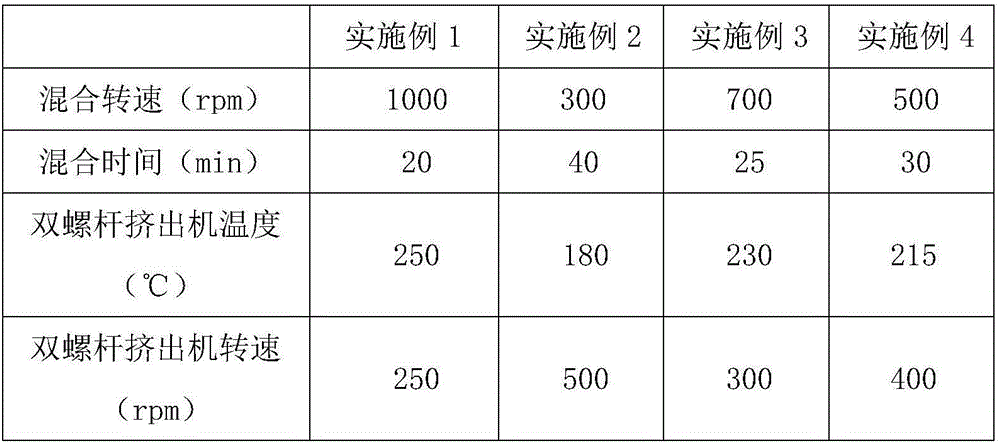

[0045] Embodiment 1-4 is four kinds of different special material formulations (referring to Table 1). The raw materials adopted in each embodiment are as follows:

[0046] (1) Polyvinylidene fluoride (PVDF): The melt index is 24 (g / 10min, 5kg, 230°C).

[0047] ⑵Titanium dioxide: trade name: R-104, supplier: DuPont Company of the United States; average particle size of powder is 0.2-0.3 microns

[0048] (3) Polymethyl methacrylate (PMMA): The melt index is 24 (g / 10min, 5kg, 230°C) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com