Patents

Literature

394 results about "Polybutyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Infobox references. Poly(methyl methacrylate) (PMMA), also known as acrylic or acrylic glass as well as by the trade names Crylux, Plexiglas, Acrylite, Lucite, and Perspex among several others (see below), is a transparent thermoplastic often used in sheet form as a lightweight or shatter-resistant alternative to glass.

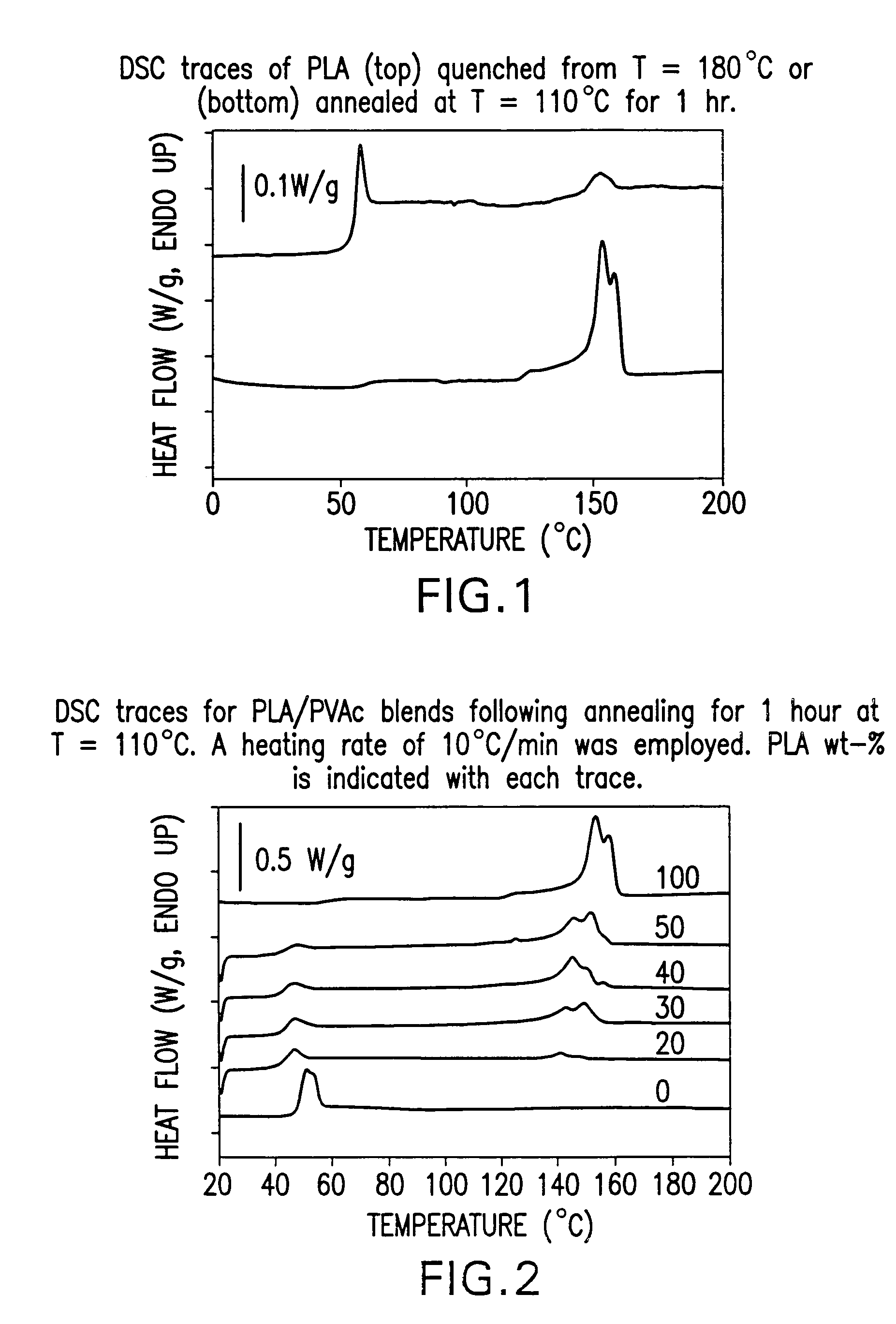

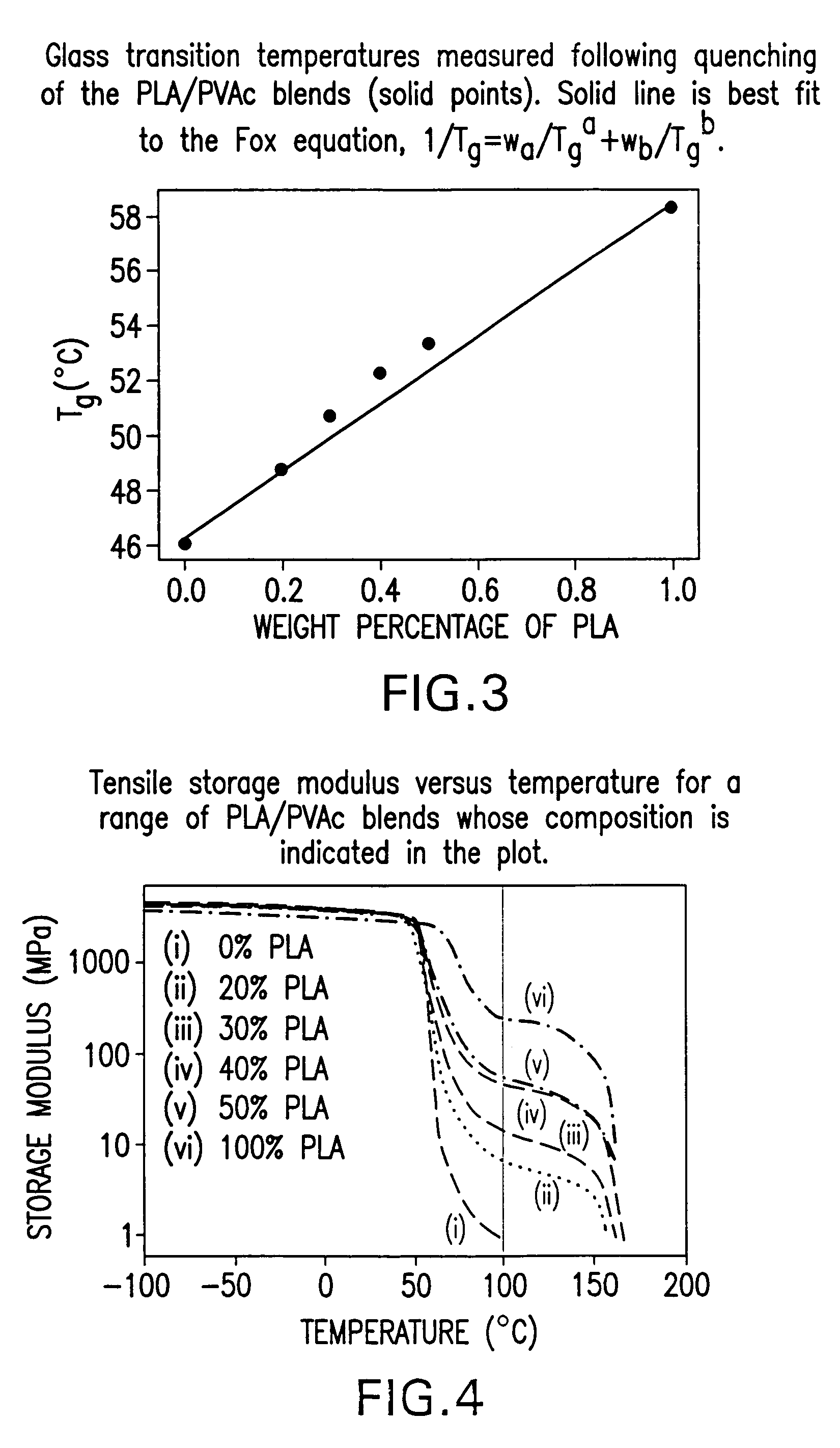

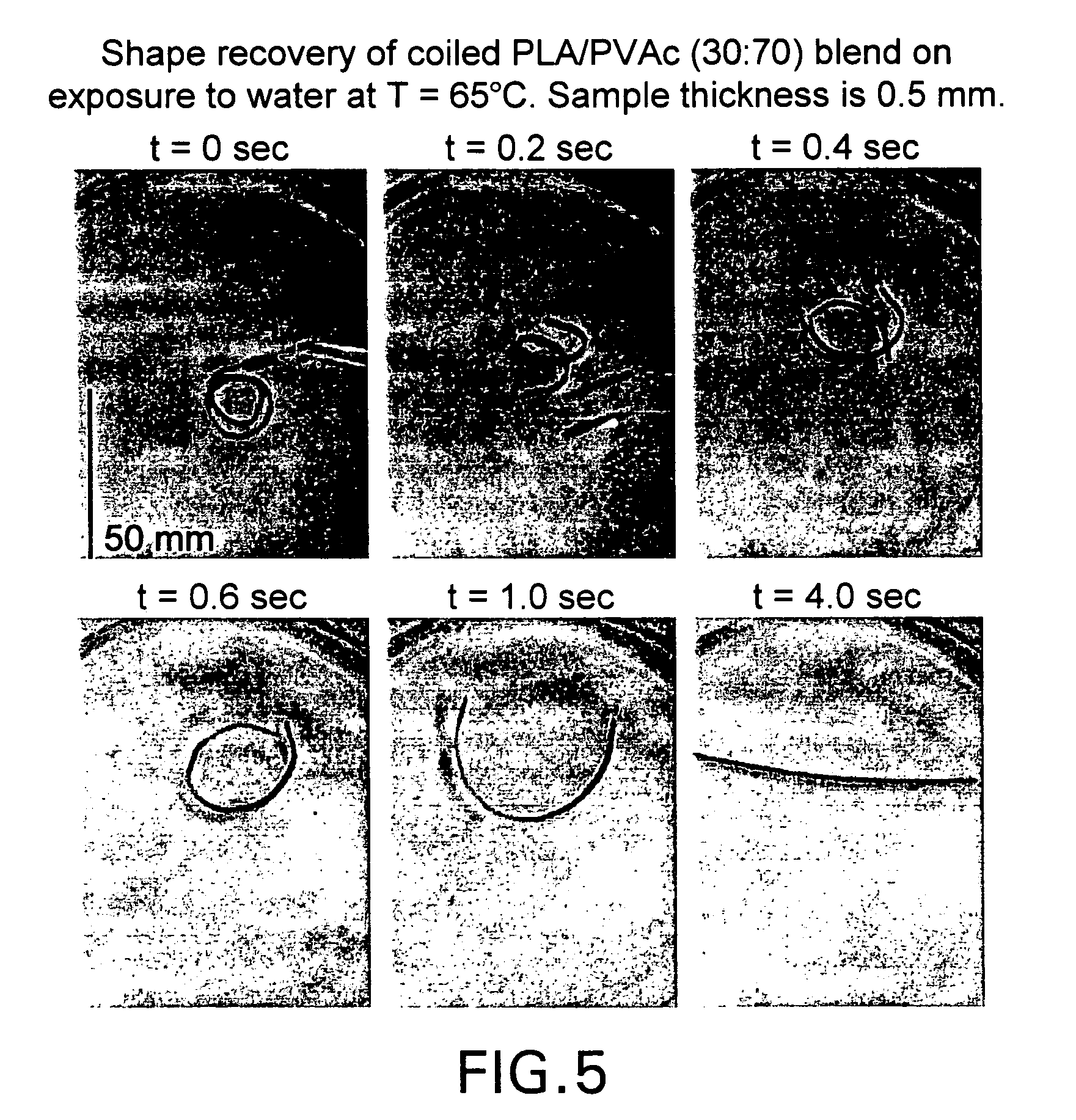

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS20040122174A1High modulusImprovement in critical temperatureDental impression compositionsPoly(methyl methacrylate)Ethyl acrylate

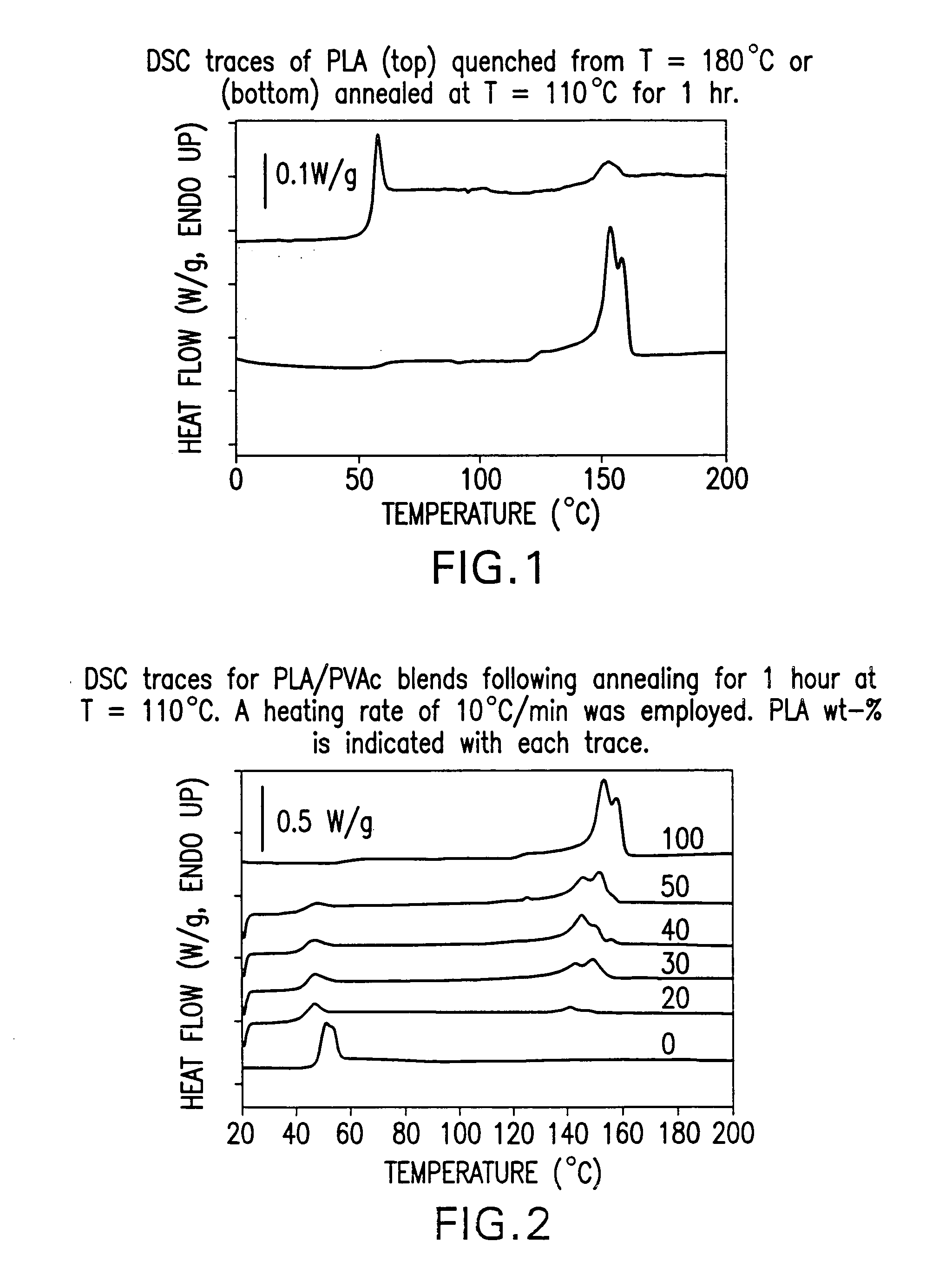

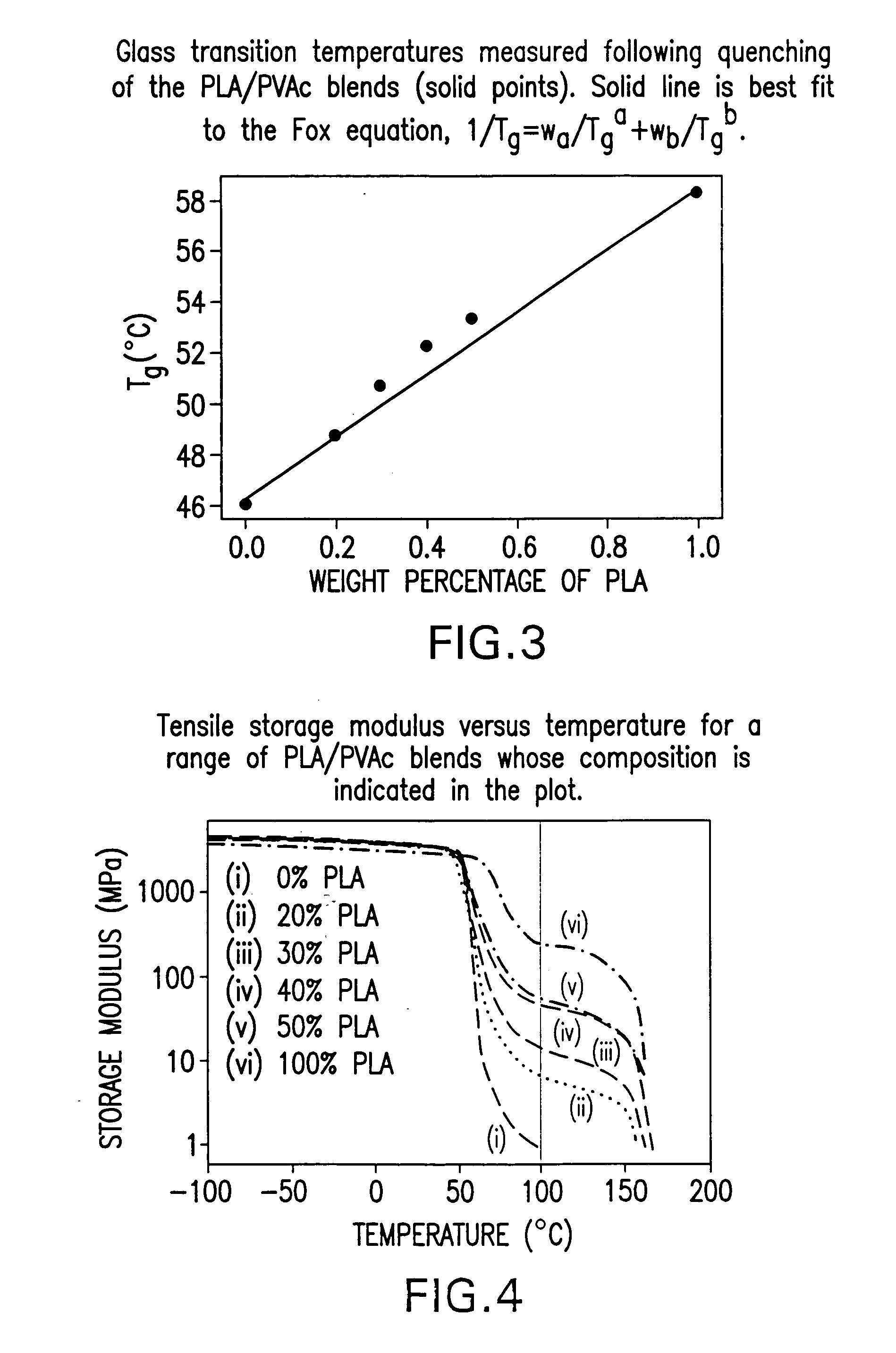

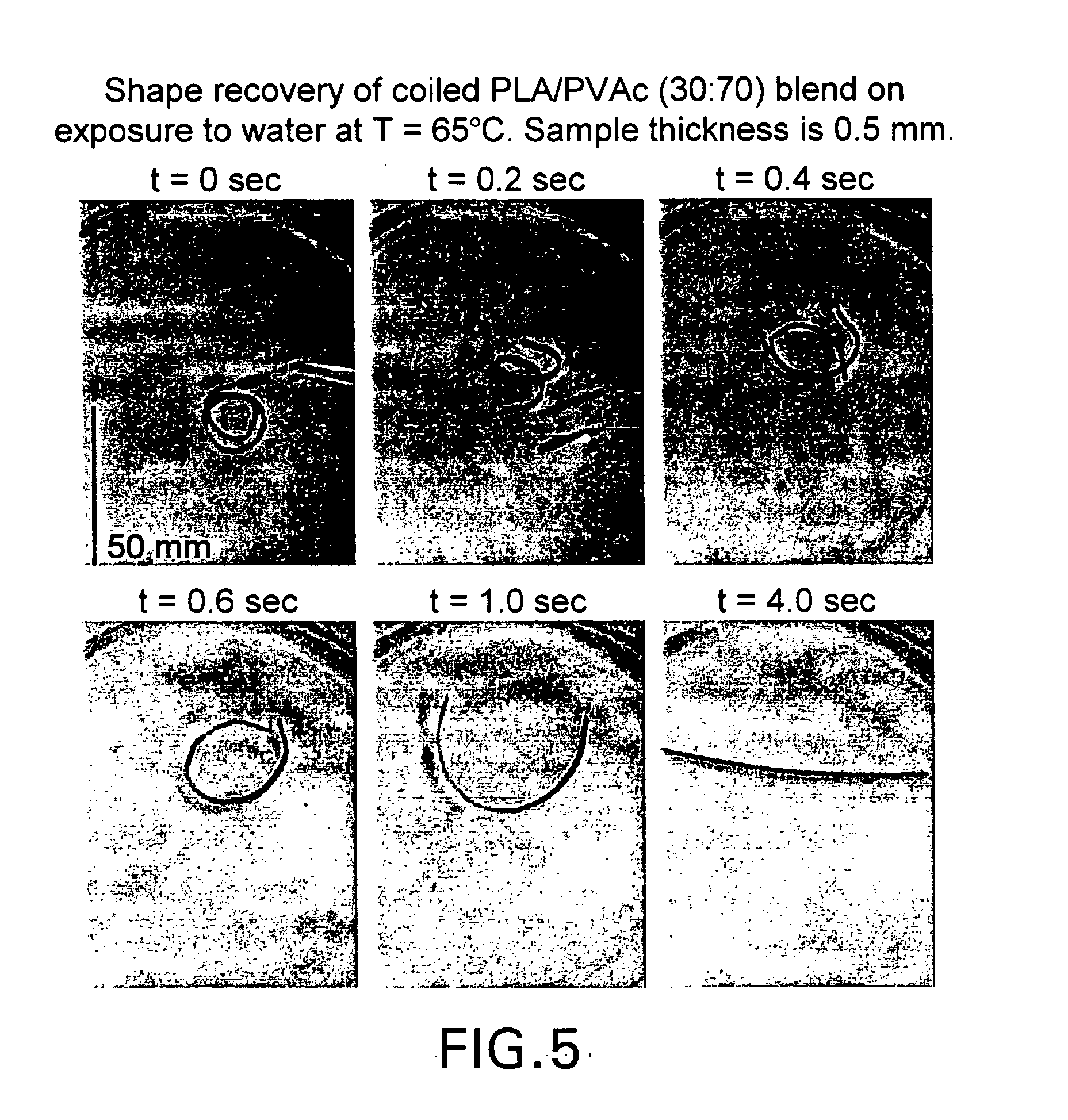

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

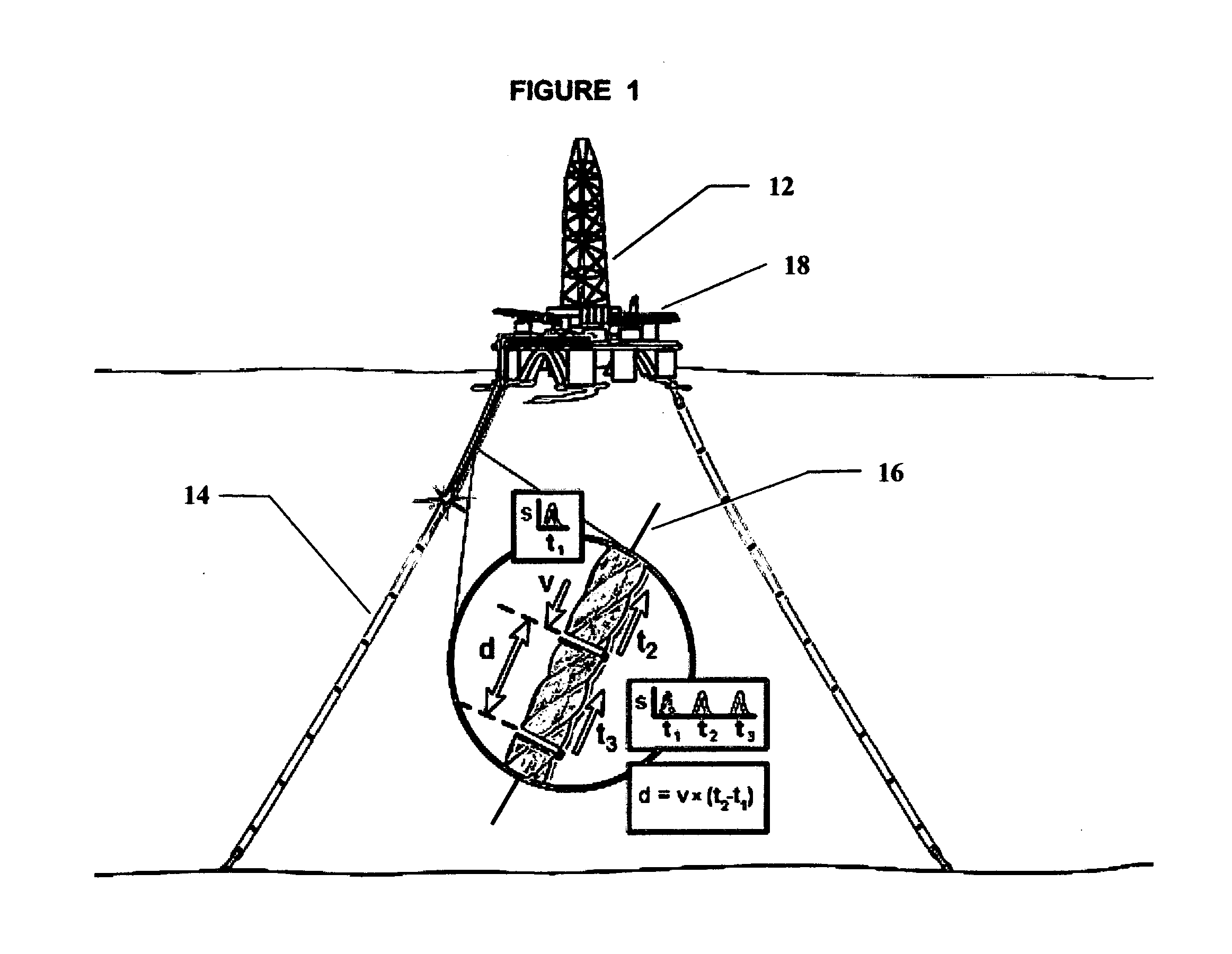

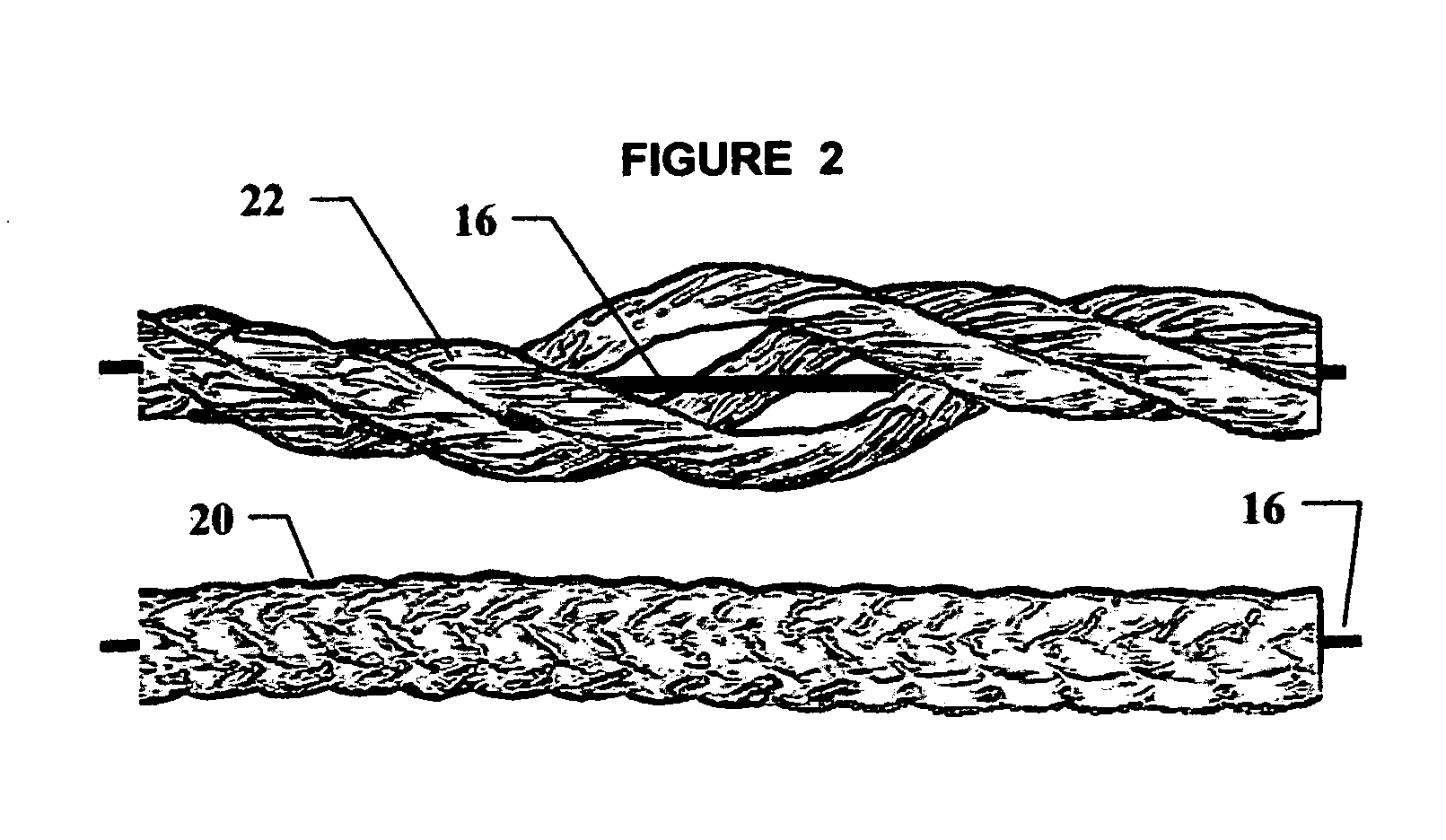

Measurement of large strains in ropes using plastic optical fibers

InactiveUS20050226584A1Minimal intrusionPrevent slippingControlOptical rangefindersTime domainEngineering

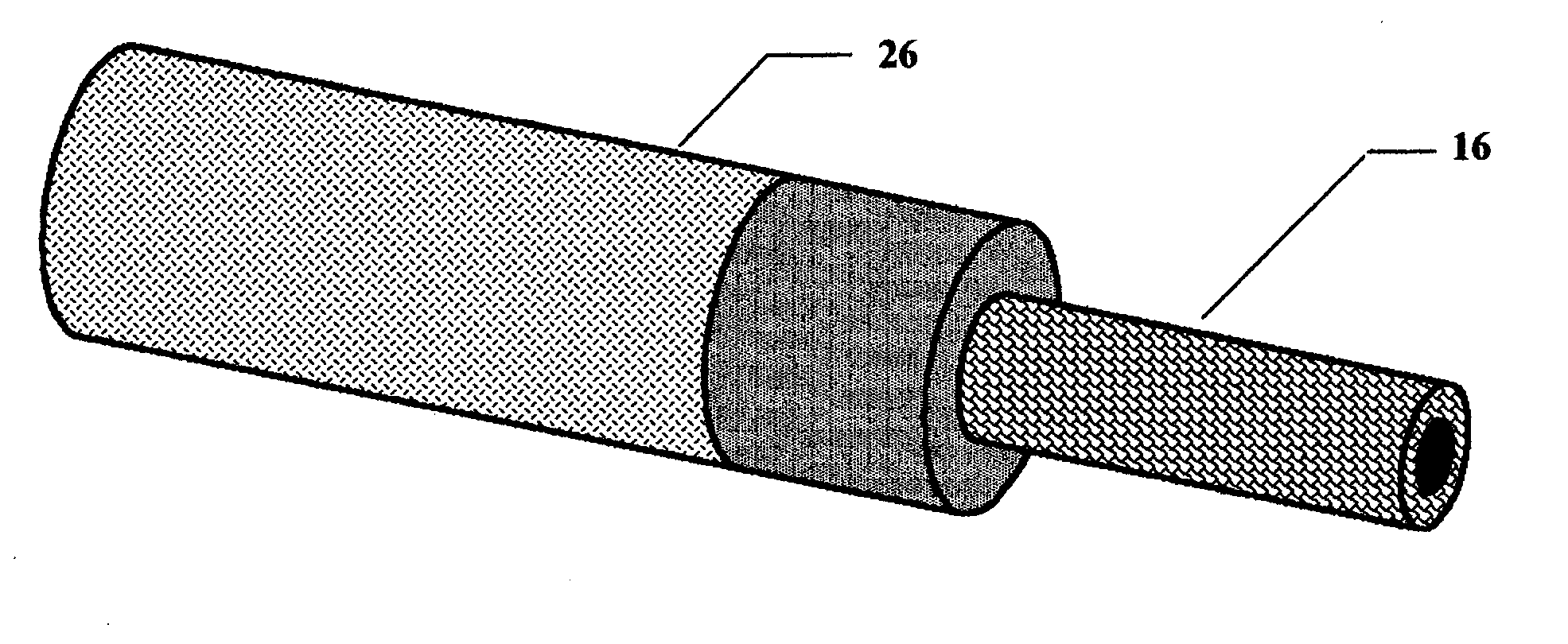

A method for the direct measurement of large strains in ropes in situ using a plastic optical fiber, for example, perfluorocarbon or polymethyl methacrylate and Optical Time-Domain Reflectometer or other light time-of-flight measurement instrumentation. Protective sheaths and guides are incorporated to protect the plastic optical fiber. In one embodiment, a small rope is braided around the plastic optical fiber to impose lateral compressive forces to restrain the plastic optical fiber from slipping and thus experience the same strain as the rope. Methods are described for making reflective interfaces along the length of the plastic optical fiber and to provide the capability to measure strain within discrete segments of the rope. Interpretation of the data allows one to calculate the accumulated strain at any point in time and to determine if the rope has experienced local damage.

Owner:WILLIAMS JERRY GENE +2

Process for producing polymethylmethacrylate molding materials with a neutral color

Products based on polymethylmethacrylate (PMMA) so resistant to yellowing and so highly transparent that even the edges of plates produced from this material have a neutral colour, i.e. do not display any yellow tone. This effect is obtained by the admixture of 5 to 50 ppm inorganic, reducing phosphorus compounds after polymerisation. This enables the brightener content to be reduced under 10 ppb, and so the end product may also be used in contact with foodstuffs.

Owner:EVONIK ROEHM GMBH

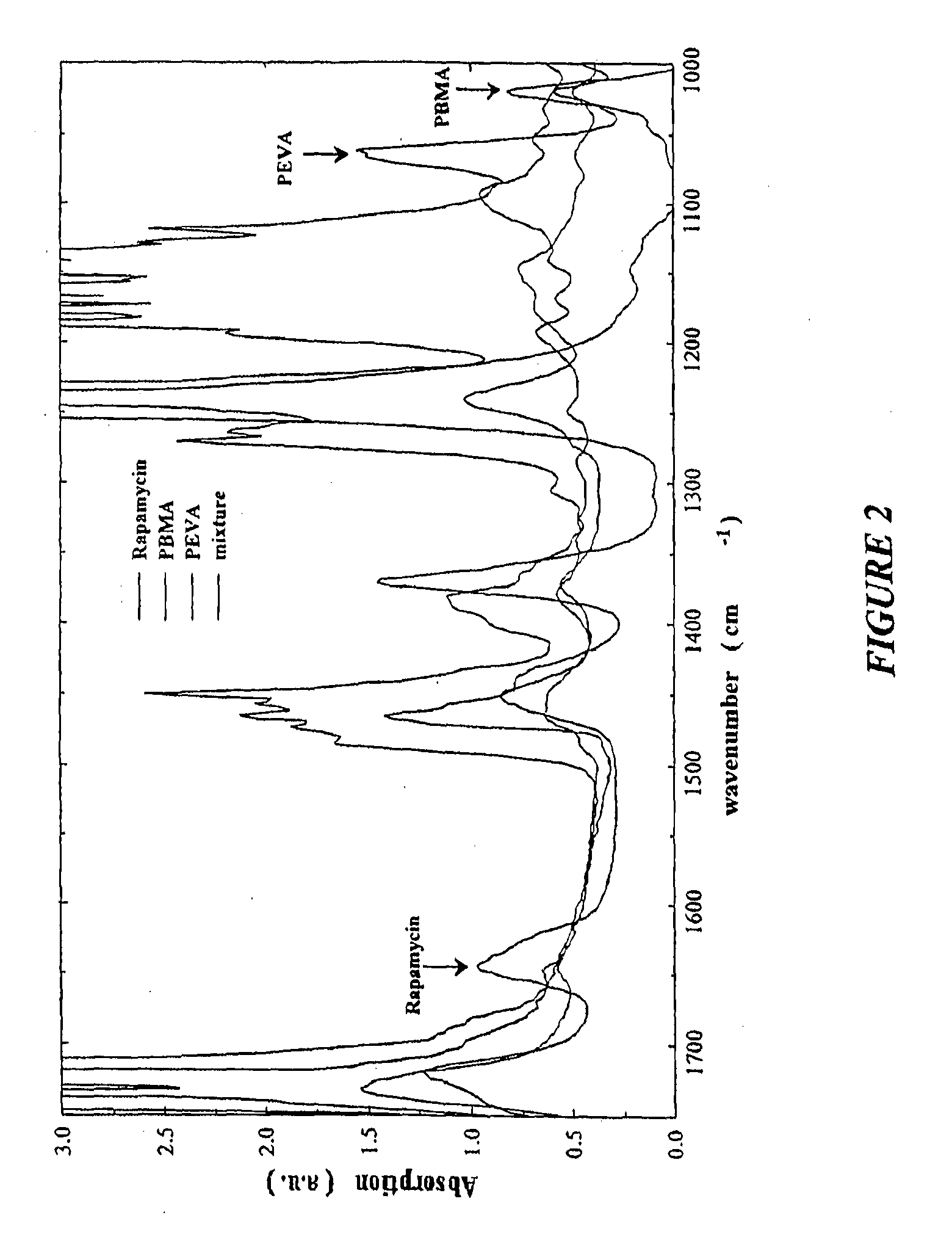

Stent with polymer coating containing amorphous rapamycin

InactiveUS20090062909A1Extensive adhesionBulk propertiesStentsSurgeryPolymer coatingsPolybutyl methacrylate

A coated coronary stent, comprising: a stainless steel sent framework coated with a primer layer of Parylene C; and a rapamycin-polymer coating having substantially uniform thickness disposed on the stent framework, wherein the rapamycin-polymer coating comprises polybutyl methacrylate (PBMA), polyethylene-co-vinyl acetate (PEVA) and rapamycin, wherein substantially all of the rapamycin in the coating is in amorphous form and substantially uniformly dispersed within the rapamycin-polymer coating.

Owner:MICELL TECH INC

Blends of amorphous and semicrystalline polymers having shape memory properties

InactiveUS7208550B2High modulusDental impression compositionsPoly(methyl methacrylate)Glycol synthesis

Blends of amorphous and semicrystalline polymers having shape memory properties were prepared by blending a crystalline polymer such as poly(vinylidene fluoride), polylactide, poly(hydroxxybutyrate), poly(ethylene glycol) polyethylene, polyethylene-co-vinyl acetate, poly(vinyl chloride), poly(vinylidene chloride) and copolymers of poly(vinylidene chloride) and poly(vinyle chloride) and an amorphous polymer such as poly(vinyl acetate), poly methyl acrylate, poly ethyl acrylate, atactic poly methyl methacrylate, isotactic poly methyl methacrylate, syndiotactic poly methyl methacrylate and other poly alkyl methacrylates. The method for preparing the polymeric materials and applications thereof, for example, as smart medical devices, are also disclosed.

Owner:UNIV OF CONNECTICUT

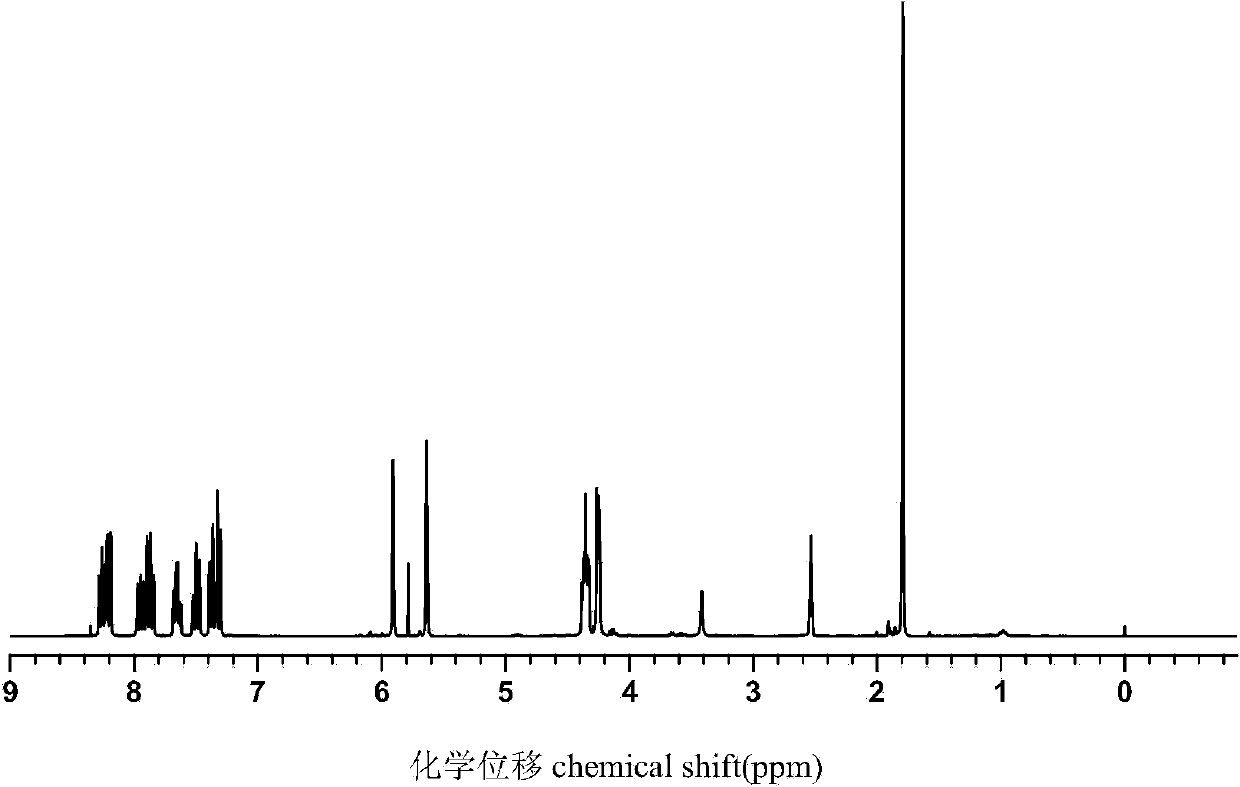

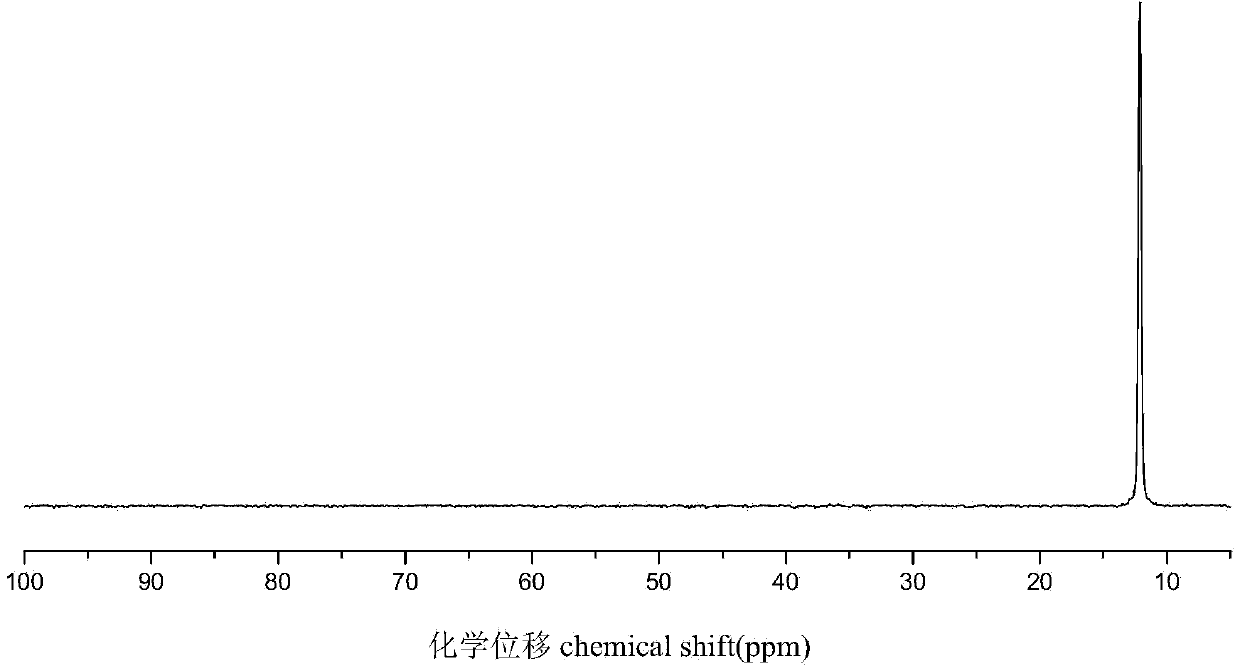

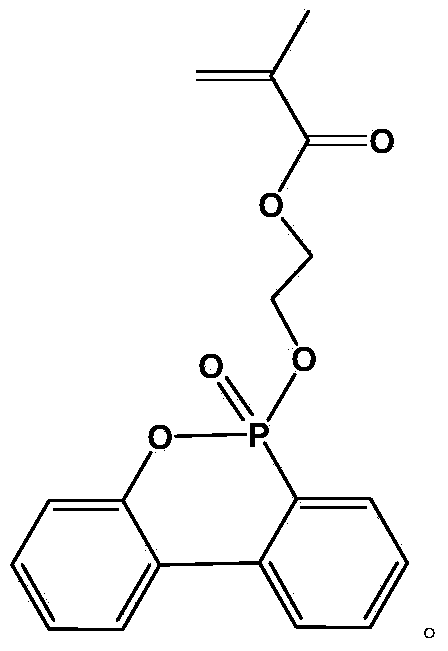

Flame-retardant monomer containing DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) groups and preparation method and application of flame-retardant monomer

InactiveCN103755742AMild reaction conditionsHigh yieldGroup 5/15 element organic compoundsChemistryFire retardant

The invention discloses a flame-retardant monomer containing DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) groups, and a preparation method and an application of the flame-retardant monomer, and relates to a compound. The method comprises the steps of sequentially adding an organic solvent, carbon tetrachloride and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into a reaction flask, putting in an ice water bath, adding hydroxyethyl methylacrylate and an acid-binding agent while stirring, after temperature rise reaction, decompressing, and performing suction filtration to remove acid-binding agent salt, purifying a crude product through spin steaming, washing and dryness, and obtaining a product, namely the flame-retardant monomer containing the DOPO groups. The flame-retardant monomer containing the DOPO groups can be applied in preparing a flame-retardant high molecular material. A reaction condition is mild, the productivity is high, the product purification and separation are simple, and the extended production is easy. The monomer is introduced into a polymer matrix such as polystyrene and polymethyl methacrylate by a free radical copolymerization manner, an intrinsic flame-retardant polymer material is prepared, and the defects of poor compatibility of an additive flame retardant and the matrix, high loss possibility during use, poor water resistance and the like are overcome.

Owner:XIAMEN UNIV

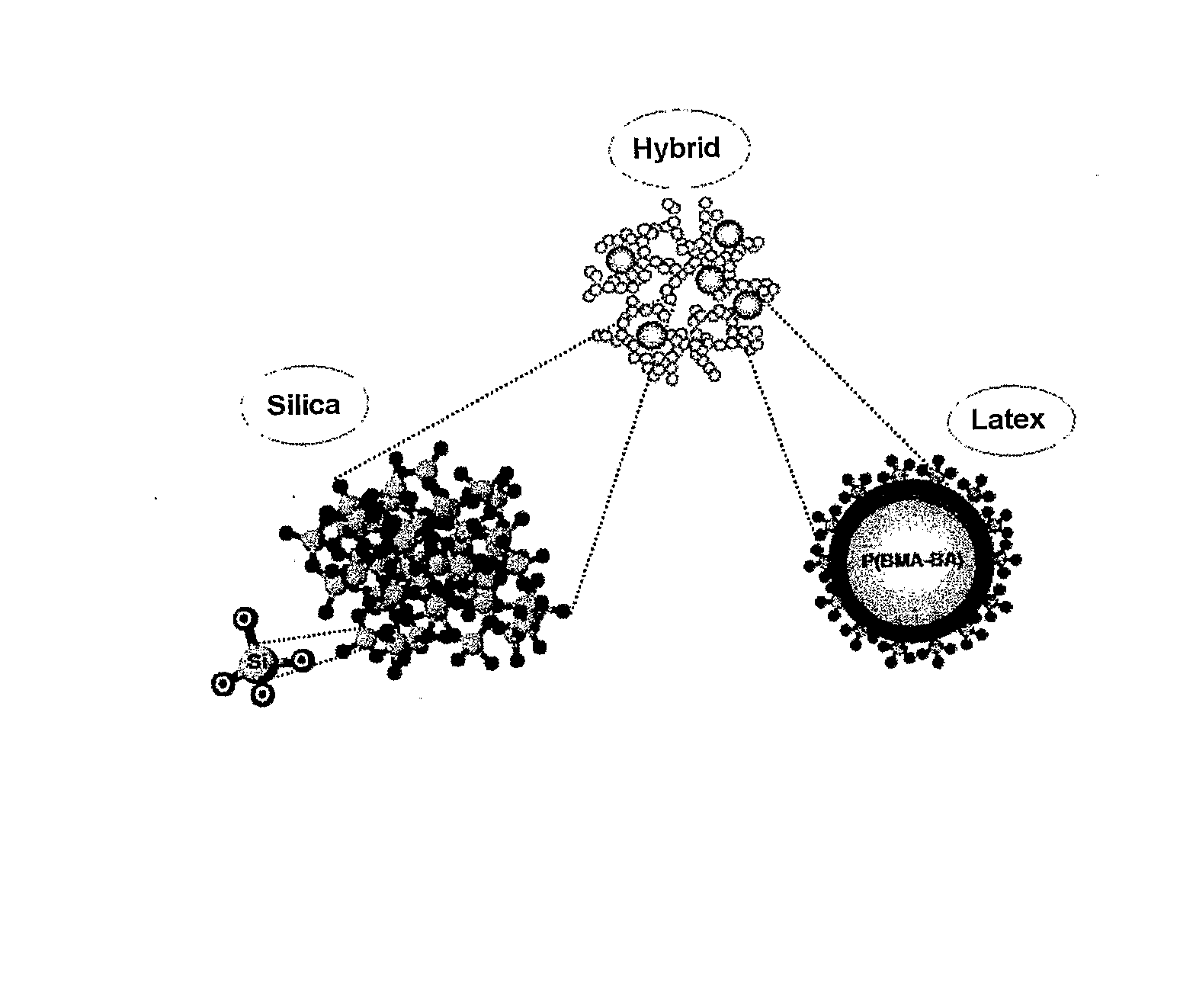

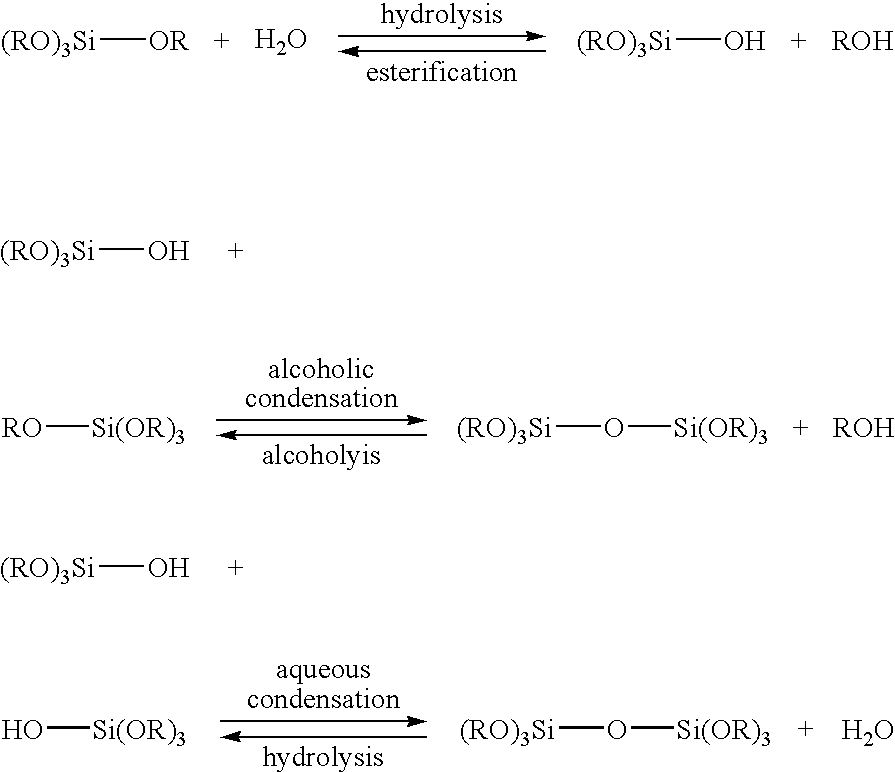

Process for the Preparation, Under Subcritical Conditions, of Monolithic Xerogels and Aerogels of Silica/Latex Hybrids, Modified with Alkoxysilane Groups

InactiveUS20080188575A1Improve insulation performanceHigh mechanical strengthSilicaOther chemical processesColloidal silicaMethacrylate

The invention relates to a process for the preparation of monolithic xerogels and aerogels of silica / latex hybrids under subcritical conditions. In the two-stage synthesis of these alcogels in the presence of an acid-base catalyst, the hydrolysis and polycondensation of a silicon alkoxide are carried out in an organic medium containing excess water. A latex consisting of polybutyl methacrylate and polybutyl acrylate, modified with alkoxysilane groups, is first synthesized and then incorporated in the mixture either in the first stage in order to effect its co-hydrolysis with the silicon alkoxide, or in the second stage to effect its co-condensation with the previously hydrolysed colloidal silica. The resulting alcogels are aged, washed, and dried under subcritical conditions. This process gives hybrid products containing 0.1-50 wt-% of latex and having a density of 300-1300 kg / m3, a porosity of 40-85%, a specific surface area of 400-900 m2 / g and a mean pore diameter of 2-12 nm. The products are resistant to atmospheric humidity and moisture, have better mechanical properties than the corresponding inorganic products, and can be used as thermal, acoustic and electrical insulators.

Owner:INST SUPERIOR TECH

Preparation method of nano particles with high refractive index and polymer nano composite film material

The preparation method of nano composite film material by using nano microparticles with high refractive index and polymer includes the following three steps: preparing ZnS nano microparticles for surface modification, preparing organic polymer monomer and polymer with high refractive index and preparing nano composite film. In the organic solvent of zinc metal salt the organic small molecule surface modifier with function group is added, and the hydrogen sulfide gas is introduced to synthesize ZnS nano colloidal microparticles, and the polymer base material for combining ZnS nano microparticles can be polymethyl methacrylate, polybutyl methacrylate, polystyrene, epoxyresin, polymer large monomer, optimally can be polyurethane oligomer and polyurethane acrylate large monomer with high refractive index, finally the above-mentioned materials can be made into the invented nano composite film.

Owner:JILIN UNIV

Nanometer fluorouracil coat artificial crystalloid and the preparing method

InactiveCN101036804ASuppress turbidityLow toxicityCoatingsIntraocular lensPosterior capsule opacificationChitosan nanoparticles

The invention relates to a intraocular lens. At present the Poly-Methyl Methacrylate (PMMA) intraocular lens conventional for clinical treatment of cataract always causes inflammatory treaction after implantation. Posterior capsule opacification is also a major compalication after cataract surgery. The invention selects fluorouracil to solve the above problems. Based on weak penetrating force of chitosan nanoparticles in eyes and the relation between the phagocytosis amount of conjunctival epithelial cells to nanoparticles and the particle size of nanoparticles, the fluorouracil nanoparticles preparation is prepared using chitosan-poly(acrylic acid) as carrier, composite coated on the surface of PMMA intraocular lens. The invantion also provides a preparation method thereof. The said intraocular lens not only increases the biocompatibility of the intraocular lens, but also inhibites posterior capsule opacification pafter cataract surgery. The said intraocular lens can also prevent anterior membrane after implantation of intraocular lens and after-cataract.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

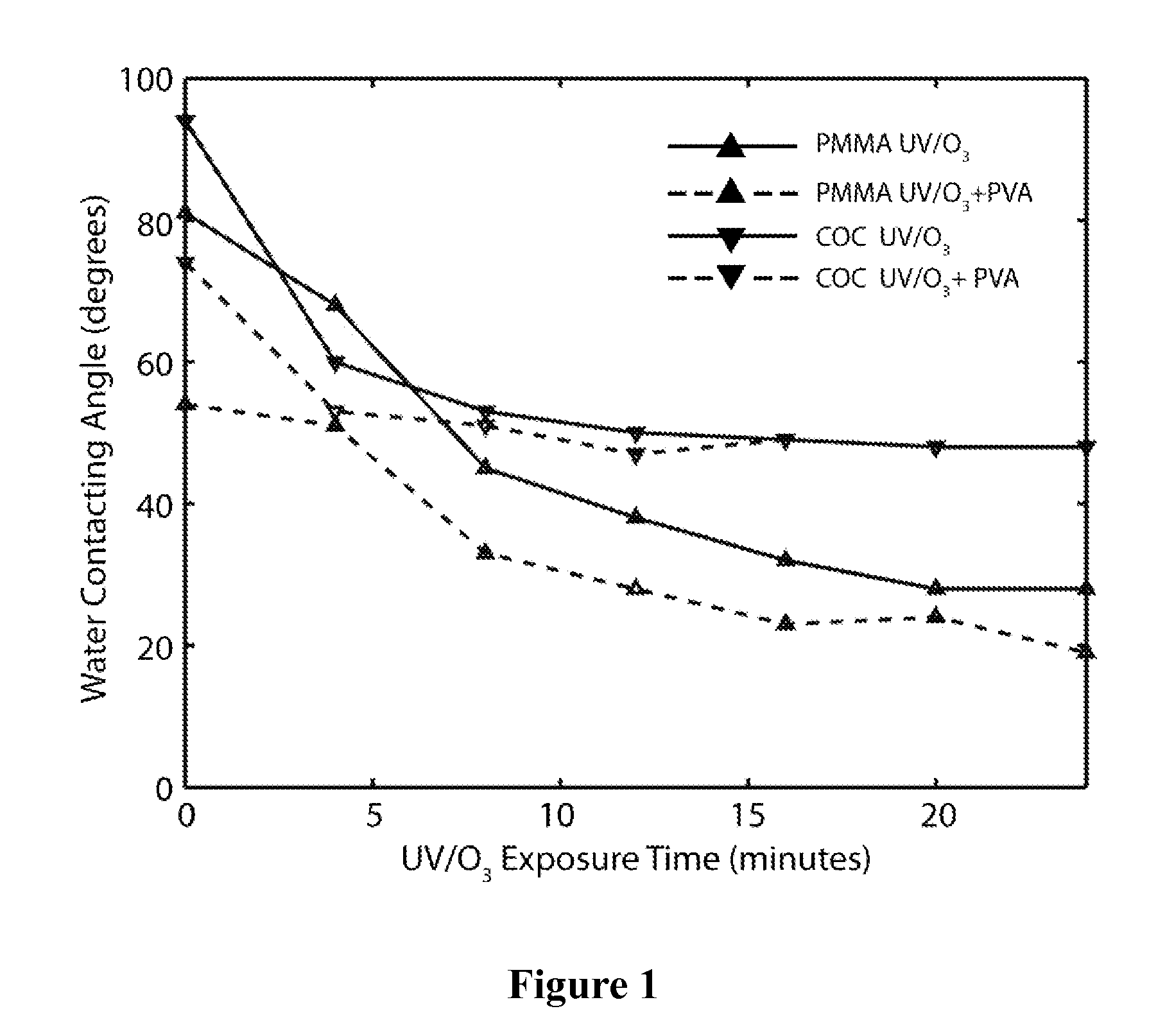

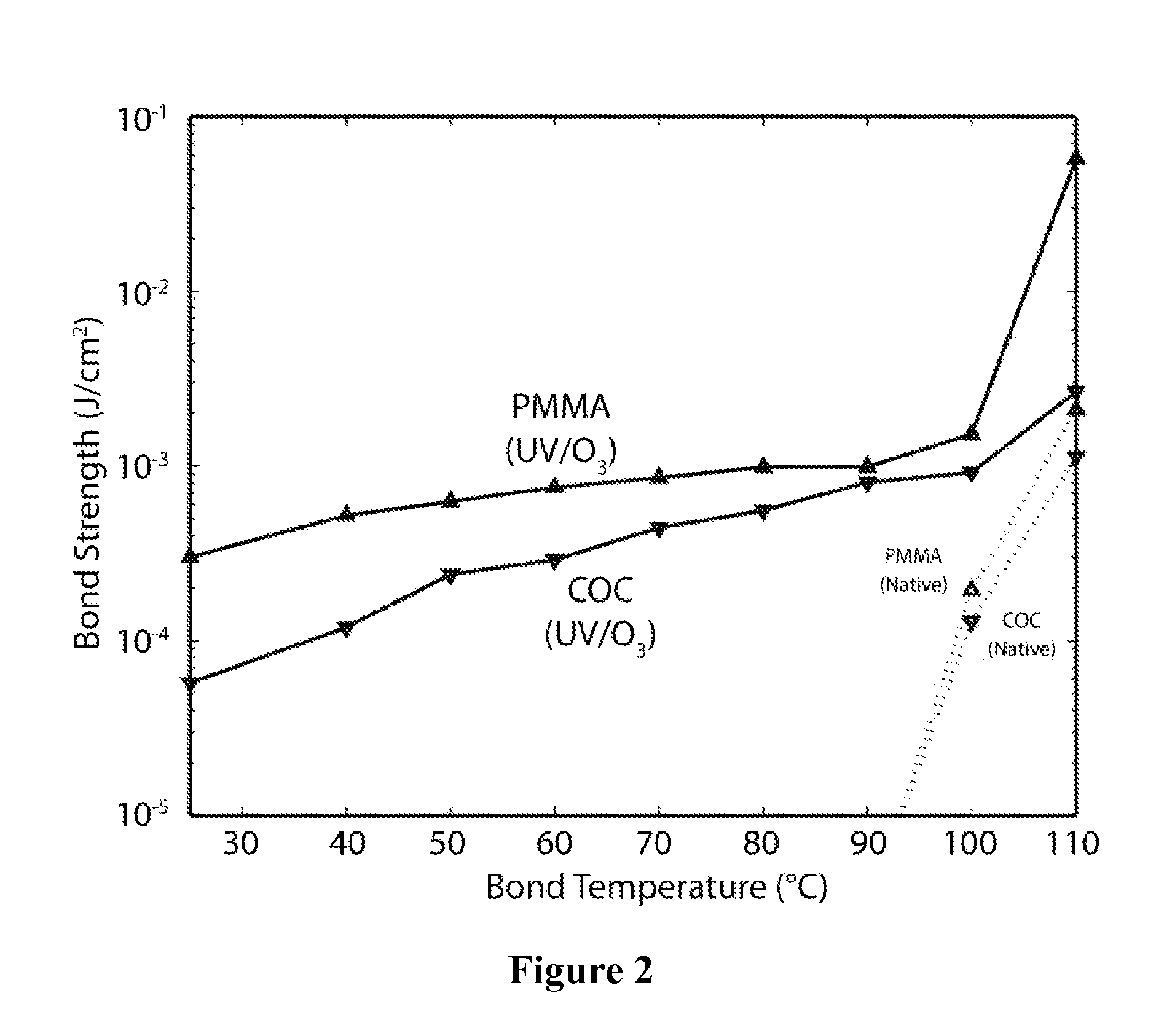

Low Temperature Polymer Bonding Using UV/Ozone Surface Treatment

InactiveUS20090227755A1High bonding strengthLow costPretreated surfacesGroup 3/13 element organic compoundsThermoplasticVitrification

The present invention relates to a method for bonding two surfaces to one another. The invention particularly pertains to the use of such method in which one of the surfaces is a polymeric plastic (and more preferably a polymeric thermoplastic (especially poly-(methyl methacrylate) (“PMMA”) or cyclic olefin copolymer (“COC”)). More particularly, the invention relates to treating at least one of the contacting surfaces with UV in the presence of oxygen to thereby generate ozone (O3) and atomic oxygen under conditions of temperature below that of the glass transition temperature of the polymeric plastic. The UV / O3-mediated bonding results in high bond strength and zero-deformation method. This bonding method can be applied to micro / nano-scale polymer devices, and particularly to microfluidic devices, for a low cost, high throughput, high yield advantage.

Owner:UNIV OF MARYLAND

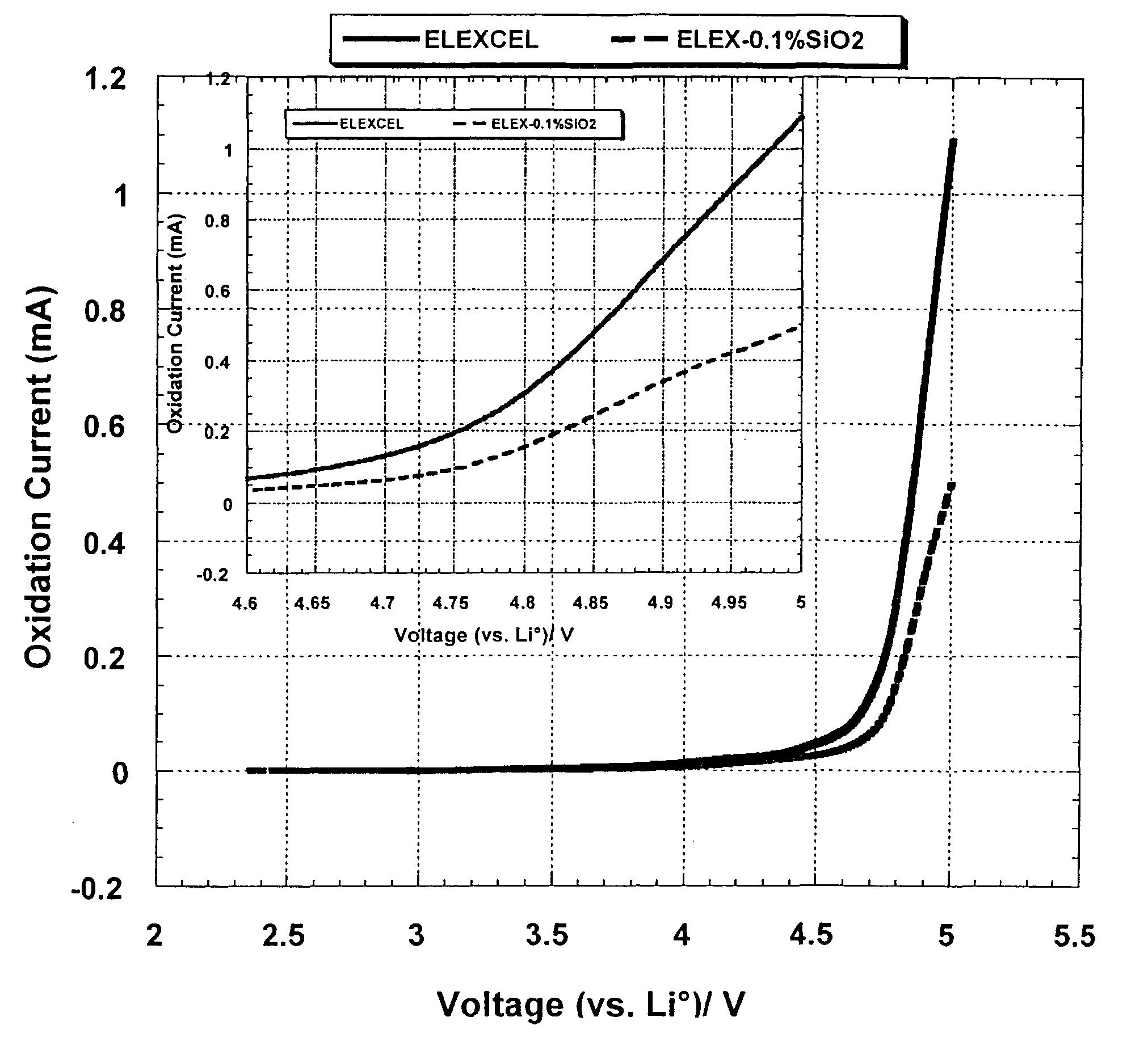

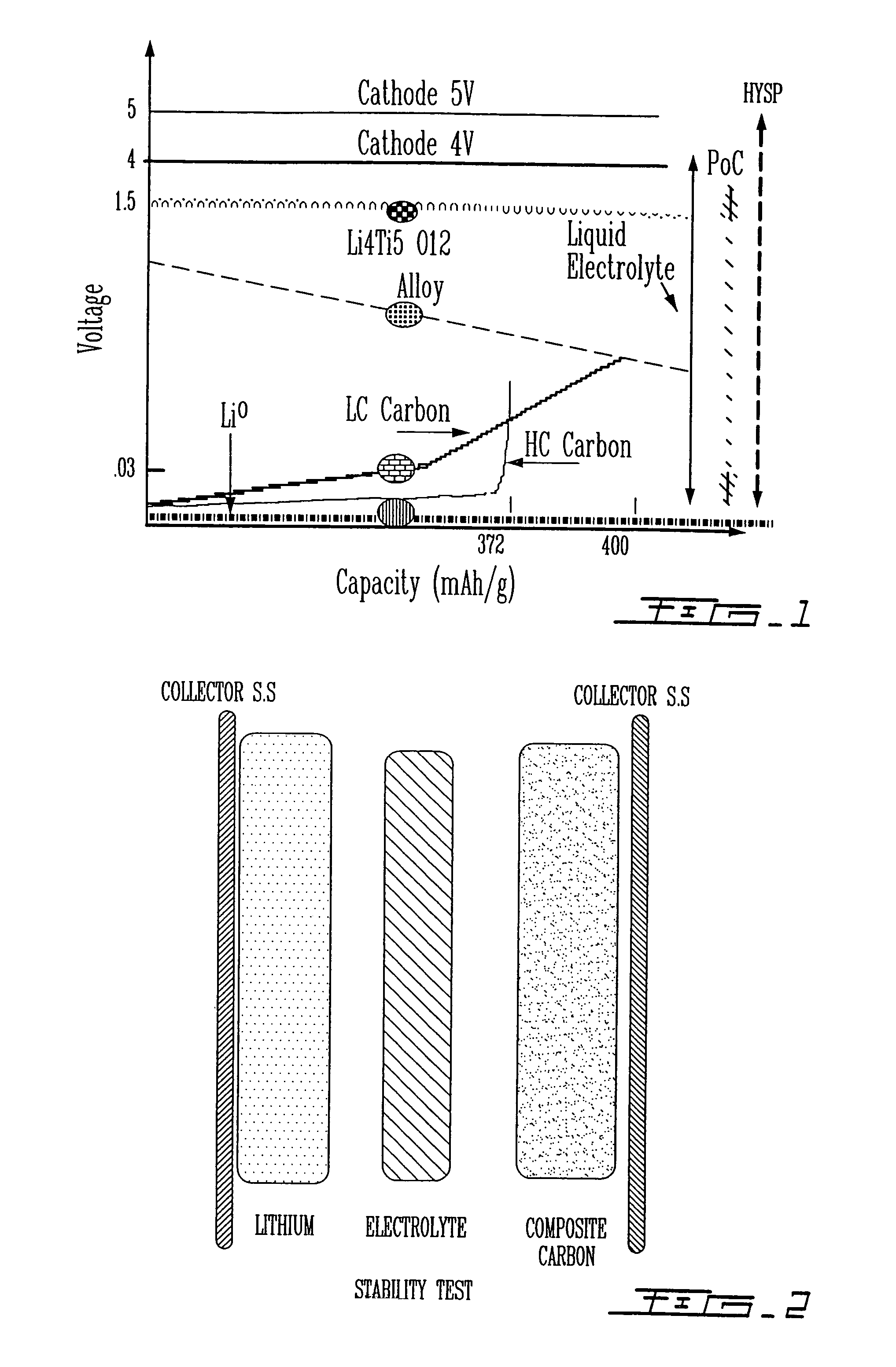

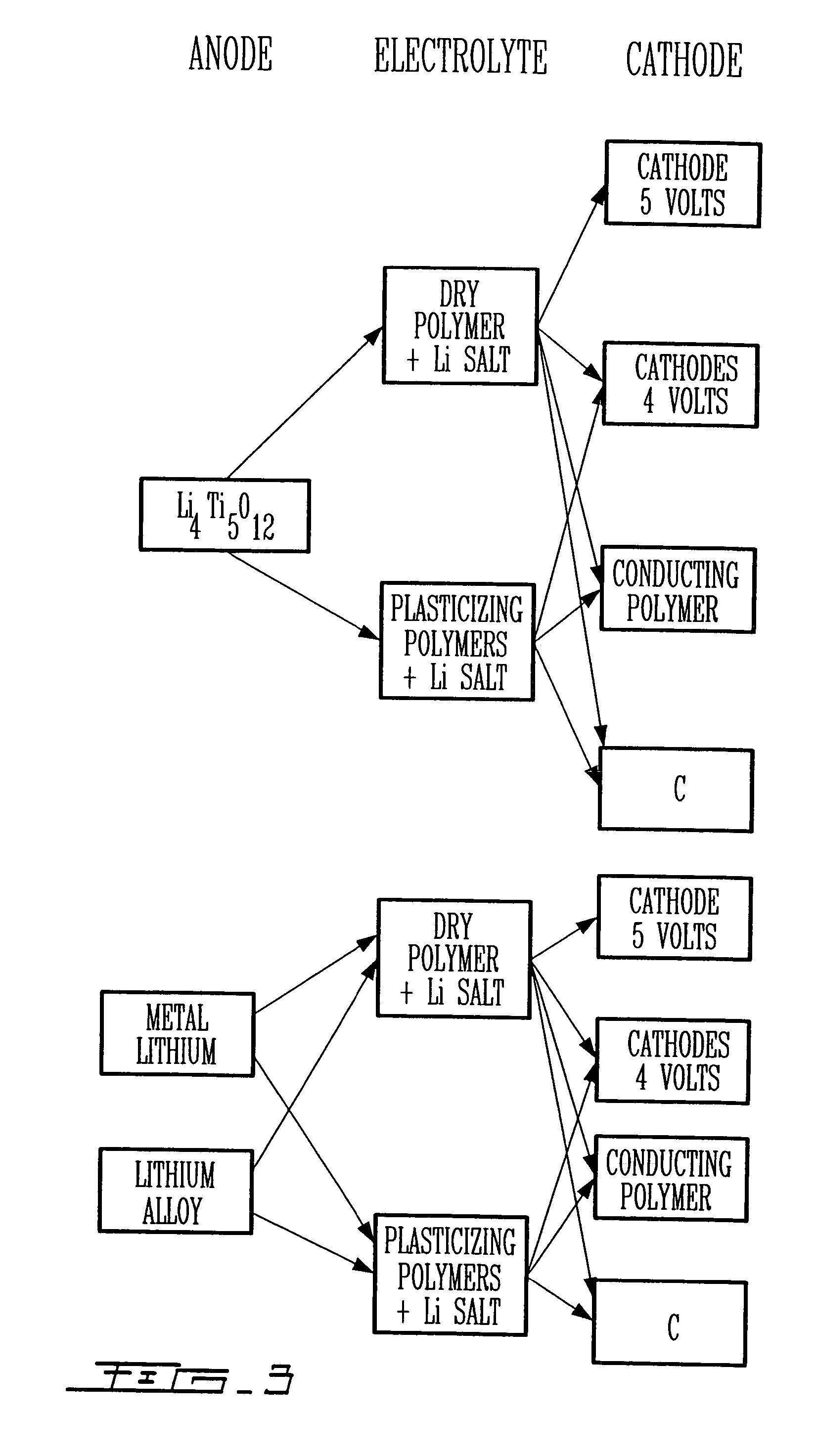

Polymer electrolyte with high stability, its use in electrochemical systems

ActiveUS7897674B2Hybrid capacitor electrolytesHybrid capacitor electrodesPolymer electrolytesTetrafluoroethylene

Polymer electrolyte for an electrochemical generator based on at least a four branched polymer, at least a poly(vinylyldienefluoride), a poly(vinyldiene fluoro-co-hexafluoropropene copolymer), a poly(tetrafluoroethylene), a poly(ethylene-co-propylene-co-5-methylene-2-norbornene) or an ethylene propylene-diene copolymer, a polyol, a poly(methylmethacrylate, a poly(acrylonitrile), SiO2Al2O3, or nano TiO2 non coated or coated with an organic material. This electrolyte allows to prepare electrolytic compositions that can be used in high performance electrochemical devices.

Owner:HYDRO QUEBEC CORP

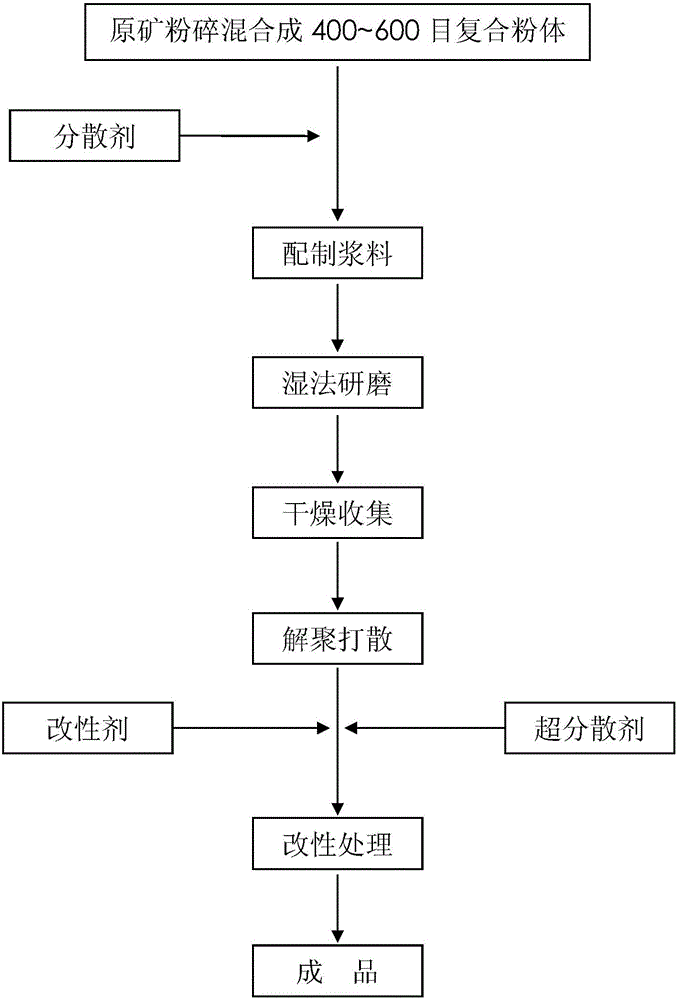

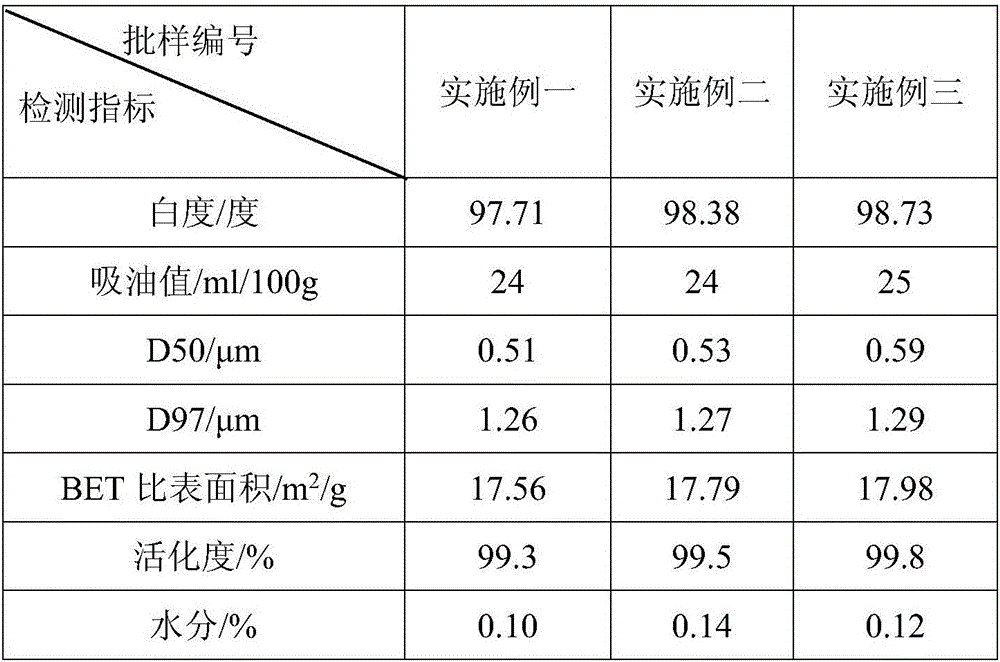

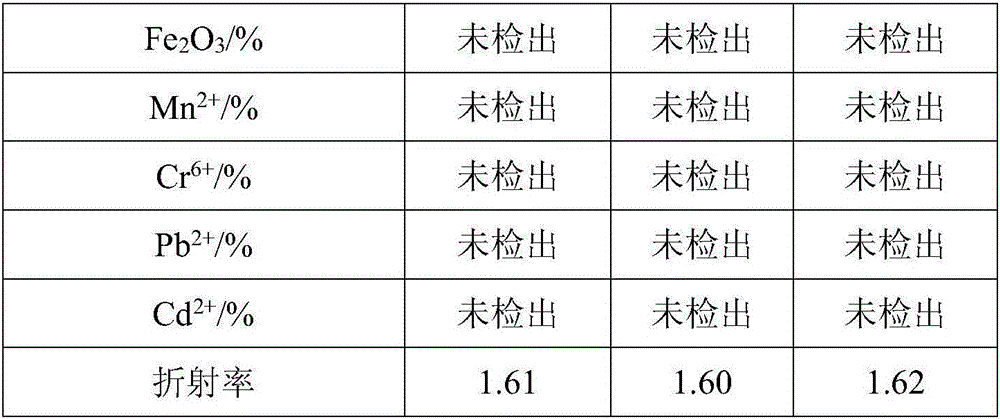

Preparation method of modified superfine calcium carbonate powder and product of preparation method

InactiveCN106433220AGood dispersionModified dispersion effect is goodPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolyesterDispersity

The invention provides a preparation method of modified superfine calcium carbonate powder. The preparation method comprises following steps: raw material mixing, slurry preparation, wet grinding, drying collection, depolymerization scattering and modified treatment, wherein a dispersing agent at least comprises ammonium polyacrylate salt, sodium hexametaphosphate and sodium polyacrylate salt; a modifying agent comprises one or more of octadecylamine, polymethyl methacrylate, a titanate coupling agent and a silane coupling agent; and a hyperdispersant comprises one or more of a polyester type hyperdispersant, a polyether type hyperdispersant, a polyacrylate hyperdispersant and a polyolefin hyperdispersant. By virtue of the preparation method, the dispersity of the powder can be improved, the dry-wet cover effects of building coatings can be improved, and the addition amount of titanium dioxide can be reduced.

Owner:JIANGXI GUANGYUAN CHEM

Molded plastic parts made of casting resins and inorganic fillers, presenting improved mechanical and thermal properties and improved flame-resistance

InactiveUS6624226B1Improve mechanical propertiesHigh impact strengthShell moldingMechanical property

By copolymerisation of compounds which are acid or have a hydroxy or epoxy function in a casting resin with a filler contents of between 10 and 80%, moulded parts on a polymethylmethacrylate basis are obtained which pass the B1-test even without addition of fire-retardant agents and in addition present improved mechanical properties.

Owner:EVONIK ROEHM GMBH

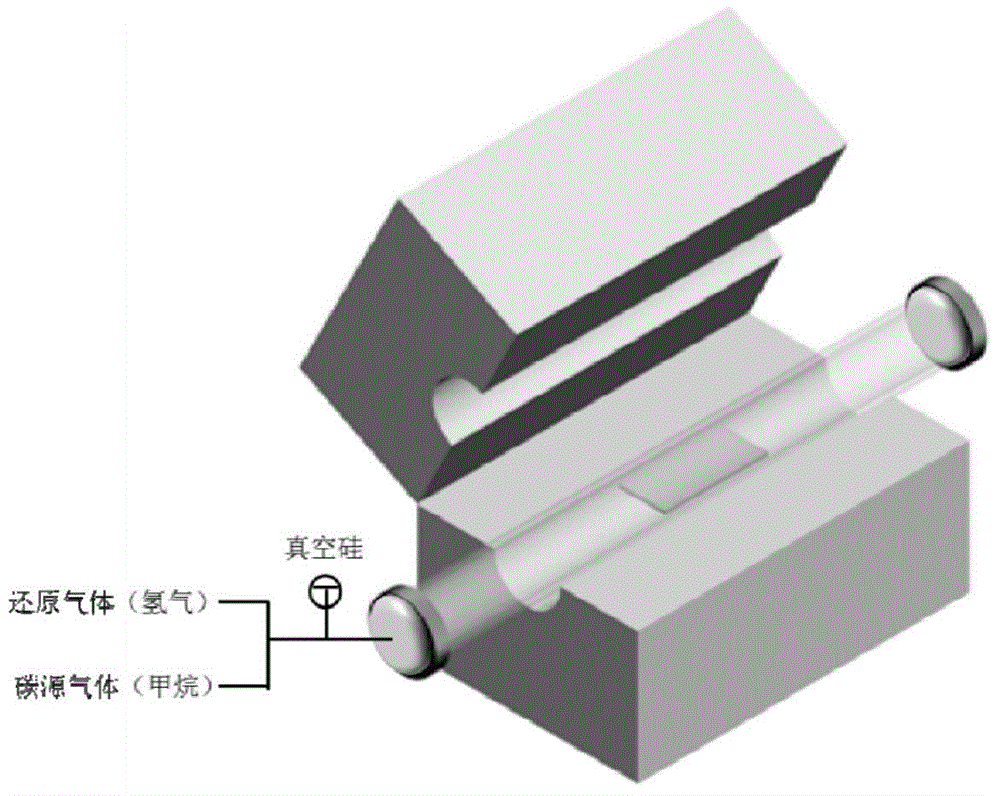

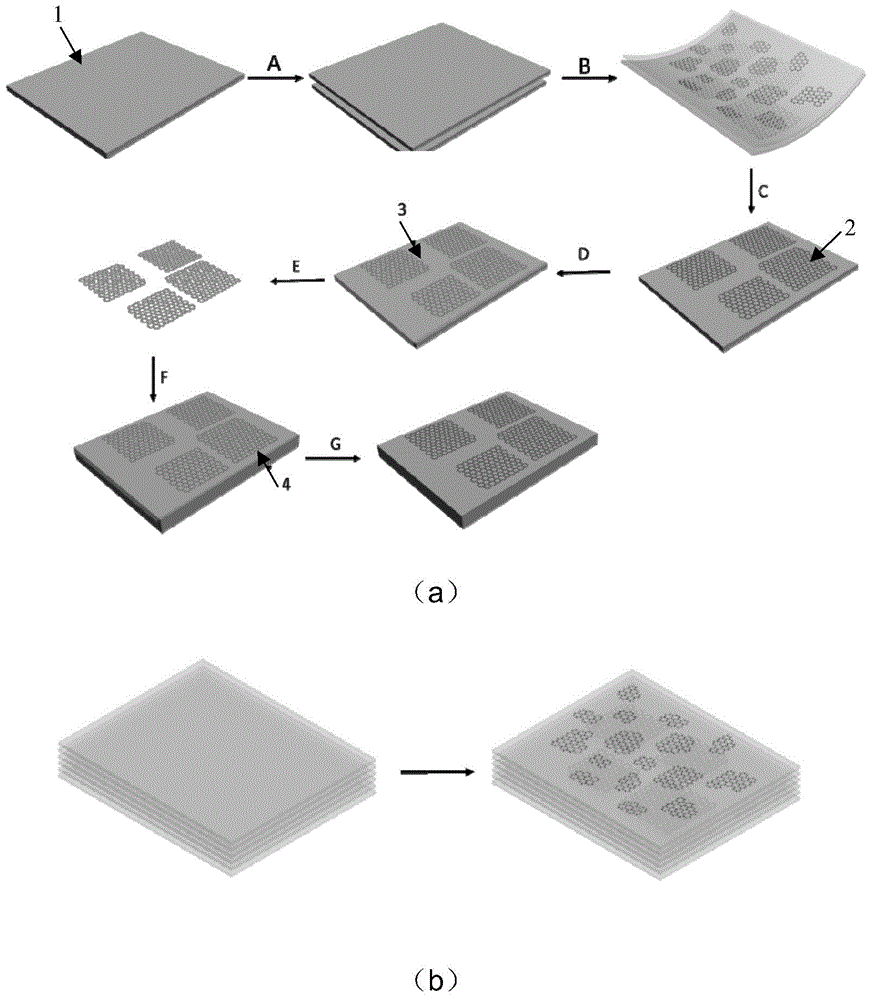

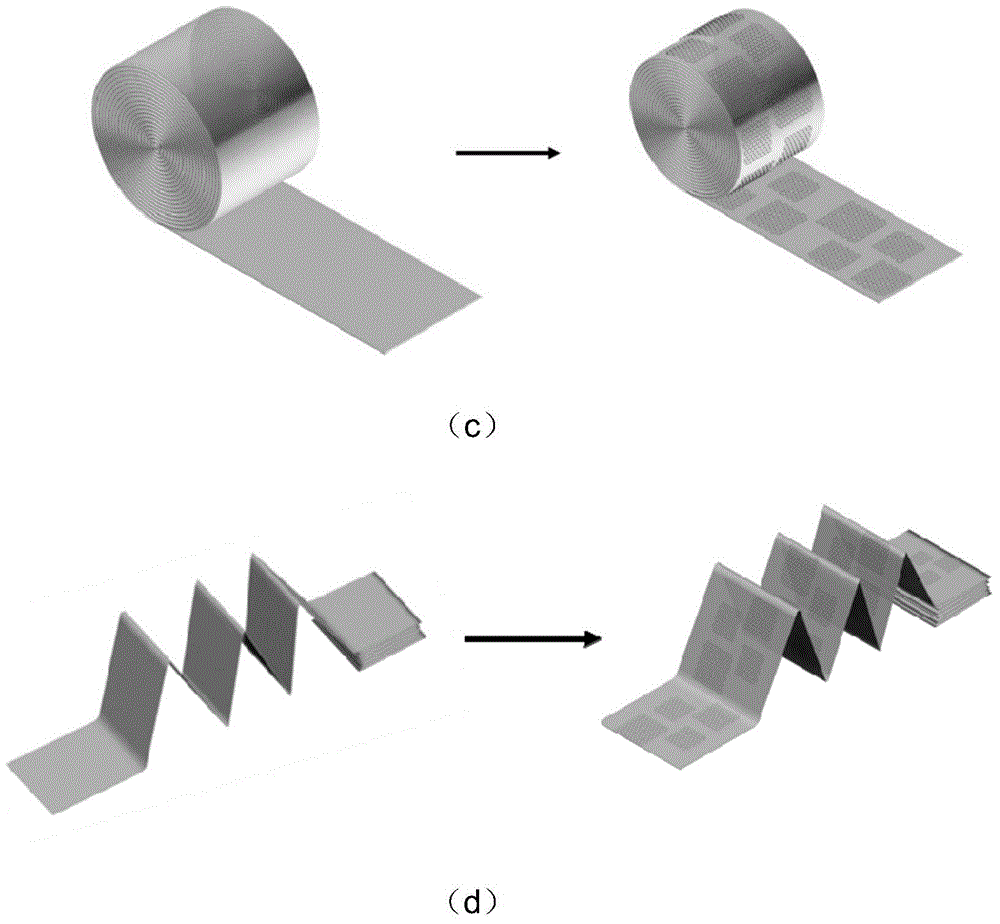

Large monocrystal graphene and preparation method thereof

The invention relates to a large monocrystal graphene and a preparation method thereof. The preparation method comprises the following steps: 1) in a non-reducing gas atmosphere, carrying out annealing treatment on a copper base; 2) while introducing reducing gas into a reactor, carrying out annealing reduction on the copper base subjected to annealing treatment in the step 1); and 3) depositing graphene on the surface opposite the substrate on the gap formed by the two copper bases subjected to annealing reduction by a chemical vapor deposition process, thereby obtaining the isolated large monocrystal graphene. The preparation method can also further comprise the following steps: by using polymethyl methacrylate (PMMA) or polyethylene terephthalate (PET) as a medium, transferring the large monocrystal graphene onto the target base, and adjusting the growth time and gas flow rate in the graphene growth process to quickly prepare the isolated large monocrystal graphene sample. The method does not need longer preparation time or any expensive monocrystal base.

Owner:PEKING UNIV

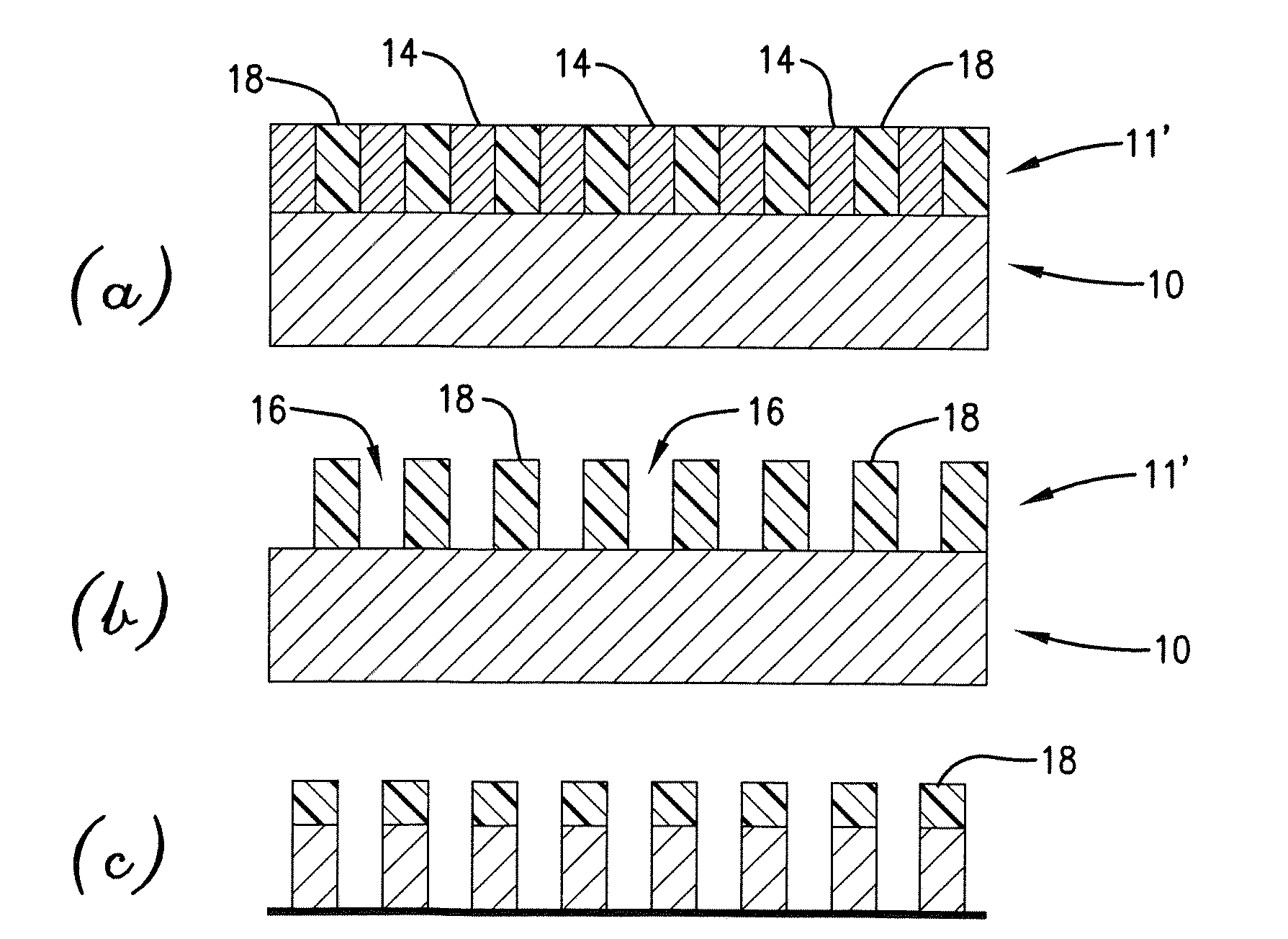

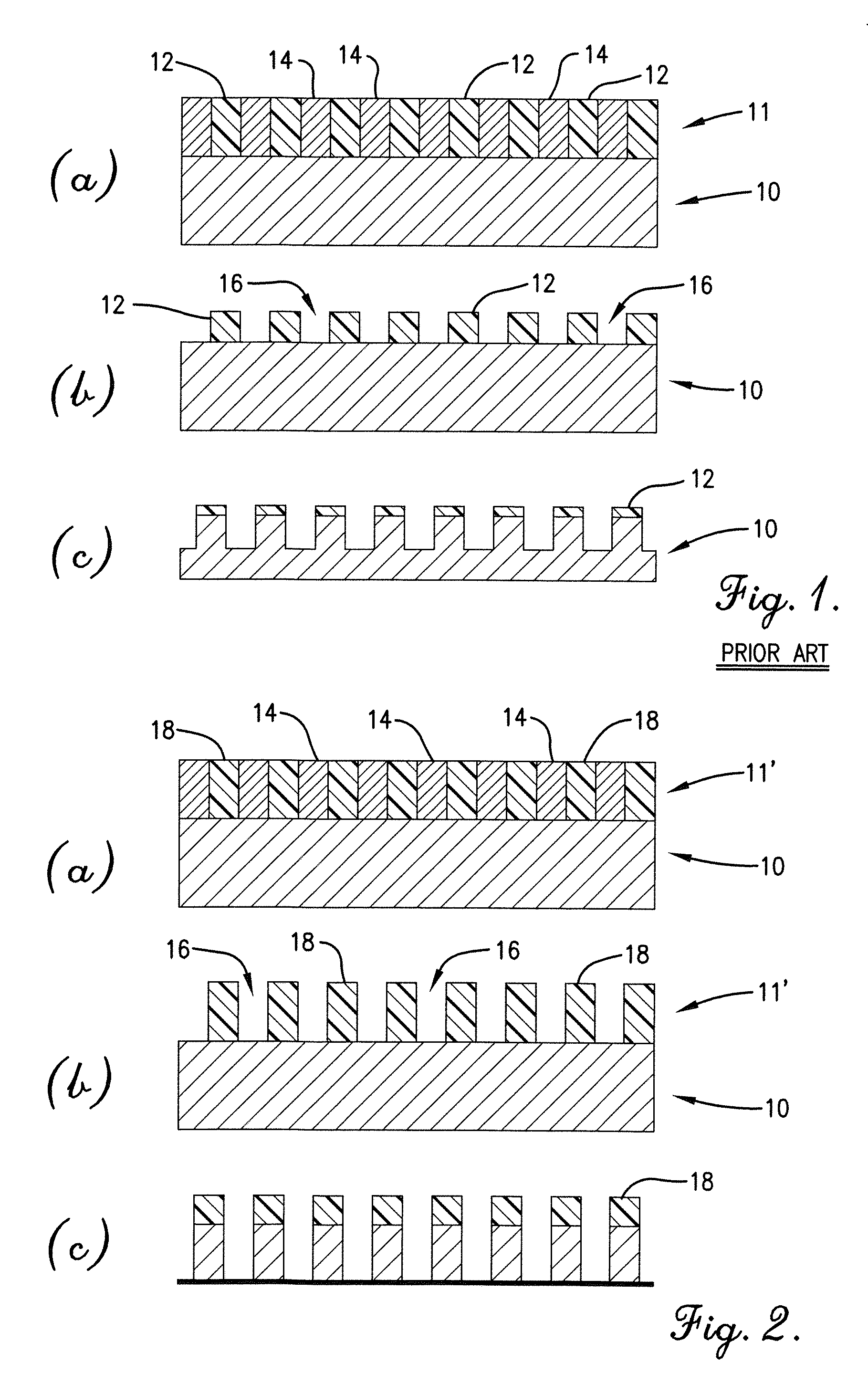

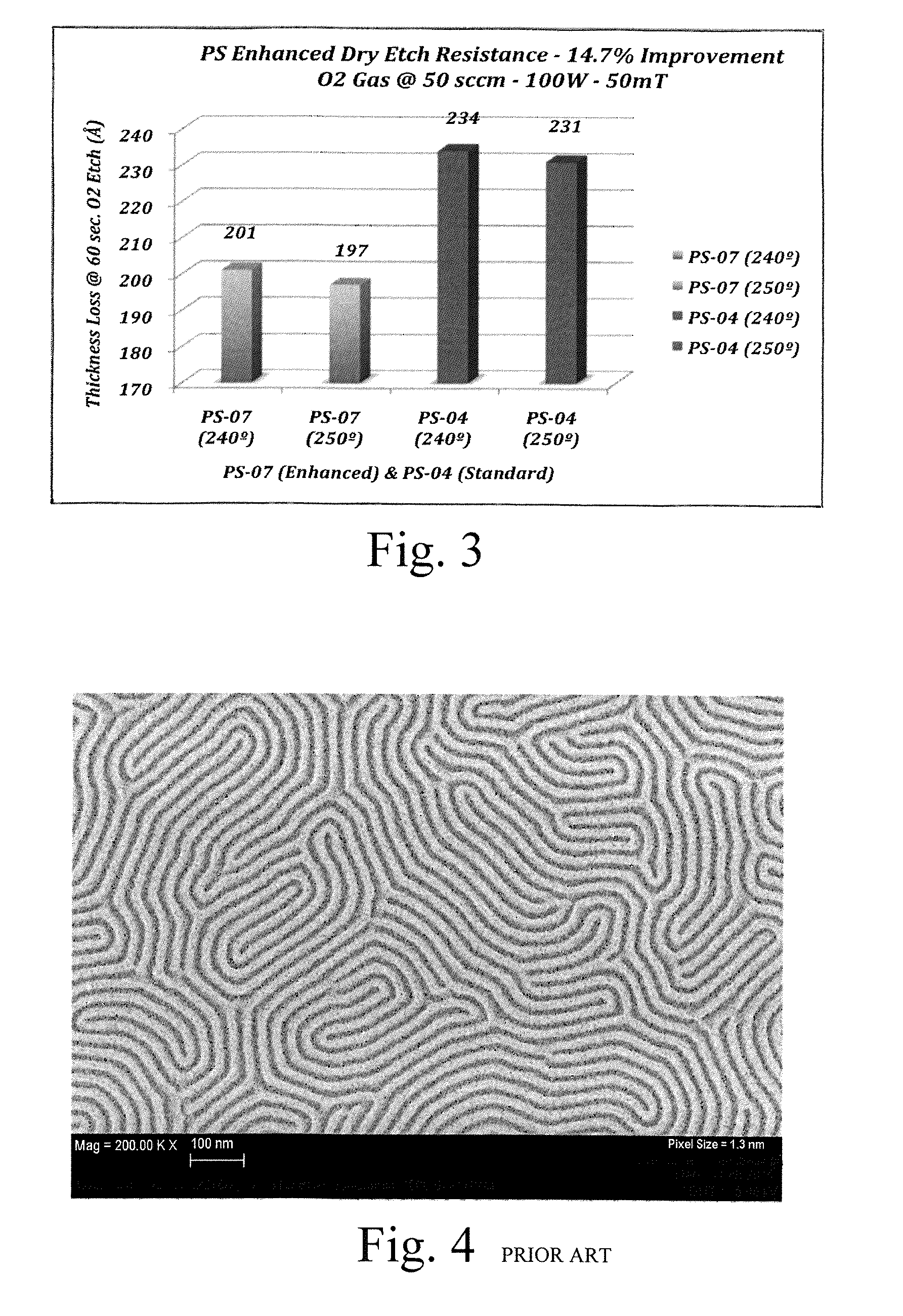

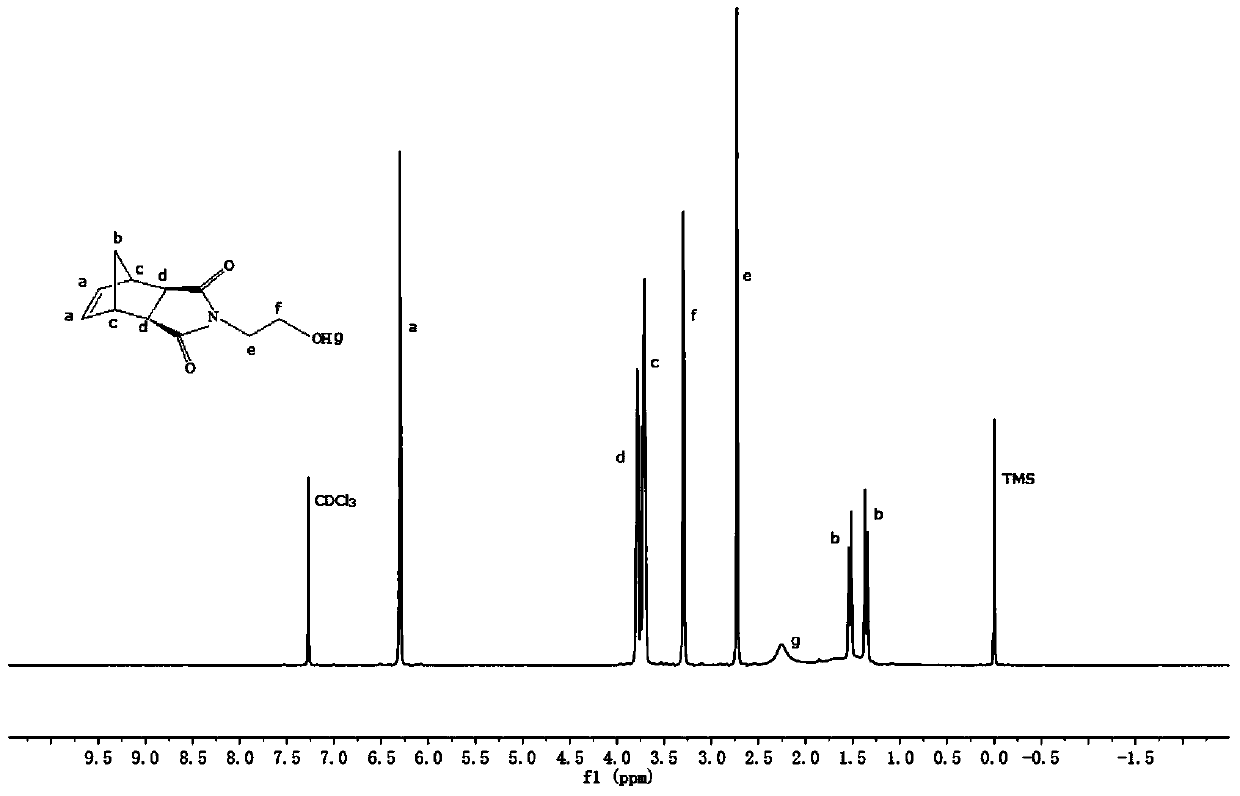

Highly etch-resistant polymer block for use in block copolymers for directed self-assembly

ActiveUS20140299969A1Easy alignmentSurface energyPhotomechanical apparatusSemiconductor/solid-state device manufacturingSelf assemblePolystyrene

Compositions for directed self-assembly (DSA) patterning techniques are provided. Methods for directed self-assembly are also provided in which a DSA composition comprising a block copolymer is applied to a substrate and then self-assembled to form the desired pattern. The block copolymer includes at least two blocks of differing etch rates, so that one block (e.g., polymethylmethacrylate) is selectively removed during etching. Because the slower etching block (e.g., polystyrene) is modified with an additive to further slow the etch rate of that block, more of the slow etching block remains behind to fully transfer the pattern to underlying layers.

Owner:BREWER SCI

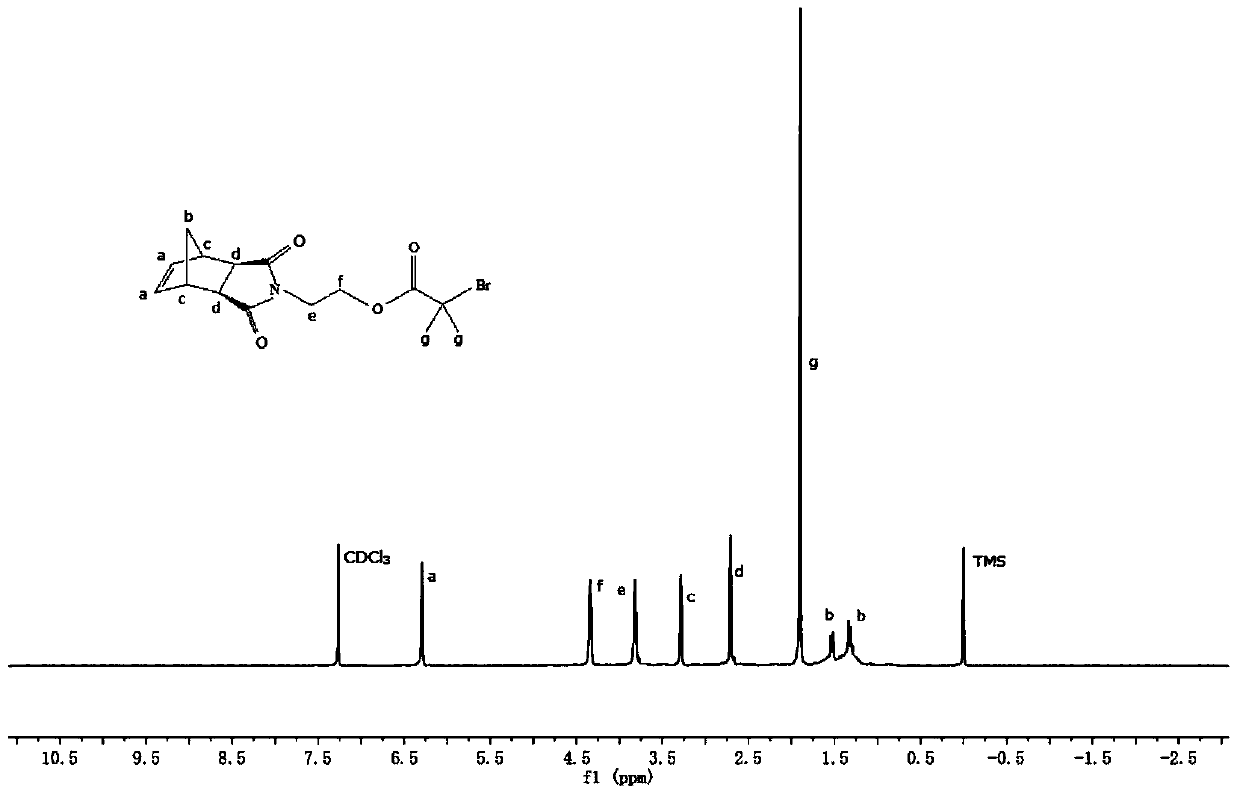

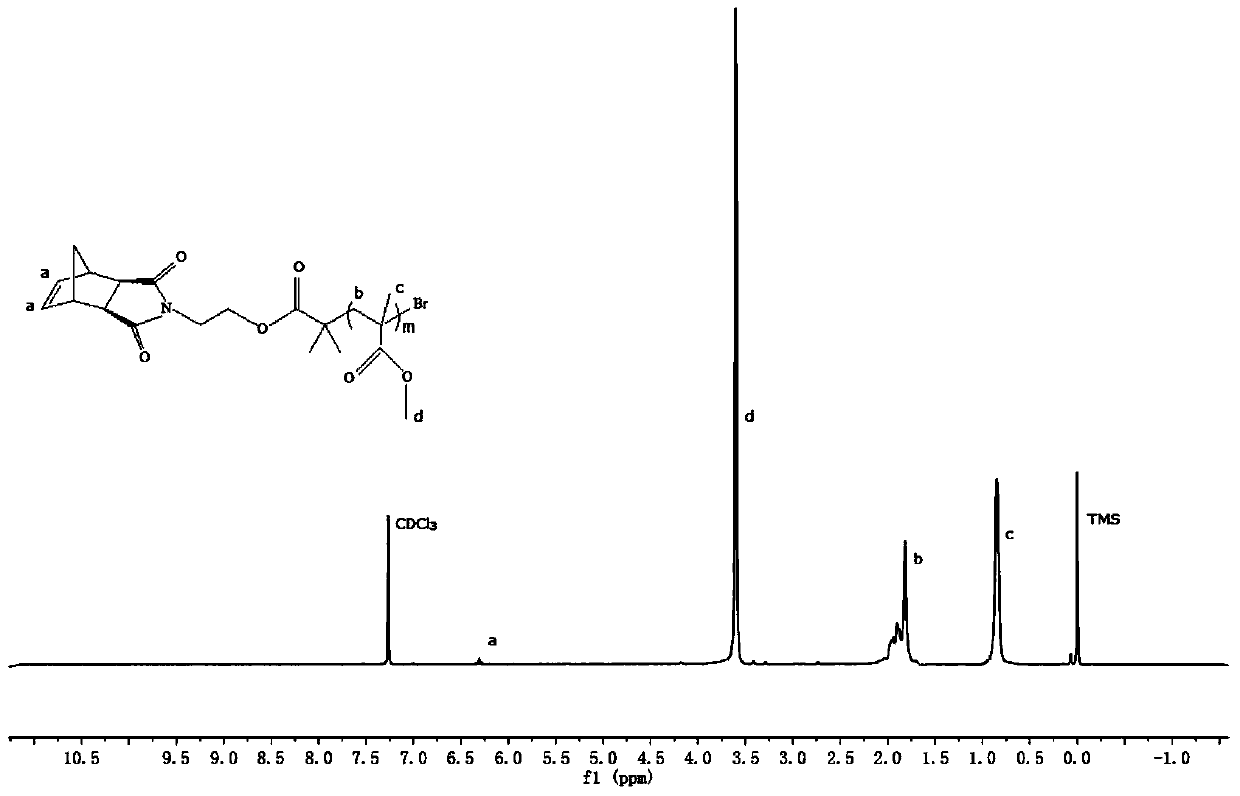

Brush-like block copolymer with macromolecules at chain ends and preparation method thereof

The invention relates to a brush-like block copolymer with macromolecules at chain ends and a preparation method thereof, belonging to the technical field of high-polymer crystalline materials. The block copolymer provided by the invention can form ordered nano-structure photon crystals by self-assembly, and has the characteristic of adjustable chemical and mechanical properties. The chemical expression of the block copolymer is (N-PMMA)y-b-(N-PS)x, and the molecular weight is 3*10<5>-4*10<6>; in the expression, x=y; N-PMMA is norbornene polymethyl methacrylate macromolecule monomer of which the number-average molecular weight is 6000; and N-PS is norbornene polystyrene macromolecule monomer of which the number-average molecular weight is 6000. The preparation method of the brush-like block copolymer is a ring-opening metathesis polymerization method; and the block copolymer prepared by the method has very low winding of the side chain, and can quickly form the ordered nano-structure photon crystals by self-assembly.

Owner:CHANGCHUN UNIV OF SCI & TECH

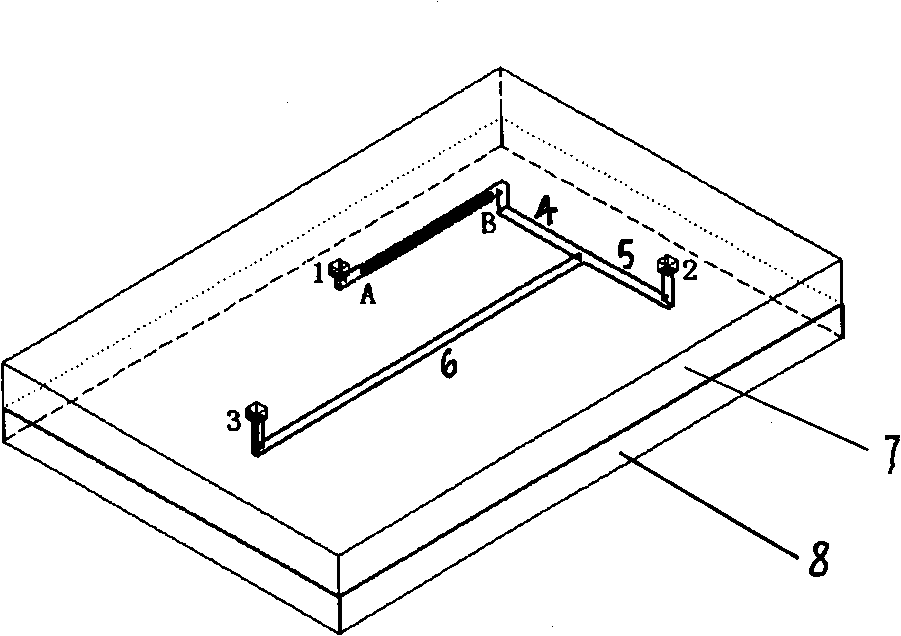

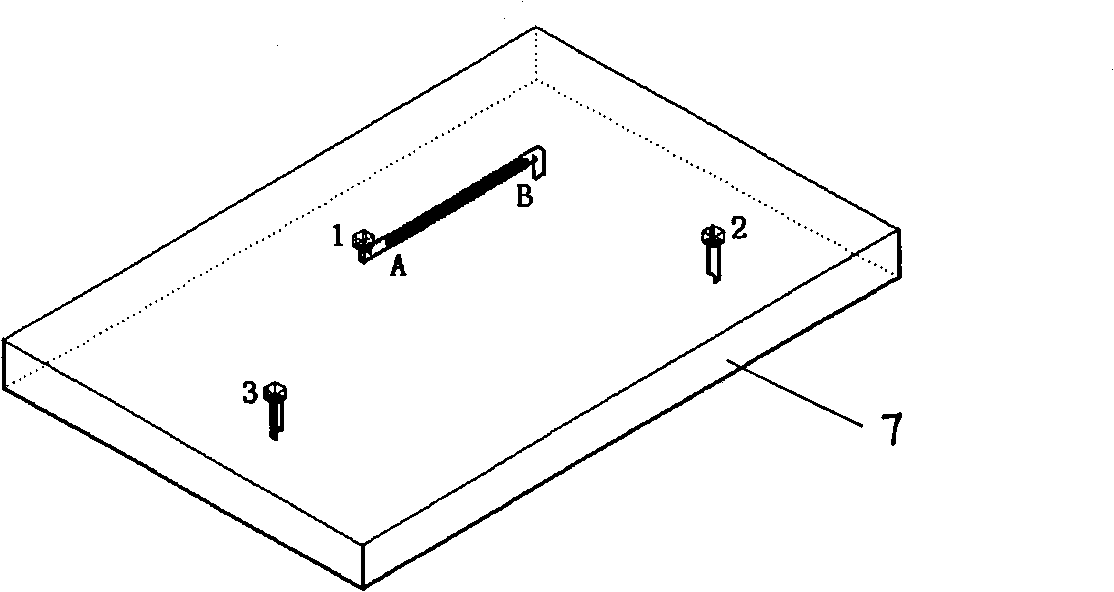

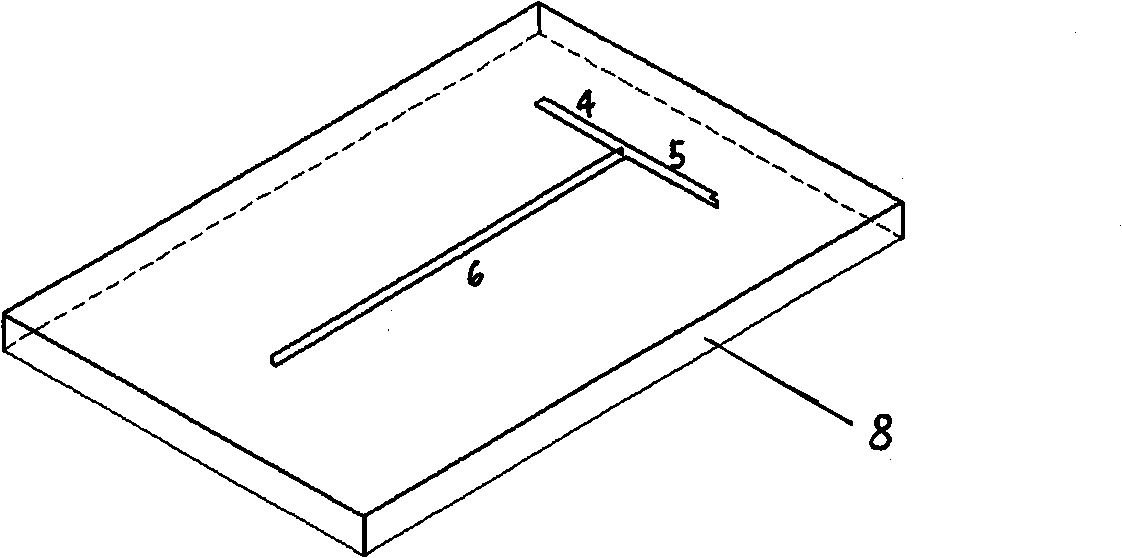

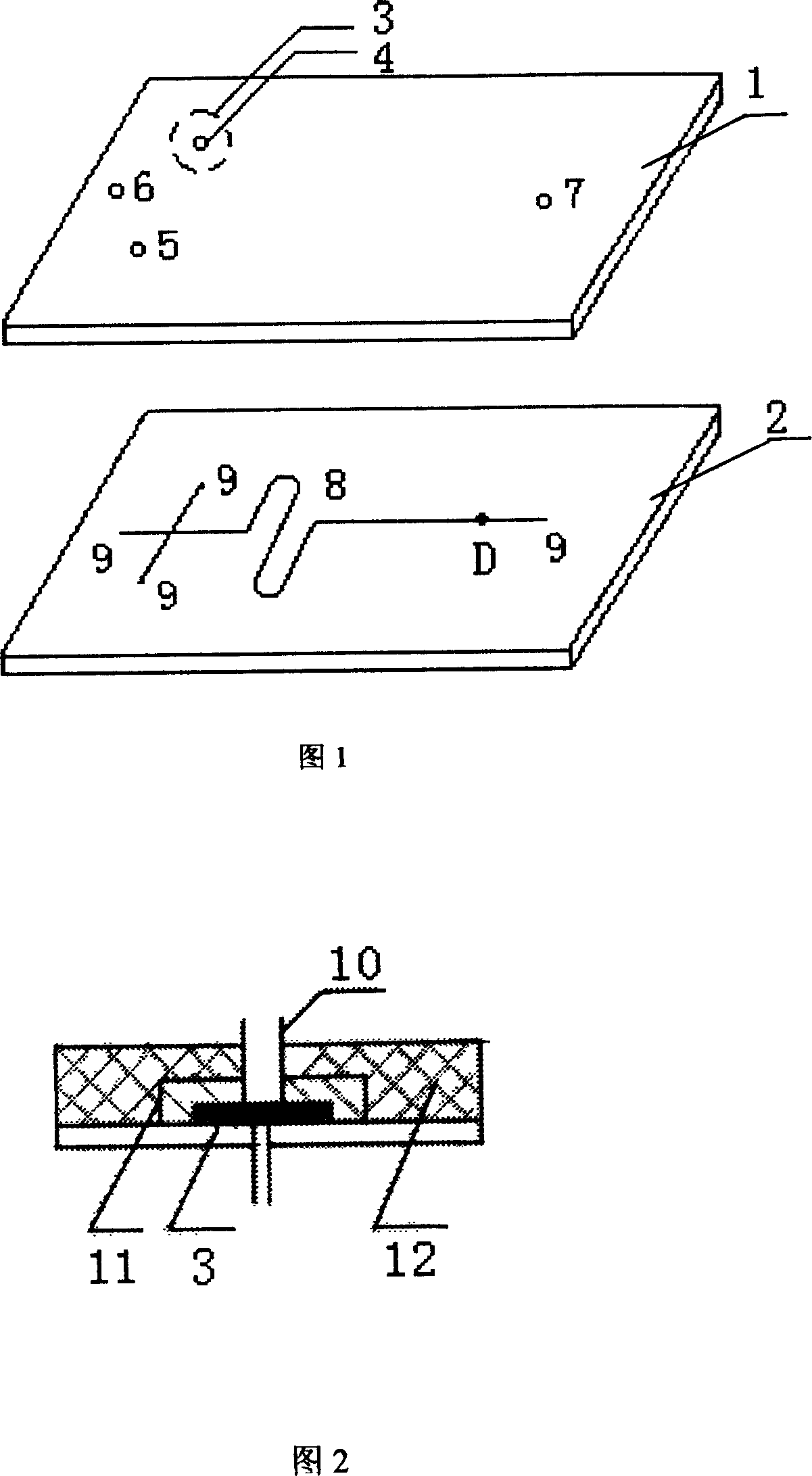

Three-dimensional microflow control chip containing in-situ poly(butyl methacrylate) preprocess integral column

InactiveCN101358912ARealize integrationEffective control positionPreparing sample for investigationBiological testingIn situ polymerizationPolymethyl methacrylate

The invention pertains to the technology field of micro total analysis, relating to a three-dimensional micro-flow control chip which includes an in-situ polybutyl methacrylate pretreatment integral pole. The polymer butyl methacrylate pretreatment integral pole is prepared by ultraviolet-radiated in-situ polymerization in the micro-channel on the micro-flow control chip; the substrate of the micro-flow chip can adopt glass, silicon, polymethyl methacrylate (PMMA) or poly(dimethylsiloxane) (PDMS), and the like as base materials, and etched with micro-channel networks for fluid mixing and reaction; the cover plate adopts PDMS integral casting method to fabricate the micro-channels of the solid-phase extracting and processing unit, a fluid lead-in / lead-out hole is arranged at the position corresponding to each micro-channel opening of the substrate, and is directly bounded with the substrate, and integration of the sample pretreatment integral pole and the micro-flow control chip micro-pipeline network is realized. The chip has the advantages of easy fabrication, low cost, small sampling quantity, rapid compartment analysis, and is applicable to pretreatment, analysis and test of sophisticated biochemical samples.

Owner:CHONGQING UNIV

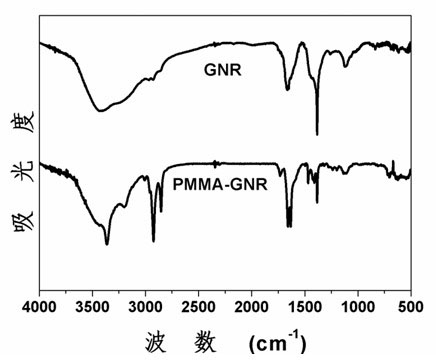

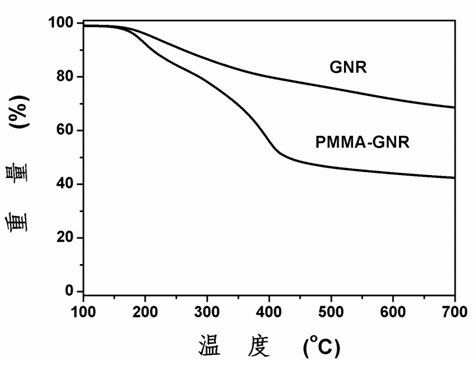

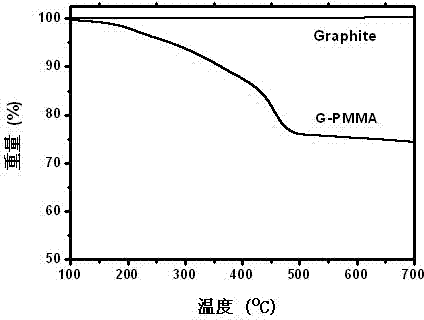

Preparation method of modified polymethyl-methacrylate graphene nanoribbon (PMMA-GNR)

The invention relates to a preparation method of modified polymethyl-methacrylate graphene nanoribbon (PMMA-GNR). The preparation method comprises the following steps of: longitudinally cutting a multi-walled carbon nanotube through oxidation to prepare the GNR, and dispersing the GNR on N, N- dimethyl formamide to obtain a dispersion liquid of the GNR; adding PMMA and azodiisobutyronitrile into the dispersion liquid and then performing a heating reaction on the mixed liquid; and pouring products into methyl alcohol, and performing the procedures of centrifuging, washing and vacuum drying on the mixed liquid to obtain the graphene-enhanced PMMA composition. Compared with that of a PMMA body, the tensile strength of the PMMA composition, namely the modified GNR with the 0.5% of PMMA, is improved by 78.5%, and the Young modulus of the PMMA composition is improved by 111%, so that the mechanical property of the composite material is improved remarkably.

Owner:SHANGHAI JIAO TONG UNIV

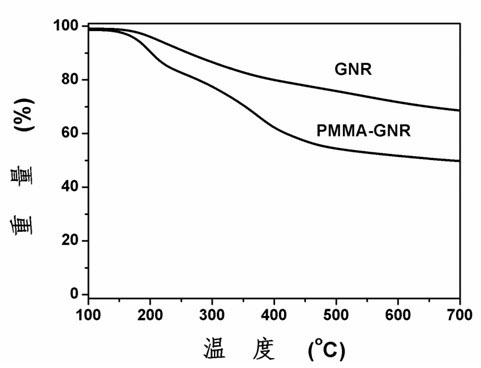

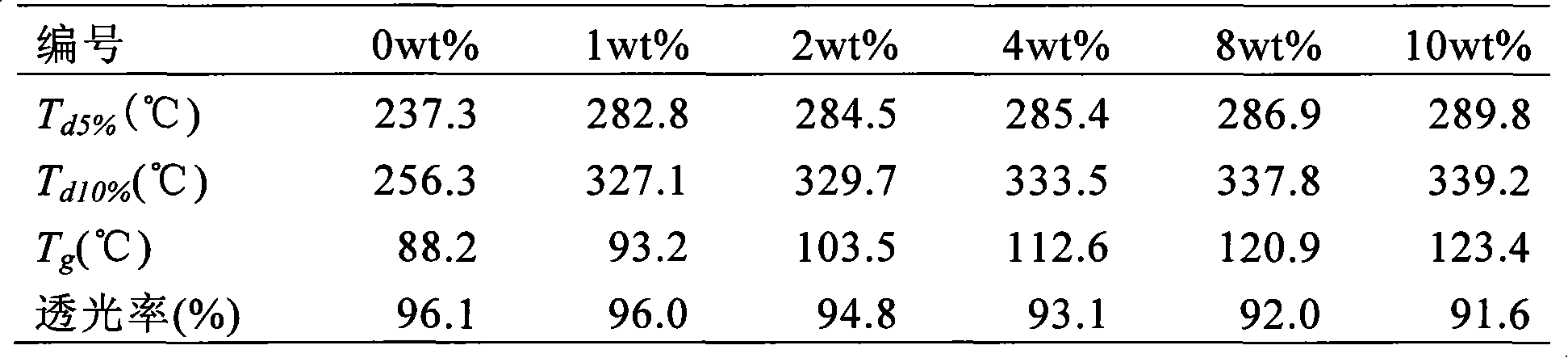

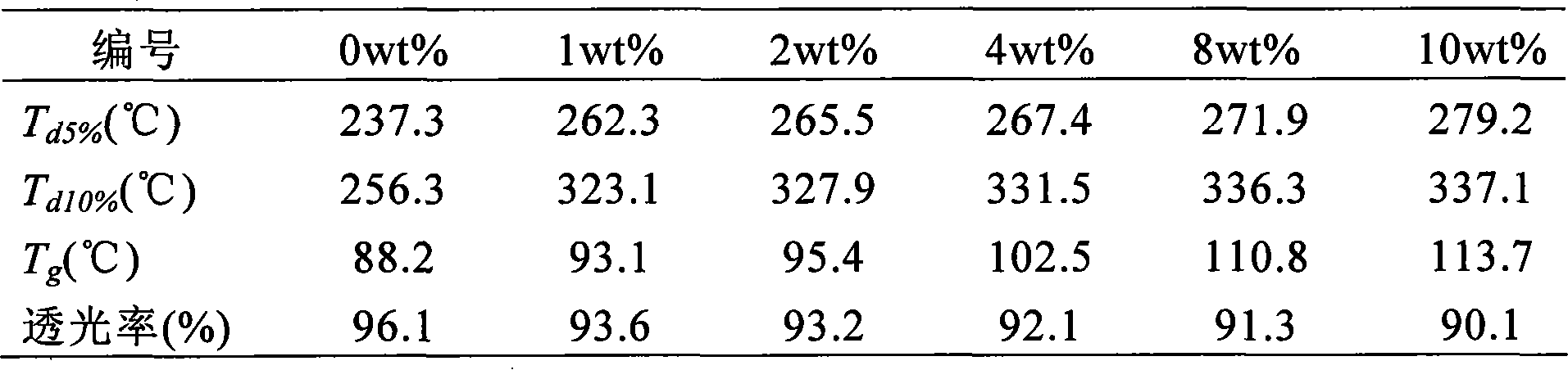

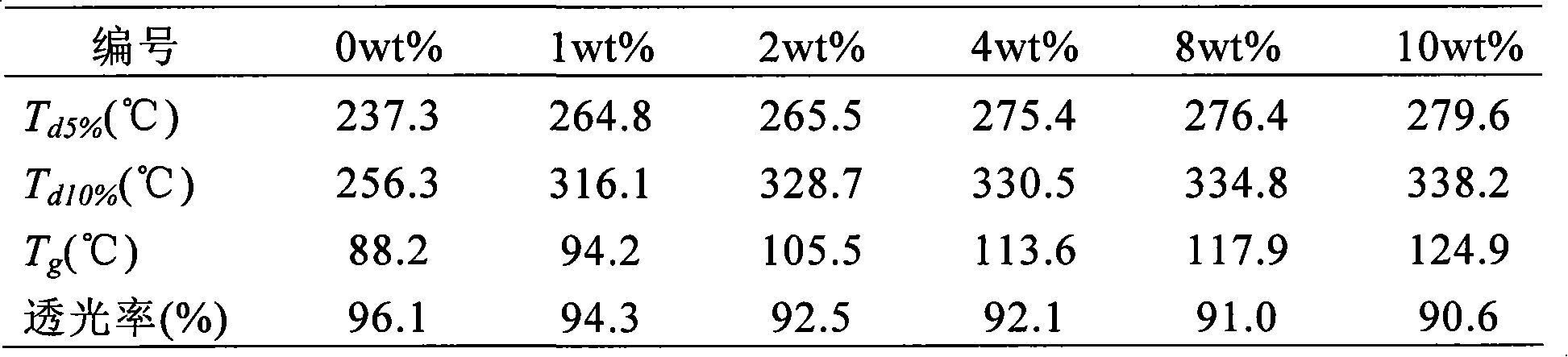

Method for preparing transparent heat-resistant polymethyl methacrylate nano-composite membrane

The invention relates to a method for preparing a transparent heat-resistant polymethyl methacrylate nano-composite membrane. The method comprises the following steps: dispersing montmorillonite into deionized water, and stirring the mixture at a temperature of 50 to 90 DEG C for 2 to 6 hours to obtain a montmorillonite suspension for standby; dissolving polymethyl methacrylate into solvent to prepare polymethyl methacrylate solution; and mixing the montmorillonite suspension and the polymethyl methacrylate solution uniformly, casting the mixture at a temperature lower than 150 DEG C, and volatilizing the solvent to prepare the transparent heat-resistant polymethyl methacrylate nano-composite membrane. The content of the montmorillonite in the membrane is more than 0 weight percent and less than or equal to 10 weight percent. Compared with the prior art, the method for preparing the transparent heat-resistant polymethyl methacrylate nano-composite membrane has reasonable process and simple operation; and the nano-composite membrane cast from the polymethyl methacrylate and the montmorillonite by a solvent blending method has the advantages of convenient shaping, adjustable thickness, high transparency, good heat resistance, high use temperature and the like, and can be widely used in the industries such as external decoration materials, optical materials and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

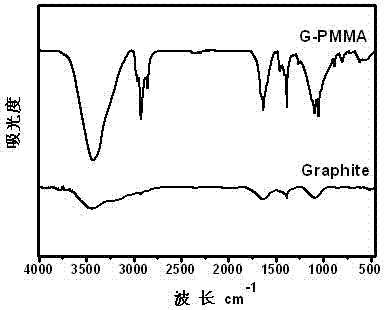

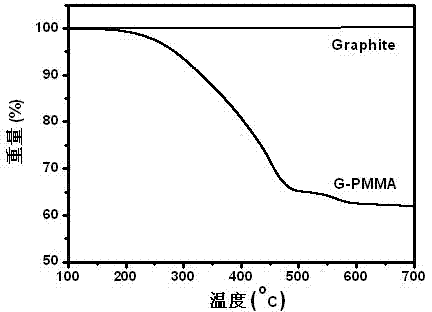

Graphene modified poly-methyl methacrylate composite and preparation method thereof

InactiveCN102408658AImprove thermal stabilityHigh breaking strengthPoly(methyl methacrylate)Young's modulus

The invention relates to a graphene modified poly-methyl methacrylate composite and preparation method thereof, wherein the method comprises the following steps: stripping graphite from 1-methyl-2-pyrrolidone by solvent ultrasonic method and preparing grapheme solution, and adding methymethacrylate and azodiisobutyronitrile and heating them, and reacting them; pouring the product into methanol, and sequentially centrifuging, washing and vacuum drying it to obtain graphene enhanced poly-methyl methacrylate composite. The 0.5% graphene enhanced poly-methyl methacrylate composite synthetized by one-step method in the invention, wherein the tensile strength is 115% higher than the pure poly-methyl methacrylate polymer, and Young modulus is raised by 221%, and excellent mechanical property is revealed. The thermogravimetric analysis displays shows that in comparison with the poly-methyl methacrylate, the temperature for the graphene enhanced poly-methyl methacrylate composite material comprising 0.5% of the invention when the thermogravimetric loss reaches 10% is raised by about 30 degrees centigrade, which means the composite material prepared by the invention has higher heat stability.

Owner:SHANGHAI JIAO TONG UNIV

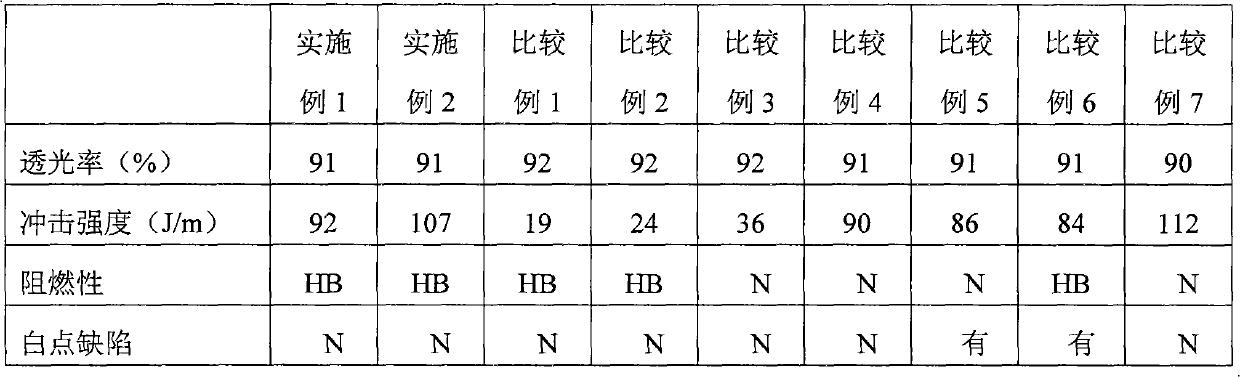

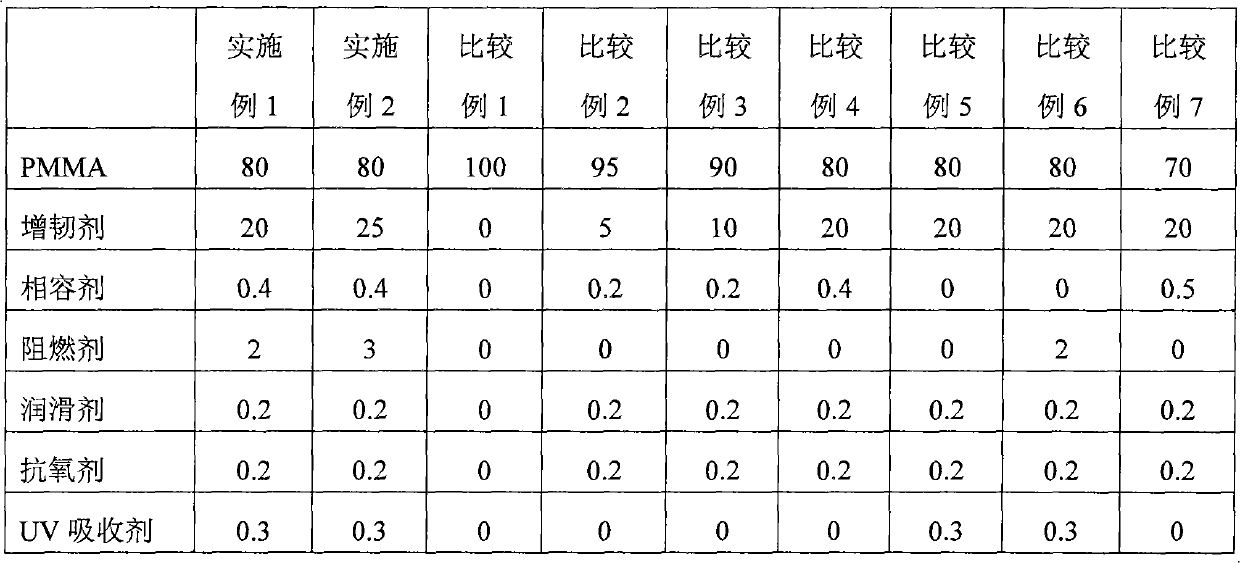

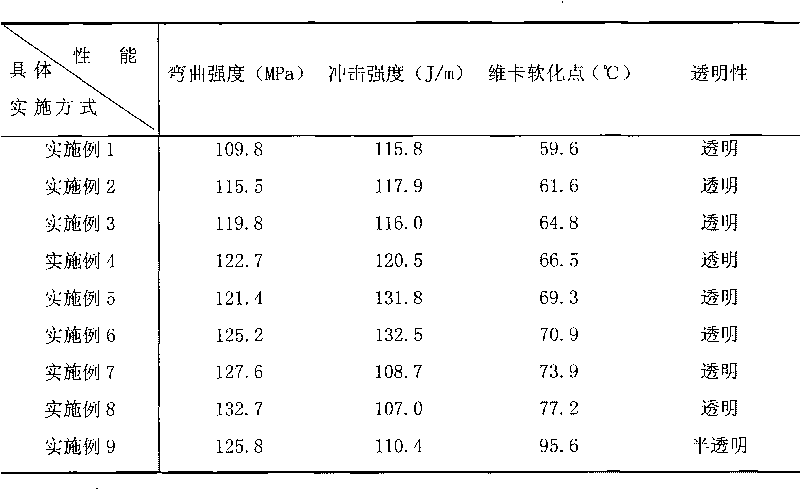

Polymethylmethacrylate composition and preparation method thereof

The invention provides a polymethylmethacrylate composition and a preparation method thereof. The polymethylmethacrylate composition comprises the following components in percentage by weight: 20-70% of polymethylmethacrylate resin, 5-25% of flexibilizer, 0.2-2% of compatilizer, 0.05-5% of flame retardant, 0.1-1% of lubricant, 0.1-1% of UV absorbent and 0.15-2% of antioxygen. The preparation method of the polymethylmethacrylate composition comprises the following steps: weighing the components of the polymethylmethacrylate composition according to the weight proportion; mixing the polymethylmethacrylate, the compatilizer and the flame retardant for 10-30 minutes, then adding the flexibilizer and mixing for 10-30 minutes, and finally adding the lubricant, the UV absorbent and the antioxygen and mixing for 10-30 minutes; and melting, mixing, extruding and granulating the well mixed raw materials in the eight regions of a twin-screw extruder. The polymethylmethacrylate composition of the invention has high processing yield, high light transmittance, high surface hardness, favorable toughness, chemical stability, weather resistance and fire resistance.

Owner:SINOPLAST NEW MATERIAL

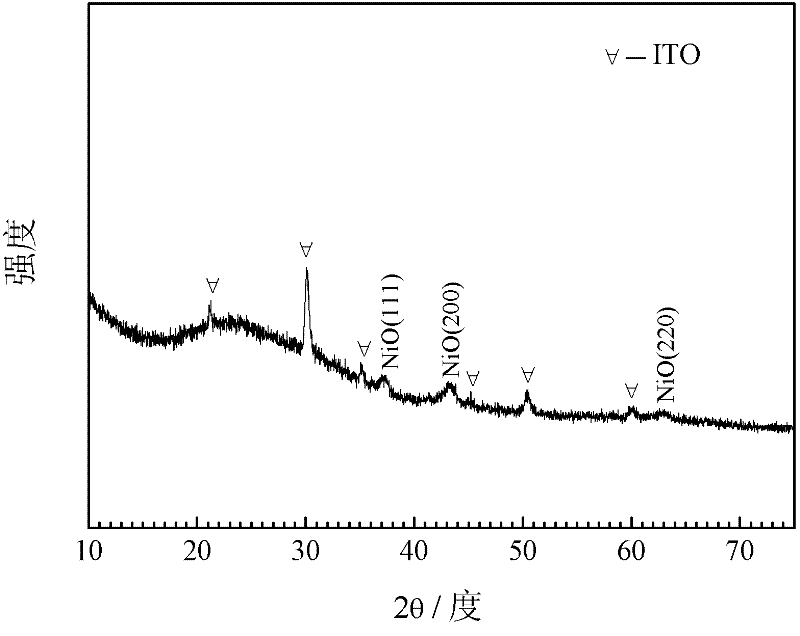

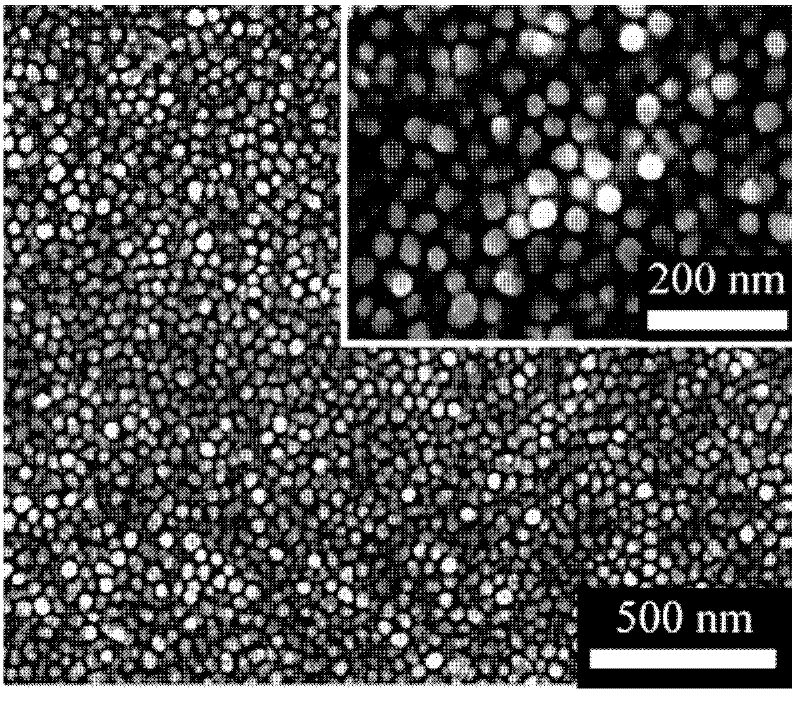

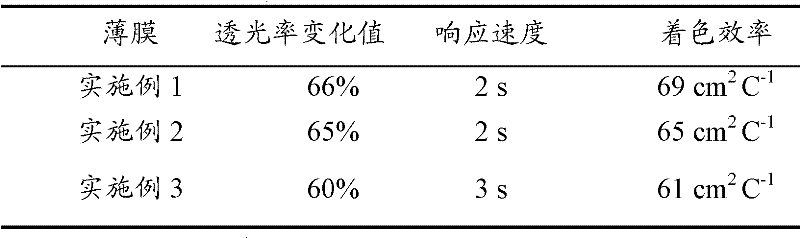

Nickel oxide electrochromic film and preparation method thereof

InactiveCN102515564AFast electrochemical reactionLarge specific surface areaNanotechnologyNickel oxides/hydroxidesArchitectural glassPolystyrene

The invention discloses a nickel oxide electrochromic film and a preparation method thereof. The nickel oxide electrochromic film is a NiO nanowire array film, the diameter of the NiO nanowire is 5-100 nm, and the length is 50 nm to 5 mu m. The preparation method comprises the following steps of: taking polymethylmethacrylate-b-polystyrene segmented copolymer as a template, preparing a precursor Ni(OH)2 nanowire array in a water solution of Ni(NO3)2 and NaNO3 through the cathode electrodeposition method, dissolving the precursor Ni(OH)2 nanowire array in a toluene solution to remove the template, and carrying out head treatment to obtain the NiO nanowire array film. The nickel oxide electrochromic film has good properties, quick color change, high coloring efficiency and excellent cycling stability. The nickel oxide electrochromic film can be assembled into various electrochromic devices and has broad application prospects in the fields of information storage, architectural glass, smart windows, large screen display and the like.

Owner:ZHEJIANG SCI-TECH UNIV

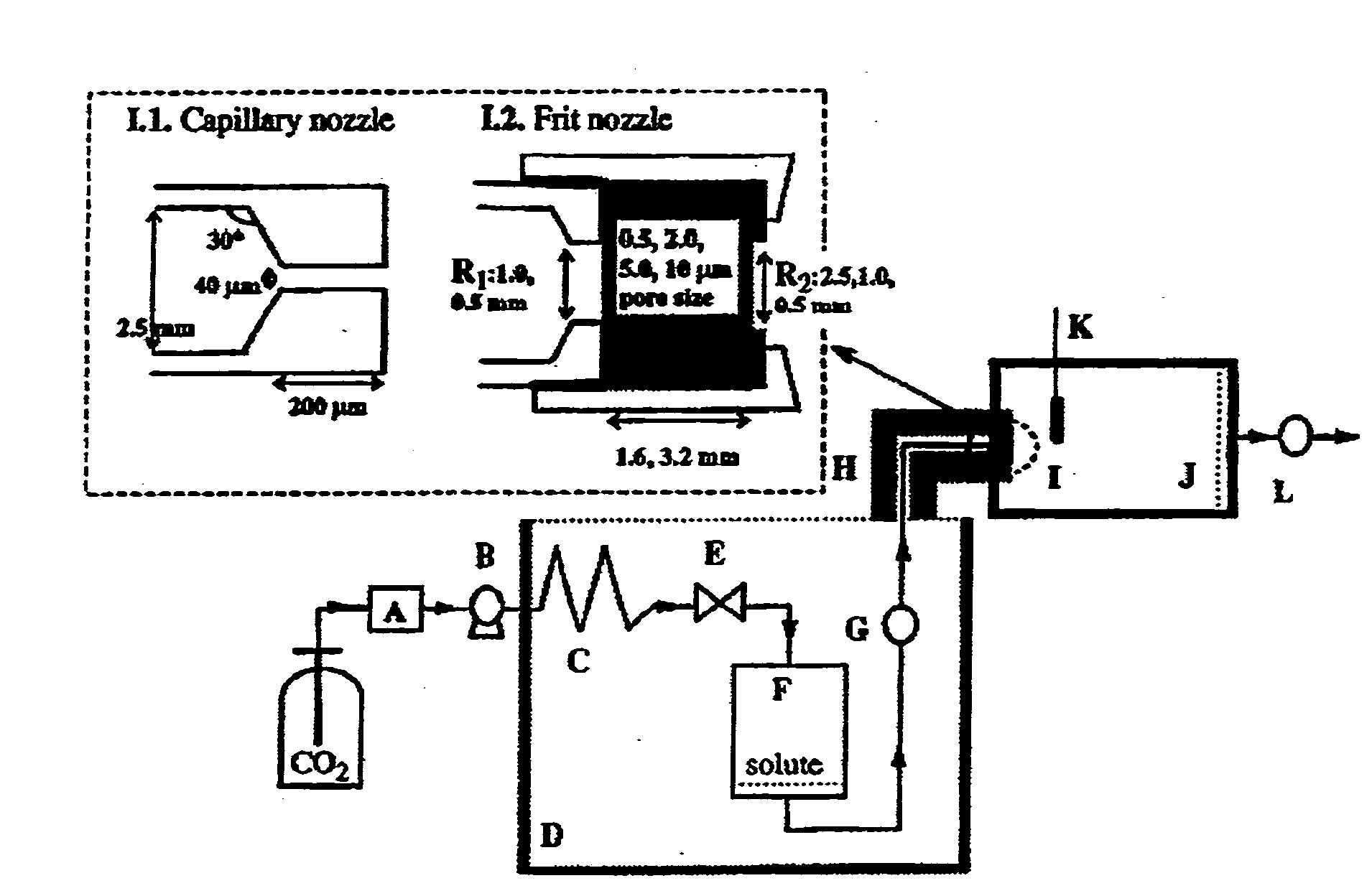

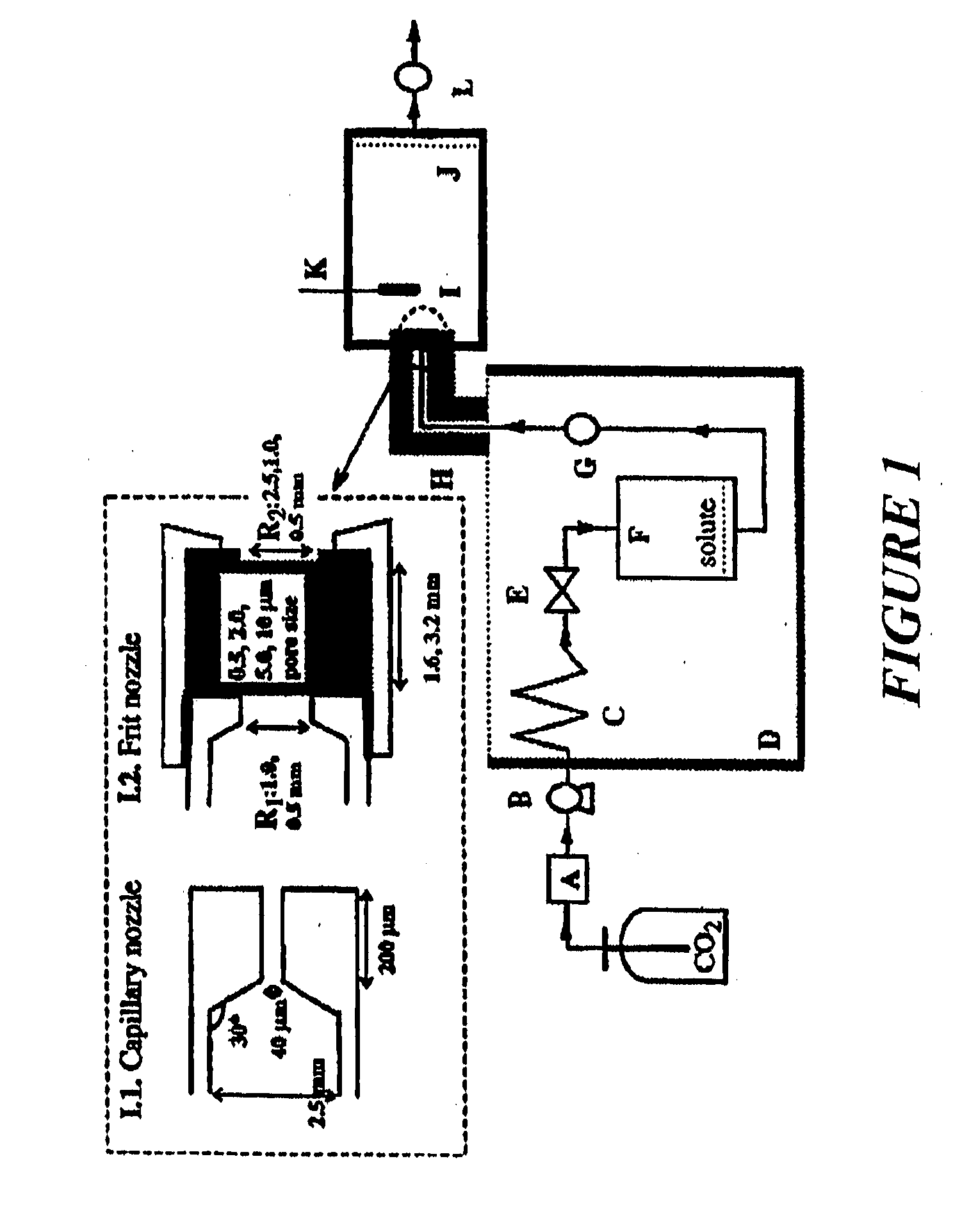

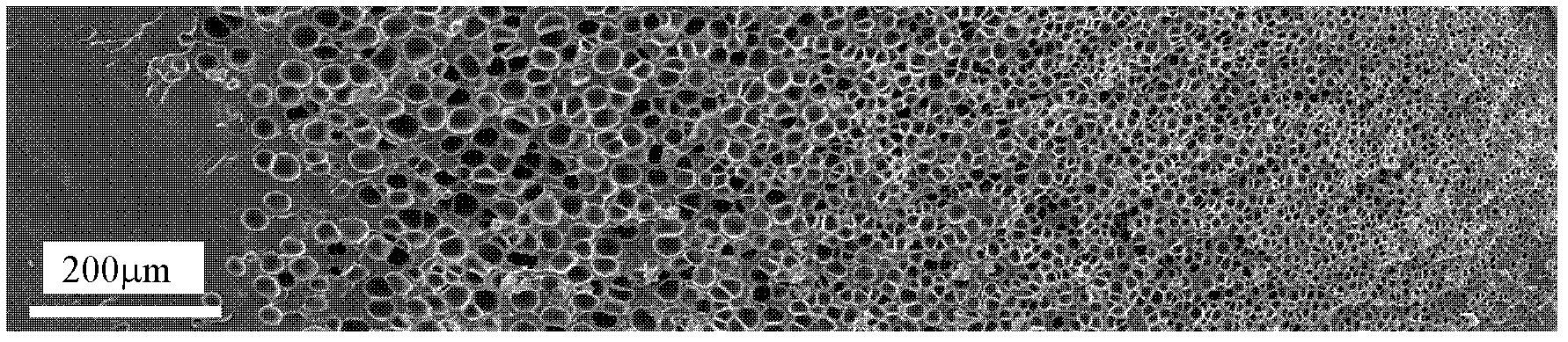

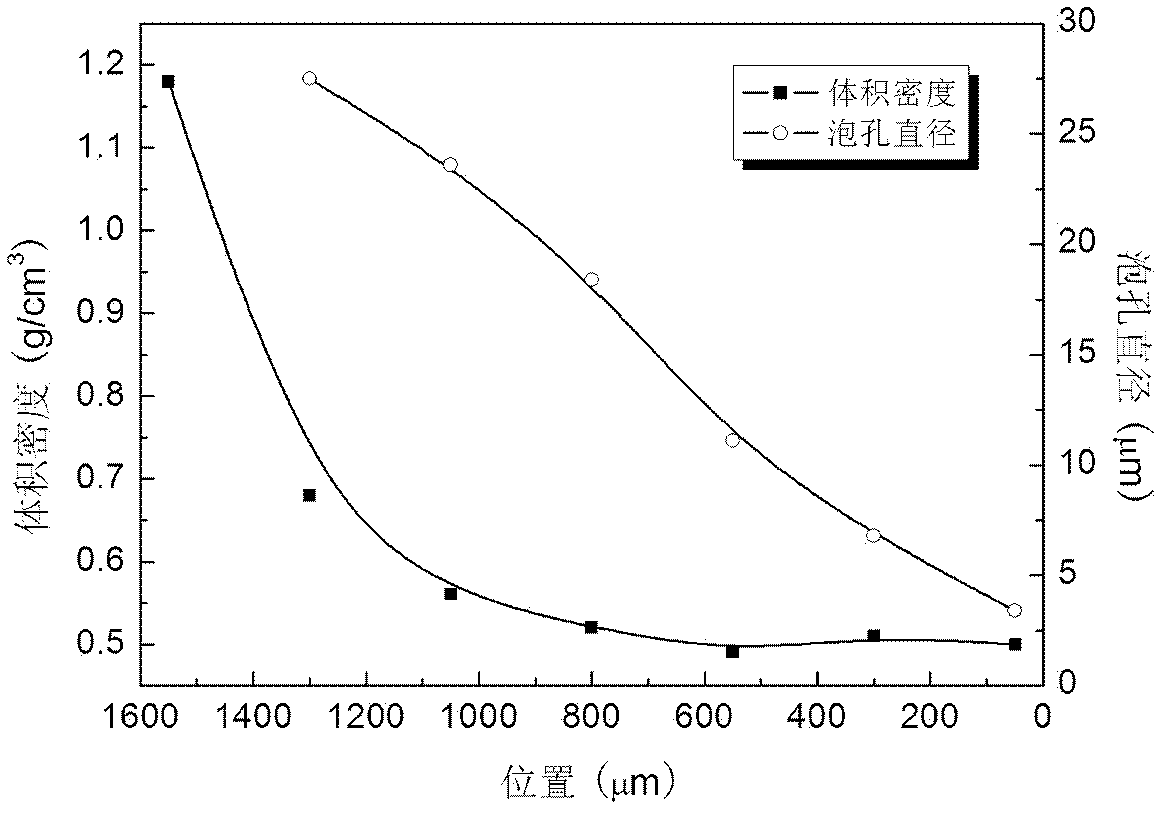

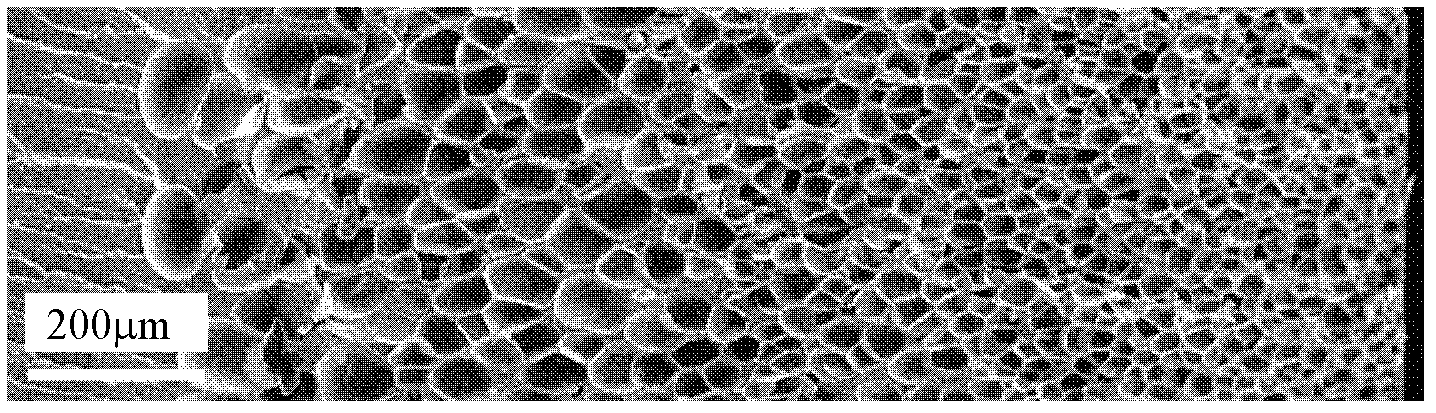

Preparation method of polymethyl methacrylate (PMMA) cellular gradient material

The invention relates to a preparation method of a polymethyl methacrylate (PMMA) cellular gradient material. The method specifically comprises: placing a unidirectionally opened die loaded with PMMA into an autoclave, controlling the oriented adsorption of highpressure carbon dioxide in PMMA to form a concentration gradient, with the pressure of the carbon dioxide controlled at 10-30MPa and the temperature maintained at 50-150DEG C, preserving the heat and pressure for 1-60min, then conducting pressure releasing, and finally cooling a sample to room temperature with an ice-water mixture, thus obtaining the cellular gradient material. A cellular structure with a small cell diameter and a thin cell wall forms in a high concentration carbon dioxide diffusion area on the surface layer, a cellular structure with a large cell diameter and a thick cell wall forms in a low concentration area of the central section, and the innermost layer is compact PMMA matrixes. The porosity of the sample changes from high to low continuously from the surface layer to the inner layer. With a cell diameter controlled at micron magnitude, the gradient material provided in the invention has good dimensional stability, wide porosity variation range and high mechanical strength.

Owner:WUHAN UNIV OF TECH

Poly(lactic acid)/poly(methyl methacrylate) alloy material and preparation method thereof

The invention relates to a poly(lactic acid) / poly(methyl methacrylate) alloy material and a preparation method thereof. The alloy material comprises the following components in percentage by mass: 50 to 90 percent of poly(lactic acid), 10 to 50 percent of poly(methyl methacrylate), 0.1 to 2 percent of heat stabilizer, and 0.1 to 2 percent of lubricant, wherein the sum of mass percentages of the components is 100 percent. The material and the method have the advantages that: the method selects the poly(methyl methacrylate) and the poly(lactic acid) for melt blending, and the obtained polymer alloy material solves the problems that a transparent poly(lactic acid) material has poor heat resistance and is difficult to use in summer; a semitransparent material with high heat resistance is prepared by performing annealing treatment on polymer alloy, which effectively extends the application range of the poly(lactic acid); and the method is simple, can finish the preparation of the polymer alloy material through conventional plastic processing means, and is suitable for industrialized production.

Owner:SHANGHAI UNIV

Transparent polyvinyl chloride toughening modifier with three-layer nuclear shell structure and preparation method thereof

The invention relates to a transparent polyvinyl chloride toughening modifier with a three-layer nuclear shell structure and a preparation method thereof. The modifier has a three-layer structure using polyvinyl chloride as an inner core, polybutadiene as a middle layer and polymethyl methacrylate as an outermost layer. The modifier is prepared by adopting an emulsion graft polymerization method, and then subjected to coagulation and drying post treatment to form an impact modifier with a three-layer nuclear shell structure. The transparent polyvinyl chloride toughening modifier with the three-layer nuclear shell structure synthesized by the method is used for modifying the polyvinyl chloride, and a structure test shows that: when the using amount of the transparent polyvinyl chloride toughening modifier with the three-layer nuclear shell structure is 5 percent of the total weight of the polyvinyl chloride, the impact strength can reach 1,300 J / m; a sample band is in ductile fracture, and the impact strength thereof is improved by more than 20 times compared with a pure polyvinyl chloride material; and simultaneously, good light transmittance of a blend can be ensured.

Owner:深圳市恒得源环保新材料科技有限公司

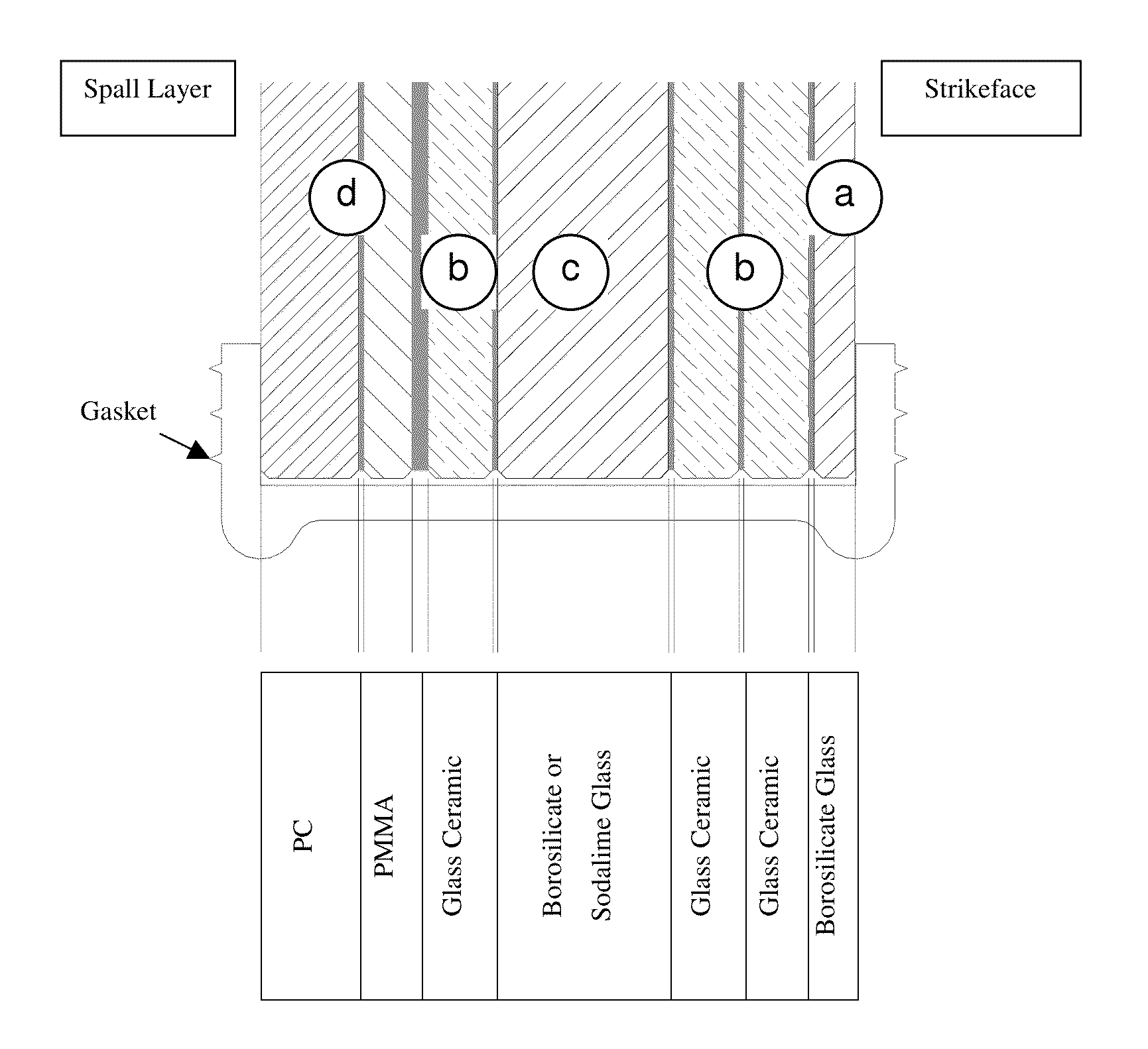

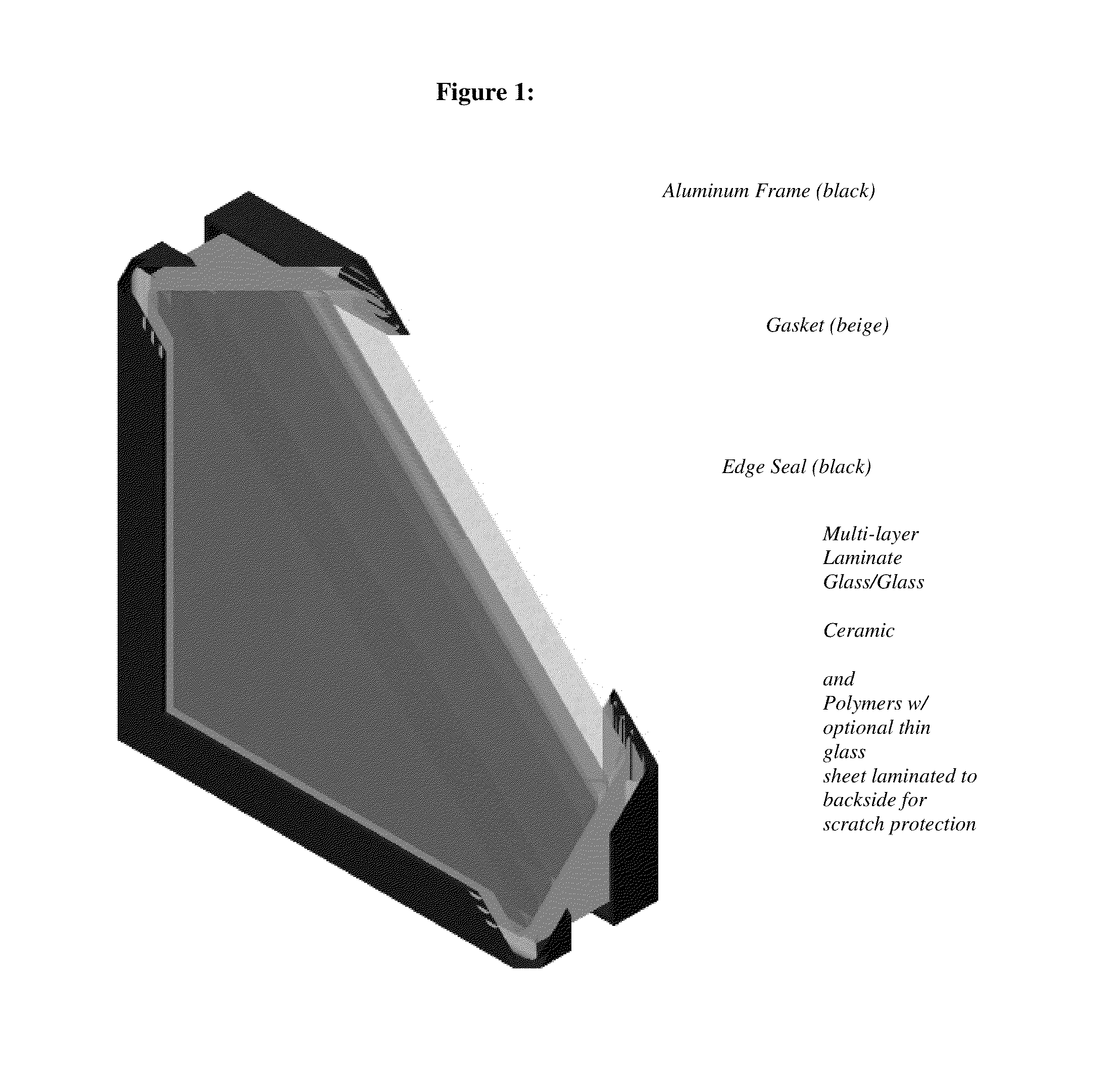

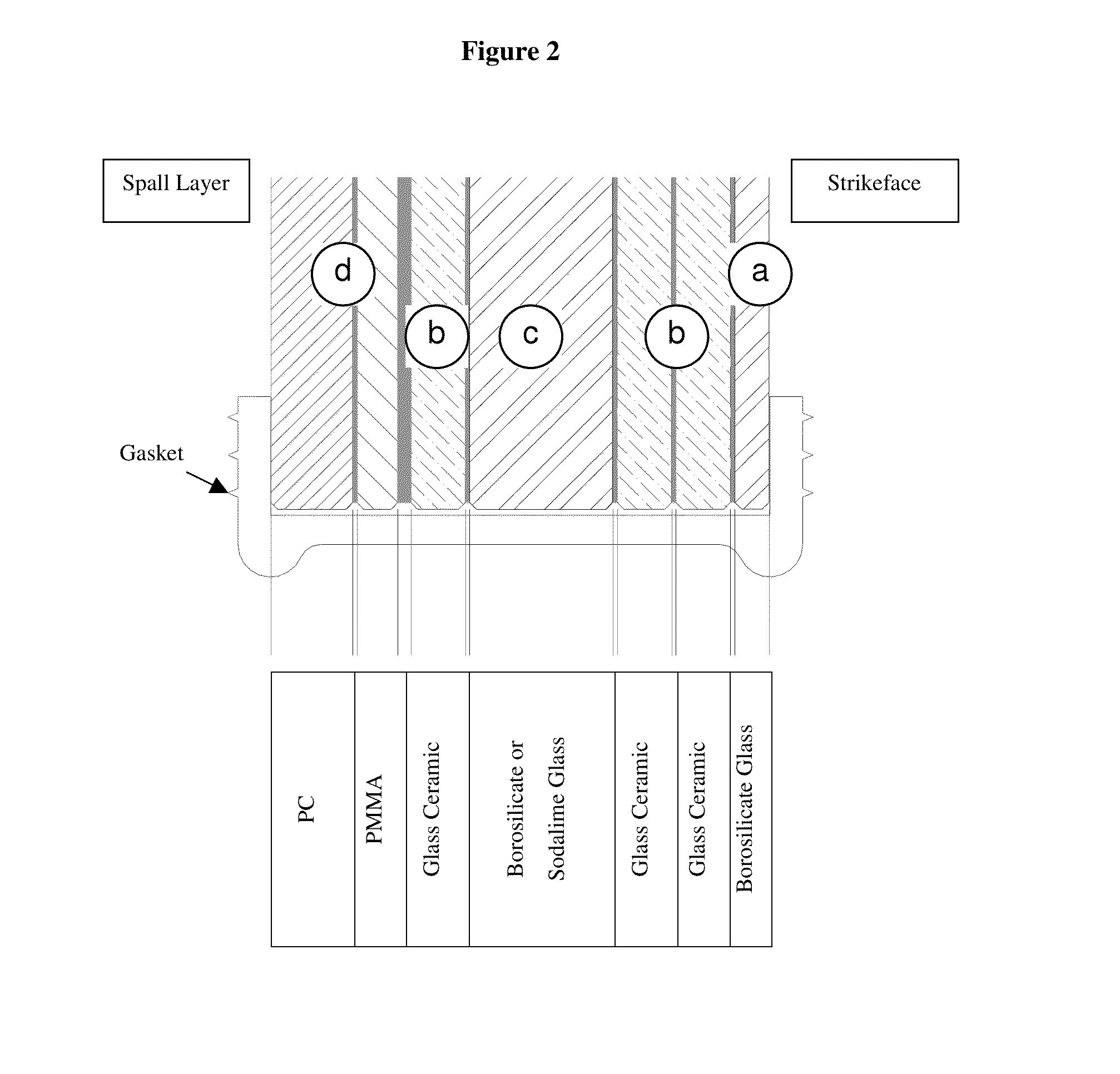

Lightweight transparent armor window

ActiveUS20130305912A1Minimal weightMinimal costSynthetic resin layered productsGlass/slag layered productsPolymer sciencePolyvinyl alcohol

The invention relates to a lightweight transparent armor laminate comprising layers of borosilicate glass, layers of transparent glass-ceramics and a polymer spall layer of polycarbonate and / or polymethyl methacrylate. The layers are bound by polyurethane and / or polyvinylbutyral interlayer films.

Owner:ORAN SAFETY GLASS INC

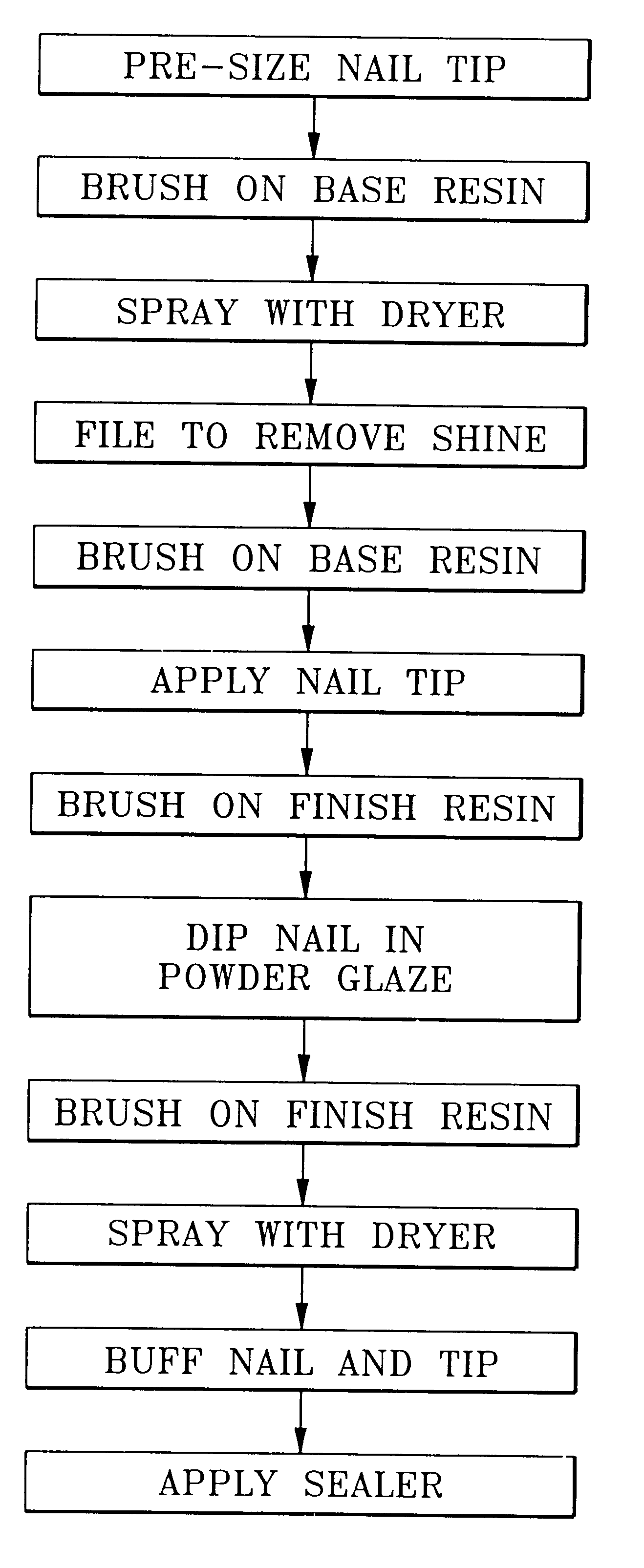

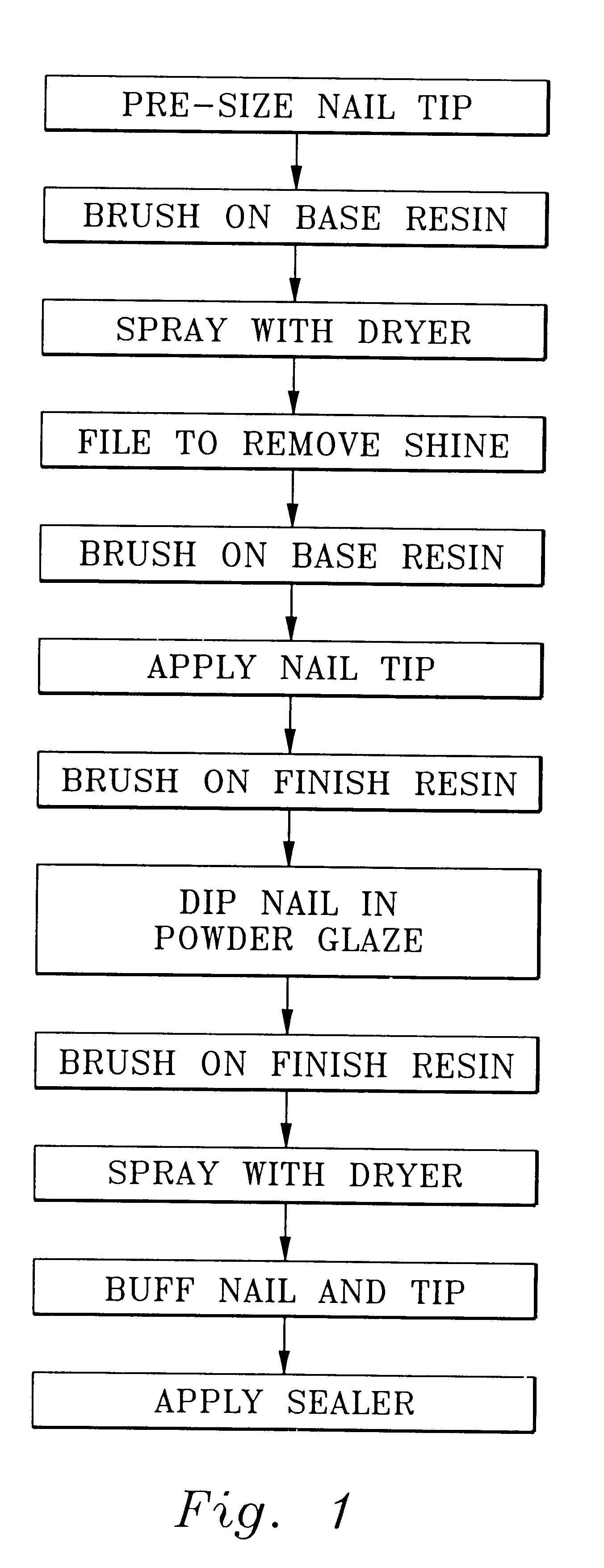

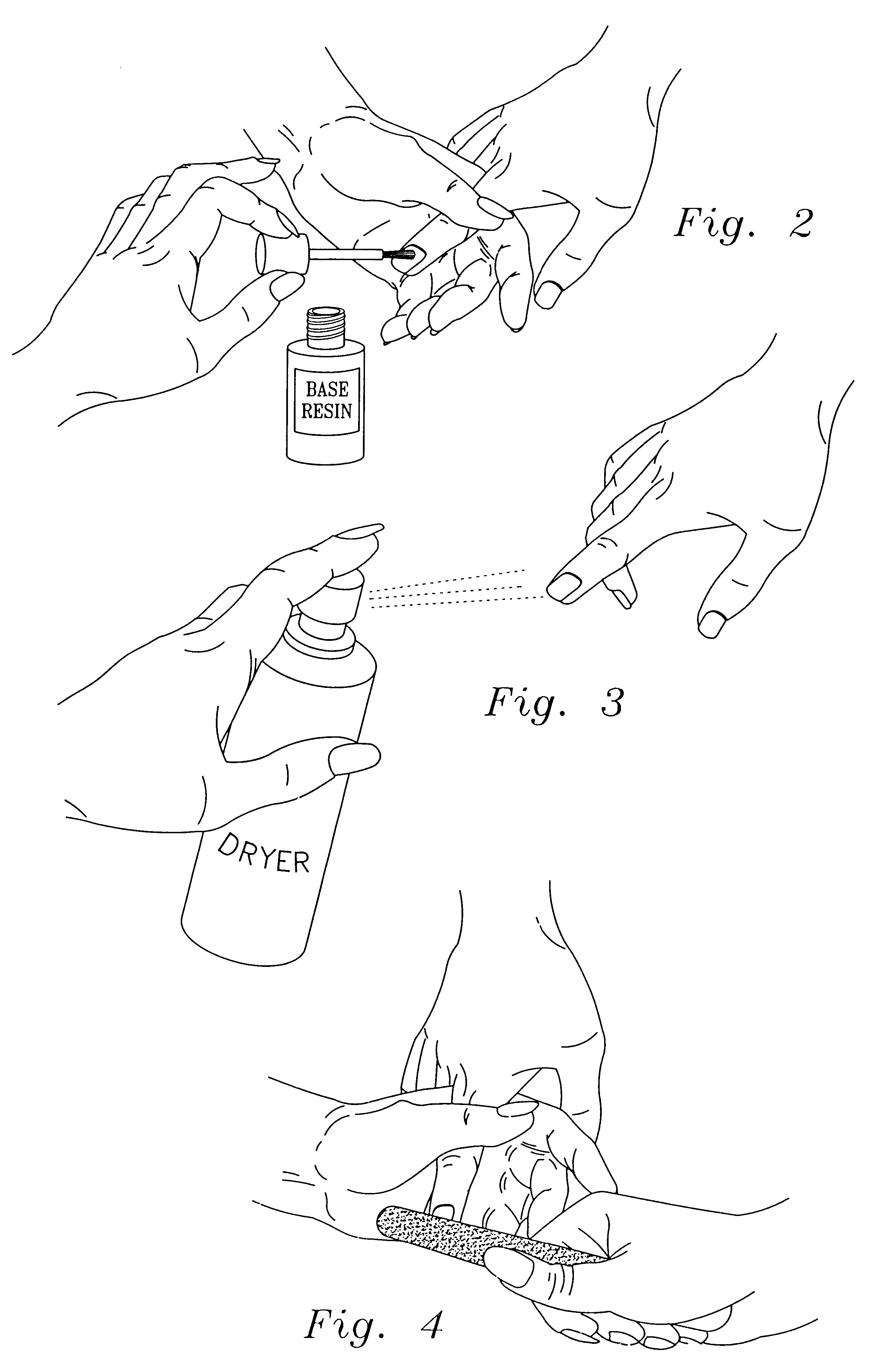

Method of applying nail tips and composition

InactiveUS6250311B1Easy to installAesthetically pleasingCurling devicesManicure/pedicureMethacrylateBenzoyl peroxide

This patent specification discloses a method and compositions for applying an artificial finger nail tip to a natural finger nail. The method applies: (i) multiple brush-on coatings of a mixture of ethyl-2-cyanoacrylate, poly methyl methacrylate, and hydroquinone; (ii) several spray coatings of an aromatic dryer of ethyl acetate and aromatic amines; and (iii) at least one dip of glaze powder of poly (ethyl or ethyl / methyl) methacrylate, benzoyl peroxide, and silica as an opaquing agent. The preferred method is very easy to perform and does not require any use of polymer solvents or grinding or filing steps.

Owner:BACKSCRATCHERS

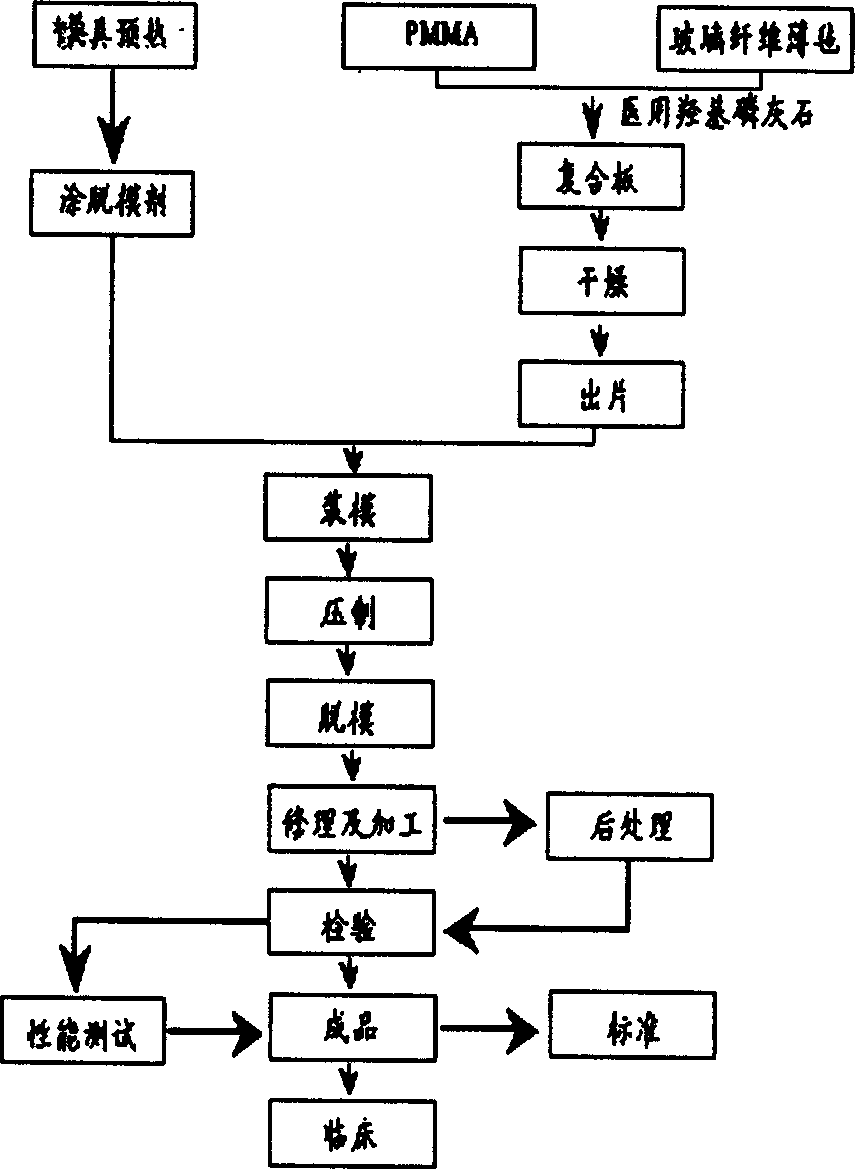

Method for preparing artificial head bones made from composite material and for modifying surface

An artificial skull with high surficial bioactivity is prepared from methyl polymethacrylate, biological carbon (or glass) fibres and hydroxy apatite (or beta-tricalcium phosphate) micropowder through laminating or hot pressing, and immersing in simulative body fluid.

Owner:WUHAN UNIV OF TECH

Thermoformable photovoltaic backsheet

InactiveUS20120024353A1PV power plantsSynthetic resin layered productsFluoropolymerPolybutyl methacrylate

The invention relates to high Tg monolithic and multi-layer thermoformable film or sheet useful as a backsheet on a photovoltaic module (PV). A methacrylic-based material is preferred. The film or sheet is formed of a composition having a Tg greater than 110° C. The methacrylic composition may be a blend of a polymethyl methacrylate polymer and a miscible or semi-miscible high Tg polymer, or may be a copolymer containing primarily methyl methacrylate monomer units. The backsheet is optionally covered with a fluoropolymer or acrylic / fiuoropolymer covering on the outside (side facing the environment). The back-sheet can be clear, white, and / or pigmented. The film or sheet is especially useful in concentrating photovoltaic modules (CPV), and is also useful in thin film photovoltaic modules.

Owner:ARKEMA FRANCE SA

Micro-fluidic chip containing sample pre-treatment film and production method therefor

InactiveCN101008594AHigh selectivityHigh analytical sensitivityComponent separationPreparing sample for investigationChannel networkCompound structure

This invention relates to one micro flow control chip and its process method with sample pre-process film, wherein, the chip is composed of bottom slice and cover slice; the bottom slice uses glass, silicon, PMMA or PDMS as basic materials to etch flow mixture and reaction micro channel network; the cover slice adopts PDMS process sealed to bottom slice; in the relative position of each channel opening liquid guide hole for micro flow; putting sample process film in the pointing position to sample entrance imbedded into cover slice.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com