Patents

Literature

149results about How to "Good moisture and heat aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin composite, and preparation method thereof and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

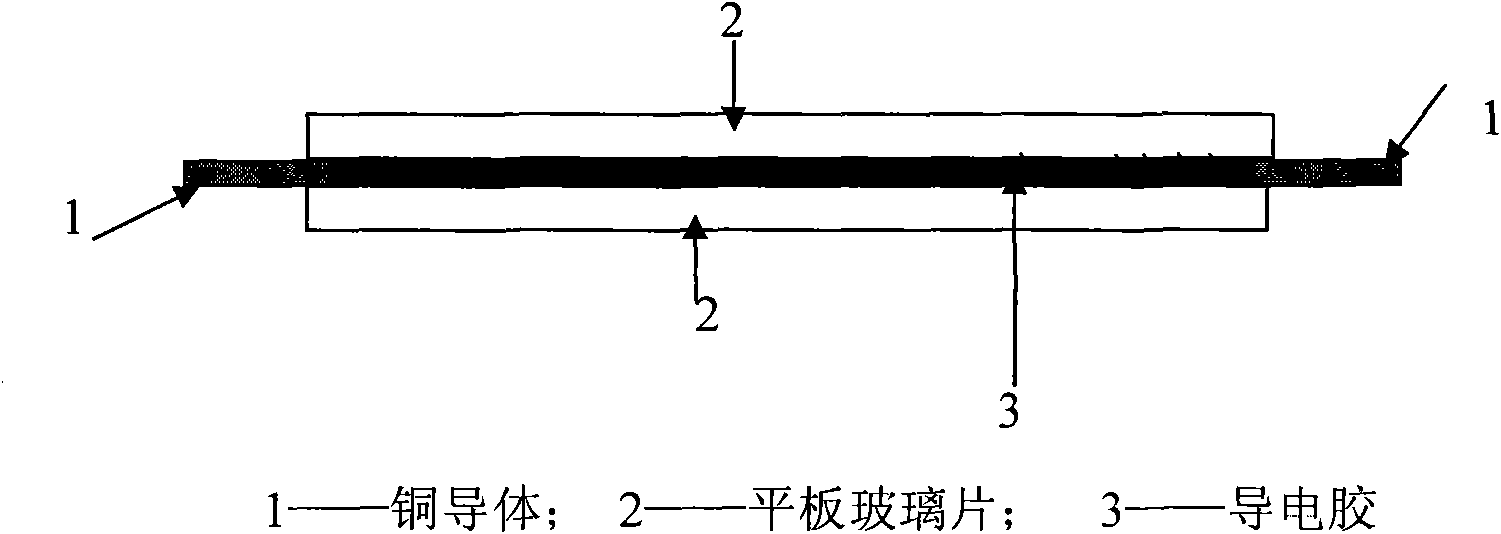

High-performance conducting resin and preparation method thereof

InactiveCN101781540AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a high-performance conducting resin, comprising the following components: epoxy, latent curing agent, active toughener and conducting particles. The preparation method comprises the following steps: adding the epoxy and the active toughener in a reaction bulb to react, then adding the latent curing agent, uniformly stirring, adding the surface-treated conducting particles, uniformly stirring, and defoaming in vacuum to obtain the high-performance conducting resin. The conducting resin in characterized in that the bonding strength reaches up to 24.1 MPa; the volume resistivity is 4.30*10<-5>-2.12*10<-4> ohm.cm; the Tonset thermal decomposition temperature reaches up to 398.7 DEG C; the water absorption is only 0.2%; and storage life at the room-temperature is as long as more than 3 months. The invention has the advantages of simple preparation process, low cost, convenient operation and convenient reaction material source, can complete the preparation process in universal devices, is beneficial to realizing industrial production, and has wide application prospects in the fields of electronic components, resonators, relays, electronic capacitors and the like.

Owner:DONGHUA UNIV +1

EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and preparation method thereof

InactiveCN103756579AImprove barrier propertiesImprove hydrolysis resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantAging resistance

The invention discloses an EVA (Ethylene Vinyl-Acetate) packaging glue film with high gas-water barrier property and a preparation method thereof. The glue film is prepared from the following raw materials in parts by weight: 100 parts of an EVA copolymer, 0.5-5 parts of a crosslinking agent, 0.1-0.5 part of an antioxidant, 0.1-0.5 part of an ultraviolet absorber, 0.05-0.5 part of a light stabilizer, 0.1-3 parts of a silane coupling agent and 0.01-55 parts of a water resistant. The preparation method comprises the following steps: plastifying and extruding; stretching; drawing; rolling and the like. The glue film disclosed by the invention has the beneficial effects that the EVA glue film obtained by the invention has good gas-water barrier property and hydrolysis resistance as well as better damp-heat aging resistance.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

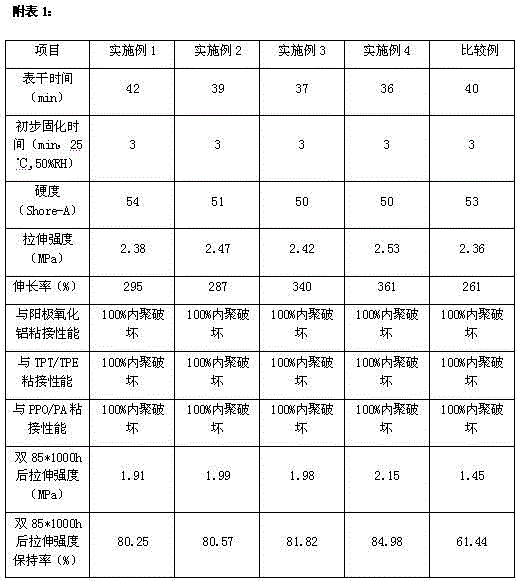

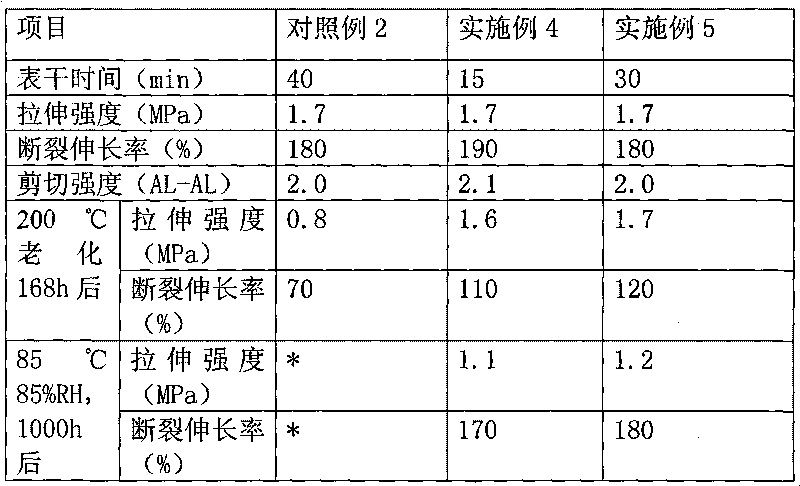

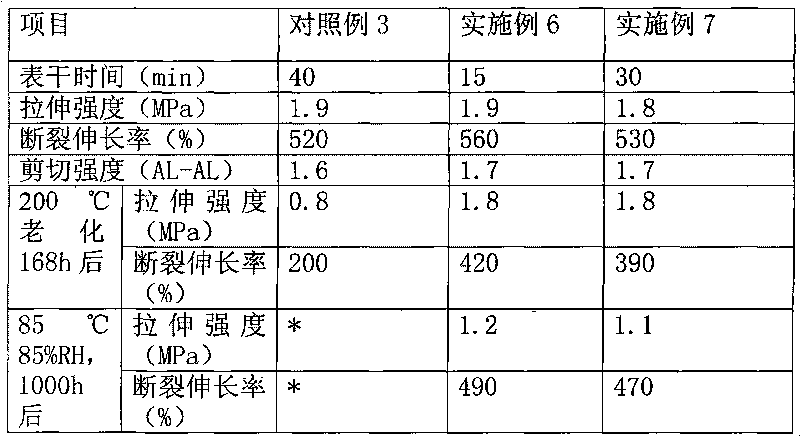

Two-component silicone sealant for solar module resisting damp, heat and ageing and preparation method thereof

InactiveCN102977840AWide range of adhesionImprove room temperature strengthNon-macromolecular adhesive additivesOther chemical processesChemistrySilicone sealant

The invention discloses two-component silicone sealant for a solar module resisting damp, heat and ageing and a preparation method thereof. The sealant consists of a component A and a component B, wherein the component A adopts polydimethylsiloxane as the major material; and the component B comprises dispersion mediums, fillers, cross linking agent, coupling agent and catalyst; the component A comprises the following components in parts by weight: 100 parts of a, omega-dihydroxy polydimethylsiloxane with viscosity of 5000-50000cps, 3 to 20 parts of plasticizer and 50 to 150 parts of fillers; the component B comprises the following components in parts by weight: 100 parts of dispersion mediums, 10 to 45 parts of fillers, 20 to 50 parts of cross linking agent, 5 to 40 parts of silane coupling agent and 0.5 to 2 parts of catalyst; and the ratio of the component A to the component B in parts by weight is 100: (10-20). The sealant has the advantages of fast deep curing, wide adhesion, high strength of normal temperature and excellent resistance to damp, heat and ageing; after ageing for 1000 hours under the double-85 condition, the strength retention rate can be up above 80%; and the sealant is suitable for machine gluing, can largely improve module productivity, and adapts to the requirements of solar module mass production.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

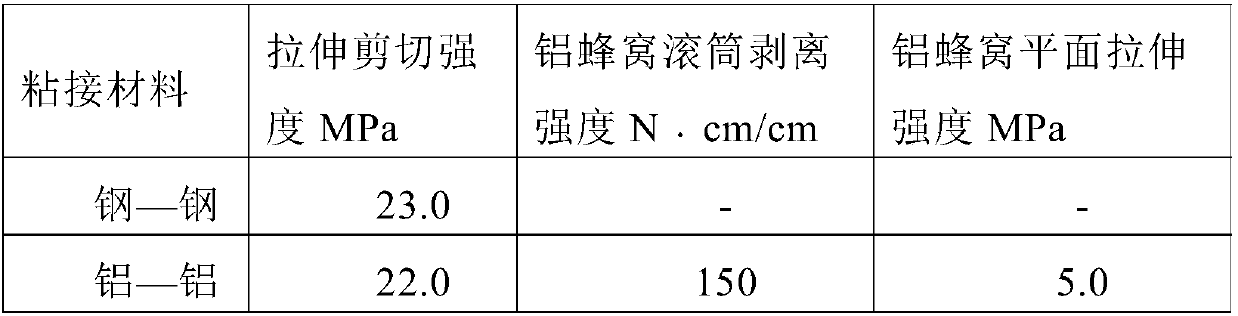

Adhesive composition with single-component epoxy structure

InactiveCN102911631AGood moisture and heat aging resistanceIncreased shear strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyDiluent

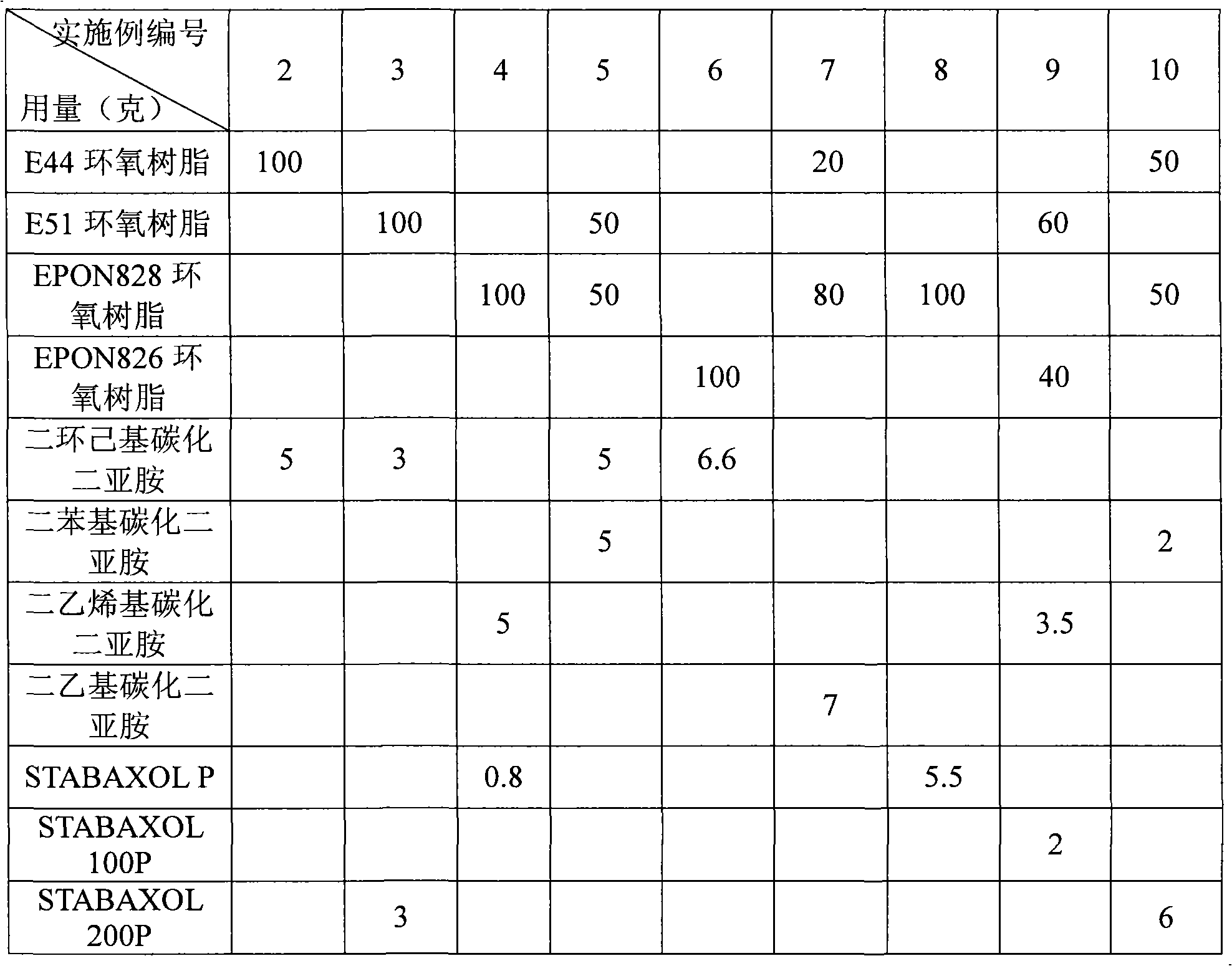

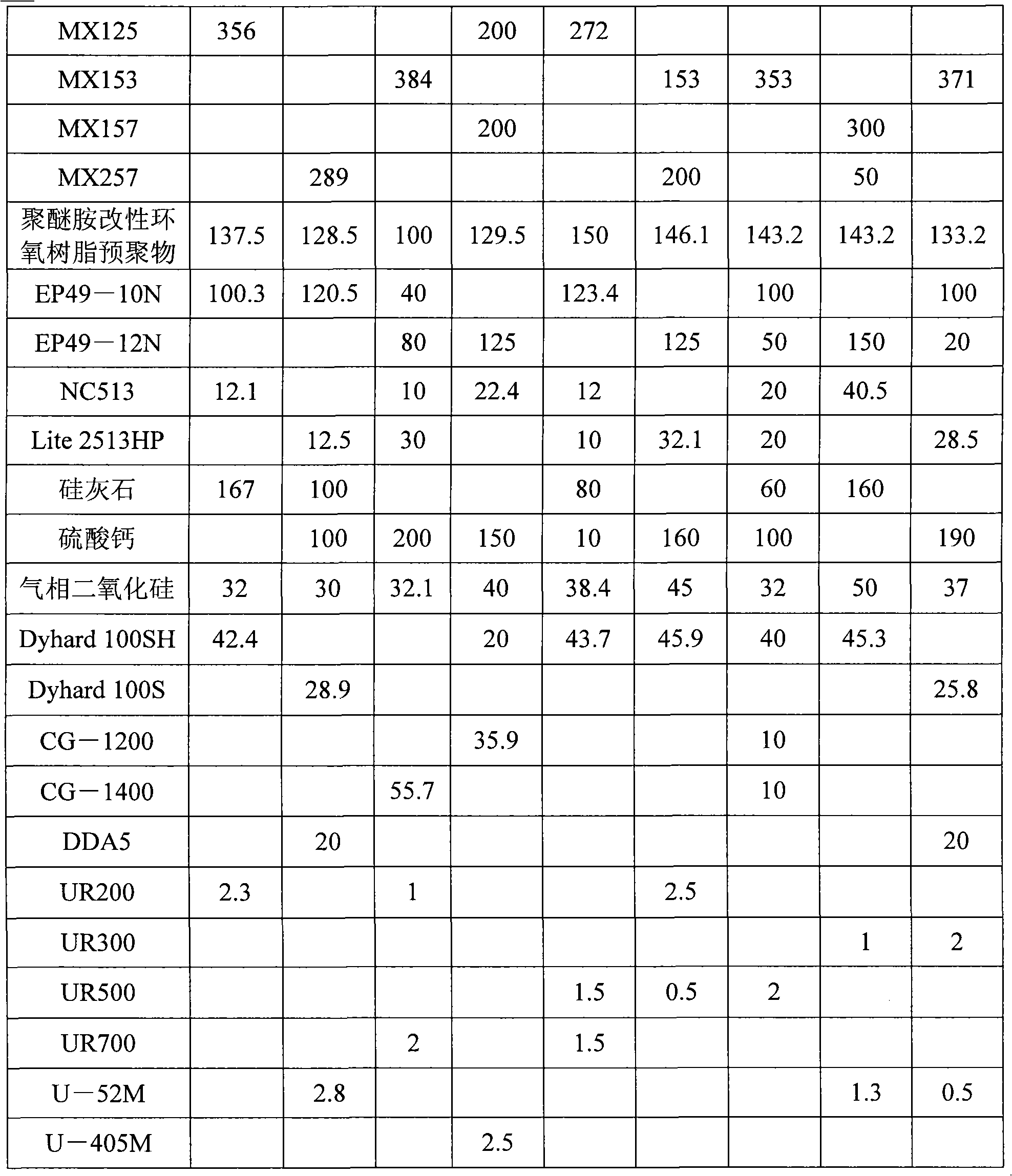

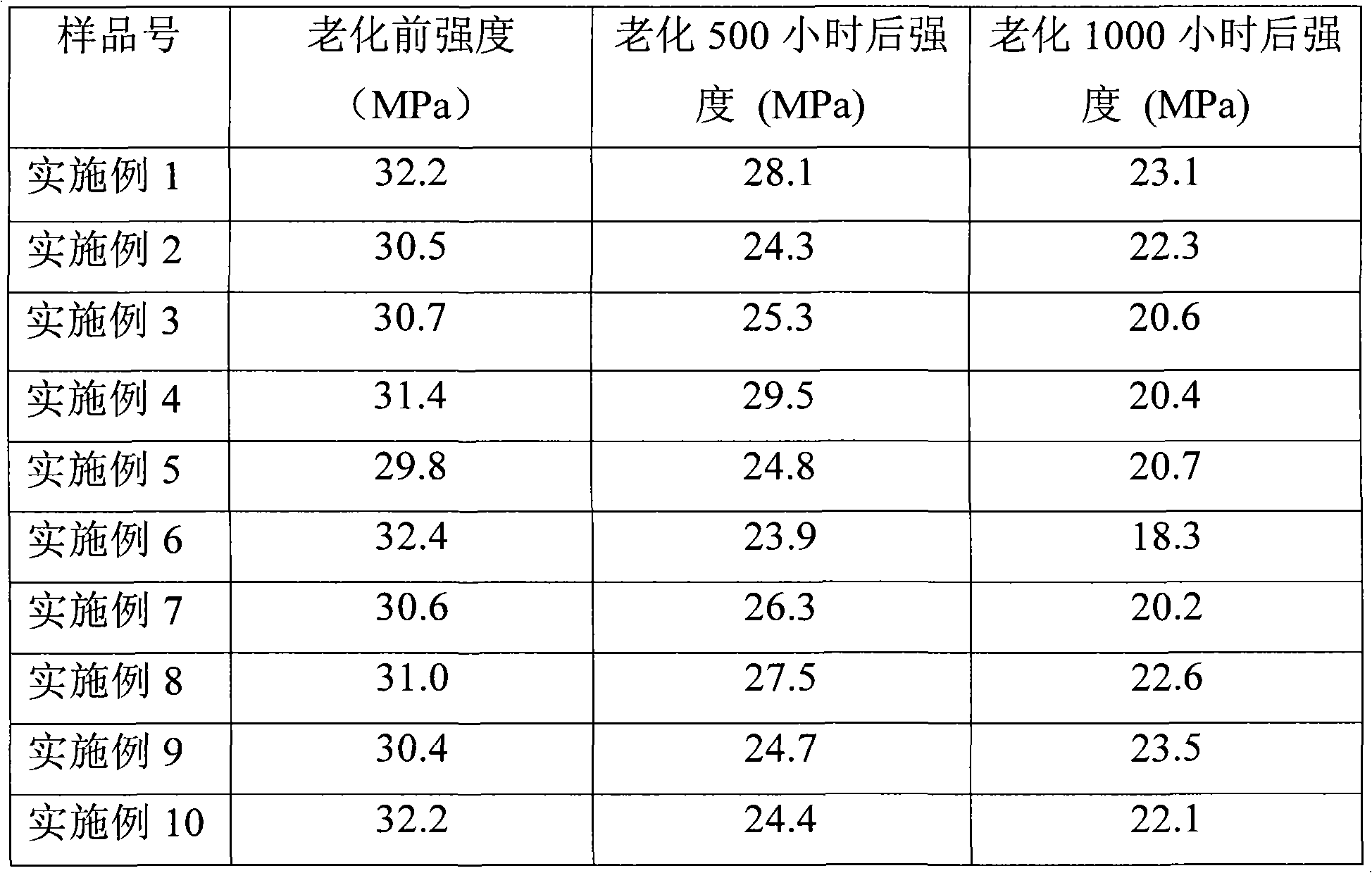

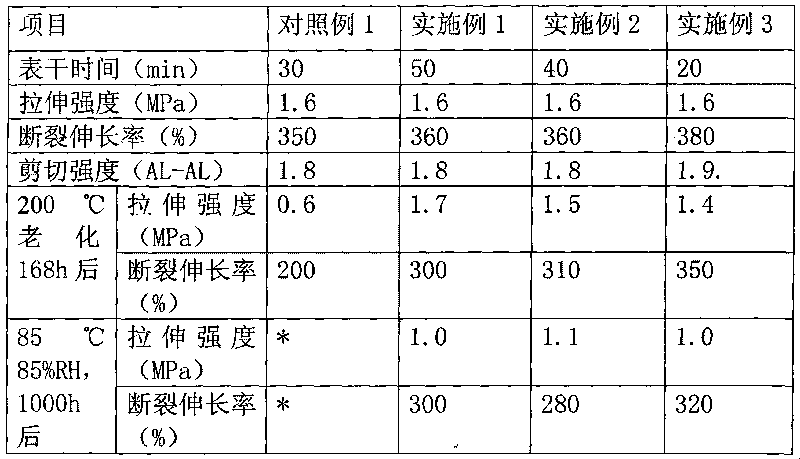

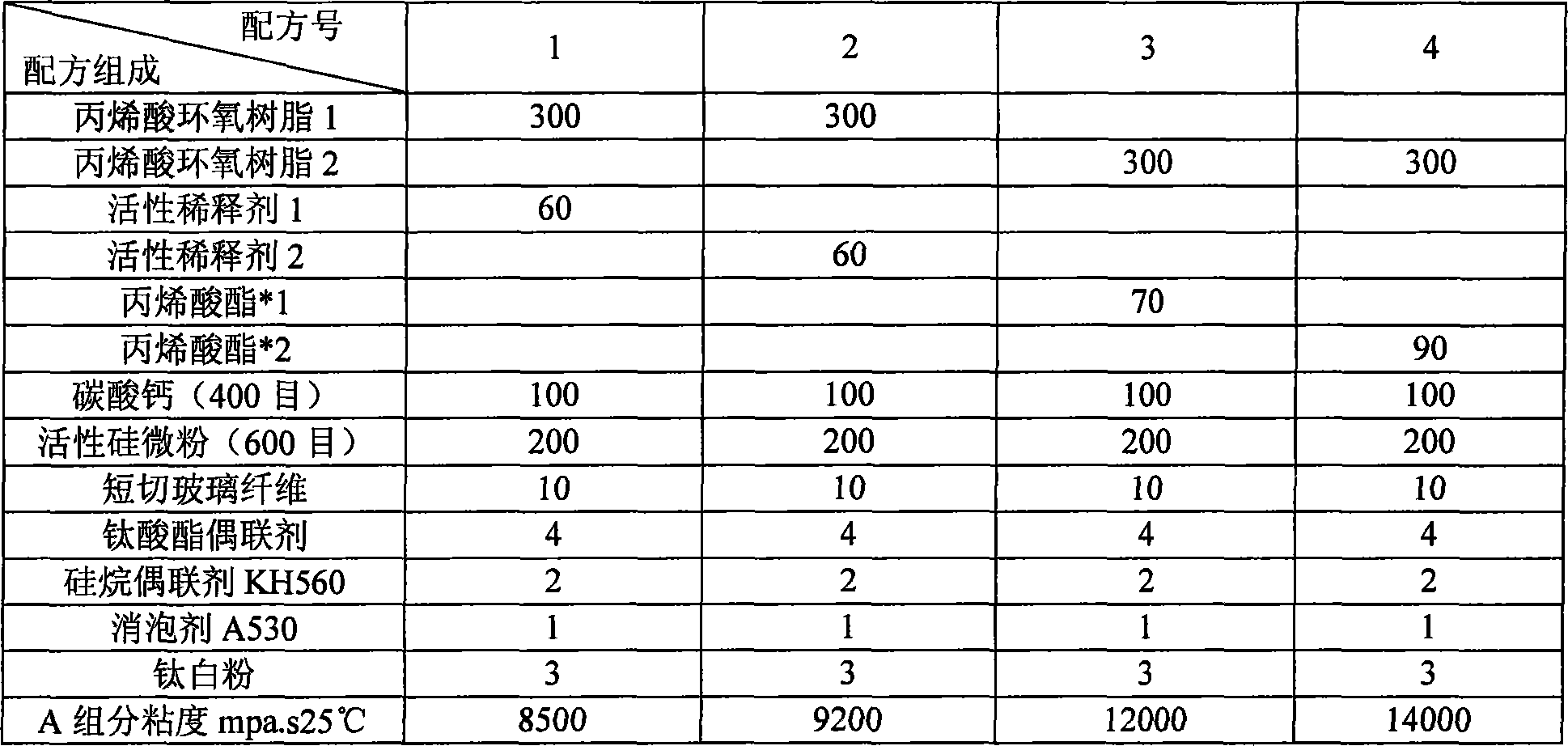

The invention relates to an adhesive composition with a single-component epoxy structure. The adhesive composition comprises at least one unmodified epoxy resin, a toughness modified epoxy resin, a polyether amine modified epoxy prepolymer, a damp and heat ageing resistant additive comprising a carbodiimide structure, a curing agent, an optional curing accelerator, an optional phosphating modified epoxy resin, and one or more of other optional components as follows: a filling, a monofunctional epoxy reaction type diluent, a thixotropic agent and a mixture thereof.

Owner:HENKEL CORP

Bi-component room temperature vulcanizing silicone rubber for photovoltaic component

InactiveCN101717582AImprove the shortcomings of poor aging resistanceExcellent outdoor aging resistanceOther chemical processesAdhesivesThermal ageingNitrogen gas

The invention discloses a bi-component room temperature vulcanizing silicone rubber for a photovoltaic component, which comprises an A component and a B component. During use, the A component and the B component are uniformly coated on a work piece according to proportion through a bi-component glue spreader. The bi-component room temperature vulcanizing silicone rubber is characterized in that: the A component is prepared by grinding the following raw materials in part by weight: 100 parts of hydroxyl-terminated dimethyl silicone polymer, 20 to 50 parts of plasticizer, 60 to 100 parts of stuffing and 6 to 10 parts of thixotropic agent through a three-roll grinder; the B component is prepared by mixing the following raw materials in part by weight: 5 to 10 parts of cross-linking agent, 0.2 to 1.5 parts of compound catalyst, 1 to 2 parts of adhesion agent and 0.5 to 1.5 parts of catalyst carrier under the protection of nitrogen. The invention overcomes the shortcomings of poor aging resistance of the room temperature vulcanizing silicone rubber catalyzed by conventional organotin, and has characteristics of excellent outdoor aging resistance, good adhesiveness, fast curing speed, no reversion after the curing and no color change; the invention greatly improves the high temperature resistance and the damp-heat aging resistance, and can meet the requirement on the process procedure by controlling the curing speed.

Owner:YANTAI DARBOND TECH

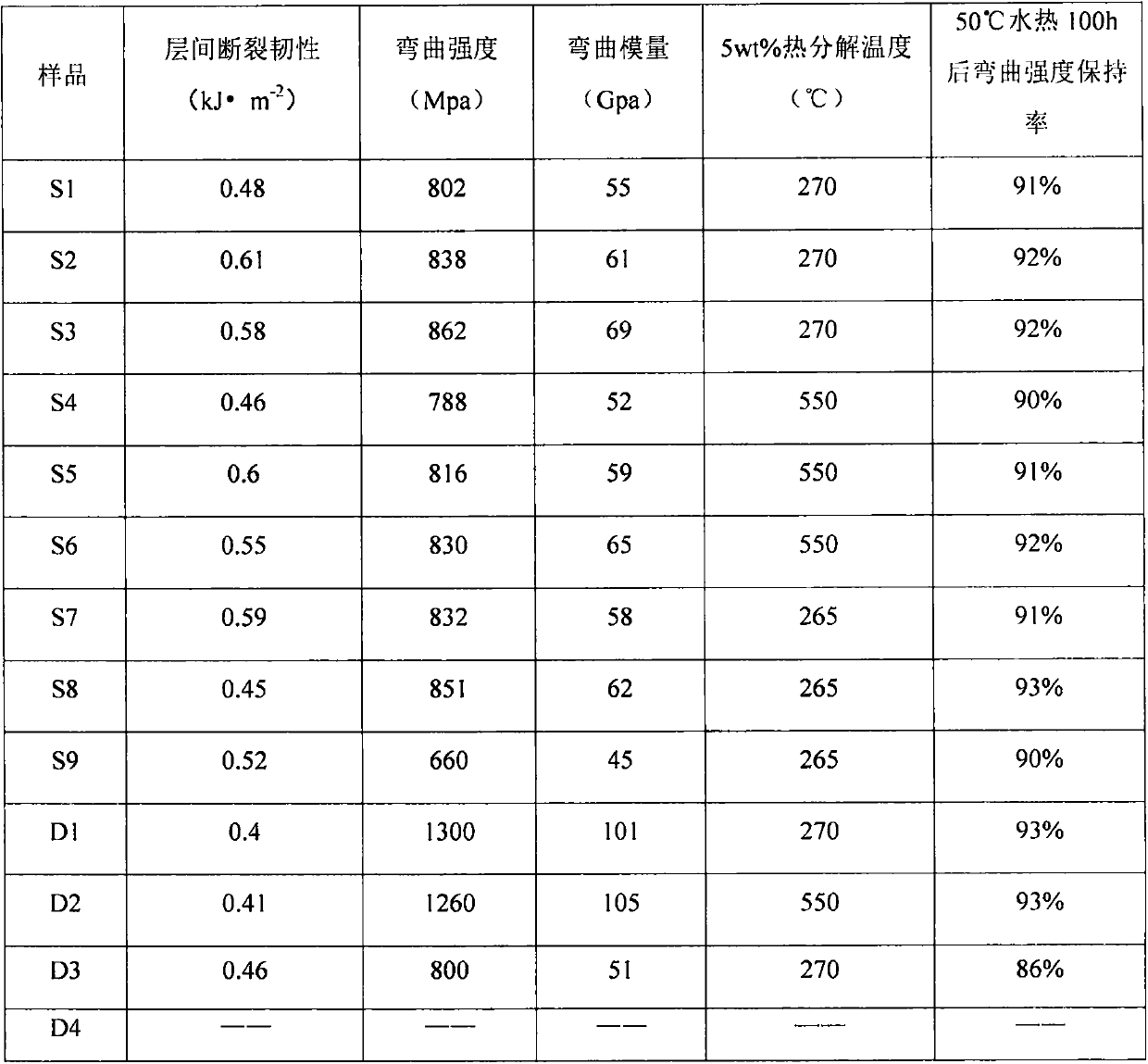

Composite material taking carbon fiber/polyimide fiber hybrid fabric as enhancing body and preparation method thereof

ActiveCN107793700AImprove toughnessImprove impact resistanceWoven fabricsConjugated synthetic polymer artificial filamentsFiberCarbon fibers

The invention provides a composite material taking a carbon fiber / polyimide fiber hybrid fabric as the enhancing body and a preparation method thereof. The composite material is prepared by spinning or weaving carbon fibers and polyimide fibers to obtain carbon fiber / polyimide fiber hybrid fabrics; and then compounding carbon fiber / polyimide fiber hybrid fabrics with a filling material to obtain the composite material. Polyimide fibers are taken as one of the main materials of the enhanced body, the problem that the composite material is very fragile when only carbon fibers are taken as the enhancing body is solved, on the premise that the mechanical strength of the composite material is not influenced; and moreover, the impact resistant performance and the insulation property of the composite material are greatly improved. The composite material can be used to produce bulletproof clothes, bulletproof bags, bulletproof armoring, bulletproof guard boards, bulletproof helmets, safety helmets, collision resistant walls, collision resistant protective boards, bumpers, brake discs, grinding wheels, friction materials, and the like. Furthermore, the composite material can be used to enhance and reinforce bridges and buildings.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Synthetic method of waterborne polyurethane adhesive

ActiveCN105400481ARaw materials are easy to getLow costPolyureas/polyurethane adhesivesDispersion stabilityPolyurethane adhesive

A synthetic method of waterborne polyurethane adhesive is as below: reacting dehydrated polyol, an ionic group-containing diol chain extender and diisocyanate in a reactor, then adding a solvent 1 and a catalyst, continuing the reaction, then adding castor oil or modified castor oil and a solvent 2, reacting, adding a neutralizing agent for neutralization to obtain the intermediate, adding a sulfonic acid group-containing diamine chain extender to the intermediate, stirring, then adding deionized water, uniformly dispersing, then adding an aqueous solution of small molecule diamine chain extender, reacting, removing the solvent under vacuum to obtain a milky white waterborne polyurethane dispersion liquid, and preparing glue by using the milky white aqueous polyurethane dispersion liquid, a thickener, a curing agent and a substrate wetting agent to obtain the waterborne polyurethane adhesive. The waterborne polyurethane adhesive provided by the present invention has the advantages of high solid content, good dispersion stability, high initial bonding strength and good resistance to damp-heat aging.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Photovoltaic backplane adhesive and preparation method thereof

ActiveCN102887988AImprove hydrolysis resistanceImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterHexafluoropropylene

The invention discloses a photovoltaic backplane adhesive which comprises a component A and a component B, wherein the component A contains hydrolysis resistant polyester polyol, and component B comprises an isocyanate curing agent; and the molar ratio of the isocyanate group in the isocyanate curing agent and the hydroxyl in the hydrolysis resistant polyester polyol is (0.9-1.3):1. The photovoltaic backplane adhesive adopts the hydrolysis resistant polyester polyol and the isocyanate curing agent, and the molar ratio of the isocyanate group and the hydroxyl in the hydrolysis resistant polyester polyol is (0.9-1.3):1, so that the hydrolysis resistance, the adhesive property and the weather fastness of the prepared photovoltaic backplane adhesive are improved. The photovoltaic backplane adhesive can be used for interlamination compounding of a film, and is especially suitable for the interlamination compounding of a photovoltaic backplane, thus being suitable for splicing and compounding the photovoltaic backplanes made of polyethylene terephthalate (PET), polyvinylidene fluoride (PDVF), tetrafluoroethylene-hexafluoropropylene-vinylidene fluoride (THV), polyvinyl fluoride (PVF), polyethylene (PE) and other films.

Owner:CSI SOLAR POWER GROUP CO LTD +1

Preparation method of polyester chip for solar battery back film

InactiveCN105542138AImprove crystallization abilityReduce contentPhotovoltaic energy generationSemiconductor devicesSolid phasesChemistry

The present invention discloses a preparation method of a polyester chip for a solar battery back film. A polyester chip semi-finished product with intrinsic viscosity of 0.60-0.64 dl / g and terminal carboxyl group content of 12-18 mol / t is subjected to solid phase polycondensation to obtain the polyester chip for solar battery back film with intrinsic viscosity of 0.75-0.80 dl / g and terminal carboxyl group content of 5-10 mol / t. The preparation method has simple reaction conditions and low production costs; the obtained polyester chip can be separately produced into polyester film suitable for solar battery back without the addition of an anti-hydrolysis agent or an ultraviolet absorber, wherein the polyester film has good water vapor barrier property, resistance to wet heat aging and resistance to light aging. The method is not only friendly to the environment and human, but also avoids the problems of uneven dispersion and inconsistency of product performance of blend film production.

Owner:HEFEI LUCKY SCI & TECH IND

Polyurethane resin combination and preparation method and using method thereof

The invention provides a polyurethane resin composition, its preparation method, and using method of the same used as filling material of railway plate type dreg-free track convex block. The polyurethane resin composition is mainly used as filling material of railway plate type dreg-free track convex block, and mainly includes: polyether or polyester polyol, isocyanate or prepolymer of the same, pigment, filling and other auxiliary agent. Advantages of the prepared polyurethane resin are: construction manufacturability is better, bonding to cement of cured resin is good; the polyurethane resin is resistant of ultraviolet ray irradiation, moisture, heat, ageing and fatigue, and owns appropriate elasticity and integrated mechanical capability.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Composition of unsaturated resin, preparation method, and method of application

This invention provides an unsaturated resin composition, its preparation method, and its application as the filler of the slab-free track cam plate. The unsaturated resin composition is mainly composed of unsaturated resin, pigment, filler, peroxide initiator, and other additives. The unsaturated resin composition has such advantages as high processability, and high adhesiveness to cement after cured, appropriate elasticity, good comprehensive mechanical properties, and high UV, humidity, heat, aging and fatigue resistance.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

Epoxy resin structural adhesive and preparation method thereof

InactiveCN101906282AHigh strengthImprove toughnessNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyAdhesive

The invention discloses an epoxy resin structural adhesive and a preparation method thereof, belonging to the technical filed of chemical adhesive preparation. The used raw material consists of a resin system, an adhesive component A and a curing agent system component B, and the component A and component B are completely mixed and then cured at room temperature. The structural adhesive in the invention has the advantages of high strength and toughness, good creep resistance, little creep strain, good fatigue resistance and shock resistance, good heat resistance, medium resistance and corrosion resistance, particularly good muggy and aging resistance, excellent creep rupture strength, enough safety and reliability, good flame retardant property, low stress, high strength, high adhesive force, high reliability and the like, and complies with environmental requirements. The epoxy resin structural adhesive is mainly used for adhering composite materials, such as manufacturing yachts, building houses with composite boards, adhering and manufacturing containers made of large-scale composite materials, and the like.

Owner:强军锋

Resin composition for base material of solar backboard

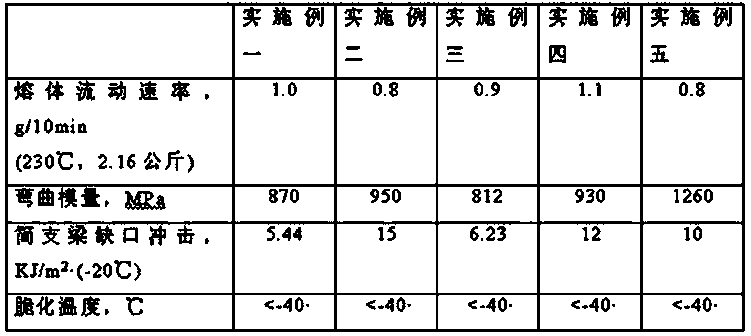

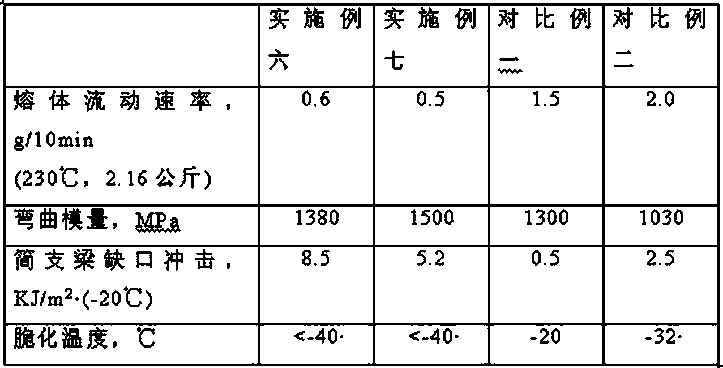

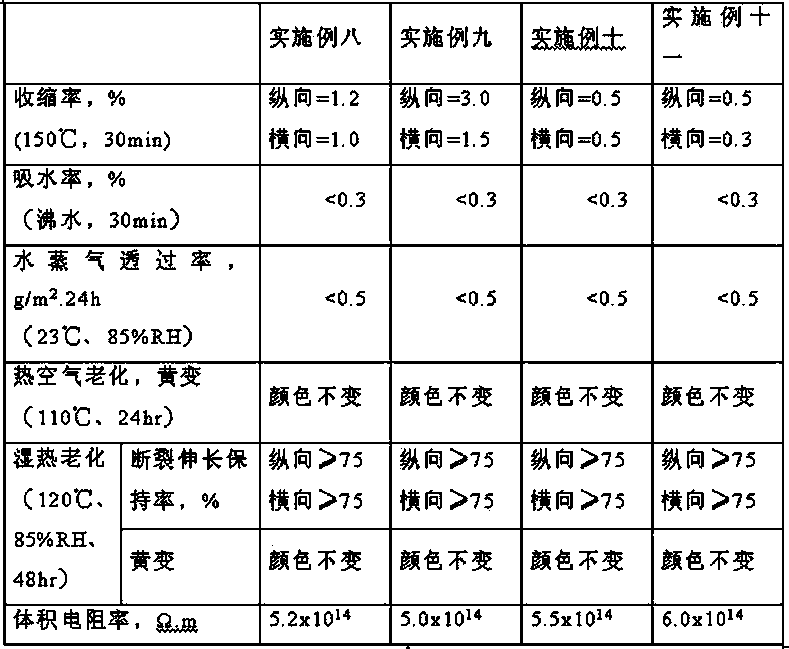

ActiveCN103897266AImprove low temperature resistanceGood moisture and heat aging resistanceSemiconductor devicesWater vapor permeabilityBoPET

The invention discloses a resin composition for a base material of a solar backboard. The resin composition comprises the following components in parts by weight: 100 parts of component A and 20-100 parts of component B, wherein the component A is homo-polypropylene, segmented co-polypropylene or the mixture of homo-polypropylene and segmented co-polypropylene; the DSC (differential scanning calorimetry) melting point of the component A is 160-165 DEG C, and the melt flow rate is 1-2g / 10 minutes; the component B is homo-polyethylene, co-polyethylene or the mixture of homo-polyethylene and co-polyethylene; the DSC (differential scanning calorimetry) melting point of the component B is 120-135 DEG C, the melt flow rate is 1-2g / 10 minutes, and the density is 0.941-0.959 g / cm<3>. The base material of the solar backboard prepared from the novel resin composition developed by the invention has excellent low-temperature resistance, damp-heat aging resistance and electrical insulating performance and low saturated water absorption rate and water vapor permeability, and can be used for replacing an existing BOPET (biaxially oriented polyester film).

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Modified polypropylene composite material and preparation method of same

ActiveCN108034147AImprove scratch resistanceLow costHeat deflection temperaturePolypropylene composites

The invention discloses a modified polypropylene composite material which includes, by weight, 35-90 parts of polypropylene resin, 8-35 parts of basalt fibers, 0.1-5 parts of a scratch resistant agent, 0.5-5 parts of a coupling agent, and 0.2-5 parts of a compatibilizer. The basalt fibers are selected from at least one of non-twist continuous basalt fibers and short-cut basalt fibers. The non-twist continuous basalt fibers are 1200-2400 tex non-twist continuous basalt fibers and the short-cut basalt fibers are 0.2-10 mm short-cut basalt fibers; preferably, the basalt fibers are pre-treated inacetic acid being 1.0-3.0 mol / L for 1-3 h. The modified polypropylene composite material has low cost, high thermal deformation temperature, good tensile strength, high bending modulus and excellent damp-heat-resistance, anti-aging property and scratch resistance, and can satisfy demands on vehicle-use modified polypropylene composite materials.

Owner:WUHAN JINFA TECH CO LTD +1

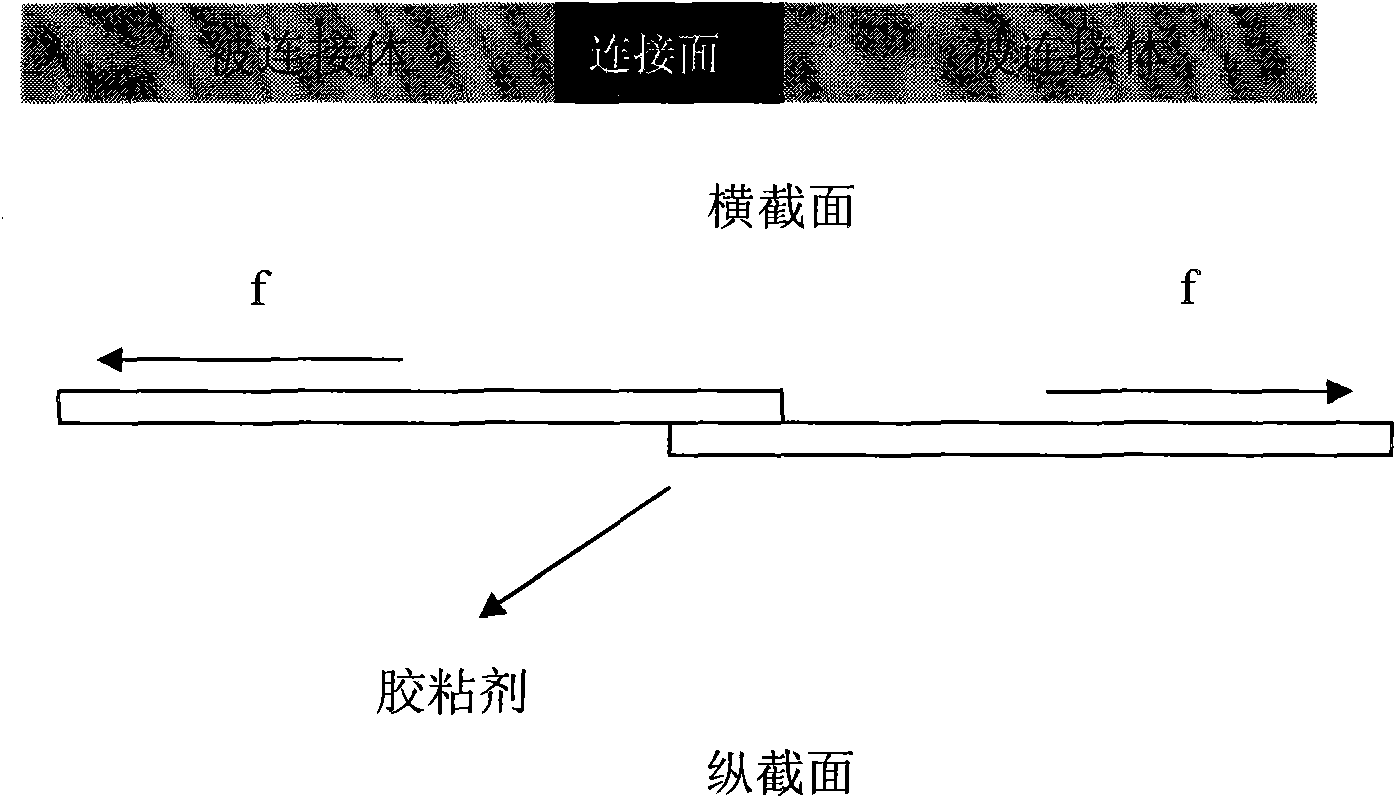

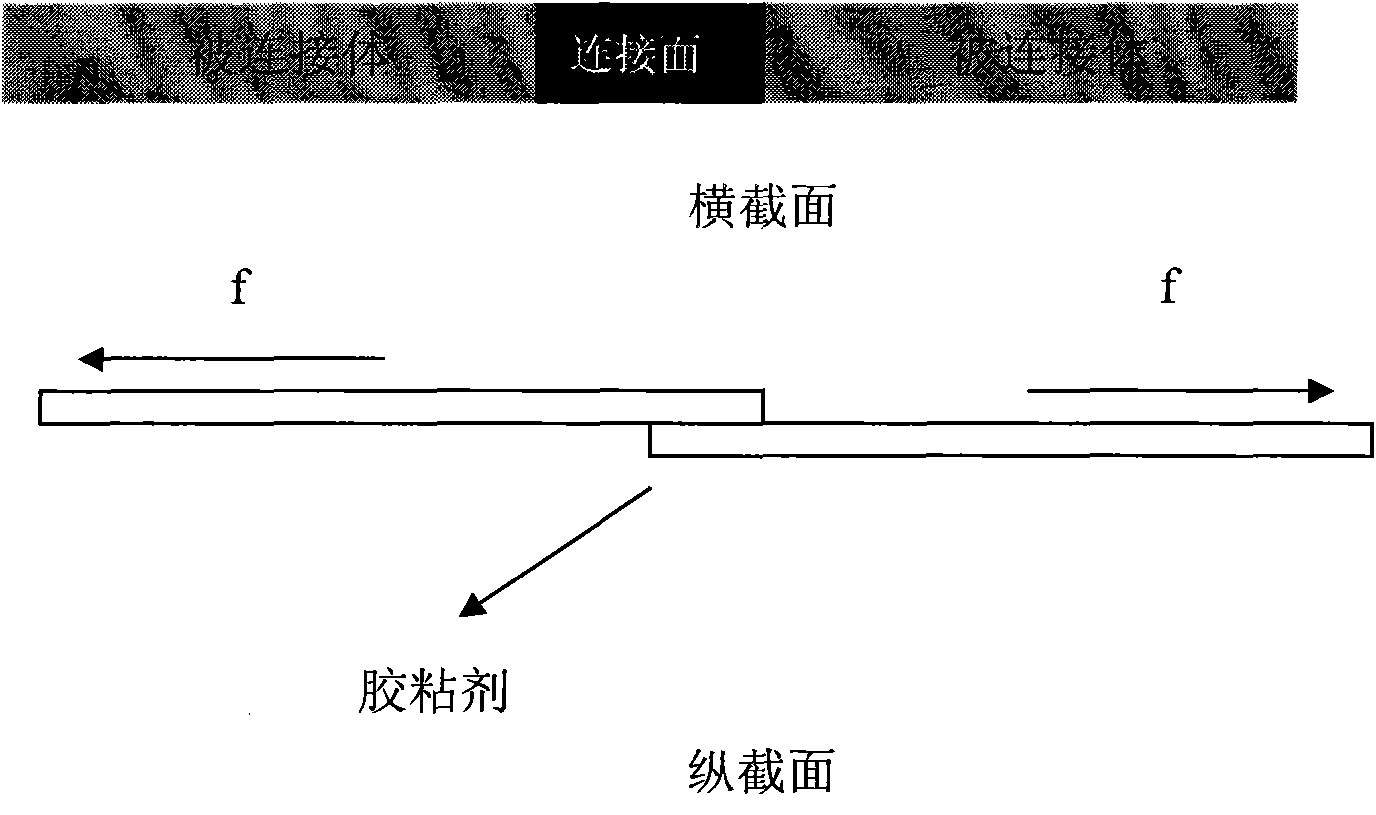

Synthesis technique of dual-component wet and heat ageing resistant epoxy building structure strengthening adhesive

The invention provides a double-component, heat and humidity resistance epoxy architecture reinforcement glue, comprising first and second components. The preparation method of the glue comprises: 1) adding reactive toughening agent thiocol, fluid epoxy resin, reactive diluent C12-14 tertiary carbonic acid ethylene oxidic ester, reactive diluent phenyl glycidyl ether and antifoaming agent by weight portion, silane coupler, discharged gas phase white carbon black and uniformly stirring, standing and defoaming to obtain first compnent: 2) uniformly stirring the isophorone diamine, metaxylene diamine, aromatic alcohol, salicylic acid and epoxy resin E44 to obtain second component curing agent by weight portion; mixing the promoter and curing agent in proportion to obtain second component. The architecture reinforcement glue without solvent can be cured at room temperature and conveniently constructed, with fine viscosity, good thixotropy, excellent resistance to heat and humidity, mechanical property and adhesive property, without toxin and pollution.

Owner:上海华夏化工材料有限公司

High-intensity epoxy cellular adhesive and preparation method thereof

ActiveCN107779147ASmall dispersion of bonding strengthImprove flame retardant performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyHigh intensity

The invention relates to a high-intensity epoxy cellular adhesive and a preparation method thereof. During use of the high-intensity epoxy cellular adhesive, a first component and a second component are mixed according to a weight ratio of (2 to 4) to 1; the first component is prepared from the following constituent raw materials in parts by weight: 30 to 55 of epoxy resin, 5 to 10 of low viscosity epoxy resin, 3 to 8 of an activated toughening agent, 10 to 20 of reinforcing filler, 10 to 20 of a flame retardant and 0.3 to 3 of a thixotropic agent; the second component is prepared from the following constituent raw materials in parts by weight: 50 to 90 of a toughening curing agent, 10 to 20 of a hardening curing agent and 0.3 to 1 of a coupling agent. Compared with the prior art, the high-intensity epoxy cellular adhesive has the advantages of low adhesion strength discreteness, rigidity, toughness and the like.

Owner:上海海鹰粘接科技有限公司

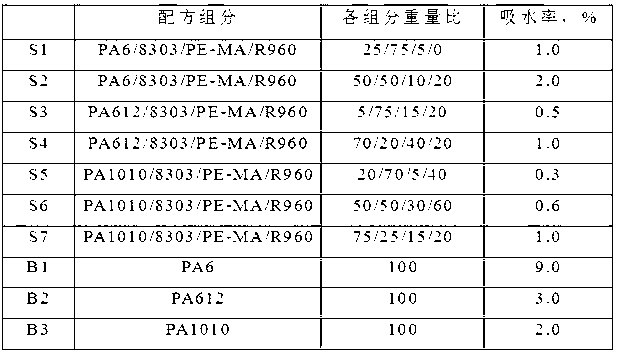

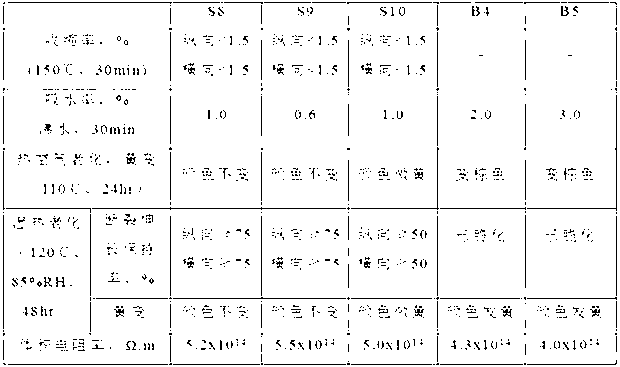

A modified polyamide resin composition and backplane substrate film prepared by the same

ActiveCN103059558AImprove heat resistanceImprove wear resistancePhotovoltaic energy generationSemiconductor devicesPolypropylenePolyamide

The present invention discloses a modified polyamide resin composition and backplane substrate film prepared by the same. The modified polyamide resin composition comprises the following components, by mass: 5-75 parts of polyamide resin, 5-75 parts of polypropylene resin, 5-50 parts of grafted polyethylene, and 0-100 parts of a filler. The grafted polyethylene is prepared from the following components via graft reaction: 100 parts of polyethylene resin, 0.5-2.0 parts of a grafting agent, and 0.03-0.2 parts of an initiator. According to the present invention, a new resin composition used for backplane substrates of solar energy assemblies is developed; the final product obtained has anti-aging, particularly anti-damp and heat aging performance, and also has low saturation water absorption, low water vapor transmission and excellent electrical insulating properties, and backplane substrate film prepared therefrom further has high adhesion and mechanical strength, and can be used for manufacturing backplane of solar energy assemblies.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Insulation adhesive material for compound photovoltaic backsheet and application

ActiveCN107353859AImprove insulation performanceImprove cohesive energyPolyureas/polyurethane adhesivesEpoxy resin adhesivesHeat resistanceAcid value

The invention discloses an insulation adhesive material for a compound photovoltaic backsheet and application. The insulation adhesive material is composed of a component A and a component B. The component A contains matrix resin, assistant resin and an assistant, wherein the matrix resin is hydroxyl polyester resin, which has a hydroxyl value of 5-30mgKOH / g, an acid value of 0.2-5mgKOH / g, a number-average molecular weight of 5000-50000, a glass transition temperature ranging from -40DEG C to 30DEG C, and is prepared by esterification polycondensation reaction of small molecular polyprotic acid and polyol under inert gas protection. The component B is a crosslinked component. During use, the component A and the component B are mixed in different proportions according to requirements. The insulation adhesive material provided by the invention not only has long-term and stable bonding performance, but also has excellent performance in heat resistance, insulation and weatherability, and can be used for preparation of high weather resistant compound photovoltaic backsheets. Also, the raw materials are easily available, the process is controllable, and the operation is simple.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

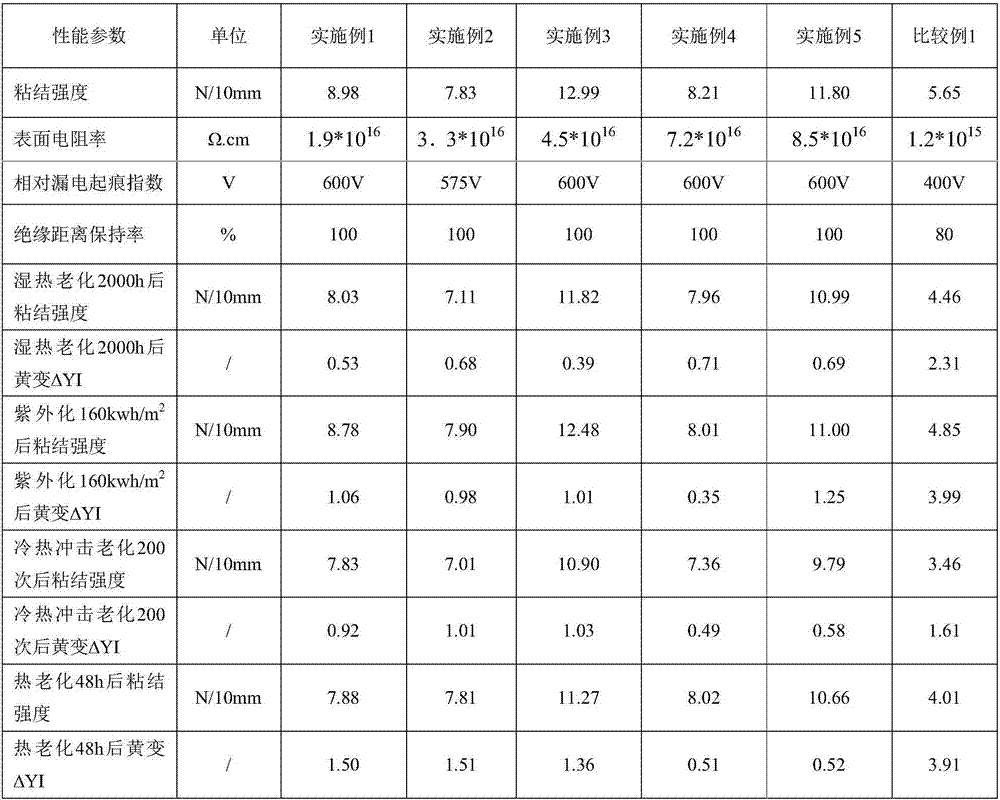

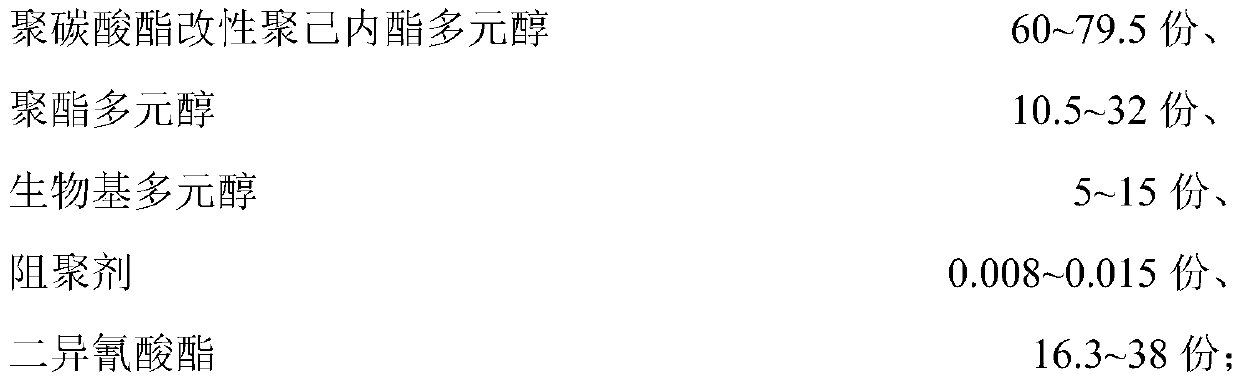

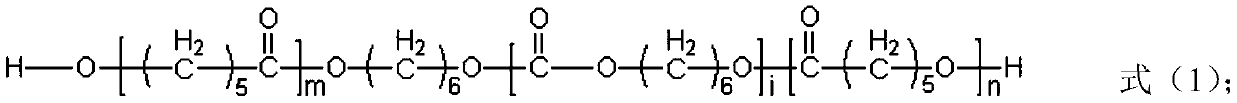

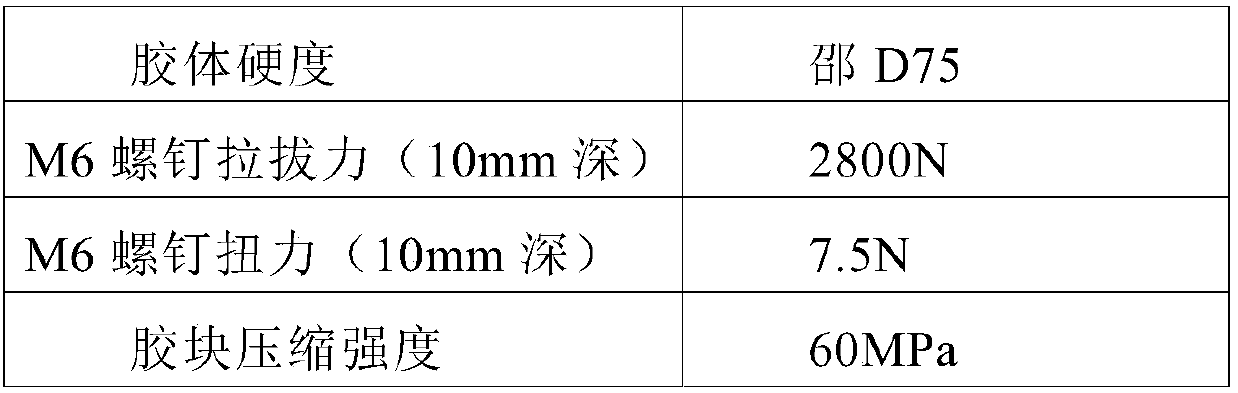

Damp-heat aging resisting NDI-based polyurethane microporous elastomer and preparation method thereof

ActiveCN110105525AGood moisture and heat aging resistanceImprove hydrolysis resistanceCross-linkElastomer

The invention provides a damp-heat aging resisting NDI-based polyurethane microporous elastomer and a preparation method thereof. The NDI-based polyurethane microporous elastomer is prepared from a component A and a component B according to the mass ratio of 100:(2.3-9.6) through a reaction. The component A comprises polycarbonate modified polycaprolactone polyhydric alcohol, polyester polyol, biobased polyol, a polymerization inhibitor and diisocyanate. The component B comprises a chain extender, a cross-linking agent, a catalyst, a foam stabilizer and a foaming agent. The NDI-based polyurethane microporous elastomer has very good damp-heat aging resisting performance, and has good hydrolysis resistance, low-temperature flexibility and physical and mechanical properties, and the use requirement under tough weather conditions such as high temperature and high humidity can be completely met. The preparation method is short in technological process, easy to operate, low in process cost,high in production efficiency and suitable for industrial production.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for improving adhesion of slurry of pole piece of positive pole

InactiveCN101635346AIncrease areal densityIncreased durabilityElectrode manufacturing processesPretreated surfacesVisual observationAdhesive

The invention provides a method for improving the adhesion of slurry of a pole piece of a positive pole, and a silane coupling agent is used for processing the surface for coating the slurry on the pole piece of the positive pole before coating the slurry. The silane coupling agent is adopted for processing a current collector of the positive pole before coating the slurry, thereby being capable of improving the adhesion of the slurry on the pole piece of the positive pole, improving the surface density of the slurry on the pole piece of the positive pole and having no material dropping off by visual observation. The silane coupling agent can further improve the durability and the thermal and wetting aging resistance of an adhesive.

Owner:SHENZHEN BAK BATTERY CO LTD

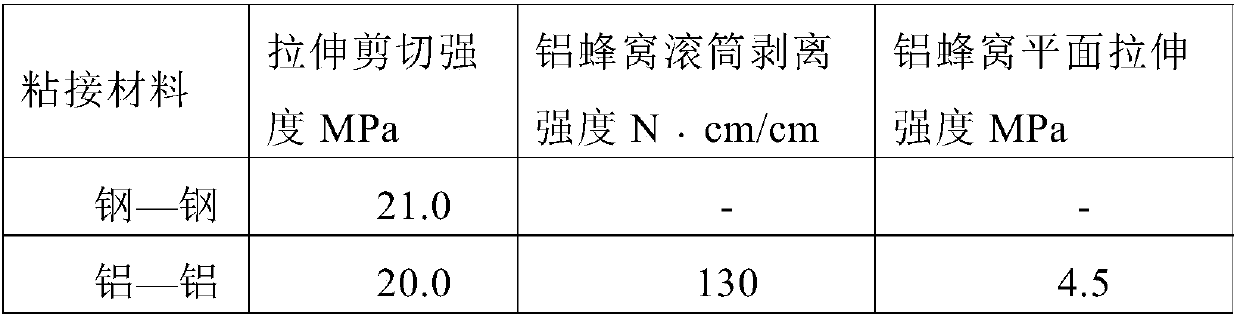

Phenolphthalein polyaryletherketone modified epoxy structure adhesive film and preparation method thereof

InactiveCN104194662AImprove heat resistanceGood moisture and heat aging resistanceFilm/foil adhesivesEpoxynovolac adhesivesEpoxyPhenolphthalein

The invention discloses a phenolphthalein polyaryletherketone modified epoxy structure adhesive film and a preparation method of the phenolphthalein polyaryletherketone modified epoxy structure adhesive film, and relates to an adhesive and a preparation method of the adhesive. The adhesive film and the preparation method of the adhesive film solve the problem that the temperature tolerance of an existing high-temperature cured epoxy structure adhesive is poor. The phenolphthalein polyaryletherketone modified epoxy structure adhesive film is prepared from a main resin, a main flexibilizer, an auxiliary flexibilizer, a curing agent and a coupling agent. The method comprises 1 weighing, 2 mixing the materials together, 3 preparing the adhesive; 4 preheating, calendaring and forming the film. The adhesive film has excellent heat resistance, damp-heat aging resistance, higher shearing strength, higher high temperature strength, and higher toughness. The method is used to prepare the phenolphthalein polyaryletherketone modified epoxy structure adhesive film, and is applied in the technical field of high polymer materials.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Composite plate pre-embedding adhesive and preparation method thereof

ActiveCN107779148ASmall dispersion of bonding strengthIncrease stiffnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention relates to a composite plate pre-embedding adhesive and a preparation method thereof. During use of the composite plate pre-embedding adhesive, a first component and a second component are mixed according to a weight ratio of (2 to 4) to 1; the first component is prepared from the following constituent raw materials in parts by weight: 20 to 45 of epoxy resin, 1 to 10 of modified epoxy resin, 1 to 10 of activated diluents, 5 to 20 of reinforcing filler, 20 to 70 of a flame retardant and 0.3 to 10 of a thixotropic agent; the second component is prepared from the following constituent raw materials in parts by weight: 50 to 90 of a toughening curing agent, 10 to 20 of a hardening curing agent, 0.3 to 1 of a coupling agent and 0.3 to 15 of a thixotropic agent. Compared with theprior art, the composite plate pre-embedding adhesive has the advantages of extremely high rigidity, toughness and the like.

Owner:上海海鹰粘接科技有限公司

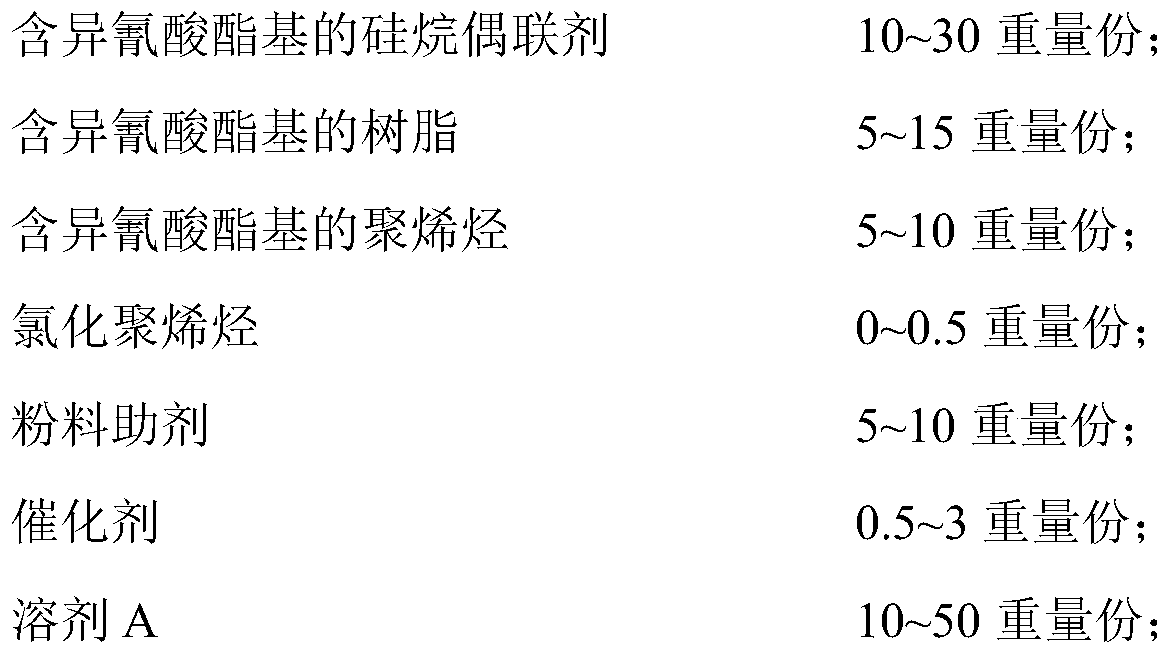

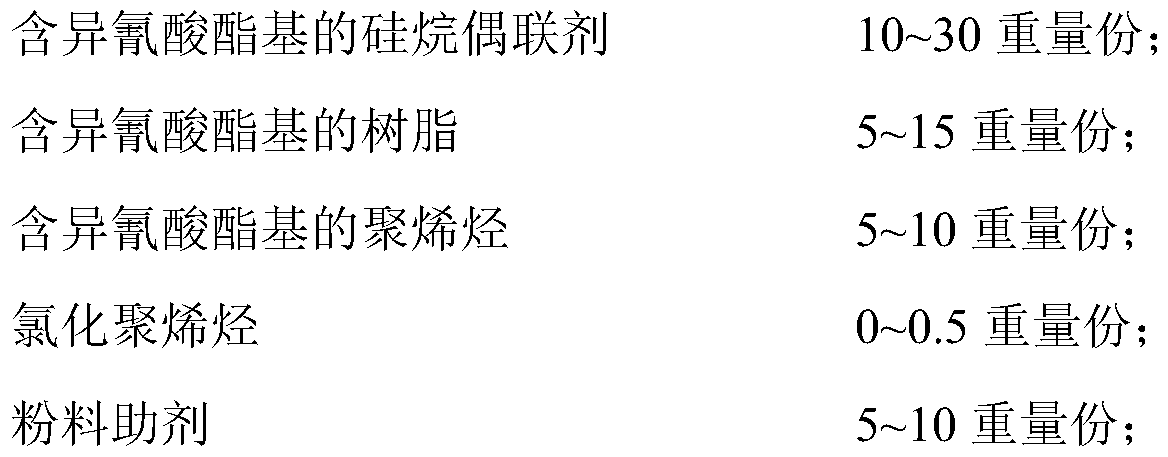

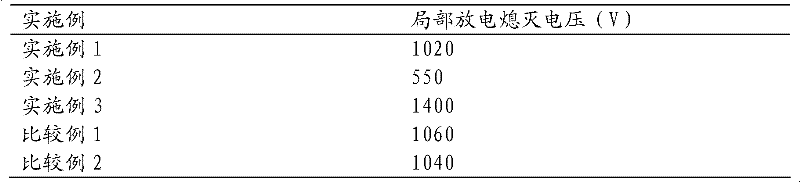

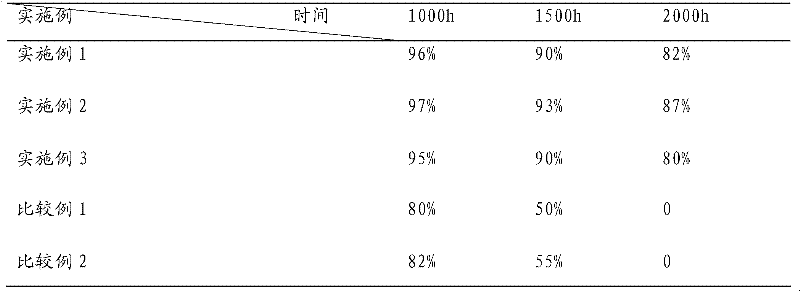

Primer coating for automobile composite material bonding and preparation method of primer coating

ActiveCN110591521AImprove toughnessIncrease chain ratioAdhesive processes with surface pretreatmentPolyester coatingsProduction linePolyolefin

The invention discloses a primer coating for automobile composite material bonding and a preparation method of the primer coating and belongs to the technical field of polyurethane adhesive bonding primer coatings. The primer coating comprises the following components in parts by weight: 10-30 parts of a silane coupling agent of which the content of an isocyanate group is 6-8wt%, 5-15 parts of a resin of which the content of an isocyanate group is 2-5wt%; 5-10 parts of polyolefin of which the content of an isocyanate group is 6-9wt%, 0-0.5 part of chloridized polyolefin is 20-45wt%, 5-10 partsof a powder aid, 0.5-1 part of a catalyst and 10-50 parts of a solvent. The primer coating is rapid in surface dry time, high in automobile composite material bonding and in addition, good in high temperature and high humidity performance; and when the primer coating is used together with a single-component polyurethane bonding adhesive, the space of a production line site can be saved, adhesiveapplication can be convenient, the production efficiency of automobile manufacturing can be improved, and the problems that a conventional single-component polyurethane adhesive primer coating cannotbe used on an automobile composite material and particularly is poor in high temperature and high humidity resistance can be solved.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

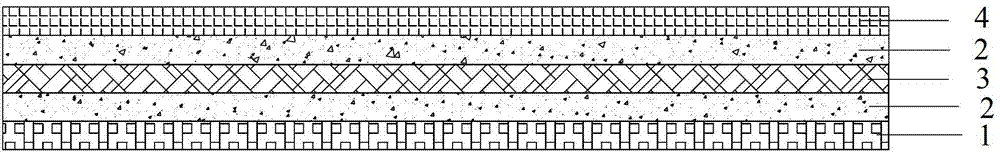

Solar rear panel and production method for same

ActiveCN102642364AImprove insulation performanceGood moisture and heat aging resistanceSynthetic resin layered productsPhotovoltaic energy generationThermal ageingCross-link

The invention provides a solar rear panel, which comprises a base layer, a weather-proof layer and a coating layer, wherein the weather-proof layer is compounded on one side of the base layer, the coating layer is composited on the other side of the base layer, and the base layer is obtained by means of cross-linking and curing polyolefin under the action of curing accelerators. The invention further provides a production method for the solar rear panel, and the polyolefin and the curing accelerators are cured into a film and then cross-linked to obtain the solar rear panel. The solar rear panel has fine aging resistance and chemical stability, and is not easy to hydrolyze or degrade, so that the obtained solar rear panel is not easy to crack, fine insulating property, humidity and heat resistance and aging resistance can be constantly kept, and the risk of component failure is reduced. Performance testing results indicate that the breaking strength retention rate of the solar rear panel is higher than 70% when the solar rear panel produced by the production method is exposed in an ultraviolet condition for 2000 hours, and the breaking strength retention rate of the solar rear panel is higher than 80% when the solar rear panel is exposed in an accelerated aging environment for 2000 hours.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

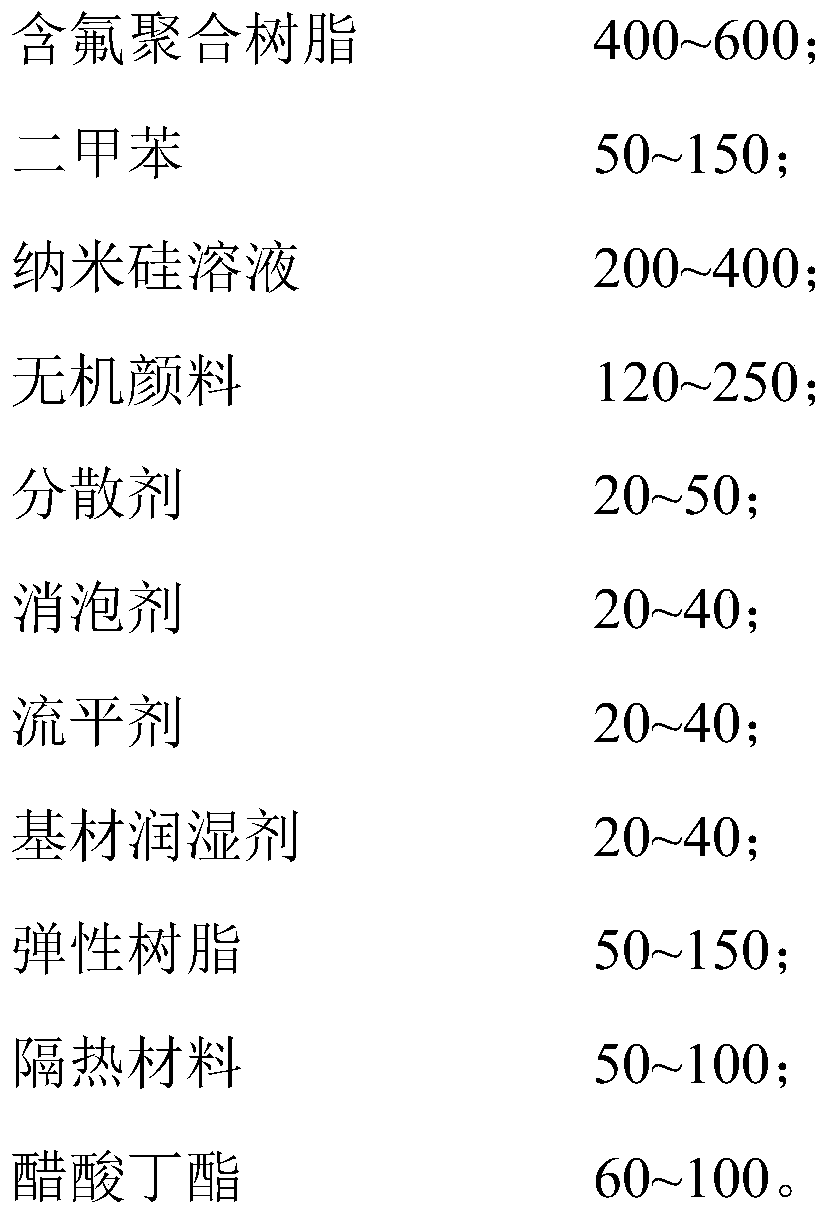

A kind of fluorine-silicon nanometer waterproof and heat-insulating composite material and preparation method thereof

ActiveCN111363421BImprove aging resistanceImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesXylyleneThermal insulation

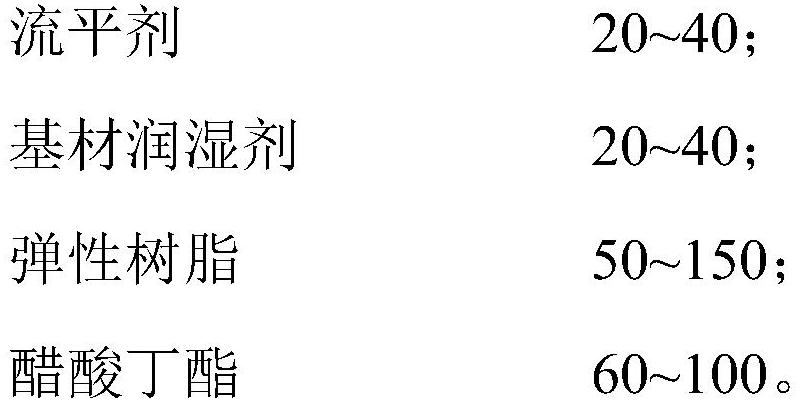

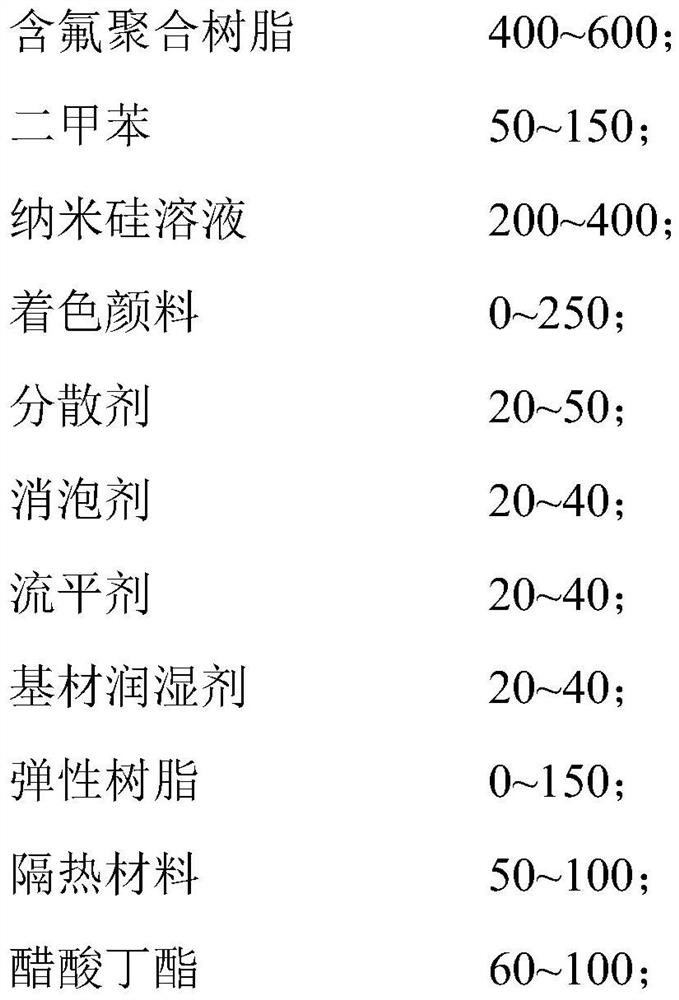

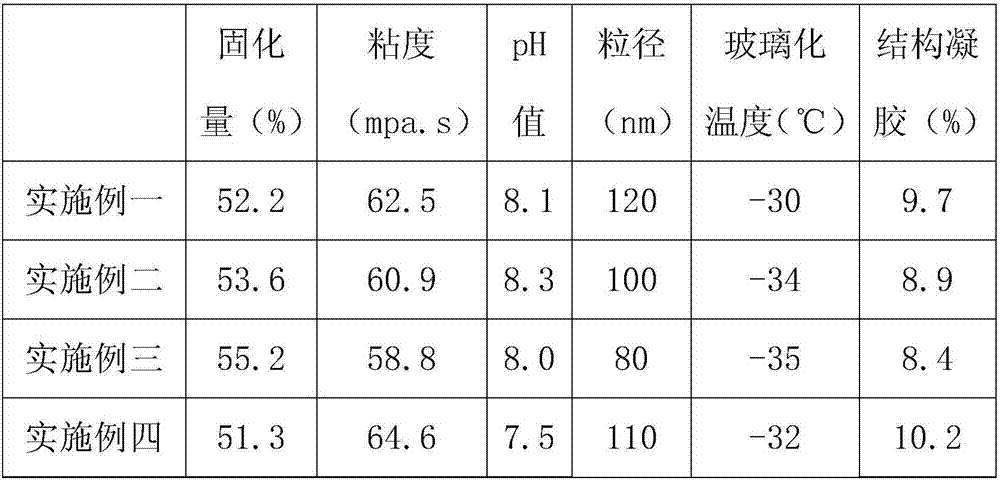

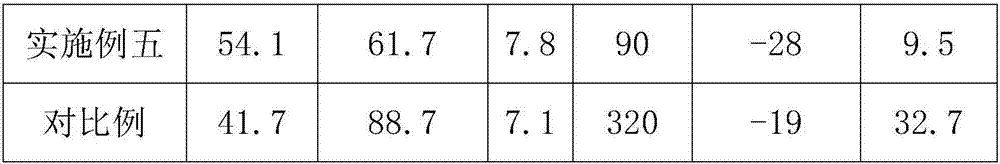

The invention discloses a fluorine-silicon nanometer waterproof and heat-insulating composite material and a preparation method thereof, comprising the steps of: 1) adding fluorine-containing polymer resin and xylene into a jacketed cylinder and stirring evenly; 2) raising the temperature of the liquid in the cylinder to 40-40 60°C, then add nano-silicon solution and stir while stirring, keep the temperature at 40-60°C, stir for 20-40 minutes, then cool to 20-30°C, the above-prepared fluorosilicon nano-resin solution is ready for use; 3) In the material Add fluorine-containing polymer resin, dispersant, and inorganic pigment powder into the tank for high-speed dispersion, and prepare a pigment slurry; 4) Add fluorosilicon nano-resin liquid into the material tank, add pigment slurry, add defoamer, leveling agent, base material Wetting agent, elastic resin, 5 thermal insulation materials, and butyl acetate are stirred to obtain the A component of the fluorosilicon nano-waterproof and heat-insulating composite material; the A component and the coating B component cross-linking agent form the fluorosilicon nano Waterproof and thermal insulation composite. The waterproof and heat-insulating paint of the invention has good weather resistance and corrosion resistance, and is environmentally friendly.

Owner:衢州传祺防水防腐工程科技有限公司

Photo/thermal initiation fast curing adhesive

ActiveCN104927732AMeet the shear strengthMeet the fatigue strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention provides a photo / thermal initiation fast curing adhesive which comprises the following components by mass: 40-70 parts of one or more epoxy resin matrixes, 20-40 parts of a latent thermal initiation curing agent, 0.5-5 parts of one or more photo initiation curing agents, 0.1-2.5 parts of one or more photosensitizers, 15-35 parts of one or more flexibilizers, and 20-40 parts of one or more fillers. A preparation method of the photo / thermal initiation fast curing adhesive comprises the following steps: at first, under the action of ultraviolet light, the photo initiation curing agents are used for initiating part of epoxy resin to perform a curing reaction, under the action of heat released during the curing reaction and an external heat source, the temperature of the cured part reaches the latent imidazole initiation reaction temperature of 70-90 DEG C, a latent imidazole complex is activated, epoxy resin is initiated to be quickly cured within 3 min, the automatic, high-quality and fast-cementing connection requirements of a car composite material are met, and the technical problems such as mismatch between the traditional adhesive curing initiation condition and the connection working condition of the car composite material are solved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Process for producing carboxylic acrylonitrile butadiene rubber latex

The invention belongs to the technical field of macromolecule chemical material production, in particular discloses a process for producing carboxylic acrylonitrile butadiene rubber latex, and aims to solve the problems that in the prior art, a rich varieties of monomers are used and the monomers are tediously added for multiple times in the carboxylic acrylonitrile butadiene rubber latex production process, the process operation is complex, the reaction temperature is relatively hard to control and the reaction time is long. The preparation method comprises the following steps: uniformly mixing deionized water, a molecular weight adjusting agent, a pH buffer agent and an emulsifier, introducing nitrogen, and vacuuming; adding butadiene, acrylonitrile, a crylic acid monomer and unsaturated carboxylic acid, and stirring so as to obtain an emulsion; heating the emulsion, adding an initiator and deionized water, and performing a heat-preservation reaction so as to obtain latex; and degassing the latex, adding aids, dispersing uniformly, cooling, and sub-packaging, thereby obtaining the carboxylic acrylonitrile butadiene rubber latex. The process is simple in production process operation, gentle in reaction condition, easy to control, free of phenomenon of temperature runaway and gel, rapid in reaction, high in conversion rate, environmentally friendly and free of pollution in production process, low in production cost and worthy of popularization.

Owner:NINGBO SHUNZE RUBBER

Graphene coated inorganic filler composite resin adhesive material

InactiveCN106010403AHigh reactivityImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemical industryConducting pathway

The invention relates to a graphene coated inorganic filler composite resin adhesive material. The material is prepared from, by weight, 20-35 parts of resin matrix, 40-60 parts of graphene coated inorganic filler and 20-30 parts of curing agent. According to the composite resin adhesive, the composite resin matrix, the composite inorganic filler and the composite curing agent are adopted, and a heat-conducting pathway and a conductive network can be effectively formed; the product has an extremely high heat-conducting property and a certain flame-retardant property, and the heat-conducting coefficient of the finally prepared composite resin adhesive is larger than 9.0 W / mK, and the electric conductivity is larger than 37 S / m; the heat-resistant property is good, and a certain anti-corrosion capability is achieved; the graphene coated inorganic filler composite resin adhesive material can be widely applied to the fields of heat-sink devices, electronic packages, electronic equipment, chemical industry energy, automobile industry, aerospace and the like.

Owner:SICHUAN WUXIN ENERGY TECH

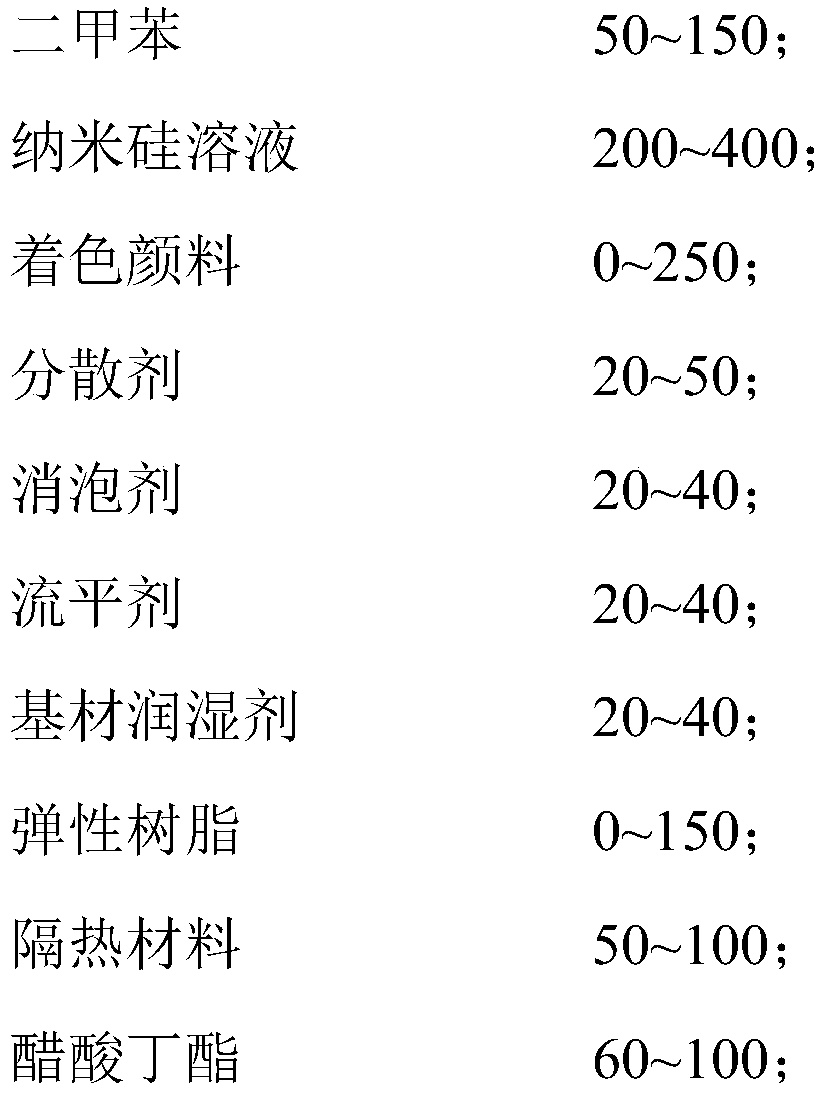

Fluorine-silicon nanometer waterproof heat-insulating composite material and preparation method thereof

ActiveCN111363421AImprove corrosion resistanceStir wellAntifouling/underwater paintsPaints with biocidesXylyleneThermal insulation

The invention discloses a fluorine-silicon nanometer waterproof heat-insulating composite material and a preparation method thereof. The preparation method comprises the following steps: 1) adding fluorine-containing polymer resin and xylene into a jacket cylinder, and carrying out uniform stirring; 2) heating liquid in the cylinder to 40-60 DEG C, then adding a nanometer silicon solution while stirring, carrying out stirring for 20-40 minutes while keeping a temperature at 40-60 DEG C, and carrying out cooling to 20-30 DEG C to obtain a prepared fluorine-silicon nanometer resin solution for later use; 3) adding fluorine-containing polymer resin, a dispersing agent and inorganic pigment powder into the material cylinder, and carrying out dispersing at a high speed to prepare pigment paste;4) adding the fluorine-silicon nanometer resin solution into the material cylinder, adding the pigment slurry, adding an antifoaming agent, a leveling agent, a substrate wetting agent, elastic resin,a thermal insulation material 5 and butyl acetate, and carrying out stirring to obtain a component A of the fluorine-silicon nanometer waterproof heat-insulating composite material, wherein the component A and a coating component B form the fluorine-silicon nanometer waterproof heat-insulating composite material. The waterproof heat-insulating coating is good in weather resistance and corrosion resistance and friendly to environment.

Owner:衢州传祺防水防腐工程科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com