Damp-heat aging resisting NDI-based polyurethane microporous elastomer and preparation method thereof

A technology of microporous elastomer and microporous elasticity, which is applied in the field of polyurethane materials, can solve the problems of low mechanical strength, poor dynamic performance and increase intermolecular distance of materials, achieve excellent moisture and heat aging resistance and low temperature flexibility, and improve mechanical properties Performance, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

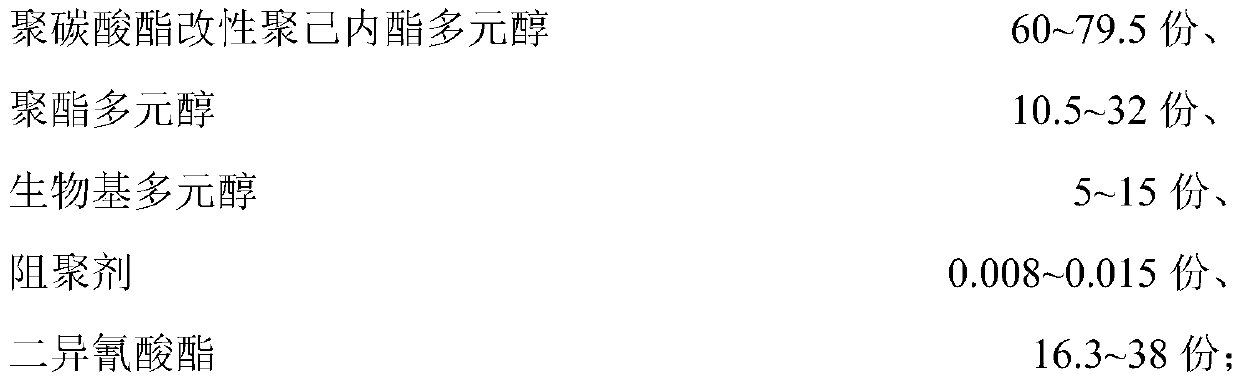

[0047] A damp heat aging resistant NDI-based polyurethane microcellular elastomer of the present invention, the NDI-based polyurethane microcellular elastomer is prepared by reacting component A and component B, wherein component A includes the following raw materials in parts by weight:

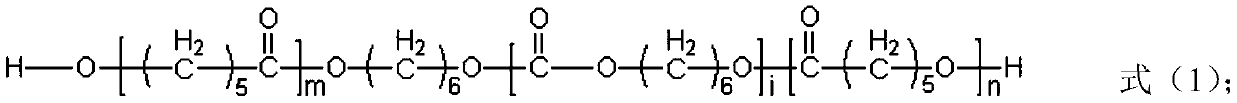

[0048] The average functionality is 2, the number-average molecular weight is 2000, and the polycarbonate-modified polycaprolactone diol of molecular structure formula as shown in formula (1) 60 parts;

[0049] 30 parts of polyadipate-ethylene glycol-trimethylolpropane-1,4-butanediol ester diol with an average functionality of 2 and a number average molecular weight of 2000;

[0050] 10 parts of dimer polyester diols with an average functionality of 2 and a number average molecular weight of 1000;

[0051] 0.012 parts of phosphoric acid;

[0052] NDI31.2 copies;

[0053] B component comprises the raw material of following weight portion:

[0054] 2.5 parts of 1,4-butanediol;

[0055] The...

Embodiment 2

[0070] A damp heat aging resistant NDI-based polyurethane microcellular elastomer of the present invention, the NDI-based polyurethane microcellular elastomer is prepared by reacting component A and component B, wherein component A includes the following raw materials in parts by weight:

[0071] The average functionality is 2, the number-average molecular weight is 2000, and the molecular structure formula is 70 parts of polycarbonate-modified polycaprolactone diols shown in formula (1);

[0072] 15 parts of polyadipate-ethylene glycol-trimethylolpropane-1,4-butanediol ester diol with an average functionality of 2 and a number average molecular weight of 2000;

[0073] 15 parts of dimer polyester diols with an average functionality of 2 and a number average molecular weight of 1000;

[0074] 0.012 parts of phosphoric acid;

[0075] NDI33.8 copies;

[0076] B component comprises the raw material of following weight portion:

[0077] 4.3 parts of 1,6-hexanediol;

[0078] Th...

Embodiment 3

[0093] A damp heat aging resistant NDI-based polyurethane microcellular elastomer of the present invention, the NDI-based polyurethane microcellular elastomer is prepared by reacting component A and component B, wherein component A includes the following raw materials in parts by weight:

[0094] The average functionality is 2, the number-average molecular weight is 2000, and the molecular structure formula is 79.5 parts of polycarbonate-modified polycaprolactone diols shown in formula (1);

[0095] 15.5 parts of polyadipate-3-methyl-1,5-pentanediol-1,4-butanediol ester diol with an average functionality of 2 and a number average molecular weight of 2000;

[0096] 5 parts of dimer polyester diols with an average functionality of 2 and a number average molecular weight of 1000;

[0097] 0.012 parts of phosphoric acid;

[0098] NDI26.9 copies;

[0099] B component comprises the raw material of following weight portion:

[0100] 1.5 parts of 1,4-butanediol;

[0101] The avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com