Fluorine-silicon nanometer waterproof heat-insulating composite material and preparation method thereof

A composite material and nano-technology, applied in antifouling/underwater coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as waterproof and heat-insulating coatings for human and environmental hazards, reduced coating protection ability, and outermost layer damage , to achieve low water vapor transmission rate, increase heat insulation performance, and prolong material life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

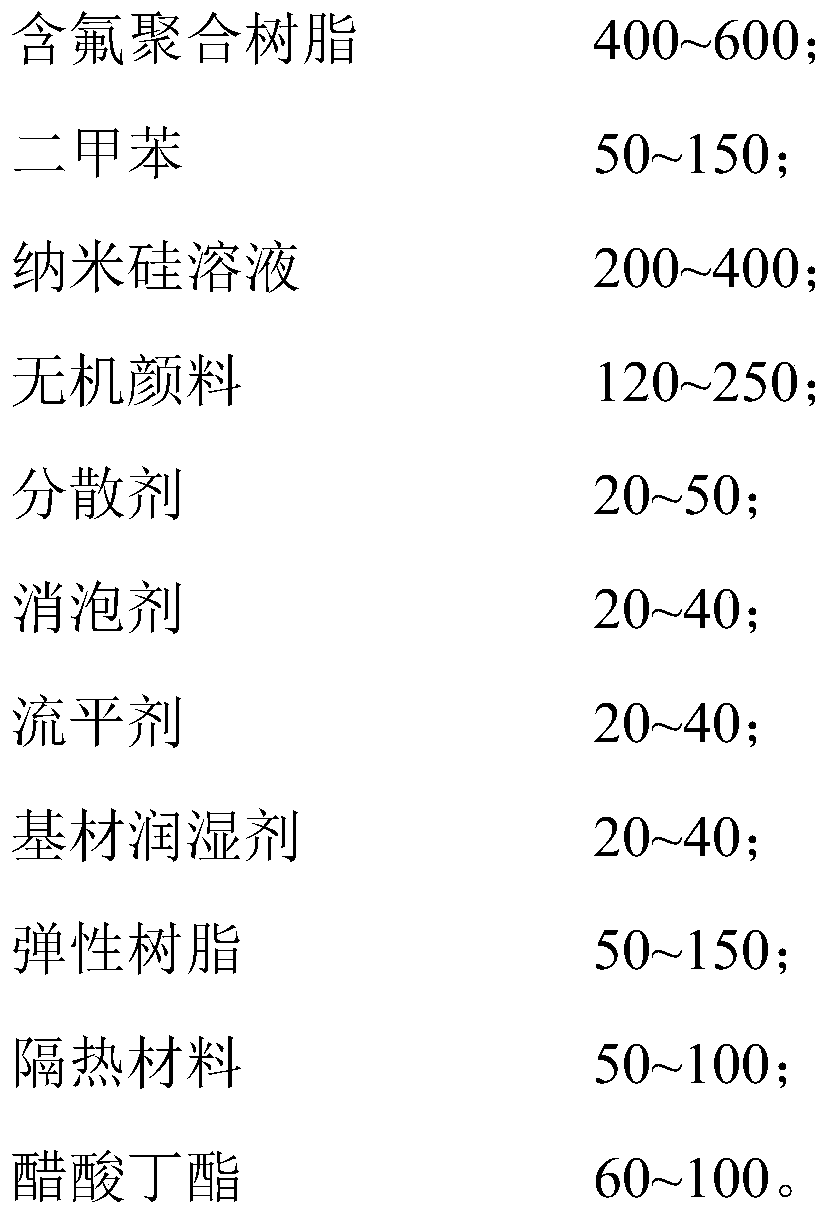

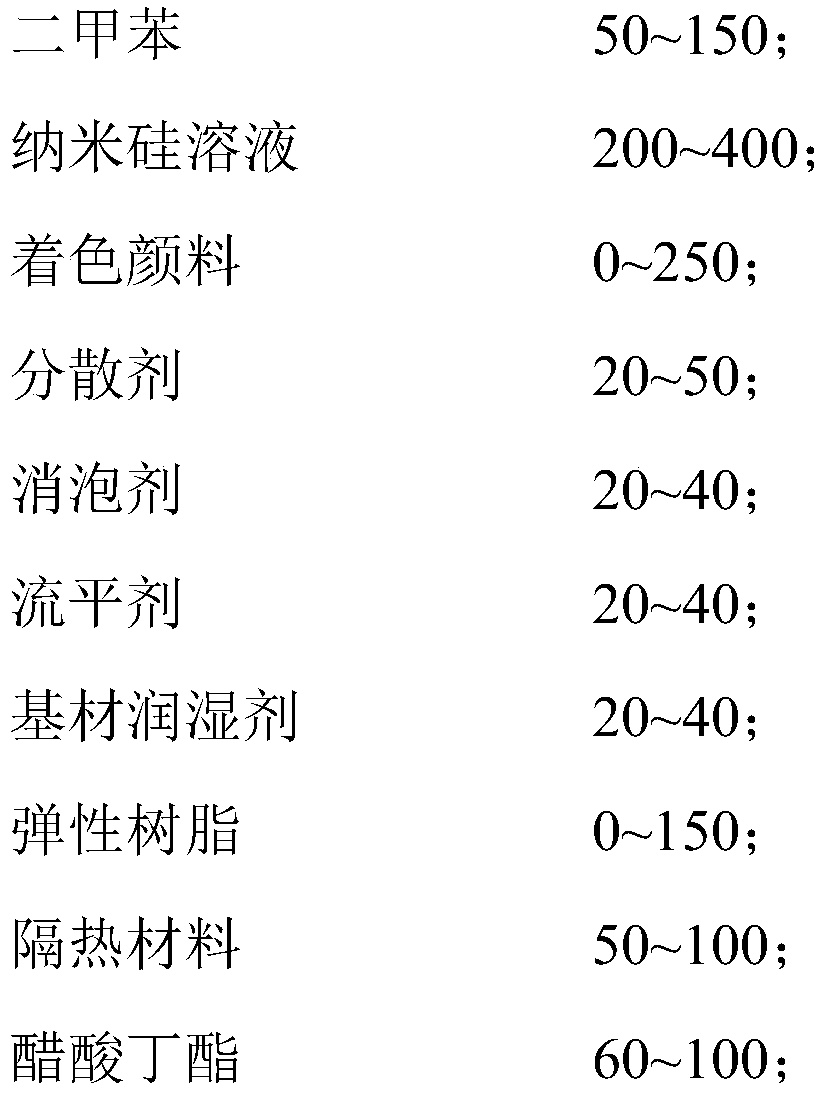

Method used

Image

Examples

Embodiment 1

[0111] A method for preparing the fluorosilicon nanometer waterproof and heat-insulating composite material, comprising the steps of:

[0112] 1) Add 500g of fluorocarbon resin and 100g of xylene into the jacketed cylinder, and stir evenly;

[0113] 2) Heat the liquid in the tank to 55°C, then add 300g of nano-silicon solution while stirring, stir at a medium speed, keep the temperature at 60°C, stir for 40 minutes, then cool to 20°C;

[0114] 3) Add 30g of defoamer, 30g of leveling agent, 30g of substrate wetting agent, 100g of elastic resin, and 80g of butyl acetate, and stir at a medium speed for 30min to obtain the fluorosilicone nano-waterproof and heat-insulating compound Material.

[0115] The medium-speed stirring speed in the step 2) and step 3) is 400r / min. Described defoamer is EFKA2035 defoamer. The leveling agent is EFKA3777 leveling agent. The substrate wetting agent is BYK-104S substrate wetting agent. The elastic resin is polyester elastic resin elastic re...

Embodiment 2

[0117] A method for preparing the fluorosilicon nanometer waterproof and heat-insulating composite material, comprising the steps of:

[0118] 1) Add 400 parts by weight of fluorocarbon resin and 50 parts by weight of xylene in the jacketed cylinder, and stir evenly;

[0119] 2) Warm up the liquid in the tank to 50°C, then add 200 parts by weight of nano-silicon solution while stirring, stir at a medium speed, keep the temperature at 50°C, stir for 20 minutes, then cool to 20°C;

[0120] 3) Add 20 parts by weight of defoamer, 20 parts by weight of leveling agent, 20 parts by weight of substrate wetting agent, 50 parts by weight of elastic resin, and 60 parts by weight of butyl acetate, and stir for 20 minutes at a medium speed, that is The fluorosilicon nanometer waterproof and heat-insulating composite material is obtained.

[0121] The medium speed stirring speed in the step 2) and step 3) is 800r / min. Described defoamer is EFKA2720 defoamer. The leveling agent is BYK-306...

Embodiment 3

[0123] 1) Add 500 parts by weight of fluorocarbon resin and 100 parts by weight of xylene in the jacketed cylinder, and stir evenly;

[0124] 2) Warm up the liquid in the tank to 55°C, then add 300 parts by weight of nano-silicon solution while stirring, stir at a medium speed, keep the temperature at 55°C, stir for 30 minutes, then cool to 25°C;

[0125] 3) Add 30 parts by weight of defoamer, 30 parts by weight of leveling agent, 30 parts by weight of substrate wetting agent, 100 parts by weight of elastic resin, and 80 parts by weight of butyl acetate, and stir at a medium speed for 25 minutes, that is The fluorosilicon nanometer waterproof and heat-insulating composite material is obtained.

[0126] The medium-speed stirring speed in the step 2) and step 3) is 600r / min. The defoamer is BYK-052 defoamer. The leveling agent is BYK-333 leveling agent. The substrate wetting agent is EFKA4010 substrate wetting agent. The elastic resin is polyester polyol resin elastic resin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com