Patents

Literature

57results about How to "Extensive adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

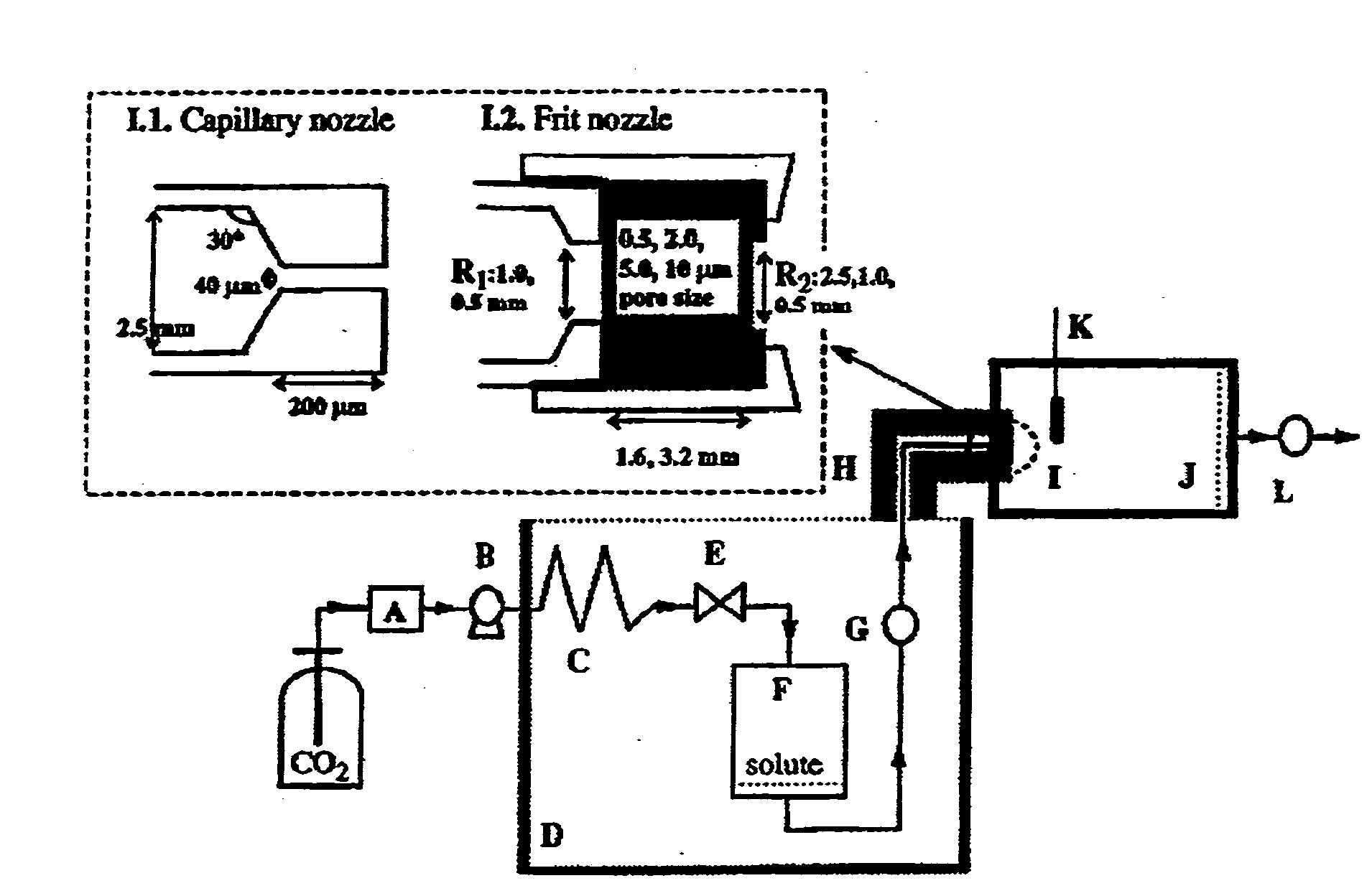

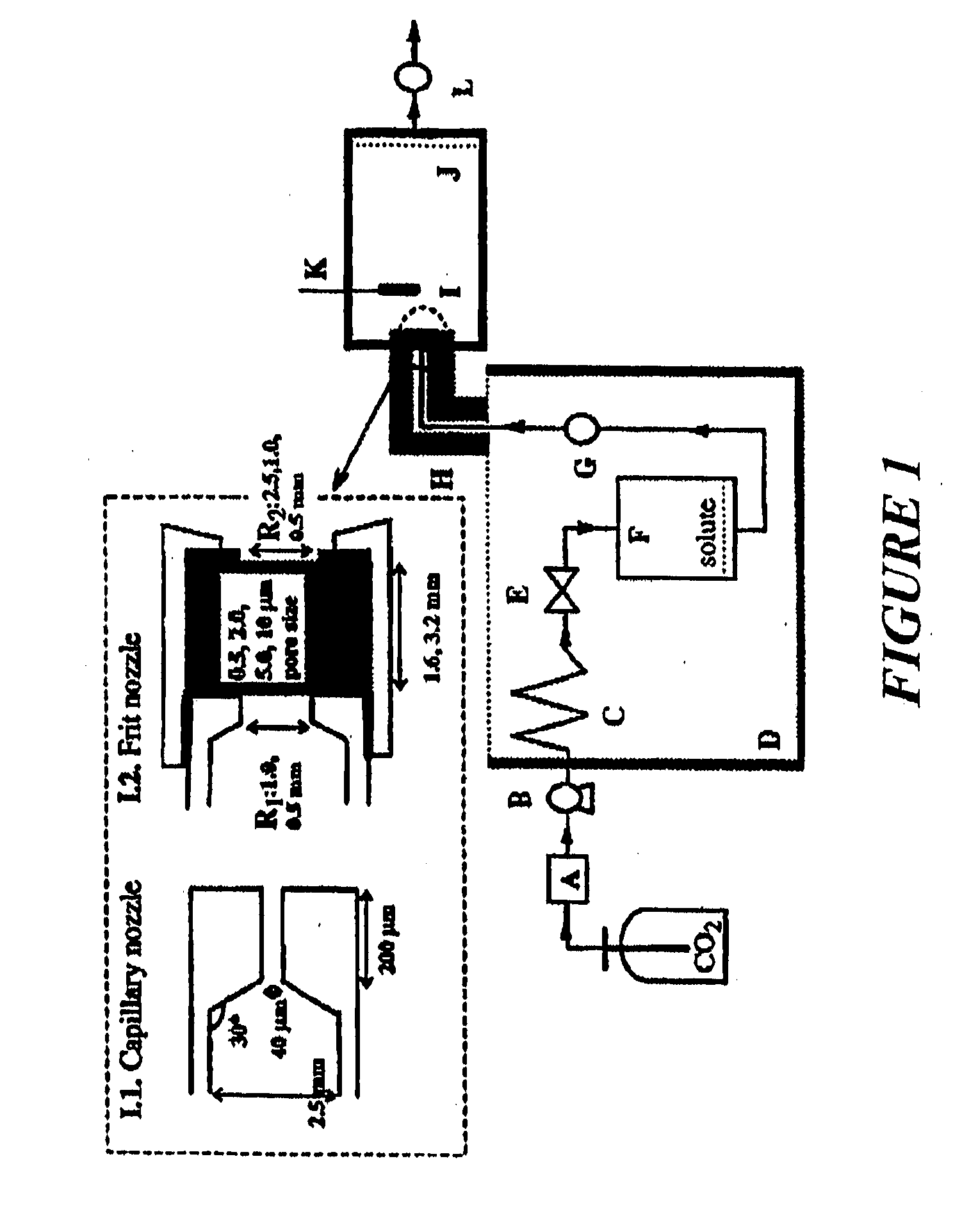

Stent with polymer coating containing amorphous rapamycin

InactiveUS20090062909A1Extensive adhesionBulk propertiesStentsSurgeryPolymer coatingsPolybutyl methacrylate

A coated coronary stent, comprising: a stainless steel sent framework coated with a primer layer of Parylene C; and a rapamycin-polymer coating having substantially uniform thickness disposed on the stent framework, wherein the rapamycin-polymer coating comprises polybutyl methacrylate (PBMA), polyethylene-co-vinyl acetate (PEVA) and rapamycin, wherein substantially all of the rapamycin in the coating is in amorphous form and substantially uniformly dispersed within the rapamycin-polymer coating.

Owner:MICELL TECH INC

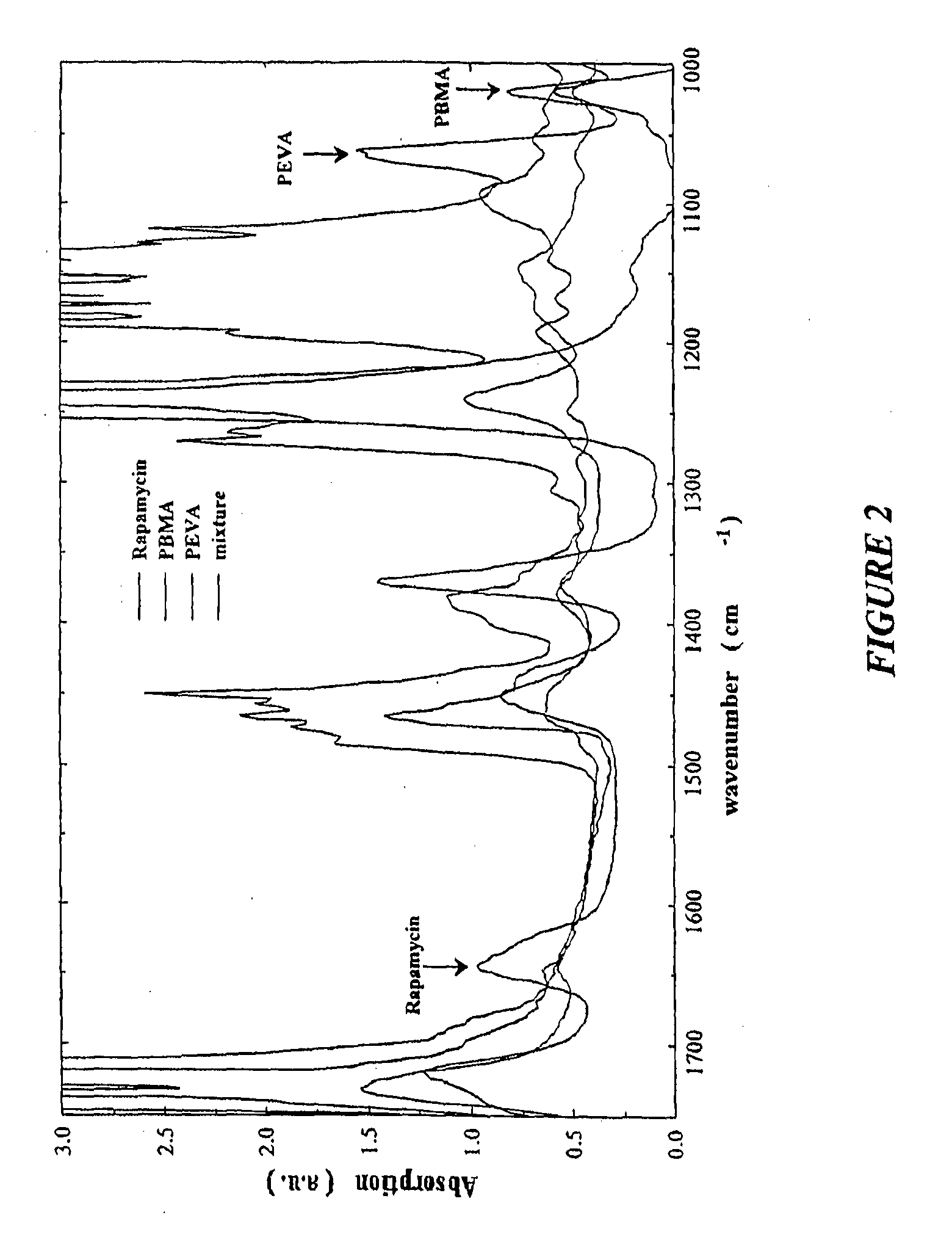

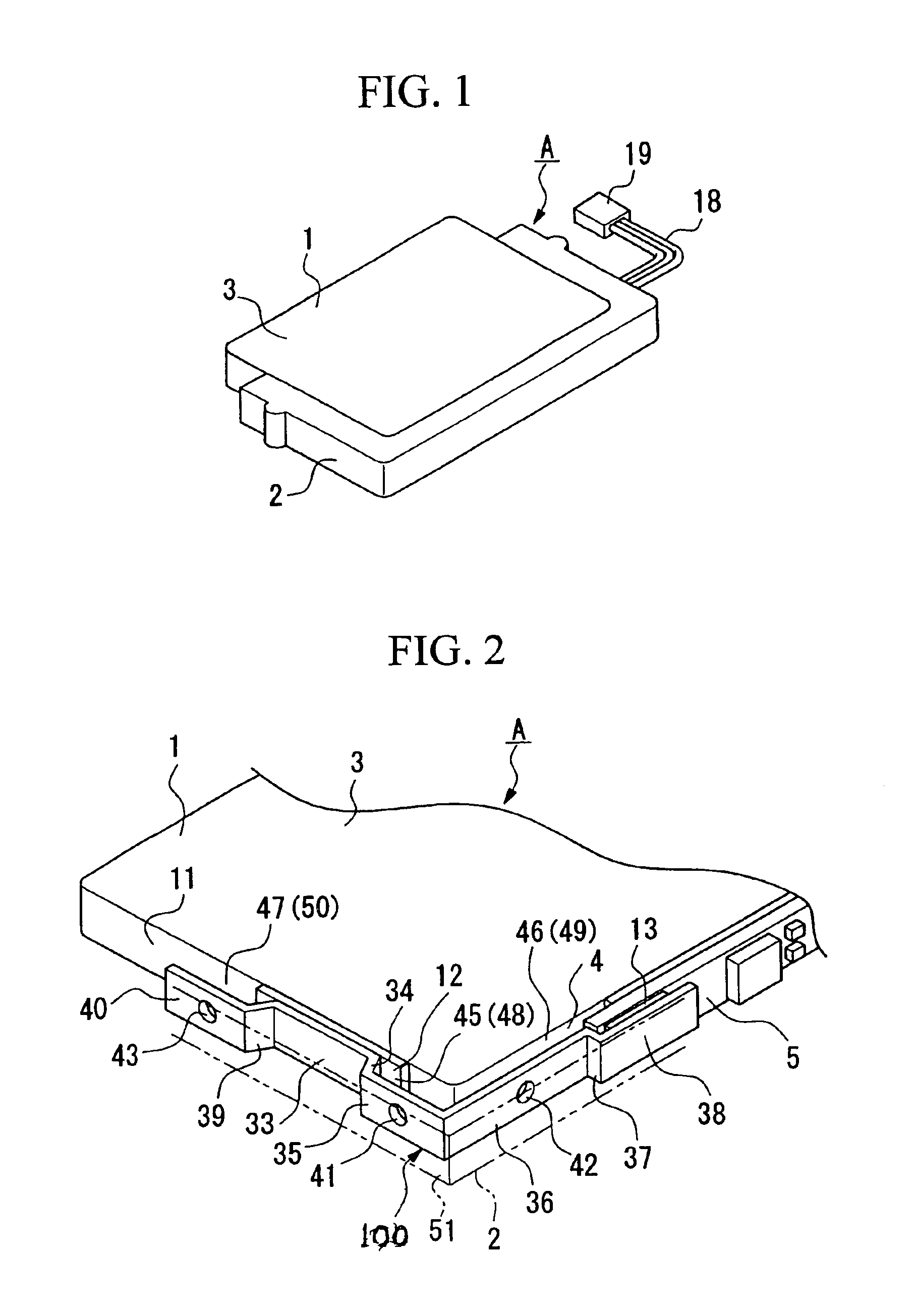

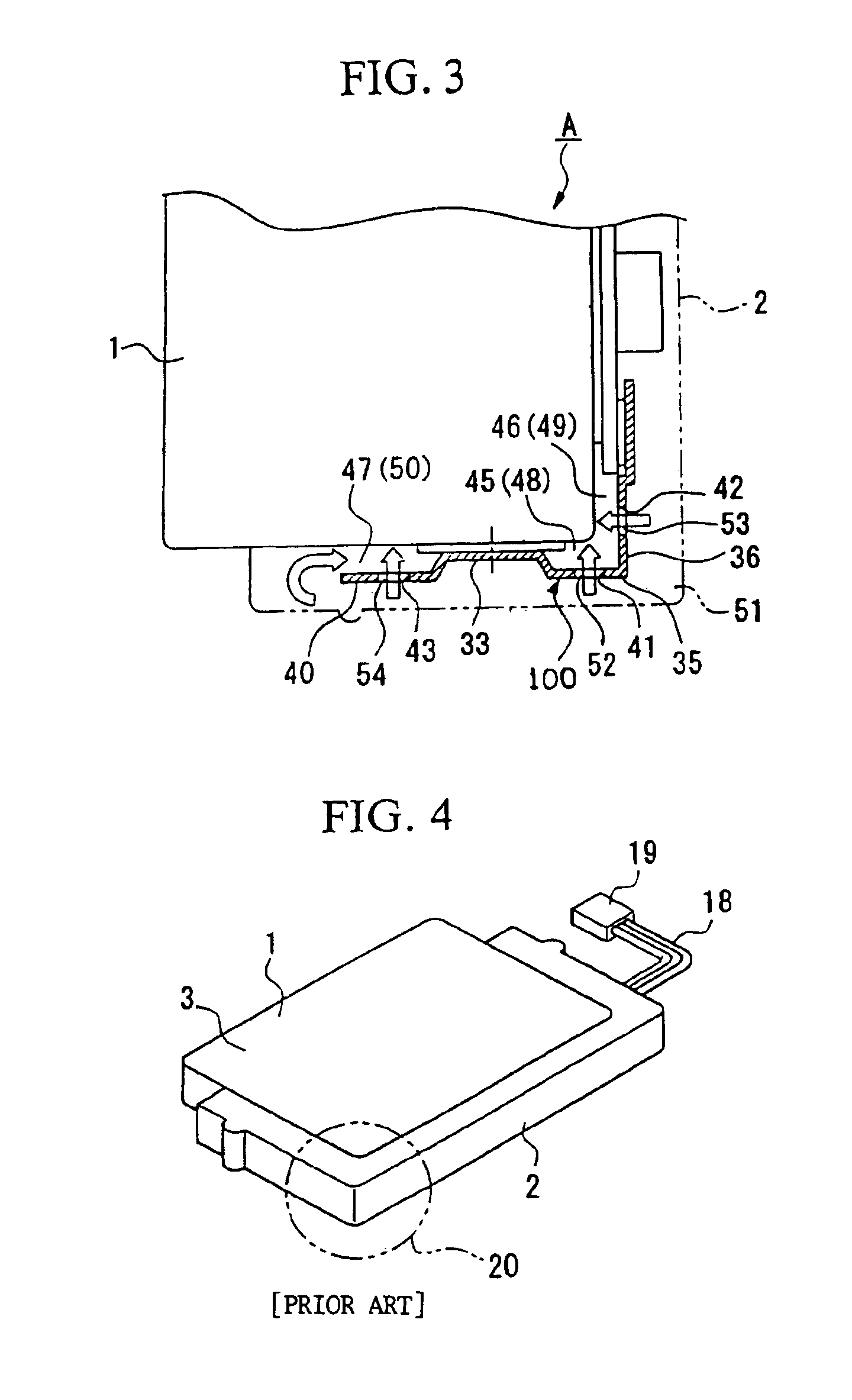

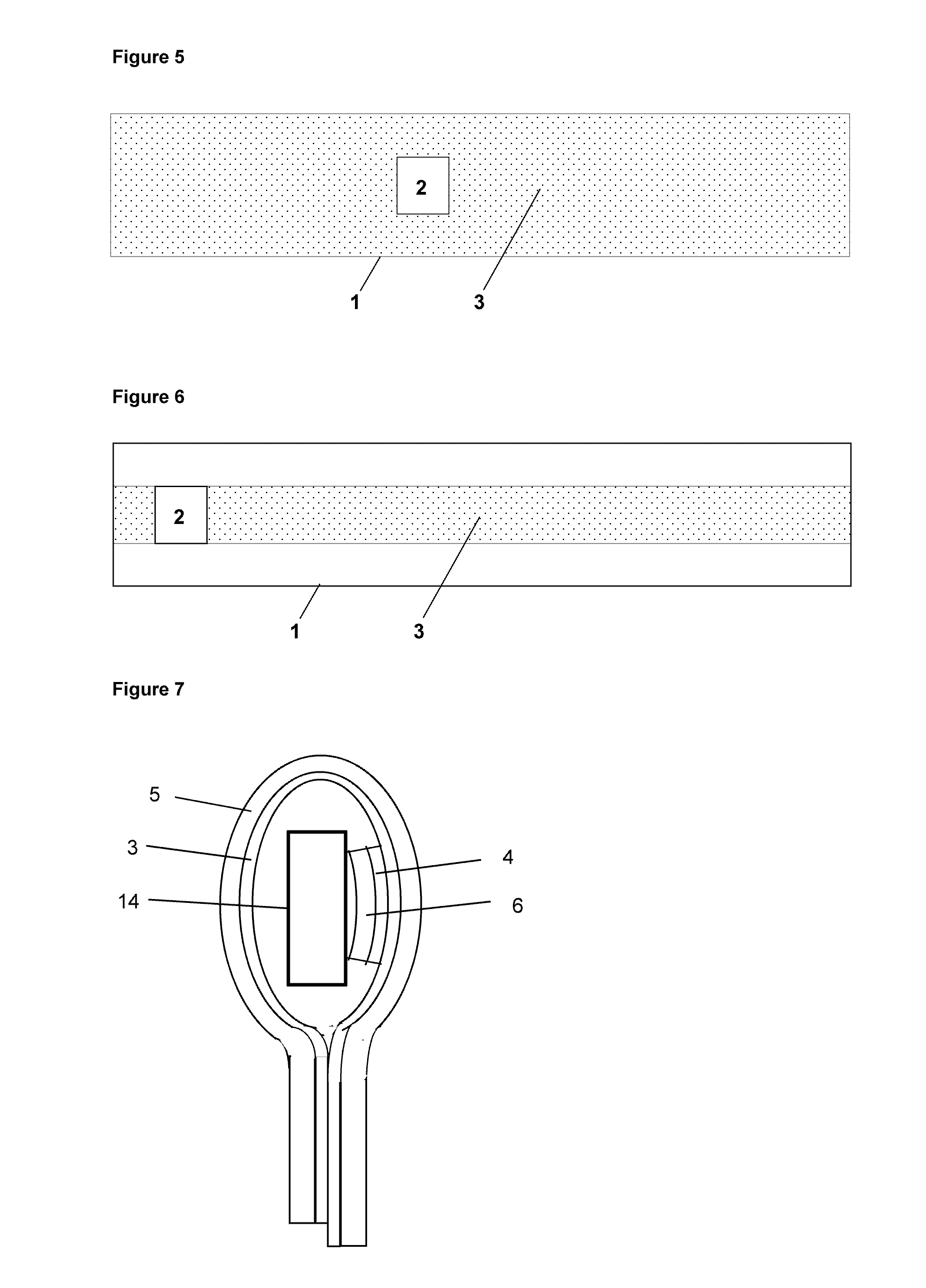

Battery having a circuit board attached to it and a molded section enveloping the battery and the circuit board

InactiveUS6929879B2Improve production yieldReliable formingPrimary cell to battery groupingSmall-sized cells cases/jacketsEngineeringElectrical and Electronics engineering

In order to provide a battery in which a molded section can be fixed to a battery cell, a battery comprises a battery cell, a circuit board which is attached to the battery cell, an electrode terminal which connects the battery cell and the circuit board electrically, a molded section which adheres the circuit board and the electrode terminal to the battery cell as an entire unit, adhesion strengthened areas which are formed between the electrode terminal and the battery, and electrode terminal inner surface resin sections which are formed in a part of the molded section of the adhesion strengthened area.

Owner:KYOCERA CORP

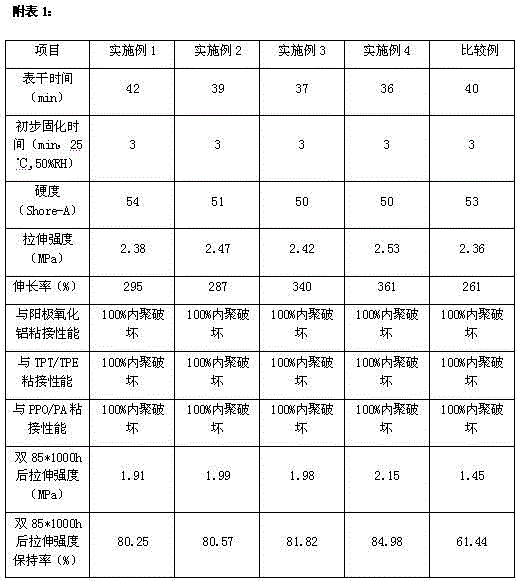

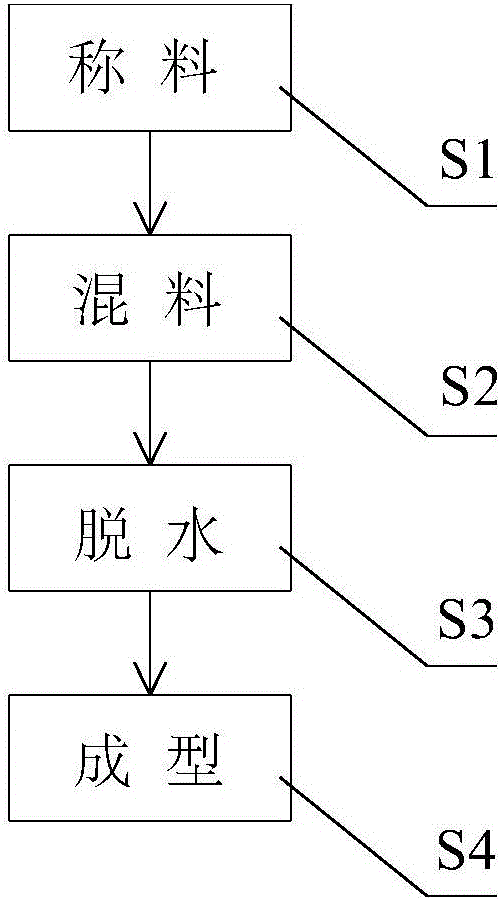

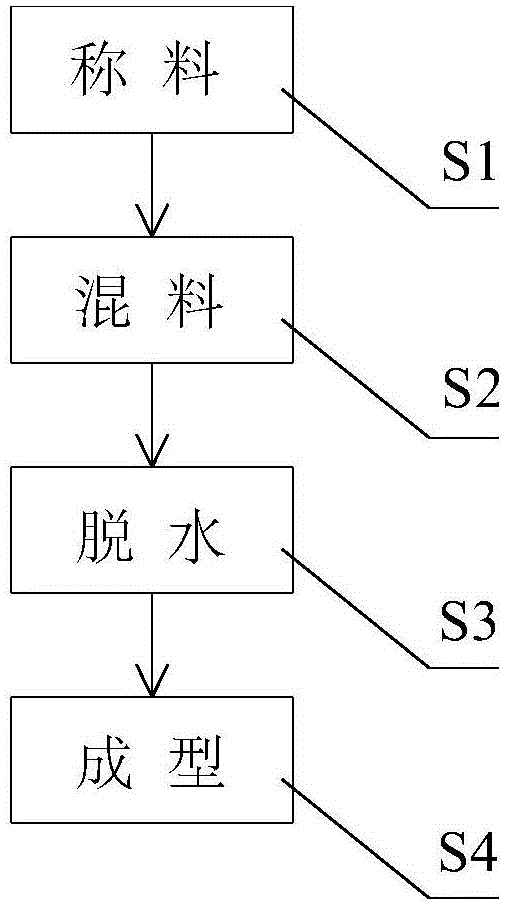

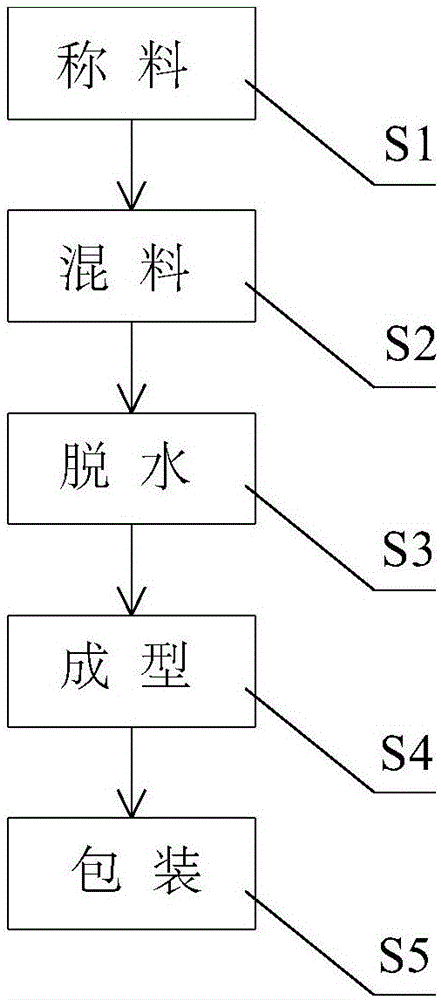

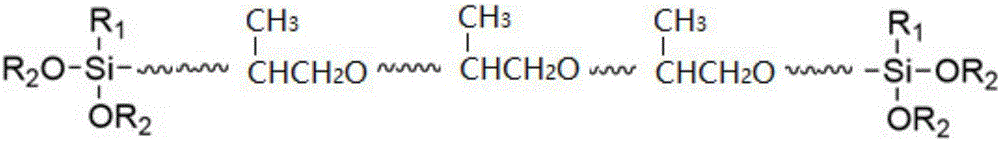

Two-component silicone sealant for solar module resisting damp, heat and ageing and preparation method thereof

InactiveCN102977840AWide range of adhesionImprove room temperature strengthNon-macromolecular adhesive additivesOther chemical processesChemistrySilicone sealant

The invention discloses two-component silicone sealant for a solar module resisting damp, heat and ageing and a preparation method thereof. The sealant consists of a component A and a component B, wherein the component A adopts polydimethylsiloxane as the major material; and the component B comprises dispersion mediums, fillers, cross linking agent, coupling agent and catalyst; the component A comprises the following components in parts by weight: 100 parts of a, omega-dihydroxy polydimethylsiloxane with viscosity of 5000-50000cps, 3 to 20 parts of plasticizer and 50 to 150 parts of fillers; the component B comprises the following components in parts by weight: 100 parts of dispersion mediums, 10 to 45 parts of fillers, 20 to 50 parts of cross linking agent, 5 to 40 parts of silane coupling agent and 0.5 to 2 parts of catalyst; and the ratio of the component A to the component B in parts by weight is 100: (10-20). The sealant has the advantages of fast deep curing, wide adhesion, high strength of normal temperature and excellent resistance to damp, heat and ageing; after ageing for 1000 hours under the double-85 condition, the strength retention rate can be up above 80%; and the sealant is suitable for machine gluing, can largely improve module productivity, and adapts to the requirements of solar module mass production.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

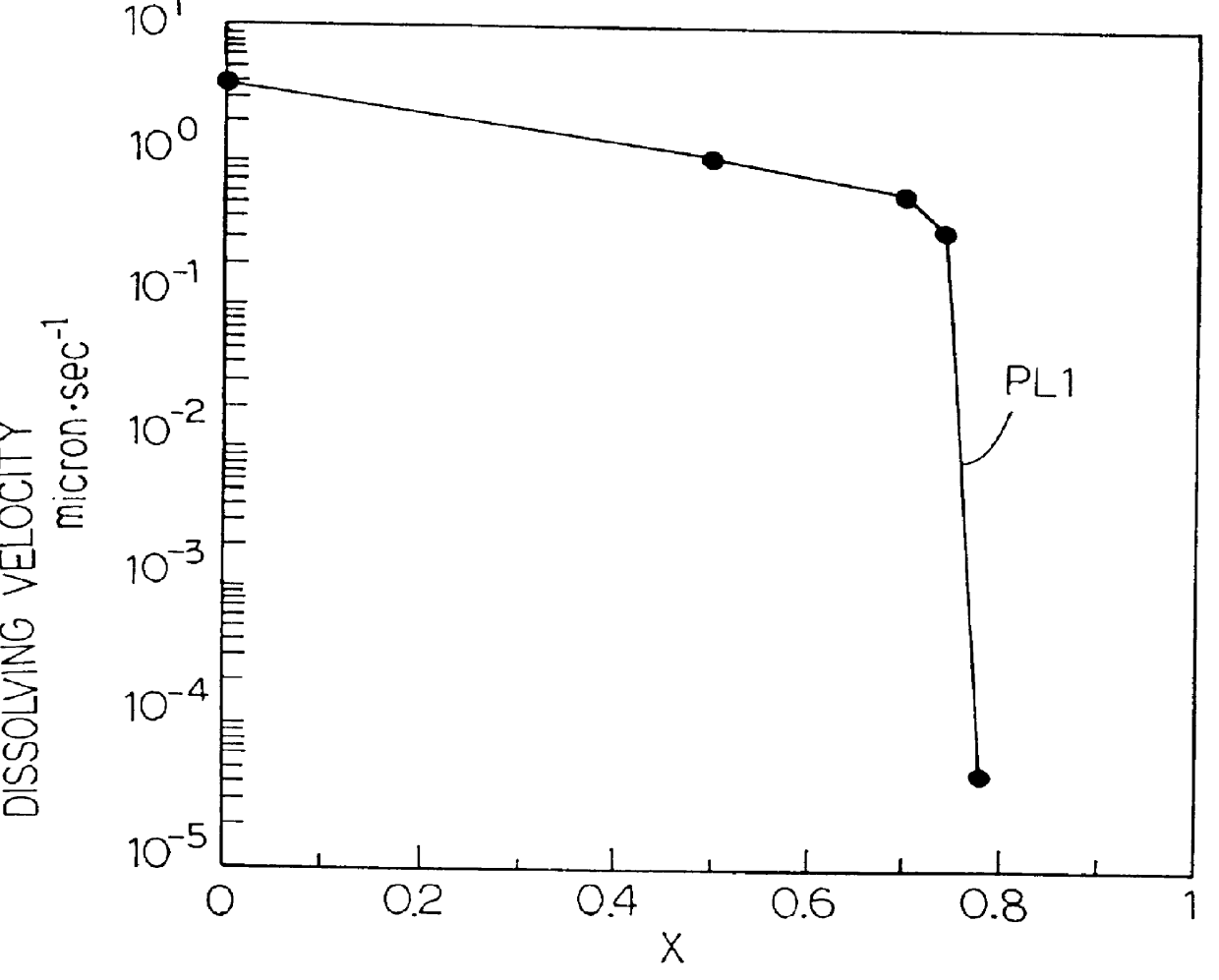

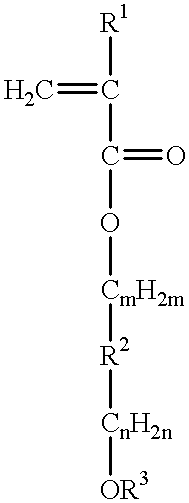

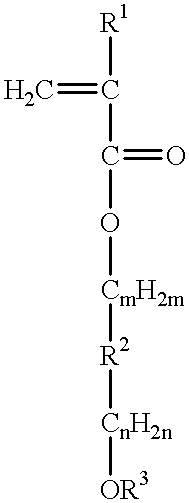

Chemically amplified resist large in transparency and sensitivity to exposure light less than 248 nanometer wavelength and process of forming mask

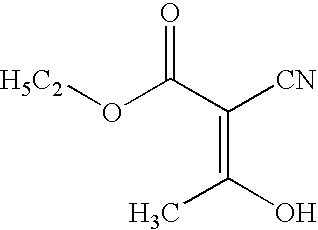

InactiveUS6030747AIncrease resistanceExtensive adhesionPhotosensitive materialsRadiation applicationsResistCarbon number

Monomers expressed by the following general formula are polymerized so as to obtain a polymer, and the polymer and a photoacid generator are dissolved in a solvent so as to form a chemically amplified resist layer large in both transparency and sensitivity to ArF excimer laser light and improved in resolution. wherein R1 represents a hydrogen atom or a methyl group, R2 represents a bridged hydrocarbon group having the carbon number between 7 and 22, m equals 0 or 1, n equals 0 or 1 and R3 represents a hydrogen atom, a methyl group or an acetyl group.

Owner:NEC CORP

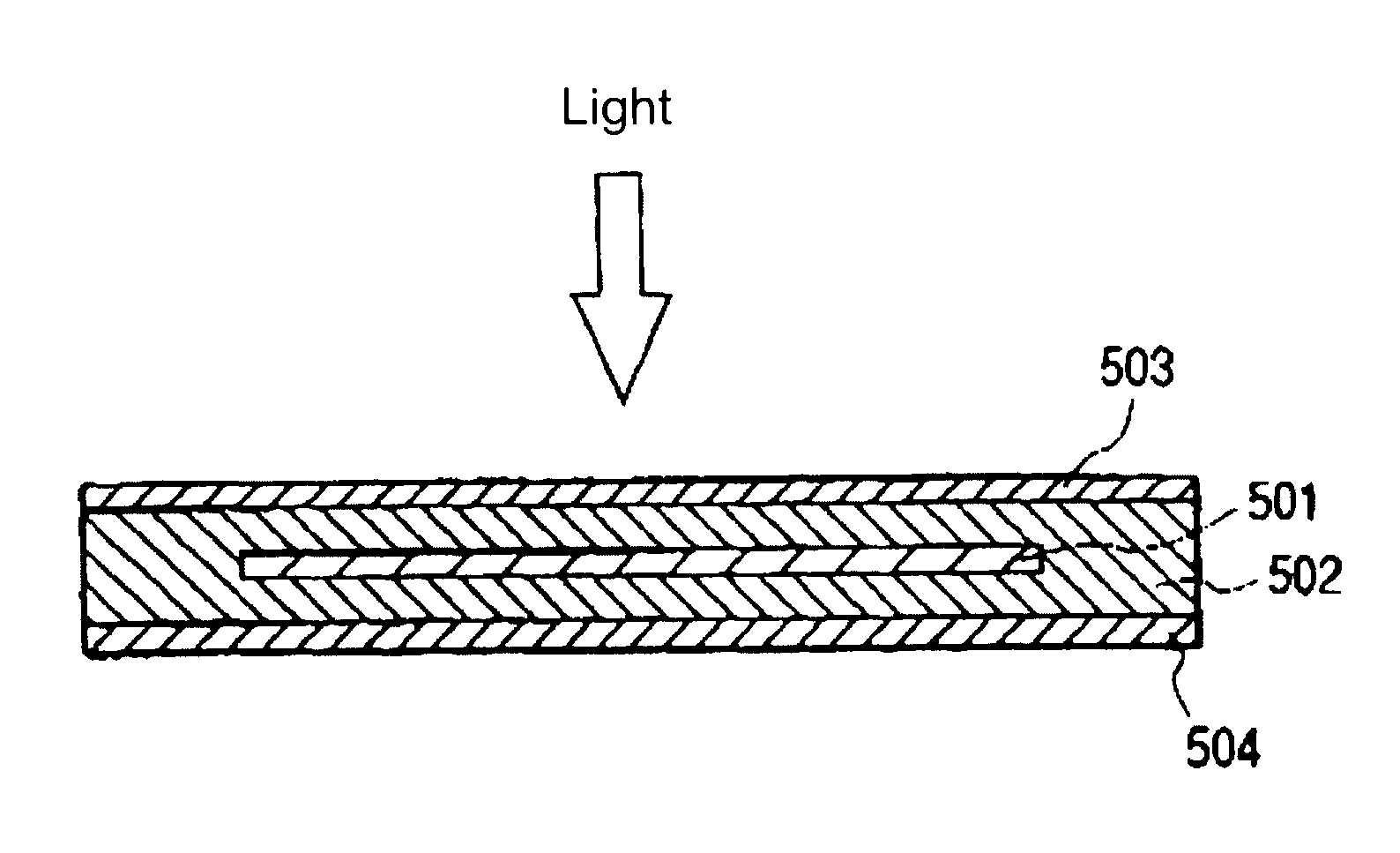

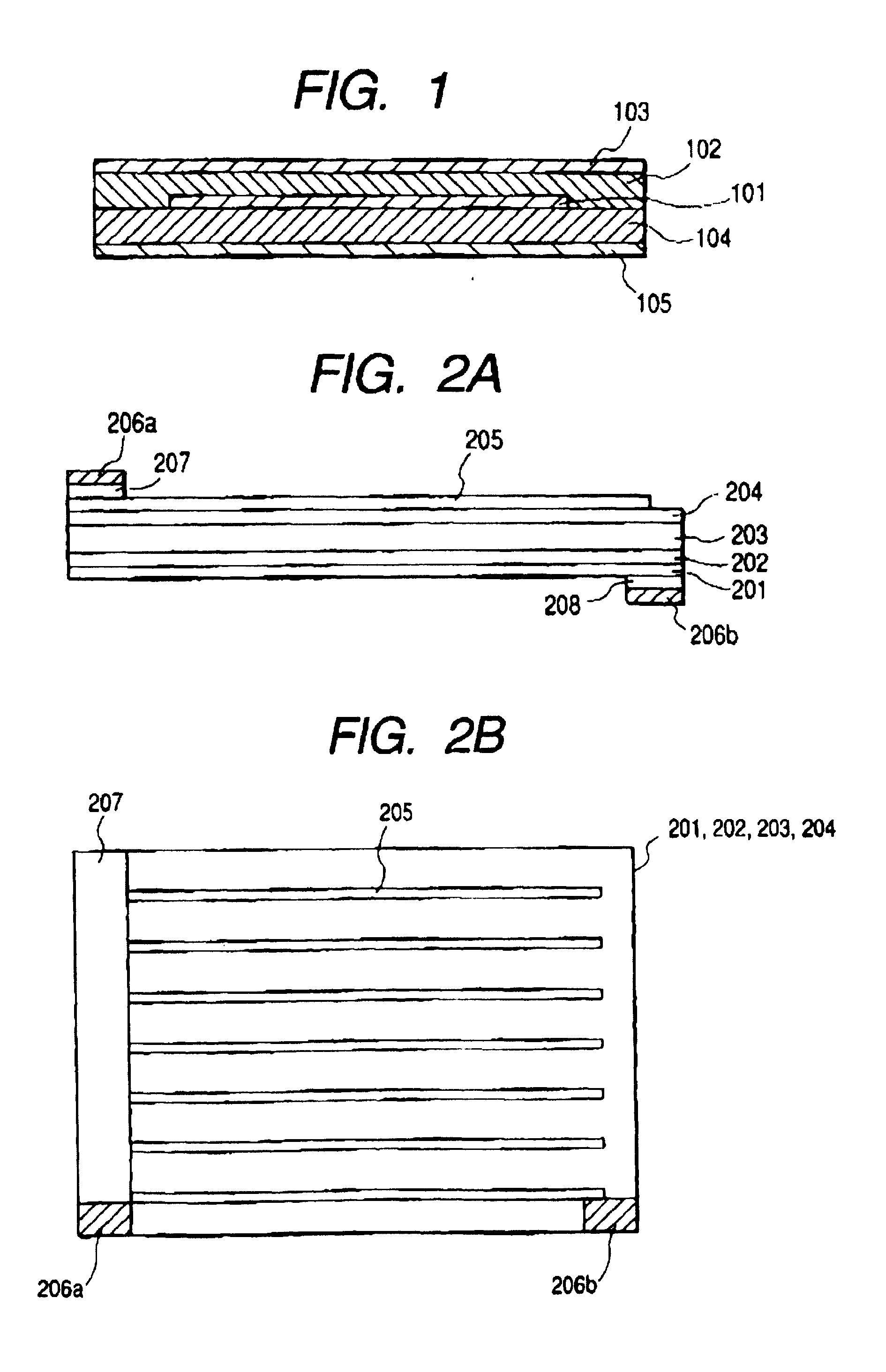

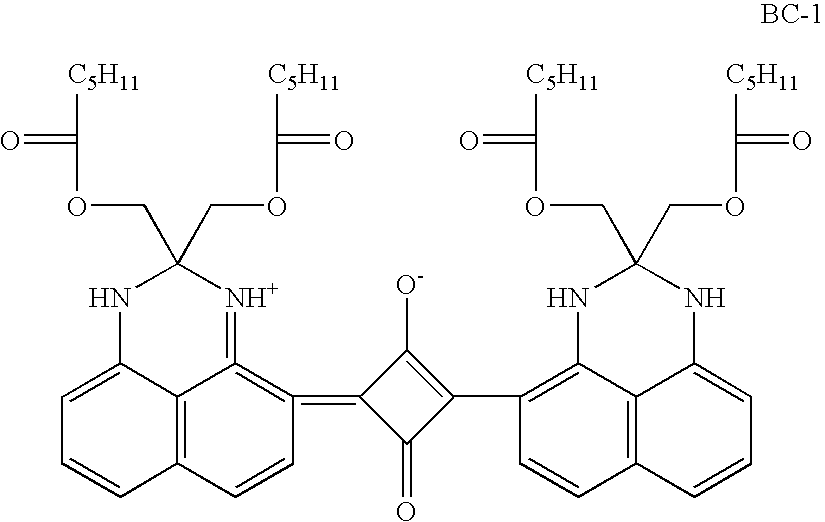

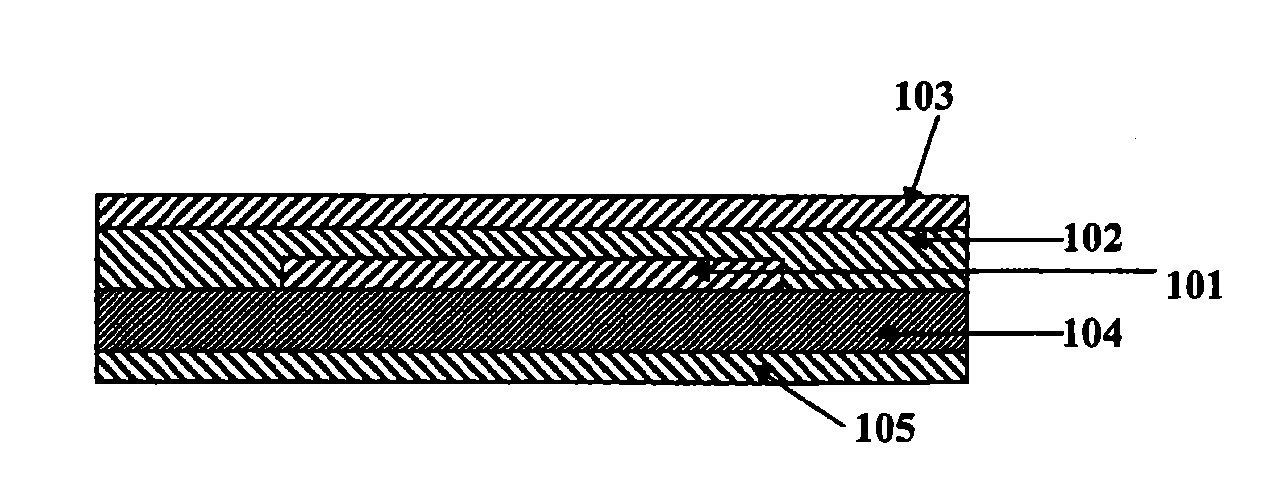

Moulding compounds for the production of solar cell modules

InactiveUS20110269883A1Efficient use ofEffective absorptionPhotovoltaic energy generationSemiconductor devicesMeth-Transmittance

Moulding composition, encompassinga) at least one polyalkyl (meth)acrylate, andb) at least one compound according to formula (I)in which the moieties R1 and R2 are independently an alkyl or cycloalkyl moiety having from 1 to 20 carbon atoms,where the moulding composition further comprisesc) at least one infrared absorber,where the transmittance of the moulding compositionat 500 nm is smaller than 89%,at 1000 nm is smaller than 80%,at 1150 nm is smaller than 70% andat 1600 nm is smaller than 77%, in each case measured by means of infrared spectroscopy at 25° C. on 3 mm plaques.The moulding composition is in particular used for the production of solar-cell modules.

Owner:EVONIK ROEHM GMBH

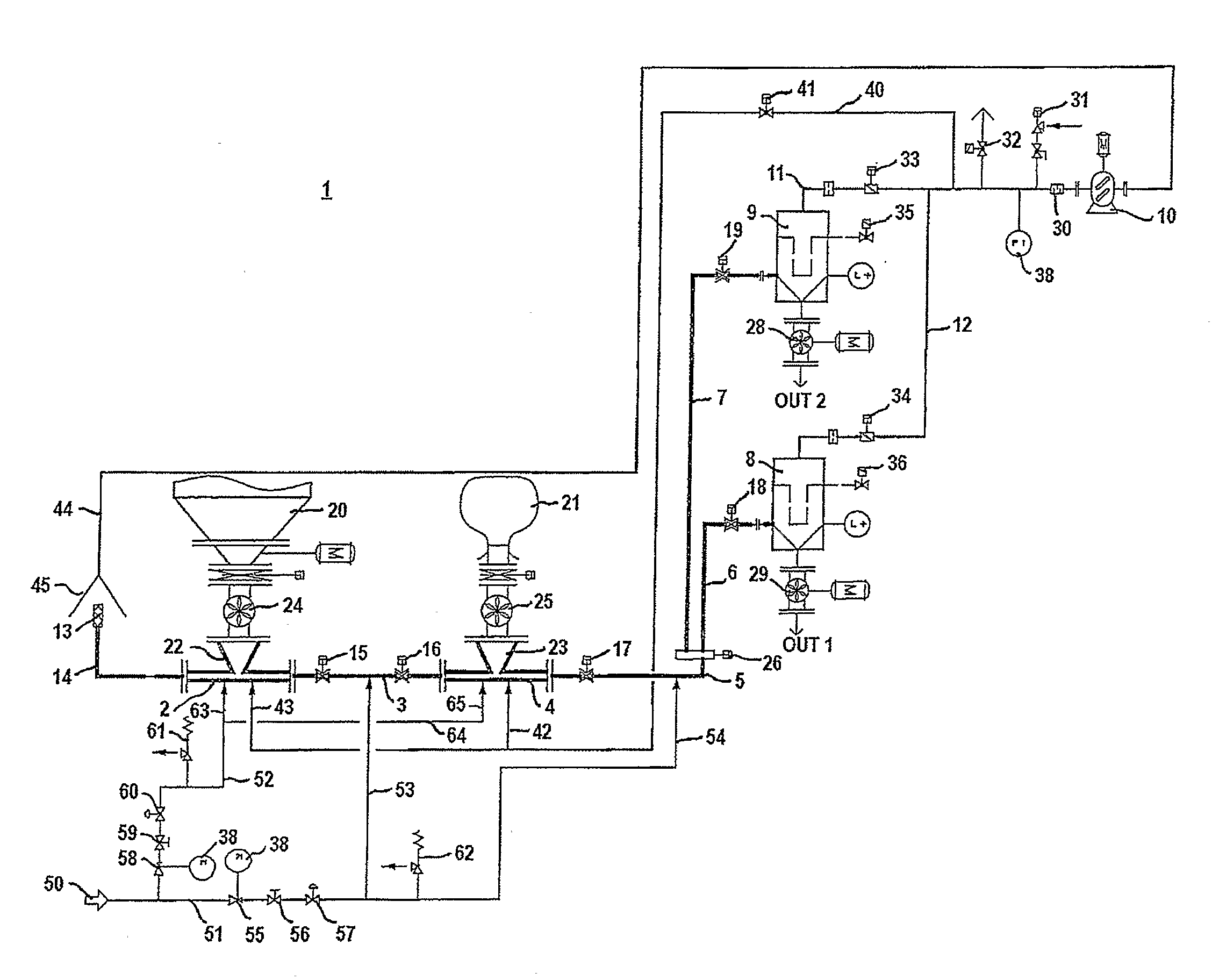

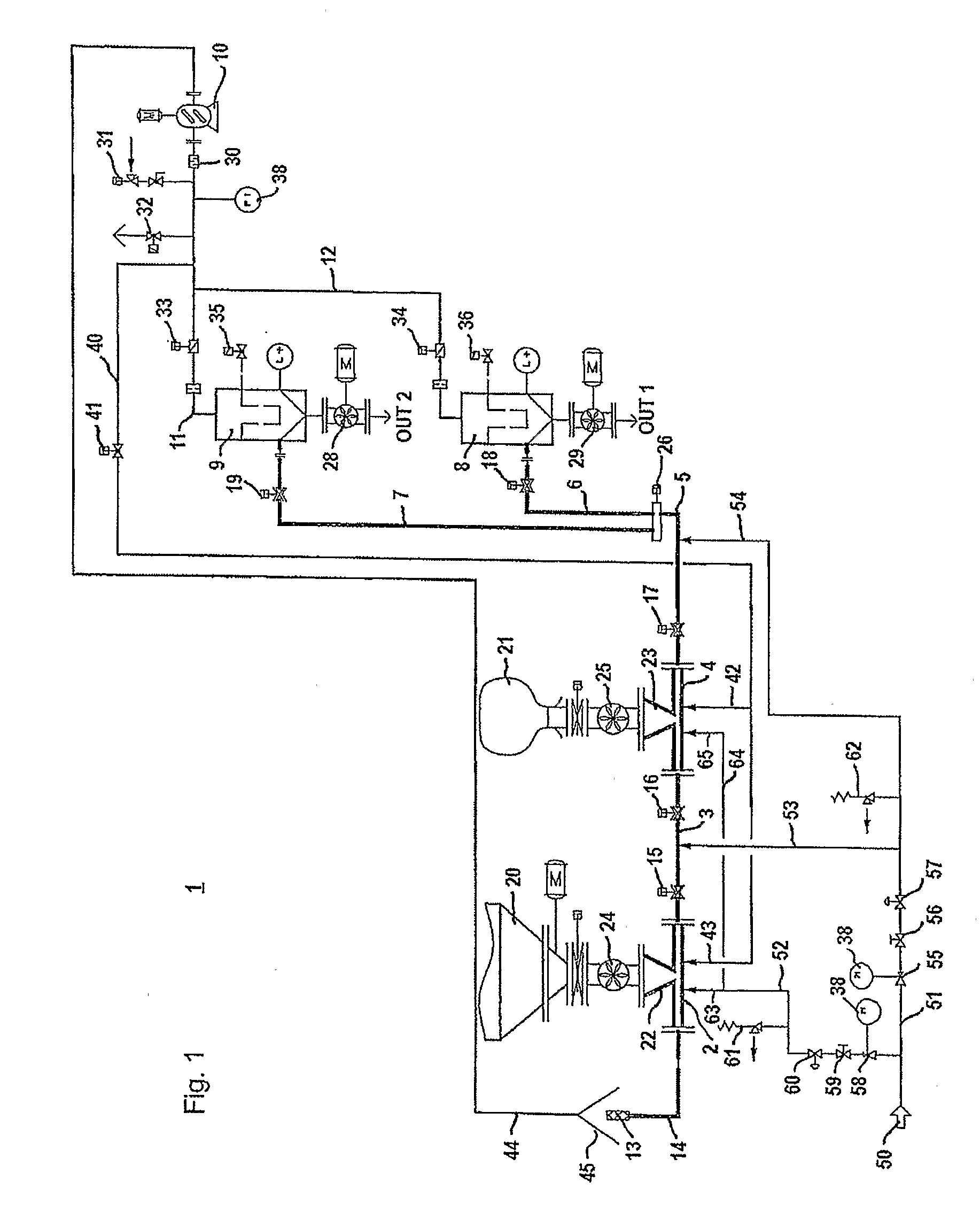

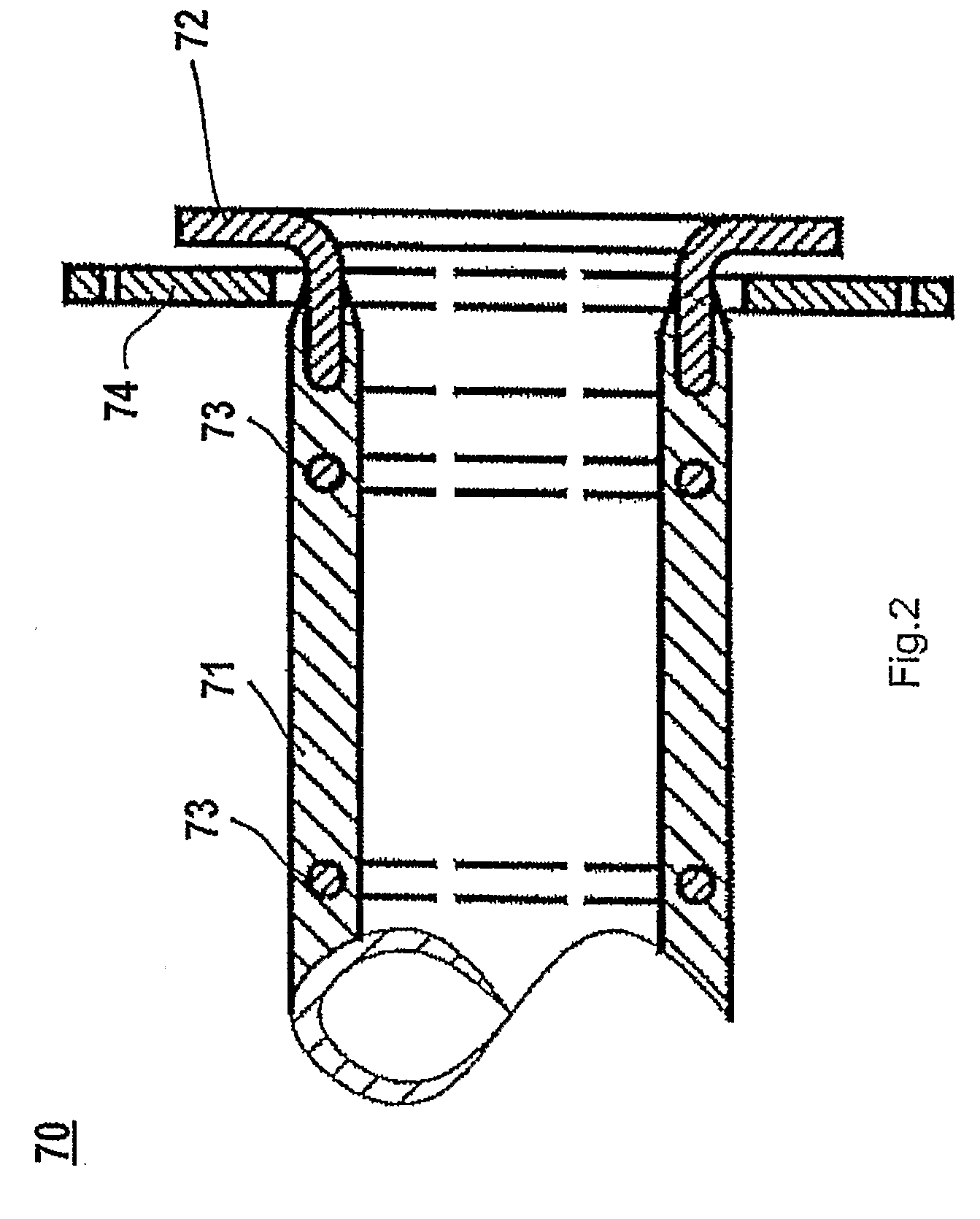

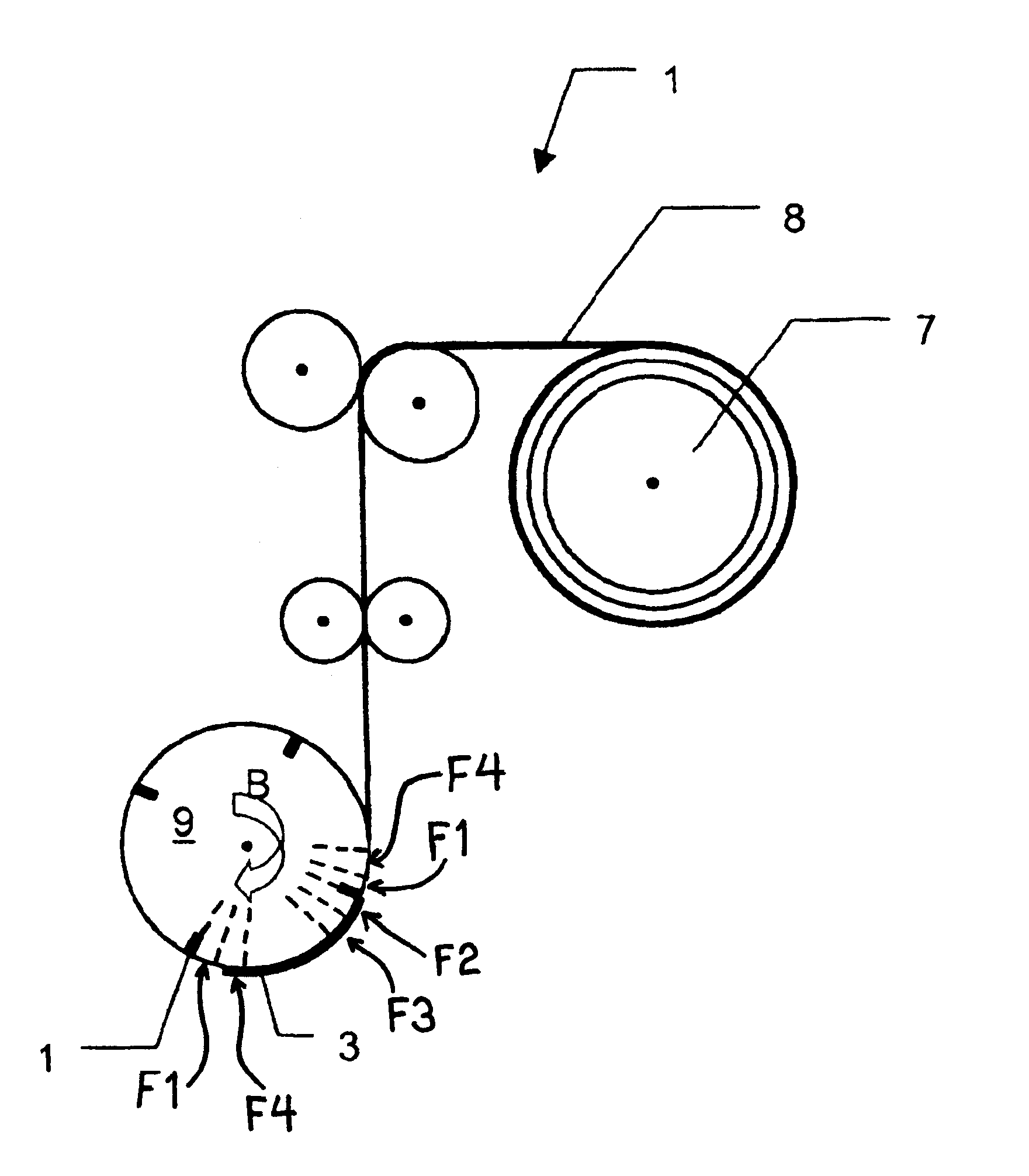

Method and system for vacuum conveying of bulk material and computer program product

InactiveUS20090304461A1Avoid stickingEfficiently prevent adherenceDigital data processing detailsBulk conveyorsEngineeringComputer program

The invention relates to a method for vacuum conveying bulk material in a vacuum conveying system (1) which comprises: a plurality of tubes (2-6) for conveying bulk material, at least some of said tubes having flexible walls (71), a vacuum blower (10) disposed at a first end of said vacuum conveying system (1) for generating a conveying gas flow within said vacuum conveying system (1), a bulk material discharging section (22, 23) for discharging bulk material into said vacuum conveying system (1), and a bulk material receiving section (8, 9) communicating with said vacuum blower (10), for receiving bulk material conveyed by said gas flow from said bulk material discharging section (22, 23). According to the invention, the method comprises the steps of: disconnecting said vacuum blower (10) from said vacuum conveying system (1); and applying pressurized gas to said vacuum conveying system (1) or at least to a subsection thereof for stretching or inflating said flexible walls (71) to thereby reduce adherence of bulk material to said flexible walls (71). Other aspects of the invention relate to a corresponding vacuum conveying system, to a controlling device and a computer program product for controlling the vacuum conveying system in accordance with the above method steps.

Owner:SUN CHEM CORP

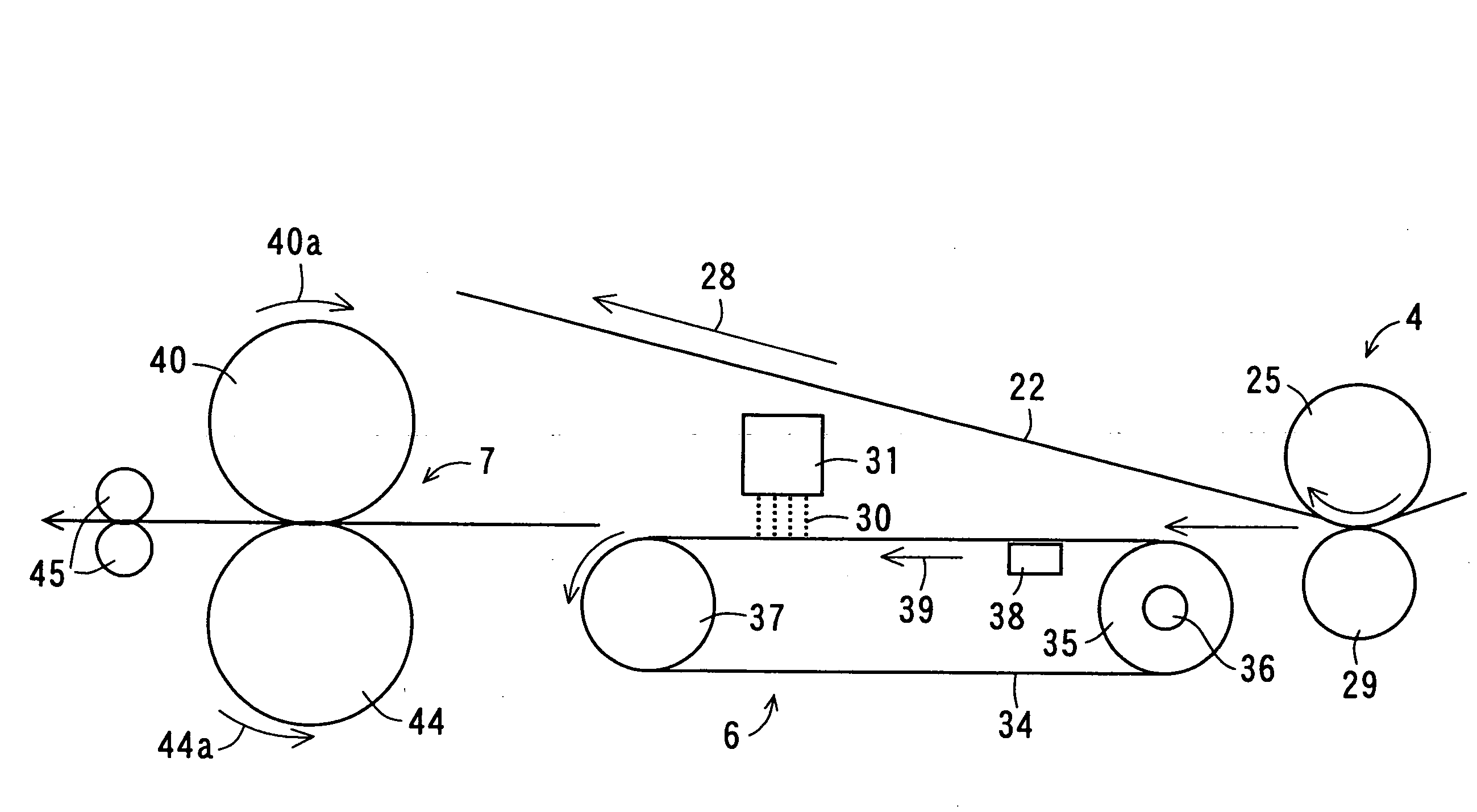

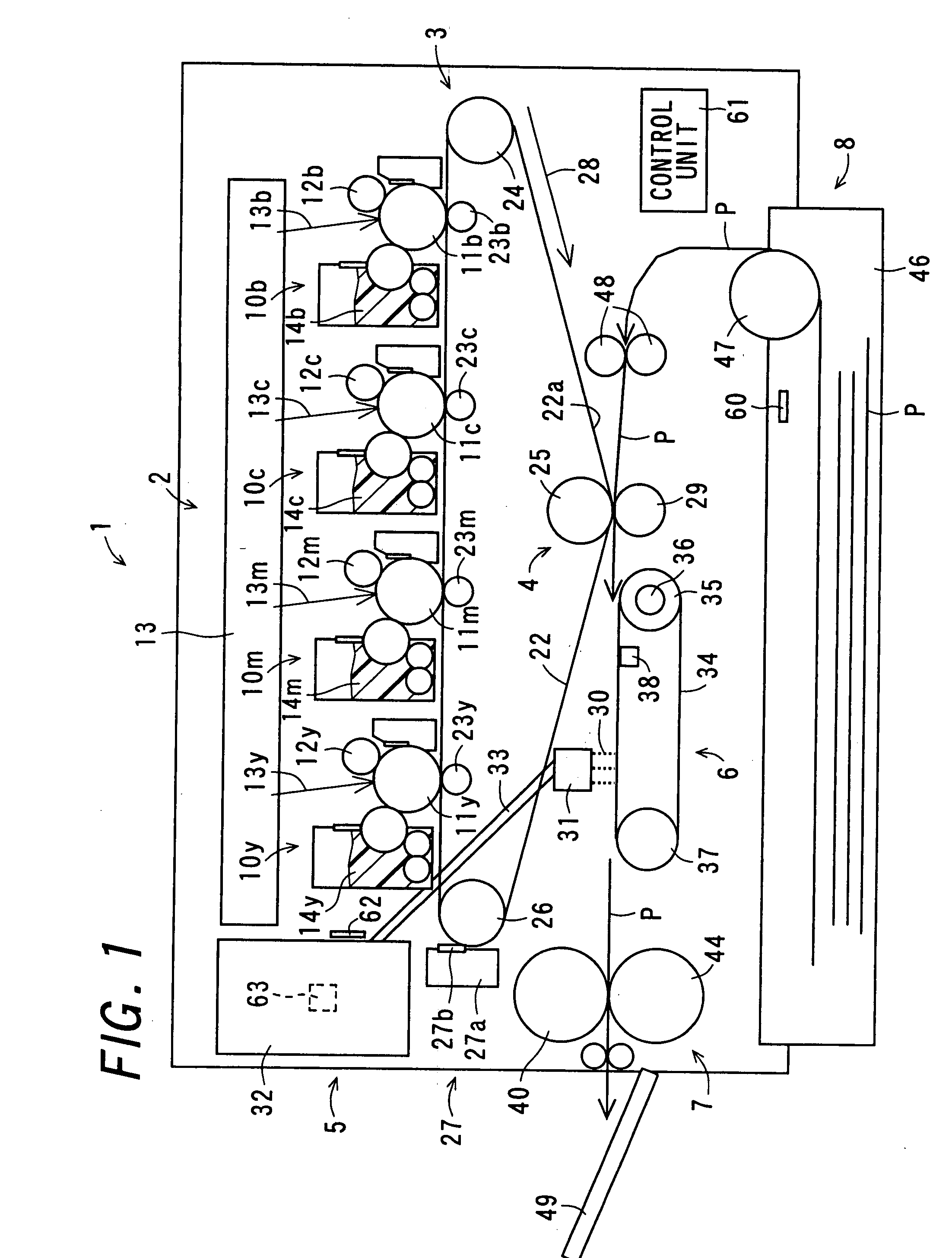

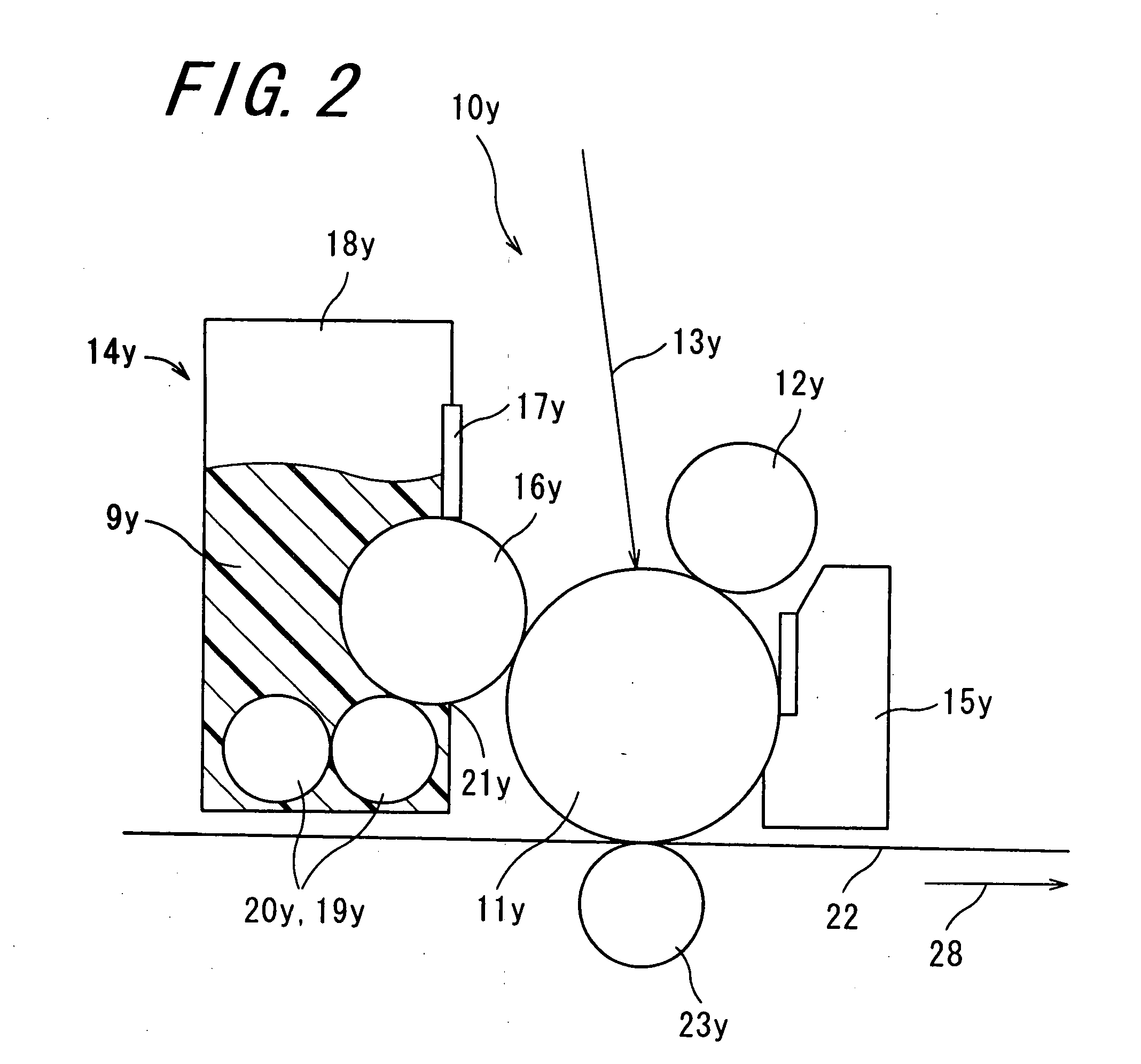

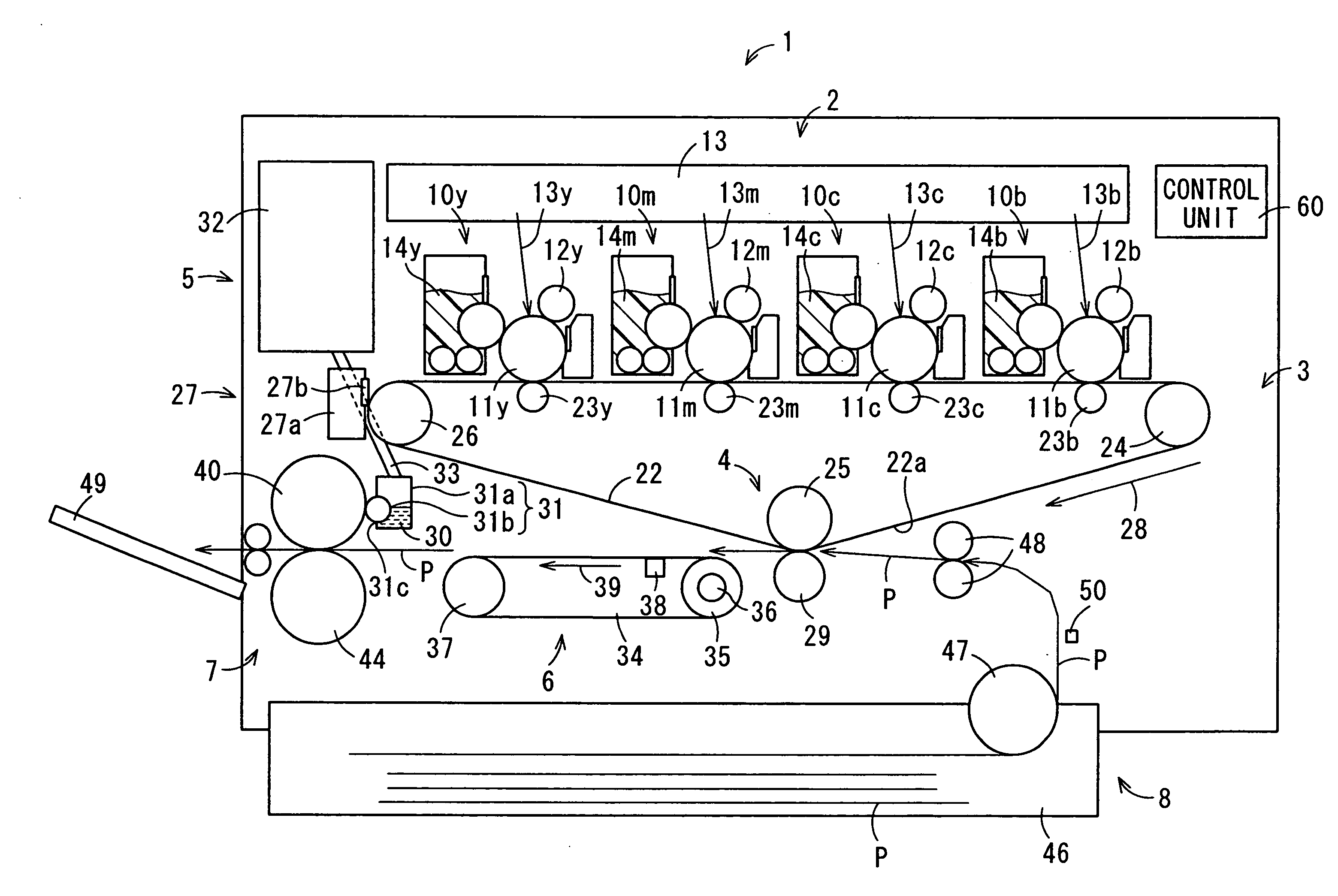

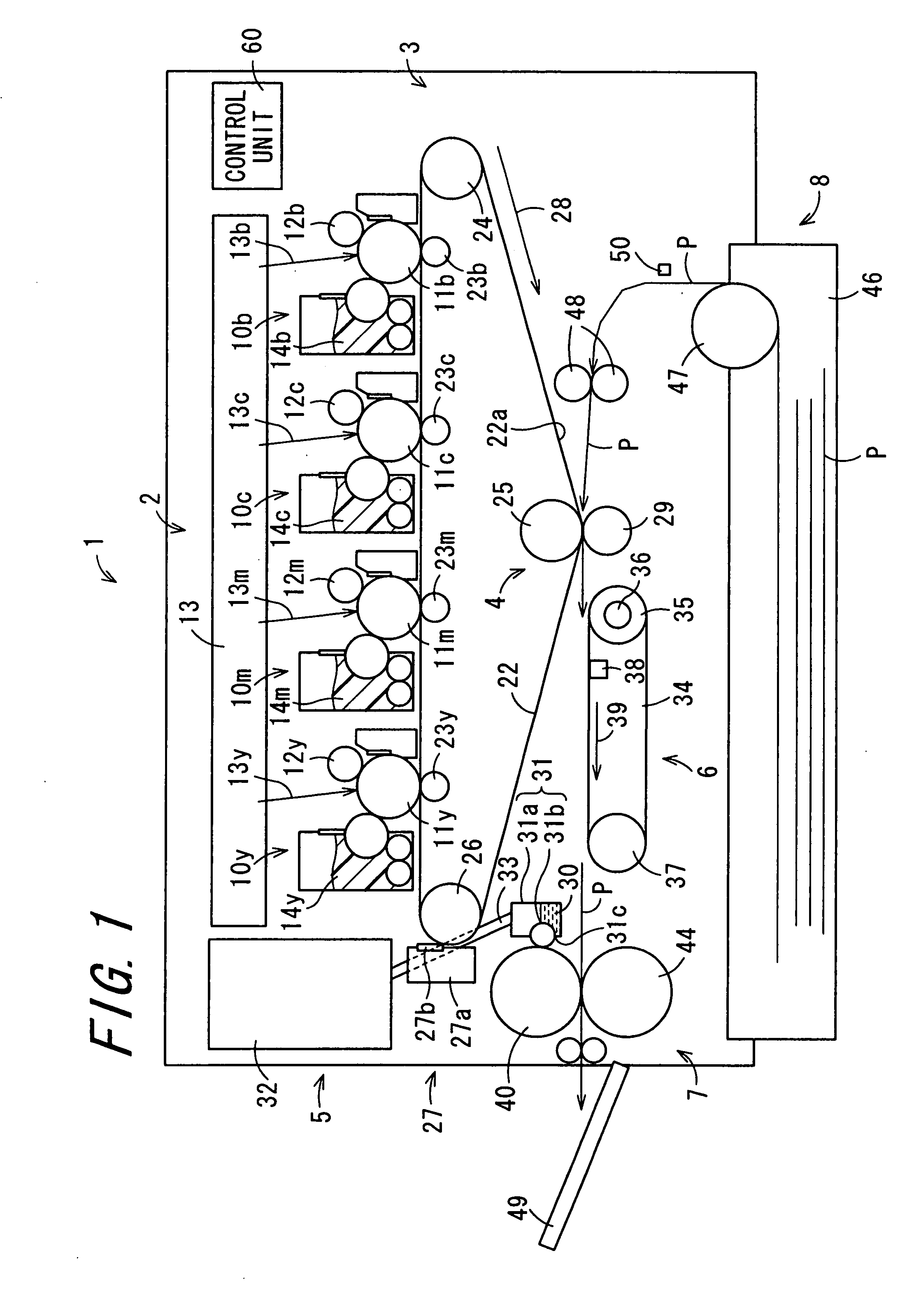

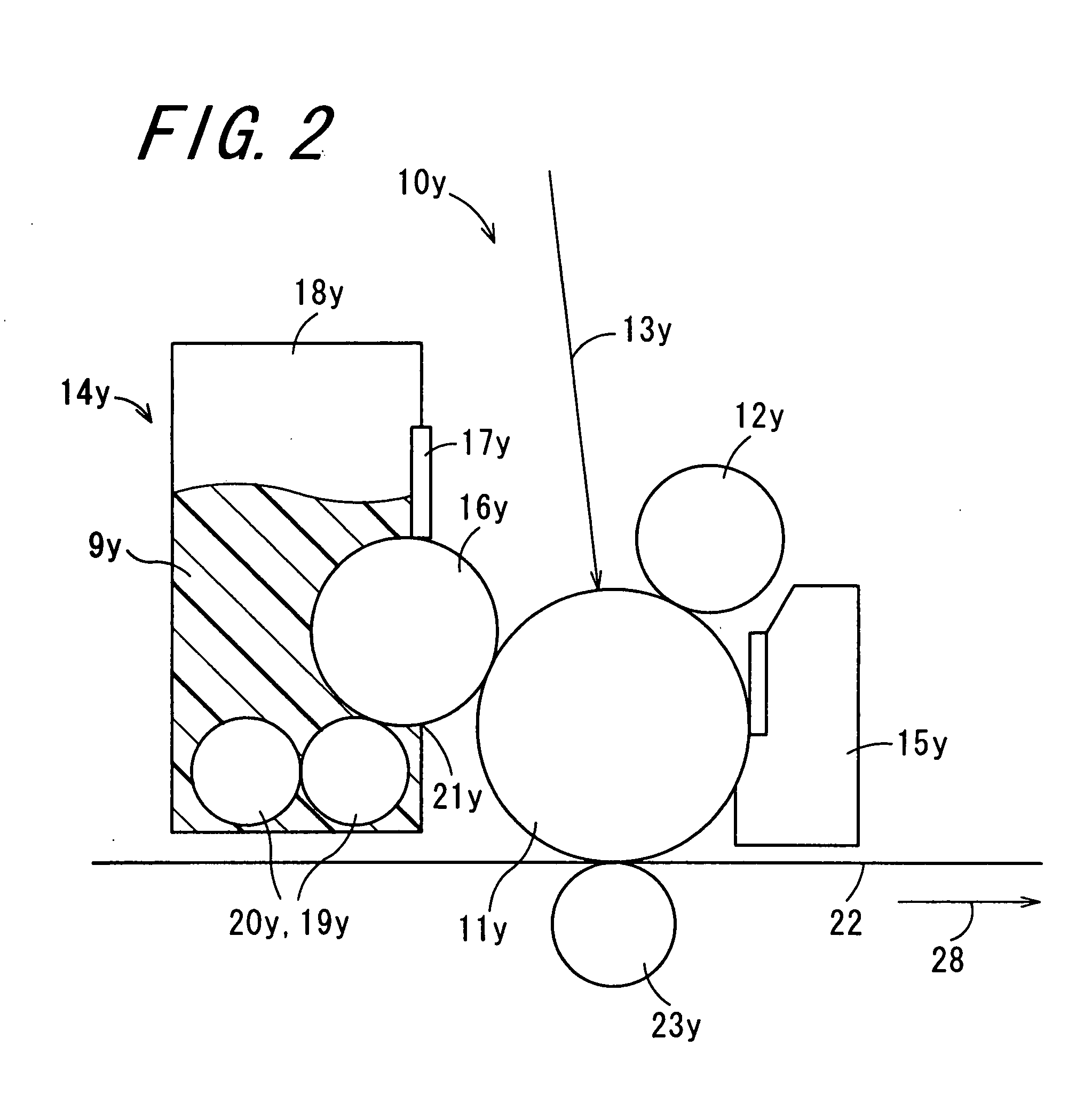

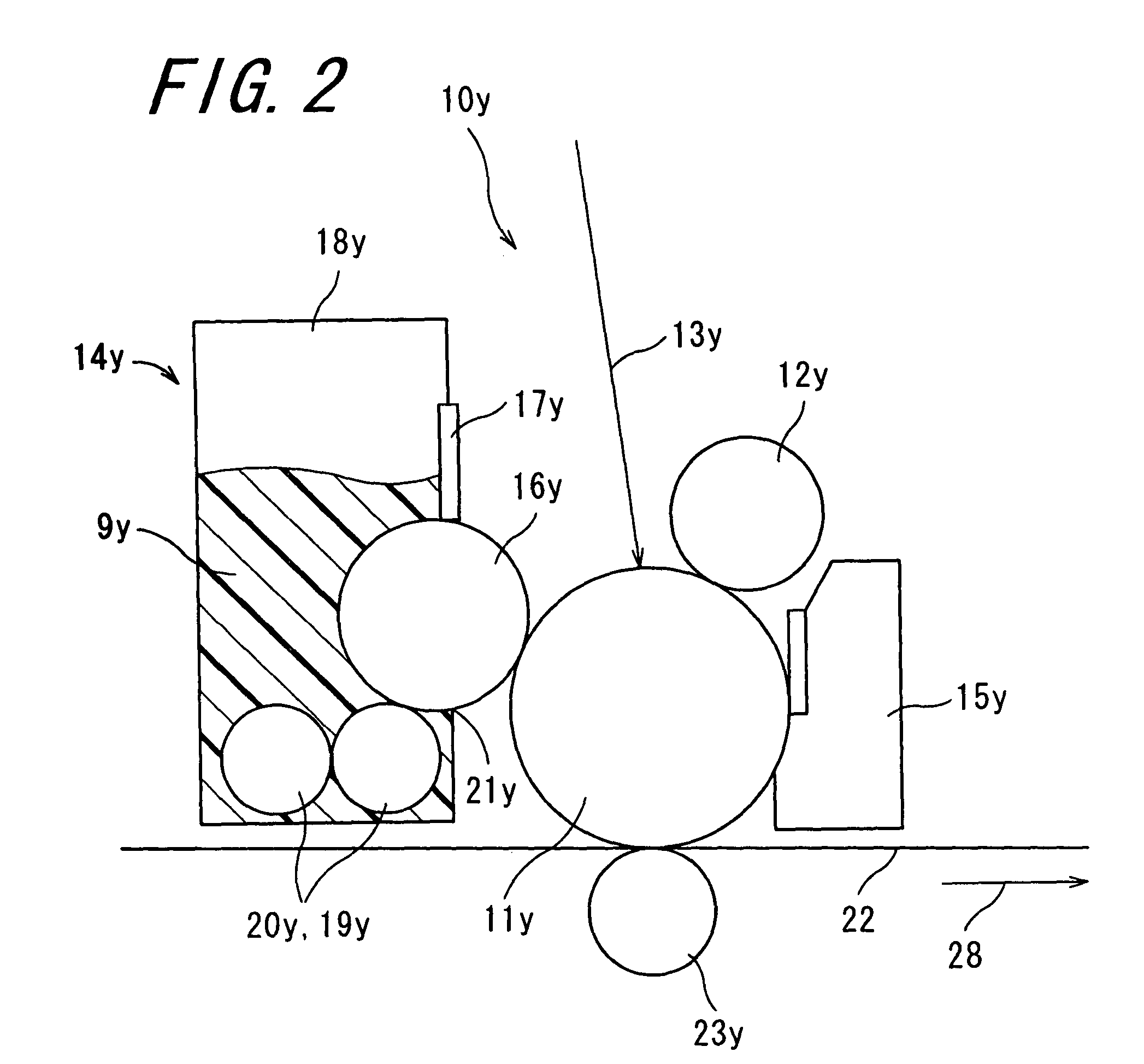

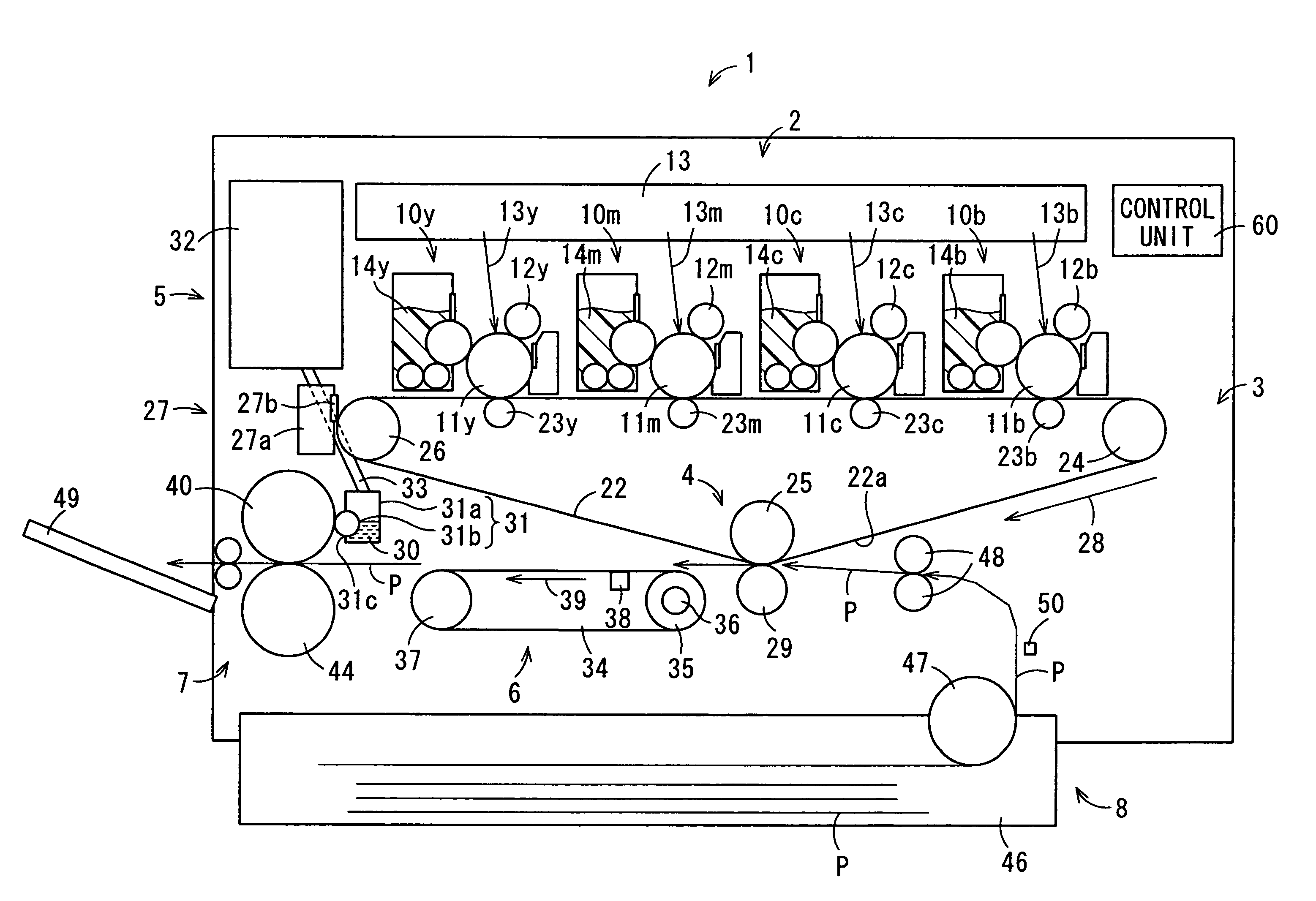

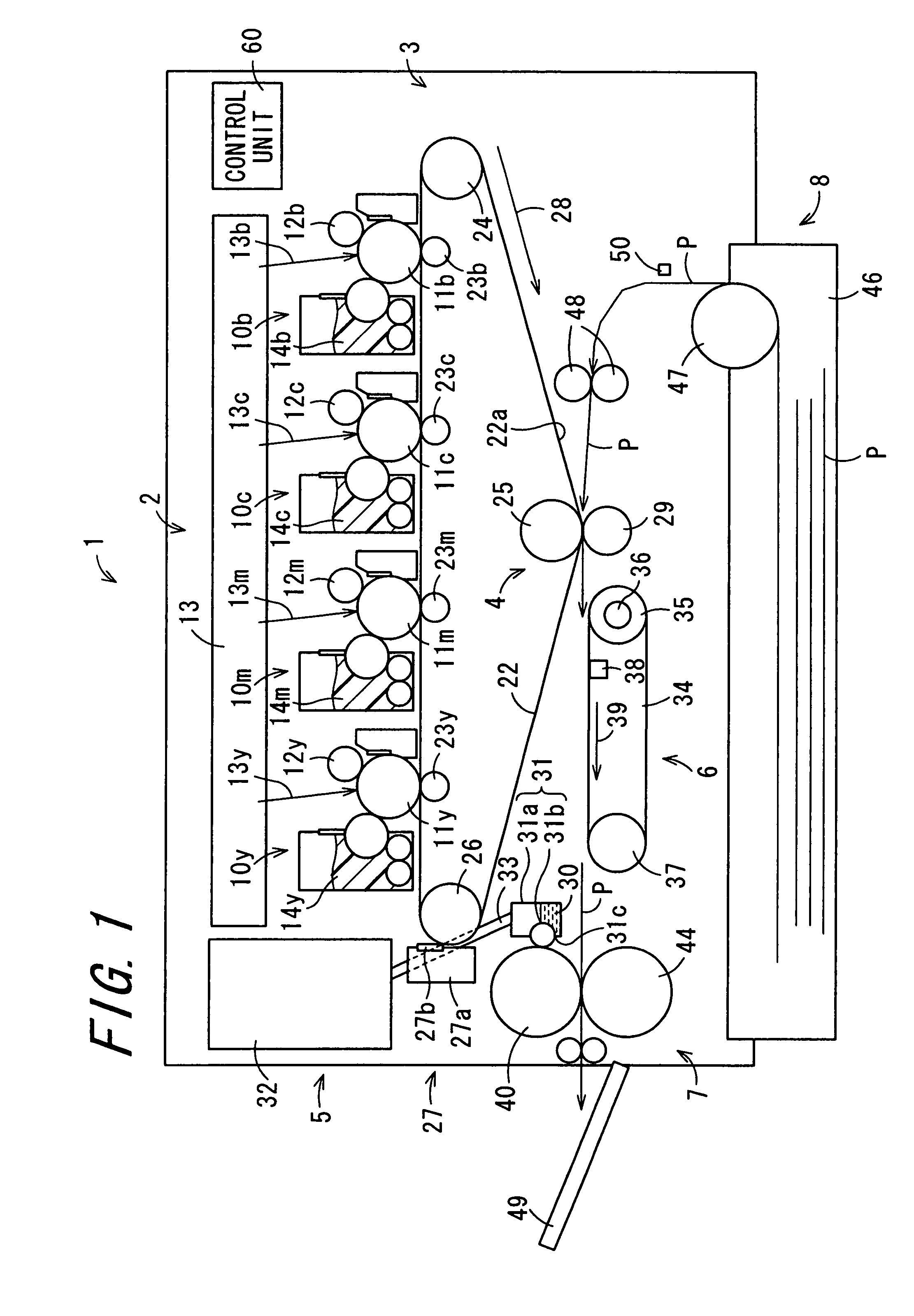

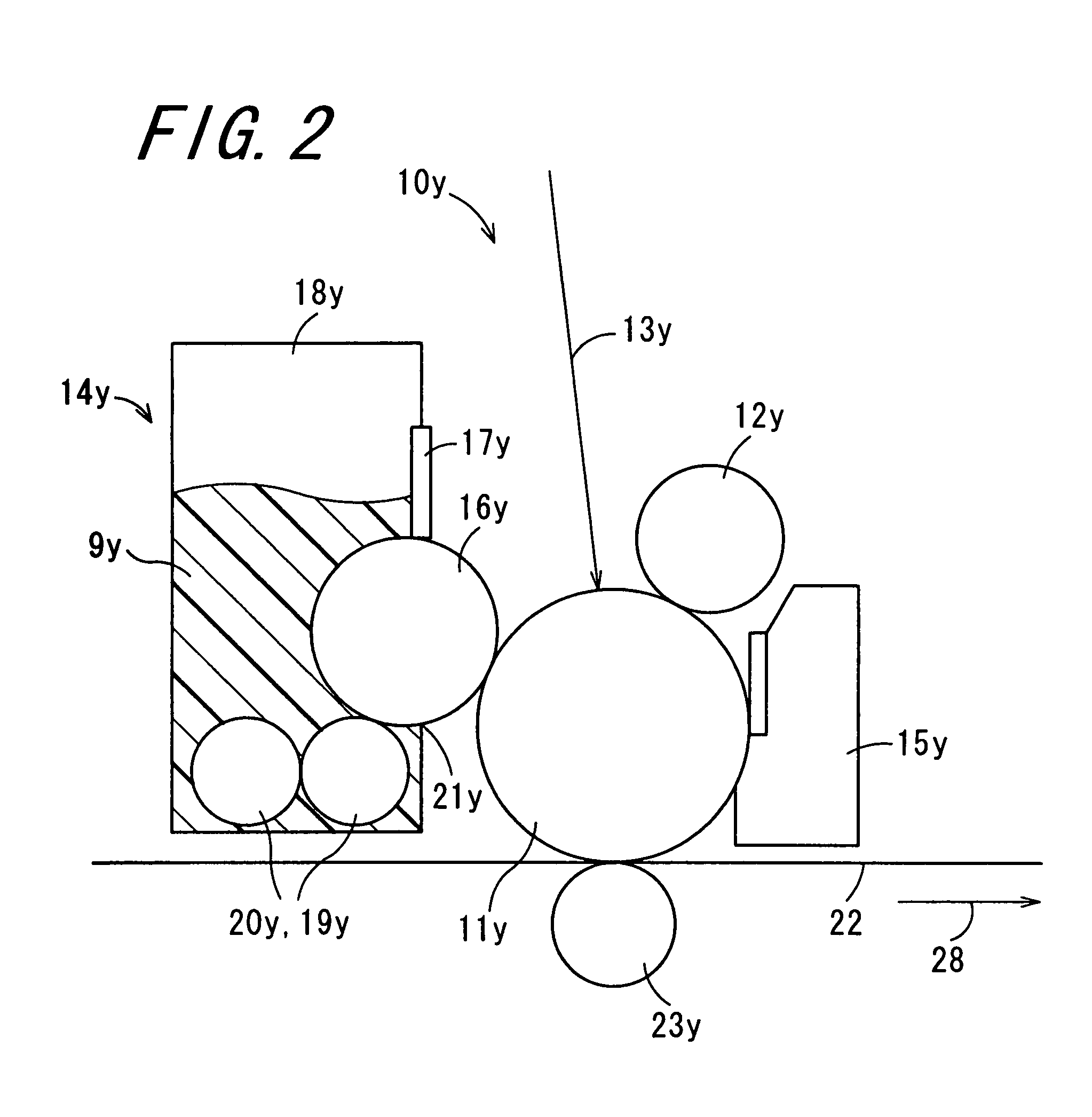

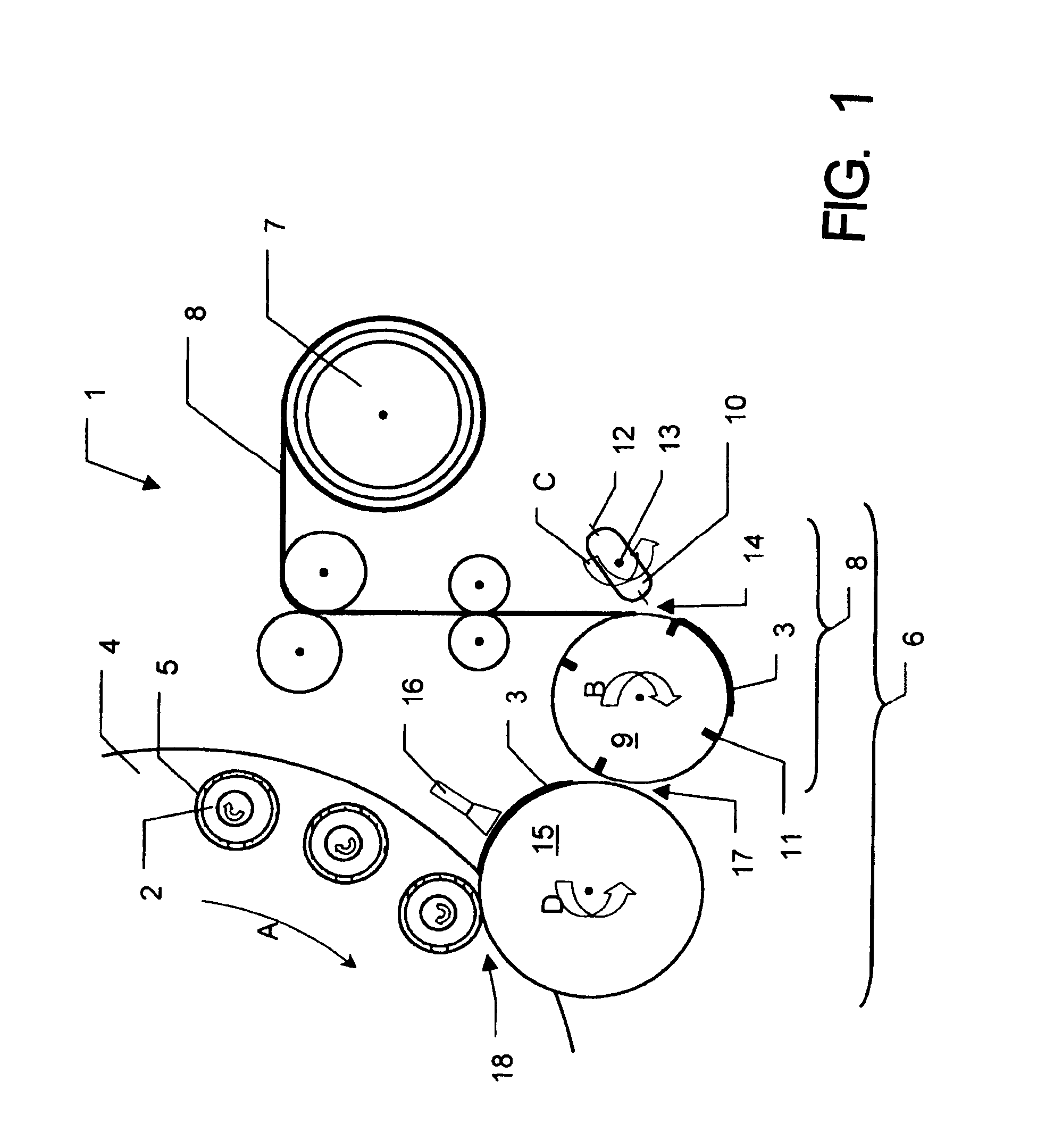

Image forming apparatus

InactiveUS20070196146A1Reduce amount of heat energyGenerates no curling or wrinklesElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a toner image forming section, an intermediate transferring section, a transferring section, a fixing solution applying section, a transporting section, a fixing section, and a recording medium feeding section. In the image forming apparatus, the fixing solution applying section includes a droplet supplying section, a recording medium detecting section, and a control unit, wherein the recording medium is heated before or at the same time when the fixing solution is applied to the recording medium by the fixing solution applying section, and a size of droplets of the fixing solution supplied to the recording medium is controlled based on the type of the recording medium.

Owner:SHARP KK

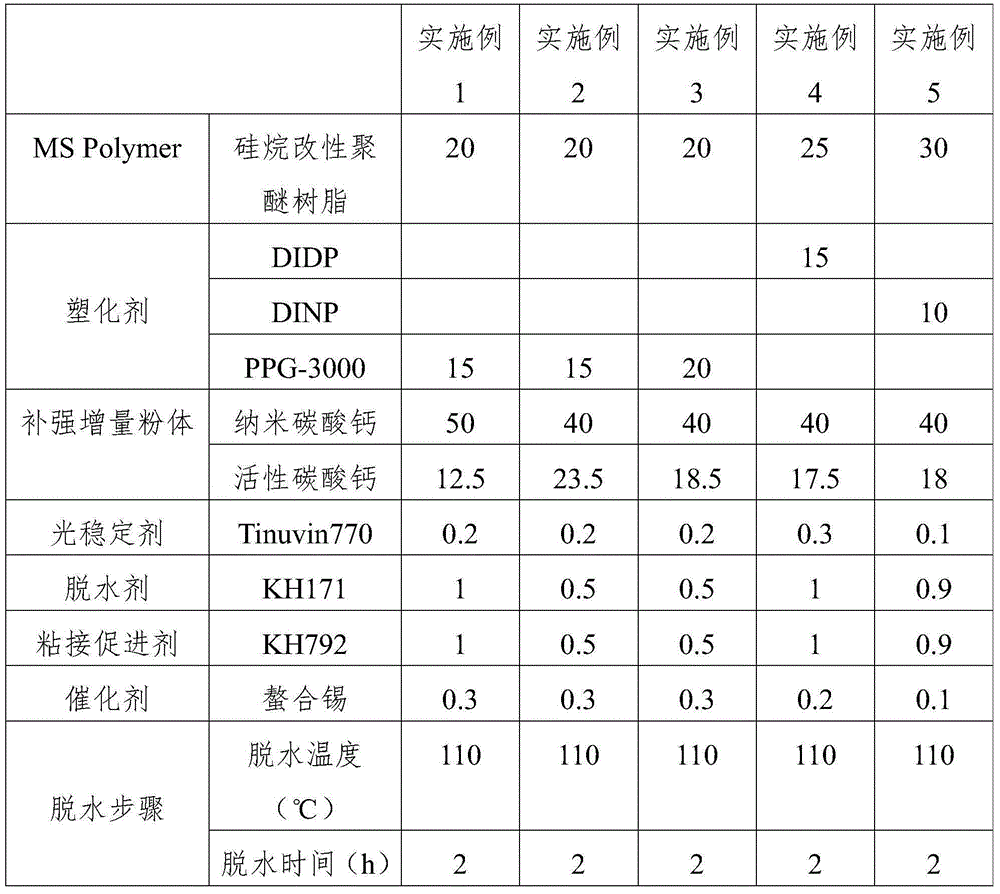

Mildew-proof silane-modified polyether sealant and preparation method therefor

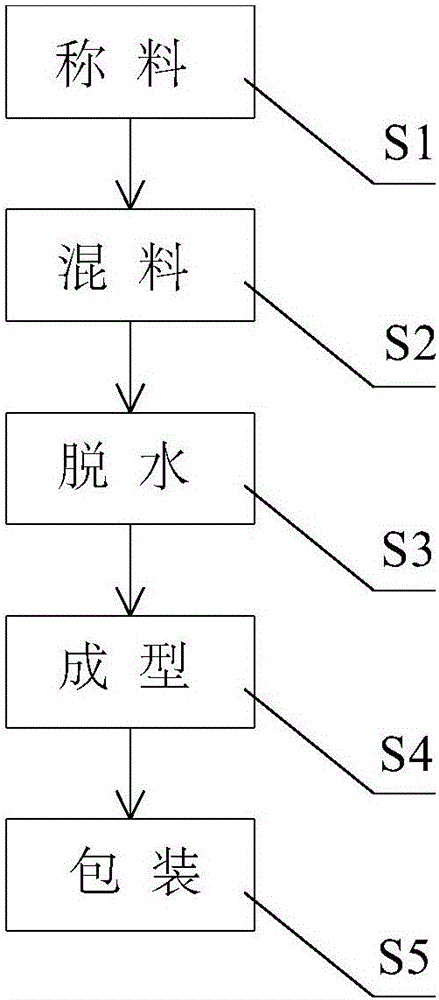

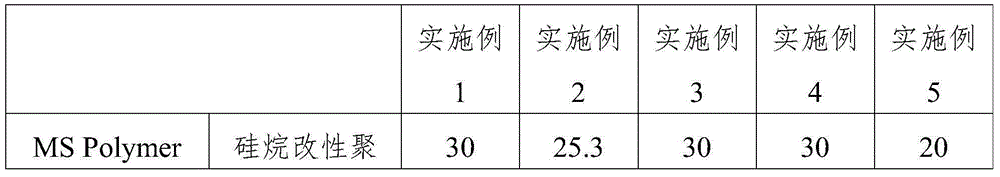

InactiveCN105111992ASolve the problem of decreased elasticityIncrease elasticityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUltraviolet

The present invention discloses mildew-proof silane-modified polyether sealant. The sealant is prepared by mixing the following raw materials in proportion by weight: 20-30% of silane-modified polyether prepolymer, 20-30% of a plasticizer, 40-50% of reinforcing incremental powder, 3-5% of a brightener, 0.1-0.5% of a thixotropic agent, 0.1-0.3% of a mildew-proof agent, 0.1-0.3% of an ultraviolet absorbent, 0.1-0.3% of a light stabilizer, 0.5-1% of a dehydrating agent, 0.5-1% of a silane coupling agent and 0.1-0.3% of a catalyst. The mildew-proof silane-modified polyether sealant provided by the present invention adopts single-component sealed package, is cured after contacting moisture under the action of a catalyst and has wide adhesion to various materials. The sealant is simple in operation, environmentally friendly, cured quickly, mildew-proof in a moist environment and is an ideal adhesive sealing material in kitchen-bath and household aspects.

Owner:深圳市隆邦新材料科技有限公司

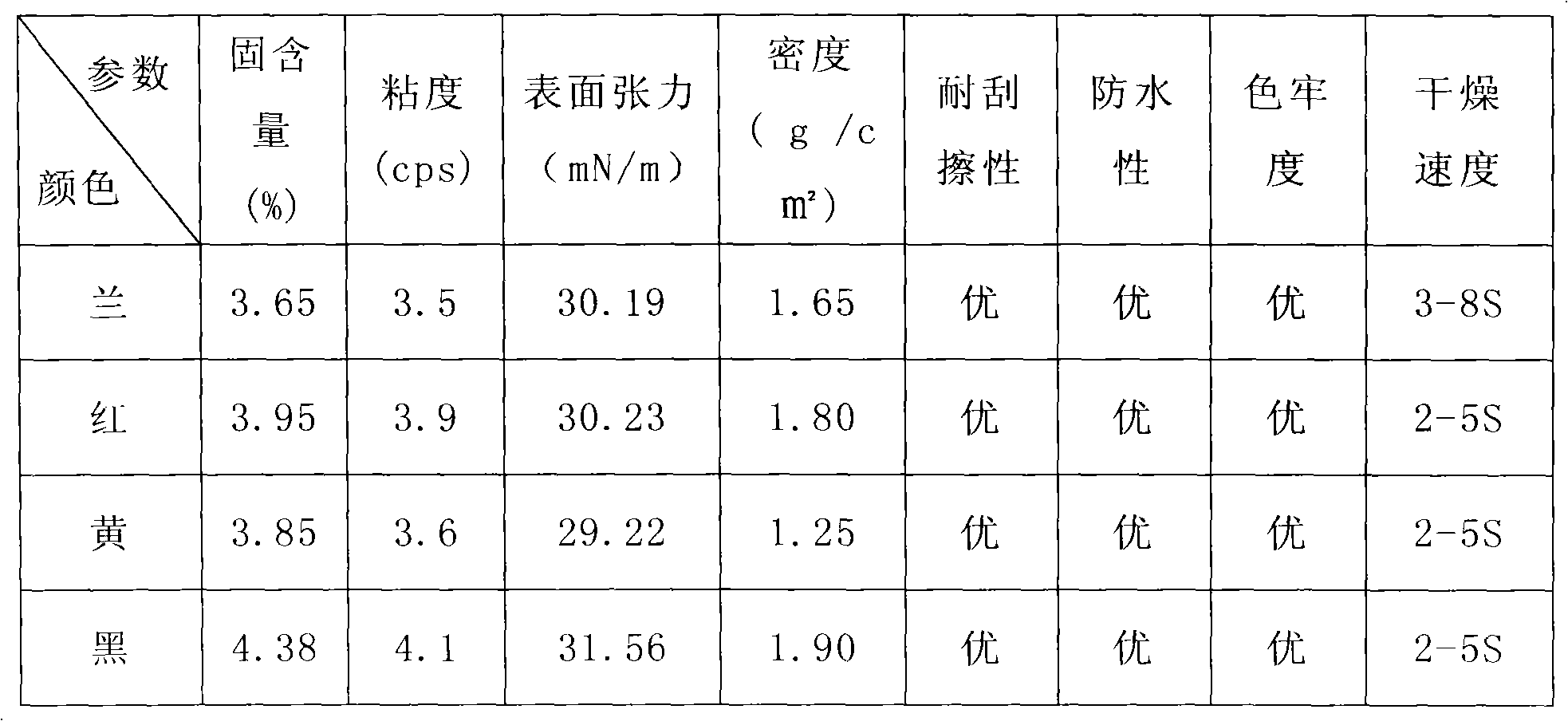

Environment-friendly solvent type dye resin ink-jet printing ink composition applied in common printing medium and preparation method thereof

InactiveCN102040887AImprove the adaptability of a wide range of bondingImprove color expressionInksOrganic solventPrinting ink

The invention relates to a solvent type dye resin ink-jet printing ink composition, particularly disclosing an environment-friendly solvent type dye resin ink-jet printing ink composition applied in a common printing medium and a preparation method thereof. The environment-friendly solvent type dye resin ink-jet printing ink composition applied in a common printing medium is characterized by comprising a colorant metal complex dye toner, a macromolecule polymerization binder, an environment-friendly organic solvent, an osmosis-prevention macromolecule polymer and a surfactant. The environment-friendly solvent type dye resin ink-jet printing ink composition applied in a common printing medium has the characteristics of environmental protection, safety, mild taste, water resistance, scraping resistance, high ink drying speed, and good adhesion of ink and the medium, and the ink has good color on the printing medium.

Owner:尹悦 +1

Chemically amplified resist large in transparency and sensitivity to exposure light less than 248 nanometer wavelength and process of forming mask

InactiveUS6287746B1Good resistance against alkaline developing solutionExtensive adhesionPhotosensitive materialsRadiation applicationsResistCarbon number

Monomers expressed by the following general formula are polymerized so as to obtain polymer, and the polymer and photoacid generator is dissolved in solvent so as to form a chemically amplified resist layer large in both transparency and sensitivity to ArF excimer laser light and improved in resolution.wherein R1 represents a hydrogen atom or a methyl group, R2 represents a bridged hydrocarbon group having the carbon number between 7 and 22, m equals 0 or 1, n equals 0 or 1 and R3 represents a hydrogen atom, a methyl group or an acetyl group.

Owner:NEC CORP

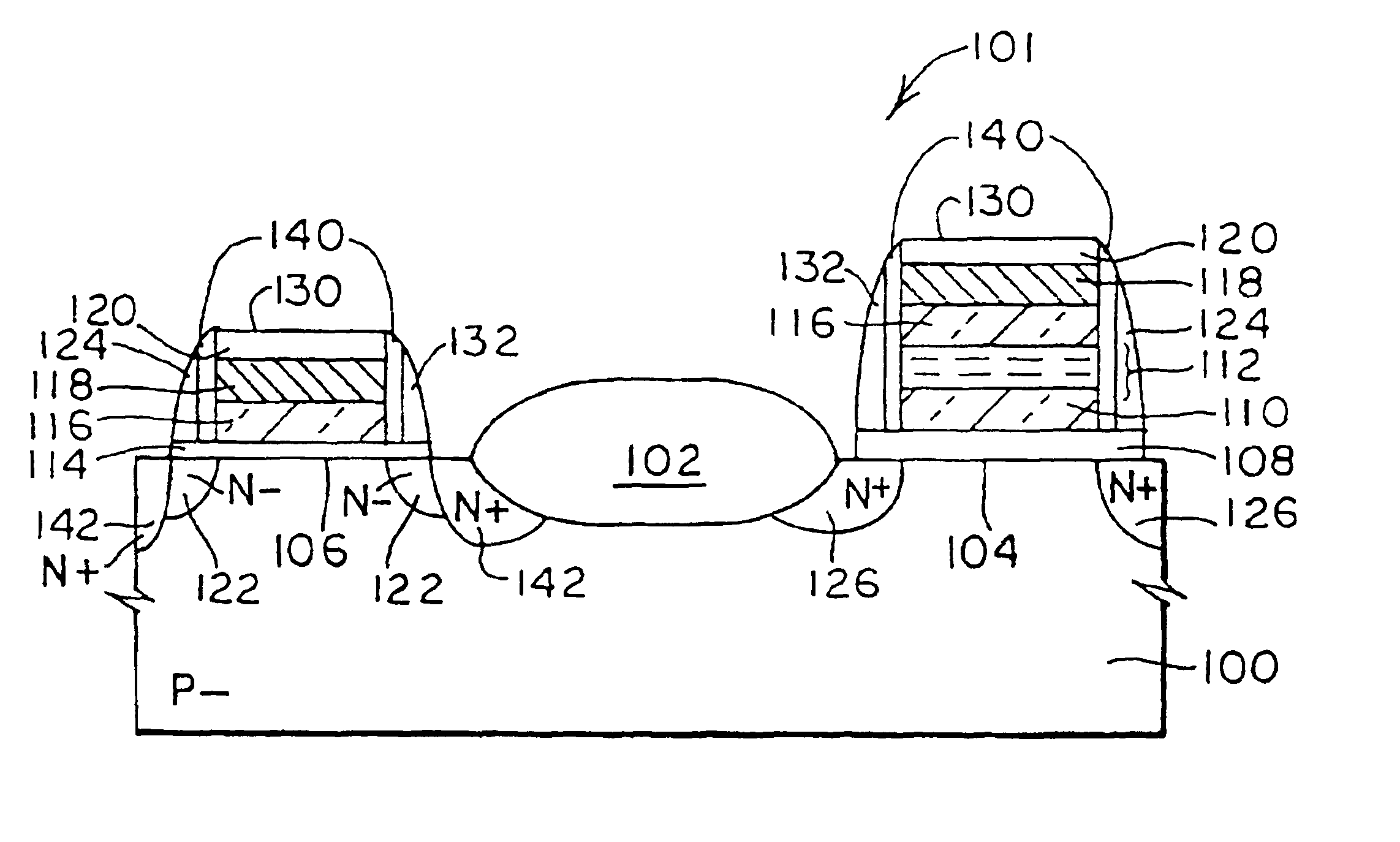

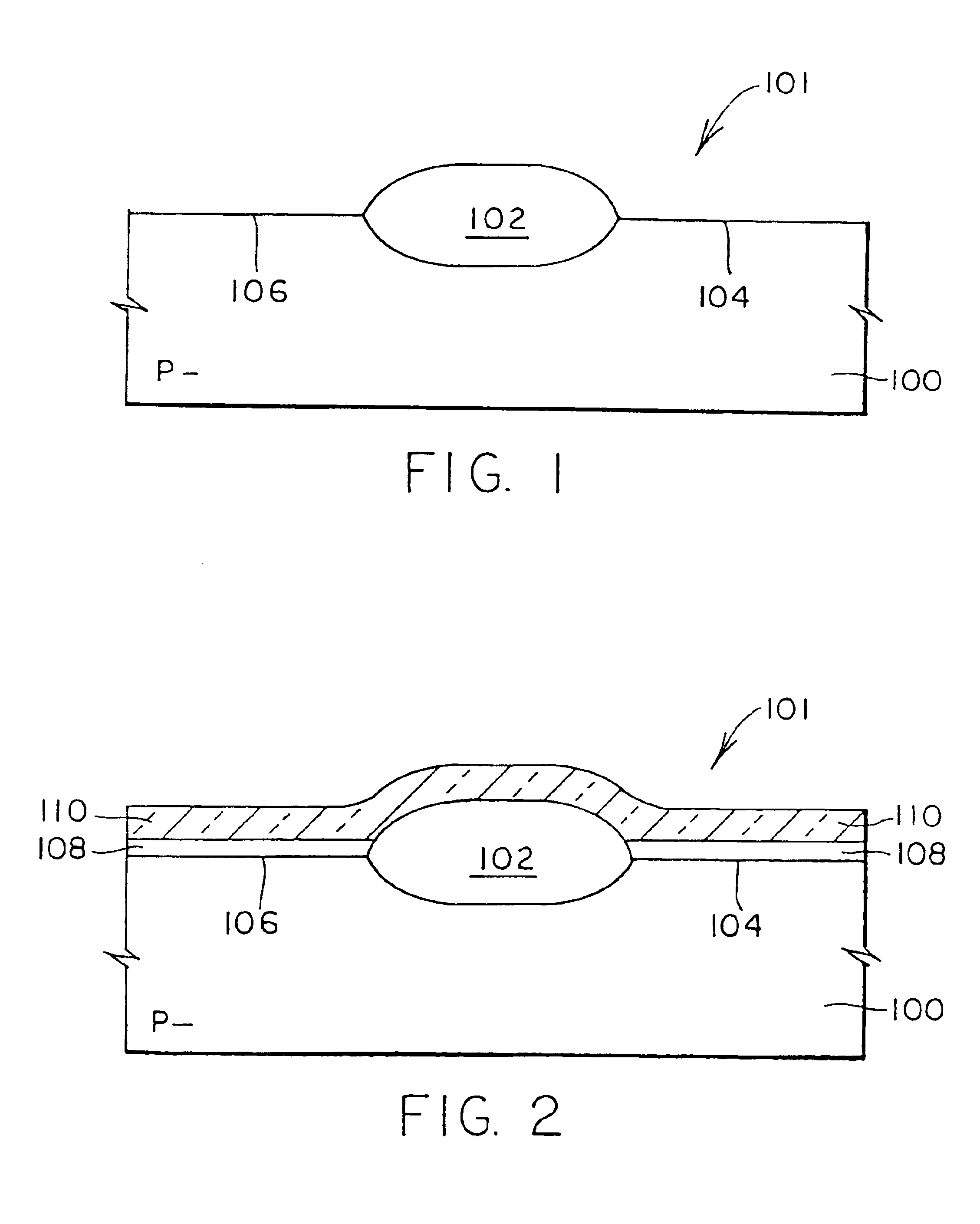

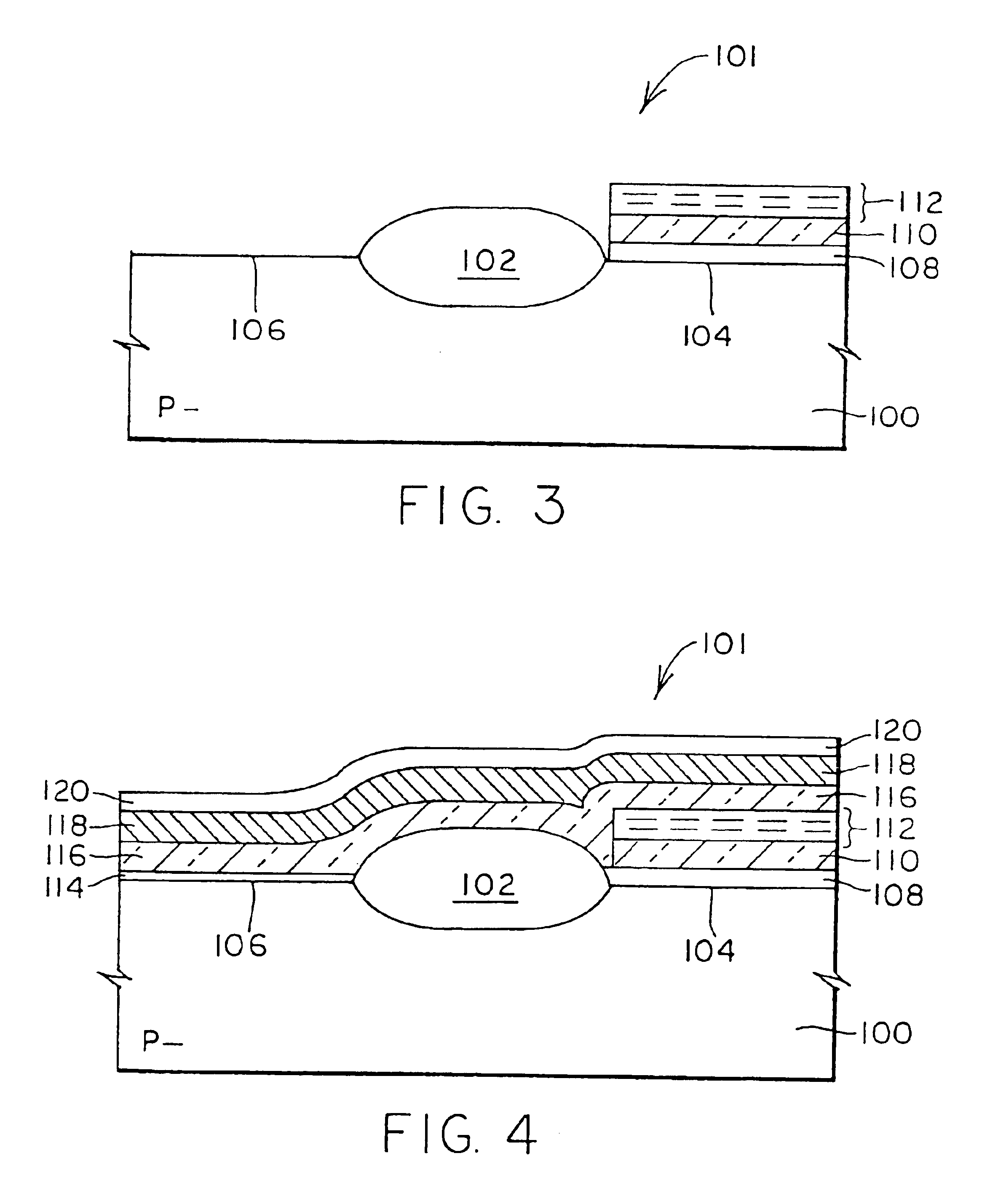

Non-oxidizing spacer densification method for manufacturing semiconductor devices

InactiveUS6849510B2Low costHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingMOSFETSalicide

Non-oxidizing spacer densification method for producing semiconductor devices, such as MOSFET devices, and that may be implemented during semiconductor fabrication with little or substantially no polycide adhesion loss experienced during spacer densification. The method may be implemented to provide good polycide adhesion characteristics with reduced process complexity over conventional methods by eliminating the need for additional process steps such as metal silicide encapsulation or polysilicon surface treatments.

Owner:MAXIM INTEGRATED PROD INC

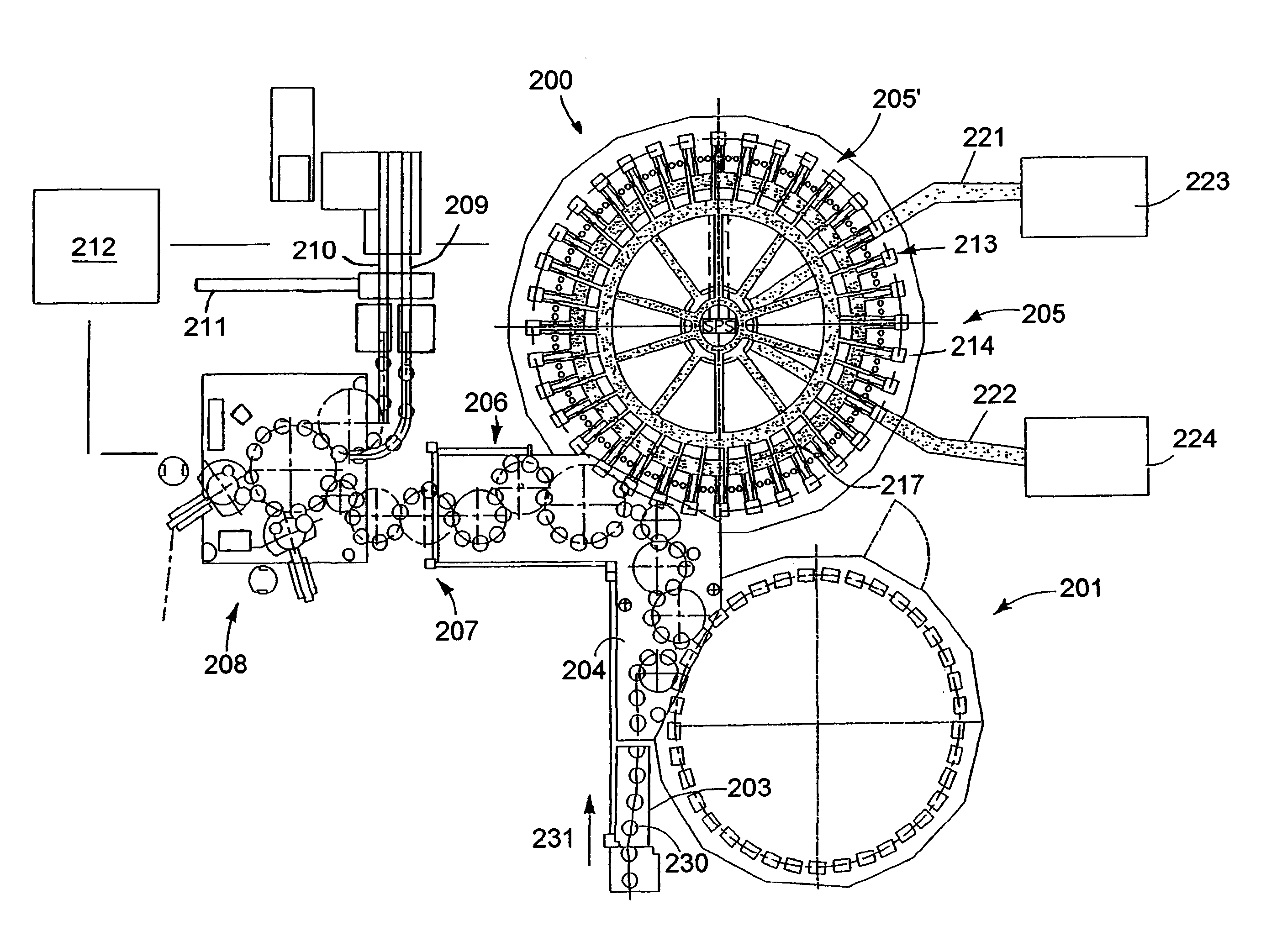

Labeling arrangement for labeling beverage bottles

InactiveUS20100059163A1Easily releaseMaximum adhesionMechanical working/deformationLamination ancillary operationsTrademarkEngineering

A labeling arrangement for labeling beverage bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

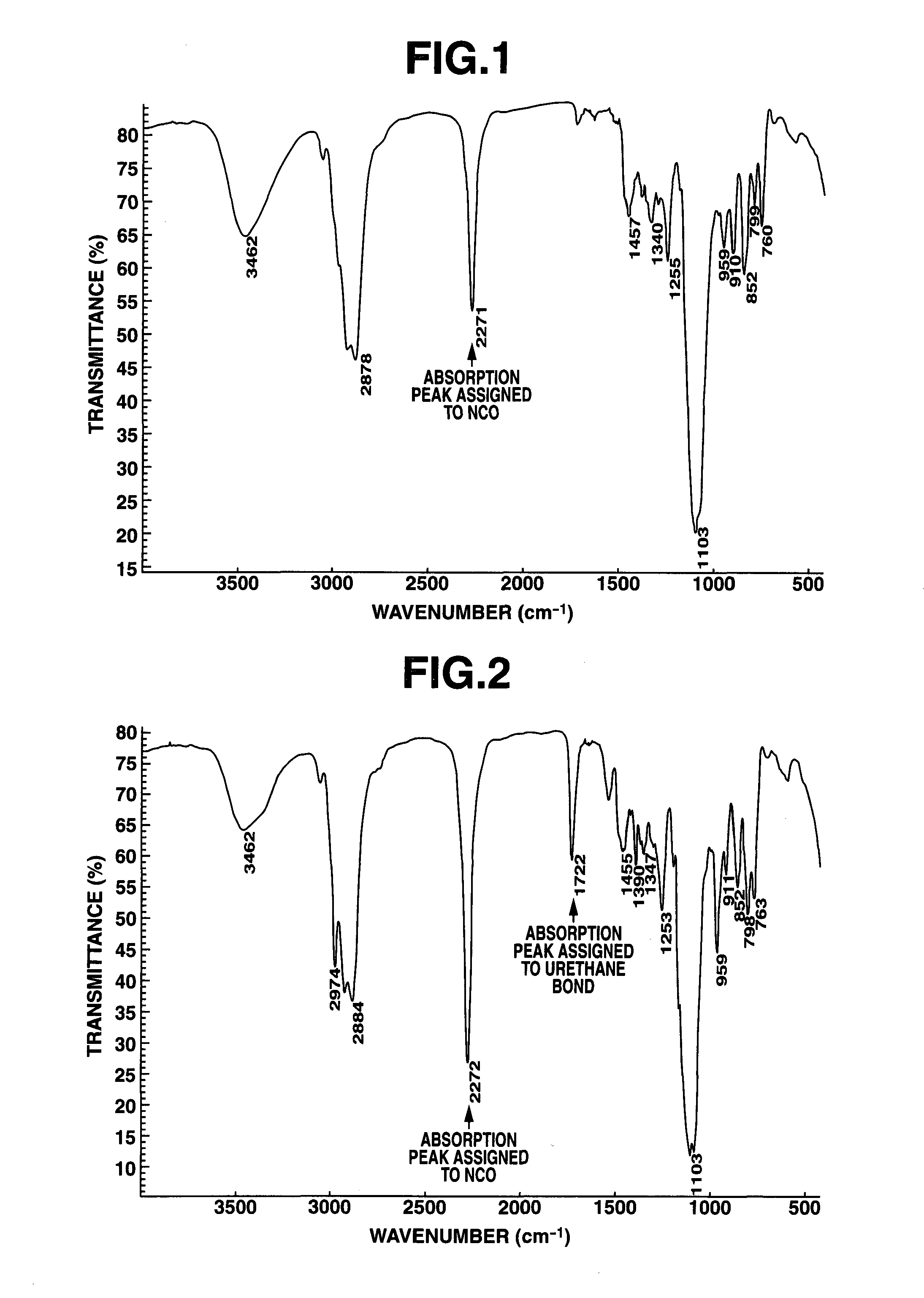

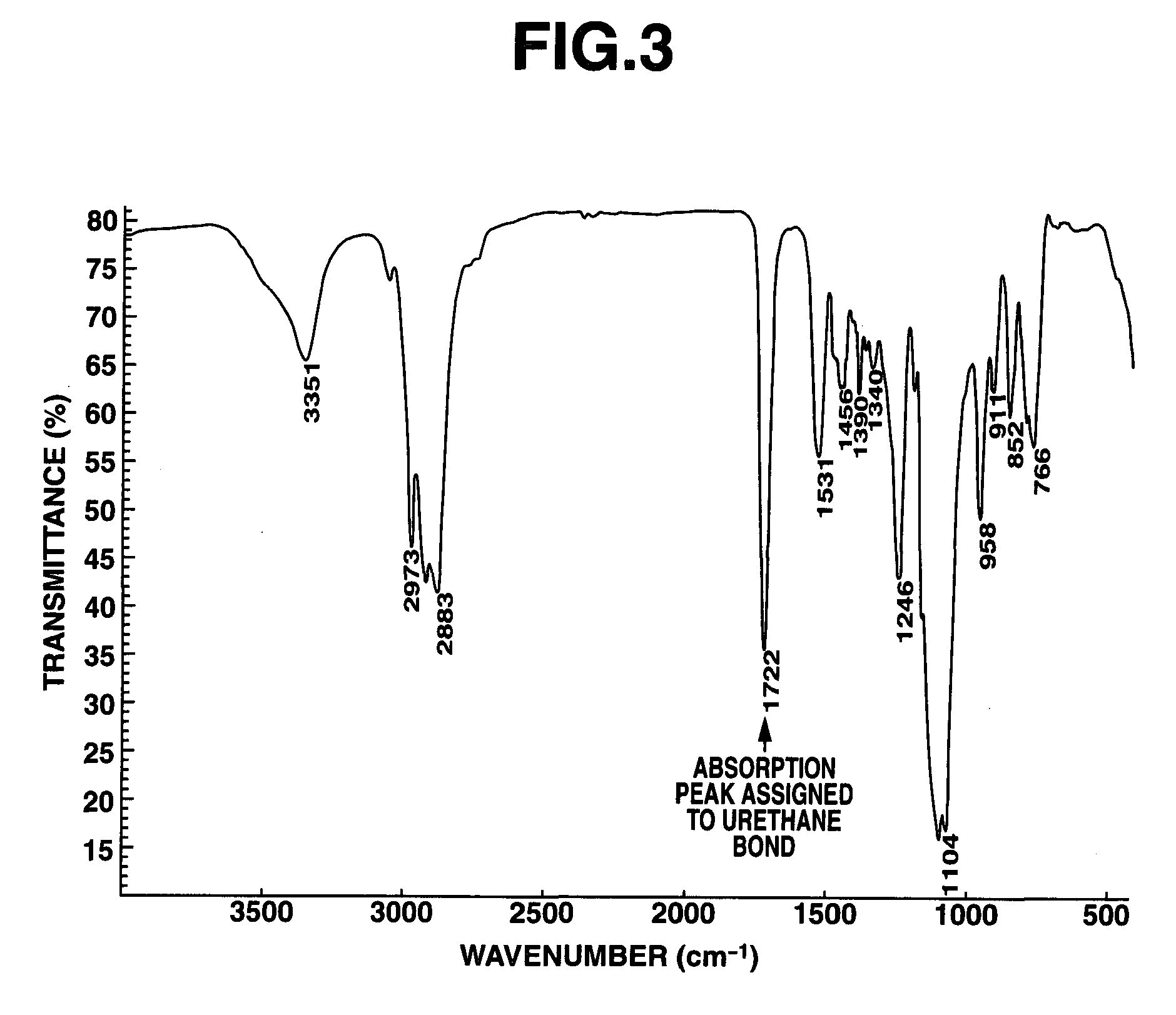

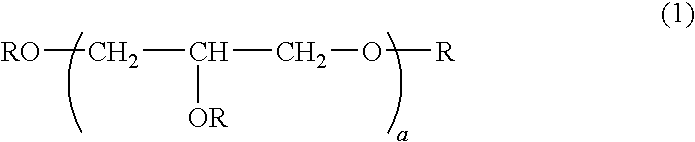

Polyfunctional epoxy-containing organosilicon compound, making method, coating composition, and coated article

ActiveUS20090286924A1Increase the number ofHigh bonding strengthGroup 4/14 element organic compoundsEpoxyEther

A polyglycidyl ether compound having a plurality of epoxy groups and a hydroxy group in the molecule is reacted with a silane coupling agent having an isocyanate group, and specifically the hydroxyl group on the polyglycidyl ether compound is reacted with the isocyanate group on the silane coupling agent. Then an organosilicon compound having a plurality of epoxy groups per alkoxysilyl group is synthesized wherein the ratio of epoxy groups to alkoxysilyl groups may be adjusted as desired. The resulting organosilicon compound is useful as a primer and resin modifier.

Owner:SHIN ETSU CHEM IND CO LTD

Multilayer article having cold seal coatings

InactiveUS20140079894A1Reduce decreaseAvoid unnecessary wasteEnvelopes/bags making machineryStampsElectrical and Electronics engineeringCoating

The present invention relates to a multilayer article comprising a first substrate with a first backing layer and comprising at least one further (second) substrate with a second backing layer, where these have been provided on respectively one side at least to some extent with a cold-seal adhesive layer and have been bonded to one another specifically via the contact between their respective cold-seal adhesive layers, to a process for the production of an article of this type, and also to the use of a printer with at least two unwind systems and with at least one cutting device for the production of articles of this type.

Owner:SIHL

Silane-modified polyether sealant and preparation method therefor

InactiveCN105111993AExtensive adhesionEasy to operateNon-macromolecular adhesive additivesOther chemical processesPlasticizerSealant

The present invention discloses silane-modified polyether sealant. The sealant is prepared by mixing the following raw materials in proportion by weight: 20-30% of silane-modified polyether prepolymer, 10-30% of a plasticizer, 50-70% of reinforcing incremental powder, 0.1-0.5% of a light stabilizer, 0.5-1% of a dehydrating agent, 0.5-1% of of an adhesion promoter and 0.1-0.5% of a catalyst. The sealant provided by the present invention is cured after contacting moisture under the action of the catalyst, simple in operation, cured quickly,and is tasteless, nontoxic, green, safe and environmentally friendly. Meanwhile, the sealant can realize strong bonding and ensure that wood floor will not warp or deform after long-period use. The sealant contains no moisture and actively isolates a back plate from invasion of ground moisture. Therefore, the sealant is an ideal adhesive sealing material in floor bonding.

Owner:深圳市隆邦新材料科技有限公司

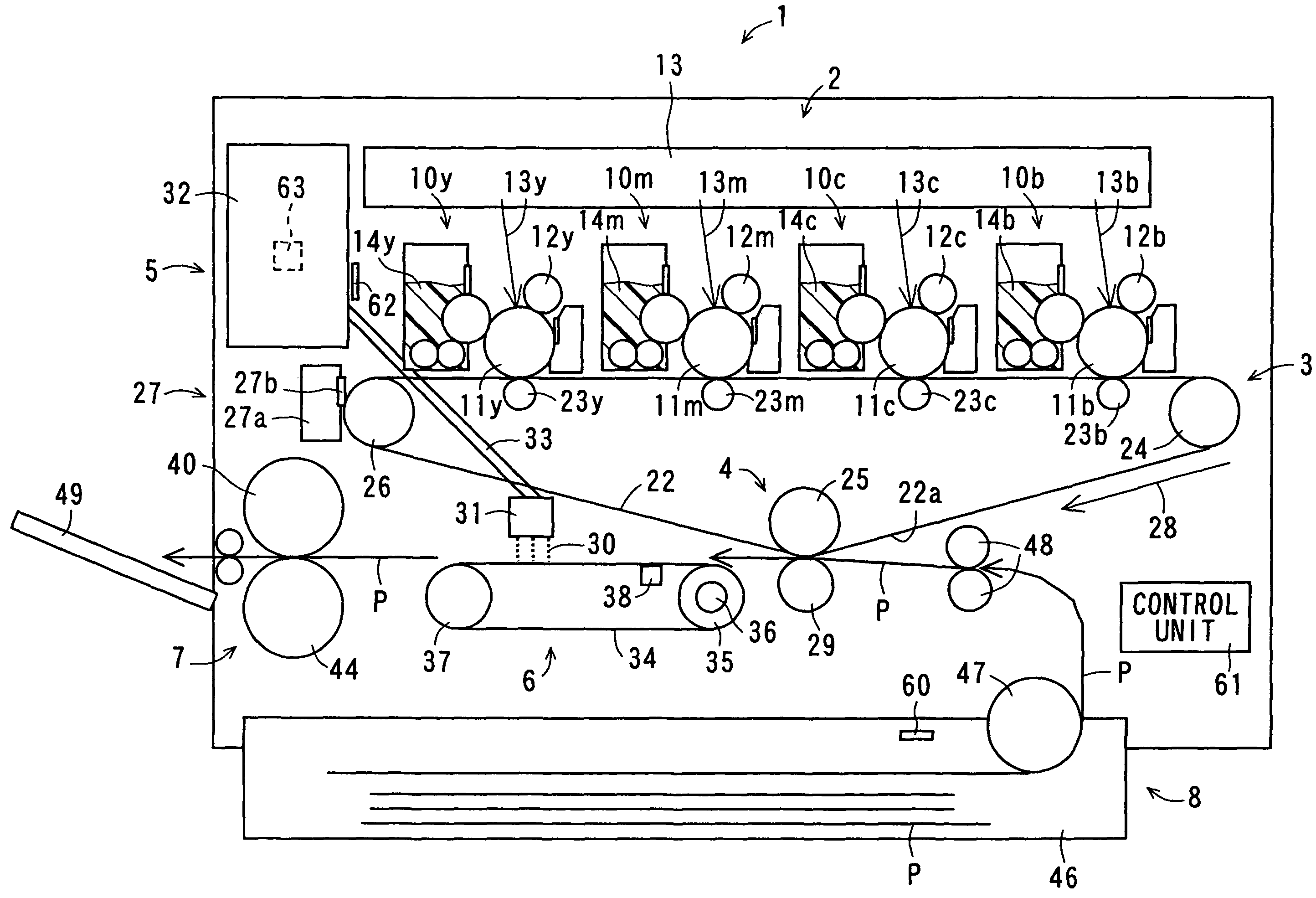

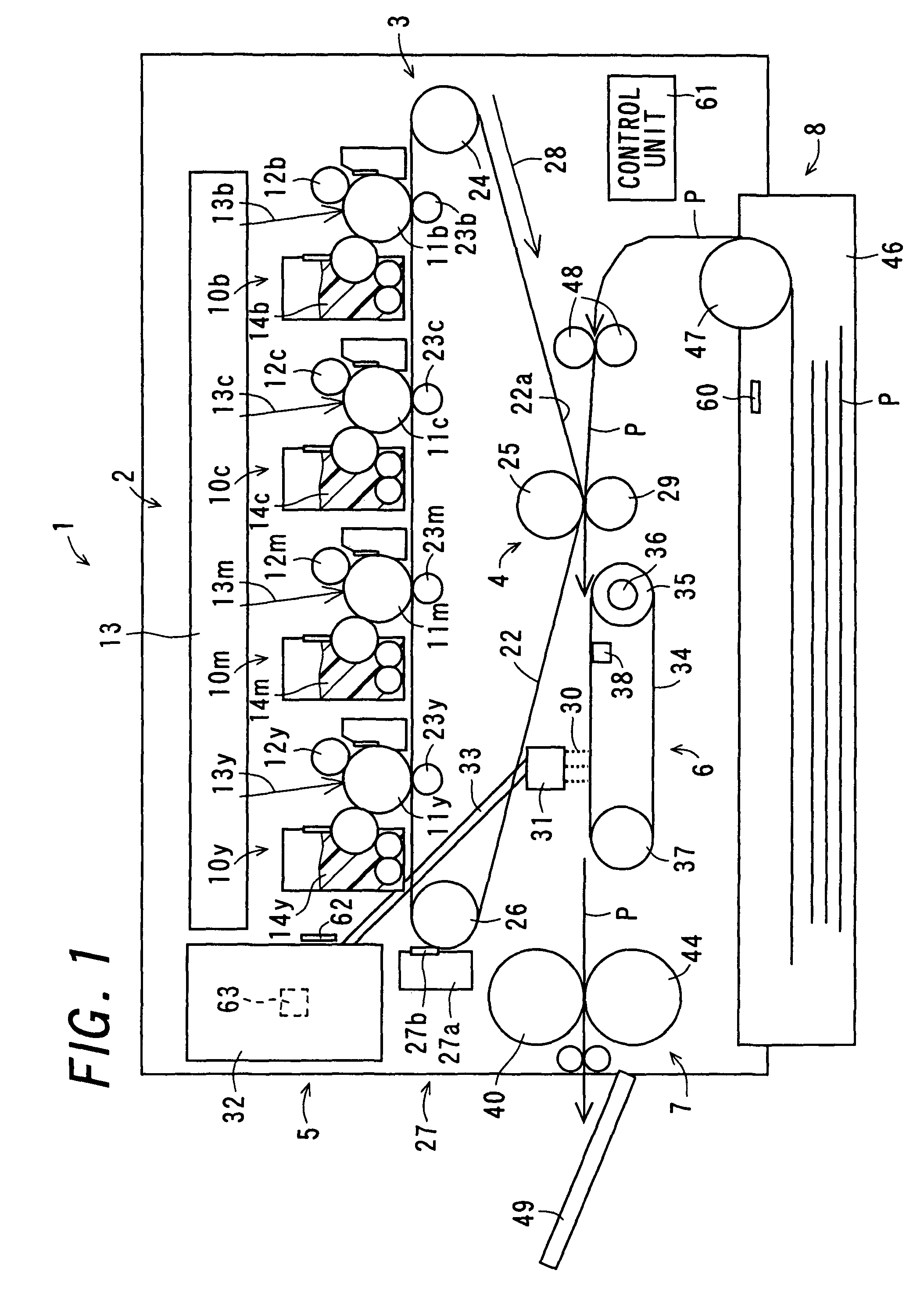

Image forming apparatus

InactiveUS20070253757A1Good colorReduce the amount requiredElectrographic process apparatusImage formationRecording media

There is provided an image forming apparatus involving wet fixing that causes no bleeding and coagulation of toner and eventually no disturbance of toner image as a result of application of a fixing fluid, generates no curling or wrinkles in a recording medium, and can fix toner with large adhesion on a recording medium through which the fixing fluid hardly permeates. An image forming apparatus includes a toner image forming section, an intermediate transfer section, a transfer section, a fixing fluid applying section, a transport section, a fixing section, a recording medium feeding section, and a recording medium detection section. In the image forming apparatus, control of application amount of a fixing fluid to a recording medium is performed by the fixing fluid applying section based on the result obtained by the recording medium detection section for the recording medium such as thickness and material.

Owner:SHARP KK

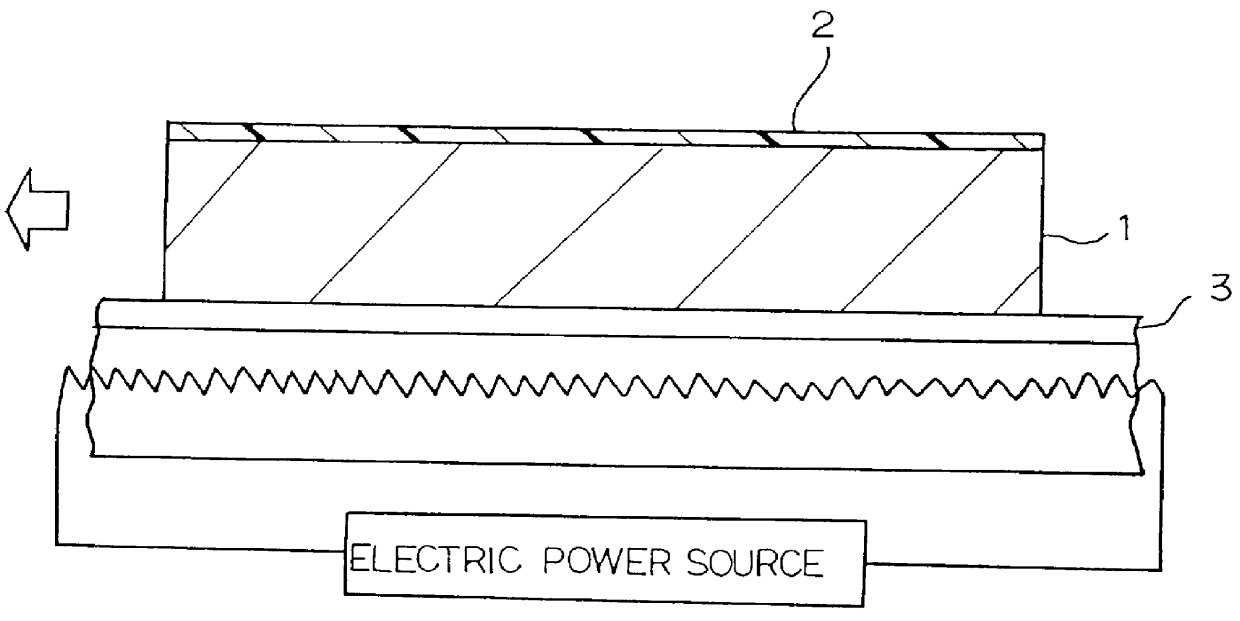

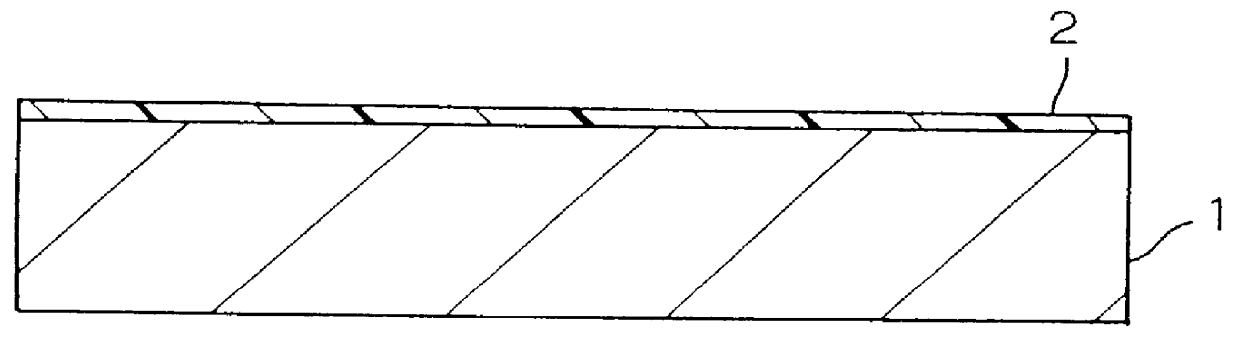

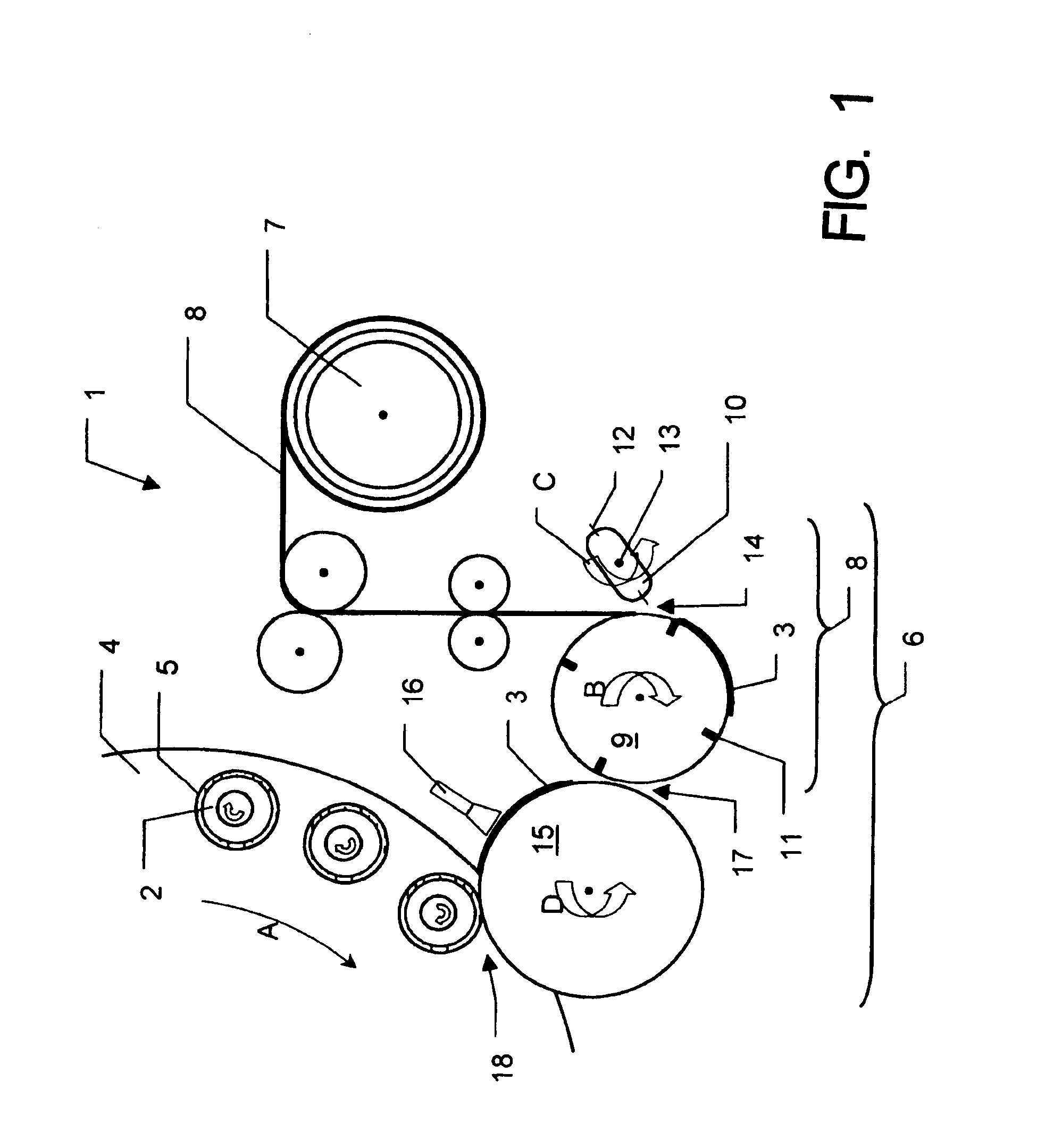

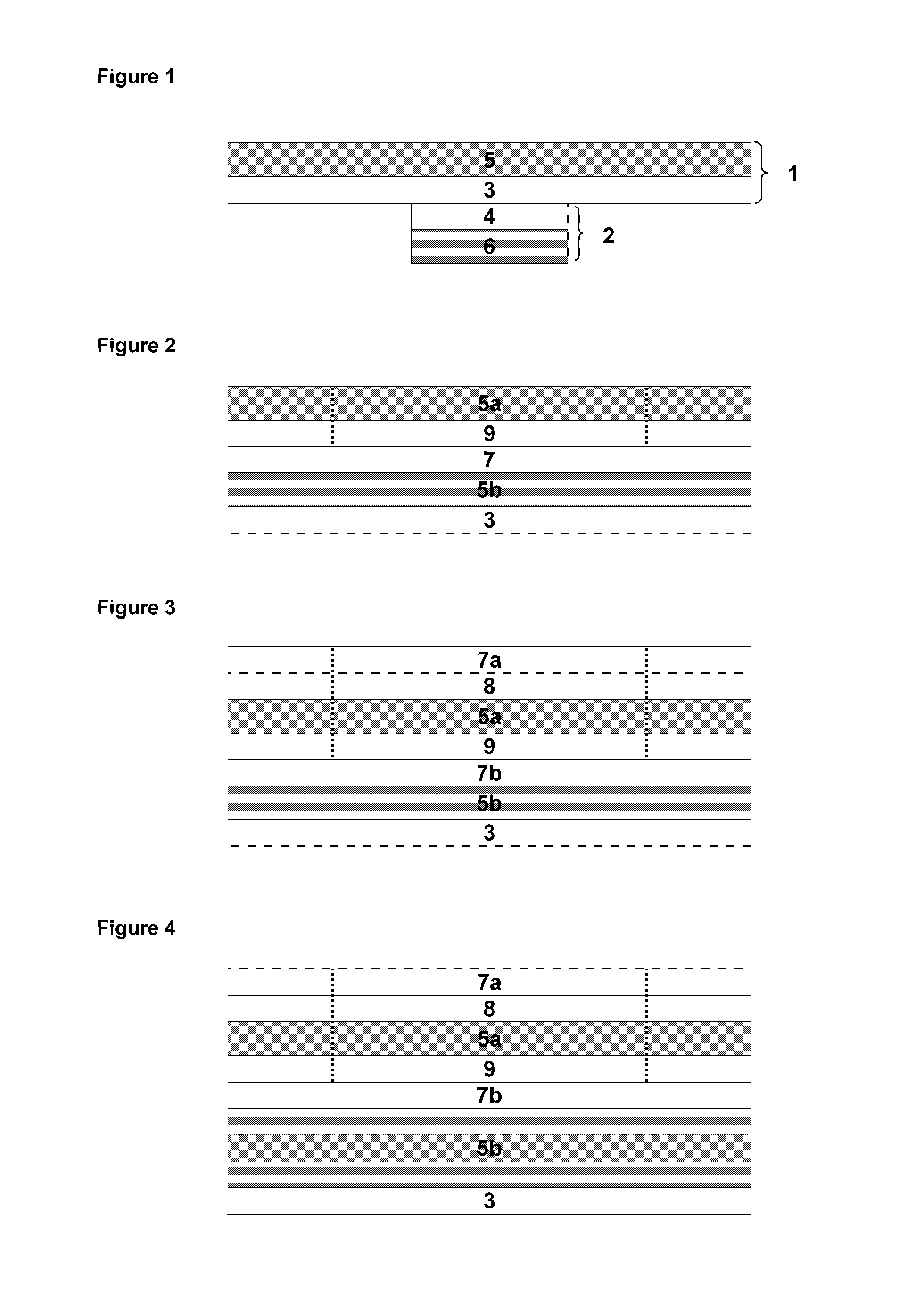

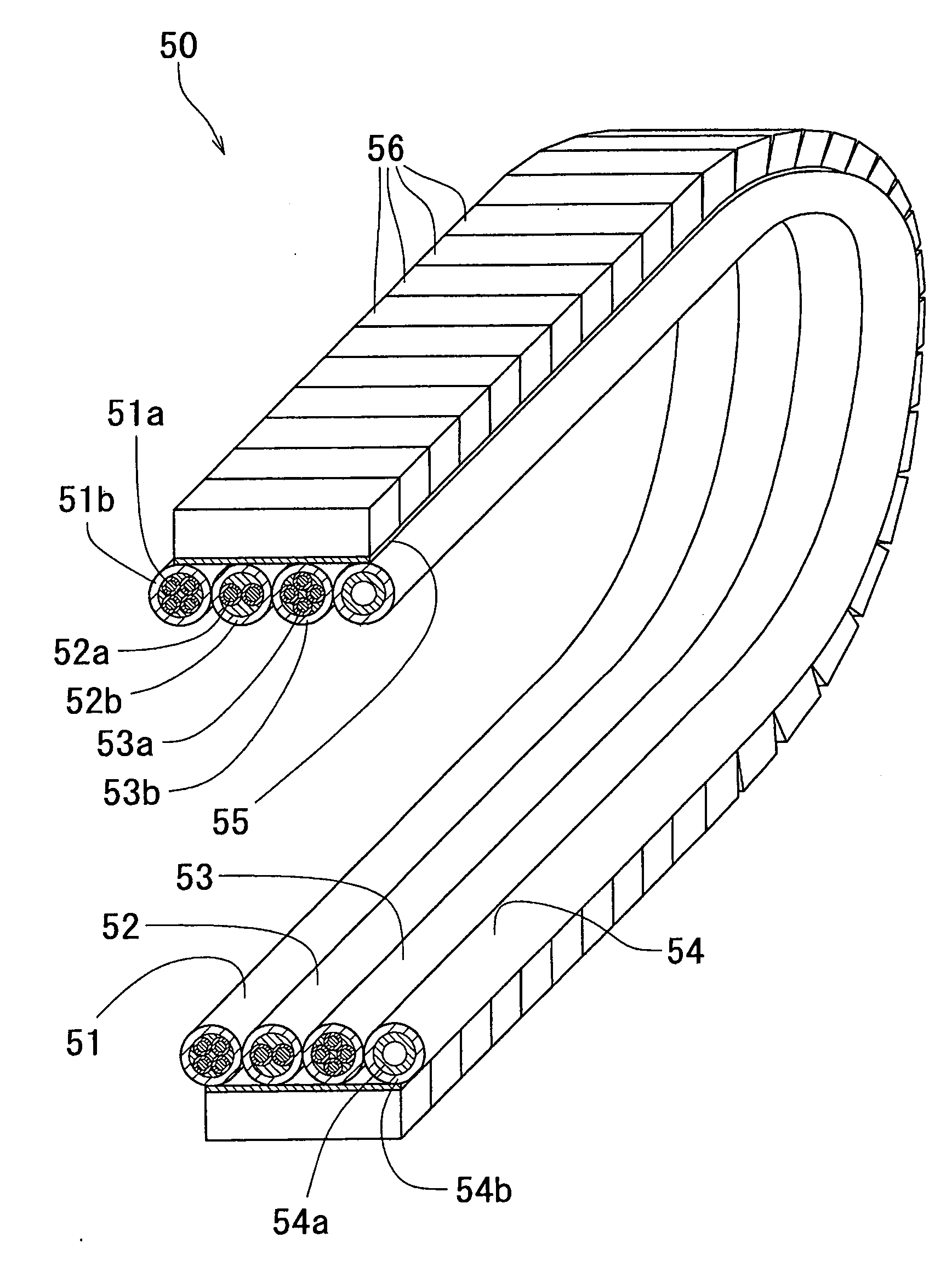

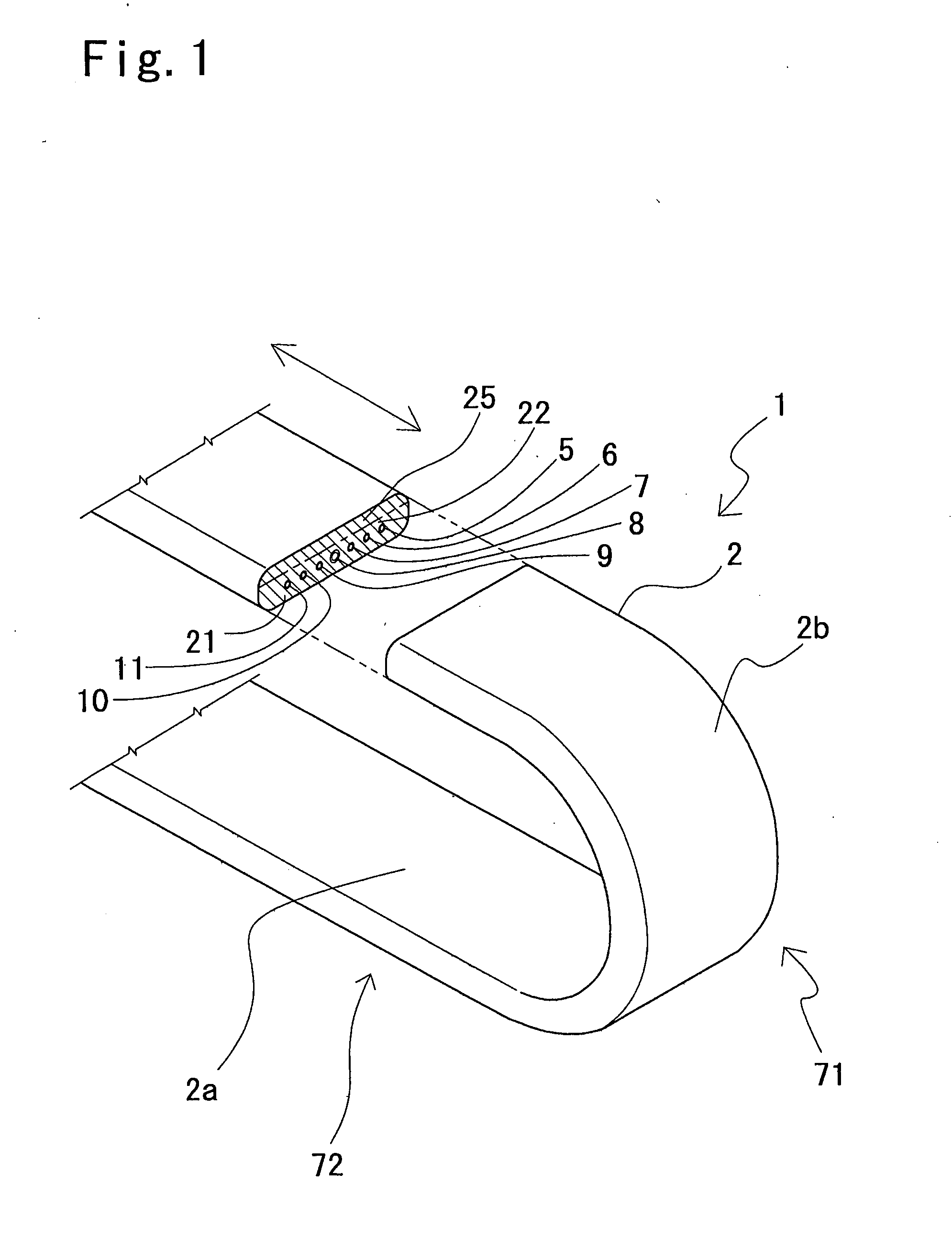

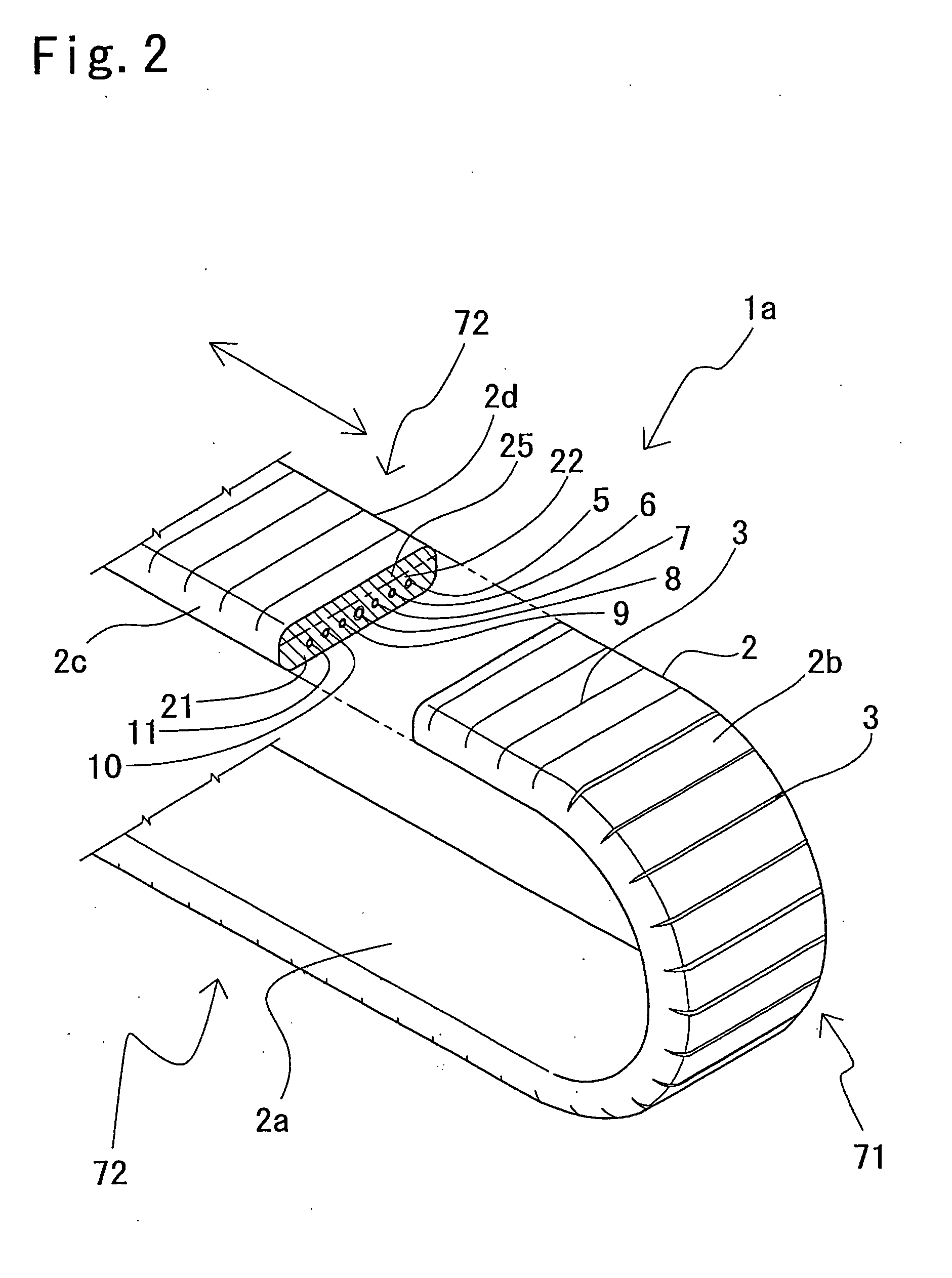

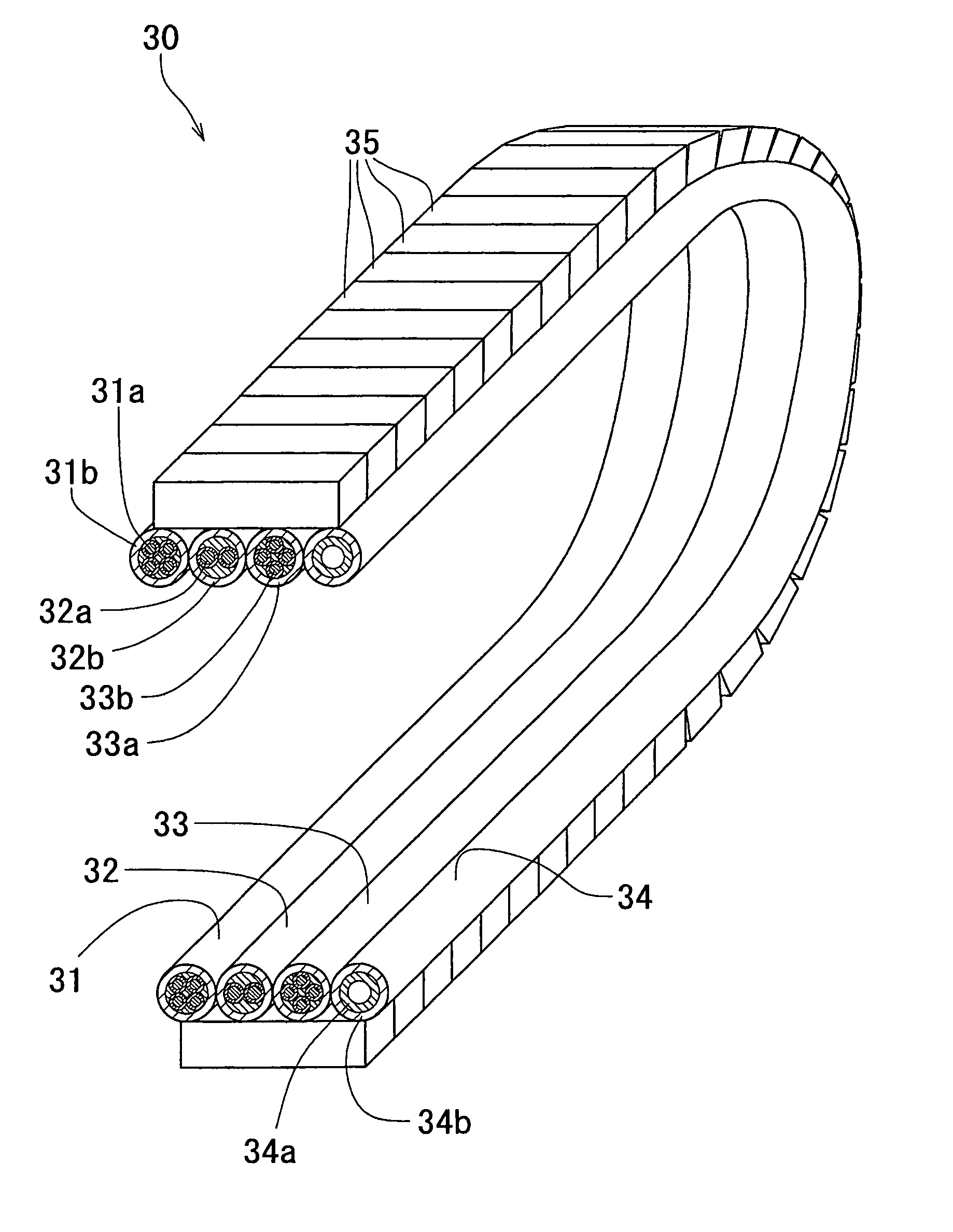

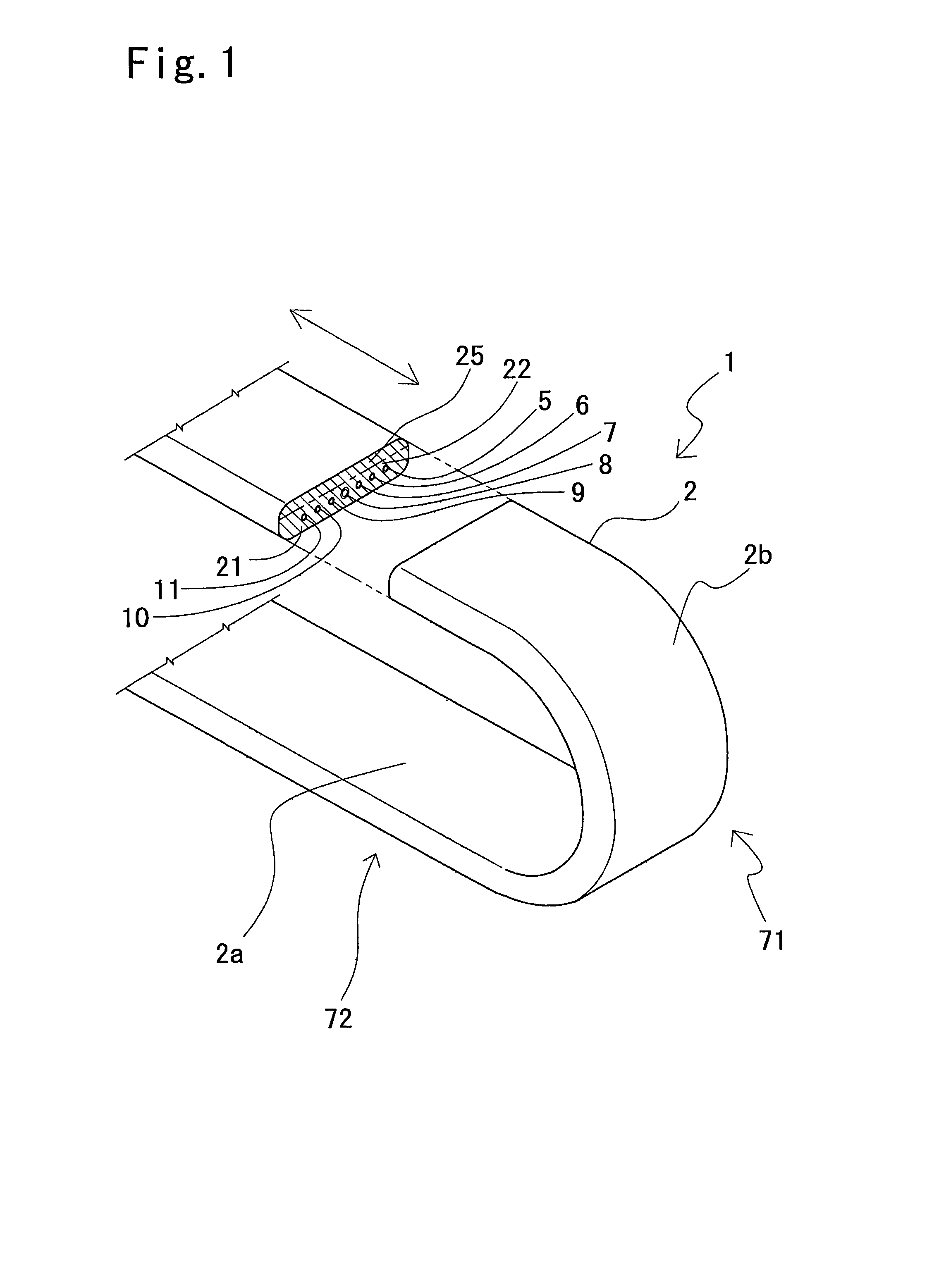

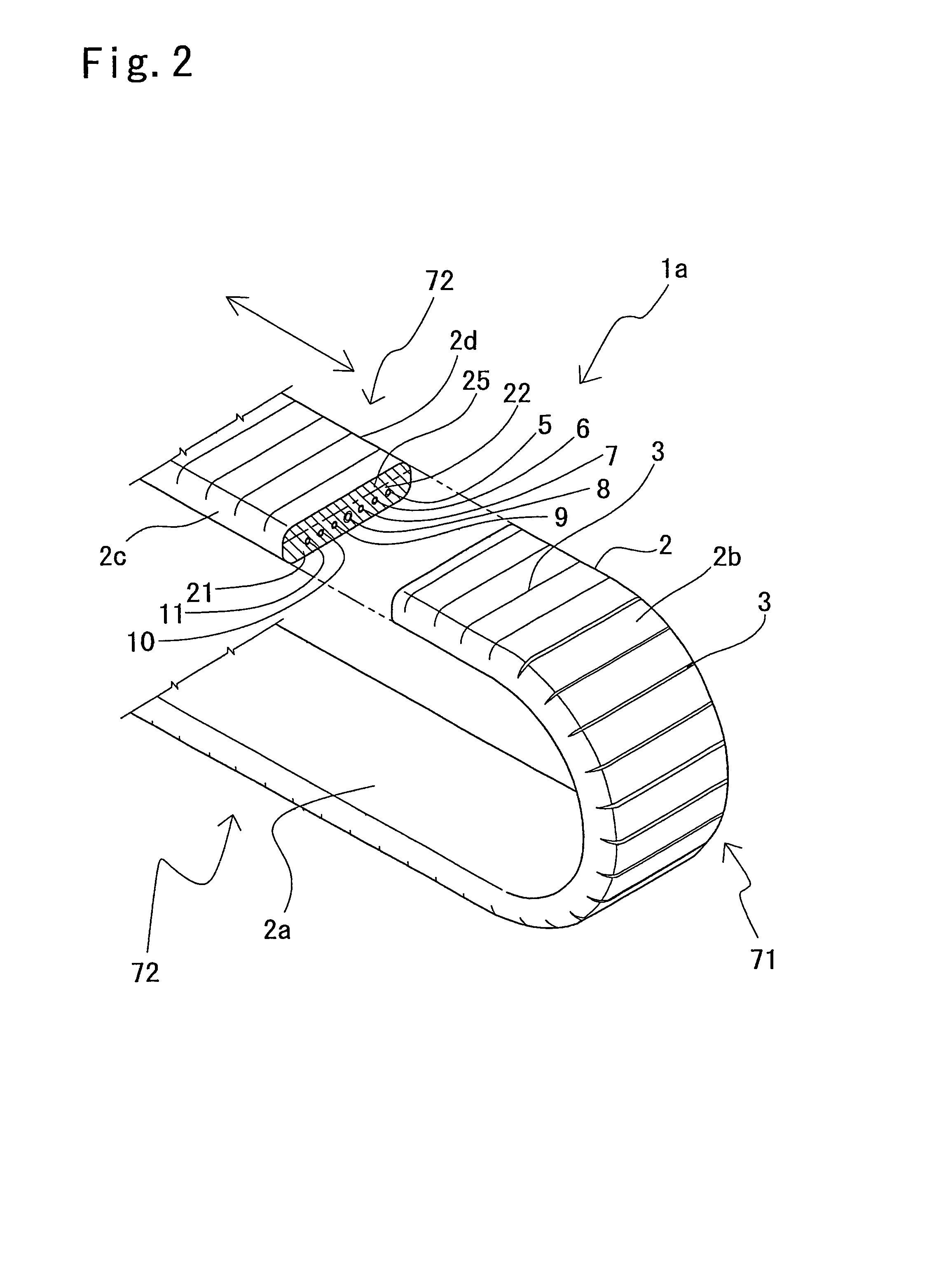

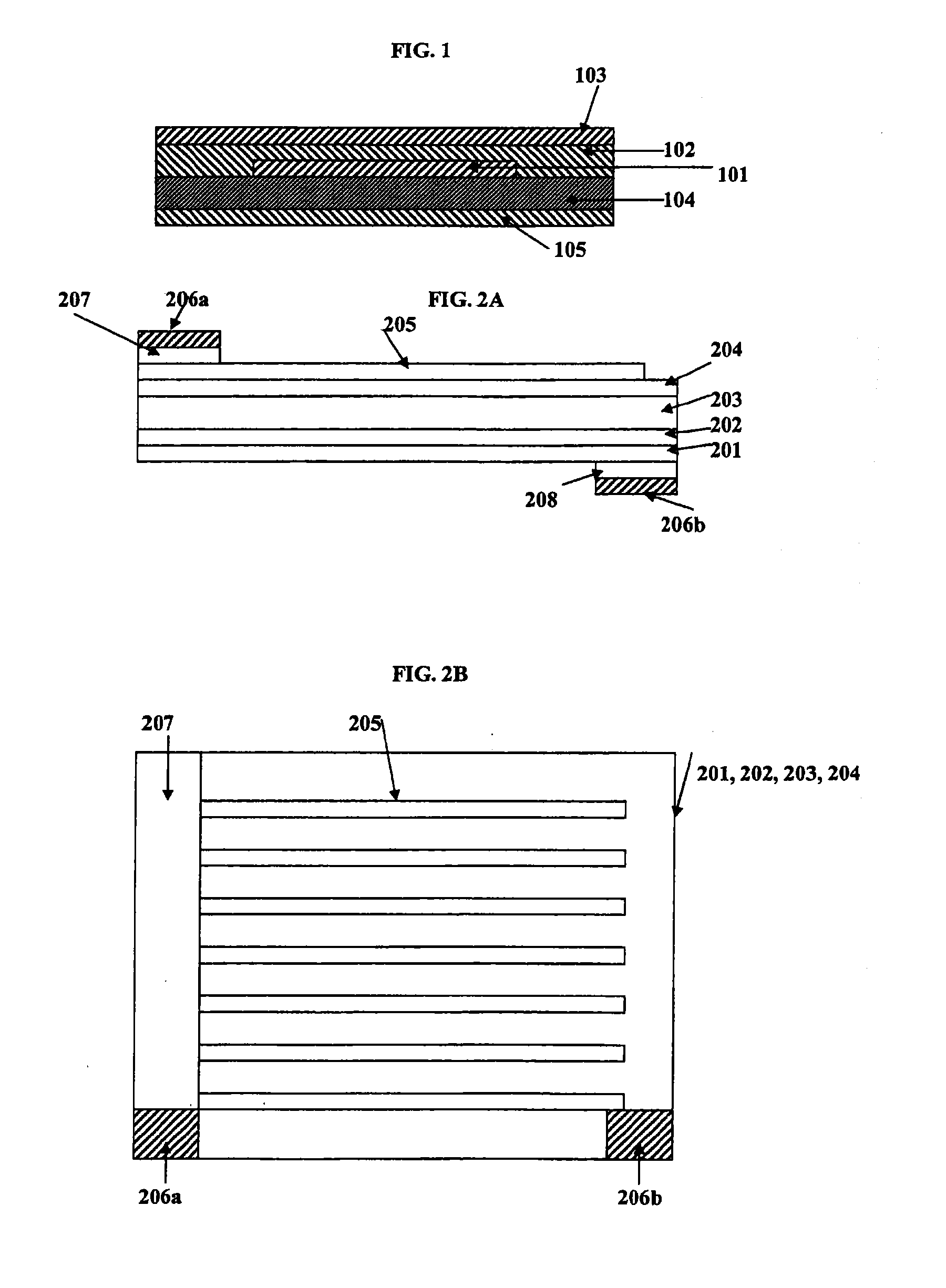

Elongated structure for movable section

ActiveUS20110204190A1Suppress of creationSuppress generationPipe supportsInsulated cablesLinear elementBiomedical engineering

In an elongated structure for a movable section, a plurality of operational linear elements such as conductive wires are arranged in parallel in a belt-like sheath member, and an outer region of the sheath member, which is defined by a bend of the sheath member, has a larger rigidity than that of an inner region of the sheath member, which is defined by the bend of the sheath member. When the sheath member 2 have the regions exhibiting the different rigidities, and when an external force is exerted on the elongated structure 1 for the movable section, it is apt to bend toward the side of the sheath member having the small rigidity, and the bent portion is maintained at a given curvature which is determined by the entire rigidity of the sheath member 2. Therefore, the elongated structure 1 for the movable section cannot easily meander while the movable end thereof is moved. Also, while the position of the bent portion is shifted, it is possible to stably carry out the movement of the movable end and the shift of the bent portion. In addition, a protective guide structure is not needed, and not only can an installing space for the elongated structure 1 for the movable section become smaller, but also it is possible to cut down a cost necessary for such a protective guide structure.

Owner:DAIDEN CO LTD

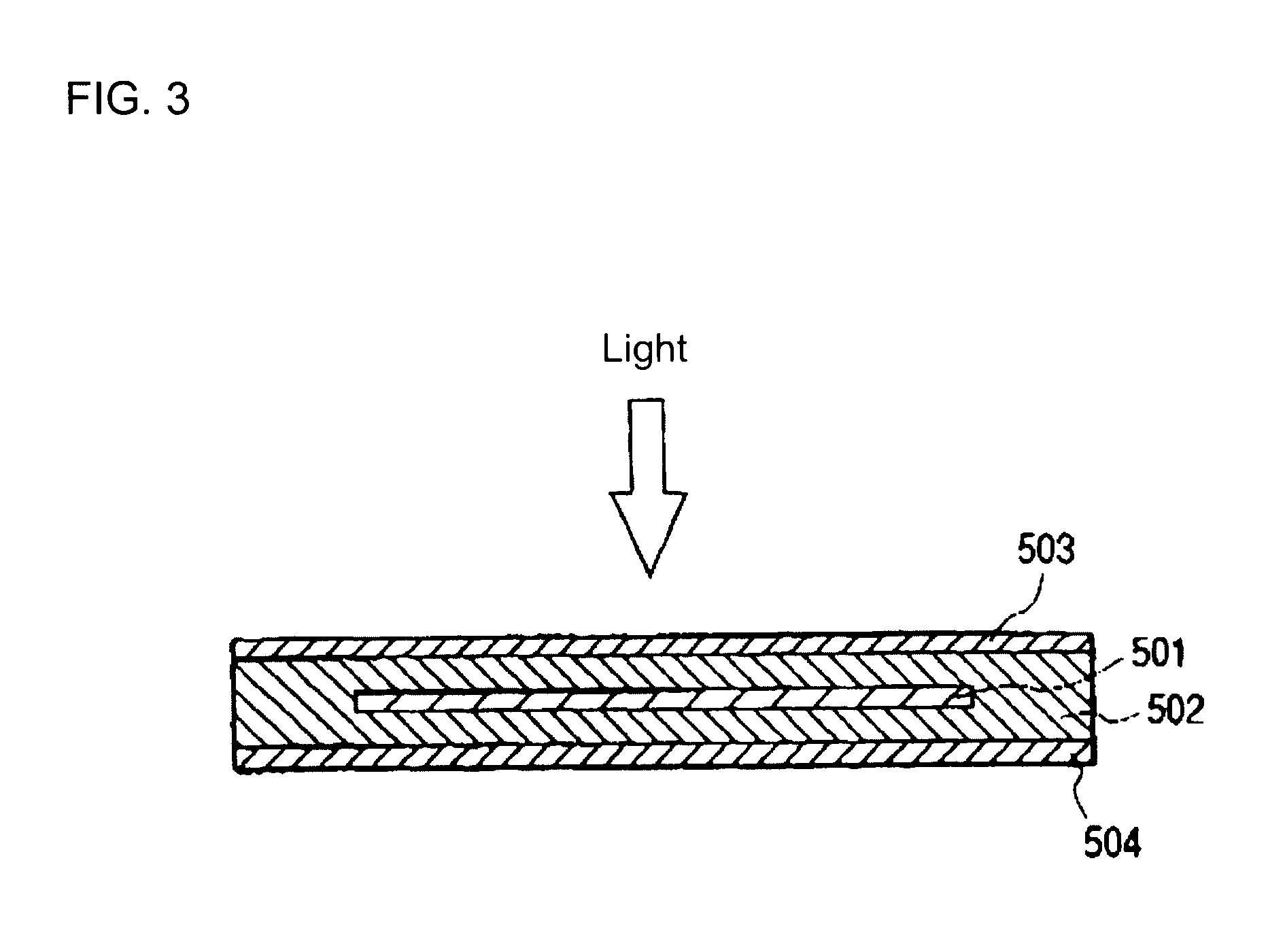

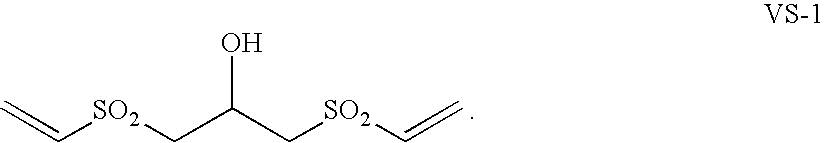

Thermally developable materials with backside conductive layer

InactiveUS20060046932A1Improve conductive efficiencyExceptional conductivityPhotosensitive materialsAblative recordingOptoelectronicsAntimonate

Thermally developable materials that comprise a support have a conductive backside layer that has increased conductive efficiency. Conductivity is provided by non-acicular metal antimonate particles that are present in an amount greater than 55 and up to 85 dry weight % at a coverage of from about 0.06 to about 0.5 g / m2, and the ratio of total binder polymers in the backside conductive layer to the non-acicular metal antimonate particles is less than 0.75:1 (dry weights). The level of conductive particles is reduced from previous uses without an unacceptable loss in conductivity. In addition, the dry thickness of the conductive layer is considerably reduced.

Owner:CARESTREAM HEALTH INC

Image forming apparatus controlling a droplet size of a fixing solution

InactiveUS7747207B2Reduce amount of heat energyGenerates no curling or wrinklesElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a toner image forming section, an intermediate transferring section, a transferring section, a fixing solution applying section, a transporting section, a fixing section, and a recording medium feeding section. In the image forming apparatus, the fixing solution applying section includes a droplet supplying section, a recording medium detecting section, and a control unit, wherein the recording medium is heated before or at the same time when the fixing solution is applied to the recording medium by the fixing solution applying section, and a size of droplets of the fixing solution supplied to the recording medium is controlled based on the type of the recording medium.

Owner:SHARP KK

Elongated structure for movable section

ActiveUS8950714B2Low costSuppress of creationPipe supportsFlexible pipesLinear elementBiomedical engineering

In an elongated structure for a movable section, a plurality of operational linear elements such as conductive wires are arranged in parallel in a belt-like sheath member, and an outer region of the sheath member, which is defined by a bend of the sheath member, has a larger rigidity than that of an inner region of the sheath member, which is defined by the bend of the sheath member. When the sheath member 2 have the regions exhibiting the different rigidities, and when an external force is exerted on the elongated structure 1 for the movable section, it is apt to bend toward the side of the sheath member having the small rigidity, and the bent portion is maintained at a given curvature which is determined by the entire rigidity of the sheath member 2. Therefore, the elongated structure 1 for the movable section cannot easily meander while the movable end thereof is moved. Also, while the position of the bent portion is shifted, it is possible to stably carry out the movement of the movable end and the shift of the bent portion. In addition, a protective guide structure is not needed, and not only can an installing space for the elongated structure 1 for the movable section become smaller, but also it is possible to cut down a cost necessary for such a protective guide structure.

Owner:DAIDEN CO LTD

Image forming apparatus

InactiveUS7546080B2Reduce the amount requiredReduce consumptionElectrographic process apparatusImage formationEngineering

Owner:SHARP KK

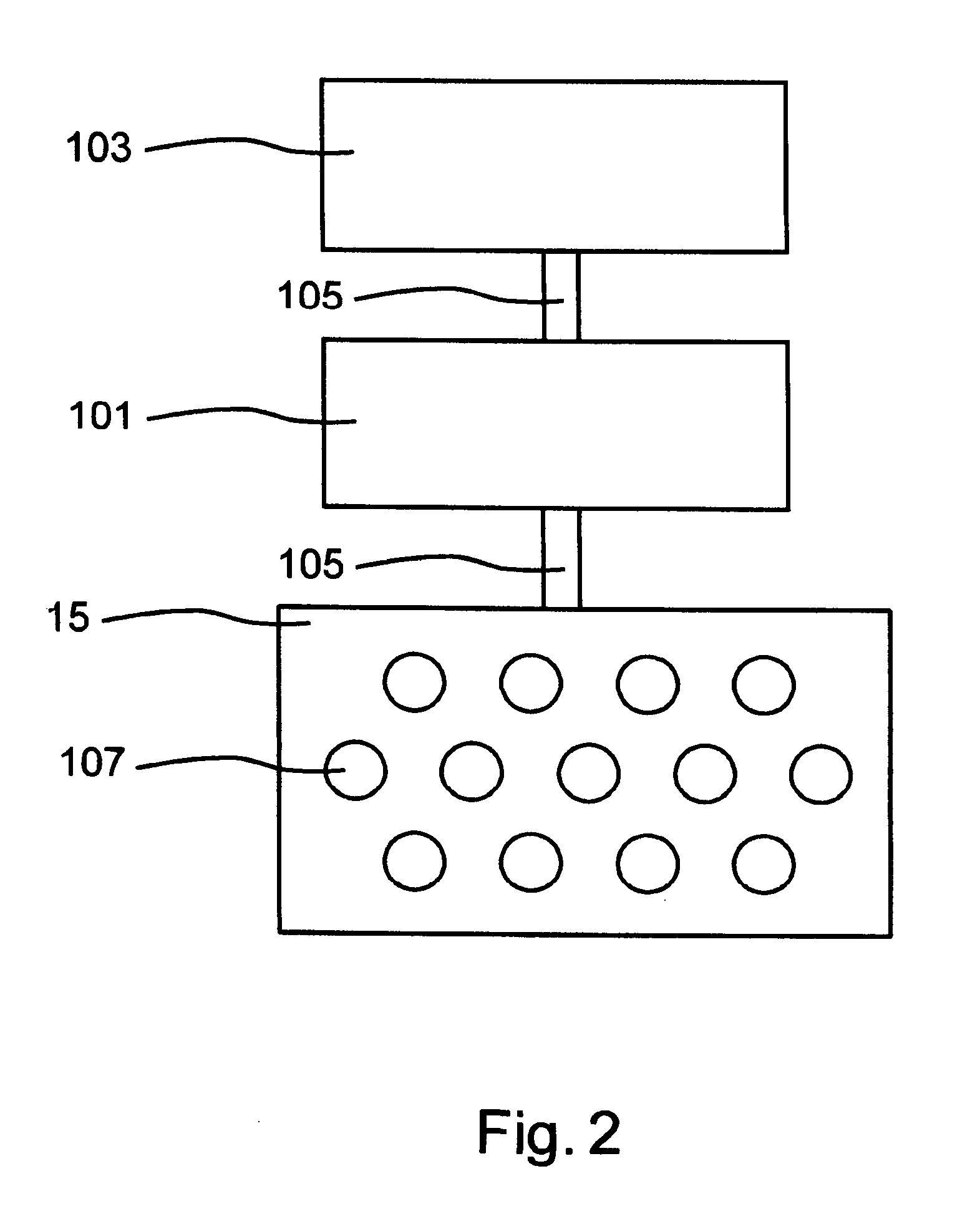

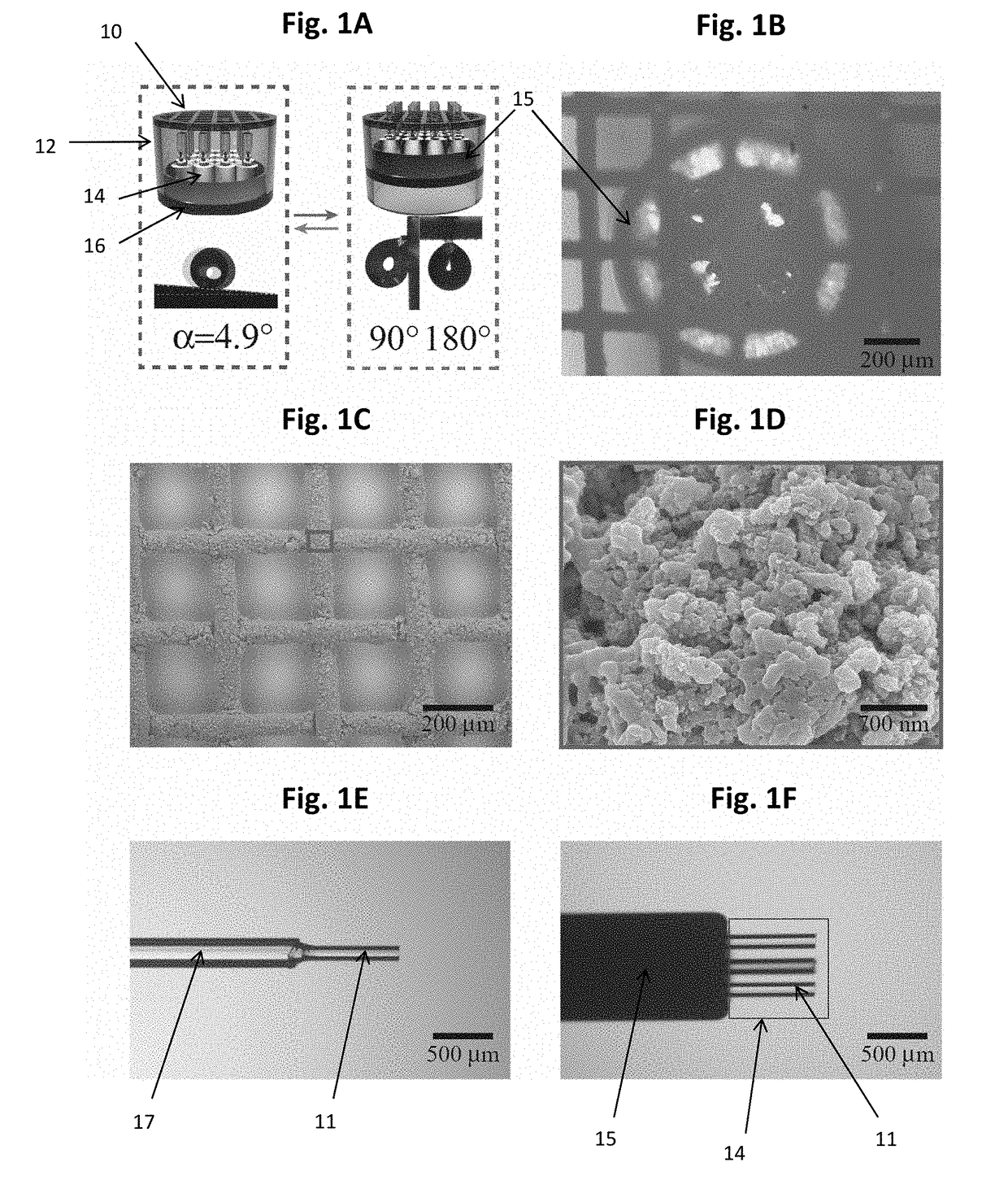

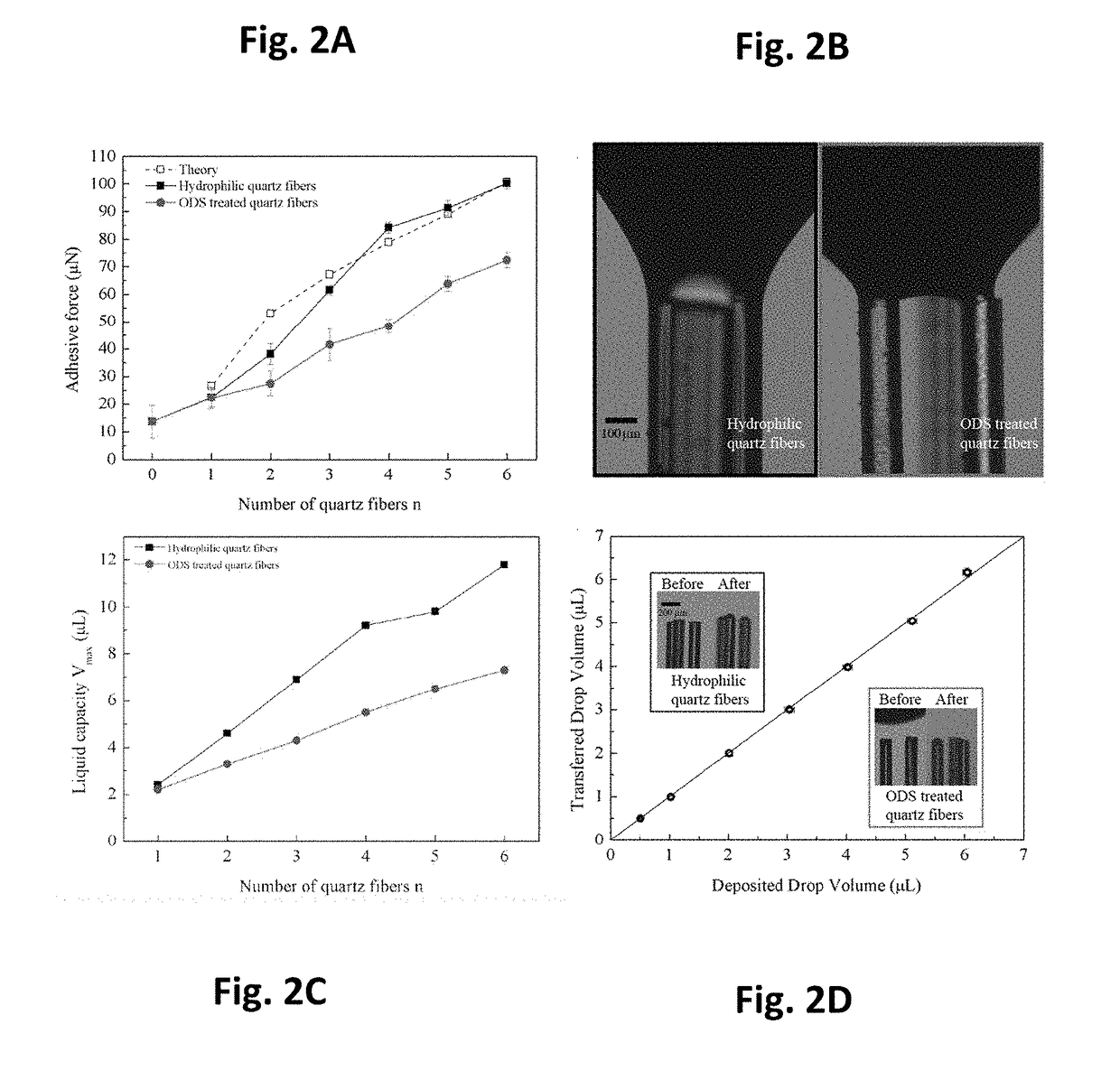

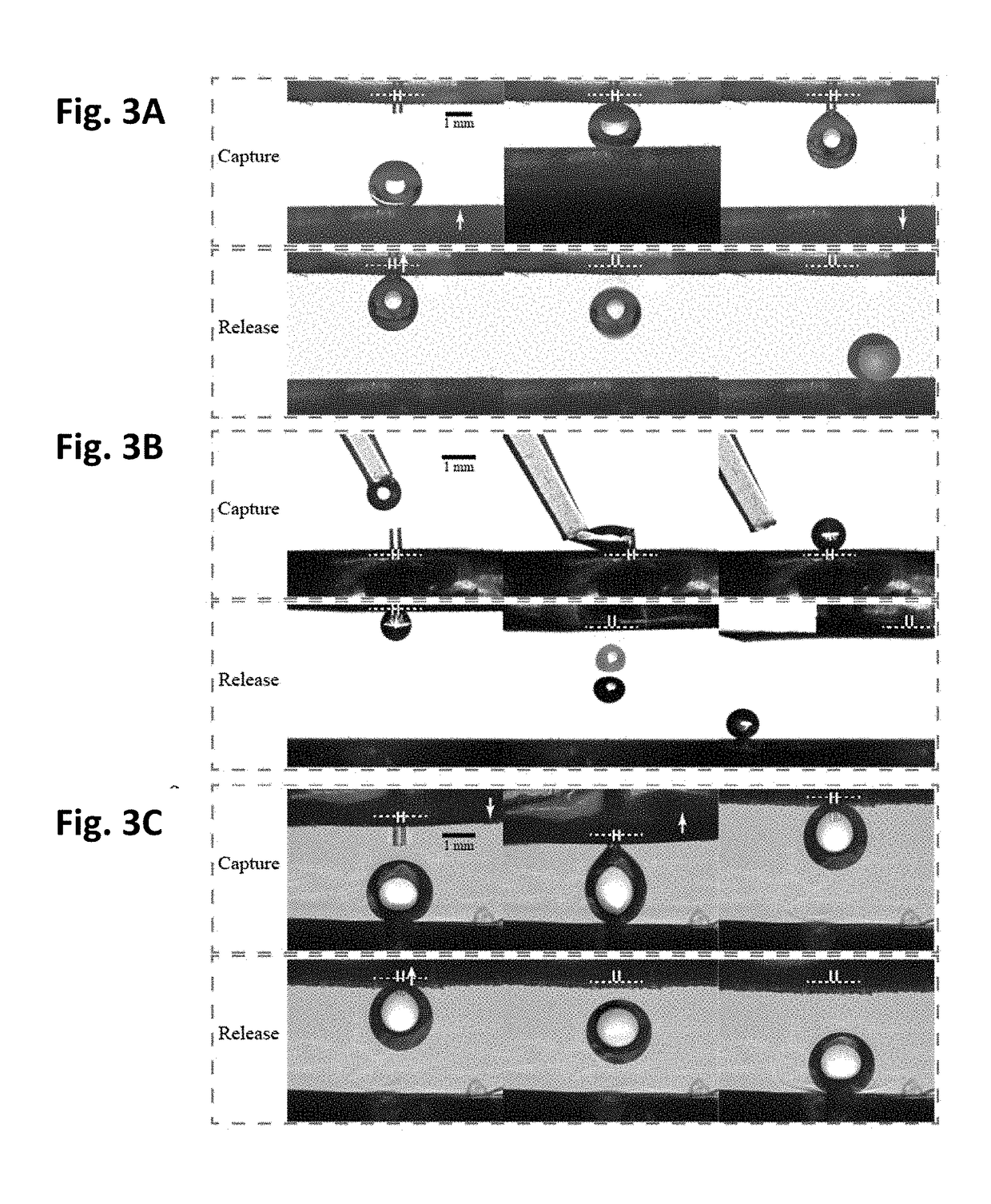

Method for rapid and precise manipulation of a tiny volume of liquid droplets

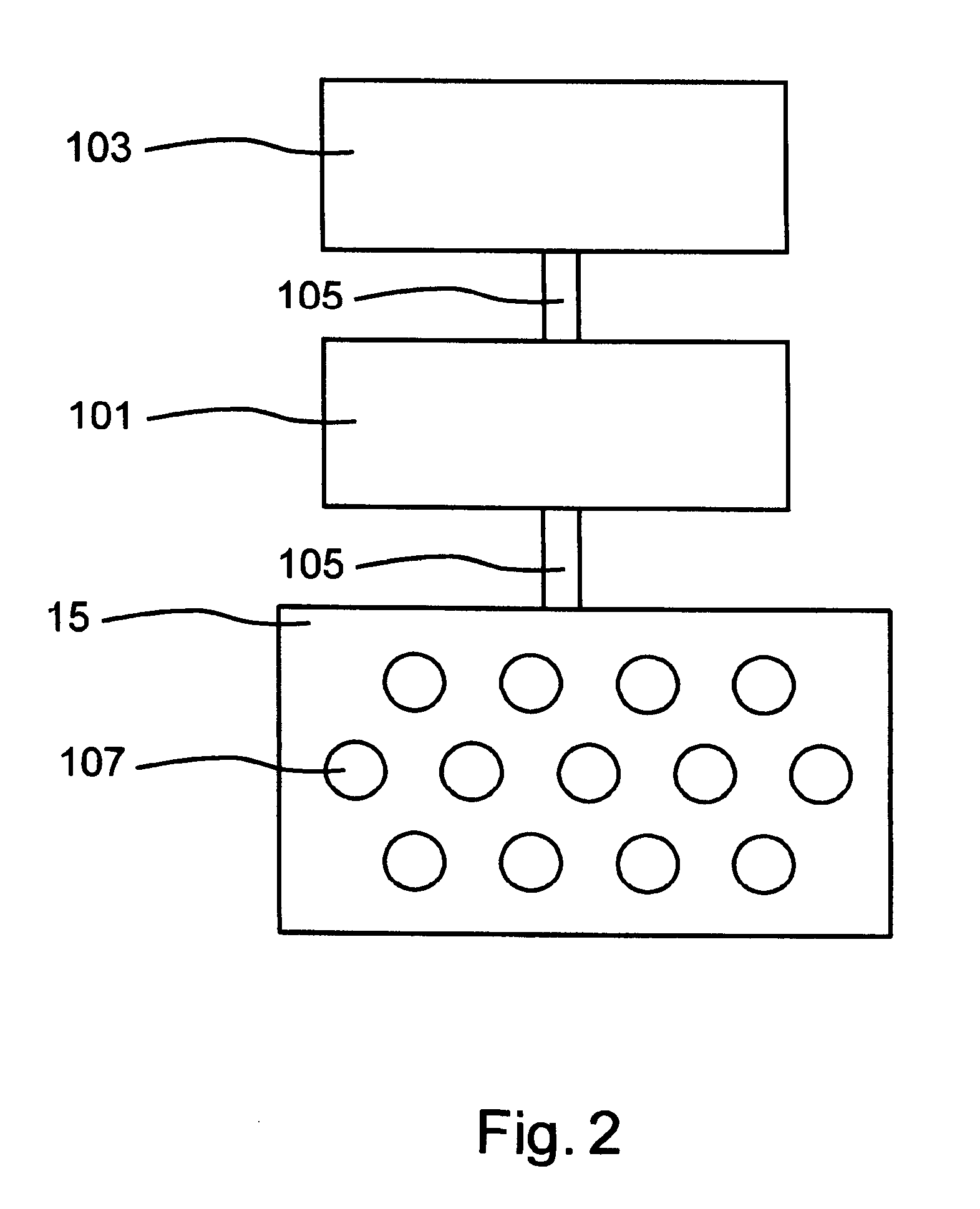

ActiveUS20170315024A1Easy to operateExtensive adhesionDispensing apparatusWithdrawing sample devicesCapillary bridgesHigh surface

An apparatus and method are provided for rapid and precise manipulation and transfer of tiny liquid droplets. by dynamically introducing microstructures with relatively high surface energy to a non-wettable surface, which surface has in-situ switchable adhesion to liquid droplets. By penetrating microstructures on the background surface, the chemical property of the surface is locally modified. Capillary bridges will form between microstructures and liquid droplets which lead to high adhesive forces. When the microstructures are retracted, the capillary bridges either pinch-off or recede, which drastically reduces the adhesion. With proper chemical modification, the surface can either manipulate a liquid droplet in air or in an immiscible carrier liquid. Tiny droplets with volumes down to nanoliter scale can be prepared and dispensed by using the surface.

Owner:THE UNIVERSITY OF HONG KONG

Rotolining process

ActiveUS7892600B2Toughness is deterioratedInhibition formationFibre treatmentCoatingsVinyl etherTetrafluoroethylene

The present invention relates to (a) the rotolining of the interior surface of a hollow article with tetrafluoroethylene / perfluoro(alkyl vinyl ether copolymer in a multicoat system, in which the undercoat also contains a powder additive, and the overcoat is preferably stabilized copolymer to form a bubble-free coating thicker than the undercoat, (b) embodiments in which the undercoat is stabilized or unstabilized copolymer, (c) use of the undercoat as a single coat system, (d) the composition for forming a bubble-free coating that adheres to the surface, arising from the presence of adhesion-promoting, non-bubble promoting metal powder being present in the composition.

Owner:THE CHEMOURS CO FC LLC

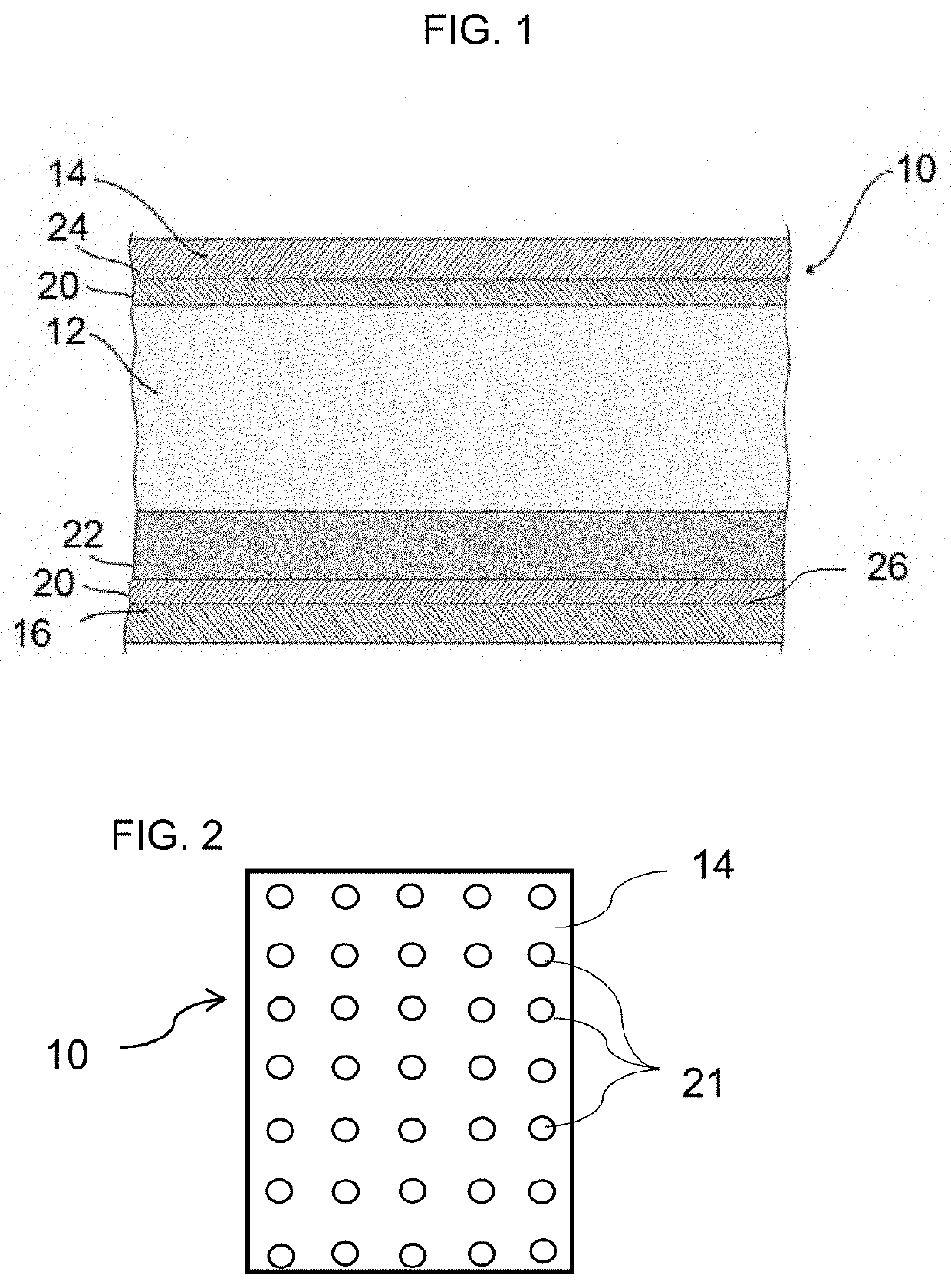

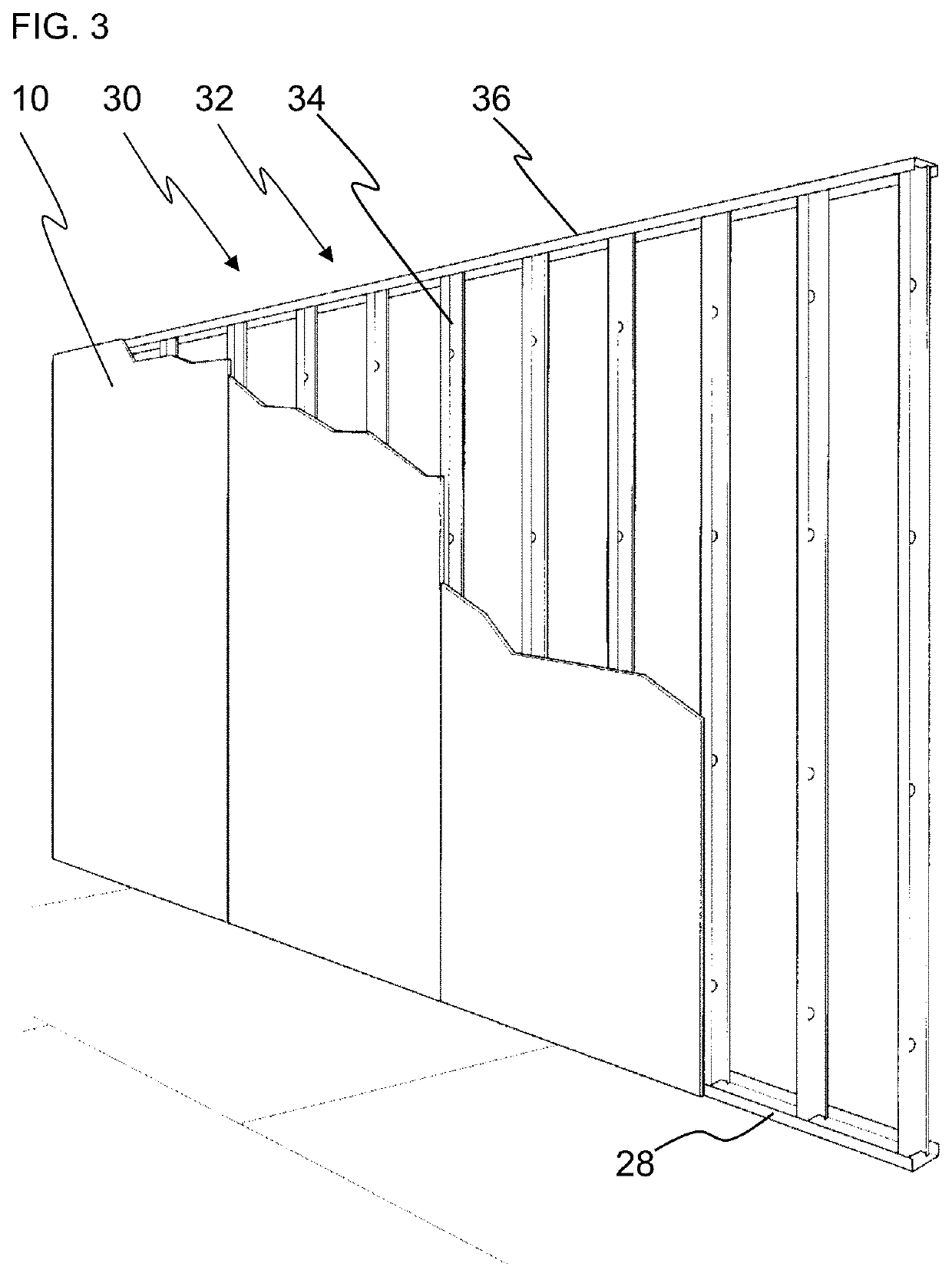

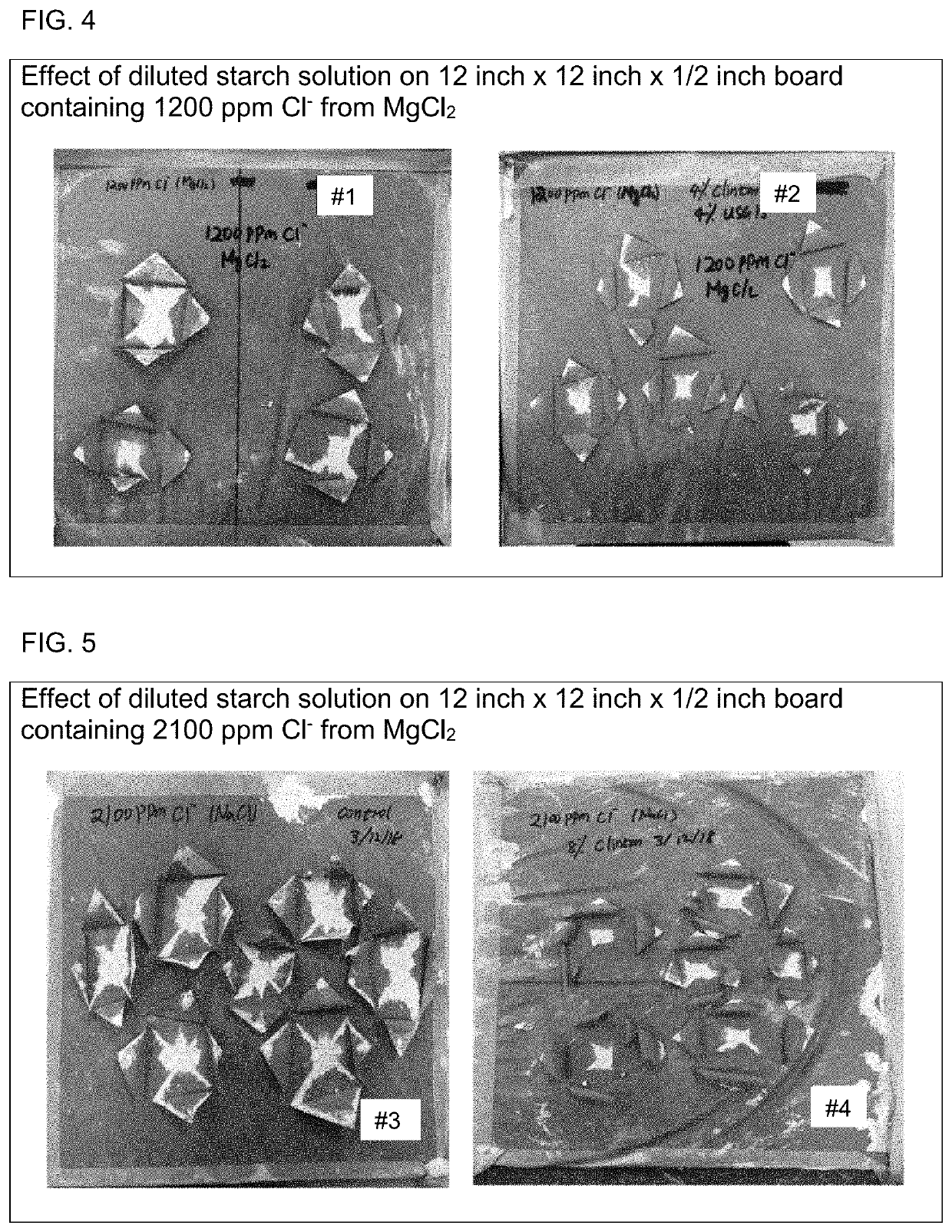

Gypsum board from gypsum having high level of chloride salt and a starch layer and methods associated therewith

ActiveUS20200055278A1Improve adhesionExtensive adhesionSpecial paperPaper coatingHemihydrate Calcium SulfateChloride salt

Gypsum boards formed from synthetic gypsum and other gypsum sources having high chloride salt concentrations. Gypsum boards may include a board core including set gypsum. A total concentration of the chloride anion in the board core ranges from about 500 ppm to about 3000 ppm, typically about 1000 ppm to about 3000 ppm, based on weight of the calcium sulfate hemihydrate. An inner surface of a front paper cover sheet contacts a first face of the board core. An inner surface of a back paper cover sheet contacts a second face of the board core. A starch layer coats the inner surface of at least one of the front and back cover sheet. Methods of making the gypsum board, and a wall system for employing the gypsum boards, are also provided.

Owner:UNITED STATES GYPSUM CO

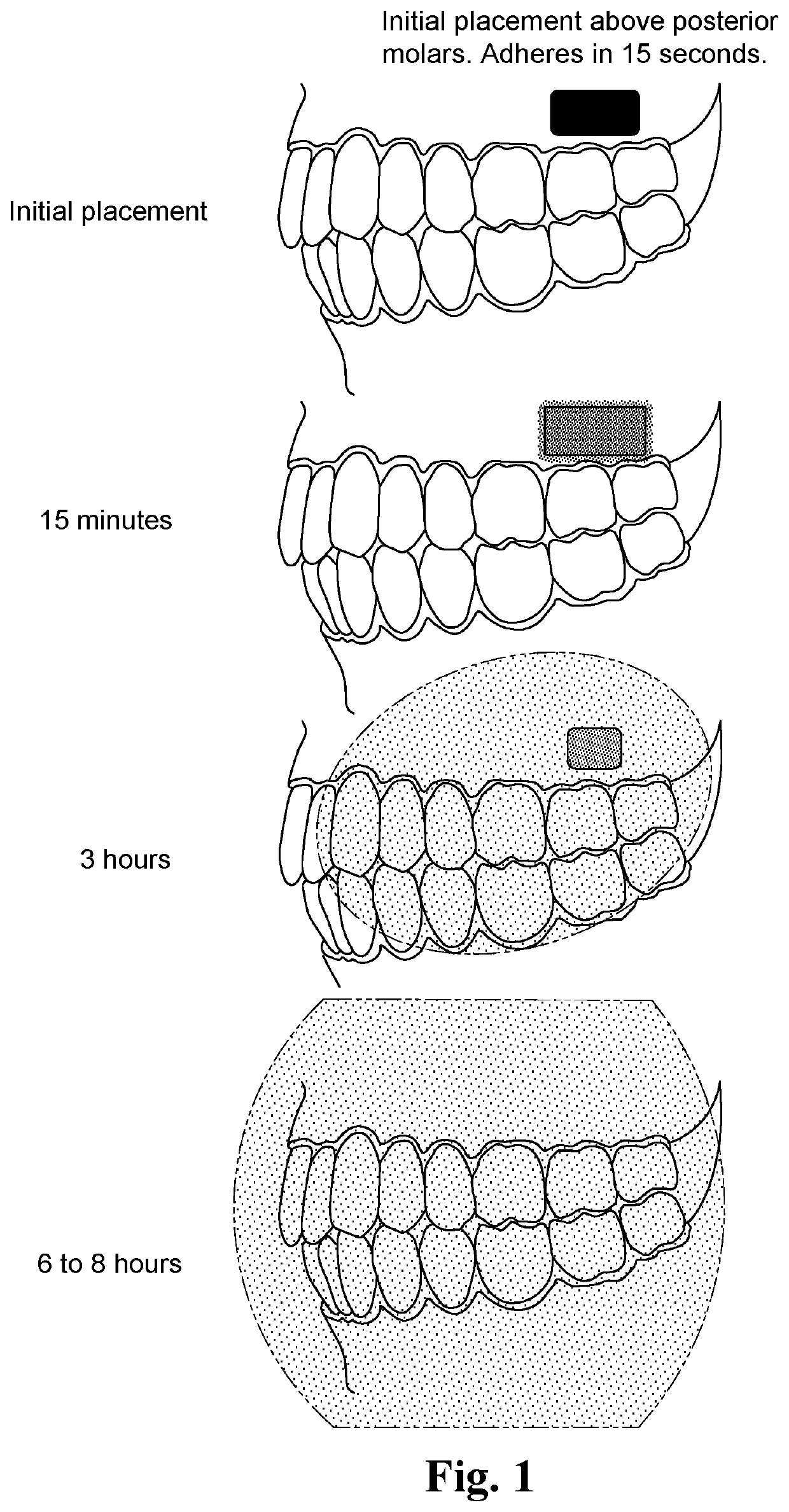

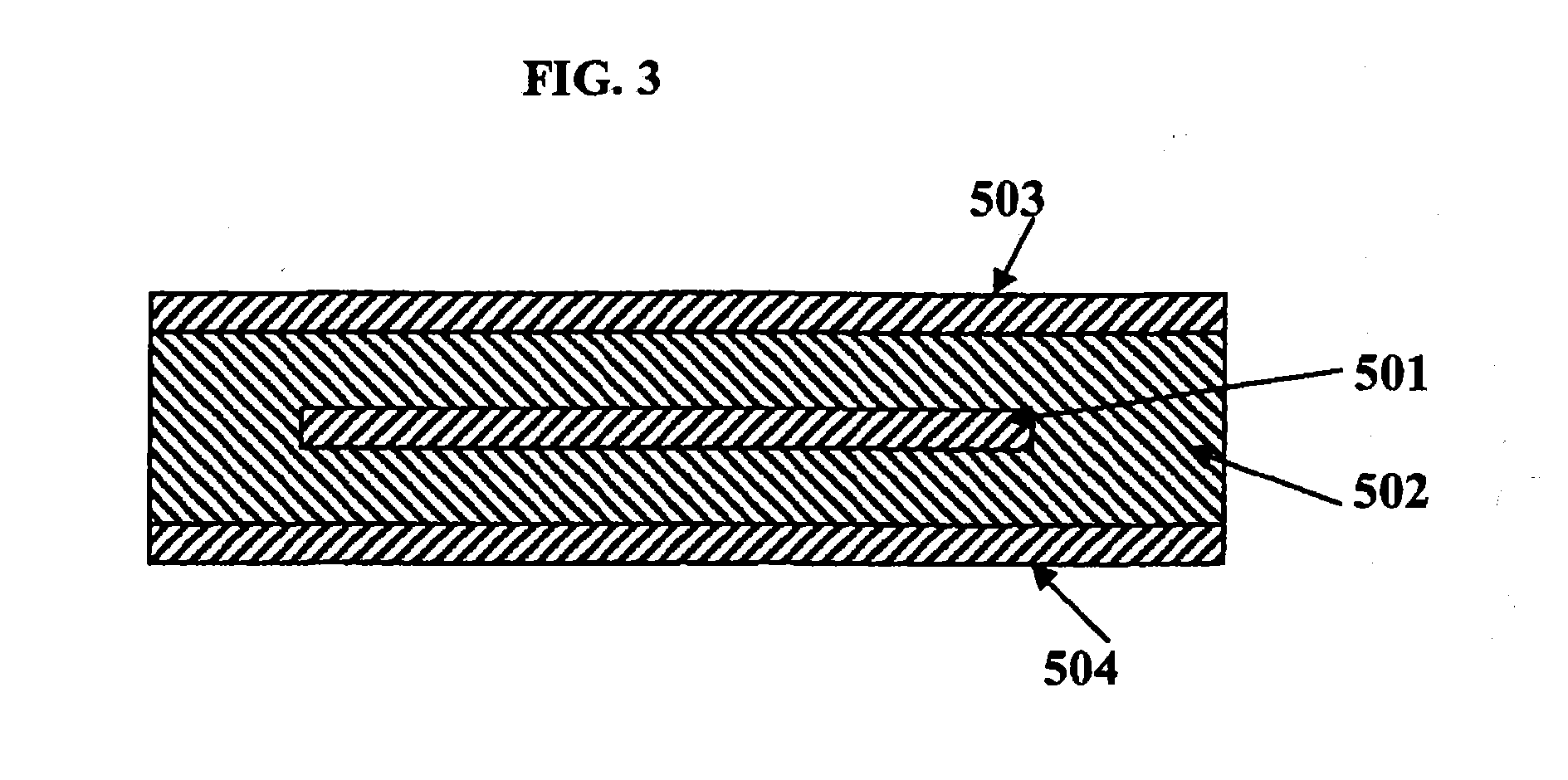

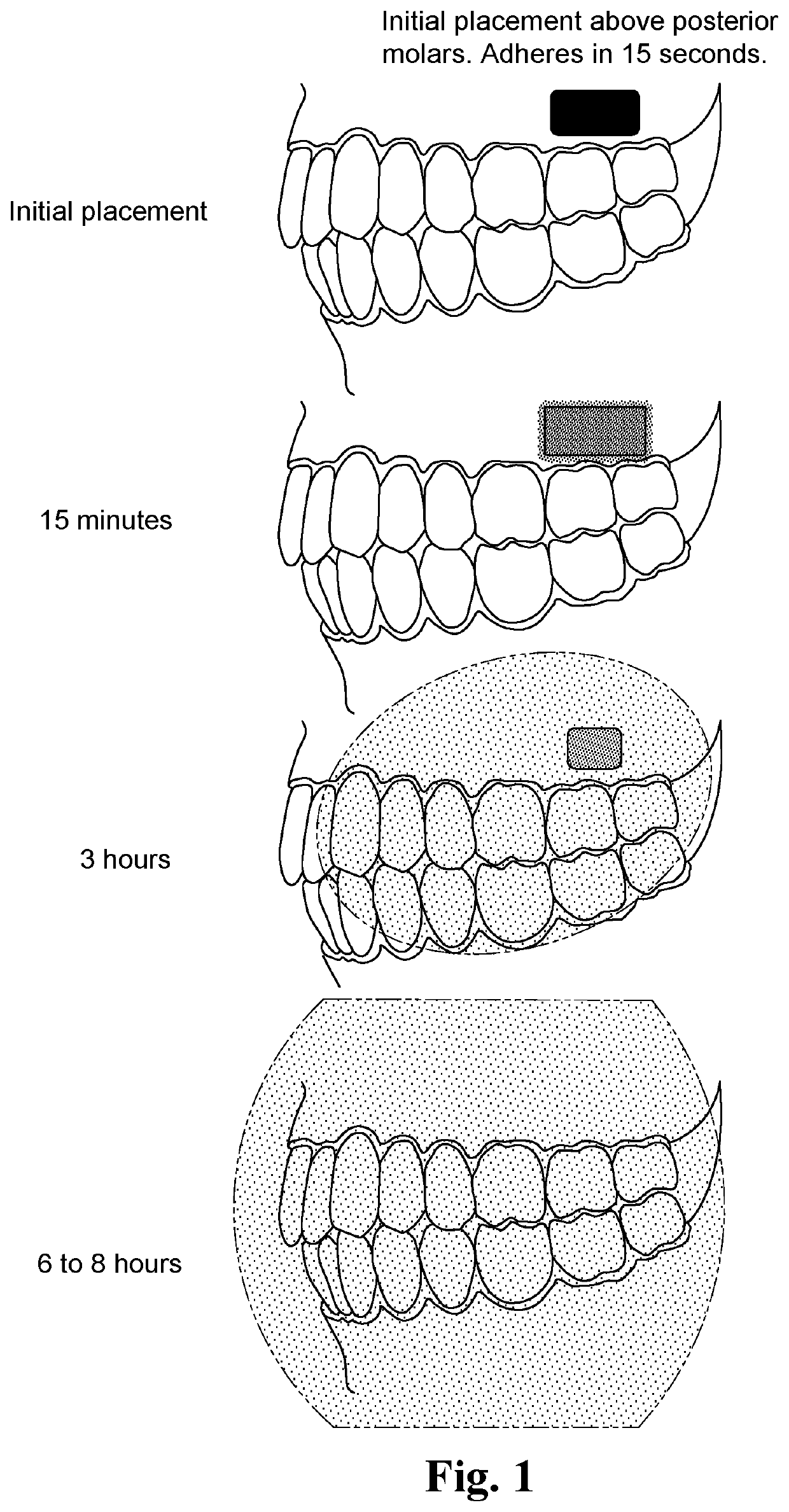

Adherent oral pharmabiotic delivery strip

ActiveUS20200155447A1Improve continued patient complianceSatisfactory performanceHydroxy compound active ingredientsPeptide/protein ingredientsPharmaceutical drugBuccal mucosa

An oral pharmabiotic system is disclosed for improving oral, dental, and systemic health by repopulating and reshaping the flora within a patient's oral environment in a manner that overcomes the deficiencies of prior oral probiotic products. By formulating the pharmabiotic system as a strip for adhesive placement within a patients' oral cavity, preferably against the buccal mucosa, alveolar mucosa, oral labial mucosa, or a dental appliance, and configuring the parameters of the strip such that neither disadhesion nor complete dissolution occurs for at least a period of at least three hours during daytime use and at least six hours during nighttime use, the probiotic payload contained within may remain in the oral cavity for a sufficient length of time required for the probiotics to activate, replicate, and displace existing harmful oral pathobiotics.

Owner:EDWARDS STEVEN J

Labeling arrangement for labeling beverage bottles

InactiveUS9340313B2Reduce maintenanceImprove securityMechanical working/deformationLamination ancillary operationsSoftware engineeringBottle

A labeling arrangement for labeling beverage bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

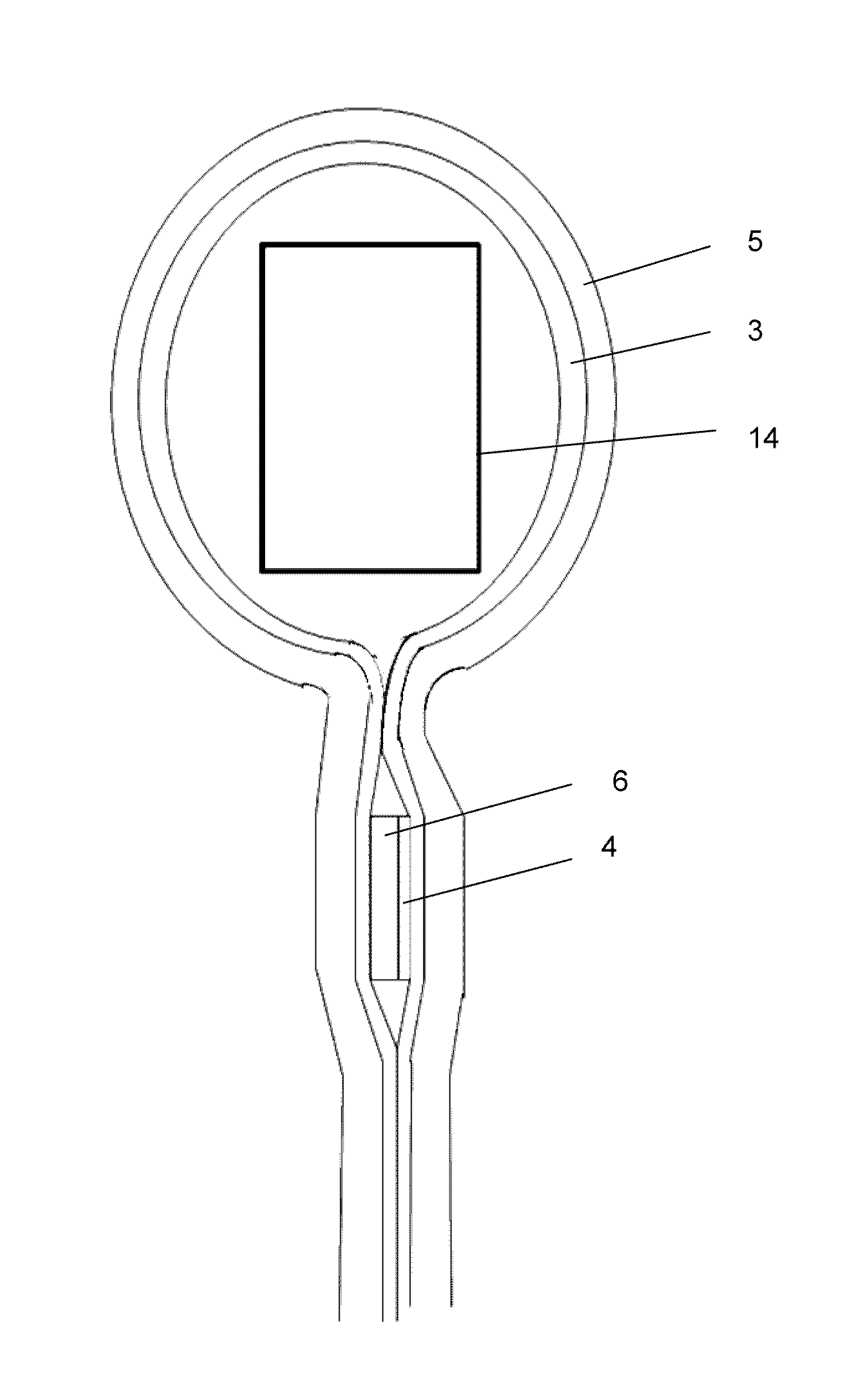

Organic silicon modified wood floor glue and preparation method thereof

ActiveCN106634772AExtensive adhesionGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolPlasticizer

The invention discloses organic silicon modified wood floor glue and a preparation method thereof. The organic silicon modified wood floor glue is prepared from the following raw materials in parts by mass: 100 parts of organic silicon modified resin, 60-90 parts of plasticizer, 200-500 parts of calcium carbonate, 2-10 parts of coupling reagent and 0.1-2.2 parts of catalyst. The organic silicon modified resin is adopted for guaranteeing the extensive adhesion of an adhesive; the organic silicon modified wood floor glue has the excellent weather-proof and anti-seismic properties of silicone adhesive, is free from toxicity, solvent and isocyanate and is low in VOC release volume; after being cured, the organic silicon modified wood floor glue is free from shrinkage and foaming; the applicable temperature scope is from -40 DEG C to 60 DEG C; a low-molecular-weight hydrophilic polyalcohol is taken as a plasticizer, so that the hydrophilic property of the cured glue is increased while the hydrolytic resistance is reduced; and the environment-friendly degumming separation can be performed in the manner of soaking in water and the wood floor can be easily replaced.

Owner:广东长鹿精细化工有限公司

Production of solar cell modules

InactiveUS20130087201A1Performance deteriorationGood weather resistanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationMeth-Compound (substance)

The invention relates to the use of a) at least one (poly)alkyl(meth)acrylate and b) at least one compound according to formula (I), wherein the radicals R1 and R2 independently represent an alkyl or cycloalkyl radical having 1 to 20 carbon atoms, for producing solar cell modules, in particular for producing light concentrators for solar cell modules.

Owner:EVONIK ROEHM GMBH

White ink slurry and application method thereof in wallpaper

The invention relates to the technical field of wallpaper and provides white ink slurry which solves the defects of poor dispersion performance, weak covering capacity and low whiteness of the white ink slurry in the prior art. In addition, the invention also provides an application method of the white ink slurry in wallpaper. The white ink slurry is prepared from the following raw materials in parts by weight: 10-20 parts of styrene-acrylic emulsion, 0-10 parts of VAE emulsion, 20-25 parts of distilled water, 1-5 parts of a thickening agent, 3-8 parts of a dispersing agent, 0-1 part of a wetting agent, 1-3 parts of a defoaming agent, 1-2 parts of a retarder, 5-10 parts of propylene glycol, 30-50 parts of kaolin and 1-10 parts of titanium pigment.

Owner:FUJIAN SUNREAL PRO ENVIRONMENTAL WALLPAPER

Adherent oral pharmabiotic delivery strip

ActiveUS11058634B2Large and malleable surface areaMaximize acceptancePeptide/protein ingredientsHydroxy compound active ingredientsPharmaceutical drugBuccal mucosa

An oral pharmabiotic system is disclosed for improving oral, dental, and systemic health by repopulating and reshaping the flora within a patient's oral environment in a manner that overcomes the deficiencies of prior oral probiotic products. By formulating the pharmabiotic system as a strip for adhesive placement within a patients' oral cavity, preferably against the buccal mucosa, alveolar mucosa, oral labial mucosa, or a dental appliance, and configuring the parameters of the strip such that neither disadhesion nor complete dissolution occurs for at least a period of at least three hours during daytime use and at least six hours during nighttime use, the probiotic payload contained within may remain in the oral cavity for a sufficient length of time required for the probiotics to activate, replicate, and displace existing harmful oral pathobiotics.

Owner:EDWARDS STEVEN J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com