Mildew-proof silane-modified polyether sealant and preparation method therefor

A silane-modified polyether and sealant technology, which is applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve the problems of environmental protection, adverse human health, and odor, and achieve rapid curing and wide adhesion The effect of adhesion and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

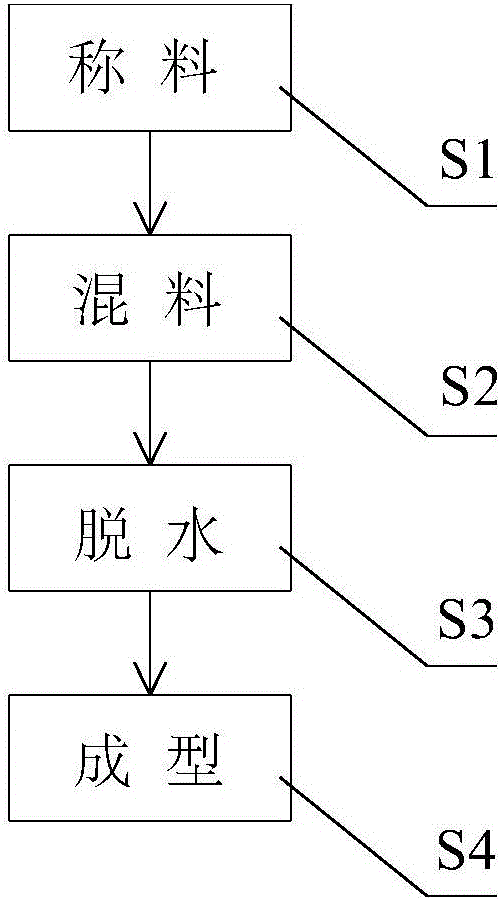

[0028] figure 1 It shows the preparation method of the first embodiment of the present invention anti-mildew silane modified polyether sealant, including:

[0029] Step S1, weighing.

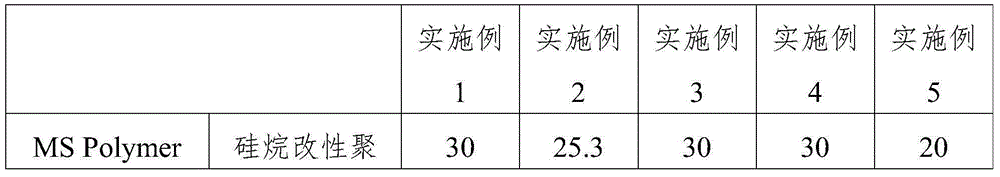

[0030] Weigh 30Kg of silane-modified polyether resin, 20Kg of diisodecyl phthalate (DIDP), 30Kg of nano-calcium carbonate, 14.3Kg of active calcium carbonate, 3Kg of titanium dioxide, 0.1Kg of sodium polyamide, and 0.1Kg of pyridyl sulfide Ketone zinc (ZincOmadine) 0.1Kg, 2-(2-hydroxy-3-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole (Tinuvin326) 0.1Kg, bis(2,2,6 , 6-tetramethyl-4-piperidinyl) sebacate (Tinuvin770) 0.1Kg, vinyltrimethoxysilane (KH171) 1Kg, aminoethylaminopropyltrimethoxysilane (KH792) 1Kg, two Dibutyltin laurate 0.3Kg.

[0031] Step S2, mixing ingredients.

[0032] The weighed silane modified polyether resin, diisodecyl phthalate, nanometer calcium carbonate, activated calcium carbonate, titanium dioxide, sodium polyamide, zinc pyrithione, 2-(2-hydroxy-3- Put tert-butyl-5-...

Embodiment 2

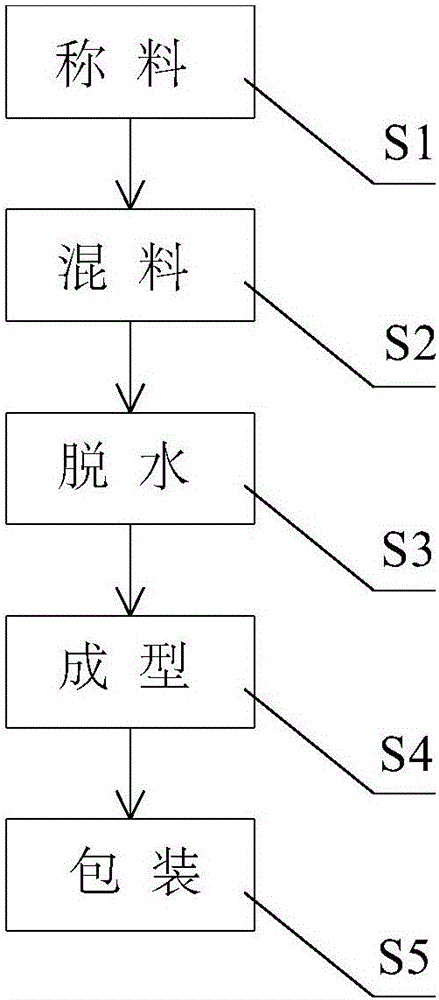

[0042] figure 2 Shows the preparation method of anti-mold silane modified polyether sealant of the second embodiment of the present invention, including:

[0043] Step S1, weighing.

[0044] Weigh 25.3Kg of silane-modified polyether resin, 30Kg of diisodecyl phthalate (DIDP), 30Kg of nano-calcium carbonate, 10Kg of active calcium carbonate, 3Kg of titanium dioxide, 0.1Kg of sodium polyamide, and 0.1Kg of pyridyl sulfide Ketone zinc (ZincOmadine) 0.1Kg, 2-(2-hydroxy-3-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole (Tinuvin326) 0.1Kg, bis(2,2,6 , 6-tetramethyl-4-piperidinyl) sebacate (Tinuvin770) 0.1Kg, vinyltrimethoxysilane (KH171) 0.5Kg, aminoethylaminopropyltrimethoxysilane (KH792) 0.5Kg , Dibutyltin dilaurate 0.3Kg.

[0045] Step S2, mixing ingredients.

[0046] The weighed silane modified polyether resin, diisodecyl phthalate, nanometer calcium carbonate, activated calcium carbonate, titanium dioxide, sodium polyamide, zinc pyrithione, 2-(2-hydroxy-3- Put tert-butyl...

Embodiment 3

[0054] In this example, the preparation method of the anti-mold silane-modified polyether sealant is roughly the same as that of the above-mentioned Example 2, and the specific steps are as follows:

[0055] Step S1, weighing.

[0056] Weigh 30Kg of silane-modified polyether resin, 20Kg of DIDP, 20Kg of nano-calcium carbonate, 23.5Kg of activated calcium carbonate, 3Kg of titanium dioxide, 0.3Kg of sodium polyamide, 0.3Kg of ZincOmadine, 0.3Kg of Tinuvin326, and 0.3Kg of Tinuvin770 0.3Kg for KH171, 1Kg for KH792, 0.3Kg for dibutyltin dilaurate.

[0057] Step S2, mixing ingredients.

[0058] Put the weighed silane-modified polyether resin, DIDP, nano-calcium carbonate, activated calcium carbonate, titanium dioxide, sodium polyamide, ZincOmadine, Tinuvin326, Tinuvin770 into the mixer, and stir at high speed to heat up the material.

[0059] Step S3, dehydration.

[0060] After the temperature of the material rose to 110° C., vacuum dehydration was started for 2 hours to reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com