Graphene modified poly-methyl methacrylate composite and preparation method thereof

A polymethyl methacrylate and graphene modification technology, applied in the field of nanocomposite materials and their preparation, can solve problems such as poor compatibility between graphene and polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The graphite is peeled off in 1-methyl-2-pyrrolidone by ultrasonic method, and the lower precipitate is removed by centrifugation to obtain a stable and well-dispersed graphene solution. In a 100ml three-necked flask, first add 50ml of exfoliated graphene solution (0.3mg / ml—where ml is the volume of 1-methyl-2-pyrrolidone), nitrogen protection, ultrasonic dispersion for 2 hours, and then add 3.0g of formazan Methyl acrylate, 0.0123g of azobisisobutyronitrile, magnetically stirred, and heated at 80°C for 48h. After the reaction, the product was poured into 300ml of methanol, and a black precipitate was produced. After centrifugation, the lower precipitate was collected, washed with tetrahydrofuran several times, and dried in a vacuum oven at 50°C to obtain a black powdery solid, which was the target product graphene-modified polymethyl methacrylate.

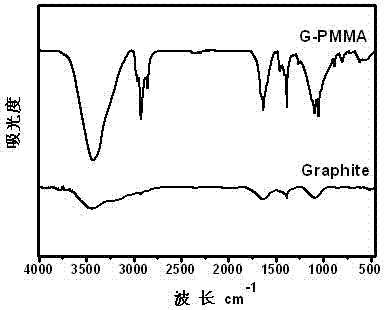

[0024] The graphene-modified polymethyl methacrylate compound that the present embodiment prepares gained, its structura...

Embodiment 2

[0030] In a 100ml three-neck flask, first add 50ml of exfoliated graphene solution (0.3mg / ml), nitrogen protection, ultrasonic dispersion for 2h, then add 1.5g of methyl methacrylate, 0.0123g of azobisisobutyronitrile, and magnetically stir , 70 ° C heating reaction 48h. After the reaction, the product was poured into 300ml of methanol, and a black precipitate was produced. After centrifugation, the lower precipitate was collected, washed with tetrahydrofuran several times, and the product was dried in a vacuum oven at 50°C to obtain a black powdery solid, which was the target product graphene-modified polymethyl methacrylate.

[0031] The graphene-modified polymethyl methacrylate compound that the present embodiment prepares gained, its structural formula is:

[0032]

[0033] Wherein: n is the polymerization degree, and its value ranges from 300 to 500, and m is the modification rate, and its value ranges from 10 to 50 / 500 carbon atoms.

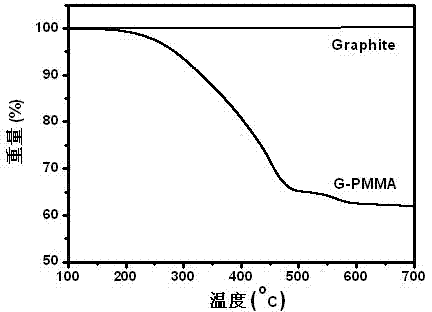

[0034] The thermogravimetric an...

Embodiment 3

[0036] In a 100ml three-necked flask, first add 50ml of exfoliated graphene solution (0.3mg / ml), nitrogen protection, ultrasonic dispersion for 2h, then add 2.25g of methyl methacrylate, 0.0123g of azobisisobutyronitrile, magnetic stirring , 80 ° C heating reaction 48h. After the reaction, the product was poured into 300ml of methanol, and a black precipitate was produced. After centrifugation, the lower precipitate was collected, washed with methanol several times, and dried in a vacuum oven at 50°C to obtain a black powdery solid, which was the target product graphene-modified polymethyl methacrylate.

[0037] The graphene-modified polymethyl methacrylate compound that the present embodiment prepares gained, its structural formula is:

[0038]

[0039] Wherein: n is the polymerization degree, and its value ranges from 300 to 500, and m is the modification rate, and its value ranges from 10 to 50 / 500 carbon atoms.

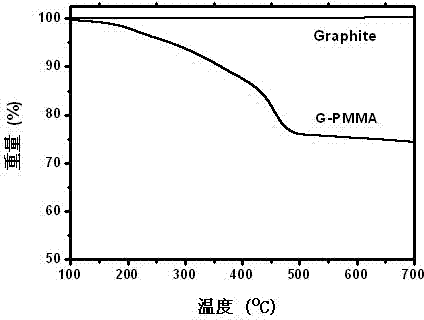

[0040] The thermogravimetric analysis data of present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com