Primer coating for automobile composite material bonding and preparation method of primer coating

A technology of composite materials and primers, which is applied in the bonding methods, adhesives, coatings and other directions of surface pretreatment, can solve the problems of poor moisture and heat resistance, and achieve excellent moisture and heat aging resistance, stable performance and good adhesion. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

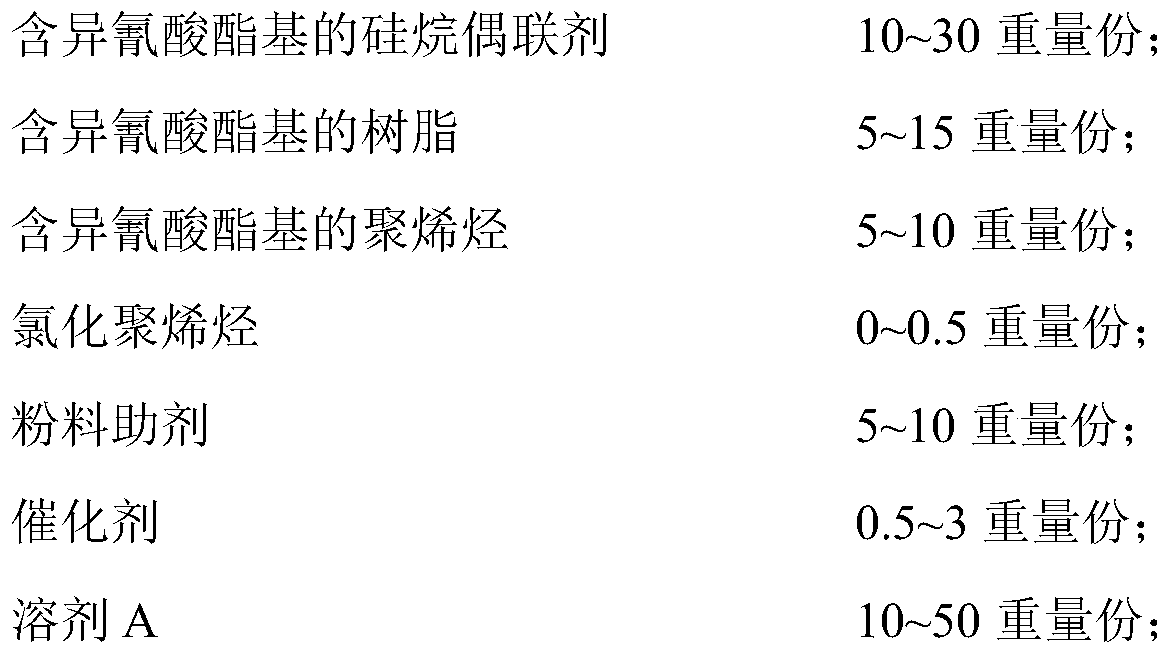

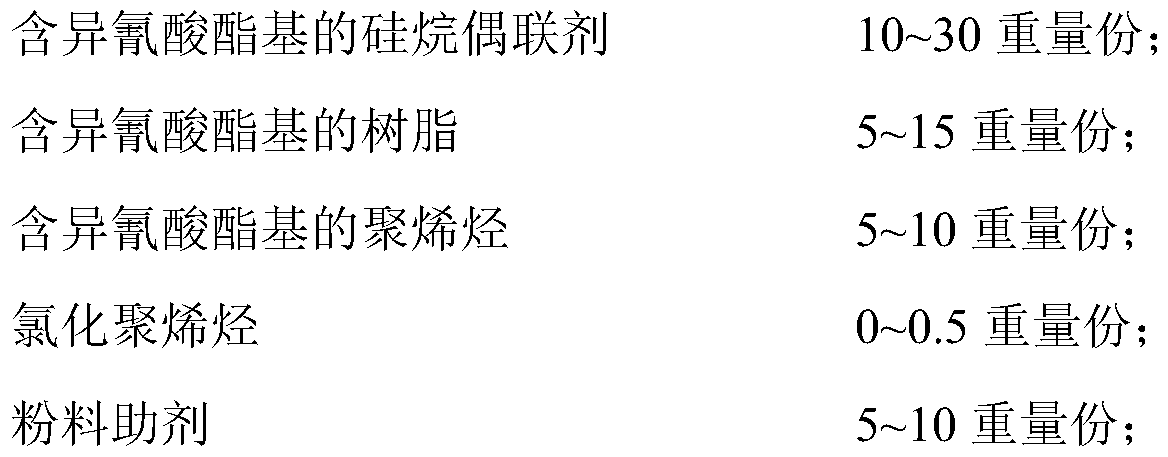

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix MDI and D20 with isocyanate group and hydroxyl molar ratio of 1.2 to 1.6:1 and heat up to 75 to 78°C. After the reaction is complete, an isocyanate group-containing resin with an isocyanate group content of 2wt% to 5wt% is obtained. Discharge spare;

[0036] (2) Mix MDI-50 and Poly bd R45V with a molar ratio of isocyanate group to hydroxyl group of 5 to 7:1 and heat it up to 75 to 78°C, and keep it warm for reaction. After the reaction is complete, the obtained isocyanate group content is 6wt% to 9wt%. The isocyanate group-containing polyolefin is discharged for subsequent use;

[0037](3) 25 parts by weight of A-Link25, 12 parts by weight of isocyanate group-containing resin prepared in step (1), 6 parts by weight of polyolefin containing isocyanate group prepared in step (2), 0.3 parts by weight of Superchlon 822, 8 parts by weight of 2 parts by weight of carbon black, 2 parts by weight of stannous octoate and 46.7 parts by weight of ethyl acetate were mixed ...

Embodiment 2

[0039] (1) Mix HDI biuret with a molar ratio of isocyanate group to amino group of 1.2-1.6:1 and A-1110, heat it up to 75-78°C, and keep it warm for reaction. After the reaction is complete, the obtained isocyanate group content is 6wt%-8wt % isocyanate-containing silane coupling agent;

[0040] (2) Mix MDI and DA2110 with a molar ratio of isocyanate group to hydroxyl group of 1.2 to 1.6:1, heat up to 75 to 78°C, and keep warm for reaction. After the reaction is complete, an isocyanate group containing isocyanate group with an isocyanate group content of 2wt% to 5wt% is obtained The resin is discharged for standby;

[0041] (3) Mix MDI-50 and Krasol LBH-3000 with a molar ratio of isocyanate group to hydroxyl group of 5 to 7:1 and heat it up to 75 to 78°C, and keep it warm for reaction. After the reaction is complete, the obtained isocyanate group content is 6wt% to 9wt. % of polyolefin containing isocyanate group, discharging for subsequent use;

[0042] (4) 20 parts by weig...

Embodiment 3

[0044] (1) Mix MDI and DA2110 with a molar ratio of isocyanate group to hydroxyl group of 1.2 to 1.6:1, heat up to 75 to 78°C, and keep warm for reaction. After the reaction is complete, an isocyanate group containing isocyanate group with an isocyanate group content of 2wt% to 5wt% is obtained The resin is discharged for standby;

[0045] (2) Mix MDI-50 and Poly bd R45V with a molar ratio of isocyanate group and terminal hydroxyl group of 7:1, heat up to 75-78°C, and keep warm for reaction. After the reaction is complete, the isocyanate group content is 6wt%-9wt%. Polyolefin containing isocyanate groups, discharged for later use;

[0046] (3) 20 parts by weight of Link35, 12 parts by weight of isocyanate group-containing resin prepared in step (1), 9 parts by weight of polyolefin containing isocyanate group prepared in step (2), 0.1 part by weight of chlorinated polyolefin, 7 parts by weight of 2 parts by weight of silicon dioxide, 2 parts by weight of stannous octoate and 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com