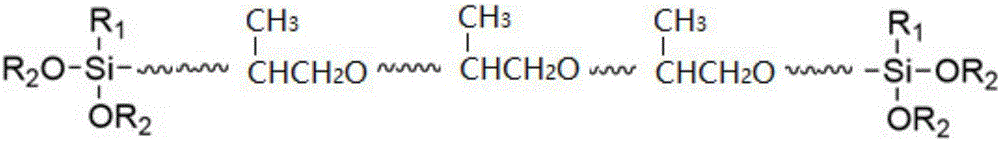

Organic silicon modified wood floor glue and preparation method thereof

A silicone and floor adhesive technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of lack of degumming agent, hard and brittle adhesive, insufficient elasticity, etc., and achieve low VOC emission and hydrophilicity. The effect of increased capacity and decreased water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of organosilicon modified wooden floor glue proportioning composition is as follows:

[0039]

[0040] Concrete preparation steps are as follows:

[0041] (1) Stir silicone-modified polyether resin, hydrophilic polypolyol, and nano-calcium carbonate in a double planetary mixer for 120 minutes at a temperature of 110-120° C., and vacuumize;

[0042] (2) Add the coupling agent and the catalyst into the planetary mixer, stir for 15-30 minutes, control the temperature at 20-55°C, and evacuate;

[0043] Its operating parameters are preferably vacuum degree 0.90MPa, rotation speed 50rpm.

Embodiment 2

[0045] A kind of organosilicon modified wooden floor glue proportioning composition is as follows:

[0046]

[0047] Concrete preparation steps are as follows:

[0048] (1) Stir silicone-modified polyether resin, hydrophilic polypolyol, and nano-calcium carbonate in a double planetary mixer for 120 minutes at a temperature of 110-120° C., and vacuumize;

[0049] (2) Add the coupling agent and catalyst to the planetary mixer, stir for 15-30 minutes, control the temperature at 20-55°C, and vacuumize;

[0050] Its operating parameters are preferably vacuum degree 0.90MPa, rotation speed 50rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com