Composition of unsaturated resin, preparation method, and method of application

A resin composition, unsaturated technology, applied in the field of chemical materials, can solve the problems of non-compliance with the requirements of the elasticity of the block filling material, resin pulverization and cracking, migration to the surface, etc., to achieve good resistance to ultraviolet radiation and good adhesion The effect of power and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

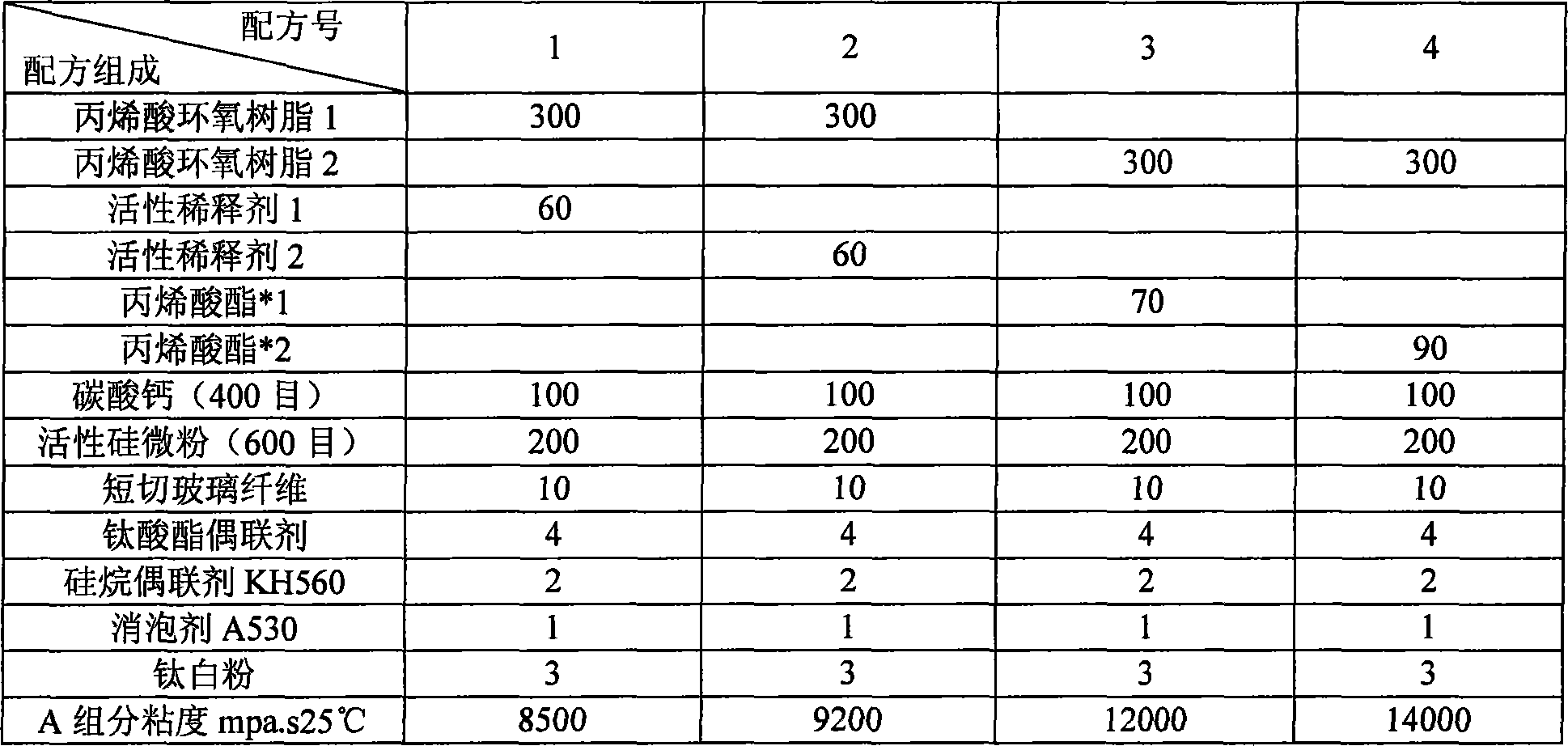

Examples

Embodiment 1

[0037] Add alicyclic glycidyl ether type epoxy resin JEw-0121 (produced by Changshu Jiafa Chemical Co., Ltd.) 300g, JEw-0112 (produced by Changshu Jiafa Chemical Co., Ltd.) 200g, triphenyl Phosphine 2.5g, hydroquinone 1g, stir and heat up to 80-100°C, add dropwise 194g of acrylic acid, the molar ratio of carboxyl group to epoxy group is 1:1.05, keep the reaction at 80-100°C for 5 hours, then cool down to 40-50°C , test viscosity 15000mpa.s25 ℃, epoxy value 0.05mol / 100g, acid value 8mgKOH / g, recorded as acrylic epoxy resin 1.

[0038] Add 500g of bisphenol A type epoxy resin DYD-128 (manufactured by Dalian Qihua Chemical Co., Ltd.), 2.5g of triphenylphosphine, and 1g of hydroquinone into a 1-liter three-necked flask, stir to raise the temperature to 80-100°C, add dropwise 196g of acrylic acid, the molar ratio of carboxyl group to epoxy group is 1:1.05, keep the reaction at 80-100°C for 5 hours, cool down to 80°C and discharge, the test viscosity is 23000mpa.s40°C, the epoxy val...

Embodiment 2

[0049] Throw 150g of tetrahydrophthalic acid, 150g of maleic acid, 213g of diethylene glycol, 400-213g of polypropylene glycol, and 1.5g of butyltin laurate in a 1-liter three-necked bottle with fractionating column, electric heating, stirring, and temperature controller. , stir and heat up 180-200°C, maintain the reaction, observe and measure the amount of water discharged through the top of the fractionation column, and when the theoretical amount (38-39g) is reached, the temperature is lowered by 100-120°C, and the remaining low boilers are removed under reduced pressure, and 370g of styrene is added. 5 g of p-hydroxyanisole, stirred and mixed evenly, and discharged to obtain an unsaturated polyester resin with a viscosity of 2500 mpa.s at 25 ° C.

[0050] Preface

No

project name

Technical requirements

Recipe 1

Recipe 2

Recipe 3

Recipe 4

testing method

1

AB mix sticky

Spend

mpa.s25...

Embodiment 3

[0057] The same as the method of formula 1 in Example 1, the difference is that the acrylic epoxy resin is obtained by the following preparation method: at 50-60 ° C, the acrylic acid and aliphatic glycidyl ester type epoxy resin are mixed according to the carboxyl and epoxy moles The ratio is 1: 0.5, adding 0.1% hydroquinone by weight to the total weight of acrylic acid and aliphatic glycidyl ester type epoxy resin, reacting for 1 hour to form acrylic epoxy, then adding a weight of acrylic epoxy Dilute with 20% methyl styrene or low viscosity epoxy acrylate by weight of the ester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com