Preparation method of modified polymethyl-methacrylate graphene nanoribbon (PMMA-GNR)

A technology of polymethyl methacrylate and methyl methacrylate is applied in the field of preparation of nanocomposite materials, which can solve the problems of poor interfacial force between graphene nanoribbons and polymers, and achieve significant effects and enhanced effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a 100 ml three-necked flask, add 50 ml of concentrated sulfuric acid, 8.0 g of potassium permanganate, 2.0 g of multi-walled carbon nanotubes, 70 o Mechanically stir the reaction at C for 1 h; weigh 15 mg of the solid powder obtained by the reaction, dissolve it in 30 ml of N,N-dimethylformamide, and then add 30 ml of polymethacrylic acid-modified graphene nanoribbon dispersion (0.5 mg / ml ), nitrogen protection, ultrasonic dispersion for 2 h, then added 3.0 g methyl methacrylate, 0.0246 g azobisisobutyronitrile, magnetic stirring, and heated at 80 °C for 48 h. After the reaction was finished, the product was poured into 300 ml of methanol, and a black precipitate was produced. After centrifugation, the lower precipitate was collected, washed with methanol several times, and dried in a vacuum oven at 50 °C to obtain a black powdery solid, which was the target product polymethacrylic acid-modified graphene nanobelts.

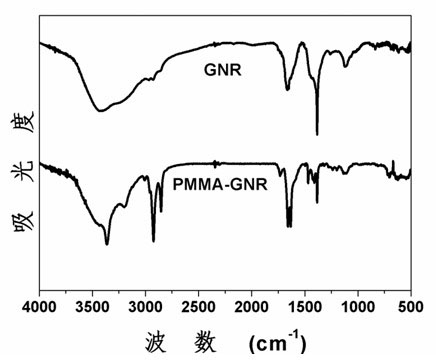

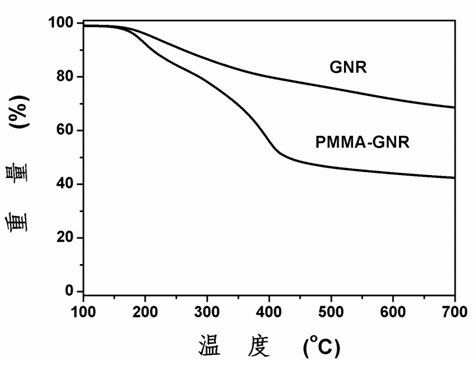

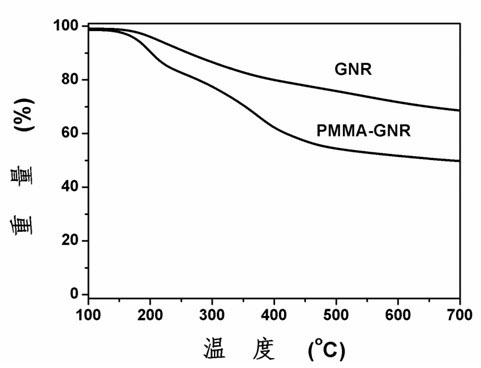

[0031] The polymethacrylic acid modified graphene...

Embodiment 2

[0037] In a 100 ml three-necked flask, add 50 ml of concentrated sulfuric acid, 8.0 g of potassium permanganate, 2.0 g of multi-walled carbon nanotubes, 70 o Mechanically stir the reaction at C for 1 h; weigh 15 mg of the solid powder obtained by the reaction, dissolve it in 30 ml of N,N-dimethylformamide, and then add 30 ml of polymethacrylic acid-modified graphene nanoribbon dispersion (0.5 mg / ml ), nitrogen protection, ultrasonic dispersion for 2 h, then adding 2.25 g methyl methacrylate, 0.0185 g azobisisobutyronitrile, magnetic stirring, and heating at 80 °C for 48 h. After the reaction was finished, the product was poured into 300 ml of methanol, and a black precipitate was produced. After centrifugation, the lower precipitate was collected, washed with methanol several times, and dried in a vacuum oven at 50 °C to obtain a black powdery solid, which was the target product, polymethacrylic acid-modified graphene nanobelts.

[0038] The polymethacrylic acid modified grap...

Embodiment 3

[0043] In a 100 ml three-necked flask, add 50 ml of concentrated sulfuric acid, 8.0 g of potassium permanganate, 2.0 g of multi-walled carbon nanotubes, 70 oMechanically stir the reaction at C for 1 h; weigh 15 mg of the solid powder obtained from the reaction, dissolve it in 30 ml of N,N-dimethylformamide, and then add 30 ml of polymethacrylic acid-modified graphene nanoribbon dispersion (0.5 mg / ml) , nitrogen protection, ultrasonic dispersion for 2 h, then added 1.5 g methyl methacrylate, 0.0123 g azobisisobutyronitrile, magnetic stirring, 80 ℃ heating reaction for 48 h. After the reaction was finished, the product was poured into 300 ml of methanol, and a black precipitate was produced. After centrifugation, the lower precipitate was collected, washed with methanol several times, and dried in a vacuum oven at 50 °C to obtain a black powdery solid, which was the target product polymethacrylic acid-modified graphene nanobelts.

[0044] The polymethacrylic acid modified graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com