Large monocrystal graphene and preparation method thereof

A single crystal graphene, polymethyl methacrylate technology, applied in the field of large single crystal graphene and its preparation, can solve the problems of expensive single crystal substrate, long time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

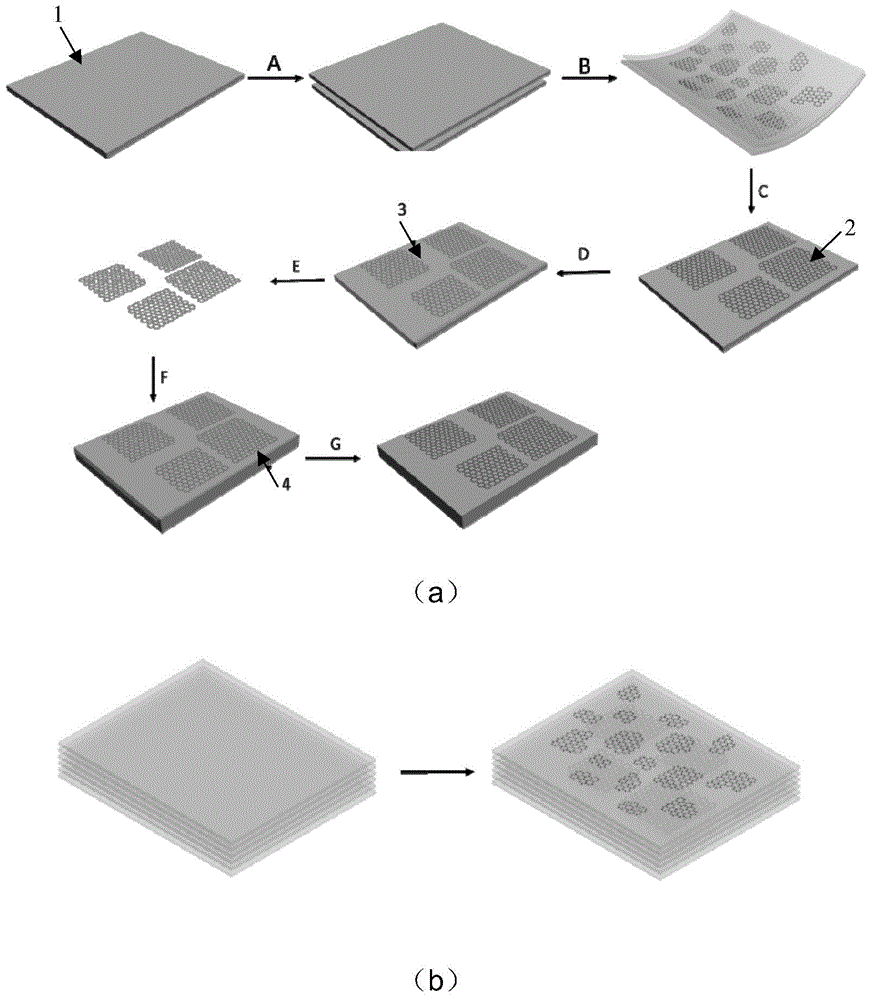

[0048] Example 1. Two separate stacked copper foils quickly prepare isolated large single crystal graphene:

[0049] 1) Use a polishing solution composed of phosphoric acid and ethylene glycol according to a ratio of 3:1 (v / v) and deionized water to clean the copper foil (produced by Alfa Aesar, purity 99.8%, thickness 25μm), and cut the copper foil To stack the two pieces neatly, the distance between the two copper foils measured with a vernier caliper does not exceed 30μm;

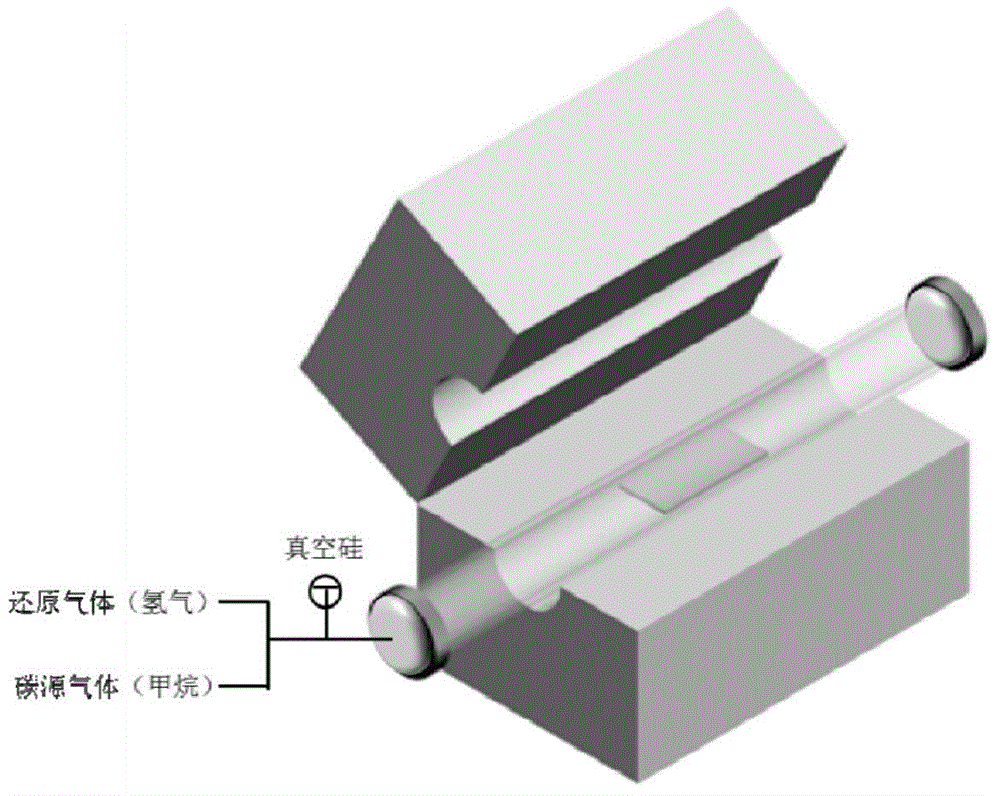

[0050] 2) Place the stacked copper foil in a sleeve with a magnetic control device, and then place the sleeve in a tube furnace, pump it to the lowest air pressure, and purge it for 2-3 times at a low pressure of 1Pa Raise the temperature of the furnace body to 1035℃ under vacuum and gas-free conditions and keep it for 30 minutes;

[0051] 3) Keep the temperature of the furnace body constant, and pass in hydrogen gas with a flow rate of 100 sccm for 5 minutes;

[0052] 4) Keep the furnace temperature and hydrog...

Embodiment 2

[0060] Example 2. Two discretely stacked copper foils quickly prepare continuous large single crystal graphene films:

[0061] 1) Use a polishing solution composed of phosphoric acid and ethylene glycol according to a ratio of 3:1 (v / v) and deionized water to clean the copper foil (produced by Alfa Aesar, purity 99.8%, thickness 25μm), and cut the copper foil To stack the two pieces neatly, the distance between the two copper foils measured with a vernier caliper does not exceed 30μm;

[0062] 2) Put the stacked copper foil in a sleeve with a magnetic control device, and then put the sleeve in a tube furnace, pump it to the lowest air pressure, and purge it for 2-3 times at a low pressure of 1Pa Raise the temperature of the furnace body to 1035℃ under vacuum and gas-free conditions and keep it for 30 minutes;

[0063] 3) Keep the temperature of the furnace body constant, and pass in hydrogen gas with a flow rate of 100 sccm for 5 minutes;

[0064] 4) Keep the temperature of the furna...

Embodiment 3

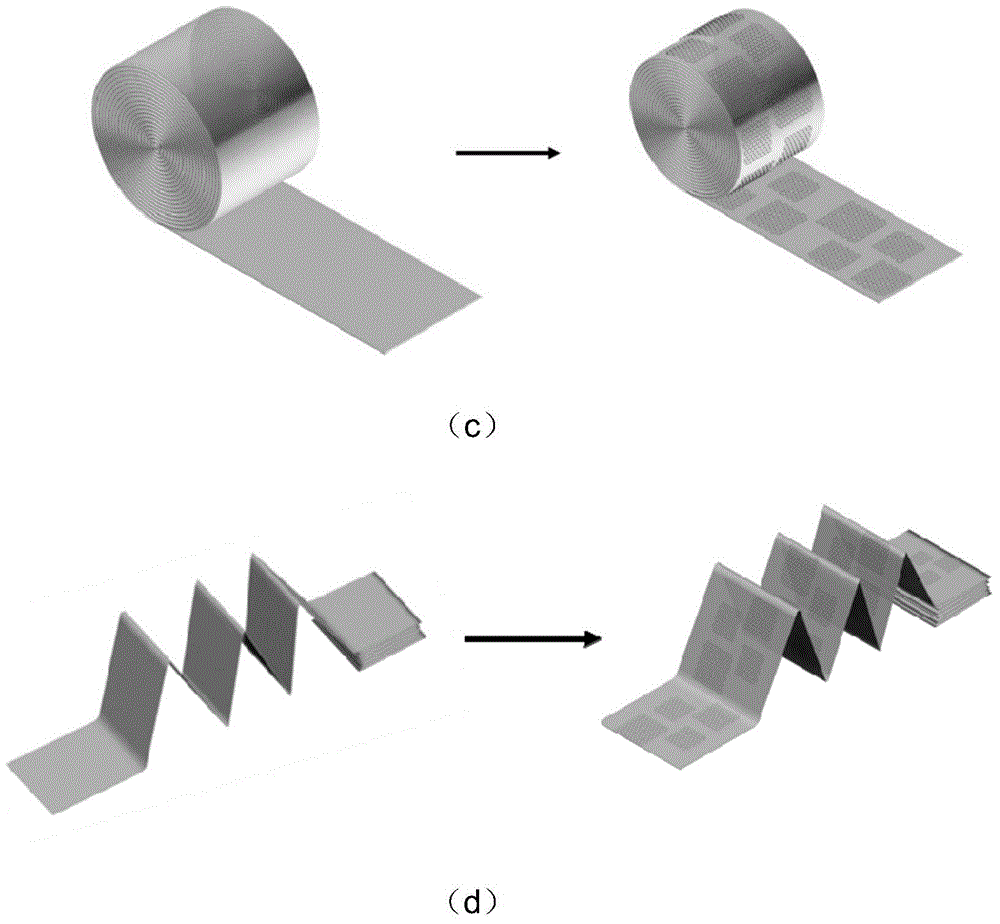

[0069] Example 3. Single crystal graphene prepared in large quantities by convolving copper foil.

[0070] 1) Use a polishing solution composed of phosphoric acid and ethylene glycol in a ratio of 3:1 (v / v) and deionized water to clean large-area copper foil (manufactured by Alfa Aesar, purity 99.8%, thickness 25μm), Figure 8 (A) is a physical photo of a large area of copper foil;

[0071] 2) Convolve the cleaned large-area copper foil into a roll, use a vernier caliper to measure that the distance between the two copper foils does not exceed 30μm, then put it into a sleeve with a magnetic control device, and then place the sleeve in a tube furnace , Under the state of pumping to the lowest pressure, purge 2-3 times, raise the temperature of the furnace body to 1035 ℃ under the highest vacuum without gas, and keep it for 30 minutes. Figure 8 (B) is a physical photo of a large area of copper foil convolution;

[0072] 3) Keep the temperature of the furnace body constant, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com